Development of Novel Semi-Stranded Windings for High Speed Electrical Machines Enabled by Additive Manufacturing

Abstract

1. Introduction

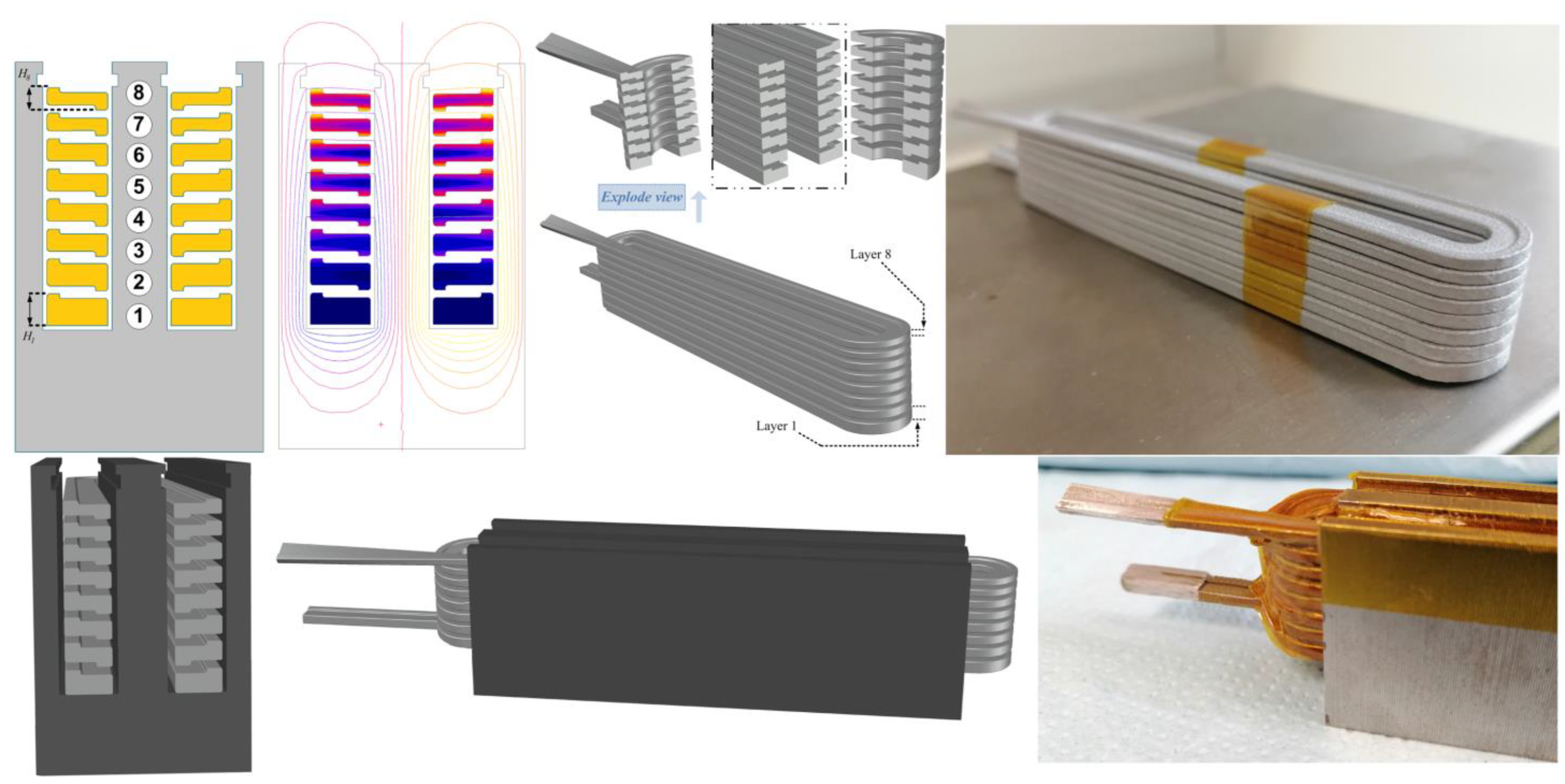

2. Additive Manufacturing for Electrical Machines Windings

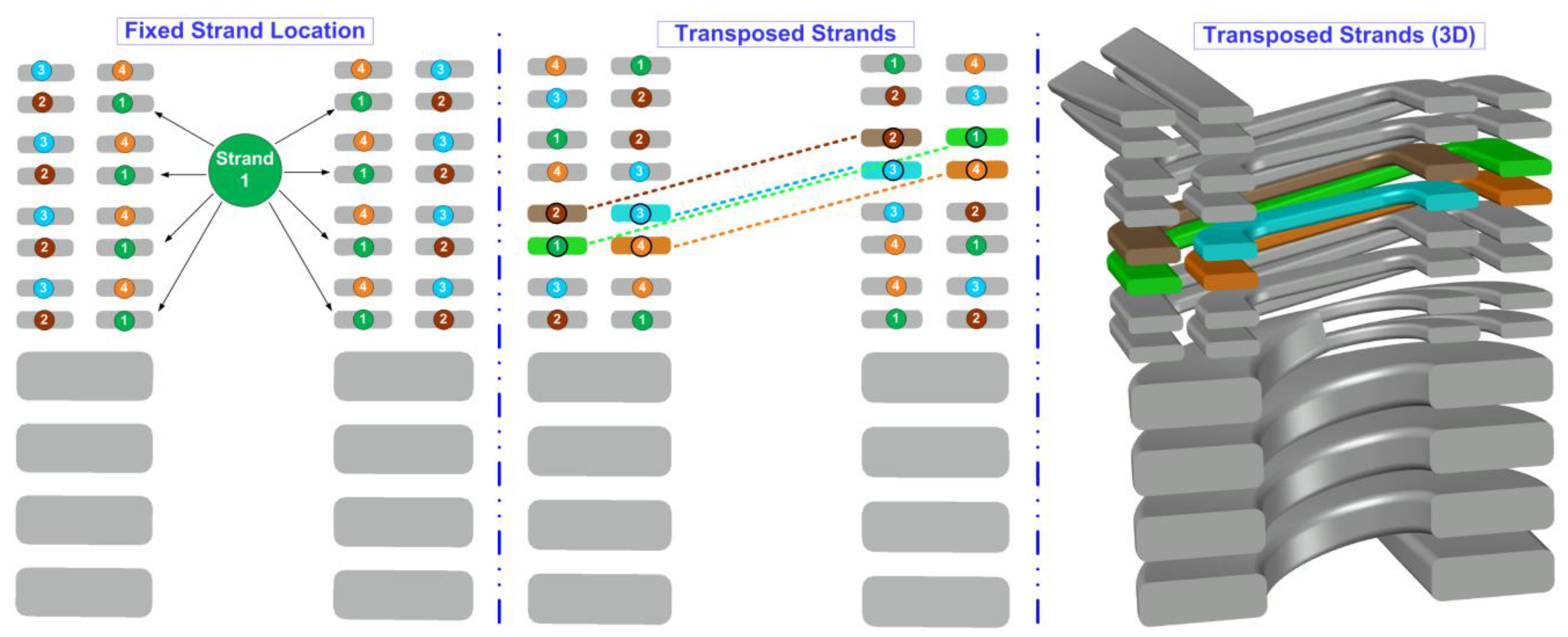

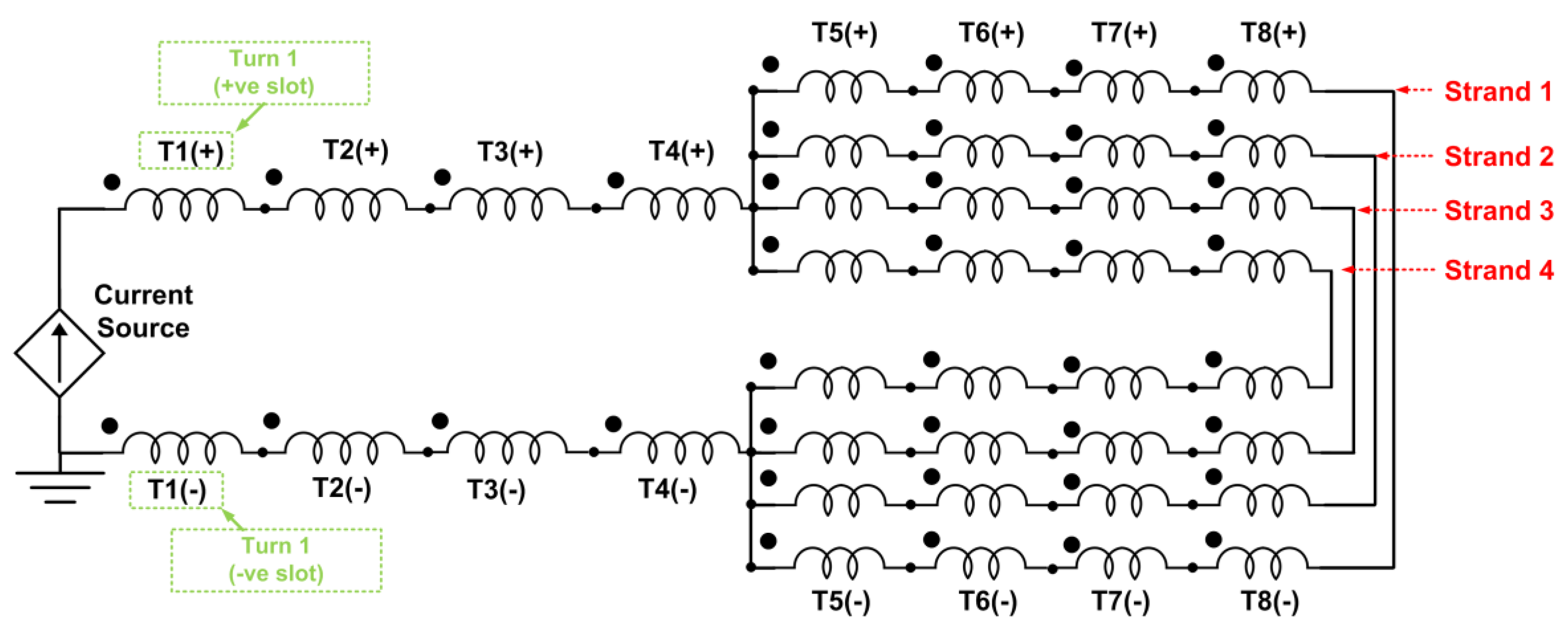

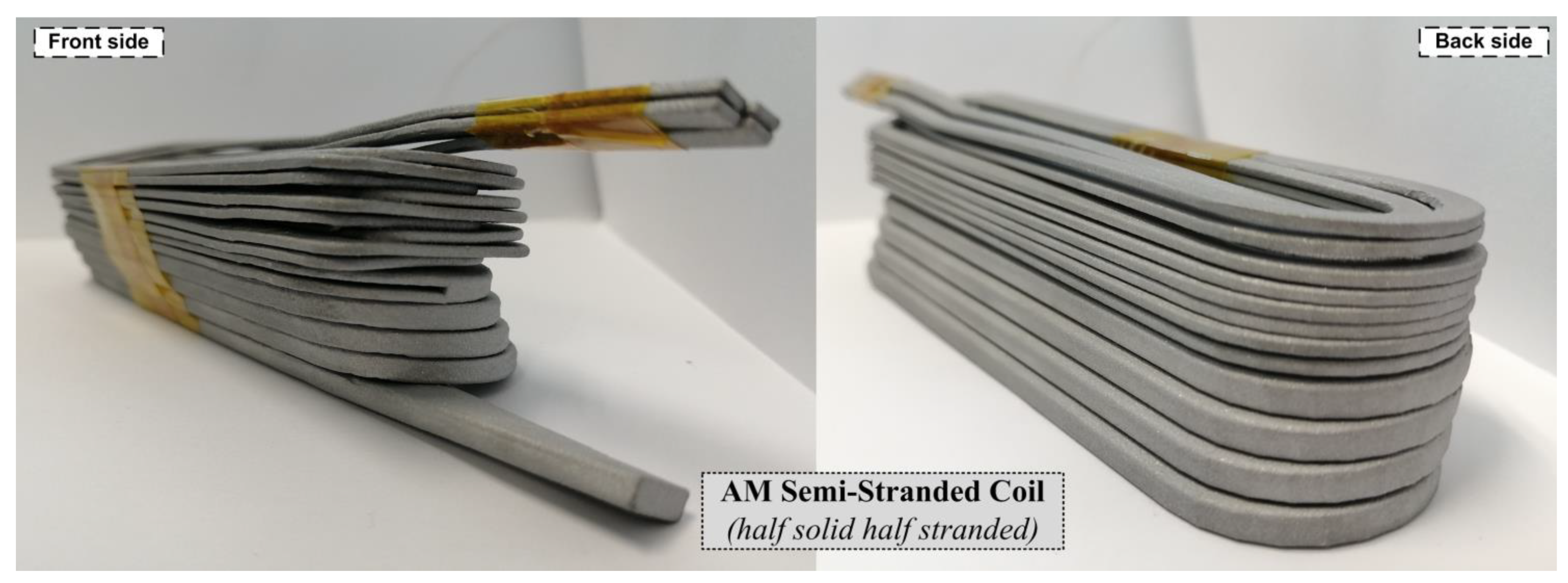

3. Semi-Stranded Coils: A New Concept

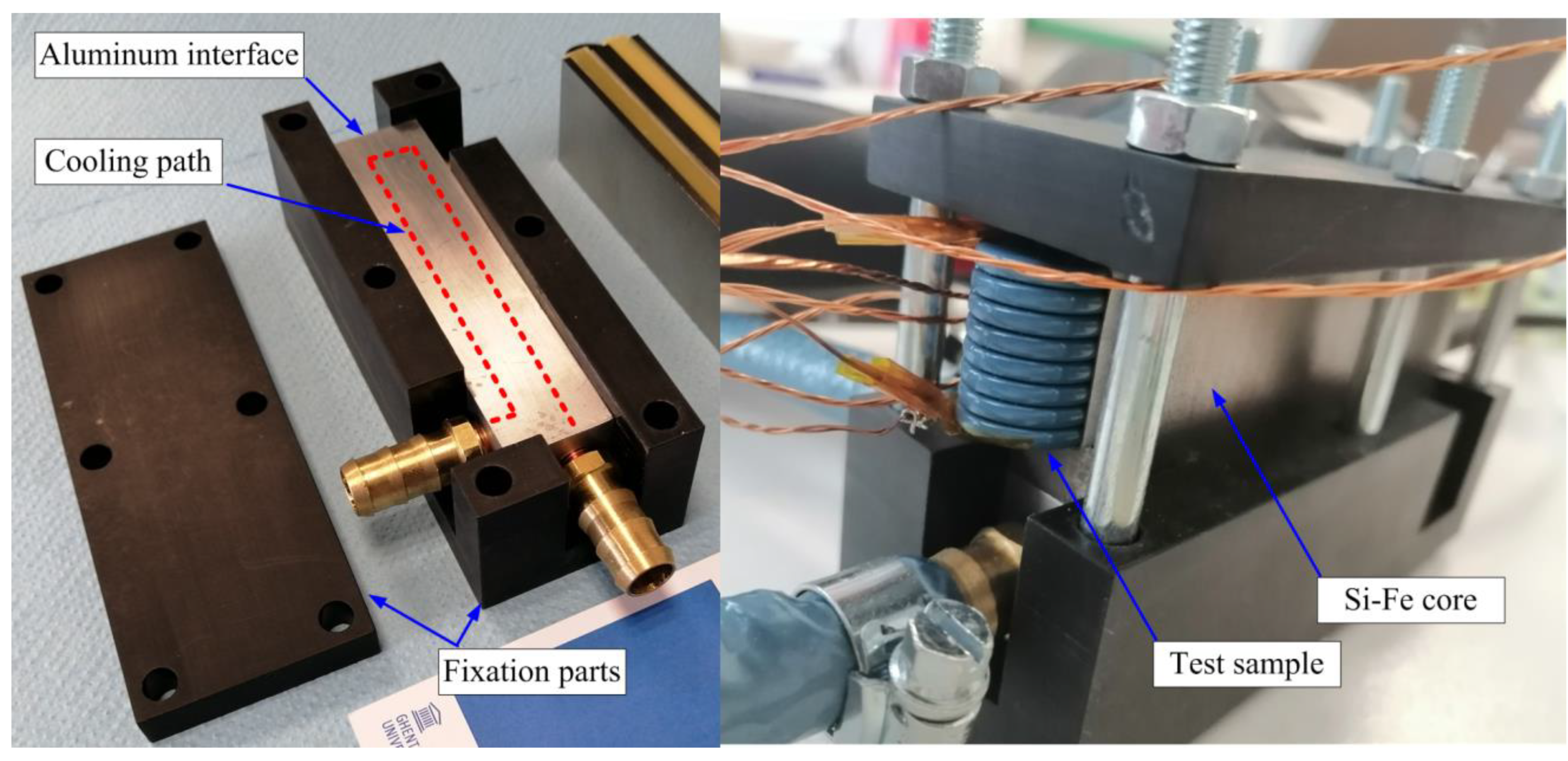

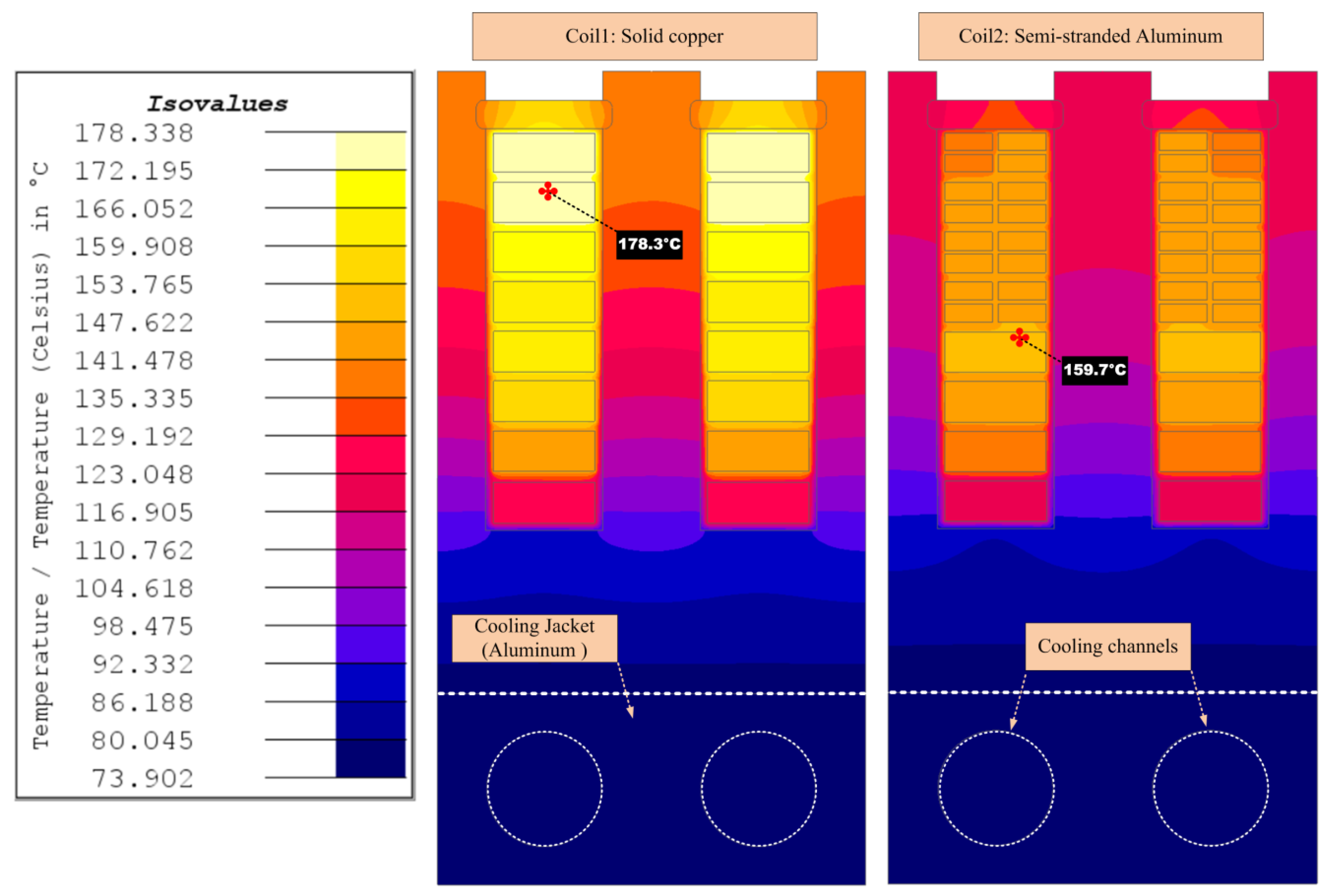

4. Thermal Performance Comparison

5. Sample Preparation and Loss Measurement

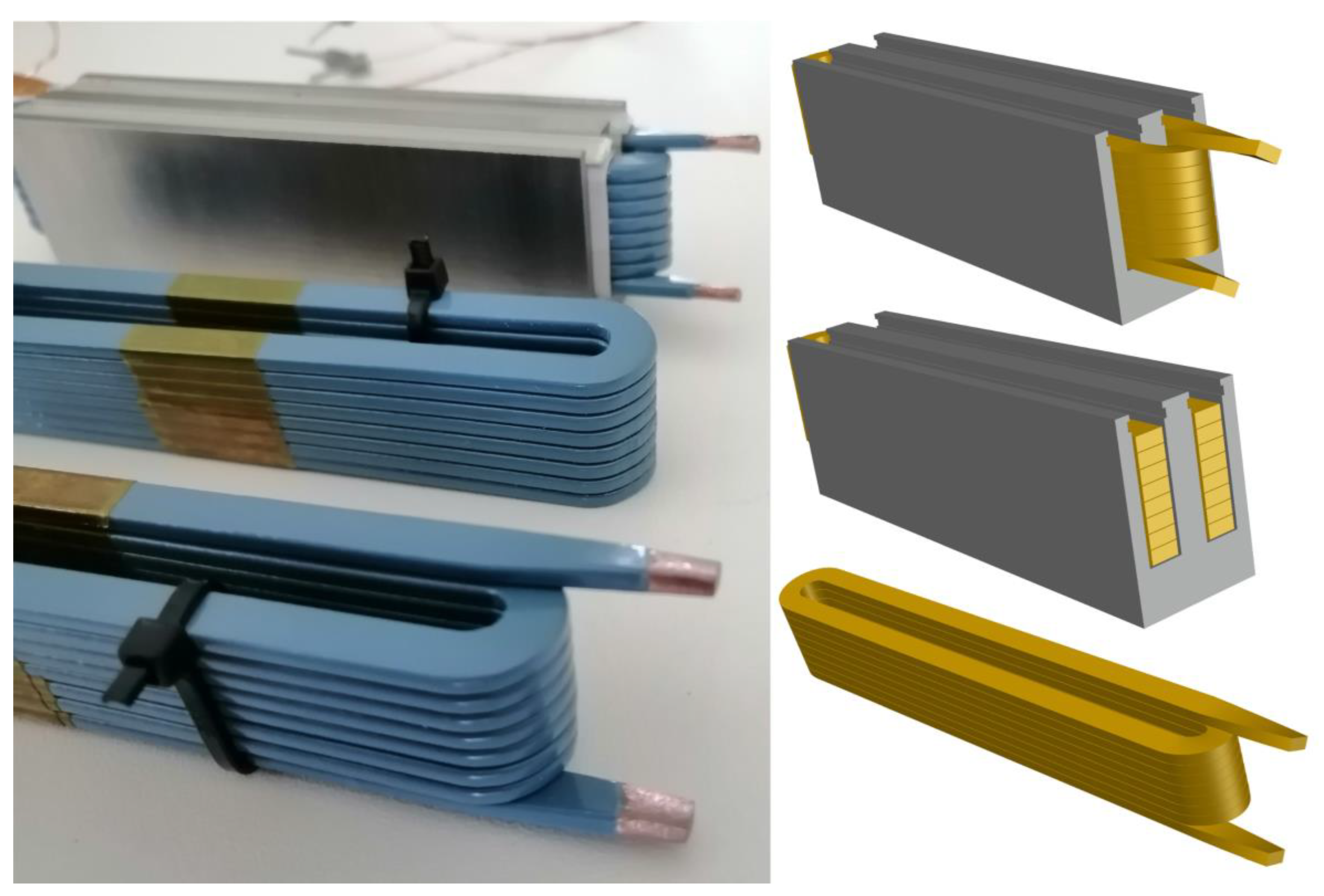

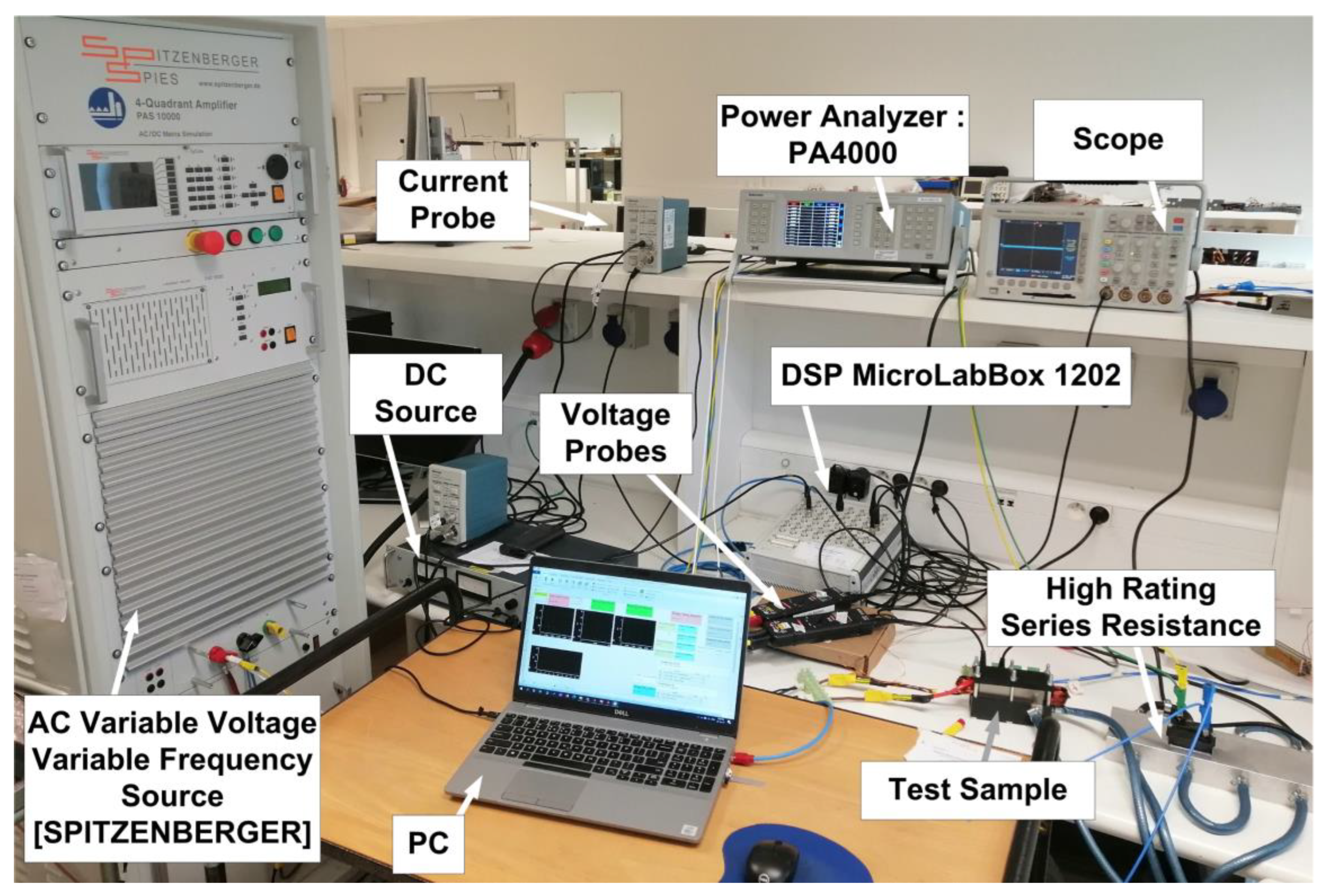

5.1. Sample Preparation

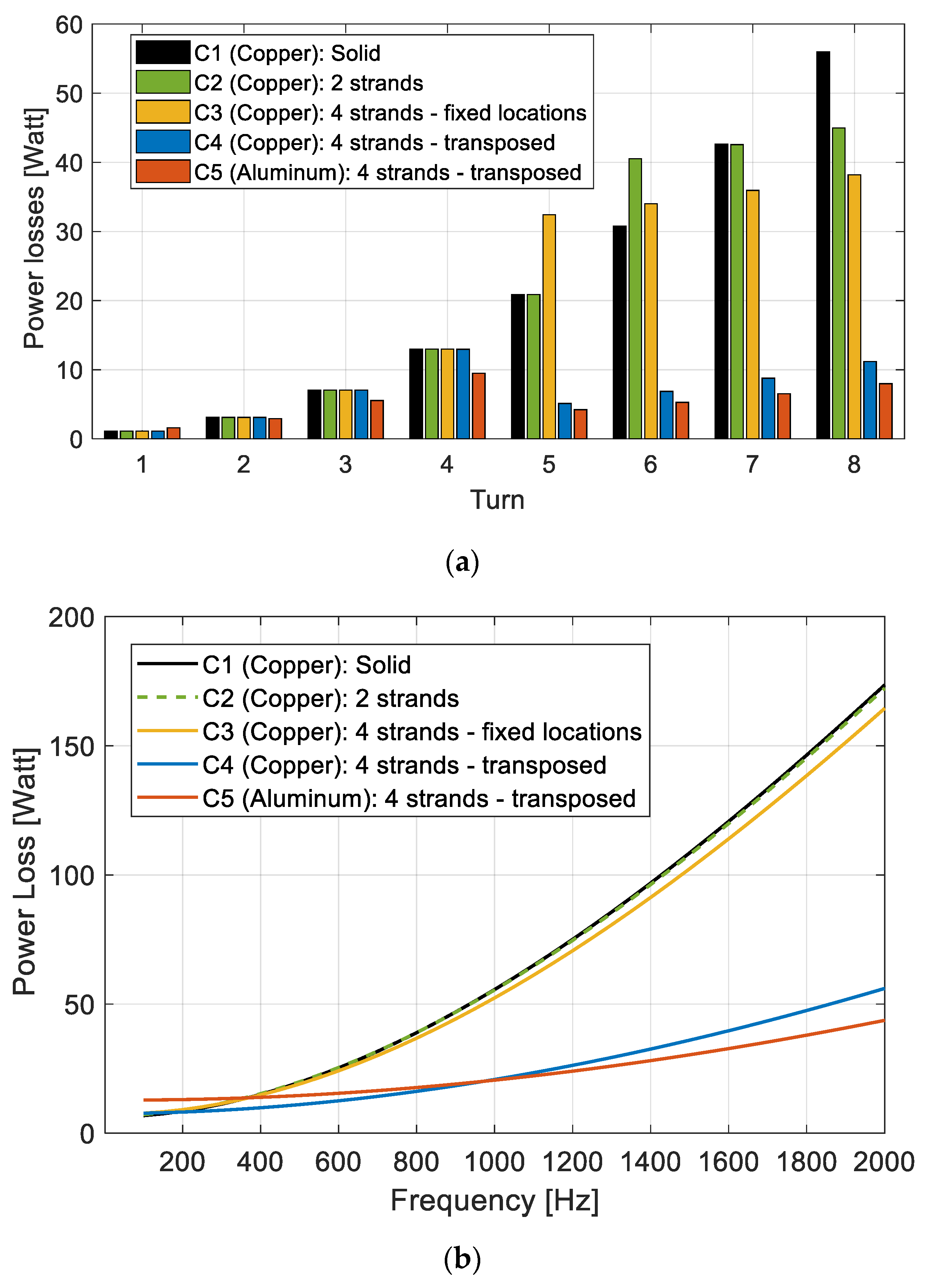

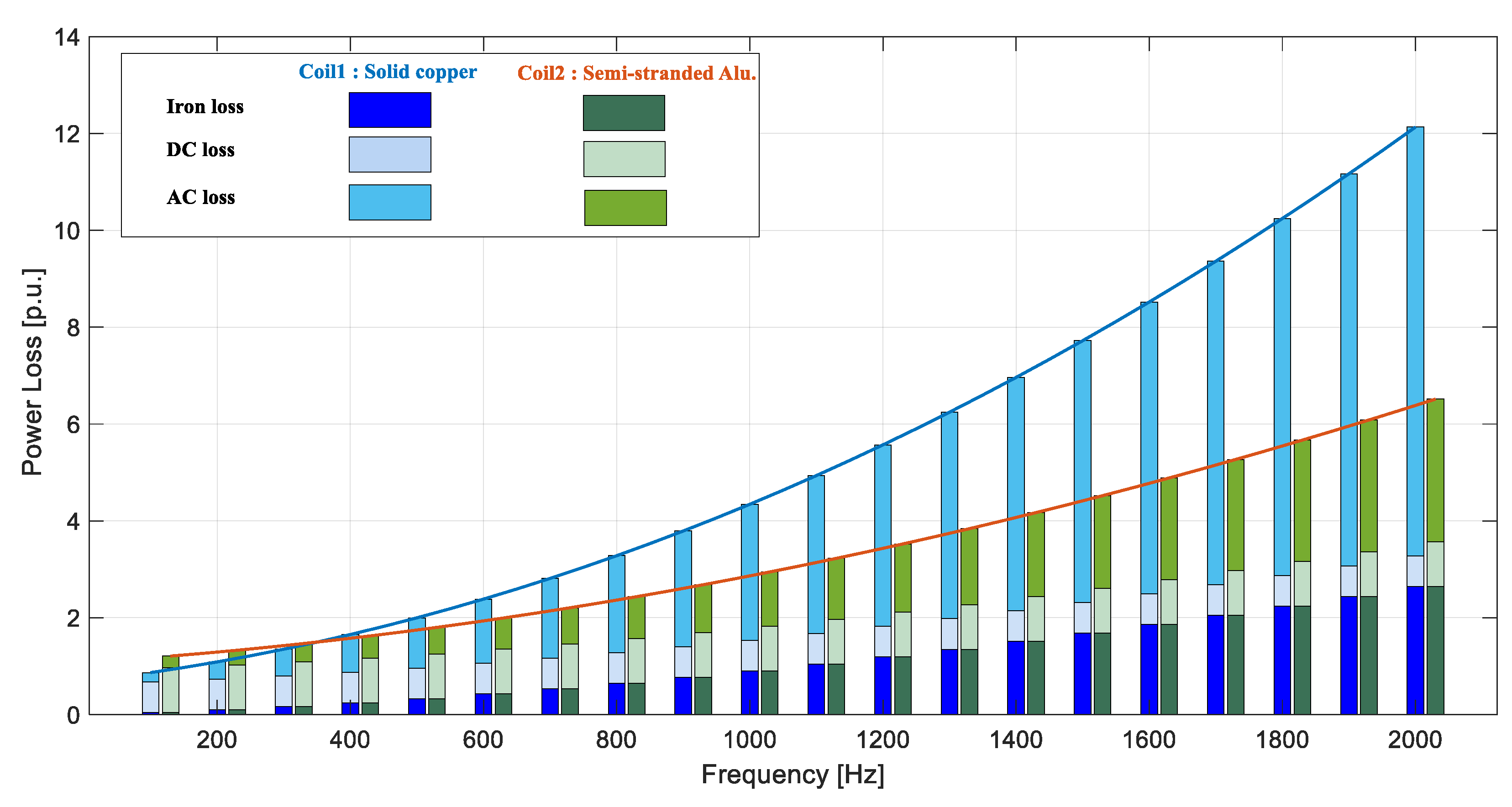

5.2. AC Loss Measurements

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Standard, B. Mercedes-Benz EV Threatens Tesla with Record 1000 KM on Single Charge. Available online: https://www.business-standard.com/article/automobile/mercedes-benz-ev-threatens-tesla-with-record-1-000-km-on-single-charge-122041500616_1.html (accessed on 20 April 2022).

- Selema, A. Development of a Three-Phase Dual-Rotor Magnetless Flux Switching Generator for Low Power Wind Turbines. IEEE Trans. Energy Convers. 2020, 35, 828–836. [Google Scholar] [CrossRef]

- Selema, A.; Gulec, M.; Ibrahim, M.N.; Sprangers, R.; Sergeant, P. Selection of Magnet Wire Topologies with Reduced AC Losses for the Windings of Electric Drivetrains. IEEE Access 2022, 10, 121531–121546. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, X.; Wu, S.; Cui, S.; Gerada, C.; Yan, H. Eddy Current Losses Analysis and Optimization Design of Litz-Wire Windings for Air-Core Compulsators. IEEE Trans. Plasma Sci. 2019, 47, 2532–2538. [Google Scholar] [CrossRef]

- Selema, A.; Ibrahim, M.N.; Sergeant, P. Metal Additive Manufacturing for Electrical Machines: Technology Review and Latest Advancements. Energies 2022, 15, 1076. [Google Scholar] [CrossRef]

- Selema, A.; Van Coppenolle, M.; Ibrahim, M.N.; Sergeant, P. Multi-physic design of ultra-efficient smart motor enabled by additive manufacturing. Zenodo 2022. [Google Scholar] [CrossRef]

- Selema, A.; Ibrahim, M.N.; Vansompel, H.; Sergeant, P. Development of Yokeless Axial Flux Machine Using 3D-Printed Shape-Profiled Core. In Proceedings of the 2022 IEEE International Conference on Electrical Machines (ICEM), Valencia, Spain, 5–8 September 2022. [Google Scholar]

- Selema, A.; Ibrahim, M.N.; Sergeant, P. Electrical Machines Winding Technology: Latest Advancements for Transportation Electrification. Machines 2022, 10, 563. [Google Scholar] [CrossRef]

- Selema, A.; Ibrahim, M.N.; Sergeant, P. Non-Destructive Electromagnetic Evaluation of Material Degradation Due to Steel Cutting in a Fully Stacked Electrical Machine. Energies 2022, 15, 7862. [Google Scholar] [CrossRef]

- Hong, H.-S.; Liu, H.-C.; Jeong, G.-C.; Lee, J. Design of high-end SynRM based on 3D printing technology. In Proceedings of the 2016 IEEE Conference on Electromagnetic Field Computation (CEFC), Miami, FL, USA, 13–16 November 2016; p. 1. [Google Scholar]

- Ranjan, R.; Tangudu, J. Thermal design of high power-density additively-manufactured induction motors. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014; pp. 1325–1331. [Google Scholar]

- Waterman, J.; Clucas, A.; Costa, T.B.; Zhang, Y.; Zhang, J. Numerical modeling of 3D printed electric machines. In Proceedings of the 2015 IEEE International Electric Machines & Drives Conference (IEMDC), Coeur d’Alene, ID, USA, 10–13 May 2015; pp. 1286–1291. [Google Scholar]

- Selema, A.; Beretta, M.; Van Coppenolle, M.; Tiismus, H.; Kallaste, A.; Ibrahim, M.; Rombouts, M.; Vleugels, J.; Kestens, L.; Sergeant, P. Evaluation of 3d-Printed Magnetic Materials for Additively-Manufactured Electrical Machines. J. Magn. Magn. Mater. 2023; in press. [Google Scholar] [CrossRef]

- An, B.W.; Kim, K.; Lee, H.; Kim, S.-Y.; Shim, Y.; Lee, D.-Y.; Song, J.Y.; Park, J.-U. High-Resolution Printing of 3D Structures Using an Electrohydrodynamic Inkjet with Multiple Functional Inks. Adv. Mater. 2015, 27, 4322–4328. [Google Scholar] [CrossRef] [PubMed]

- Vaithilingam, J.; Simonelli, M.; Saleh, E.; Senin, N.; Wildman, R.D.; Hague, R.J.M.; Leach, R.K.; Tuck, C.J. Combined Inkjet Printing and Infrared Sintering of Silver Nanoparticles using a Swathe-by-Swathe and Layer-by-Layer Approach for 3-Dimensional Structures. ACS Appl. Mater. Interfaces 2017, 9, 6560–6570. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Hu, D.; Li, L.; Li, C.-F.; Jiu, J.; Chen, C.; Ishina, T.; Sugahara, T.; Suganuma, K. Printable and Flexible Copper–Silver Alloy Electrodes with High Conductivity and Ultrahigh Oxidation Resistance. ACS Appl. Mater. Interfaces 2017, 9, 24711–24721. [Google Scholar] [CrossRef] [PubMed]

- Raab, S.J.; Guschlbauer, R.; Lodes, M.A.; Körner, C. Thermal and Electrical Conductivity of 99.9% Pure Copper Processed via Selective Electron Beam Melting. Adv. Eng. Mater. 2016, 18, 1661–1666. [Google Scholar] [CrossRef]

- Gradl, P.R.; Protz, C.; Greene, S.E.; Ellis, D.; Lerch, B.; Locci, I. Development and Hot-fire Testing of Additively Manufactured Copper Combustion Chambers for Liquid Rocket Engine Applications. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10–12 July 2017; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2017. [Google Scholar]

- Louvis, E.; Fox, P.; Sutcliffe, C.J. Selective laser melting of aluminium components. J. Mater. Process. Technol. 2011, 211, 275–284. [Google Scholar] [CrossRef]

- Selema, A.; Ibrahim, M.N.; Sergeant, P. Mitigation of High-Frequency Eddy Current Losses in Hairpin Winding Machines. Machines 2022, 10, 328. [Google Scholar] [CrossRef]

- Fateri, M.; Gebhardt, A.; Hötter, J.-S.; Knothe, M.; Schmidt, F.; Rieper, H. Numerical and Experimental Investigation of Selective Laser Melting of Silver. In Proceedings of the Fraunhofer Direct Digital Manufacturing Conference (DDMC 2012), Berlin, Germany, 14–15 March 2012; Available online: https://www.researchgate.net/publication/264548342_Numerical_and_Experimental_Investigation_of_Selective_Laser_Melting_of_Silver (accessed on 2 January 2023).

- Singh, G.; Missiaen, J.-M.; Bouvard, D.; Chaix, J.-M. Copper extrusion 3D printing using metal injection moulding feedstock: Analysis of process parameters for green density and surface roughness optimization. Addit. Manuf. 2021, 38, 101778. [Google Scholar] [CrossRef]

- Rosochowski, A.; Presz, W.; Olejnik, L.; Richert, M. Micro-extrusion of ultra-fine grained aluminium. Int. J. Adv. Manuf. Technol. 2007, 33, 137–146. [Google Scholar] [CrossRef]

- Wu, F.; EL-Refaie, A.M.; Al-Qarni, A. Additively Manufactured Hollow Conductors for High Specific Power Electrical Machines: Aluminum vs Copper. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Vancouver, BC, Canada, 10–14 October 2021; pp. 4397–4404. [Google Scholar]

- Simpson, N.; North, D.J.; Collins, S.M.; Mellor, P.H. Additive Manufacturing of Shaped Profile Windings for Minimal AC Loss in Electrical Machines. IEEE Trans. Ind. Appl. 2020, 56, 2510–2519. [Google Scholar] [CrossRef]

- Selema, A.; Ibrahim, M.N.; Sergeant, P. Additively Manufactured Ultralight Shaped-Profile Windings for HF Electrical Machines and Weight-Sensitive Applications. IEEE Trans. Transp. Electrif. 2022, 8, 4313–4324. [Google Scholar] [CrossRef]

- Selema, A.; Ibrahim, M.N.; Sprangers, R.; Sergeant, P. Effect of Using Different Types of Magnet Wires on the AC Losses of Electrical Machine Windings. In Proceedings of the 2021 IEEE International Electric Machines & Drives Conference (IEMDC), Hartford, CT, USA, 17–20 May 2021; pp. 1–5. [Google Scholar]

- Nonneman, J.; Schoonjans, T.; T’Jollyn, I.; Selema, A.; Sprangers, R.; De Paepe, M. Thermal Property Determination of Different Electric Machine Wire Types by Model Variable Fitting on Measurements. In Proceedings of the 2022 IEEE International Conference on Electrical Machines (ICEM), Valencia, Spain, 5–8 September 2022; pp. 1383–1389. [Google Scholar]

- Zhao, Y.; Li, D.; Pei, T.; Qu, R. Overview of the rectangular wire windings AC electrical machine. CES Trans. Electr. Mach. Syst. 2019, 3, 160–169. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Selema, A.; Ibrahim, M.N.; Sergeant, P. Development of Novel Semi-Stranded Windings for High Speed Electrical Machines Enabled by Additive Manufacturing. Appl. Sci. 2023, 13, 1653. https://doi.org/10.3390/app13031653

Selema A, Ibrahim MN, Sergeant P. Development of Novel Semi-Stranded Windings for High Speed Electrical Machines Enabled by Additive Manufacturing. Applied Sciences. 2023; 13(3):1653. https://doi.org/10.3390/app13031653

Chicago/Turabian StyleSelema, Ahmed, Mohamed N. Ibrahim, and Peter Sergeant. 2023. "Development of Novel Semi-Stranded Windings for High Speed Electrical Machines Enabled by Additive Manufacturing" Applied Sciences 13, no. 3: 1653. https://doi.org/10.3390/app13031653

APA StyleSelema, A., Ibrahim, M. N., & Sergeant, P. (2023). Development of Novel Semi-Stranded Windings for High Speed Electrical Machines Enabled by Additive Manufacturing. Applied Sciences, 13(3), 1653. https://doi.org/10.3390/app13031653