Experimental and Numerical Simulations of Climatic Loads in Insulating Glass Units by Controlled Change of Pressure in the Gap

Abstract

:1. Introduction

2. Materials and Methods

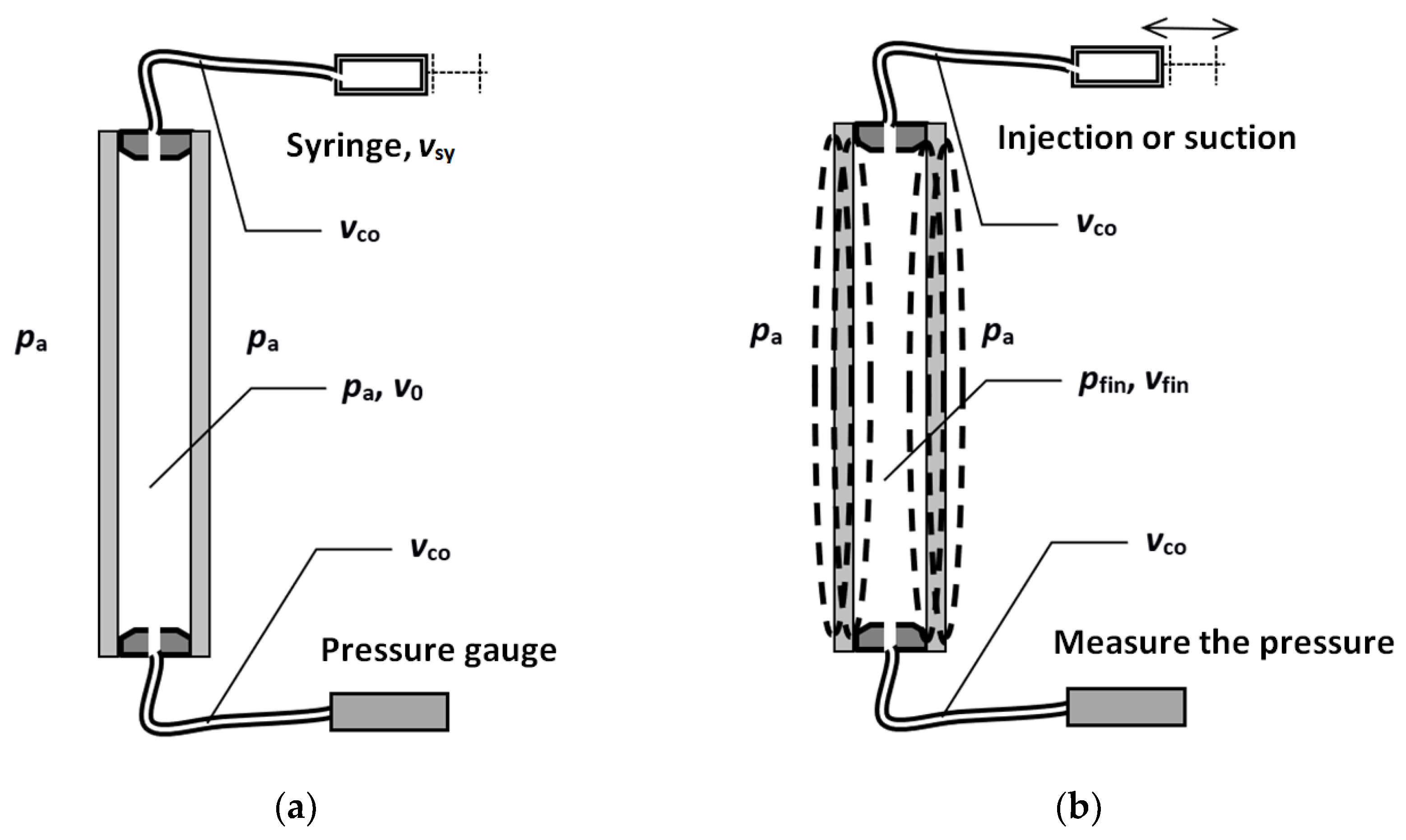

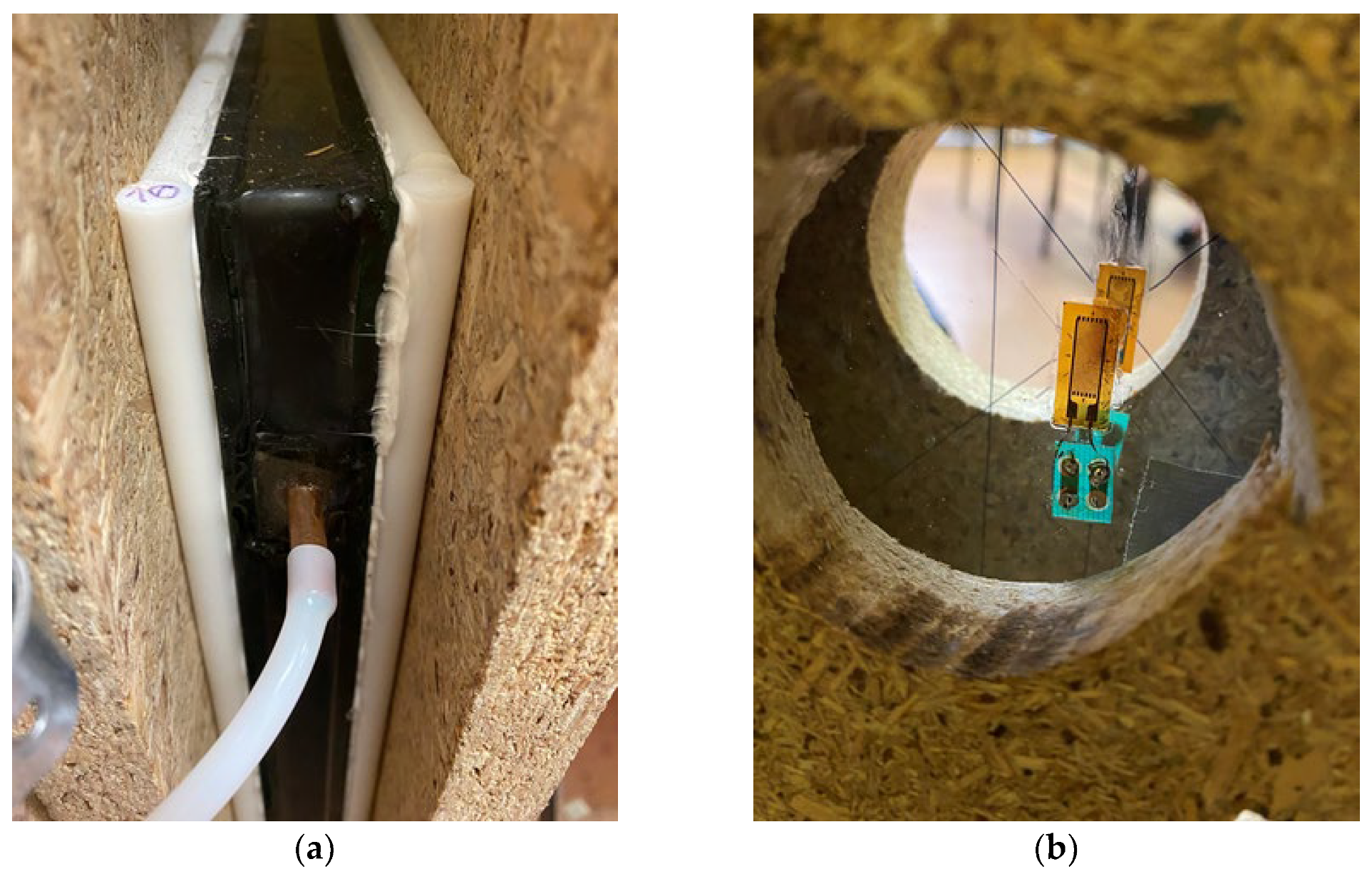

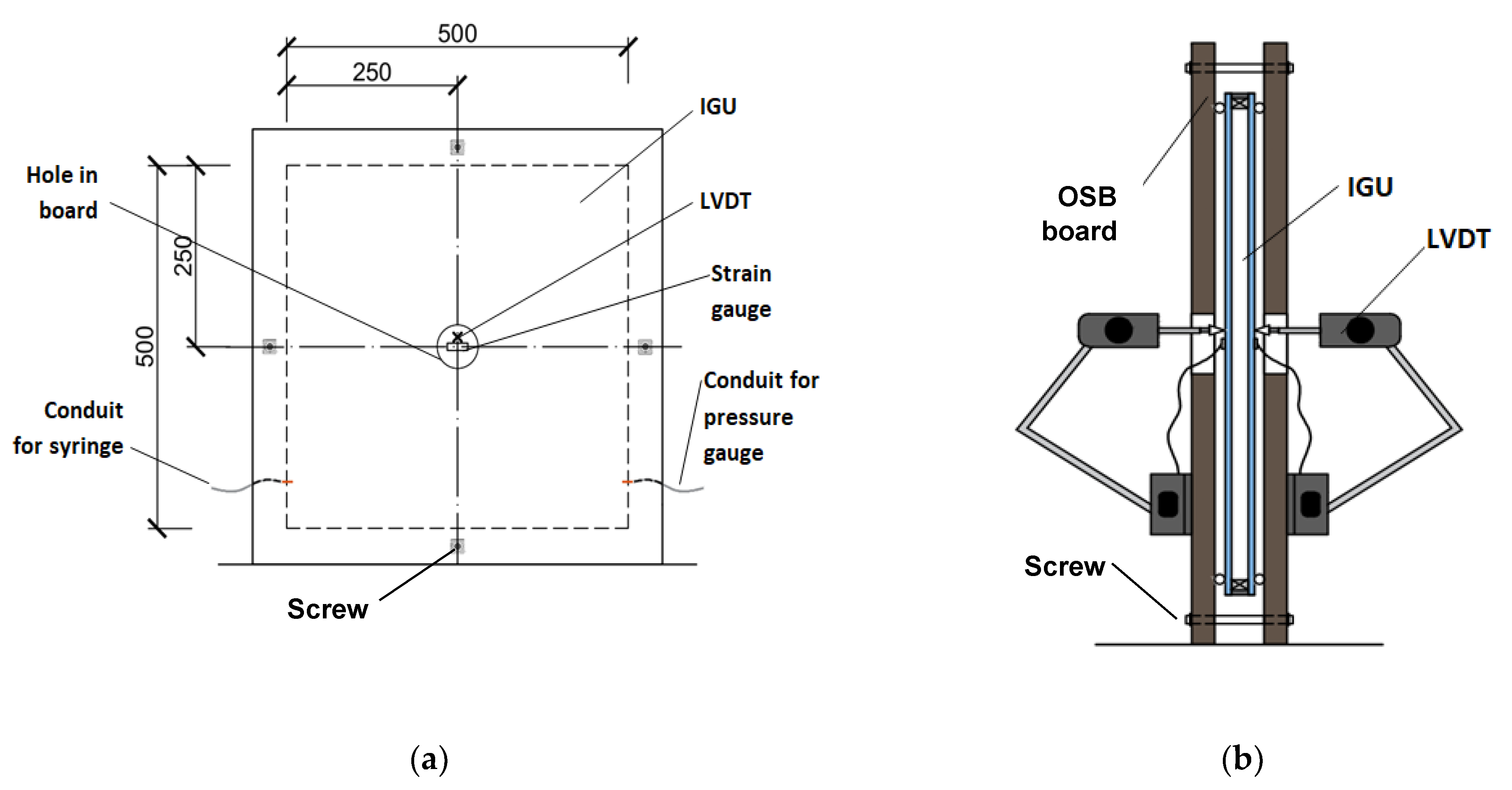

2.1. Experiments

2.2. Analytical Model

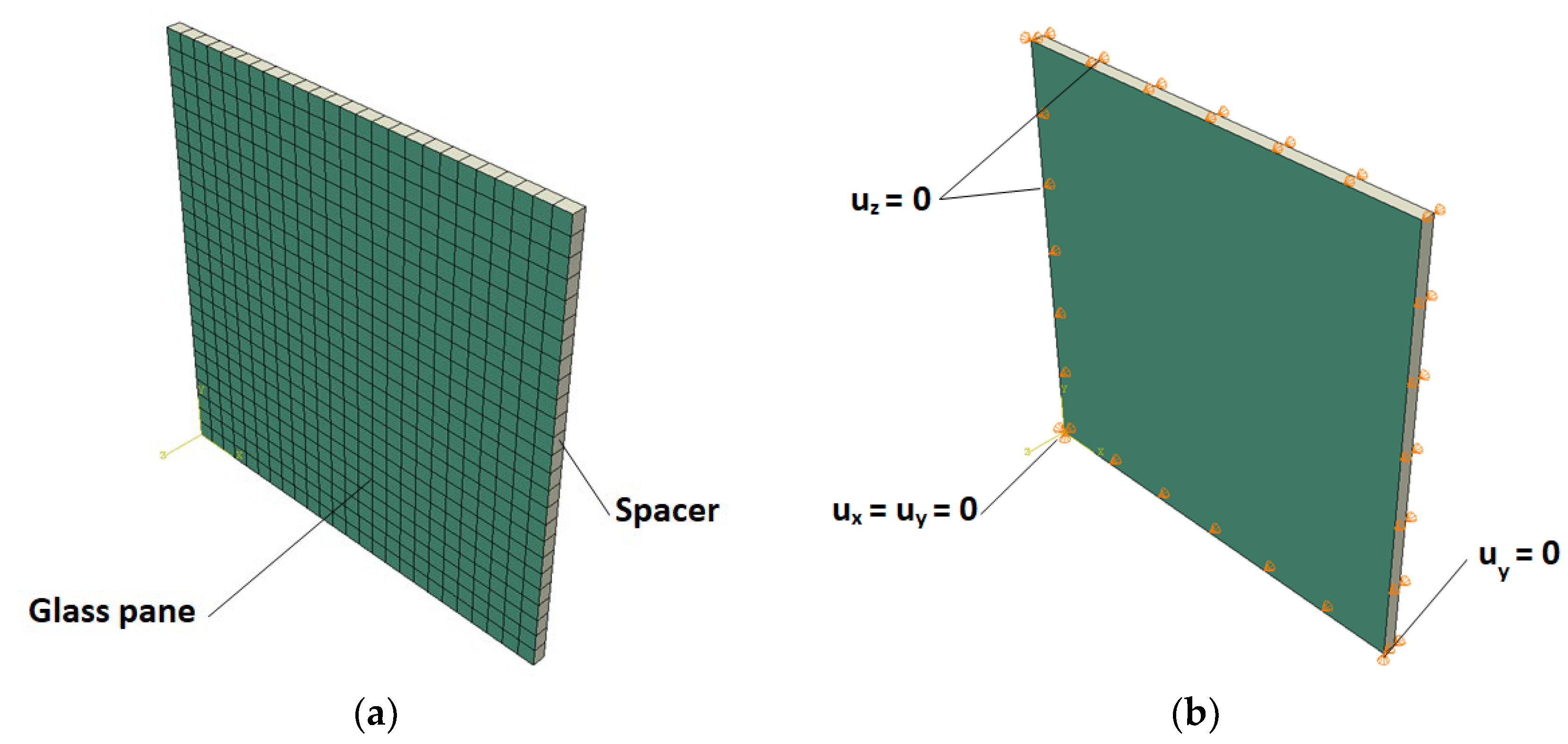

2.3. Numerical Simulations

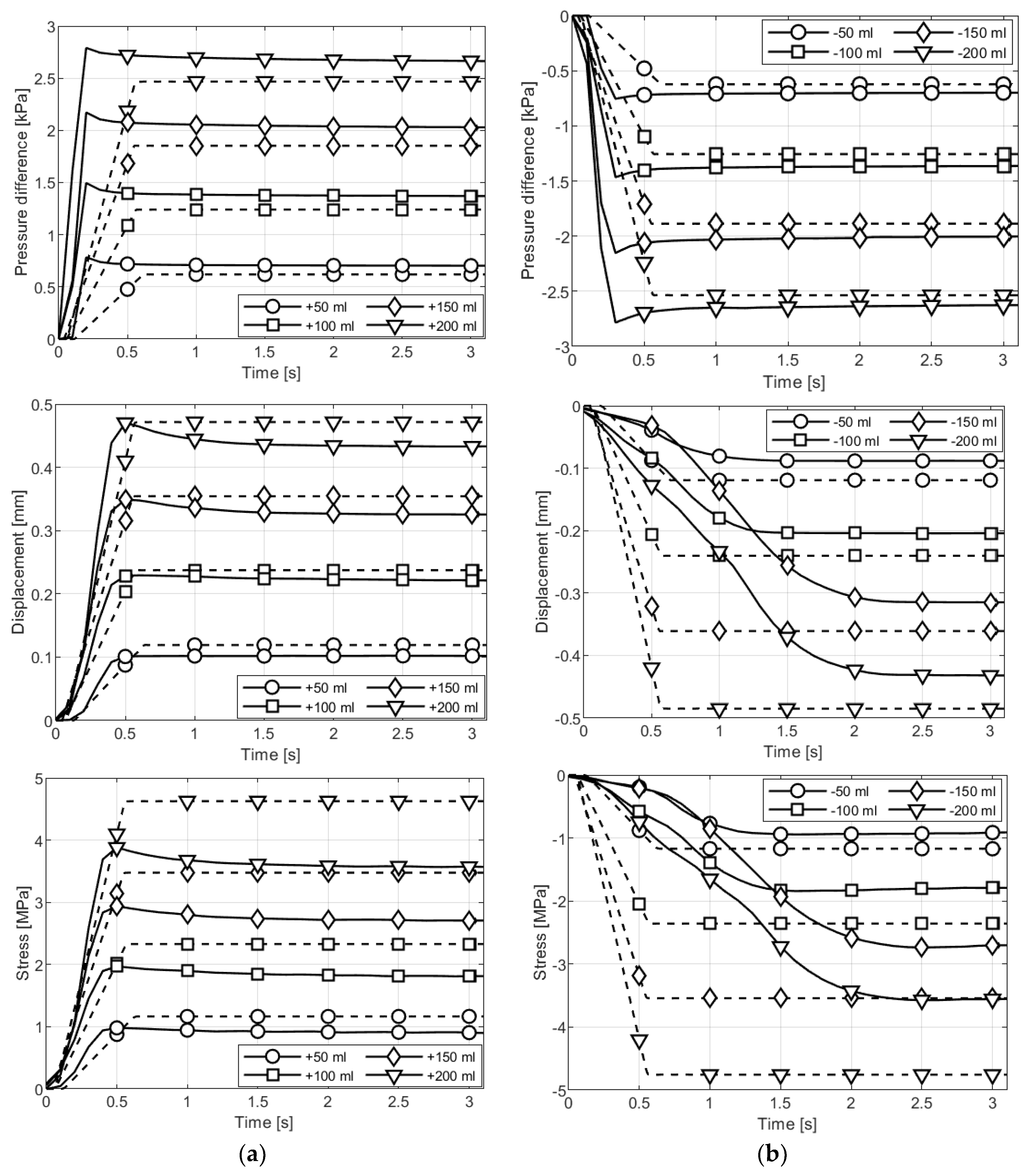

3. Results and Discussion

4. Conclusions and Further Work

- The results obtained from the analytical and numerical models are in good agreement; they do not differ by more than 12% (mostly much less), which proves the correctness of the assumptions for the analyses. The differences result from different ways of defining the gas input parameters in the gap;

- During the tests, it was found that the rapid injection/withdrawal of gas causes a sudden increase (in absolute value) of the pressure difference, which decreases and stabilizes almost instantly. The difference is, on average 7%. This is due to adiabatic effects resulting from the high rate of gas transformation. We plan to analyze it in more detail in future work;

- The results from the numerical and analytical models, in terms of the pressure difference, underestimate the values obtained in the tests by an average of 8%, while for deflections and stresses, they overestimate them by 16% and 32%, respectively. This indicates a rotational stiffness at the edges of the panes resulting from the properties of the connection of the glass pane with the spacer, seal and support rod. As part of the research in the near future, we plan to improve these models, considering the rotational stiffness of the panes’ edges.

- Simulating climatic loads in IGUs by the controlled change of pressure in the gap is inexpensive and can be used by other researchers or company laboratories. IGUs with different types of spacers and different methods of their installation in window frames or façade systems can be tested. It is also possible to define a specific amount of injected/extracted air to model specific climatic loading for assumed locations and operating conditions.

- The experience gained from this research will be used in planned tests with curved IGUs in the near future. This particularly applies to the use of the methodology of experimental research that proved its applicability in the case of the tested flat glass. Experimental tests with curved IGUs are expensive to carry out for a large number of samples; therefore, a validated numerical model is actually the only way to analyze their mechanical behavior under climatic loads.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Galuppi, L.; Royer-Carfagni, G. Betti’s Analytical Method for the load sharing in double glazed units. Compos. Struct. 2020, 235, 111765. [Google Scholar] [CrossRef]

- Galuppi, L.; Royer-Carfagi, G. Green’s functions for the load sharing in multiple insulating glazing units. Int. J. Solids Struct. 2020, 206, 412–425. [Google Scholar] [CrossRef]

- Feldmeier, F. Klimabelastung und Lastverteilung bei Mehrscheiben-Isolierglas. Stahlbau 2006, 75, 467–478. [Google Scholar] [CrossRef]

- Feldmeier, F. Bemessung von Dreifach-Isolierglas. Stahlbau Spez. 2011—Glas./Glass Build. 2011, 80, 75–80. [Google Scholar] [CrossRef]

- Buddenberg, S.; Hof, P.; Oechsner, M. Climate loads in insulating glass units: Comparison of theory and experimental results. Glass Struct. Eng. 2016, 1, 301–313. [Google Scholar] [CrossRef] [Green Version]

- Stratiy, P. Numerical-and-Analytical Method of Estimation Insulated Glass Unit Deformations Caused by Climate Loads. In International Scientific Conference Energy Management of Municipal Transportation Facilities and Transport EMMFT 2017; Murgul, V., Popovic, Z., Eds.; Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2017; Volume 692, pp. 970–979. [Google Scholar]

- EN 16612:2020; Glass in Building. Determination of the Lateral Load Resistance of Glass Panes by Calculation. CEN: Brussels, Belgium, 2020.

- Respondek, Z. Heat Transfer Through Insulating Glass Units Subjected to Climatic Loads. Materials 2020, 13, 286. [Google Scholar] [CrossRef] [Green Version]

- Respondek, Z.; Kozłowski, M.; Wiśniowski, M. Deflections and Stresses in Rectangular, Circular and Elliptical Insulating Glass Units. Materials 2022, 15, 2427. [Google Scholar] [CrossRef]

- Solvason, K.R. Pressures and Stresses in Sealed Double Glazing Units; Technical Paper No. 423; Division of Building Research, National Research Council Canada: Ottawa, ON, Canada, 1974. [Google Scholar]

- Curcija, C.; Vidanovic, S. Predicting Thermal Transmittance of IGU Subject to Deflection; Lawrence Berkeley National Laboratory, Environmental Energy Technologies Division: Berkeley, CA, USA, 2012. [Google Scholar]

- Galuppi, L. Practical expressions for the design of DGUs. The BAM approach. Eng. Struct. 2020, 221, 110993. [Google Scholar] [CrossRef]

- Bedon, C.; Amadio, C. A linear formulation for the ULS design of glass elements under combined loads: Application to IGUs. Glass Struct. Eng. 2018, 3, 289–301. [Google Scholar] [CrossRef]

- Bedon, C.; Amadio, C. Buckling analysis and design proposal for 2-side supported double Insulated Glass Units (IGUs) in compression. Eng. Struct. 2018, 168, 23–34. [Google Scholar] [CrossRef]

- ASTM E1300-16; Standard Practice for Determining Load Resistance of Glass in Buildings. ASTM: West Conshohocken, PA, USA, 2016.

- Velchev, D.; Ivanov, I.V. A finite element for insulating glass units. In Challenging Glass 4 & COST Action TU0905 Final Conference 2014; Louter, C., Bos, F., Belis, J., Lebet, J.P., Eds.; Taylor & Francis Group: London, UK, 2014; pp. 311–318. [Google Scholar]

- Bedon, C.; Amadio, C. Mechanical analysis and characterization of IGUs with different silicone sealed spacer connections—Part 1: Experiments. Glass Struct. Eng. 2020, 5, 301–325. [Google Scholar] [CrossRef]

- Bedon, C.; Amadio, C. Mechanical analysis and characterization of IGUs with different silicone sealed spacer connections—Part 2: Modelling. Glass Struct. Eng. 2020, 5, 327–346. [Google Scholar] [CrossRef]

- Sielicki, P.W.; Bedon, C.; Zhang, X. Performance of TGU Windows under Explosive Loading. In Soft Target Protection; Hofreiter, L., Berezutskyi, V., Figuli, L., Zvaková, Z., Eds.; NATO Science for Peace and Security Series C: Environmental Security; Springer: Dordrecht, The Netherlands, 2020. [Google Scholar]

- Heiskari, J.; Romanoff, J.; Laakso, A.; Ringsberg, J.W. On the thickness determination of rectangular glass panes in insulating glass units considering the load sharing and geometrically nonlinear bending. Thin-Walled Struct. 2022, 171, 108774. [Google Scholar] [CrossRef]

- Colldecarrera, T.; Torres, J.; Bover, A. Simulation Tool for the Analysis of Simple Flat and Cylindrical Insulated Glass Units. In Challenging Glass Conference Proceedings; Challenging Glass 7; 2020; Volume 7. [Google Scholar]

- Tibolt, M.; Hechler, O.; Odenbreit, C. Analytical extension of a climate load model for undercut point fitted IGU. Challenging Glass 4 & COST Action TU0905 Final Conference; CRC Press: Boca Raton, FL, USA, 2014; pp. 199–208. [Google Scholar]

- Kralj, A.; Drev, M.; Žnidaršič, M.; Černe, B.; Hafner, J.; Jelle, B.P. Investigations of 6-pane glazing: Properties and possibilities. Energy Build. 2019, 190, 61–68. [Google Scholar] [CrossRef]

- Respondek, Z. Influence of Insulated Glass Units Thickness and Weight Reduction on their Functional Properties. Open Eng. 2018, 8, 455–462. [Google Scholar] [CrossRef]

- Lori, G.; Van Den Brande, K.; Van Den Bossche, N.; De Bleecker, H.; Belis, J. A simple numerical tool for superimposition of climatic load and wind load in Closed Cavity Facades: Importance of a coupled PE-thermal-mechanical model. Glass Struct. Eng. 2022, 7, 487–506. [Google Scholar] [CrossRef]

- Bao, M.; Gregson, S. Sensitivity study on climate induced internal pressure within cylindrical curved IGUs. Glass Struct. Eng. 2019, 4, 29–44. [Google Scholar] [CrossRef]

- Sack, N.; Rose, A. Untersuchungen zur Umsetzbarkeit von Druckentspanntem Mehrscheiben-Isolierglas. Institute for Window Technology Rosenheim. 2014. Available online: https://www.ift-rosenheim.de/documents/10180/671018/FA_GR1406.pdf/2d0f2a7b-4c25-4133-900f-48953b6bfdad (accessed on 17 March 2022).

- Rose, A. Zmiana ciśnienia wewnątrz szyb zespolonych (IGU). Wyniki badań, praktyczna realizacja i perspektywy. Świat Szkła 2017, 1, 12–17. [Google Scholar]

- SWISSPACER AIR. The Solution for Pressure-Equalized Insulating Glazing Units. Available online: https://en.swisspacer.com/sites/en.swisspacer.com/files/AIR_Product_Broch_IGU_EN_2-0.pdf (accessed on 17 March 2022).

- EN 1279-1:2018; Glass in Building—Insulating Glass Units—Part 1: Generalities, System Description, Rules for Substitution, Tolerances and Visual Quality. CEN—European Committee for Standardization: Brussels, Belgium, 2018.

- Hart, R.; Goudey, H.; Arasteh, D.; Curcija, D.C. Thermal performance impacts of center-of-glass deflections in installed insulating glazing units. Energy Build. 2012, 54, 453–460. [Google Scholar] [CrossRef] [Green Version]

- Penkova, N.; Krumov, K.; Zashkova, L.; Kassabov, I. Heat transfer and climatic loads at insulating glass units in window systems. Int. J. Adv. Sci. Eng. Technol. 2017, 5, 22–28. [Google Scholar]

- McMahon, S.; Norville, H.S.; Morse, S.M. Experimental investigation of load sharing in insulating glass units. J. Archit. Eng. 2018, 24, 04017038. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, J.; Laakso, A.; Huang, D. Mechanical response of anticlastic cold bending insulating glass and its coupling effect with uniform load. PLoS ONE 2021, 16, e0250463. [Google Scholar] [CrossRef] [PubMed]

- Respondek, Z.; Major, I. Study of Deflection in Insulating Glass Units Under Climatic Loads Simulation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 603, 032060. [Google Scholar] [CrossRef]

- Testo 400—Universal IAQ Instrument ver. 0970 4011 en 05, Testo SE % Co. KGaA. 2022. Available online: https://static-int.testo.com/media/1f/c3/9d43e2c6c57f/testo-400-Instruction-Manual.pdf (accessed on 2 January 2022).

- Wielokanałowe tensometryczne systemy pomiarowe. Available online: http://www.tenmex.pl/index.php?action=wktsp (accessed on 2 January 2022). (In Polish).

- Wüest, T.; Luible, A. Increased thermal induced climatic load in insulated glass units. J. Facade Des. Eng. 2016, 4, 91–113. [Google Scholar] [CrossRef] [Green Version]

- ABAQUS®; Version 6.14; Simulia. Dassault Systemes: Newport, RI, USA, 2014.

- Jensen, W.B. The universal gas constant. Chem. Educ. Today 2003, 80, 731–732. [Google Scholar] [CrossRef]

- Rajput, R.K. Engineering Thermodynamics: A Computer Approach; Transatlantic Publishers: London, UK, 2003. [Google Scholar]

- EN 572–1:2012; Glass in Buildings—Basic soda lime silicate glass products Part 1: Definitions and general physical and mechanical properties. CEN—European Committee for Standardization: Brussels, Belgium, 2012.

- Vieira da Rosa, A.; Ordóñez, J.C. Chapter 2—A Minimum of Thermodynamics and of the Kinetic Theory of Gases. In Fundamentals of Renewable Energy Processes, 4th ed.; Elsevier: Amsterdam, Netherlands, 2022; pp. 49–104. [Google Scholar]

| Series | Volume of Injected/Sucked Gas [mL] | Equivalent Change of Gas Temperature in Gap ΔTsim [°C] | Equivalent Change in Atmospheric Pressure Δpsim [kPa] |

|---|---|---|---|

| 1 | +50 | 3.977 | −1.334 |

| 2 | +100 | 7.954 | −2.652 |

| 3 | +150 | 11.934 | −3.953 |

| 4 | +200 | 15.908 | −5.236 |

| 5 | −50 | −3.950 | +1.342 |

| 6 | −100 | −7.845 | +2.684 |

| 7 | −150 | −11.685 | +4.023 |

| 8 | −200 | −15.471 | +5.364 |

| Material | E [GPa] | μ [-] | Volume Density [kg/m3] | Inelastic Heat Friction [-] | Specified Heat Capacity [J/(kg∙K)] |

|---|---|---|---|---|---|

| Glass | 70 × 109 | 0.23 | 2500 | 0.9 | 720 |

| Spacer | 1 × 109 | 0.49 | 1000 | 0.9 | 113 |

| Test Series | pmax [kPa] | pstab [kPa] | wmax [mm] | wstab [mm] | σmax [MPa] | σstab [MPa] |

|---|---|---|---|---|---|---|

| +50 mL | ||||||

| EXP | 0.783 ± 0.006 | 0.701 ± 0.006 (−10.47%) | 0.102 ± 0.100 | 0.100 ± 0.100 (−1.96%) | 0.967 ± 0.038 | 0.899 ± 0.038 (−7.03%) |

| FEM | - | 0.619 | - | 0.119 | - | 1.170 |

| ANA | - | 0.689 | - | 0.120 | - | 1.210 |

| −50 mL | ||||||

| EXP | −0.755 ± 0.007 | −0.699 ± 0.007 (−7.42%) | −0.088 ± 0.008 | −0.088 ± 0.008 (0.00%) | −0.940 ± 0.038 | −0.911 ± 0.038 (−3.09%) |

| FEM | - | −0.623 | - | −0.119 | - | −1.282 |

| ANA | - | −0.690 | - | −0.120 | - | −1.210 |

| +100 mL | ||||||

| EXP | 1.496 ± 0.007 | 1.367 ± 0.007 (−8.62%) | 0.224 ± 0.006 | 0.221 ± 0.006 (−1.69%) | 1.927 ± 0.064 | 1.803 ± 0.064 (−6.43%) |

| FEM | - | 1.243 | - | 0.238 | - | 2.352 |

| ANA | - | 1.374 | - | 0.240 | - | 2.410 |

| −100 mL | ||||||

| EXP | −1.465 ± 0.007 | −1.360 ± 0.007 (−7.17%) | −0.204 ± 0.008 | −0.205 ± 0.008 (+0.49%) | −1.836 ± 0.087 | −1.775 ± 0.087 (−3.32%) |

| FEM | - | −1.258 | - | −0.241 | - | −2.349 |

| ANA | - | −1.373 | - | −0.240 | - | −2.410 |

| +150 mL | ||||||

| EXP | 2.171 ± 0.008 | 2.021 ± 0.008 (−6.91%) | 0.329 ± 0.008 | 0.232 ± 0.008 (−1.82%) | 2.867 ± 0.060 | 2.702 ± 0.060 (−5.76%) |

| FEM | - | 1.855 | - | 0.355 | - | 3.518 |

| ANA | - | 2.054 | - | 0.360 | - | 3.610 |

| −150 mL | ||||||

| EXP | −2.153 ± 0.011 | −1.998 ± 0.011 (−7.20%) | −0.315 ± 0.011 | 0.315 ± 0.008 (+0.00%) | −2.732 ± 0.052 | −2.643 ± 0.052 (−3.26%) |

| FEM | - | −1.890 | - | −0.361 | - | −3.514 |

| ANA | - | −2.052 | - | −0.360 | - | −3.608 |

| +200 mL | ||||||

| EXP | 2.791 ± 0.008 | 2.653 ± 0.008 (−4.94%) | 0.437 ± 0.009 | 0.432 ± 0.009 (−1.14%) | 3.766 ± 0.066 | 3.555 ± 0.066 (−5.60%) |

| FEM | - | 2.471 | - | 0.472 | - | 4.699 |

| ANA | - | 2.729 | - | 0.480 | - | 4.800 |

| −200 mL | ||||||

| EXP | −2.784 ± 0.023 | −2.618 ± 0.023 (−5.96%) | −0.432 ± 0.013 | −0.433 ± 0.013 (+0.23%) | −3.567 ± 0.058 | −3.497 ± 0.058 (−1.96%) |

| FEM | - | −2.536 | - | −0.485 | - | −4.696 |

| ANA | - | −2.726 | - | −0.480 | - | −4.790 |

| Test Series | pstab | wstab | σstab |

|---|---|---|---|

| +50 mL | |||

| FEM/EXP | −11.7% | 19.0% | 30.1% |

| ANA/EXP | −1.7% | 20.0% | 34.6% |

| ANA/FEM | 11.3% | 0.8% | 3.4% |

| −50 mL | |||

| FEM/EXP | −10.9% | 35.2% | 40.7% |

| ANA/EXP | −1.3% | 36.4% | 32.8% |

| ANA/FEM | 10.8% | 0.8% | −5.6% |

| +100 mL | |||

| FEM/EXP | −9.1% | 7.7% | 30.4% |

| ANA/EXP | 0.5% | 8.6% | 33.7% |

| ANA/FEM | 10.5% | 0.8% | 2.5% |

| −100 mL | |||

| FEM/EXP | −7.5% | 17.6% | 32.3% |

| ANA/EXP | 1.0% | 17.1% | 35.8% |

| ANA/FEM | 9.1% | −0.4% | 2.6% |

| +150 mL | |||

| FEM/EXP | −8.2% | 53.0% | 30.2% |

| ANA/EXP | 1.6% | 55.2% | 33.6% |

| ANA/FEM | 10.7% | 1.4% | 2.6% |

| −150 mL | |||

| FEM/EXP | −5.4% | 14.6% | 33.0% |

| ANA/EXP | 2.7% | 14.3% | 36.5% |

| ANA/FEM | 8.6% | −0.3% | 2.7% |

| +200 mL | |||

| FEM/EXP | −6.9% | 9.3% | 32.2% |

| ANA/EXP | 2.9% | 11.1% | 35.0% |

| ANA/FEM | 10.4% | 1.7% | 2.1% |

| −200 mL | |||

| FEM/EXP | −3.1% | 12.0% | 34.3% |

| ANA/EXP | 4.1% | 10.9% | 37.0% |

| ANA/FEM | 7.5% | −1.0% | 2.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozłowski, M.; Respondek, Z.; Wiśniowski, M.; Cornik, D.; Zemła, K. Experimental and Numerical Simulations of Climatic Loads in Insulating Glass Units by Controlled Change of Pressure in the Gap. Appl. Sci. 2023, 13, 1269. https://doi.org/10.3390/app13031269

Kozłowski M, Respondek Z, Wiśniowski M, Cornik D, Zemła K. Experimental and Numerical Simulations of Climatic Loads in Insulating Glass Units by Controlled Change of Pressure in the Gap. Applied Sciences. 2023; 13(3):1269. https://doi.org/10.3390/app13031269

Chicago/Turabian StyleKozłowski, Marcin, Zbigniew Respondek, Maciej Wiśniowski, Dawid Cornik, and Kinga Zemła. 2023. "Experimental and Numerical Simulations of Climatic Loads in Insulating Glass Units by Controlled Change of Pressure in the Gap" Applied Sciences 13, no. 3: 1269. https://doi.org/10.3390/app13031269

APA StyleKozłowski, M., Respondek, Z., Wiśniowski, M., Cornik, D., & Zemła, K. (2023). Experimental and Numerical Simulations of Climatic Loads in Insulating Glass Units by Controlled Change of Pressure in the Gap. Applied Sciences, 13(3), 1269. https://doi.org/10.3390/app13031269