Fabrication of Low Electrical Percolation Threshold Multi-Walled Carbon Nanotube Sensors Using Magnetic Patterning

Abstract

1. Introduction

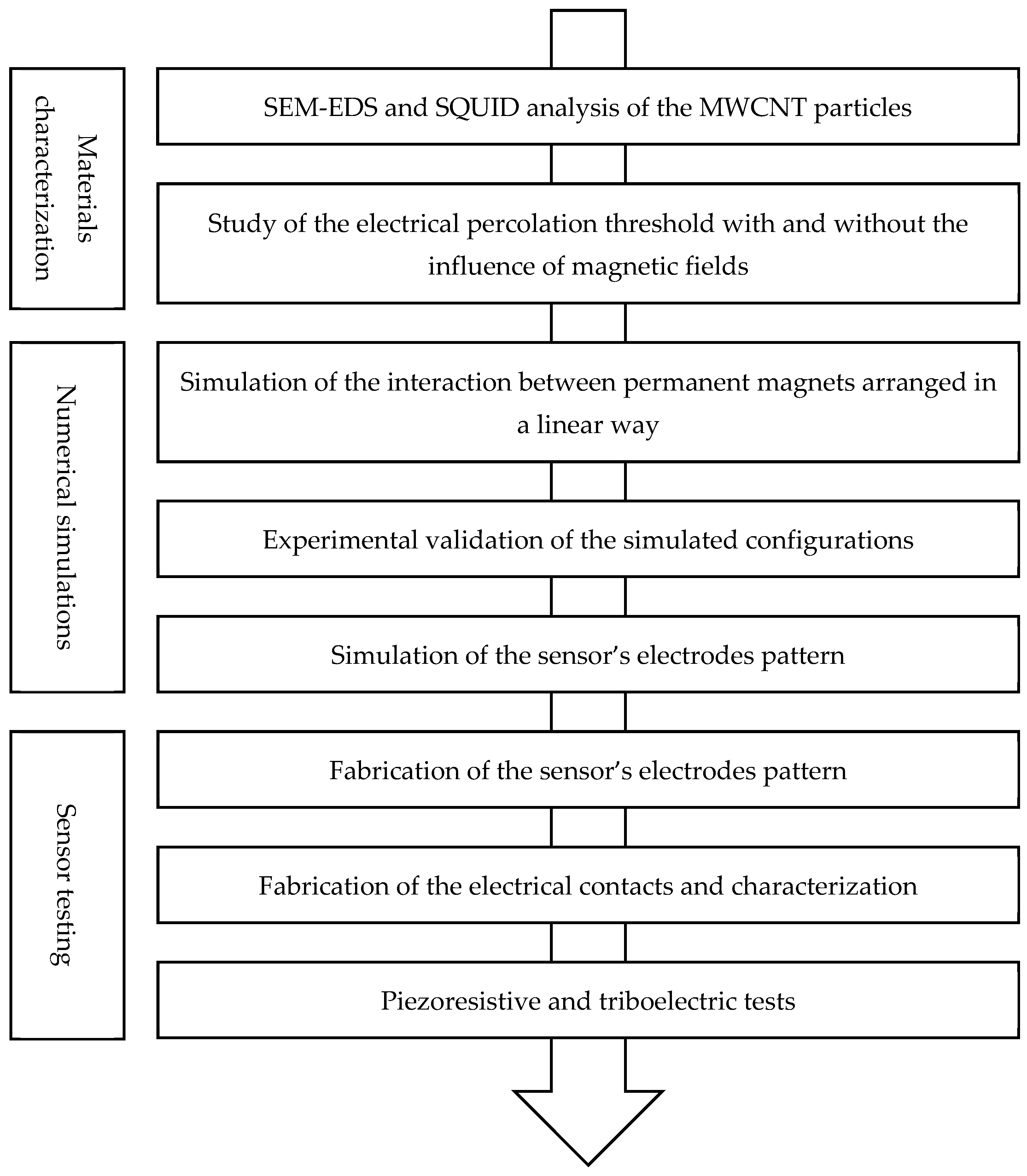

2. Materials and Methods

2.1. Materials

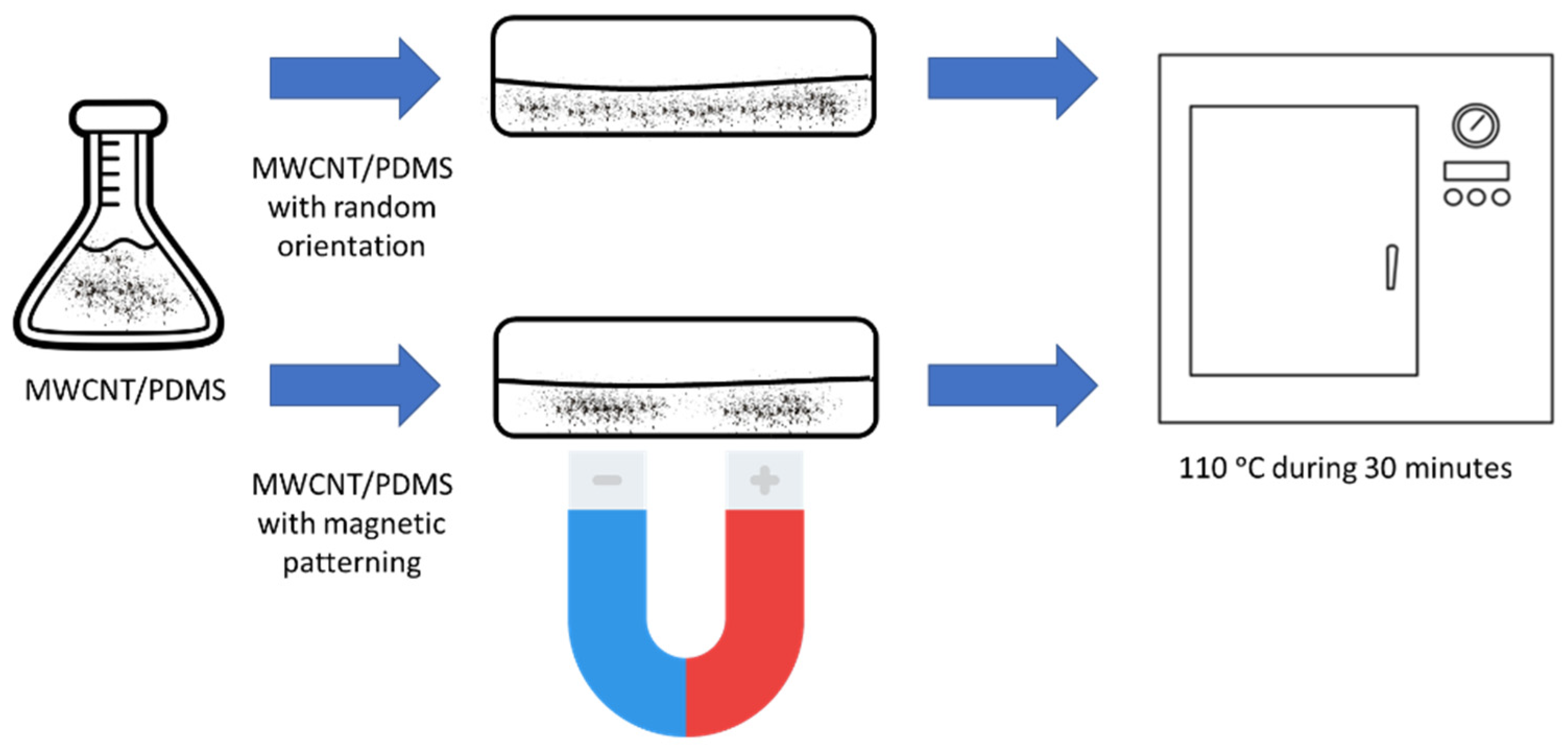

2.2. Numerical Simulation and Fabrication Processes

2.3. Experimental Tests

3. Results

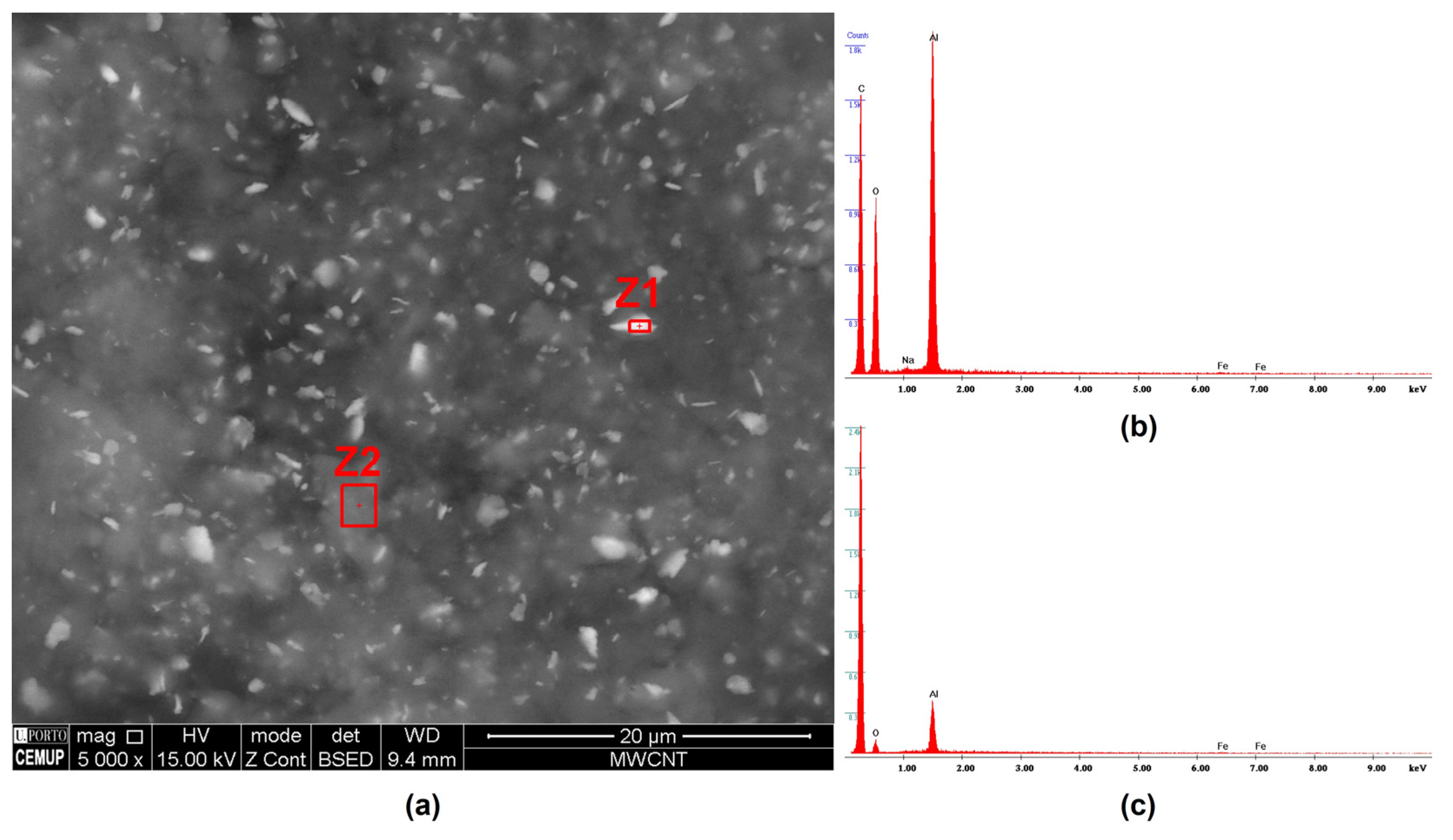

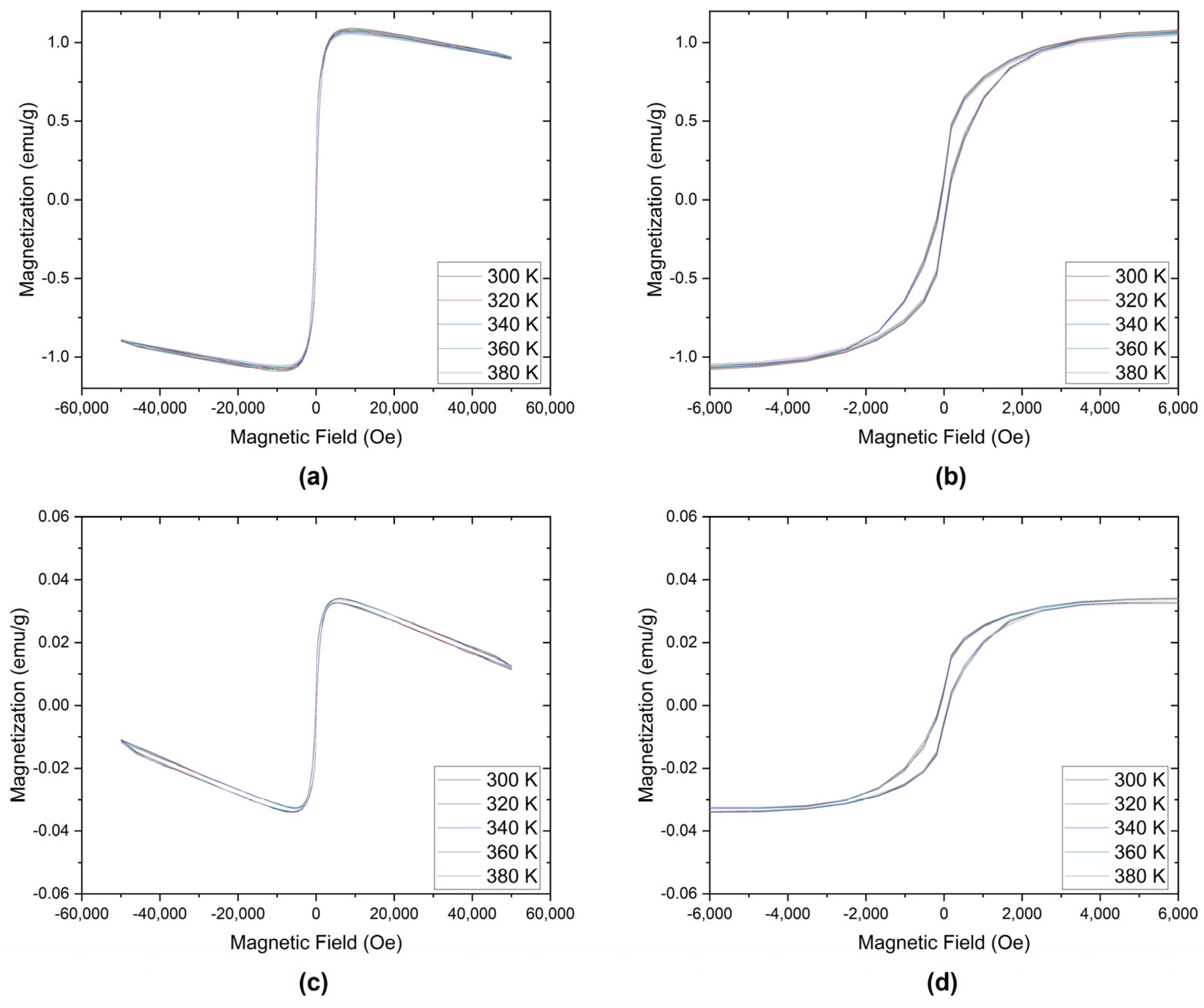

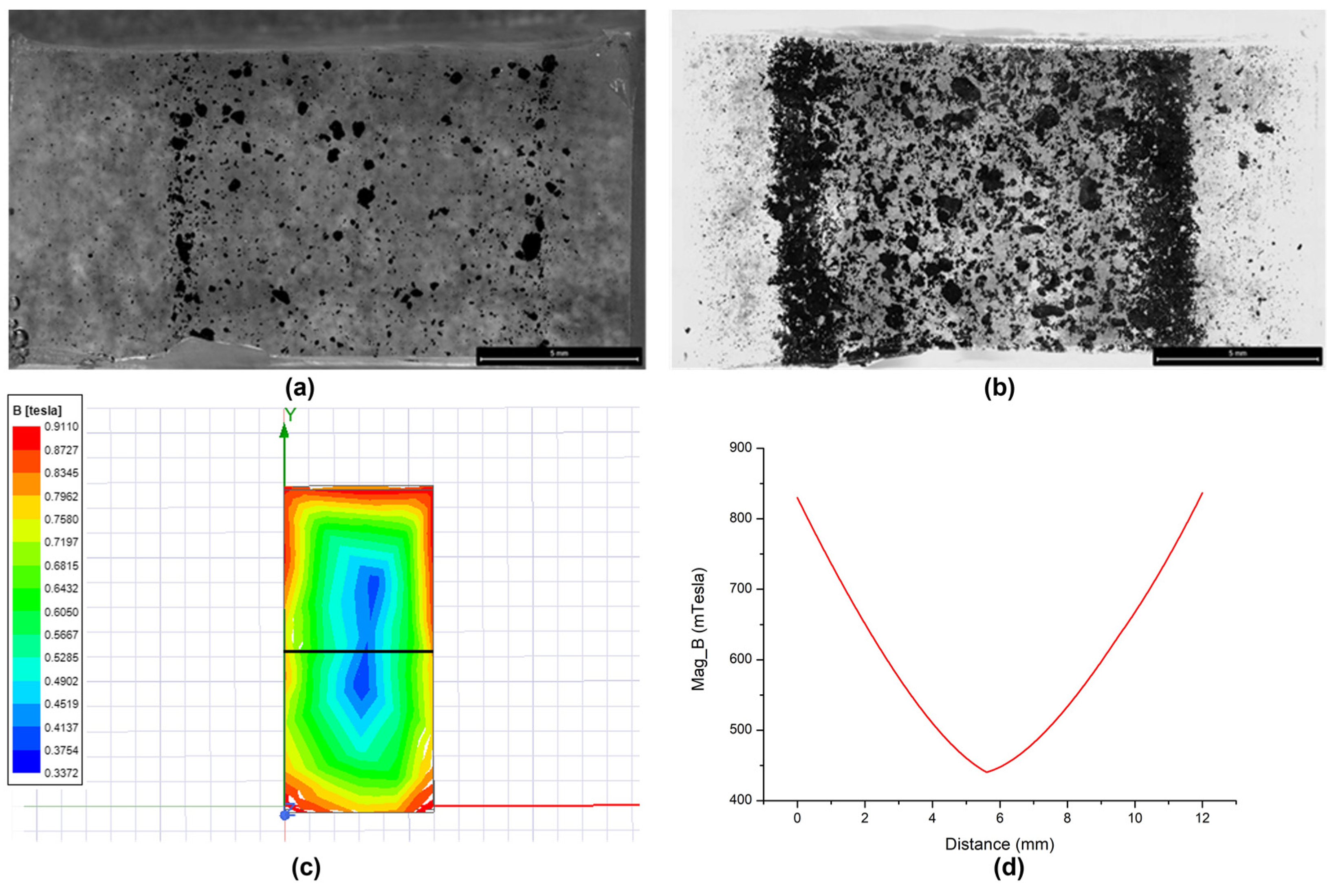

3.1. Characterization of the Magnetic Properties of MWCNTs and MWCNT/PDMS Nanocomposite

3.2. Electrical Percolation Threshold of MWCNT/PDMS under Magnetic Forces

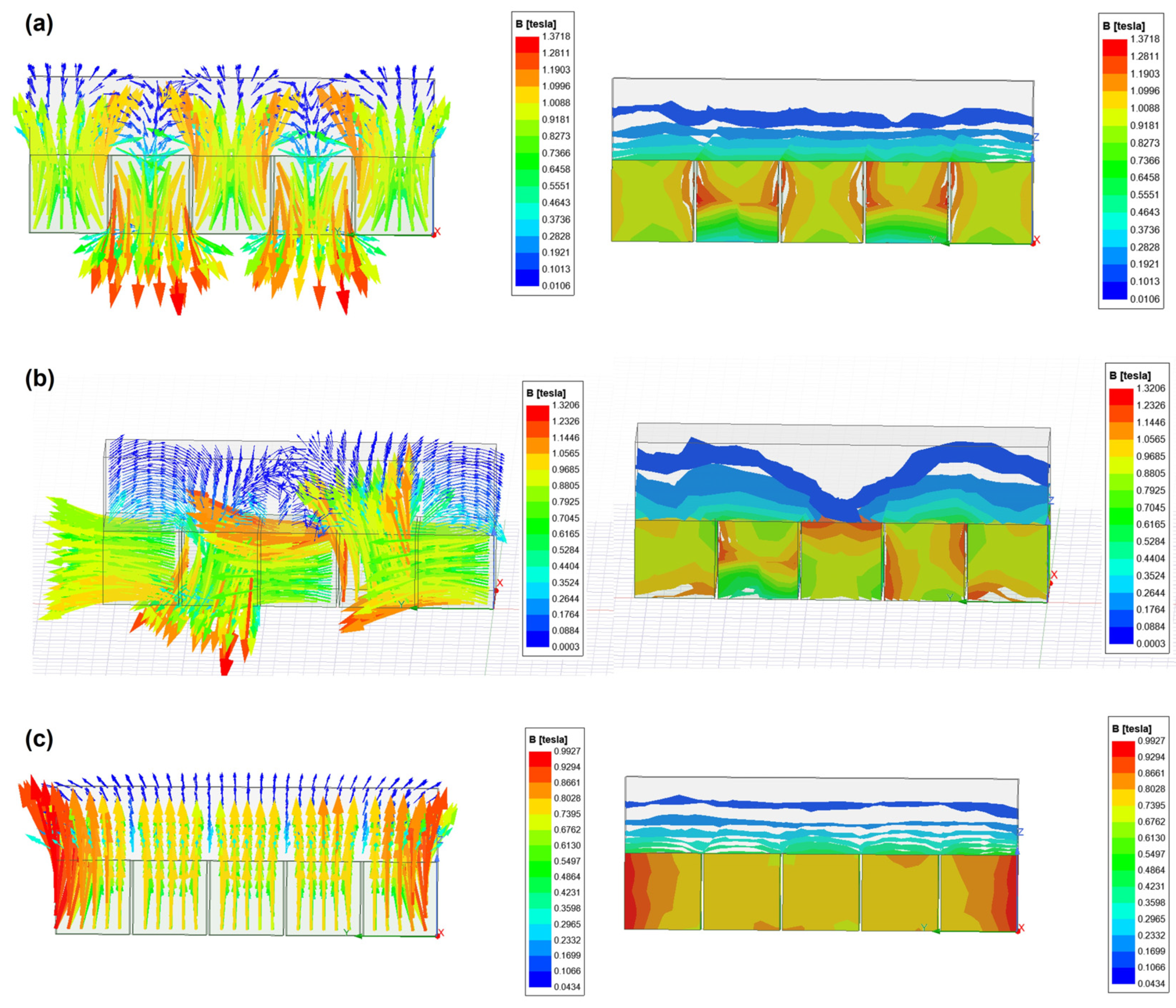

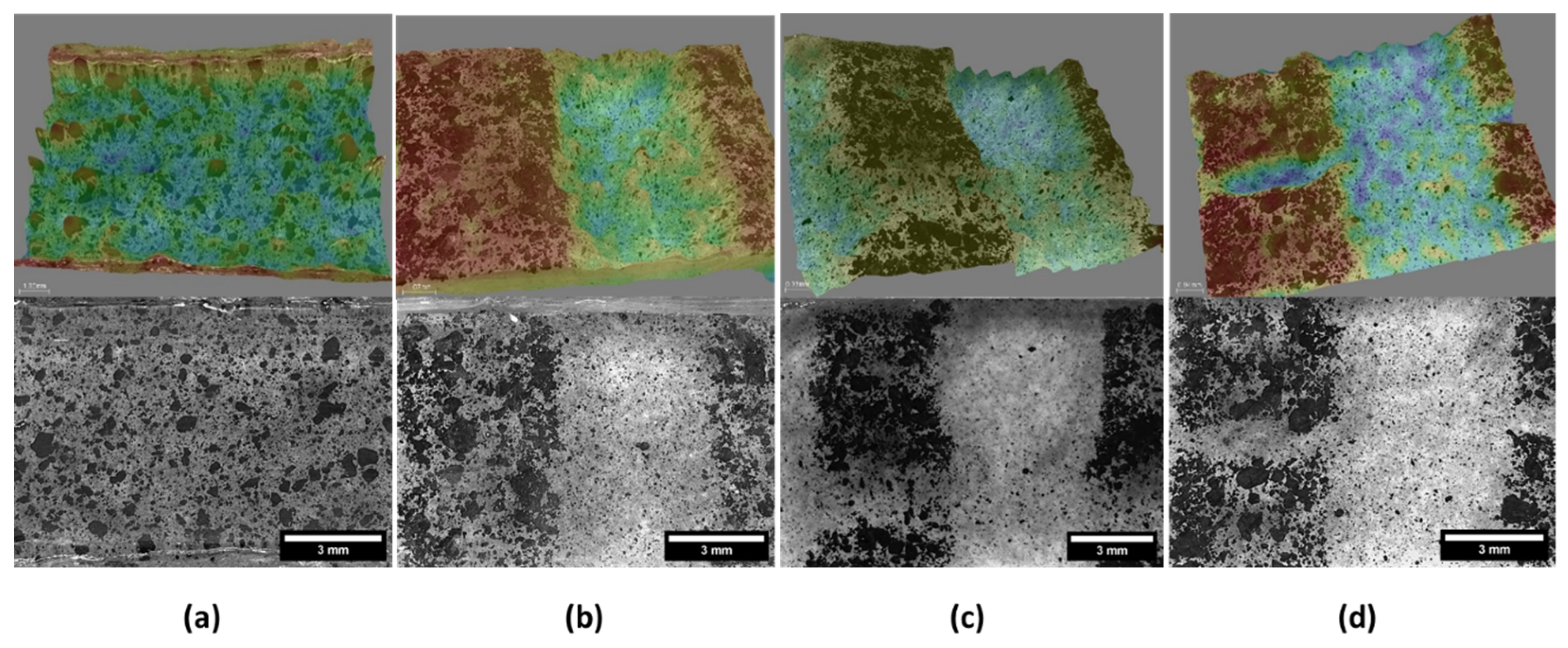

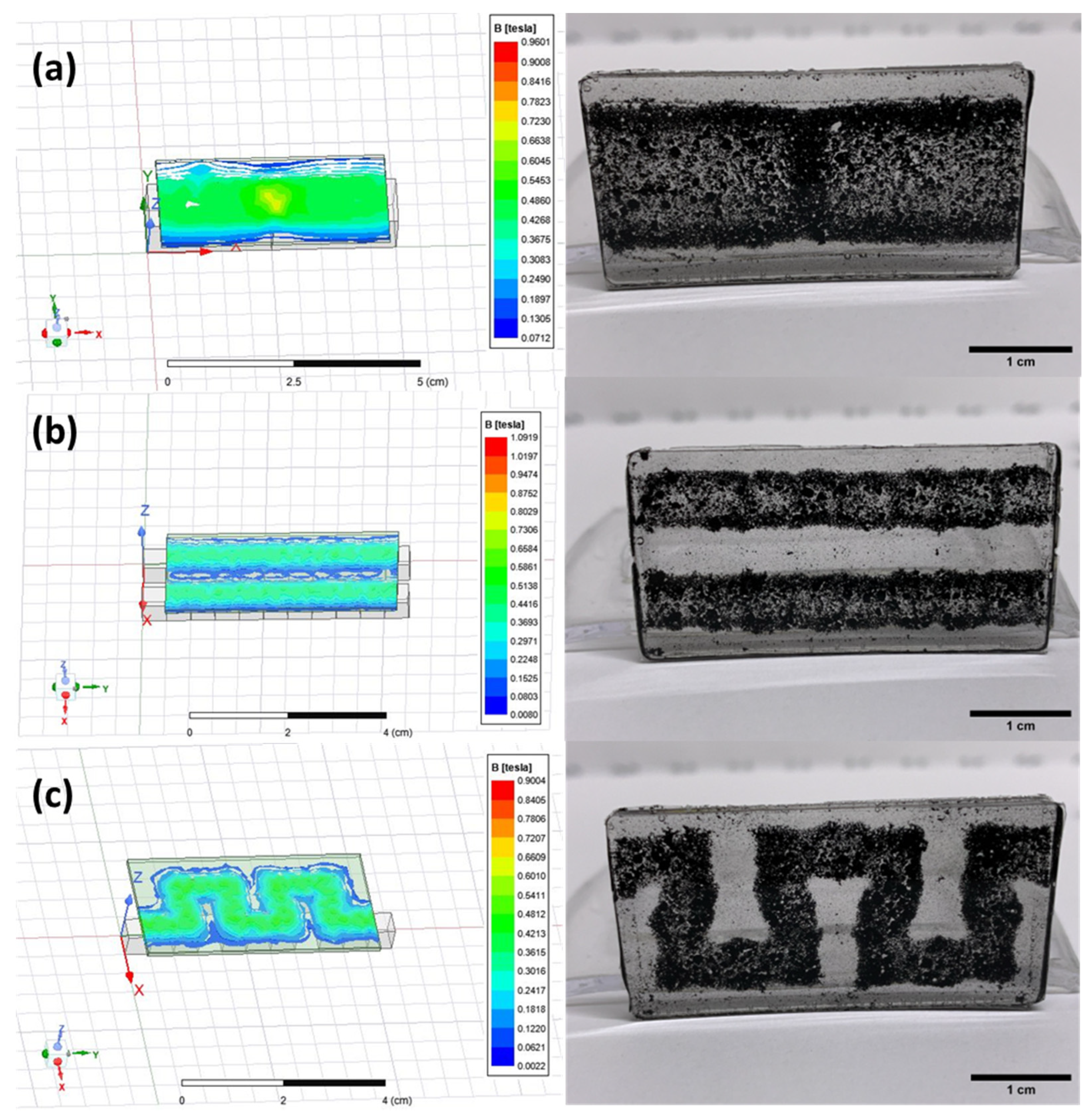

3.3. Numerical Simulations and MWCNT/PDMS Magnetic Patterning

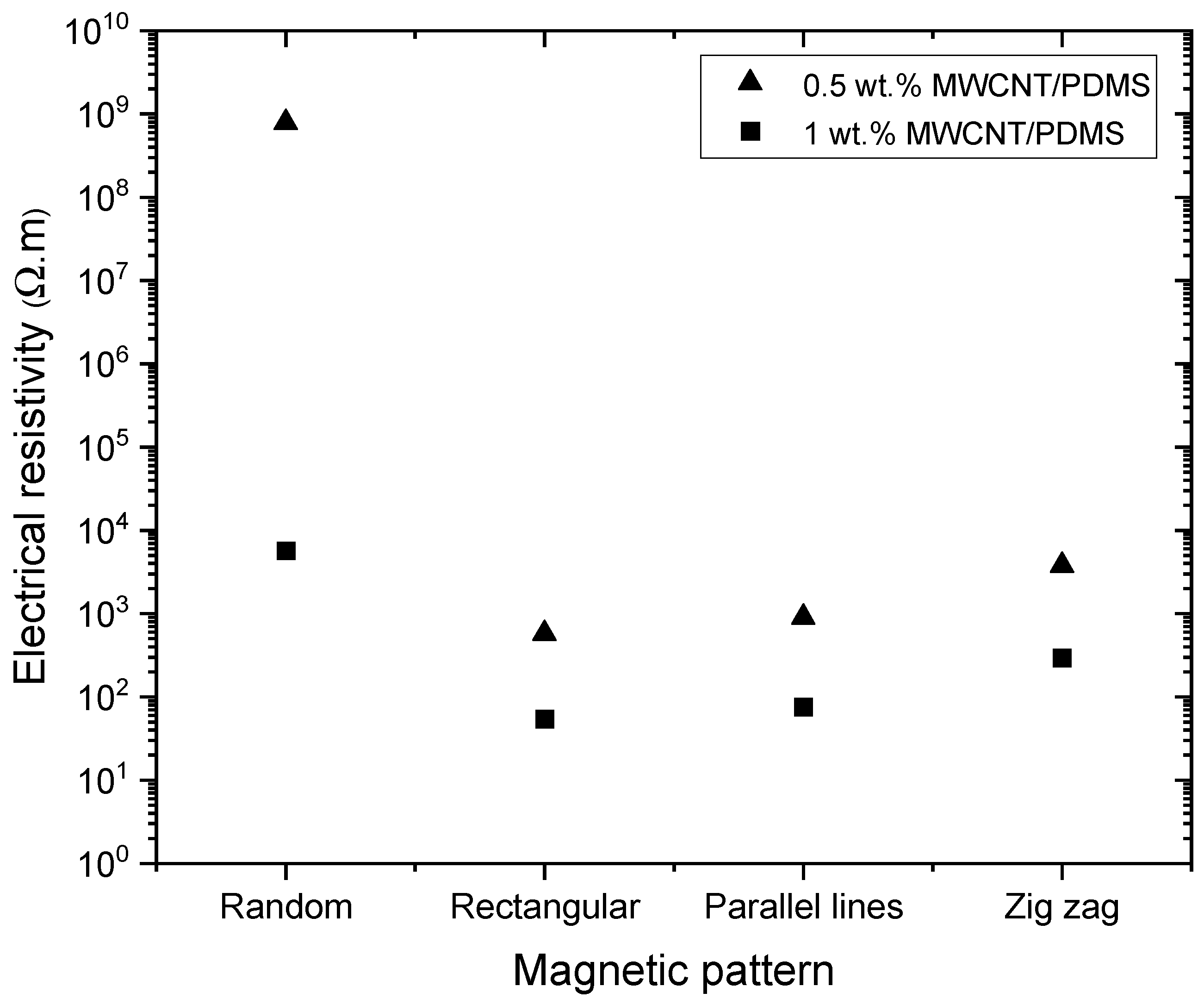

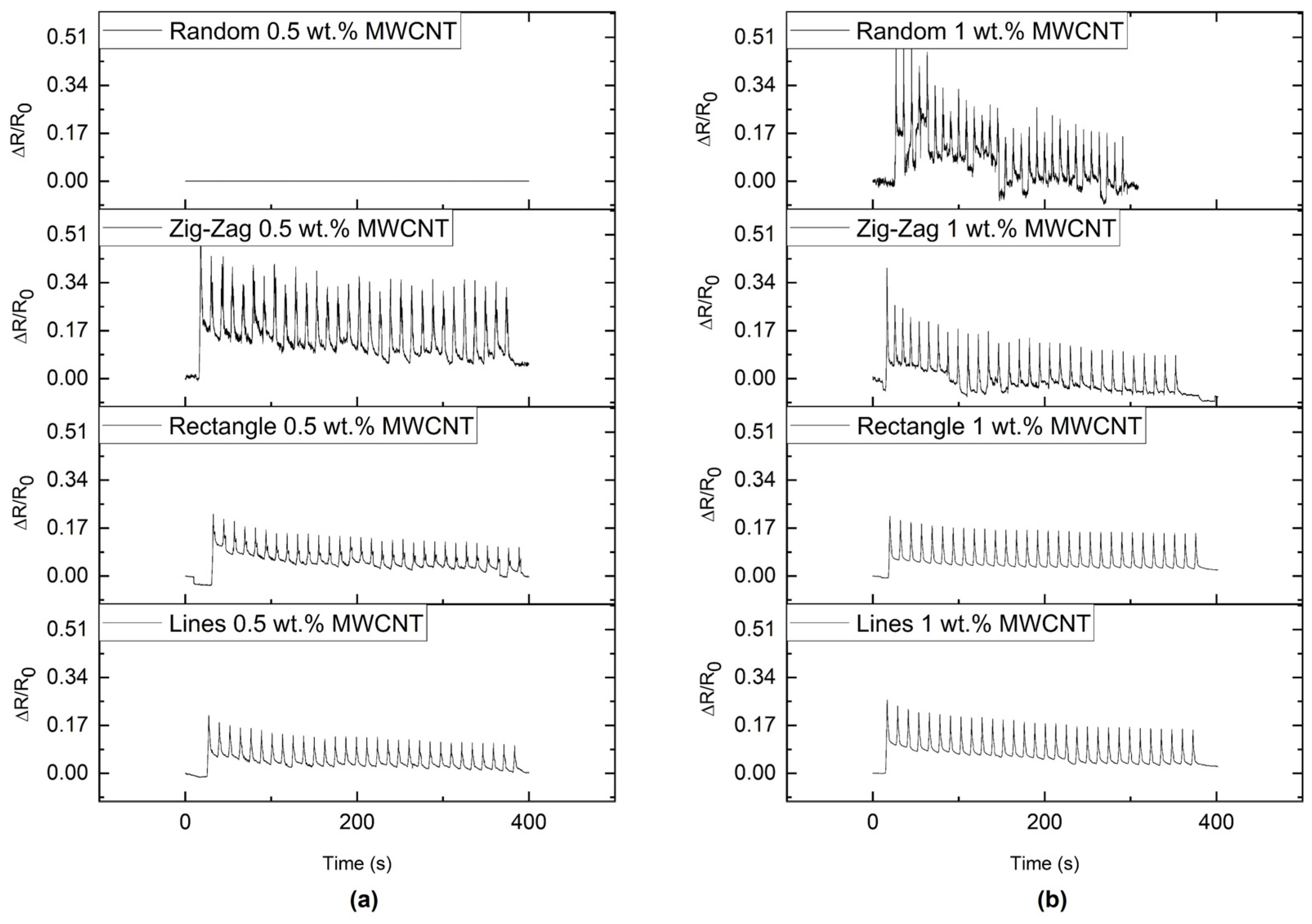

3.4. Low Electrical Percolation Threshold Piezoresistive Sensors

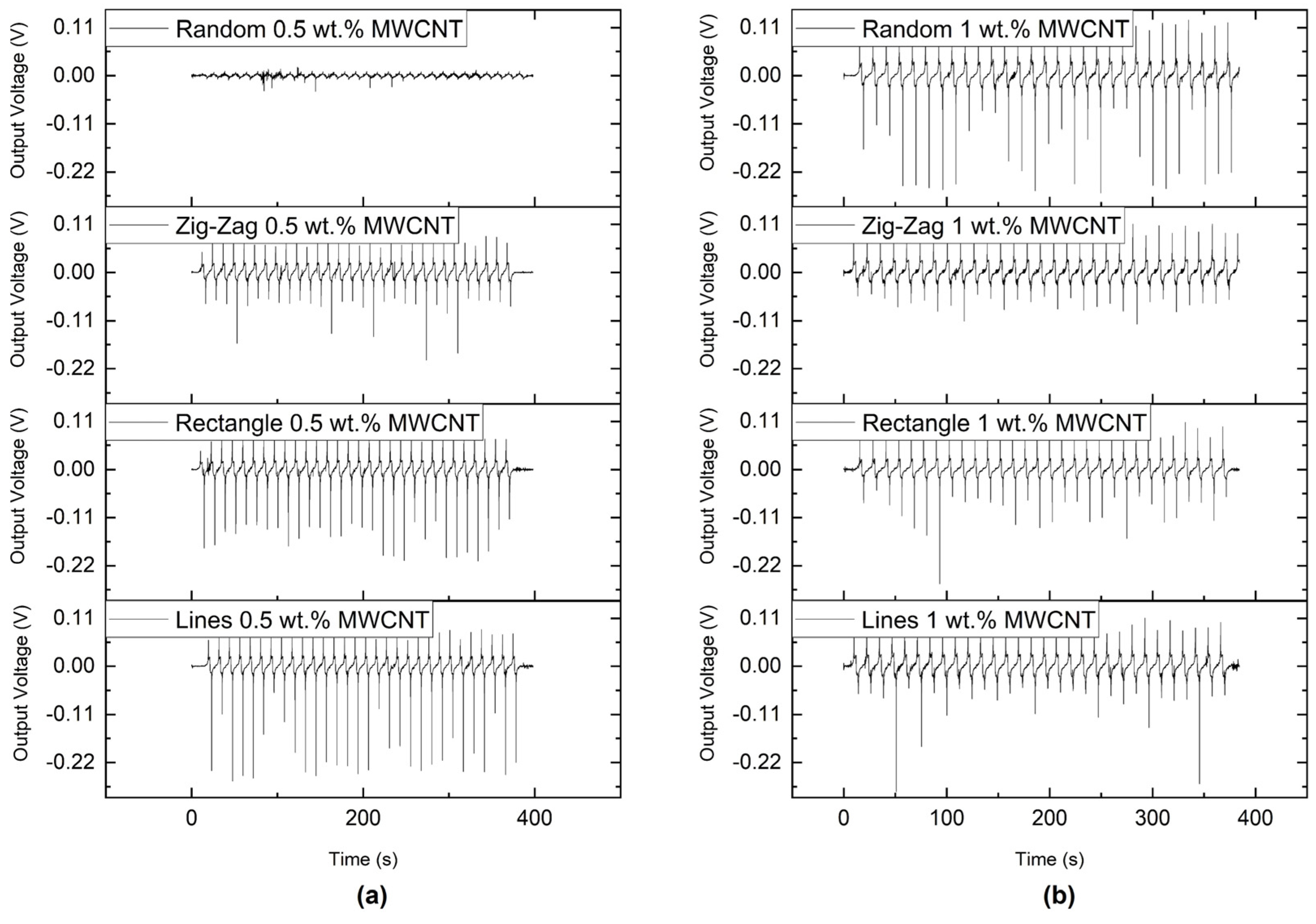

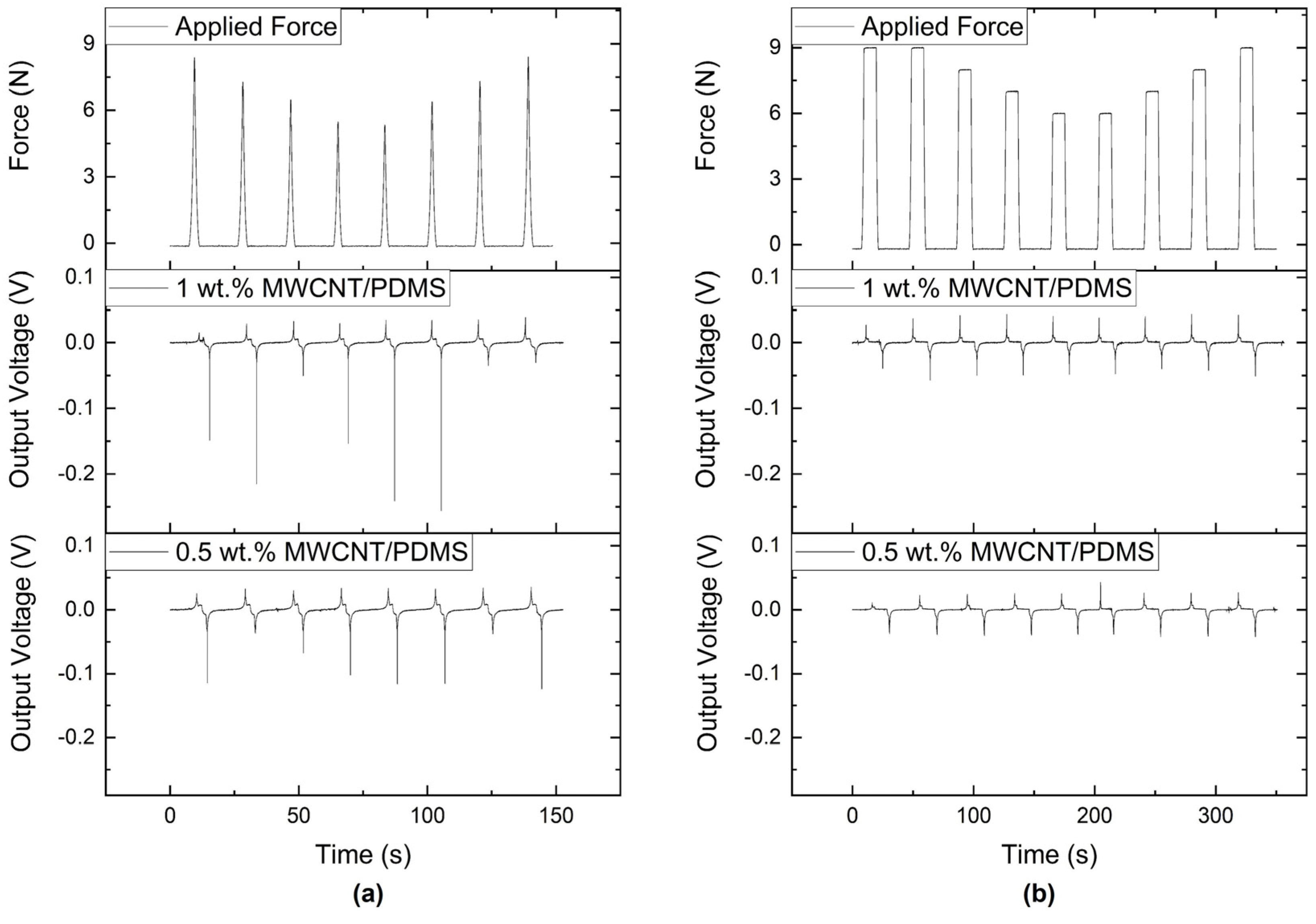

3.5. Low Electrical Percolation Threshold Triboelectric Sensors

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Liu, H.; Thostenson, E.T. 6.11 Conductive Nanocomposites for Multifunctional Sensing Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 315–351. [Google Scholar]

- Kausar, A.; Taherian, R. Effect of External Fields on Electrical Conductivity of Polymer-Based Composites. Electr. Conduct. Polym. Compos. Exp. Model. Appl. 2018, 275–295. [Google Scholar] [CrossRef]

- Xie, X.-L.; Mai, Y.-W.; Zhou, X.-P. Dispersion and alignment of carbon nanotubes in polymer matrix: A review. Mater. Sci. Eng. R. Rep. 2005, 49, 89–112. [Google Scholar] [CrossRef]

- Shrivastava, N.K.; Khatua, B.B. Development of electrical conductivity with minimum possible percolation threshold in multi-wall carbon nanotube/polystyrene composites. Carbon N. Y. 2011, 49, 4571–4579. [Google Scholar] [CrossRef]

- Salehiyan, R.; Ray, S.S. Tuning the Conductivity of Nanocomposites through Nanoparticle Migration and Interface Crossing in Immiscible Polymer Blends: A Review on Fundamental Understanding. Macromol. Mater. Eng. 2018, 304, 1800431. [Google Scholar] [CrossRef]

- McNally, T.; Pötschke, P.; Halley, P.; Murphy, M.; Martin, D.; Bell, S.E.; Brennan, G.P.; Bein, D.; Lemoine, P.; Quinn, J.P. Polyethylene multiwalled carbon nanotube composites. Polymer 2005, 46, 8222–8232. [Google Scholar] [CrossRef]

- Rudnev, V.I. Systematic analysis of induction coil failures. Heat Treat. Prog. 2006, 19, 21–26. [Google Scholar]

- Ariu, G.; Hamerton, I.; Ivanov, D. Positioning and aligning CNTs by external magnetic field to assist localised epoxy cure. Open Phys. 2016, 14, 508–516. [Google Scholar] [CrossRef]

- Fujiwara, M.; Oki, E.; Hamada, M.; Tanimoto, Y.; Mukouda, I.; Shimomura, Y. Magnetic Orientation and Magnetic Properties of a Single Carbon Nanotube. J. Phys. Chem. A 2001, 105, 4383–4386. [Google Scholar] [CrossRef]

- Ma, Y.; O Lehtinen, P.; Foster, A.S.; Nieminen, R.M. Magnetic properties of vacancies in graphene and single-walled carbon nanotubes. New J. Phys. 2004, 6, 68. [Google Scholar] [CrossRef]

- Lipert, K.; Ritschel, M.; Leonhardt, A.; Krupskaya, Y.; Büchner, B.; Klingeler, R. Magnetic properties of carbon nanotubes with and without catalyst. J. Physics Conf. Ser. 2010, 200, 72061. [Google Scholar] [CrossRef]

- Fu, X.; Ramos, M.; Al-Jumaily, A.M.; Meshkinzar, A.; Huang, X. Stretchable strain sensor facilely fabricated based on multi-wall carbon nanotube composites with excellent performance. J. Mater. Sci. 2018, 54, 2170–2180. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, C.; Zhou, Q. A Self-Powered Basketball Training Sensor Based on Triboelectric Nanogenerator. Appl. Sci. 2021, 11, 3506. [Google Scholar] [CrossRef]

- Rasel, M.S.; O Cho, H.; Kim, J.W.; Park, J.Y. A self-powered triboelectric sensor for wide-range pressure detection in wearable application. J. Phys. Conf. Ser. 2018, 1052, 012029. [Google Scholar] [CrossRef]

- Liu, P.; Sun, N.; Mi, Y.; Luo, X.; Dong, X.; Cai, J.; Jia, X.; Ramos, M.A.; Hu, T.S.; Xu, Q. Ultra-low CNTs filled high-performance fast self-healing triboelectric nanogenerators for wearable electronics. Compos. Sci. Technol. 2021, 208, 108733. [Google Scholar] [CrossRef]

- Yoon, S.G.; Chang, S.T. Microfluidic capacitive sensors with ionic liquid electrodes and CNT/PDMS nanocomposites for simultaneous sensing of pressure and temperature. J. Mater. Chem. C 2017, 5, 1910–1919. [Google Scholar] [CrossRef]

- Kwon, M.; Hong, Y. Flexible temperature sensor array of PDMS-encapsulated conductive CNT thin films fabricated by solution process. In Proceedings of the 2009 International Semiconductor Device Research Symposium, College Park, MD, USA, 9–11 December 2009; pp. 1–2. [Google Scholar]

- Jang, S.-H.; Park, Y.-L. Carbon nanotube-reinforced smart composites for sensing freezing temperature and deicing by self-heating. Nanomater. Nanotechnol. 2018, 8, 1847980418776473. [Google Scholar] [CrossRef]

- Souri, H.; Banerjee, H.; Jusufi, A.; Radacsi, N.; Stokes, A.A.; Park, I.; Sitti, M.; Amjadi, M. Wearable and stretchable strain sensors: Materials, sensing mechanisms, and applications. Adv. Intell. Syst. 2020, 2, 2000039. [Google Scholar] [CrossRef]

- Paiva, M.C.; Simon, F.; Novais, R.M.; Ferreira, T.; Proença, M.F.; Xu, W.; Besenbacher, F. Controlled Functionalization of Carbon Nanotubes by a Solvent-free Multicomponent Approach. ACS Nano 2010, 4, 7379–7386. [Google Scholar] [CrossRef] [PubMed]

- Ellis, A.; Ingham, B. Magnetic properties of multiwalled carbon nanotubes as a function of acid treatment. J. Magn. Magn. Mater. 2005, 302, 378–381. [Google Scholar] [CrossRef]

- Zoladz, F.; Rhodes, S.; Patterson, D.; Cribb, W.; Chapagain, P.; Seifu, D.; Taufour, V.; Kamali, S.; Neupane, S. Enhanced magnetic properties of aluminum oxide nanopowder reinforced with carbon nanotubes. J. Nanoparticle Res. 2020, 22, 157. [Google Scholar] [CrossRef]

- Elsi, S.; Pushpanathan, K. Role of Cu and Mn dopants on d0 ferromagnetism of ZnS nanoparticles. J. Mater. Sci. Mater. Electron. 2019, 30, 10792–10807. [Google Scholar] [CrossRef]

- Hamidi, S.; Sobhani, A.; Aftabi, A.; Najafi, M. Optical and magneto-optical properties of aligned Ni nanowires embedded in polydimethylsiloxane. J. Magn. Magn. Mater. 2015, 374, 139–143. [Google Scholar] [CrossRef]

- Huang, K.; Ning, H.; Hu, N.; Liu, F.; Wu, X.; Wang, S.; Liu, Y.; Zou, R.; Yuan, W.; Wu, L. Ultrasensitive MWCNT/PDMS composite strain sensor fabricated by laser ablation process. Compos. Sci. Technol. 2020, 192, 108105. [Google Scholar] [CrossRef]

- Wu, J.; Zheng, Y.; Li, X. Recent Progress in Self-Powered Sensors Based on Triboelectric Nanogenerators. Sensors 2021, 21, 7129. [Google Scholar] [CrossRef]

- Kao, F.-C.; Ho, H.-H.; Chiu, P.-Y.; Hsieh, M.-K.; Liao, J.; Lai, P.-L.; Huang, Y.-F.; Dong, M.-Y.; Tsai, T.-T.; Lin, Z.-H. Self-assisted wound healing using piezoelectric and triboelectric nanogenerators. Sci. Technol. Adv. Mater. 2022, 23, 1–16. [Google Scholar] [CrossRef]

- Xu, J.; Zou, Y.; Nashalian, A.; Chen, J. Leverage Surface Chemistry for High-Performance Triboelectric Nanogenerators. Front. Chem. 2020, 8, 577327. [Google Scholar] [CrossRef] [PubMed]

- Hwang, H.; Lee, K.Y.; Shin, D.; Shin, J.; Kim, S.; Choi, W. Metal-free, flexible triboelectric generator based on MWCNT mesh film and PDMS layers. Appl. Surf. Sci. 2018, 442, 693–699. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Esteves, D.S.; Durães, N.; Pedroso, R.; Melo, A.; Paiva, M.C.; Sequeiros, E.W. Fabrication of Low Electrical Percolation Threshold Multi-Walled Carbon Nanotube Sensors Using Magnetic Patterning. Appl. Sci. 2023, 13, 1437. https://doi.org/10.3390/app13031437

Esteves DS, Durães N, Pedroso R, Melo A, Paiva MC, Sequeiros EW. Fabrication of Low Electrical Percolation Threshold Multi-Walled Carbon Nanotube Sensors Using Magnetic Patterning. Applied Sciences. 2023; 13(3):1437. https://doi.org/10.3390/app13031437

Chicago/Turabian StyleEsteves, David Seixas, Nelson Durães, Rúben Pedroso, Amanda Melo, Maria C. Paiva, and Elsa W. Sequeiros. 2023. "Fabrication of Low Electrical Percolation Threshold Multi-Walled Carbon Nanotube Sensors Using Magnetic Patterning" Applied Sciences 13, no. 3: 1437. https://doi.org/10.3390/app13031437

APA StyleEsteves, D. S., Durães, N., Pedroso, R., Melo, A., Paiva, M. C., & Sequeiros, E. W. (2023). Fabrication of Low Electrical Percolation Threshold Multi-Walled Carbon Nanotube Sensors Using Magnetic Patterning. Applied Sciences, 13(3), 1437. https://doi.org/10.3390/app13031437