Processing of AZ91D Magnesium Alloy by Laser Powder Bed Fusion

Abstract

1. Introduction

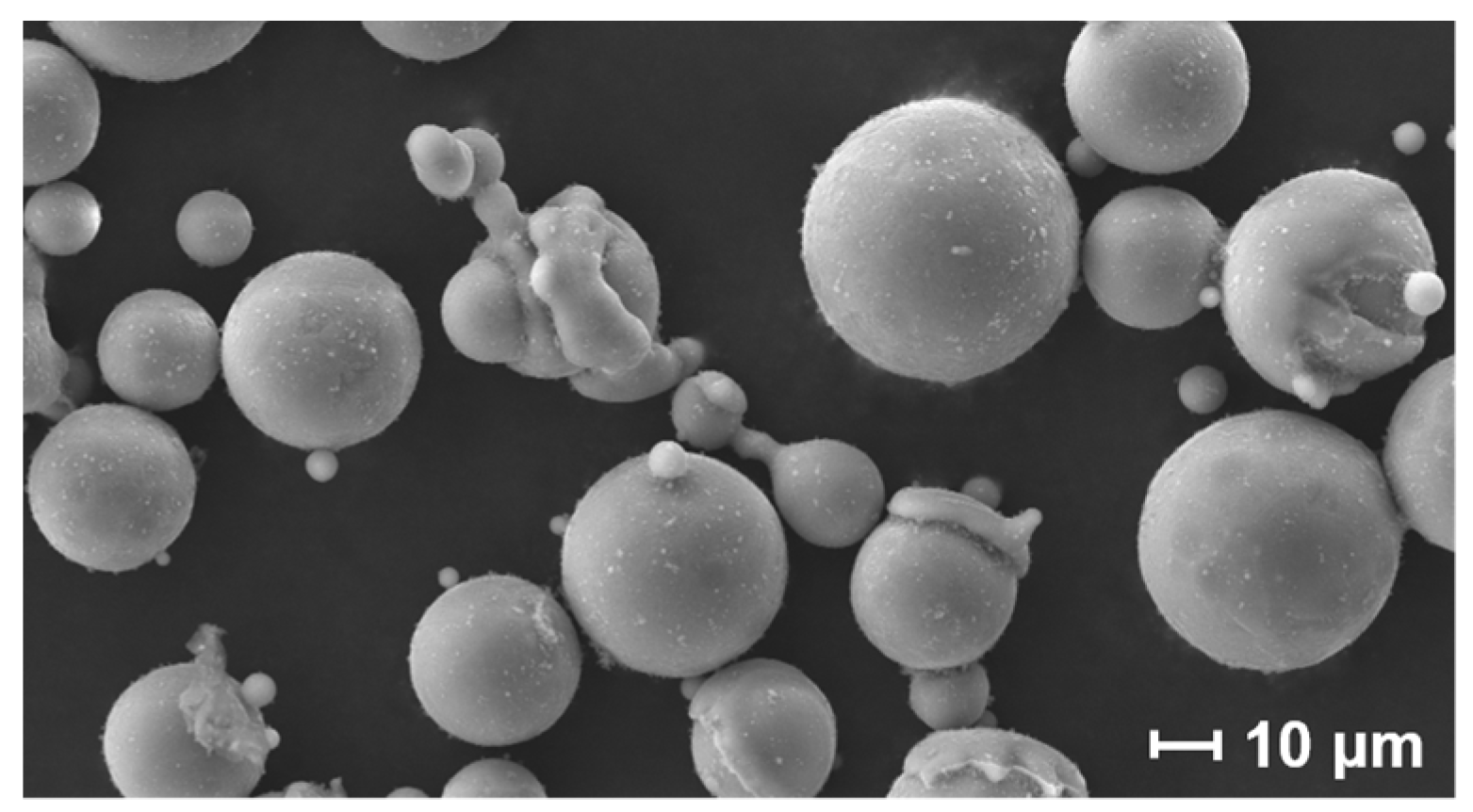

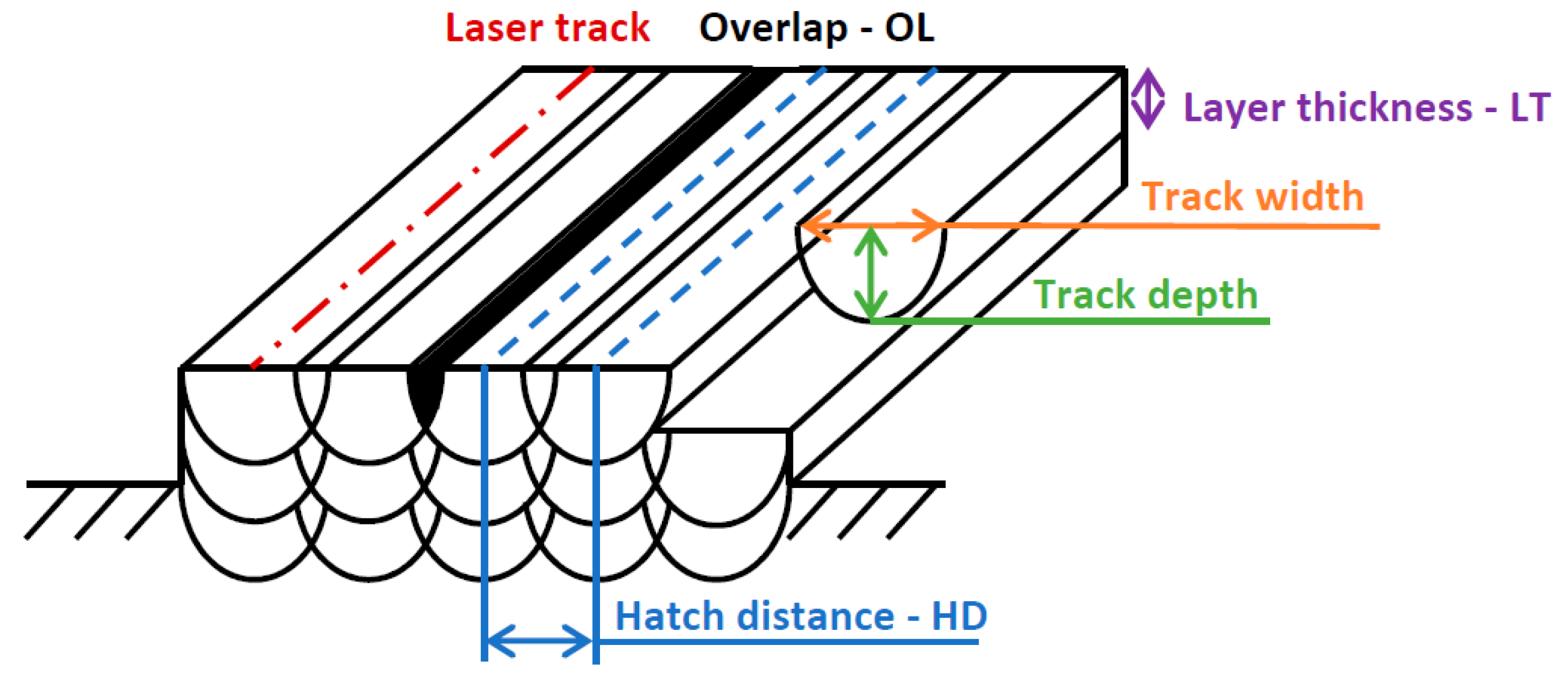

2. Materials and Methods

2.1. Fabrication of Samples

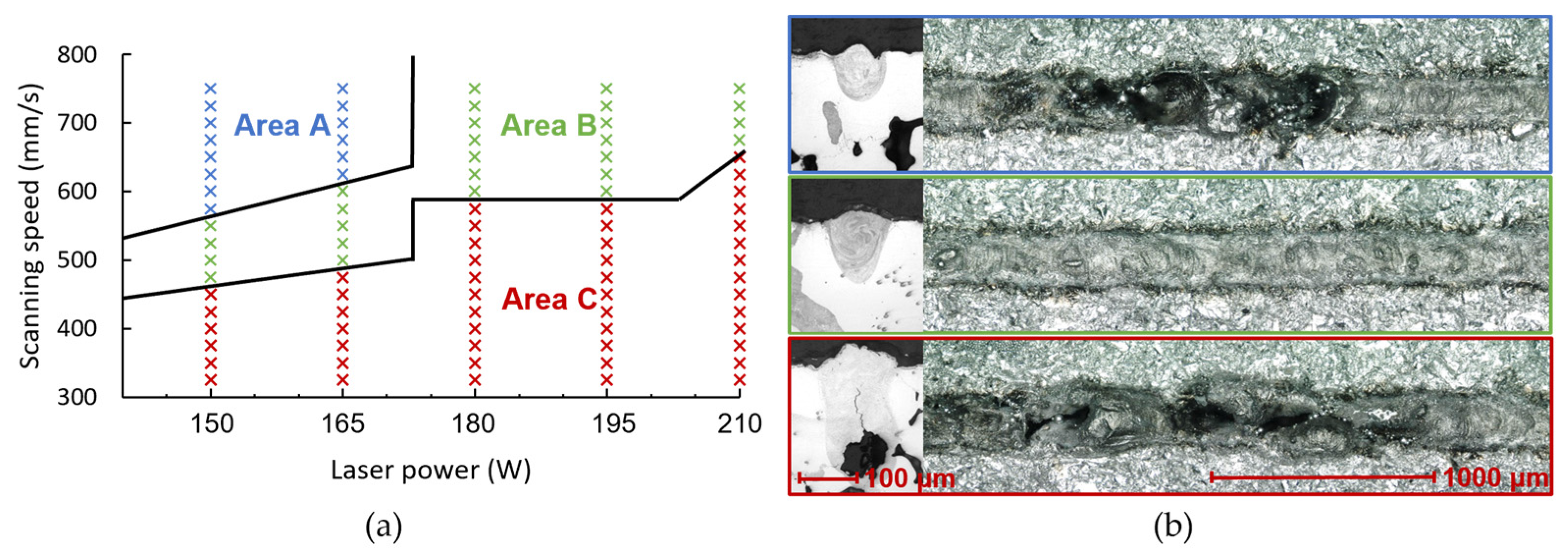

2.2. Process Parameter Development

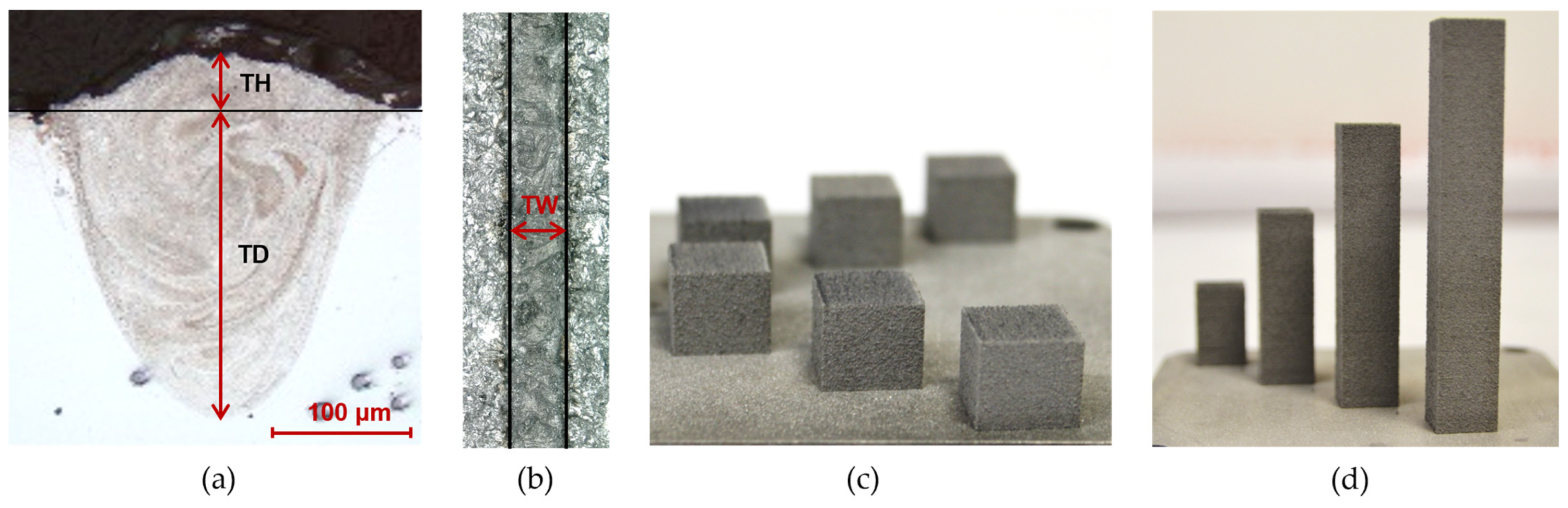

2.2.1. Single-Track Welds

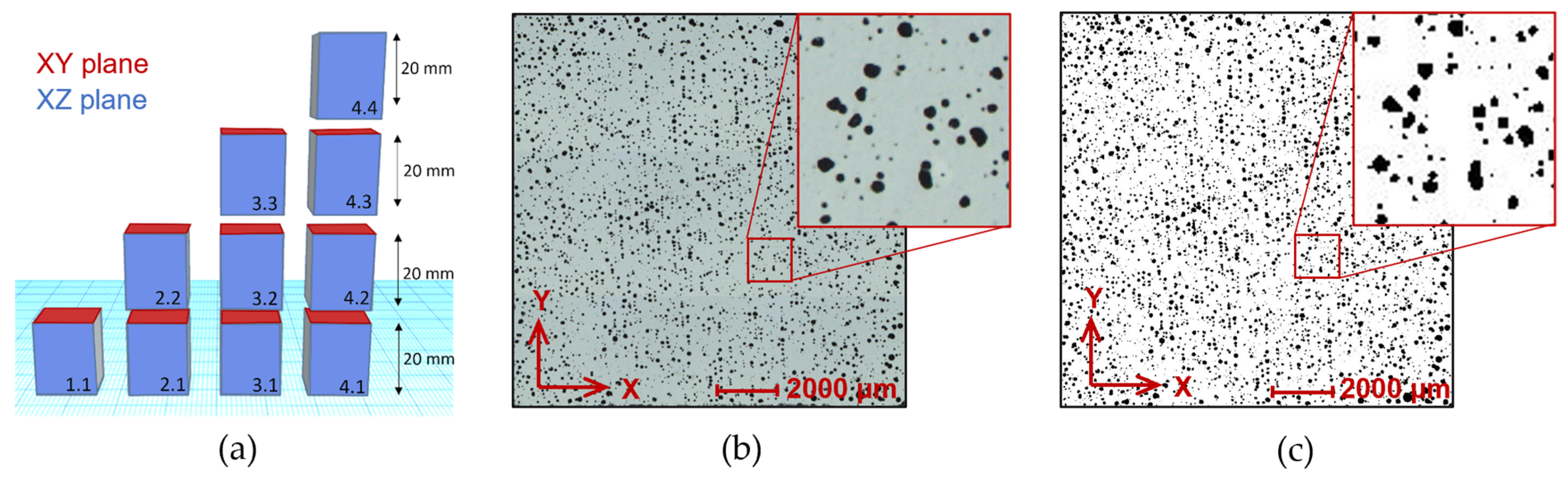

2.2.2. Bulk Samples I

2.2.3. Bulk Samples II

2.2.4. Bulk Samples III

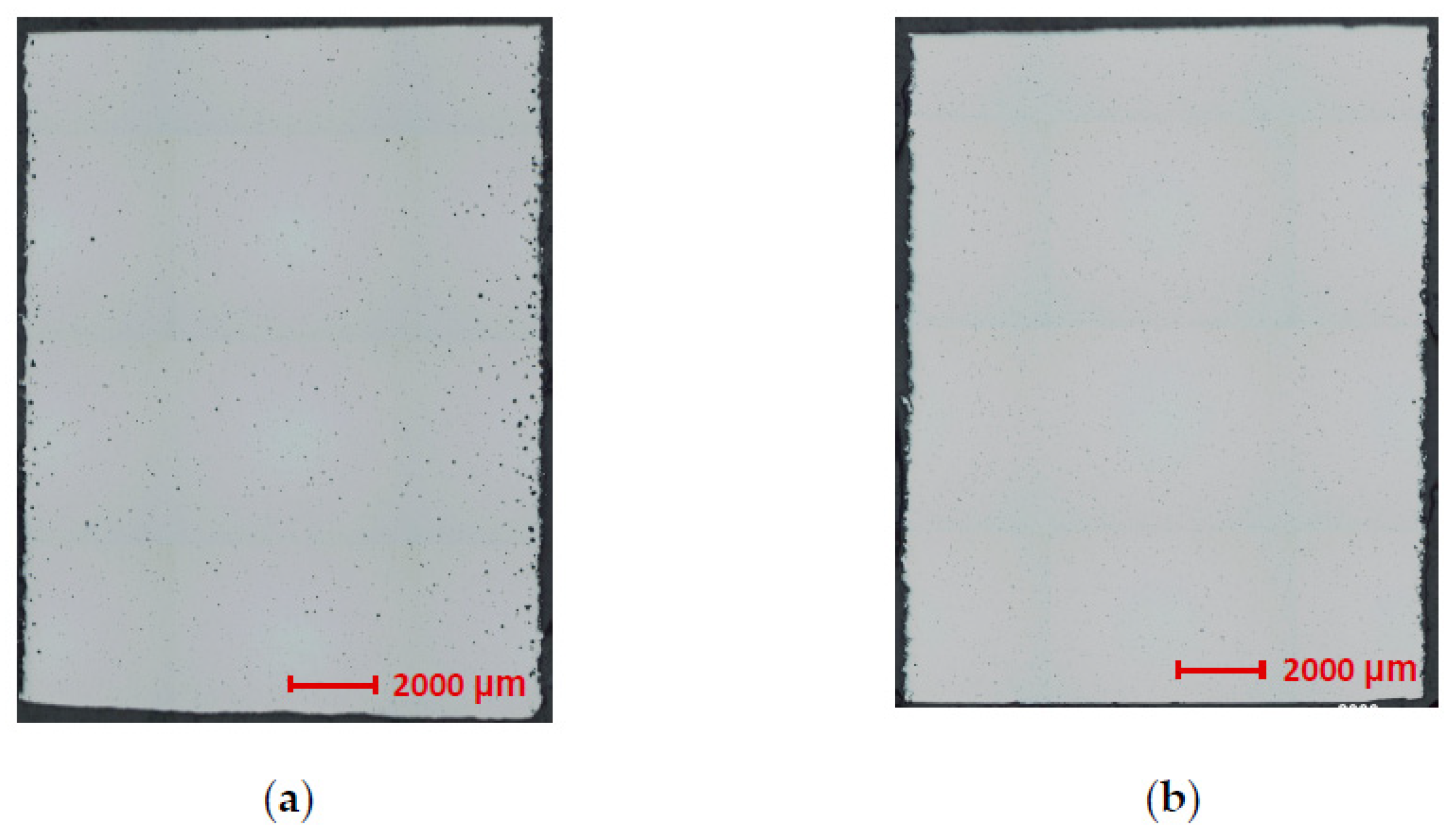

2.3. Relative Density

2.4. Mechanical Properties

2.5. Fractographical Analysis

2.6. Microstructural Analysis

2.7. Chemical Composition

3. Results and Discussion

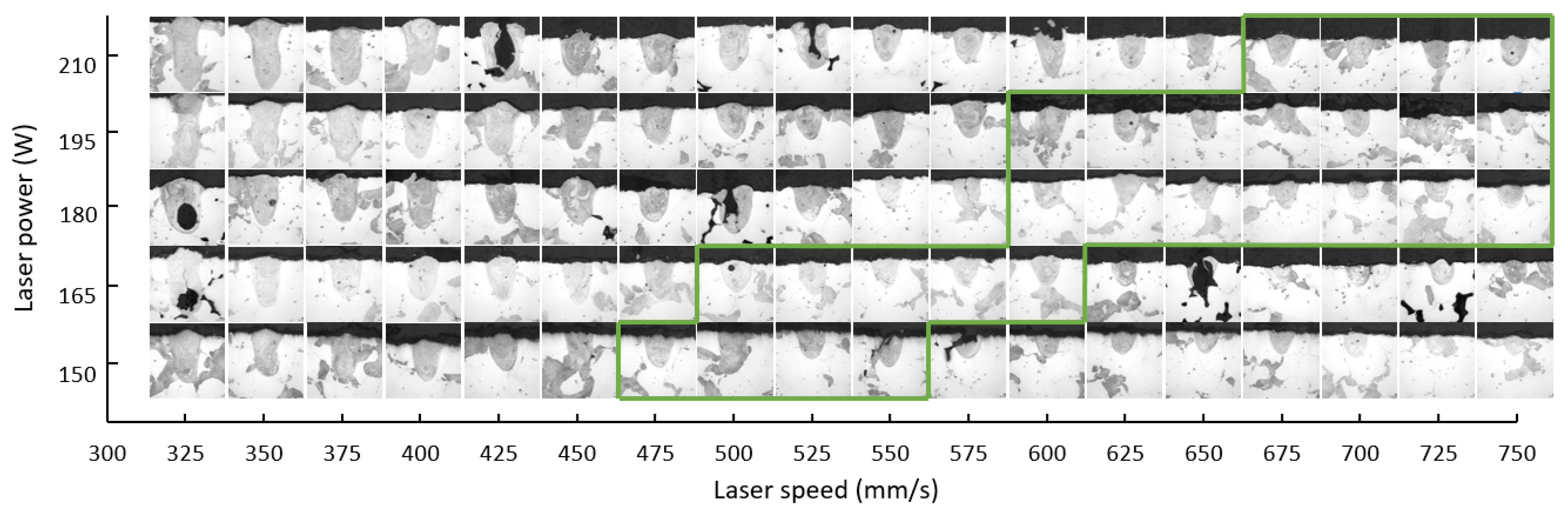

3.1. Single-Track Welds

- A—The region with a low value of input energy E = 3.7–4.7 J/mm shows a suitable depth of 179 ± 25 μm to connection with previous layers and a width of 204 ± 11 μm of the single track; however, the tracks in this region are not continuous. There are often areas where the material is not completely melted (unmelted powder particles occurred, Figure 4b—blue frame), which significantly affects both the continuity and the height of the track (32 ± 14 μm).

- B—The region with an average input energy E = 4.7–6.5 J/mm shows no cracks or pores around the weld (Figure 4b—green frame). The track depth is 218 ± 21 μm, the track height is 22 ± 2 μm and the track width is 215 ± 6 μm. Due to the relatively uniform dimensions of the track and the continuity of all tracks in this area, area B is evaluated as suitable for further testing.

- C—The region with a high value of the input energy value E = 6.5–12.7 J/mm shows an excessive depth of 338 ± 81 μm and a width of 233 ± 20 μm of single tracks. Metallographic analysis reveals the frequent occurrence of cracks and pores both in the deposit and in the surrounding material (Figure 4b—red frame), while the continuity of the deposit is not guaranteed.

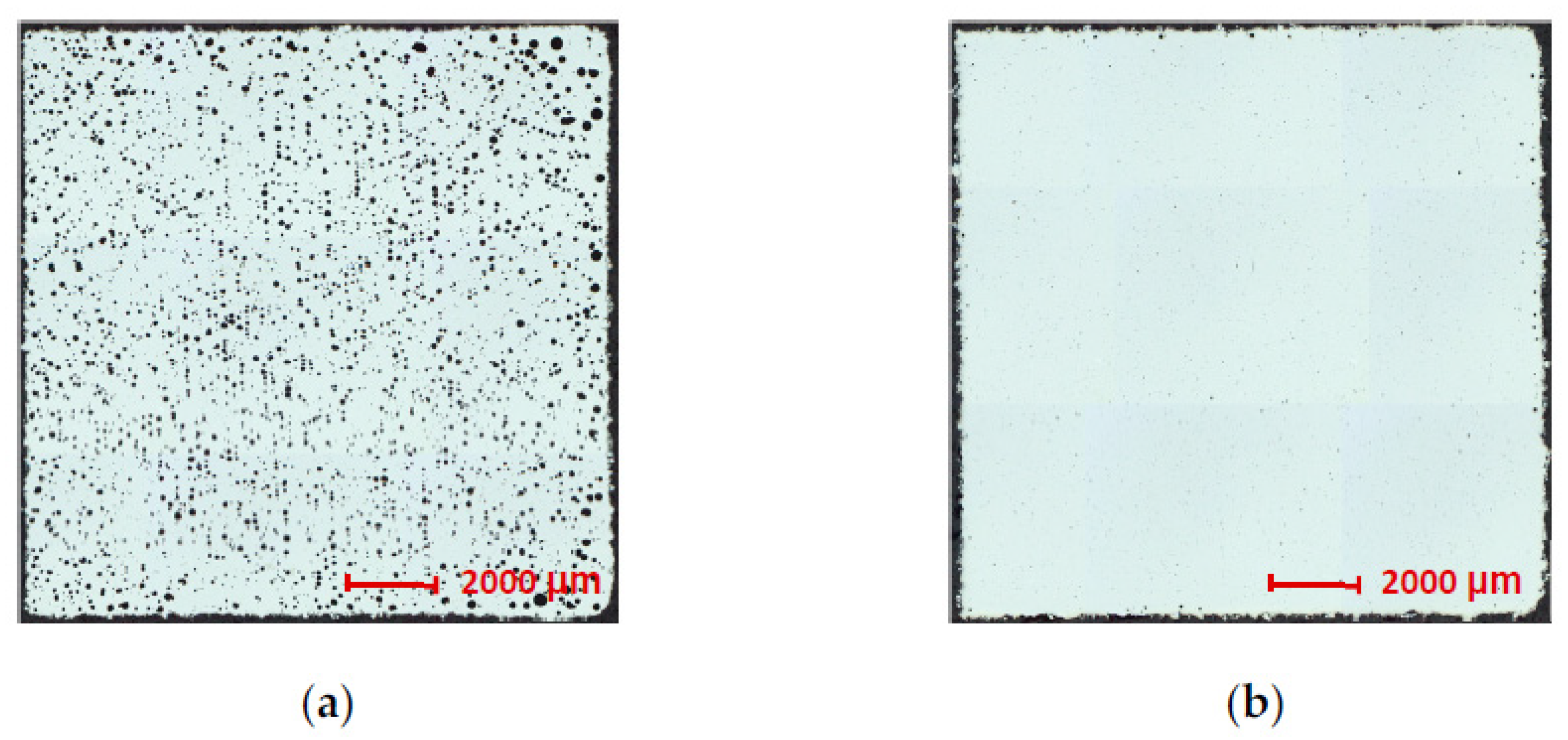

3.2. Bulk Samples I

3.3. Bulk Samples II

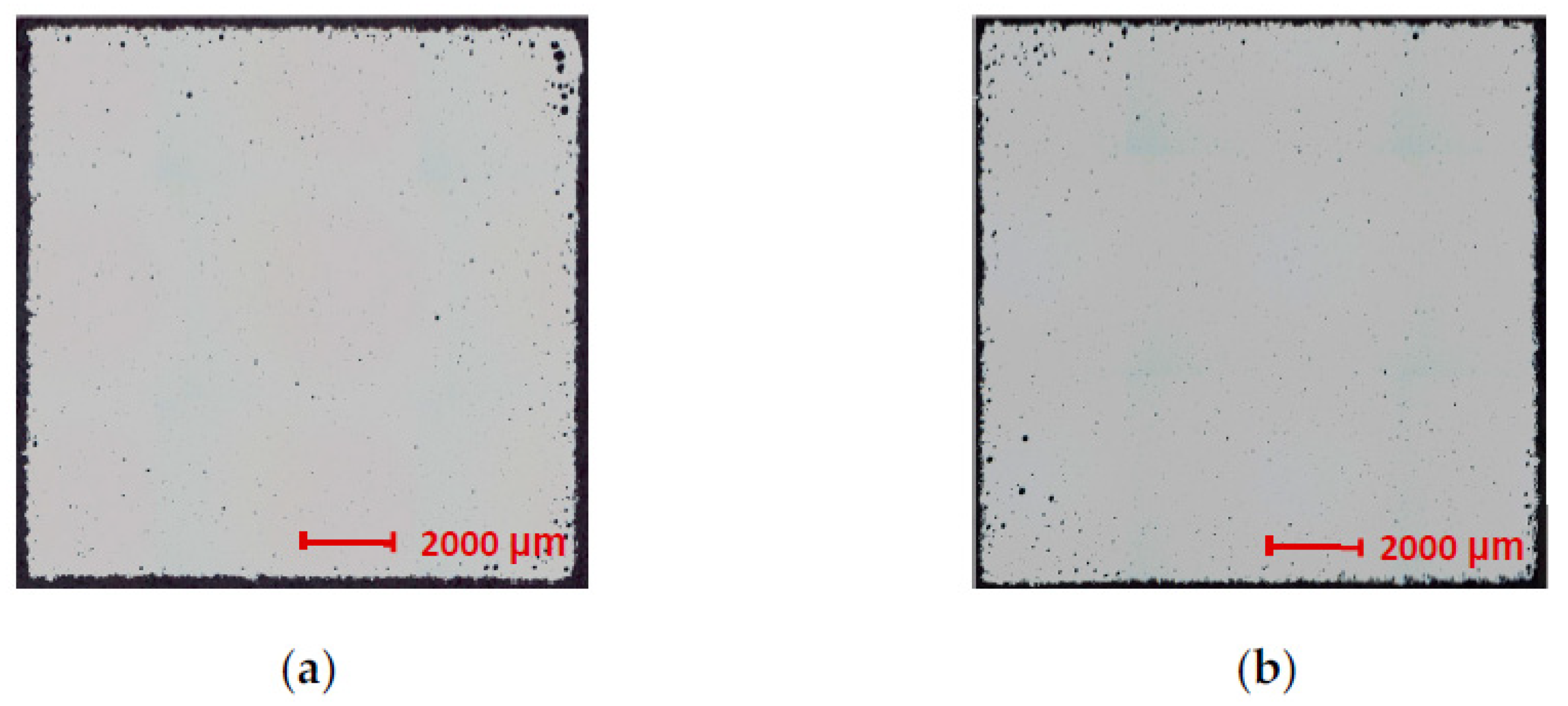

3.4. Bulk Samples III

3.5. Tensile Testing

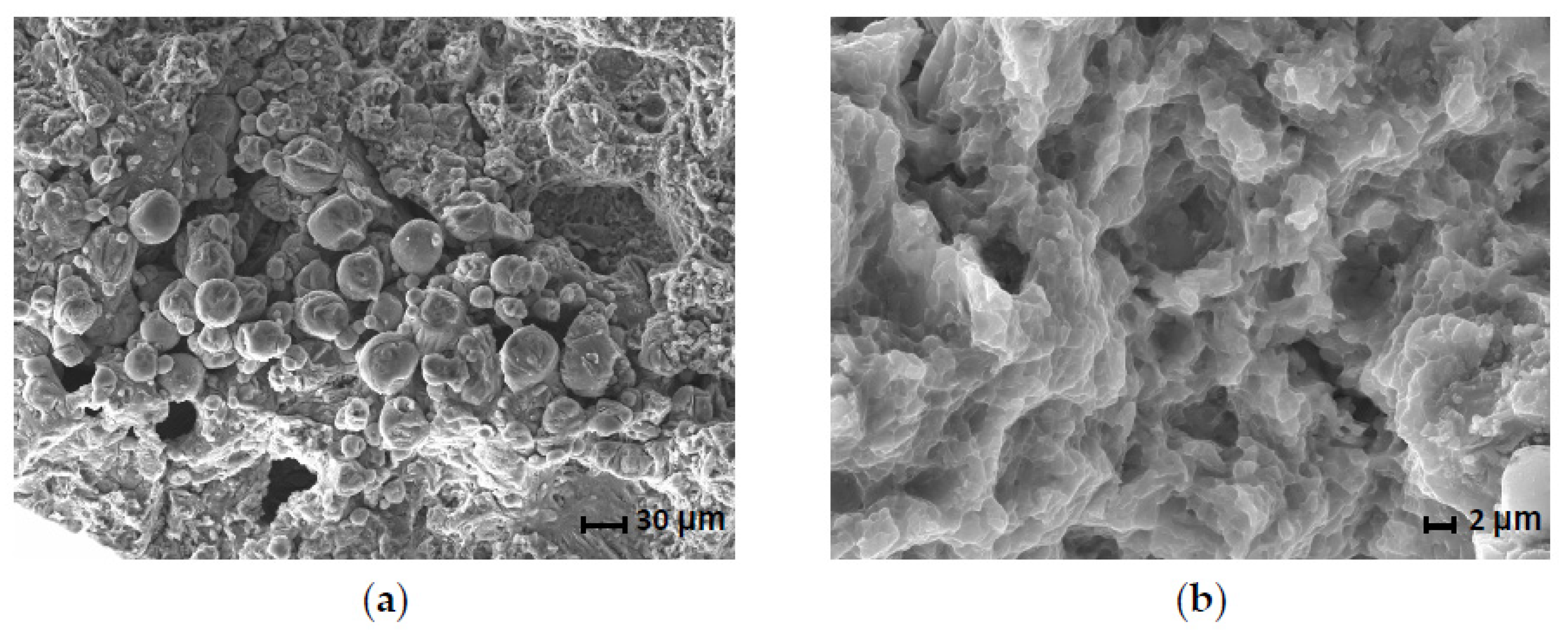

3.6. Fractographic Analysis

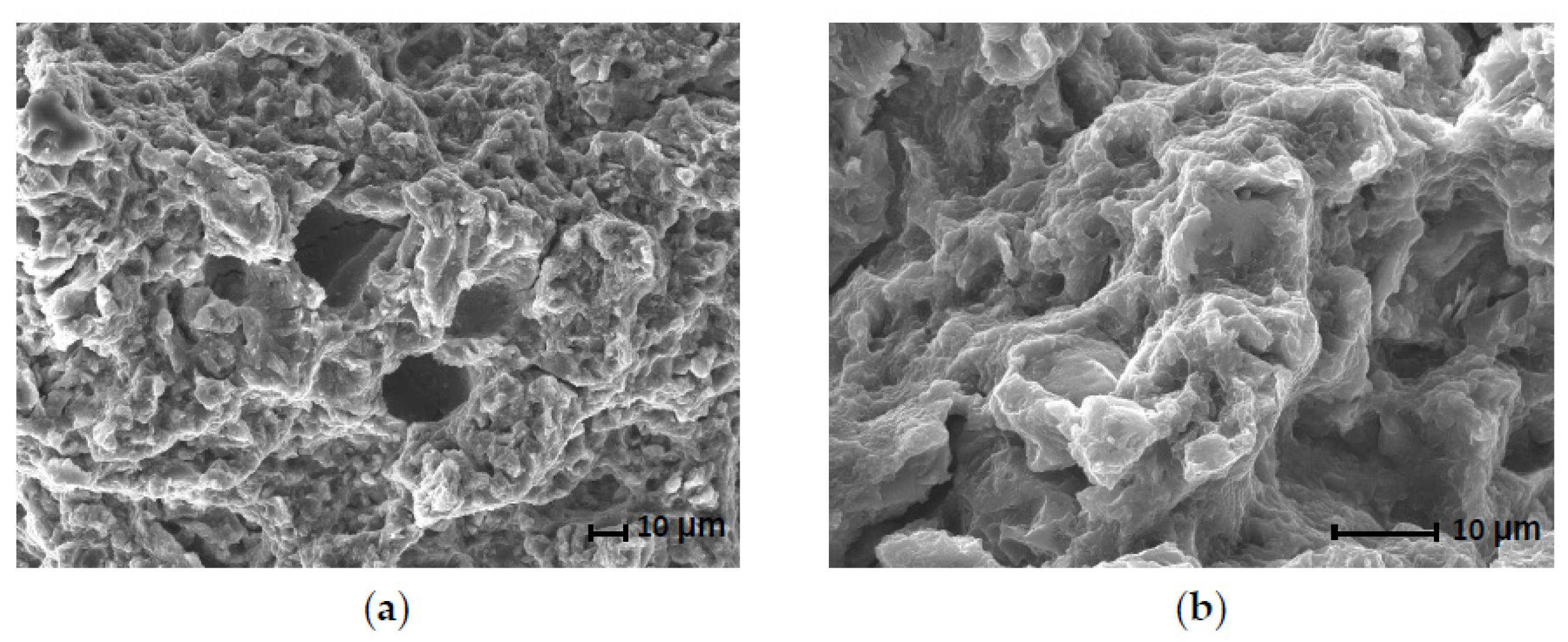

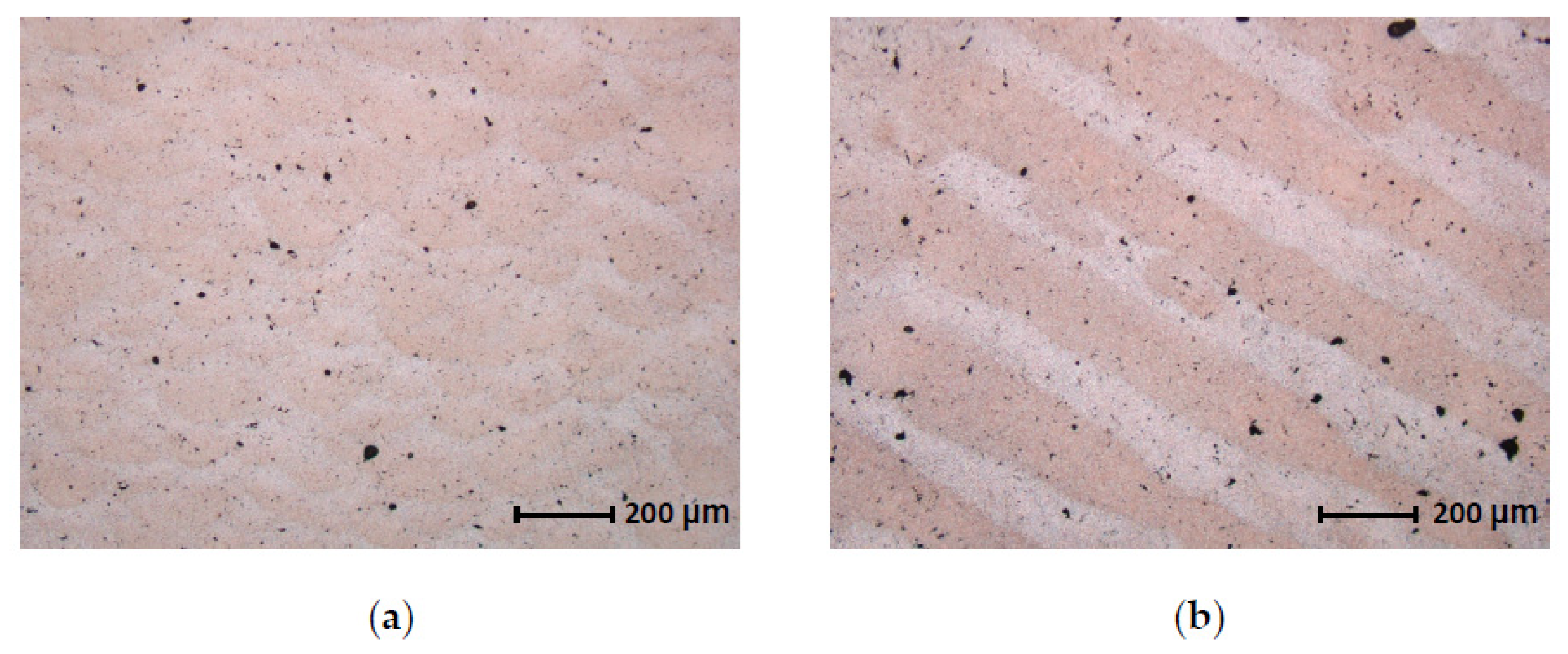

3.7. Microstructural Analysis

3.8. Chemical Composition

3.9. Future Outlook

4. Conclusions

- The process parameters of the SLM technology for the alloy AZ91D were developed and tested. With the developed parameters, a relative density of 99% and more was achieved for the cube samples. The final configuration, which resulted in low porosity and a fine, uniform microstructure, consisted of the following parameters: LP = 180 W, LS = 612.5 mm/s, HD = 0.133 mm and LT = 0.05 mm.

- The results of the tensile test showed very good mechanical properties of the material (Ys = 181 MPa, UTS = 305 MPa and A5.65 = 5.2%). Compared to the literature data, sample 7-1 showed more than twice higher ductility.

- Fractographic analysis performed after the tensile tests revealed that the damage mechanism is of low-energy ductile character with a fine dimple morphology.

- Light microscopy of the etched samples was used to obtain basic information about the microstructure of the processed material. The microstructure showed the typical structure of solidified melt pools in the longitudinal direction. In addition, the directivity of the solidified pools of the given laser trajectory was observed in the transverse direction.

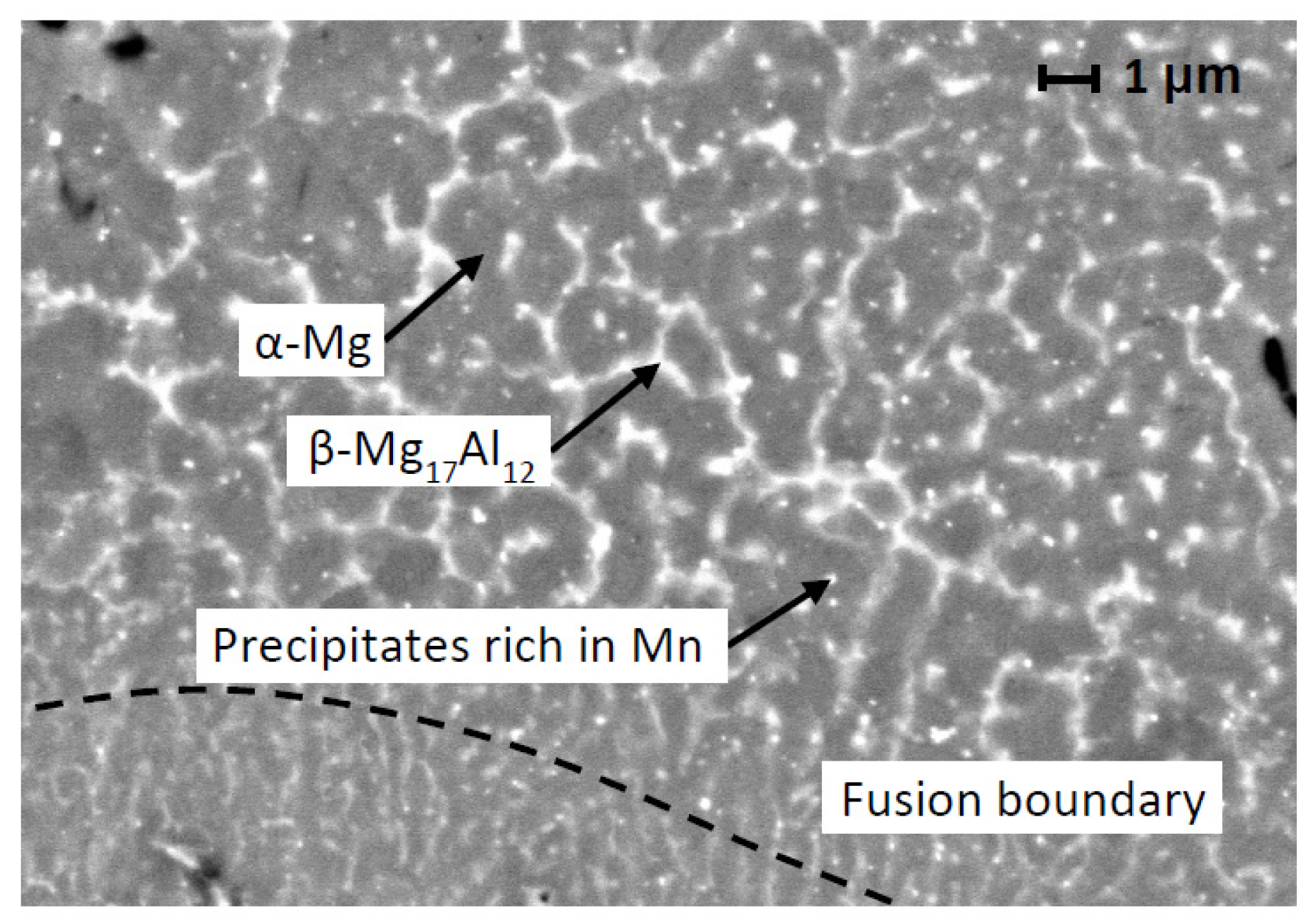

- A detailed SEM analysis revealed a fine β-Mg17Al12 phase presence within the solidified melt pools and in the areas of the fusion boundaries separating the individual pools. EDS microanalysis was used for the determination of the chemical composition of the phases in the processed material.

- The studied alloy AZ91D showed a loss of wt.% of Mg after LPBF processing due to evaporation. The other alloying elements did not significantly change, and the resulting chemical composition was in the range of the ASTM standard for AZ91D alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Manakari, V.; Parande, G.; Gupta, M. Selective Laser Melting of Magnesium and Magnesium Alloy Powders: A Review. Metals 2017, 7, 2. [Google Scholar] [CrossRef]

- Chen, J.; Tan, L.; Yu, X.; Etim, I.P.; Ibrahim, M.; Yang, K. Mechanical Properties of Magnesium Alloys for Medical Application: A Review. J. Mech. Behav. Biomed. Mater. 2018, 87, 68–79. [Google Scholar] [CrossRef] [PubMed]

- Kurzynowski, T.; Pawlak, A.; Smolina, I. The Potential of SLM Technology for Processing Magnesium Alloys in Aerospace Industry. Arch. Civ. Mech. Eng. 2020, 20, 23. [Google Scholar] [CrossRef]

- Ciesla, M.; Junak, G.; Marek, A. Fatigue Characteristics of Selected Light Metal Alloys. Arch. Metall. Mater. 2016, 61, 271–274. [Google Scholar] [CrossRef]

- Pawlak, A.; Rosienkiewicz, M.; Chlebus, E. Design of Experiments Approach in AZ31 Powder Selective Laser Melting Process Optimization. Arch. Civ. Mech. Eng. 2017, 17, 9–18. [Google Scholar] [CrossRef]

- Czerwinski, F. Oxidation Characteristics of Magnesium Alloys. JOM 2012, 64, 1477–1483. [Google Scholar] [CrossRef]

- Gangireddy, S.; Gwalani, B.; Liu, K.; Faierson, E.J.; Mishra, R.S. Microstructure and Mechanical Behavior of an Additive Manufactured (AM) WE43-Mg Alloy. Addit. Manuf. 2019, 26, 53–64. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of Selective Laser Melting: Materials and Applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Taltavull, C.; Torres, B.; López, A.J.; Rodrigo, P.; Otero, E.; Rams, J. Selective Laser Surface Melting of a Magnesium-Aluminium Alloy. Mater. Lett. 2012, 85, 98–101. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing Porosity in AlSi10Mg Parts Processed by Selective Laser Melting. Addit. Manuf. 2014, 1, 77–86. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.P. A Study of the Microstructural Evolution during Selective Laser Melting of Ti-6Al-4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Suchy, J.; Horynová, M.; Klakurková, L.; Palousek, D.; Koutny, D.; Celko, L. Effect of Laser Parameters on Processing of Biodegradable Magnesium Alloy WE43 via Selective Laser Melting Method. Materials 2020, 13, 2623. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of Keyhole-Mode Laser Melting in Laser Powder-Bed Fusion Additive Manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.H.; Leary, M.; Sharabian, E.; Cordova, L.; Gibson, I.; Downing, D.; Bateman, S.; Brandt, M.; Rolfe, B. The Effect of Absorption Ratio on Meltpool Features in Laser-Based Powder Bed Fusion of IN718. Opt. Laser Technol. 2022, 153, 108263. [Google Scholar] [CrossRef]

- Cunningham, R.; Zhao, C.; Parab, N.; Kantzos, C.; Pauza, J.; Fezzaa, K.; Sun, T.; Rollett, A.D. Keyhole Threshold and Morphology in Laser Melting Revealed by Ultrahigh-Speed x-Ray Imaging. Science 2019, 363, 849–852. [Google Scholar] [CrossRef]

- Aversa, A.; Moshiri, M.; Librera, E.; Hadi, M.; Marchese, G.; Manfredi, D.; Lorusso, M.; Calignano, F.; Biamino, S.; Lombardi, M.; et al. Single Scan Track Analyses on Aluminium Based Powders. J. Mater. Process. Technol. 2018, 255, 17–25. [Google Scholar] [CrossRef]

- Islamgaliev, R.K.; Kulyasova, O.B.; Mingler, B.; Zehetbauer, M.; Minkow, A. Structure and Fatigue Properties of the Mg Alloy AM60 Processed by ECAP. Mater. Sci. Forum 2008, 584-586, 803–808. [Google Scholar] [CrossRef]

- Ng, C.C.; Savalani, M.; Man, H.C. Fabrication of Magnesium Using Selective Laser Melting Technique. Rapid Prototyp. J. 2011, 17, 479–490. [Google Scholar] [CrossRef]

- Zhang, B.; Liao, H.; Coddet, C. Effects of Processing Parameters on Properties of Selective Laser Melting Mg-9%Al Powder Mixture. Mater. Des. 2012, 34, 753–758. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef]

- Niu, X.; Shen, H.; Fu, J.; Feng, J. Effective Control of Microstructure Evolution in AZ91D Magnesium Alloy by SiC Nanoparticles in Laser Powder-Bed Fusion. Mater. Des. 2021, 206, 109787. [Google Scholar] [CrossRef]

- Wu, C.L.; Zai, W.; Man, H.C. Additive Manufacturing of ZK60 Magnesium Alloy by Selective Laser Melting: Parameter Optimization, Microstructure and Biodegradability. Mater. Today Commun. 2021, 26, 101922. [Google Scholar] [CrossRef]

- Wei, K.; Gao, M.; Wang, Z.; Zeng, X. Effect of Energy Input on Formability, Microstructure and Mechanical Properties of Selective Laser Melted AZ91D Magnesium Alloy. Mater. Sci. Eng. A 2014, 611, 212–222. [Google Scholar] [CrossRef]

- Mostafaei, A.; Zhao, C.; He, Y.; Reza Ghiaasiaan, S.; Shi, B.; Shao, S.; Shamsaei, N.; Wu, Z.; Kouraytem, N.; Sun, T.; et al. Defects and Anomalies in Powder Bed Fusion Metal Additive Manufacturing. Curr. Opin. Solid State Mater. Sci. 2022, 26, 100974. [Google Scholar] [CrossRef]

- Phutela, C.; Aboulkhair, N.T.; Tuck, C.J.; Ashcroft, I. The Effects of Feature Sizes in Selectively Laser Melted Ti-6Al-4V Parts on the Validity of Optimised Process Parameters. Materials 2020, 13, 117. [Google Scholar] [CrossRef]

- Liu, S.; Yang, W.S.; Shi, X.; Li, B.; Duan, S.; Guo, H.; Guo, J. Influence of Laser Process Parameters on the Densification, Microstructure, and Mechanical Properties of a Selective Laser Melted AZ61 Magnesium Alloy. J. Alloys Compd. 2019, 808, 151160. [Google Scholar] [CrossRef]

- Jauer, L.; Meiners, W.; Vervoort, S.; Gayer, C.; Zumdick, N.A.; Zander, D. Selective Laser Melting of Magnesium. Key Eng. Mater. 2020, 839, 144–149. [Google Scholar] [CrossRef]

- Yang, Y.; Ling, C.; Li, Y.; Peng, S.; Xie, D.; Shen, L.; Tian, Z.; Shuai, C. Microstructure Development and Biodegradation Behavior of Additively Manufactured Mg-Zn-Gd Alloy with LPSO Structure. J. Mater. Sci. Technol. 2023, 144, 1–14. [Google Scholar] [CrossRef]

- Wei, K.; Wang, Z.; Zeng, X. Influence of Element Vaporization on Formability, Composition, Microstructure, and Mechanical Performance of the Selective Laser Melted Mg-Zn-Zr Components. Mater. Lett. 2015, 156, 187–190. [Google Scholar] [CrossRef]

- Gieseke, M.; Noelke, C.; Kaierle, S.; Wesling, V.; Haferkamp, H. Selective Laser Melting of Magnesium and Magnesium Alloys. In Magnesium Technology 2013; Springer International Publishing: Cham, Switzerland, 2013; Volume 839, pp. 65–68. [Google Scholar]

- Goldstein, I.J. Scanning Electron Microscopy and X-ray Microanalysis, 3rd ed.; Springer: New York, NY, USA, 2003; ISBN 0-306-47292-3. [Google Scholar]

- Zhou, Y.; Abbara, E.M.; Jiang, D.; Azizi, A.; Poliks, M.D.; Ning, F. High-Cycle Fatigue Properties of Curved-Surface AlSi10Mg Parts Fabricated by Powder Bed Fusion Additive Manufacturing. Rapid Prototyp. J. 2022, 28, 1346–1360. [Google Scholar] [CrossRef]

- Xu, Z.W.; Wang, Q.; Wang, X.S.; Tan, C.H.; Guo, M.H.; Gao, P.B. High Cycle Fatigue Performance of AlSi10mg Alloy Produced by Selective Laser Melting. Mech. Mater. 2020, 148, 103499. [Google Scholar] [CrossRef]

- Linares, J.M.; Chaves-Jacob, J.; Lopez, Q.; Sprauel, J.M. Fatigue Life Optimization for 17-4Ph Steel Produced by Selective Laser Melting. Rapid Prototyp. J. 2022, 28, 1182–1192. [Google Scholar] [CrossRef]

- Giganto, S.; Martínez-Pellitero, S.; Cuesta, E.; Zapico, P.; Barreiro, J. Proposal of Design Rules for Improving the Accuracy of Selective Laser Melting (SLM) Manufacturing Using Benchmarks Parts. Rapid Prototyp. J. 2022, 28, 1129–1143. [Google Scholar] [CrossRef]

| Element | Mg | Al | Zn | Mn | Si | Cu | Fe |

|---|---|---|---|---|---|---|---|

| Wt.% | Balance | 9.08 | 0.65 | 0.23 | 0.04 | <0.01 | <0.01 |

| Bulk Sample | LP (W) | LS (mm/s) | OL (%) | HD (mm) | RD (%) |

|---|---|---|---|---|---|

| 4-1 | 180 | 612.5 | 40 | 0.133 | 99.4 ± 0.02 |

| 4-2 | 197 | 669 | 54 | 0.100 | ~100 |

| Group | Sample | LP (W) | LS (mm/s) | OL (%) | HD (mm) | Ev (J/mm3) | RD (%) |

|---|---|---|---|---|---|---|---|

| 1 | 1-1 | 150 | 750 | 50 | 0.098 | 40.8 | 99.2 ± 0.02 |

| 1-2 | 150 | 475 | 30 | 0.151 | 41.8 | 99.0 ± 0.02 | |

| 1-3 | 180 | 612.5 | 40 | 0.133 | 44.2 | 99.2 ± 0.12 | |

| 1-4 | 210 | 475 | 50 | 0.126 | 70.2 | 98.0 ± 0.02 | |

| 1-5 | 180 | 612.5 | 40 | 0.133 | 44.2 | 98.9 ± 0.11 | |

| 1-6 | 210 | 750 | 30 | 0.153 | 36.6 | 98.8 ± 0.01 | |

| 1-7 | 180 | 612.5 | 40 | 0.133 | 44.2 | 99.1 ± 0.01 | |

| 2 | 2-8 | 150 | 475 | 50 | 0.108 | 58.5 | 98.4 ± 0.03 |

| 2-9 | 210 | 475 | 30 | 0.176 | 50.2 | 92.8 ± 0.05 | |

| 2-10 | 210 | 750 | 50 | 0.110 | 50.9 | 98.4 ± 0.02 | |

| 2-11 | 150 | 750 | 30 | 0.137 | 29.2 | 94.8 ± 0.11 | |

| 2-12 | 180 | 612.5 | 40 | 0.133 | 44.2 | 98.8 ± 0.04 | |

| 2-13 | 180 | 805 | 40 | 0.120 | 37.3 | 97.2 ± 0.06 | |

| 2-14 | 138 | 612.5 | 40 | 0.120 | 37.6 | 97.6 ± 0.08 | |

| 3 | 3-15 | 180 | 612.5 | 26 | 0.164 | 35.8 | 99.0 ± 0.01 |

| 3-16 | 222 | 612.5 | 40 | 0.135 | 53.7 | 99.0 ± 0.01 | |

| 3-17 | 180 | 612.5 | 54 | 0.102 | 57.6 | 99.3 ± 0.21 | |

| 3-18 | 180 | 420 | 40 | 0.144 | 59.5 | 97.7 ± 0.04 | |

| 3-19 | 180 | 612.5 | 40 | 0.133 | 44.2 | 99.4 ± 0.02 | |

| 3-20 | 180 | 612.5 | 40 | 0.133 | 44.2 | 99.0 ± 0.02 |

| Bulk Sample | Porosity (%) | RD (%) | |||

|---|---|---|---|---|---|

| Plane XY | Plane YZ | Plane XZ | Average | ||

| 4-1 | 2.1 ± 0.12 | 5.2 ± 0.34 | 3.7 ± 0.22 | 3.7 | 96.3 ± 1.26 |

| 4-2 | 4.1 ± 0.25 | 3.3 ± 0.15 | 4.7 ± 0.39 | 4.0 | 96.0 ± 0.57 |

| Height | ||||

|---|---|---|---|---|

| 80 mm | 5-4.4 | |||

| 0.7% | ||||

| 60 mm | 5-3.3 | 5-4.3 | ||

| 0.5% | 0.5% | |||

| 40 mm | 5-2.2 | 5-3.2 | 5-4.2 | |

| 0.5% | 0.4% | 0.9% | ||

| 20 mm | 5-1.1 | 5-2.1 | 5-3.1 | 5-4.1 |

| 1% | 0.7% | 0.5% | 1.1% | |

| Average porosity | 1% | 0.6% | 0.5% | 0.8% |

| Height Range | ||||

|---|---|---|---|---|

| 60–80 mm | 5-4.4 | |||

| 0.5% | ||||

| 40–60 mm | 5-3.3 | 5-4.3 | ||

| 0.7% | 0.4% | |||

| 20–40 mm | 5-2.2 | 5-3.2 | 5-4.2 | |

| 0.7% | 0.5% | 0.6% | ||

| 0–20 mm | 5-1.1 | 5-2.1 | 5-3.1 | 5-4.1 |

| 1% | 1.4% | 0.7% | 1.7% | |

| Average porosity | 1% | 1% | 0.6% | 0.8% |

| Ys (MPa) | UTS (MPa) | A5.65 (%) | |

|---|---|---|---|

| 6-1 | 182 | 196 | 0.3 |

| 7-1 | 181 | 305 | 5.2 |

| Wei SLM [23] | 254 | 296 | 1.83 |

| Niu SLM [21] | 225 ± 5 | 306.5 ± 8.4 | 2 ± 0.5 |

| Wei Cast [23] | 160 | 225 | 3 |

| Mg | Al | Zn | Mn | |

|---|---|---|---|---|

| Matrix α-Mg | 94.33 | 5.35 | 0.32 | - |

| Eutectic-phase β-Mg17Al12 | 80.27 | 15.78 | 1.40 | - |

| Precipitates rich in Mn | 79.35 | 15.31 | 1.23 | 4.11 |

| Mg | Al | Zn | Mn | |

|---|---|---|---|---|

| EDS—powder | 90.46 | 8.58 | 0.69 | 0.27 |

| EDS—after SLM | 90.22 | 8.64 | 0.89 | 0.25 |

| ASTM B94-18 standard | Bal. | 8.3–9.7 | 0.34–1.0 | 0.15–0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nopová, K.; Jaroš, J.; Červinek, O.; Pantělejev, L.; Gneiger, S.; Senck, S.; Koutný, D. Processing of AZ91D Magnesium Alloy by Laser Powder Bed Fusion. Appl. Sci. 2023, 13, 1377. https://doi.org/10.3390/app13031377

Nopová K, Jaroš J, Červinek O, Pantělejev L, Gneiger S, Senck S, Koutný D. Processing of AZ91D Magnesium Alloy by Laser Powder Bed Fusion. Applied Sciences. 2023; 13(3):1377. https://doi.org/10.3390/app13031377

Chicago/Turabian StyleNopová, Klára, Jan Jaroš, Ondřej Červinek, Libor Pantělejev, Stefan Gneiger, Sascha Senck, and Daniel Koutný. 2023. "Processing of AZ91D Magnesium Alloy by Laser Powder Bed Fusion" Applied Sciences 13, no. 3: 1377. https://doi.org/10.3390/app13031377

APA StyleNopová, K., Jaroš, J., Červinek, O., Pantělejev, L., Gneiger, S., Senck, S., & Koutný, D. (2023). Processing of AZ91D Magnesium Alloy by Laser Powder Bed Fusion. Applied Sciences, 13(3), 1377. https://doi.org/10.3390/app13031377