A Wind-Turbine-Tower-Climbing Robot Prototype Operating at Various Speeds and Payload Capacity: Development and Validation

Abstract

1. Introduction

2. Materials and Methods

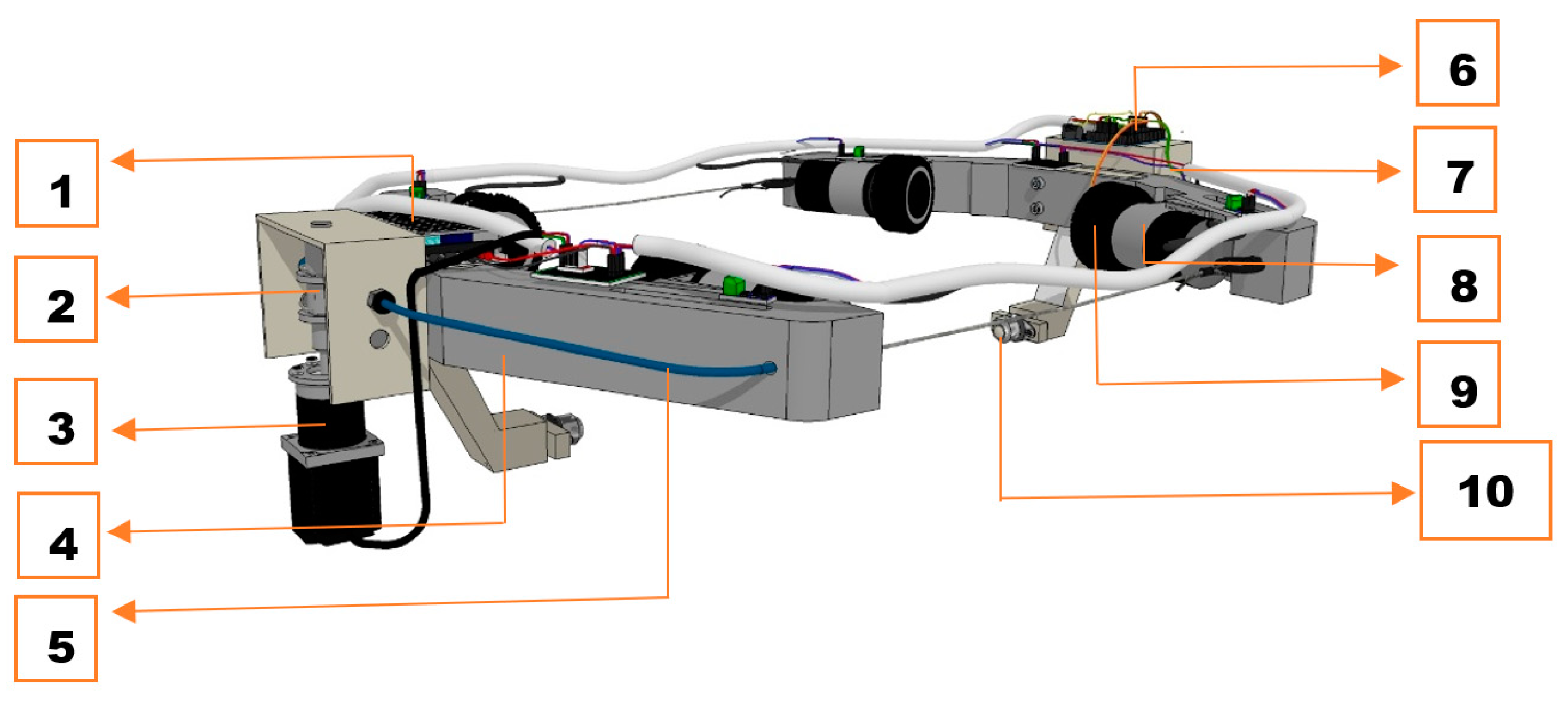

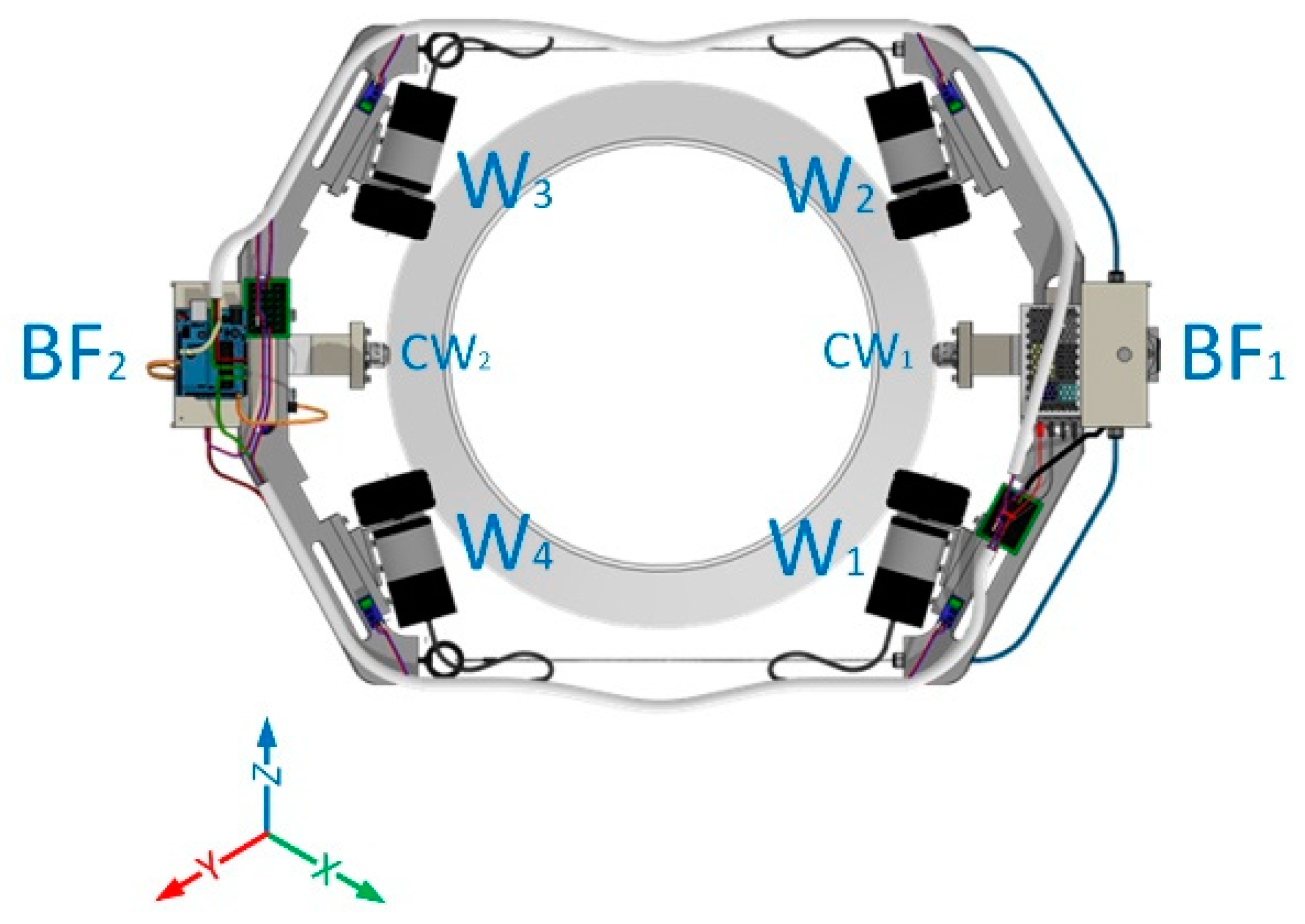

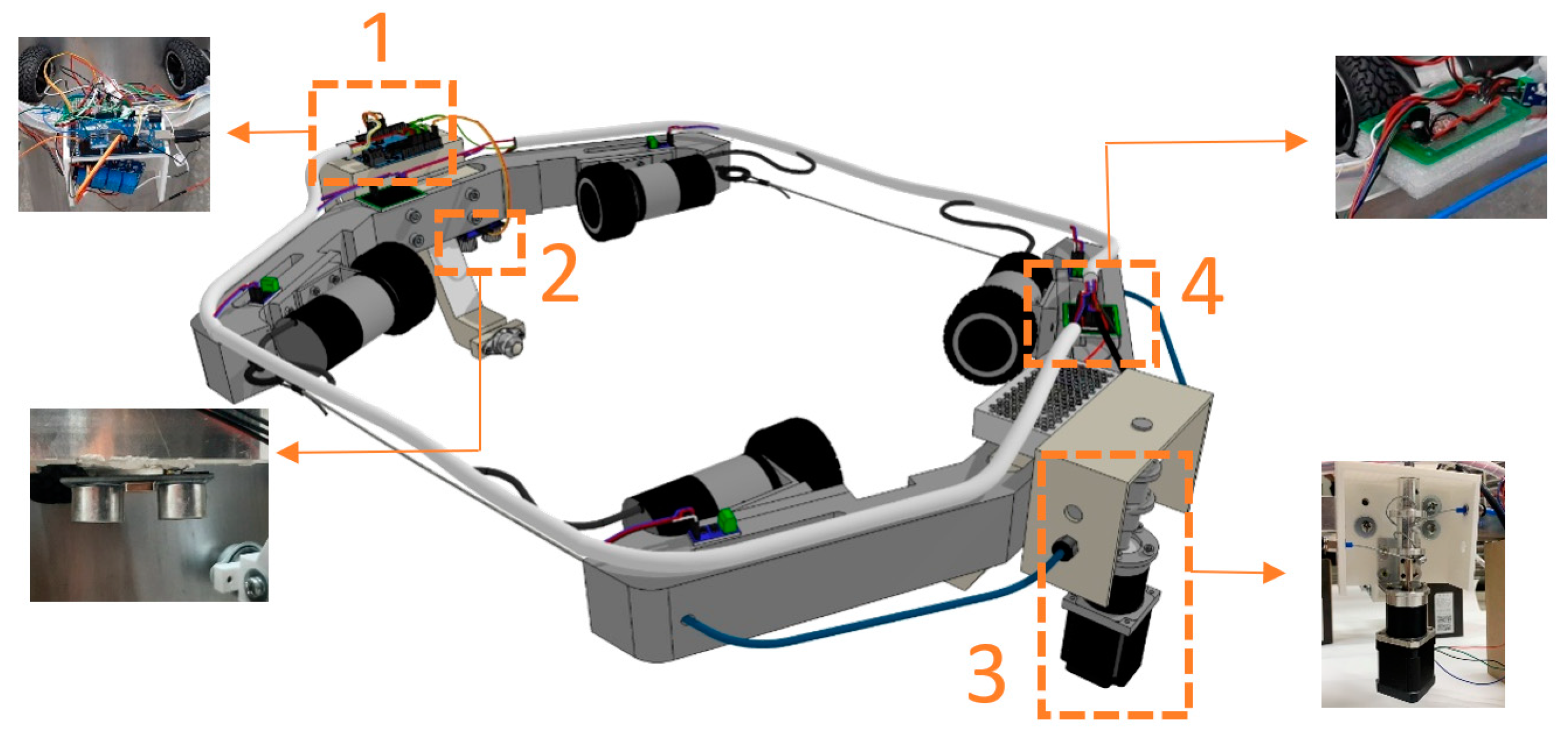

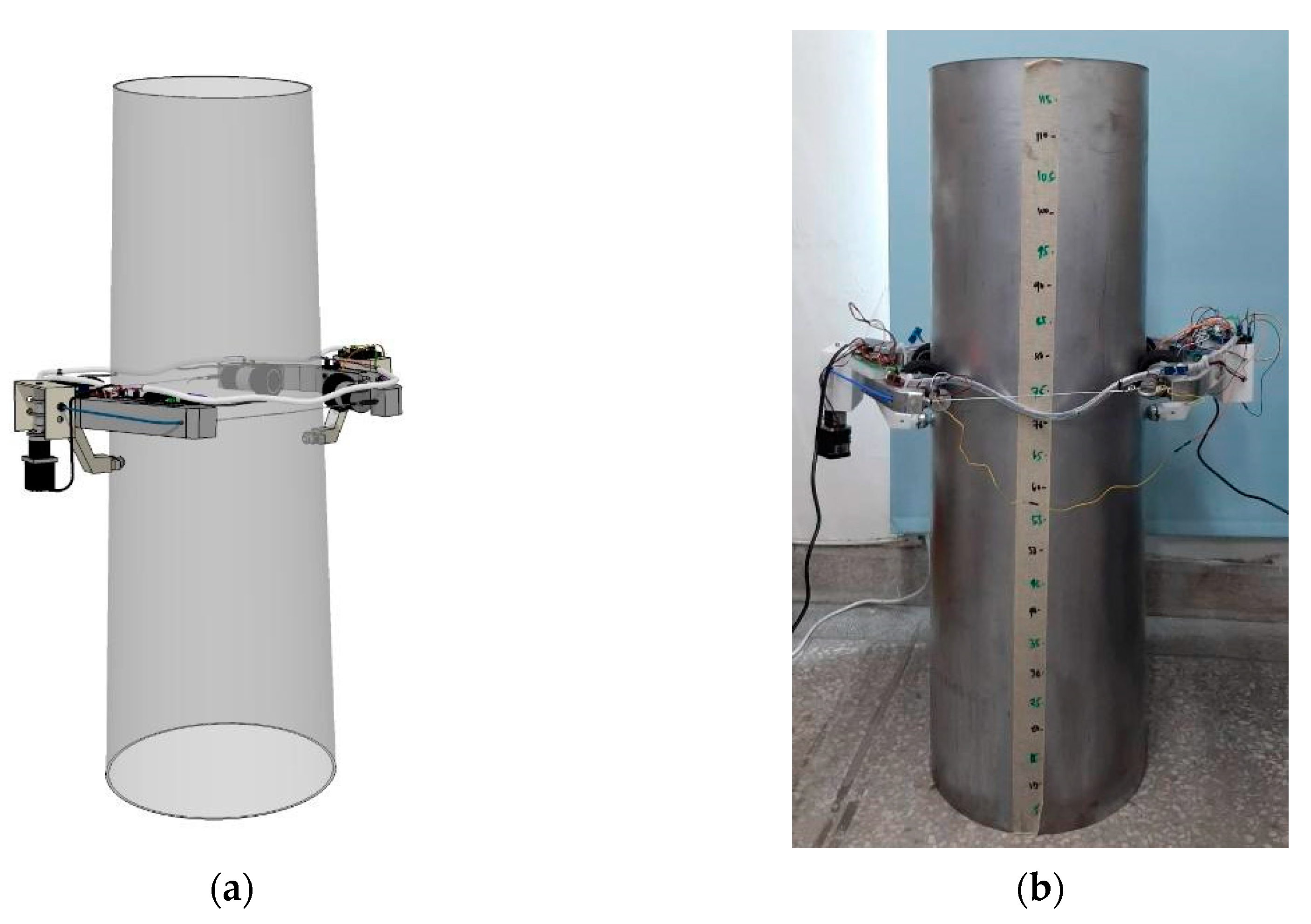

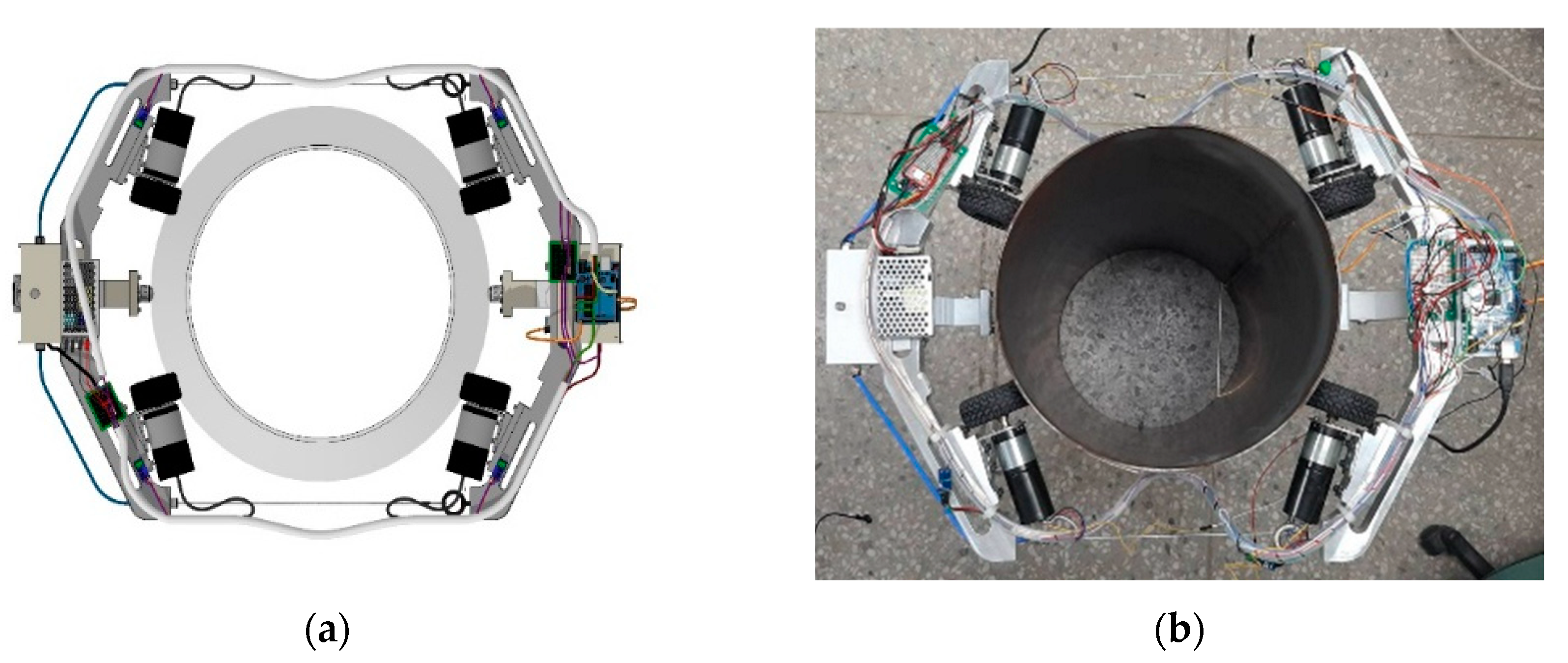

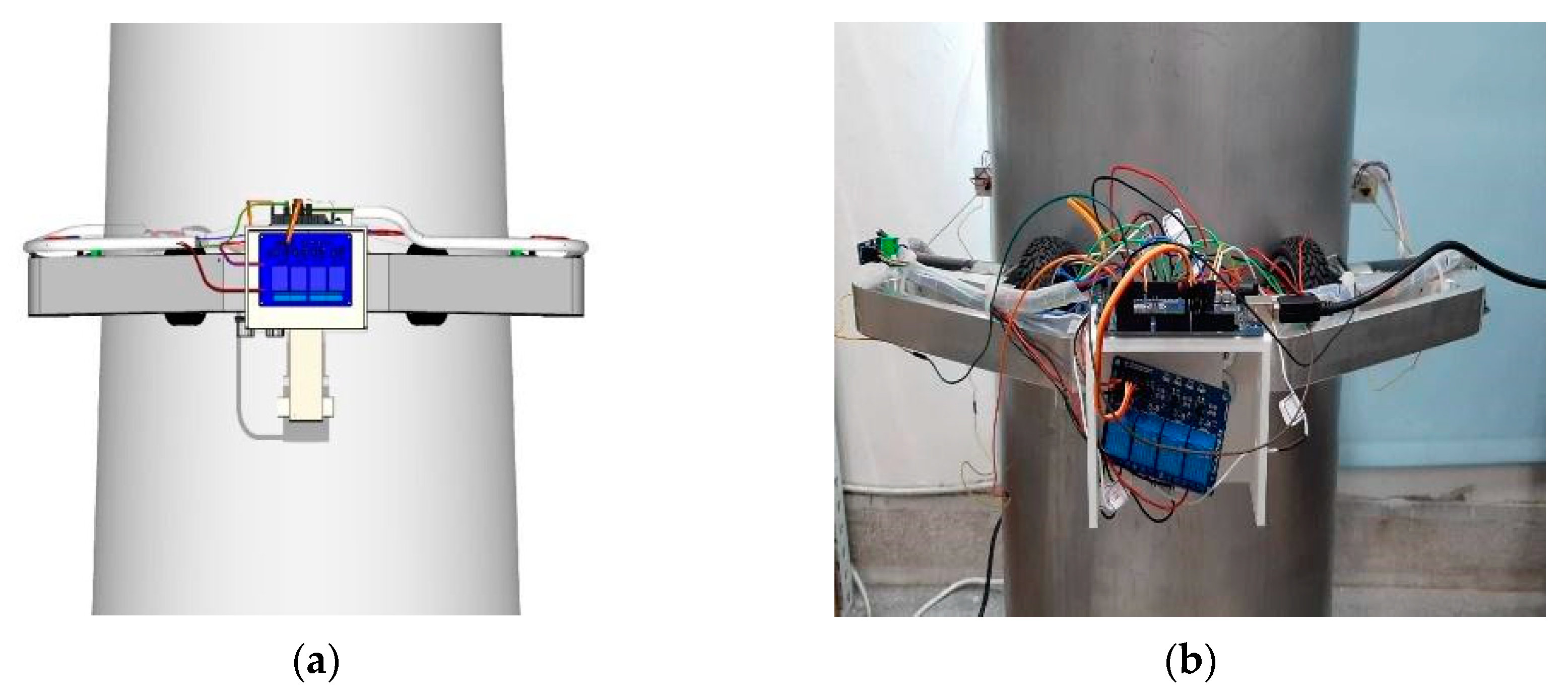

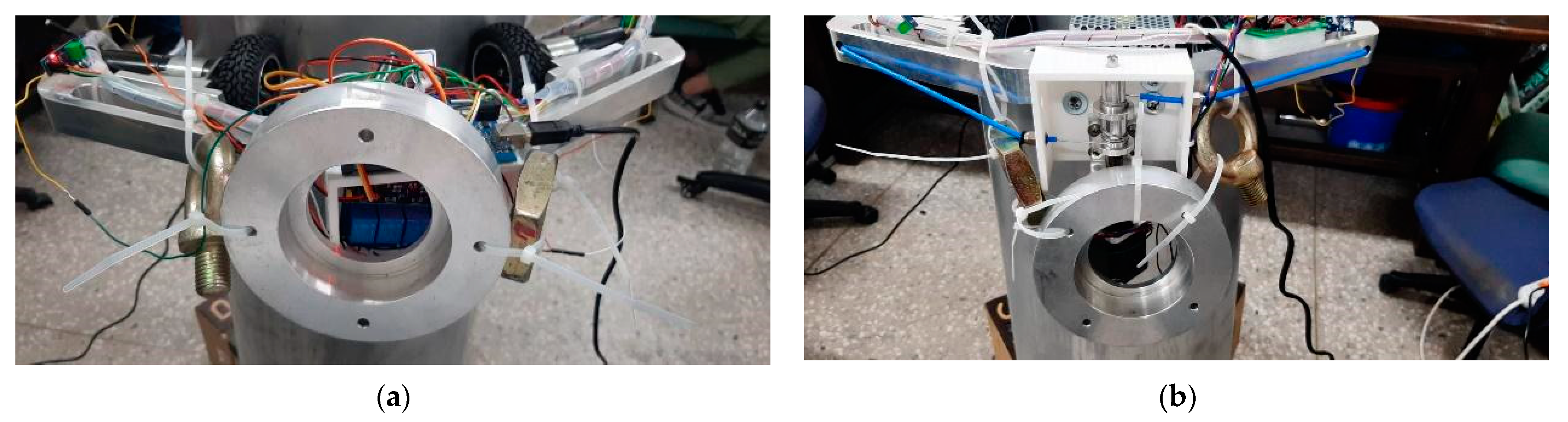

2.1. Climbing Robot Description

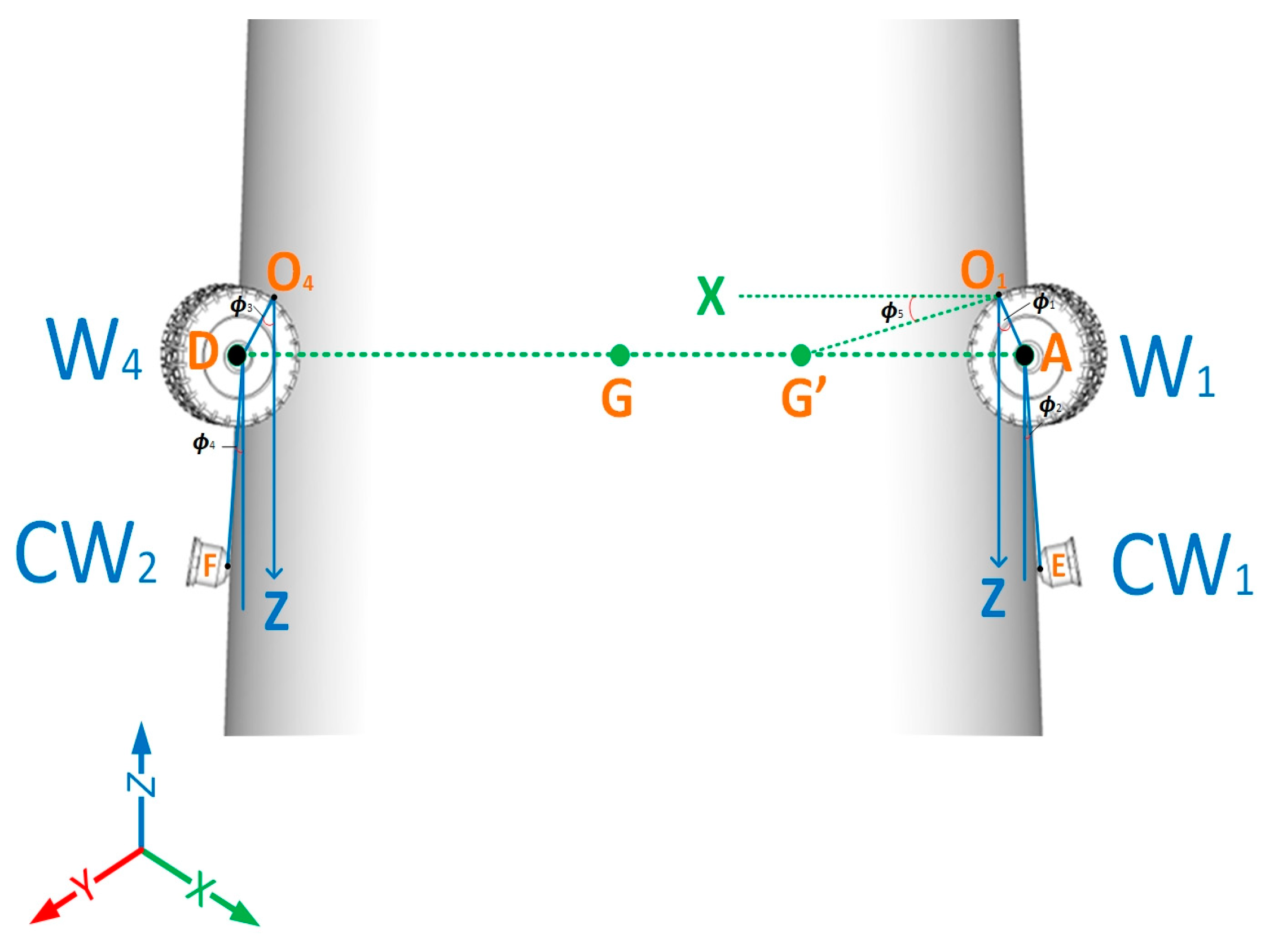

2.2. Kinematic and Dynamic Equation of Motion

2.2.1. Kinematic Analysis for Wheel 1 and Caster Wheel 1

Position of W1 and CW1

Speed of W1 and CW1

Acceleration of W1 and CW1

2.2.2. Kinematic Analysis for Wheel 4 and Caster Wheel 2

Position of W4 and CW2

Speed of W4 and CW2

Acceleration of W4 and CW2

2.2.3. Analysis of the Robot Body

Position

Speed

Acceleration

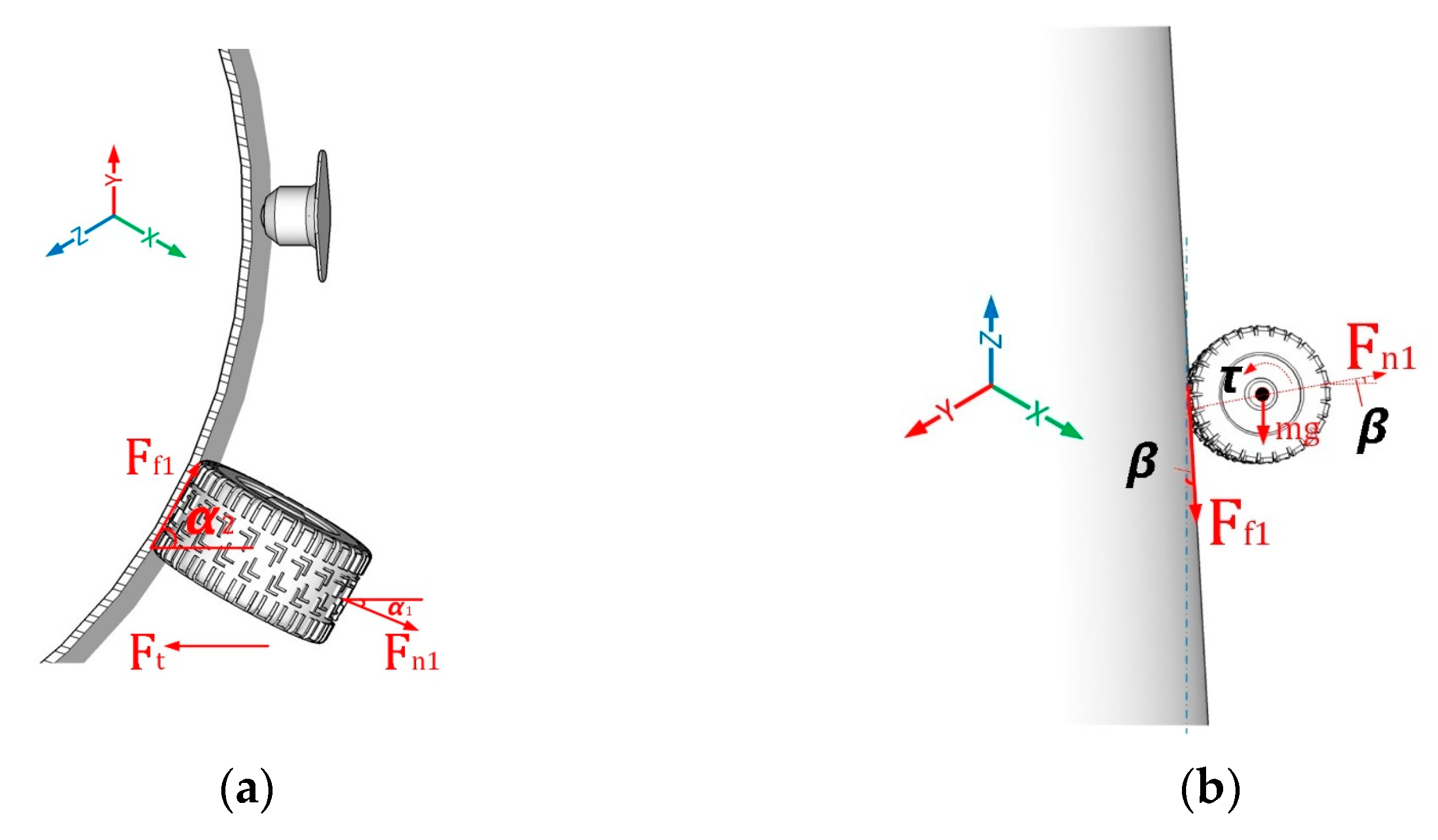

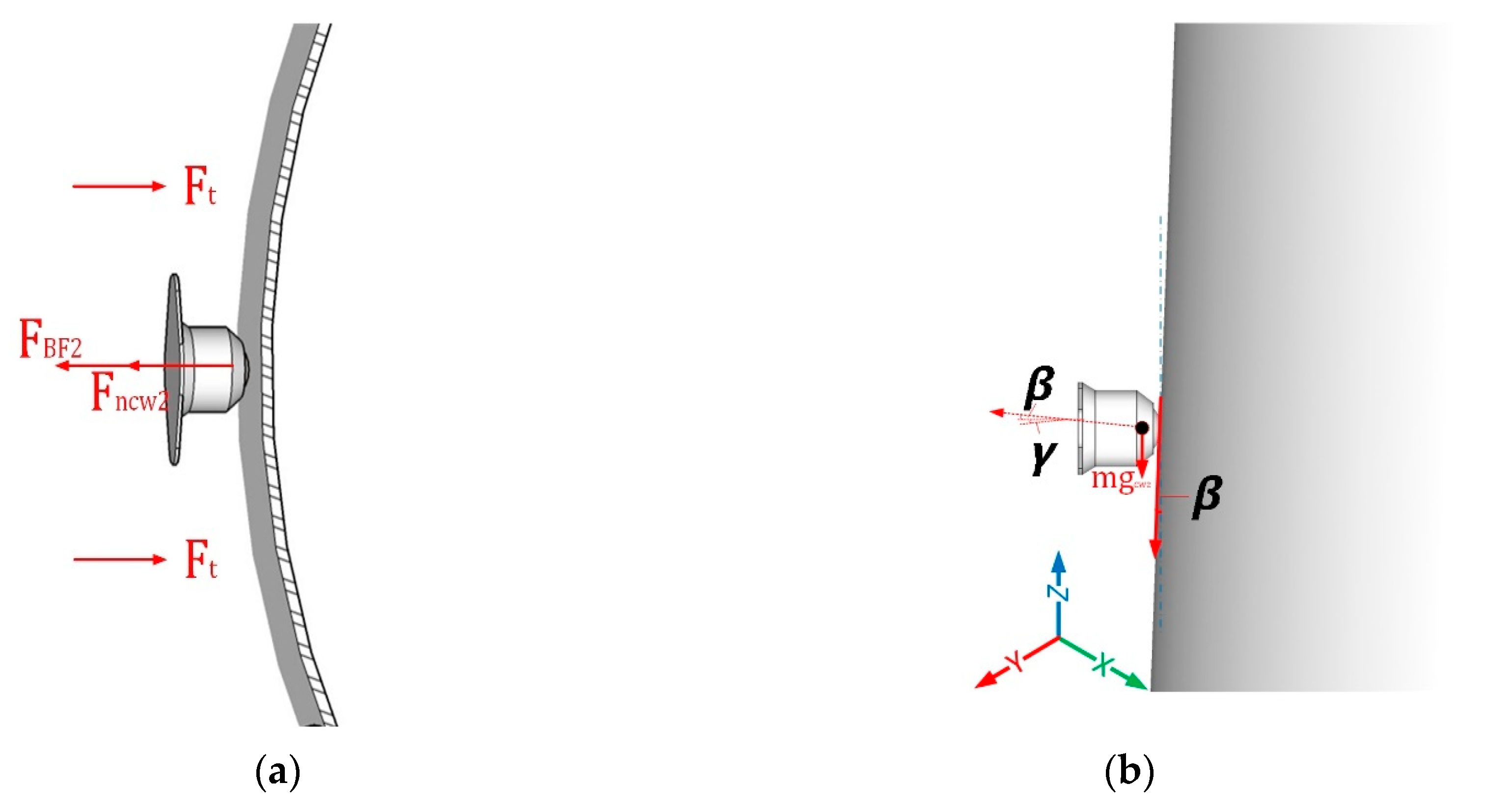

2.2.4. Dynamic Analysis of Each Robot Driving Wheel

Forces of Wheel 1

- ⤽

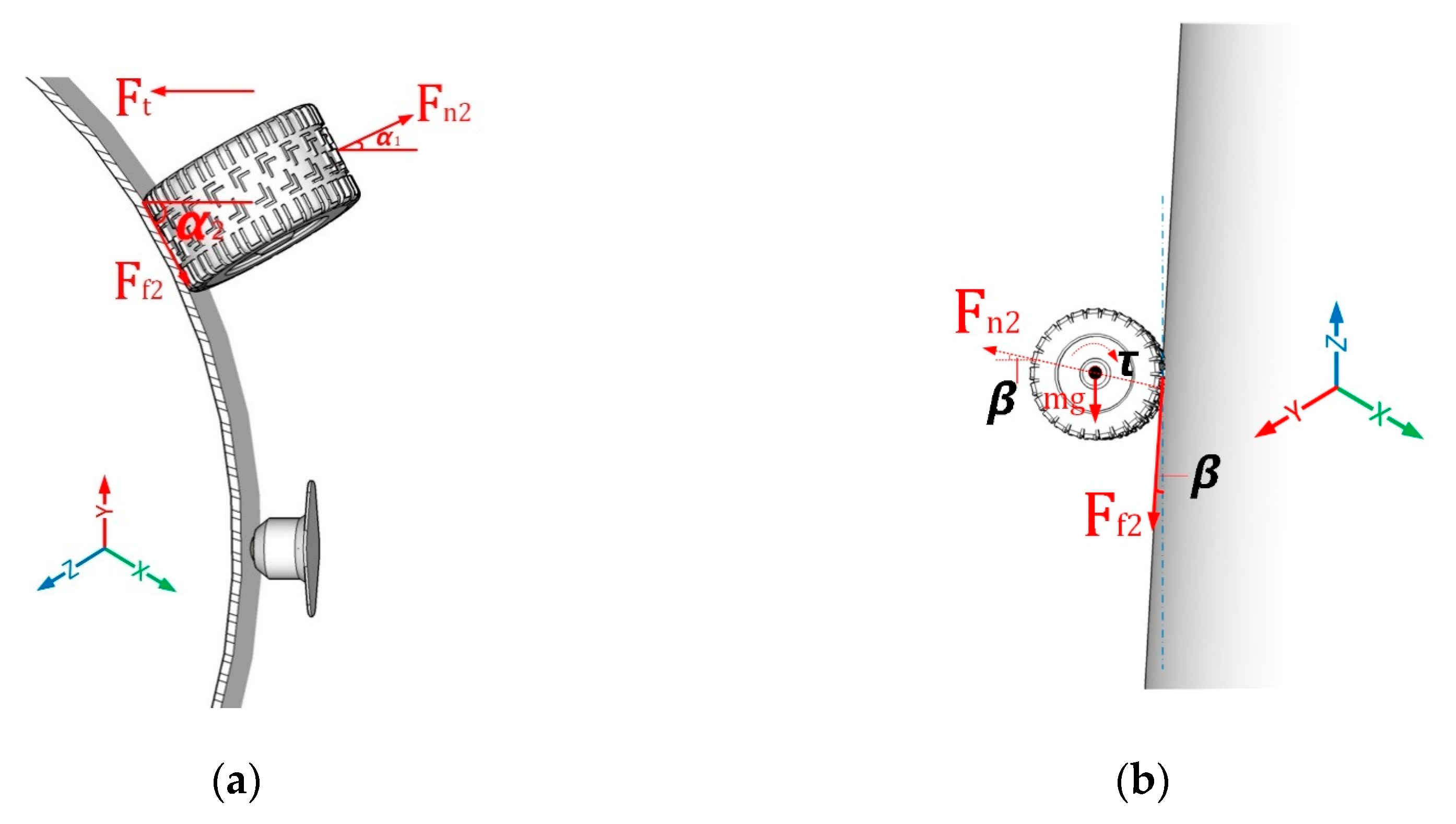

Forces of Wheel 2

- ⤼

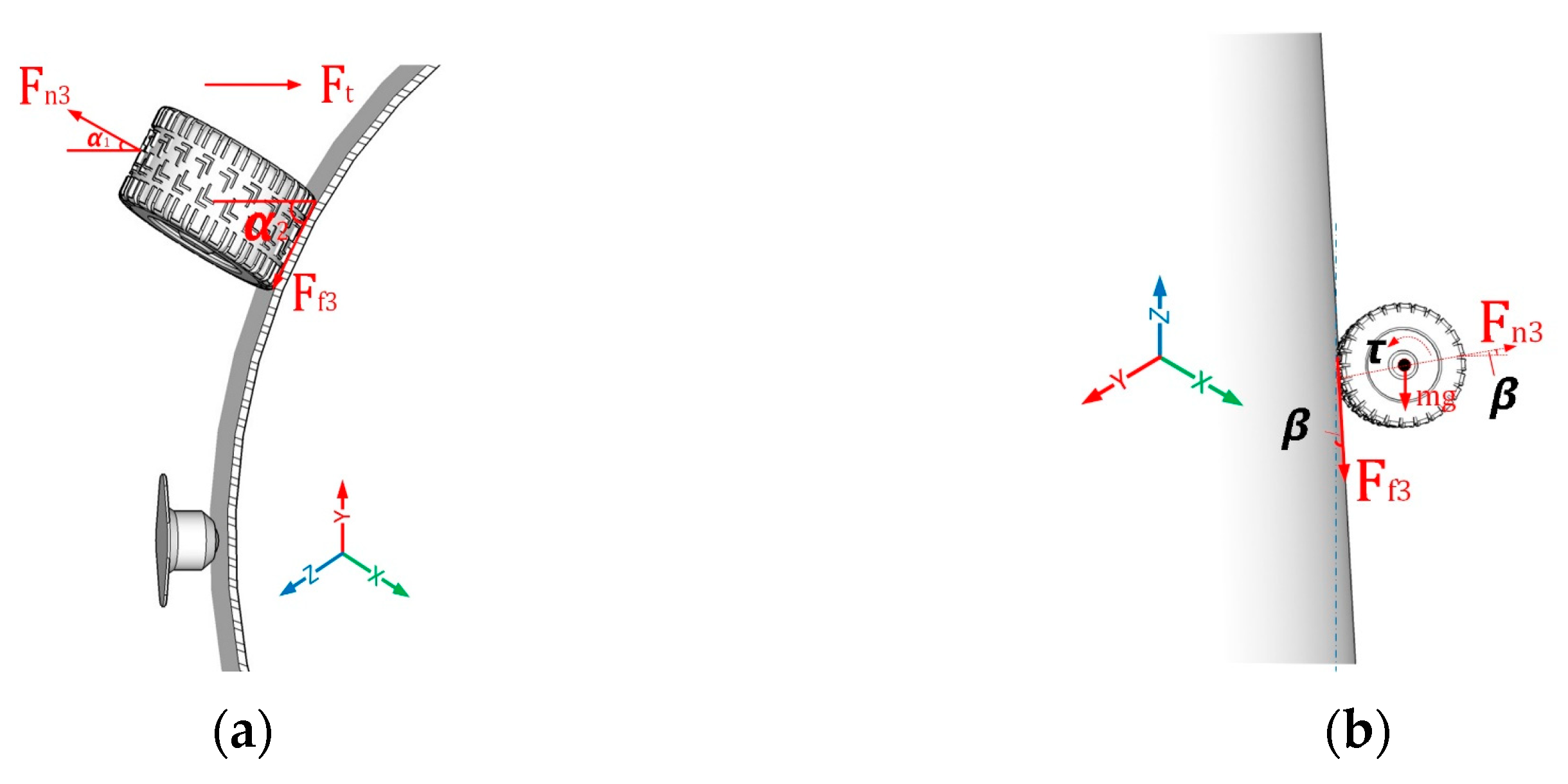

Forces of Wheel 3

- ⤽

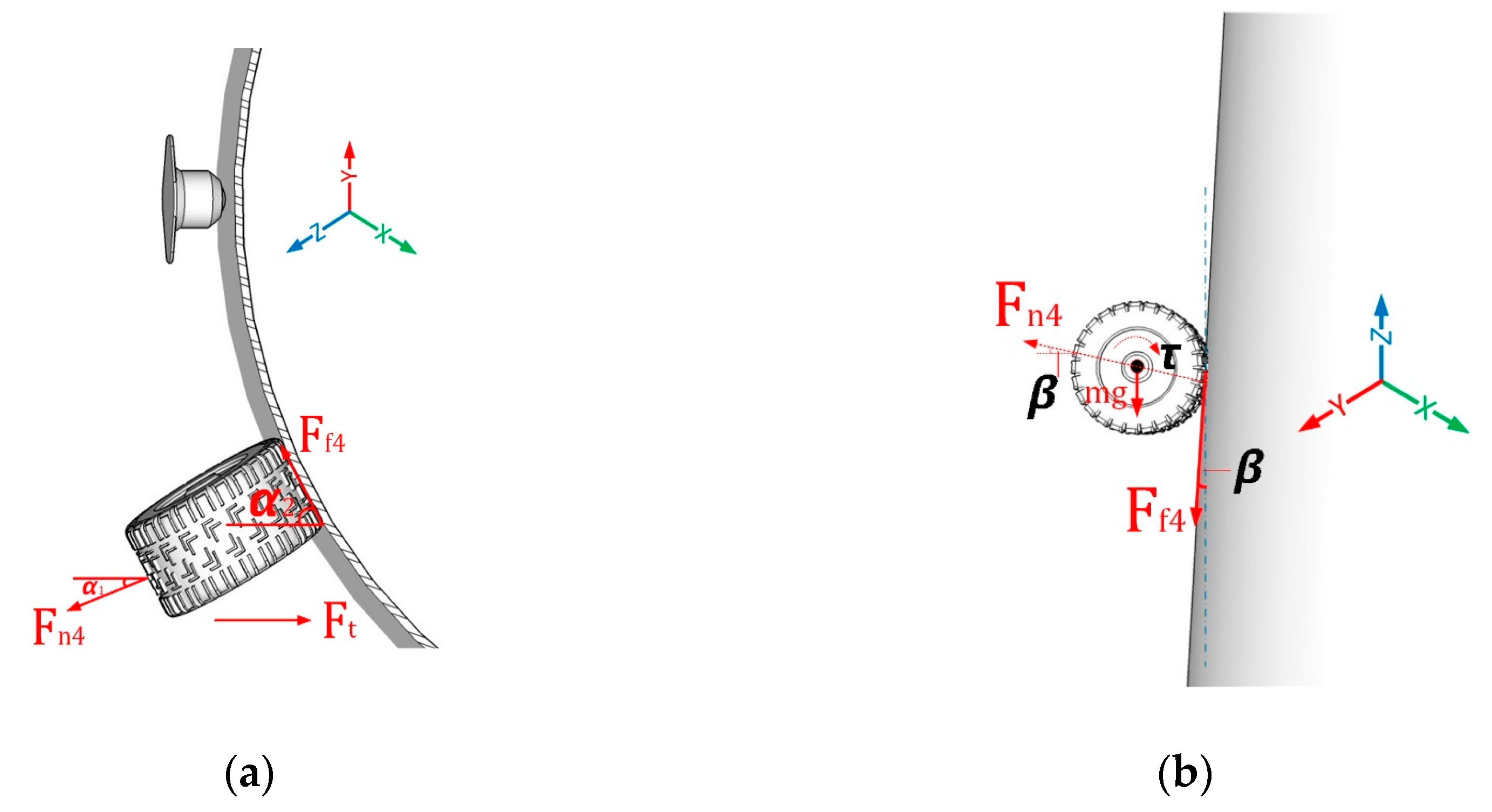

Forces of Wheel 4

- ⤼

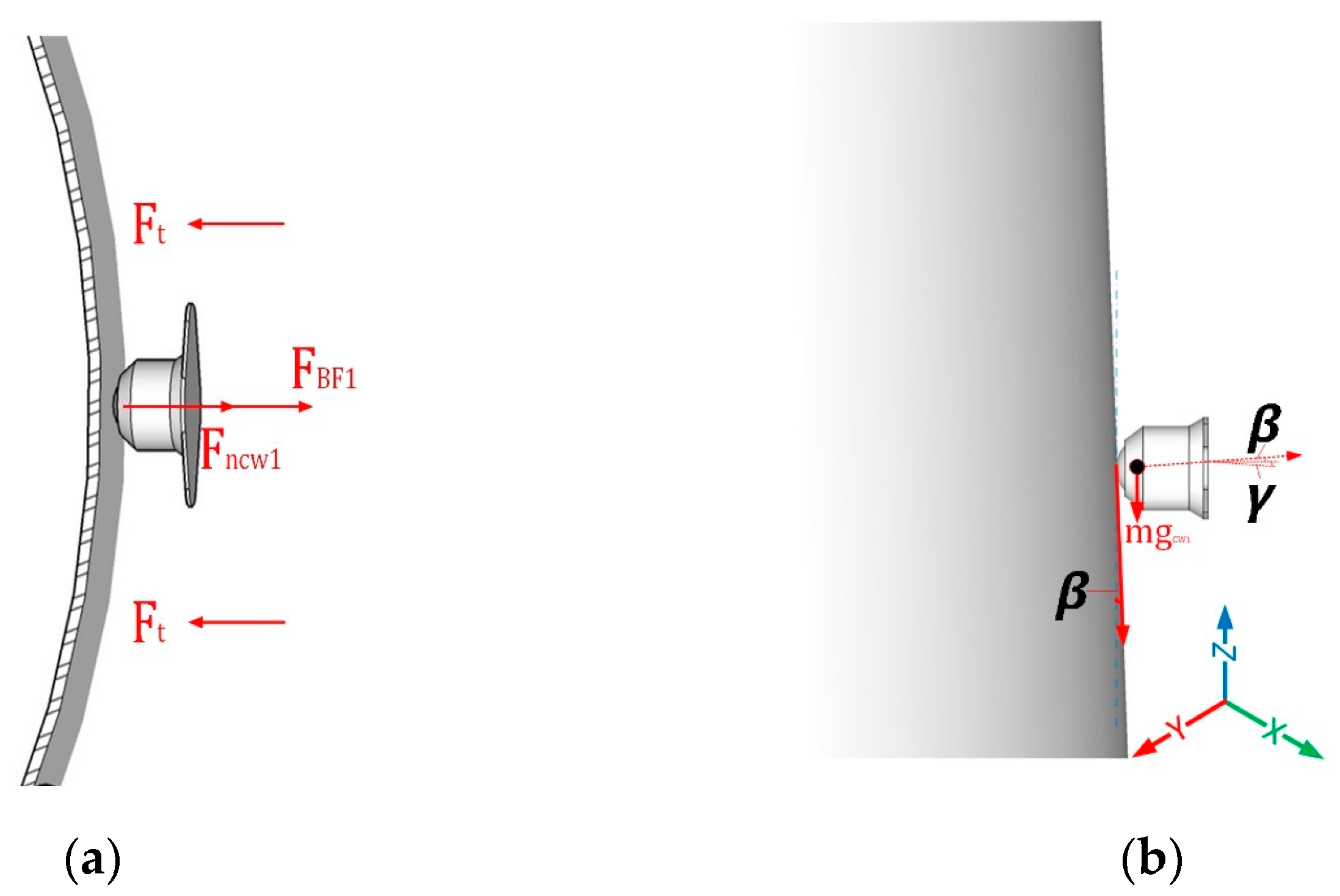

Forces on Caster Wheel 1 with Winding

Forces on Caster Wheel 2 without Winding

2.3. Control System and Experimental Set-Up

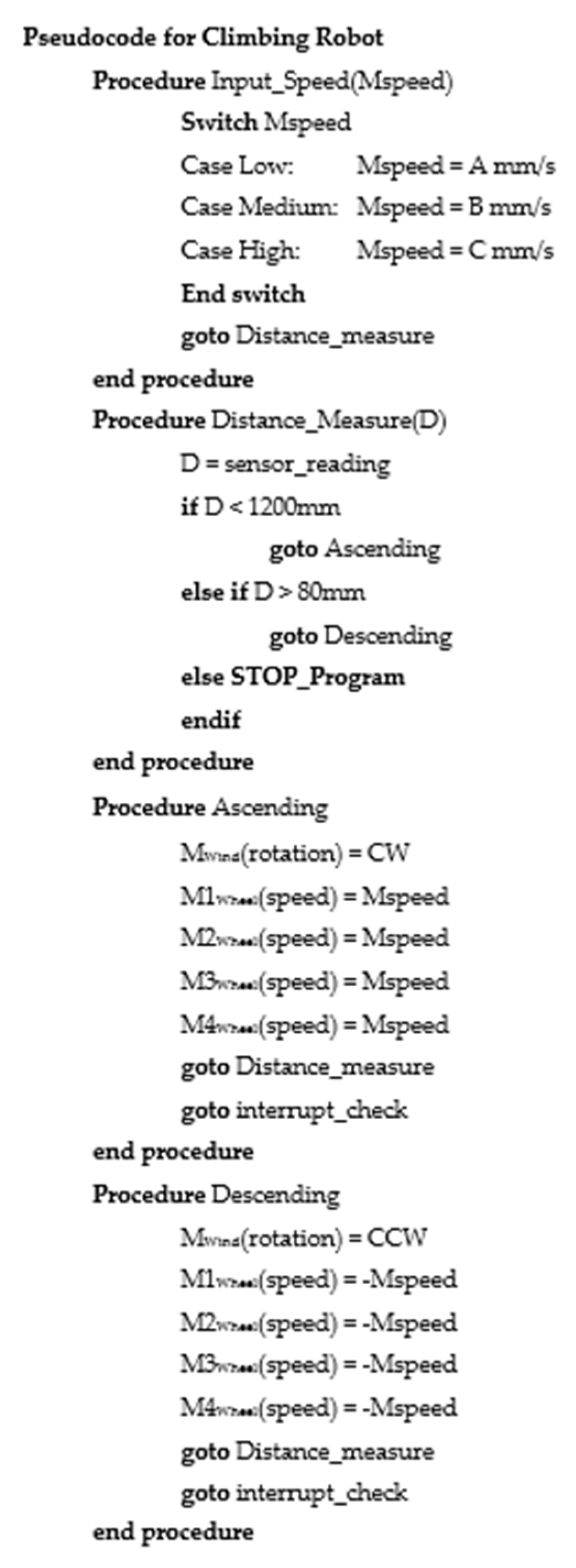

2.3.1. Control System

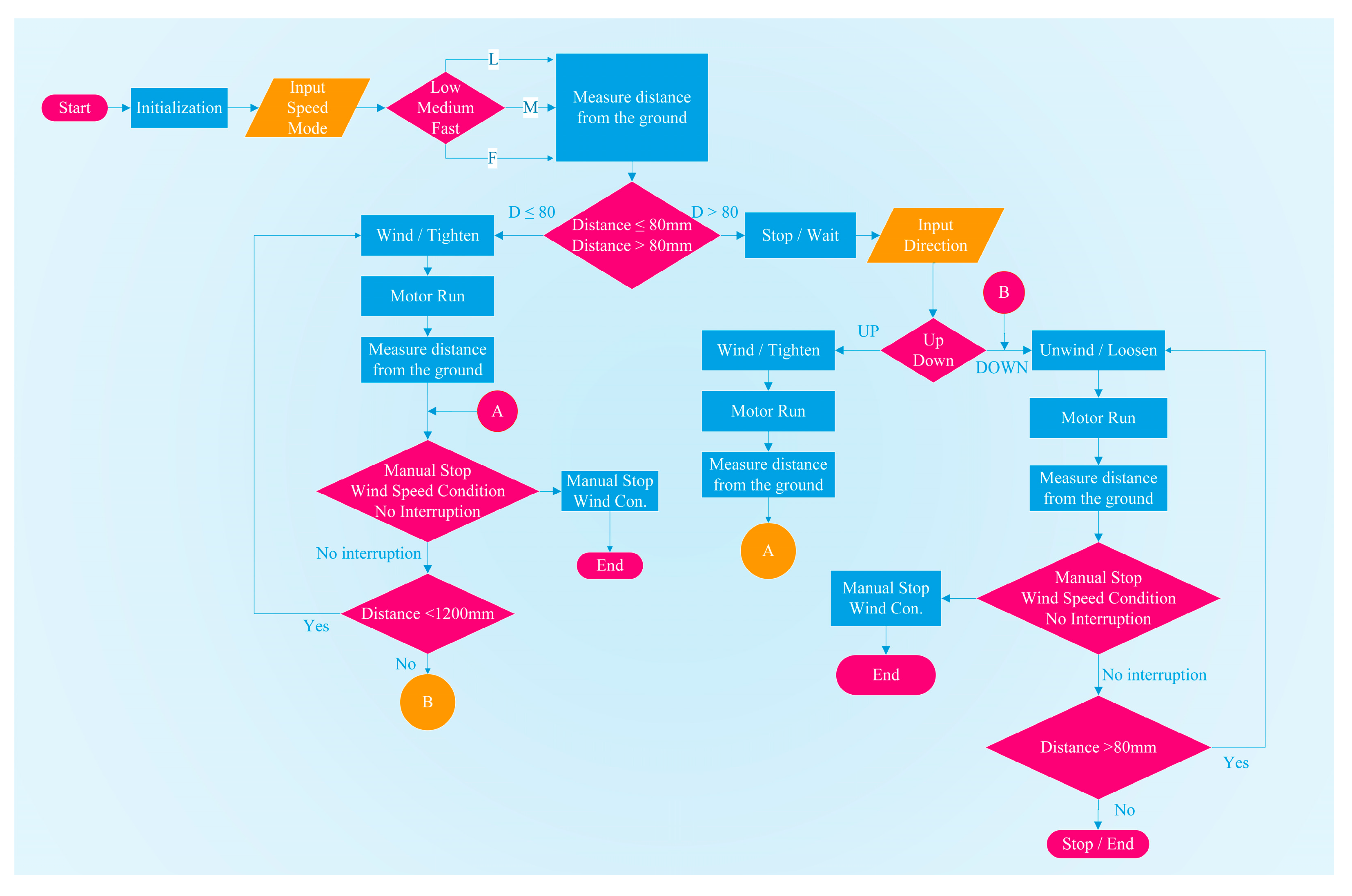

2.3.2. Control Flowchart of the Wind-Turbine-Tower-Climbing Robot

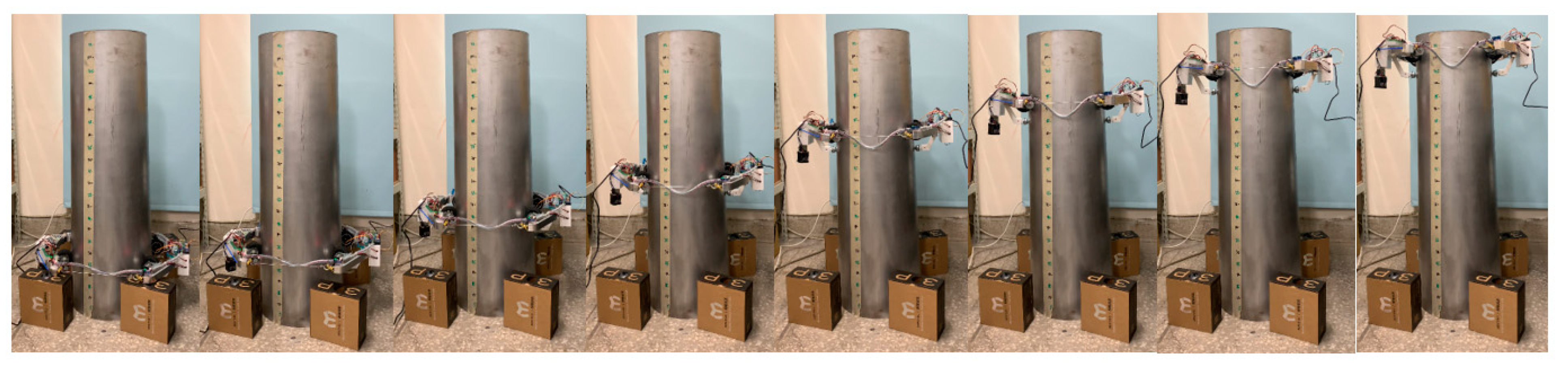

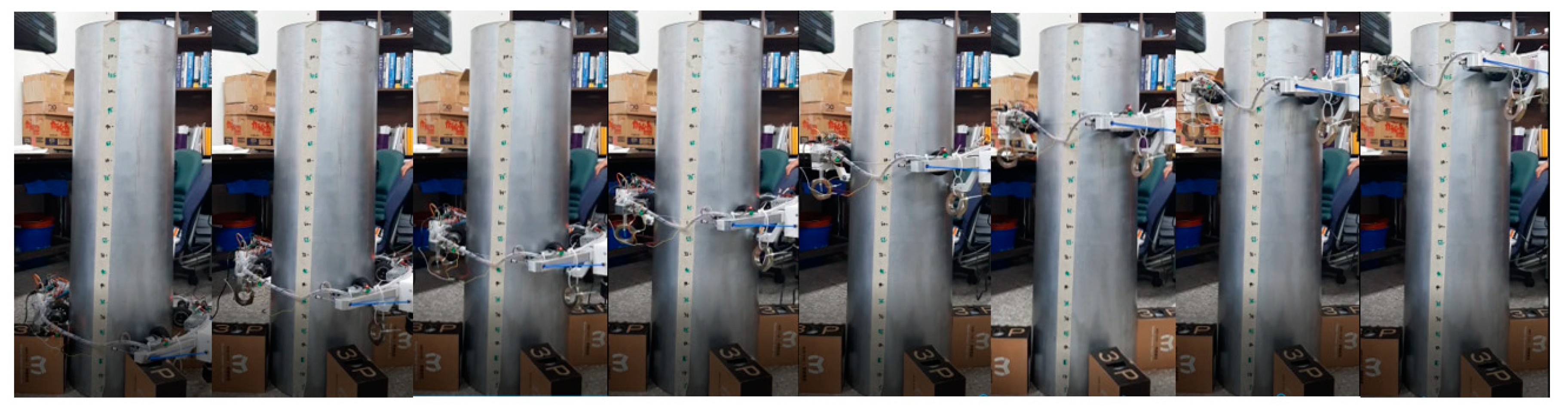

2.3.3. Experimental Set-Up

3. Results and Discussion

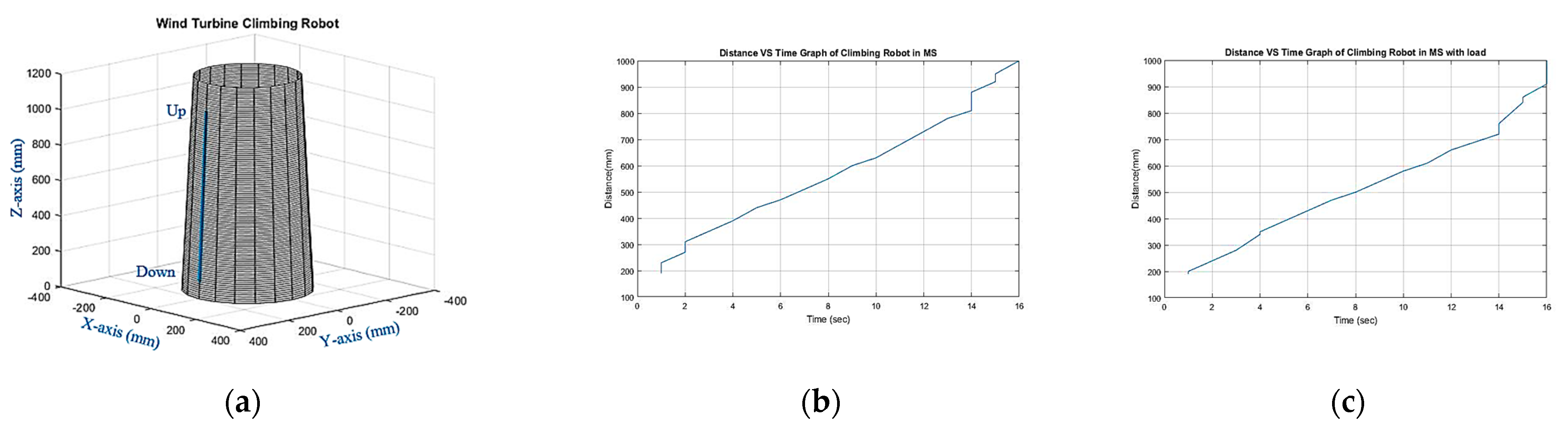

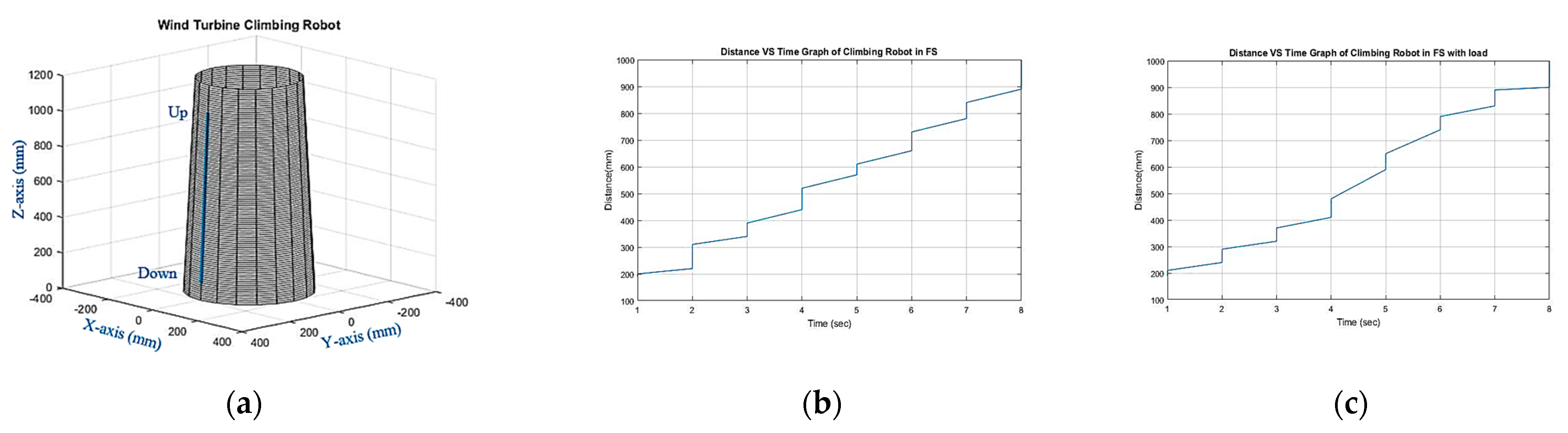

3.1. Experimental Results of Distance and Time

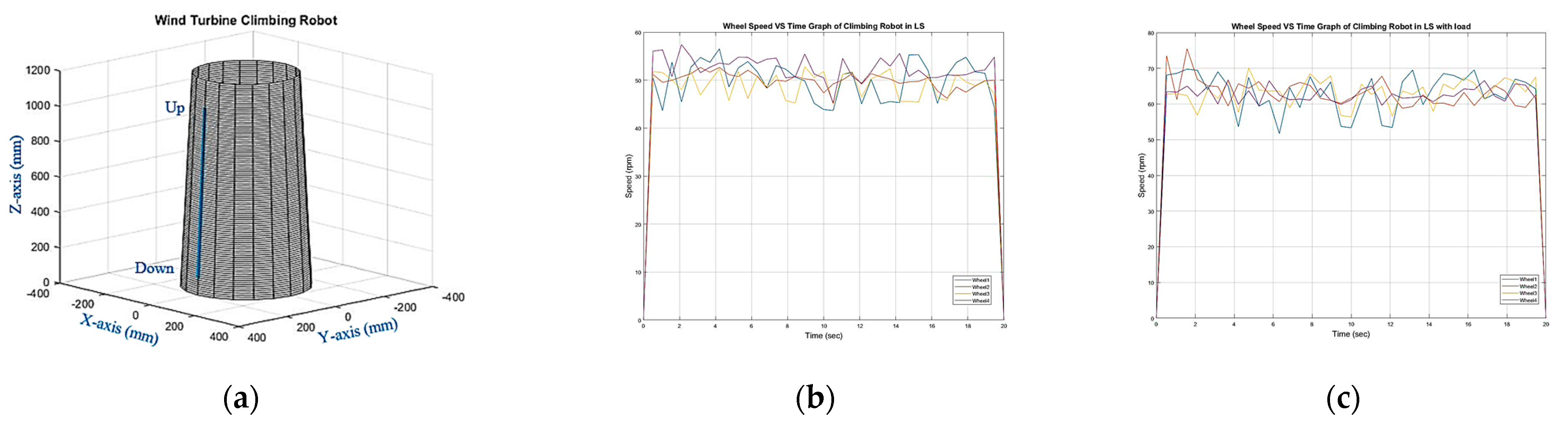

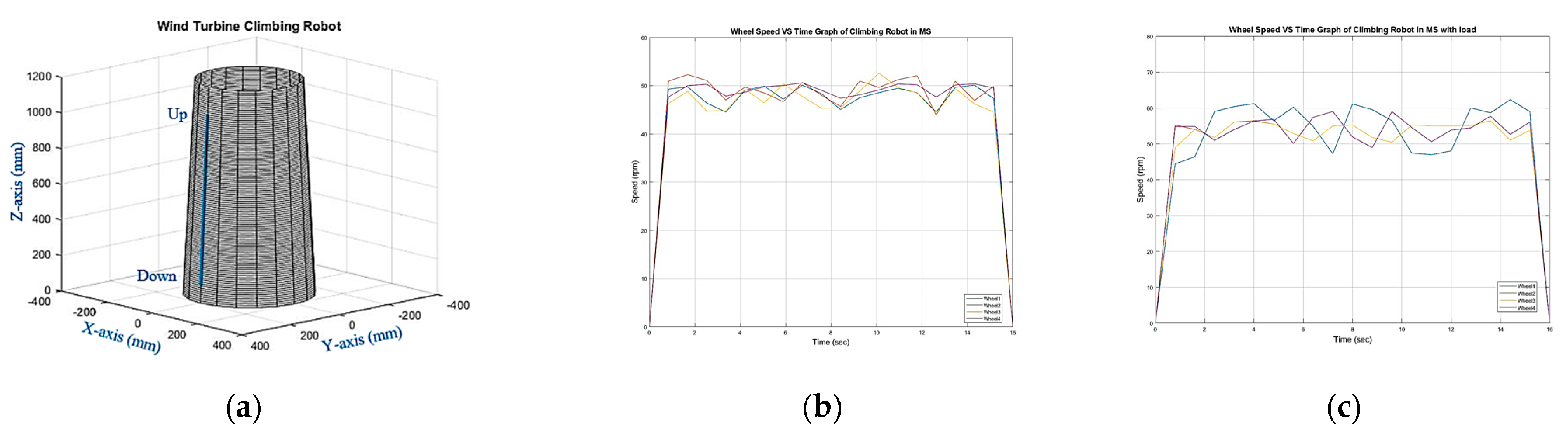

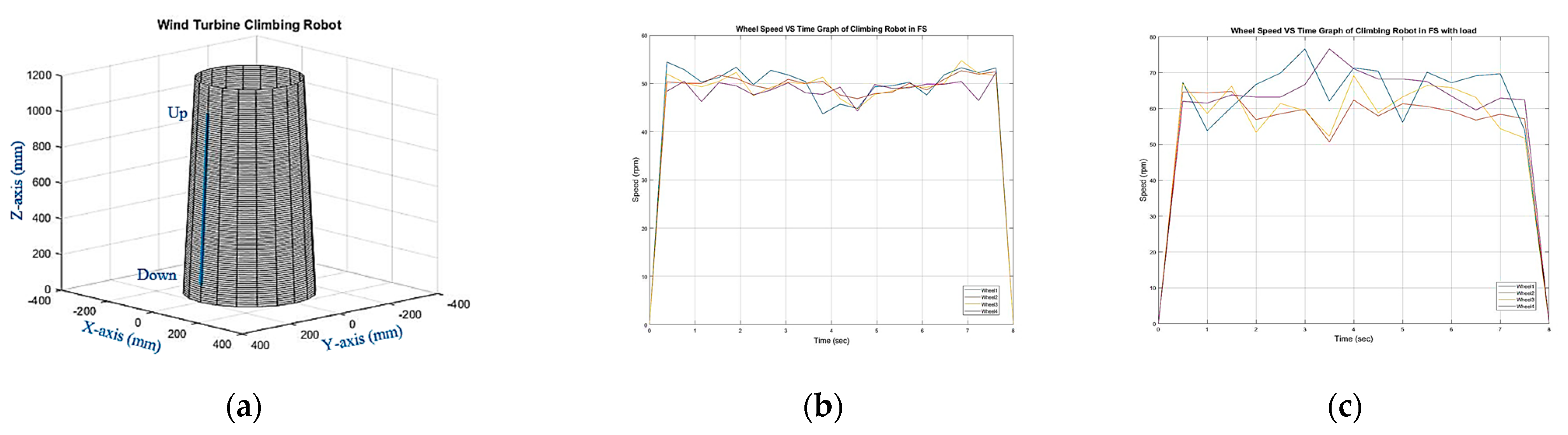

3.2. Experimental Results of (Speed) RPM and Time

4. Conclusions and Future Works

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Santos, H.B.; Teixeira, M.A.S.; Dalmedico, N.; de Oliveira, A.S.; Neves, F., Jr.; Ramos, J.E.; de Arruda, L.V.R. Model Predictive Torque Control for Velocity Tracking of a Four-Wheeled Climbing Robot. Sensors 2020, 20, 7059. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Shao, J.; Dai, F.; Zong, C.; Guo, W.; Bai, Y. Strong Magnetic Units for a Wind Power Tower Inspection and Maintenance Robot. Int. J. Adv. Robot. Syst. 2012, 9, 189. [Google Scholar] [CrossRef]

- Jeon, M.; Kim, B.; Park, S.; Hong, D. Maintenance robot for wind power blade cleaning. In Proceedings of the 29th International Symposium of Automation and Robotics in Construction, ISARC, Eindhoven, The Netherlands, 26–29 June 2012; p. 5. [Google Scholar]

- Lee, D.G.; Oh, S.; Son, H.I. Maintenance Robot for 5-MW Offshore Wind Turbines and its Control. IEEE/ASME Trans. Mechatron. 2016, 21, 2272–2283. [Google Scholar] [CrossRef]

- Guachamin-Acero, W.; Jiang, Z.; Li, L. Numerical study of a concept for major repair and replacement of offshore wind turbine blades. Wind. Energy 2020, 23, 1673–1692. [Google Scholar] [CrossRef]

- Wind Turbine | Solar Panel | Power Line | Done Inspection Company India | Pigeonis. Available online: https://pigeonis.in/solution/renewable-energy-solutions/ (accessed on 6 October 2022).

- Price, S.; Figueira, R. Corrosion Protection Systems and Fatigue Corrosion in Offshore Wind Structures: Current Status and Future Perspectives. Coatings 2017, 7, 25. [Google Scholar] [CrossRef]

- Ma, Y.; Martinez-Vazquez, P.; Baniotopoulos, C. Wind turbine tower collapse cases: A historical overview. Proc. Inst. Civ. Eng. —Struct. Build. 2019, 172, 547–555. [Google Scholar] [CrossRef]

- Cracks-in-Onshore-Wind-Turbine-Foundations.pdf. Available online: https://docs.wind-watch.org/Cracks-in-onshore-wind-turbine-foundations.pdf (accessed on 12 October 2022).

- Lacalle, R.; Cicero, S.; Álvarez, J.; Cicero, R.; Madrazo, V. On the analysis of the causes of cracking in a wind tower. Eng. Fail. Anal. 2011, 18, 1698–1710. [Google Scholar] [CrossRef]

- Cortés, E.; Sánchez, F.; Domenech, L.; Olivares, A.; Young, T.M.; O’Carroll, A.; Chinesta, F. Manufacturing issues which affect coating erosion performance in wind turbine blades. AIP Conf. Proc. 2017, 1896, 030023. [Google Scholar] [CrossRef]

- Mishnaevsky, L. Root Causes and Mechanisms of Failure of Wind Turbine Blades: Overview. Materials 2022, 15, 2959. [Google Scholar] [CrossRef] [PubMed]

- McGowan, J.G.; Hyers, R.W.; Sullivan, K.L.; Manwell, J.F.; Nair, S.V.; McNiff, B.; Syrett, B.C. A review of materials degradation in utility scale wind turbines. Energy Mater. 2007, 2, 41–64. [Google Scholar] [CrossRef]

- When Lightning Strikes: Managing Impacts on Wind Turbines. Available online: https://www.power-technology.com/analysis/when-lightning-strikes-managing-impacts-on-wind-turbines/ (accessed on 12 October 2022).

- Chen, X.; Wu, Y.; Hao, H.; Shi, H.; Huang, H. Tracked Wall-Climbing Robot for Calibration of Large Vertical Metal Tanks. Appl. Sci. 2019, 9, 2671. [Google Scholar] [CrossRef]

- Dong, W.G.; Wang, H.; Jiang, Y. Dynamic Modeling and Simulation of a Novel Wall-Climbing Robot. Appl. Mech. Mater. 2013, 336–338, 1180–1185. [Google Scholar] [CrossRef]

- Chu, B.; Jung, K.; Han, C.-S.; Hong, D. A survey of climbing robots: Locomotion and adhesion. Int. J. Precis. Eng. Manuf. 2010, 11, 633–647. [Google Scholar] [CrossRef]

- Sahbel, A.; Abbas, A.; Sattar, T. System Design and Implementation of Wall Climbing Robot for Wind Turbine Blade Inspection. In Proceedings of the 2019 International Conference on Innovative Trends in Computer Engineering (ITCE), Aswan, Egypt, 2–4 February 2019; pp. 242–247. [Google Scholar] [CrossRef]

- Bogue, R. Climbing robots: Recent research and emerging applications. Ind. Robot. 2019, 46, 721–727. [Google Scholar] [CrossRef]

- Wang, B.; Luo, H.; Jin, Y.; He, M. Path Planning for Detection Robot Climbing on Rotor Blade Surfaces of Wind Turbine Based on Neural Network. Adv. Mech. Eng. 2013, 5, 760126. [Google Scholar] [CrossRef]

- Franko, J.; Du, S.; Kallweit, S.; Duelberg, E.; Engemann, H. Design of a Multi-Robot System for Wind Turbine Maintenance. Energies 2020, 13, 2552. [Google Scholar] [CrossRef]

- Mondal, S.C.; Marquez, P.C.; Tokhi, M.O. Analysis of Mechanical Adhesion Climbing Robot Design for Wind Tower Inspection. J. Artif. Intell. Technol. 2021, 1, 219–227. [Google Scholar] [CrossRef]

- Sattar, T.P.; Rodriguez, H.L.; Bridge, B. Climbing ring robot for inspection of offshore wind turbines. Ind. Robot. Int. J. 2009, 36, 326–330. [Google Scholar] [CrossRef]

- Tavakoli, M.; Viegas, C.; Marques, L.; Pires, J.; De Almeida, A.T. OmniClimbers: Omni-directional magnetic wheeled climbing robots for inspection of ferromagnetic structures. Robot. Auton. Syst. 2013, 61, 997–1007. [Google Scholar] [CrossRef]

- Khalid, O.; Hao, G.; Desmond, C.; Macdonald, H.; McAuliffe, F.D.; Dooly, G.; Hu, W. Applications of robotics in floating offshore wind farm operations and maintenance: Literature review and trends. Wind Energy 2022, 25, 1880–1899. [Google Scholar] [CrossRef]

- Embedded Programming—Vasco Neves—Fab Academy. Available online: http://fabacademy.org/2021/labs/benfica/students/vasco-neves/assignments/week08/ (accessed on 4 January 2022).

| WT Physical Defects | Description | References |

|---|---|---|

| Corrosion | A different characteristics attack by a high or unwanted levels of humidity inside and outside the wind turbine system. | [7] |

| Cracks | It is due to extreme loads on the tower, improper manufacturing, poor material and structural design and excessive environmental factors. | [8,9] |

| Paint peel-off | The paint peel-off caused by the elements of wind, raindrops, airborne sand, temperature changes, and acidy from bug carcasses. | [11] |

| Material Degradation | It is due in part to the very large number of cycles and types of internal interfaces in the composite material components that are potential weak links; with their greater exposure to higher levels of moisture and salt. | [13] |

| Lightning Strike | It is due to tall structures that are attractive to lightning, especially when located in flat planes. | [14] |

| Other surface defects | This is caused by erosion (rain erosion, sand, and hail), or small object impacts. | [12] |

| Specifications | Values | ||

|---|---|---|---|

| Robot Weight | Body frame 1 | 6.56 kg | 3.64 kg |

| Body frame 2 | 2.92 kg | ||

| Max payload weight | 3.540 kg | ||

| Average Speed | Low | 50 mm/s | |

| Medium | 62.5 mm/s | ||

| High | 125 mm/s | ||

| Wheel rpm | Low | 45~74 rpm | |

| Medium | 44~66 rpm | ||

| High | 44~77 rpm | ||

| Winding rpm | 19~25 rpm | ||

| Angle of inclination | 1.67° | ||

| Tower height | 1200 mm | ||

| Tower diameter for climbing | 330~400 mm | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Padrigalan, K.E.; Liu, J.-H. A Wind-Turbine-Tower-Climbing Robot Prototype Operating at Various Speeds and Payload Capacity: Development and Validation. Appl. Sci. 2023, 13, 1381. https://doi.org/10.3390/app13031381

Padrigalan KE, Liu J-H. A Wind-Turbine-Tower-Climbing Robot Prototype Operating at Various Speeds and Payload Capacity: Development and Validation. Applied Sciences. 2023; 13(3):1381. https://doi.org/10.3390/app13031381

Chicago/Turabian StylePadrigalan, Kathleen Ebora, and Jui-Hung Liu. 2023. "A Wind-Turbine-Tower-Climbing Robot Prototype Operating at Various Speeds and Payload Capacity: Development and Validation" Applied Sciences 13, no. 3: 1381. https://doi.org/10.3390/app13031381

APA StylePadrigalan, K. E., & Liu, J.-H. (2023). A Wind-Turbine-Tower-Climbing Robot Prototype Operating at Various Speeds and Payload Capacity: Development and Validation. Applied Sciences, 13(3), 1381. https://doi.org/10.3390/app13031381

_Yang.png)