Development of a High-Function Fiber Stylus for Microstructure Measurement with Water-Repellent and Antistatic Coatings

Abstract

1. Introduction

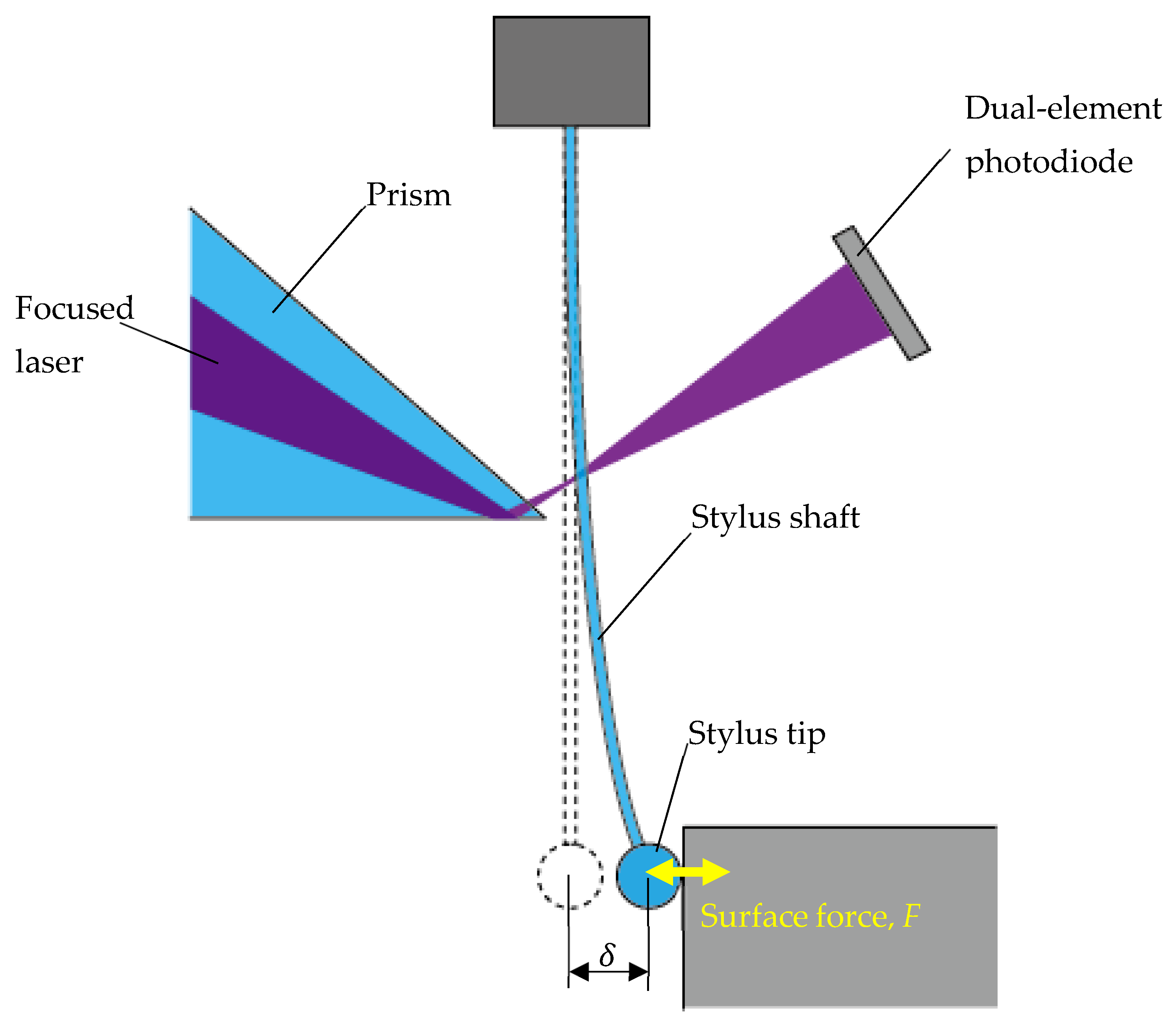

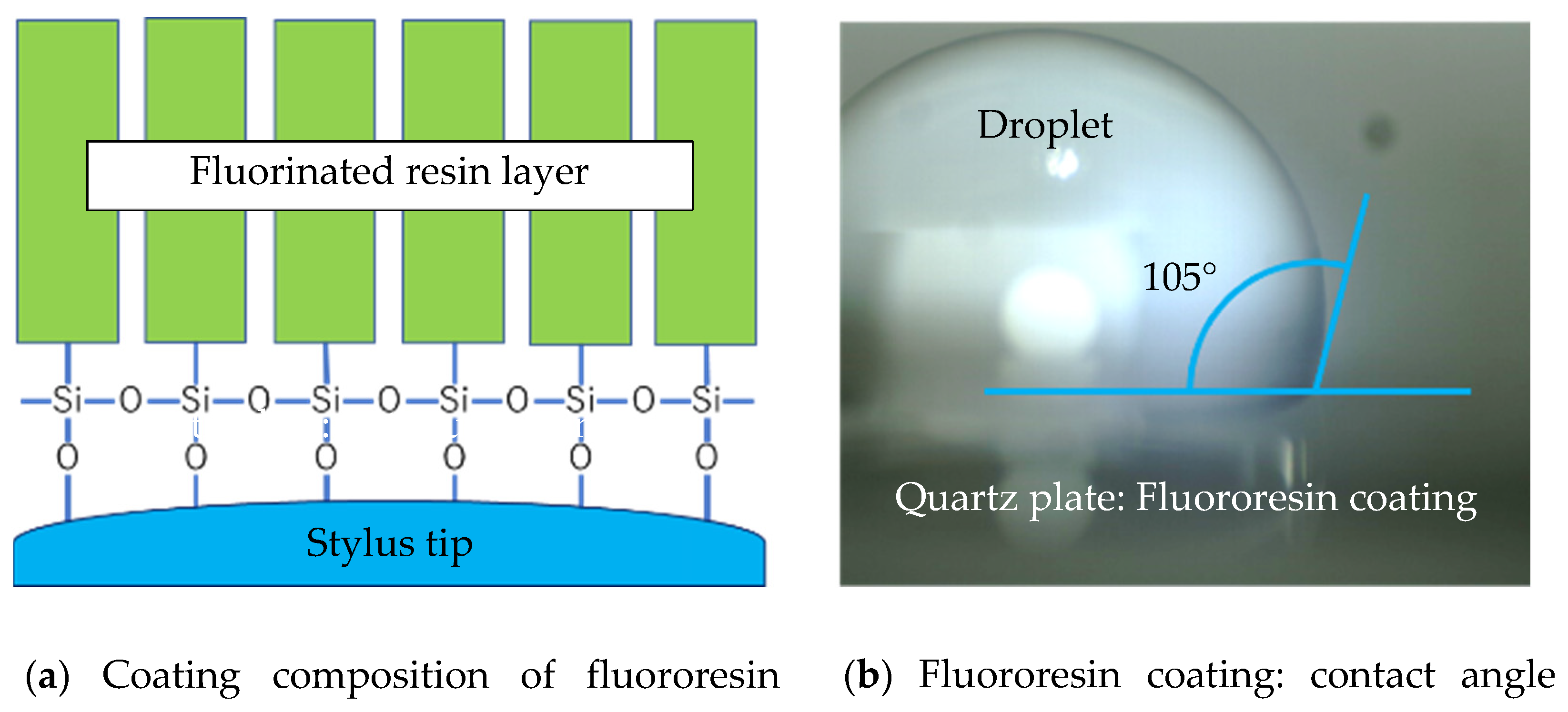

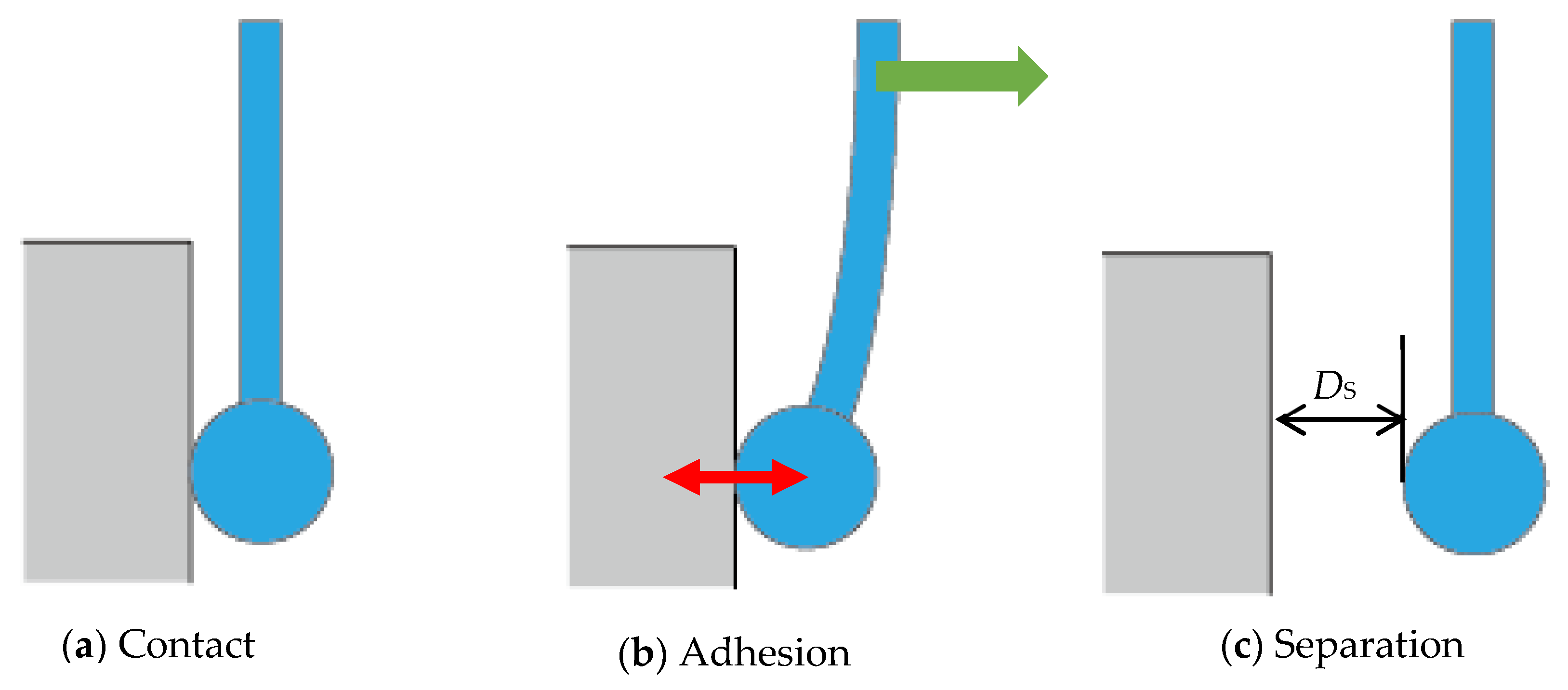

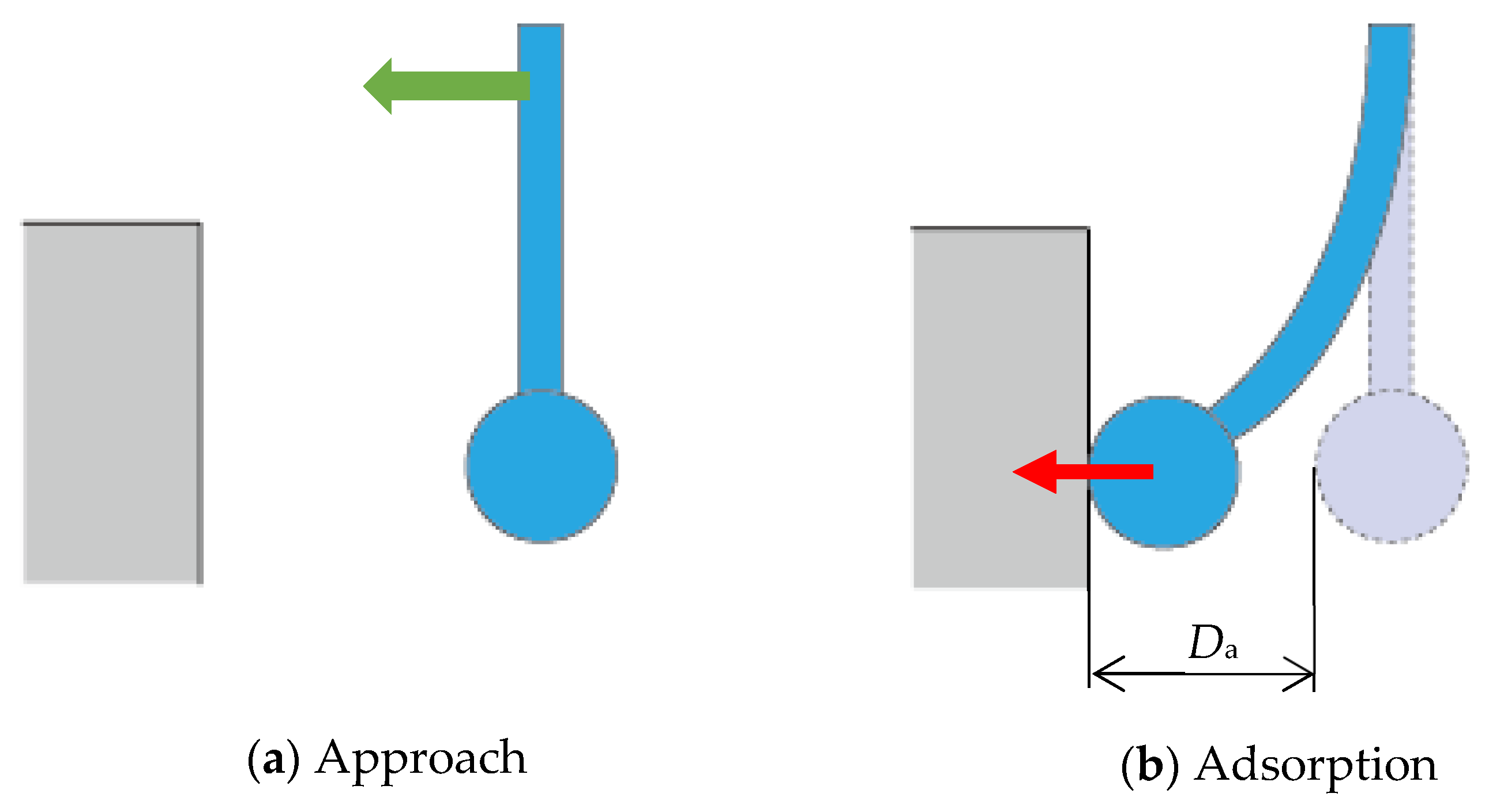

2. Effect of Surface Force

3. Reduction in Liquid Bridge Force by Applying a Water-Repellent Coating to the Stylus Tip

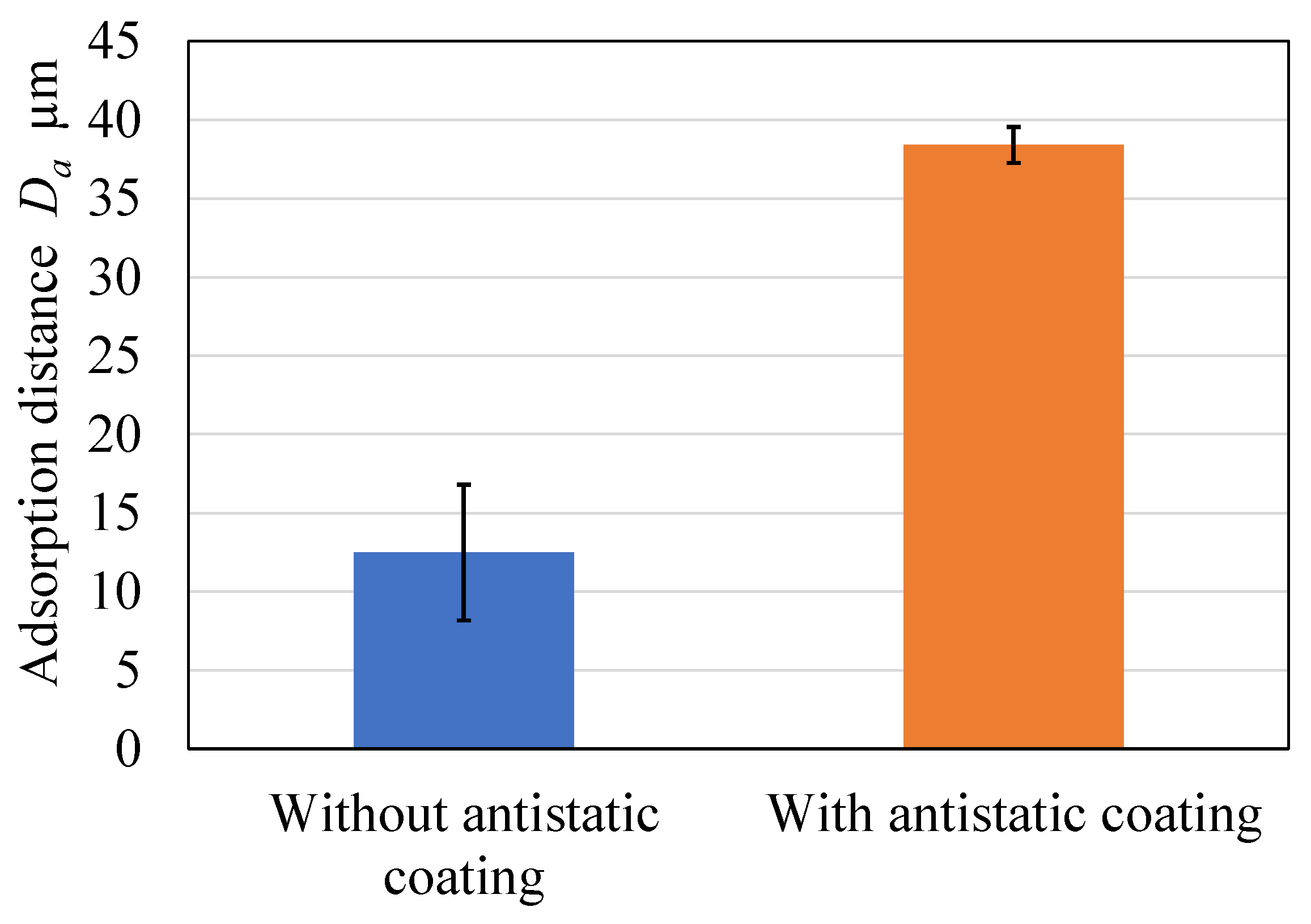

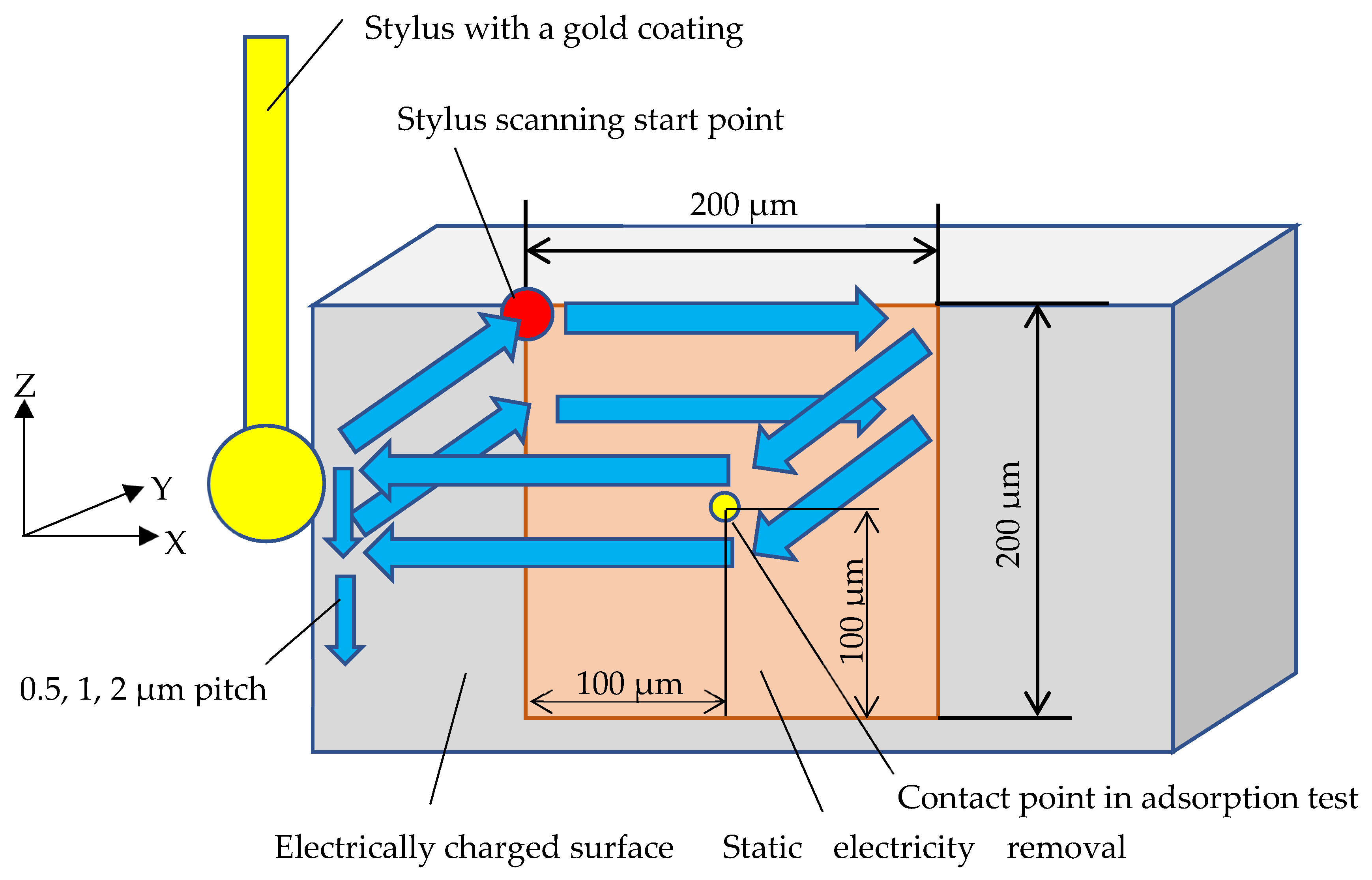

4. Reduction in Electrostatic Force by Applying an Antistatic Coating to the Stylus Tip

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Michihata, M. Surface-Sensing Principle of Microprobe System for Micro-Scale Coordinate Metrology: A Review. Metrology 2022, 2, 4. [Google Scholar] [CrossRef]

- Fang, F.Z.; Zhang, X.D.; Gao, W.; Guo, Y.B.; Byrne, G.; Hansen, H.N. Nanomanufacturing—Perspective and applications. CIRP Ann. 2017, 66, 683–705. [Google Scholar] [CrossRef]

- Thalmann, R.; Meli, F.; Küng, A. State of the Art of Tactile Micro Coordinate Metrology. Appl. Sci. 2016, 6, 150. [Google Scholar] [CrossRef]

- Metz, D.; Dietzel, A. 3-D Isotropic Tactile Microprobe Based on a Silicon Parallelogram Kinematic: From Concept to Fabrication. J. Microelectromech. Syst. 2019, 28, 63–76. [Google Scholar] [CrossRef]

- Metz, D.; Jantzen, S.; Wessel, D.; Mies, G.; Lüdenbach, J.; Stein, M.; Kniel, K.; Dietzel, A. Integration of an isotropic microprobe and a microenvironment into a conventional CMM. Meas. Sci. Technol. 2019, 30, 115007. [Google Scholar] [CrossRef]

- Feng, K.; Cui, J.; Sun, X.; Dang, H.; Shi, T.; Niu, Y.; Jin, Y.; Tan, J. Investigation of a Three-Dimensional Micro-Scale Sensing System Based on a Tapered Self-Assembly Four-Cores Fiber Bragg Grating Probe. Sensors 2018, 18, 2824. [Google Scholar] [CrossRef]

- Zou, L.; Ni, H.; Zhang, P.; Ding, X. Assembled Cantilever Fiber Touch Trigger Probe for Three-Dimensional Measurement of Microstructures. Sensors 2017, 17, 2652. [Google Scholar] [CrossRef]

- Petz, M.; Tutsch, R.; Christoph, R.; Andraes, M.; Hopp, B. Tactile–optical probes for three-dimensional microparts. Measurement 2012, 45, 2288–2298. [Google Scholar] [CrossRef]

- Michihata, M.; Takaya, Y.; Hayashi, T. Improvement of Laser Trapping Based Microprobe in Laser Shaded Condition. J. Adv. Mech. Des. Syst. Manuf. 2012, 6, 764–770. [Google Scholar] [CrossRef]

- Bian, X.; Cui, J.; Lu, Y.; Tan, J. Ultraprecision Diameter Measurement of Small Holes with Large Depth-To-Diameter Ratios Based on Spherical Scattering Electrical-Field Probing. Appl. Sci. 2019, 9, 242. [Google Scholar] [CrossRef]

- Zhang, R.; Wu, S.; Liu, L.; Lu, N.-H.; Fu, X.; Gao, S.-T.; Hu, X.-D. A CD probe with a tailored cantilever for 3D-AFM measurement. Meas. Sci. Technol. 2018, 29, 125011. [Google Scholar] [CrossRef]

- Ren, Z.; Wang, D.; Jing, W.; Wang, S.; Jiang, Z.; Ren, J.; Gu, H.; Wei, X. A probe-type high-precision micro-force sensor based on quartz DETF resonator. Meas. Sci. Technol. 2021, 32, 115107. [Google Scholar] [CrossRef]

- Ito, S.; Shima, Y.; Kato, D.; Matsumoto, K.; Kamiya, K. Development of a Microprobing System for Side Wall Detection Based on Local Surface Interaction Force Detection. Int. J. Autom. Technol. 2020, 14, 91–98. [Google Scholar] [CrossRef]

- Schuler, A.; Hausotte, T.; Sun, Z. Micro- and nanocoordinate measurements of micro-parts with 3-D tunnelling current probing. J. Sens. Sens. Syst. 2015, 4, 199–208. [Google Scholar] [CrossRef]

- Manske, E.; Fröhlich, T.; Füßl, R.; Ortlepp, I.; Mastylo, R.; Blumröder, U.; Dontsov, D.; Kühnel, M.; Köchert, P. Progress of nanopositioning and nanomeasuring machines for cross-scale measurement with sub-nanometre precision. Meas. Sci. Technol. 2020, 31, 085005. [Google Scholar] [CrossRef]

- Murakami, H.; Katsuki, A.; Sajima, T.; Uchiyama, K.; Yoshida, I.; Hamano, Y.; Honda, H. Development of measurement system for microstructures using an optical fiber probe: Improvement of measurable region and depth. Meas. Sci. Technol. 2020, 31, 075902. [Google Scholar] [CrossRef]

- Murakami, H.; Katsuki, A.; Sajima, T.; Uchiyama, K. Fabrication of Ultra-Small-Diameter Optical-Fiber Probe Using Acid-Etch Technique and CO2 Laser for 3D-Micro Metrology. Int. J. Autom. Technol. 2017, 11, 699–706. [Google Scholar] [CrossRef]

- Murakami, H.; Katsuki, A.; Sajima, T.; Suematsu, T. Study of a vibrating fiber probing system for 3-D micro-structures: Performance improvement. Meas. Sci. Technol. 2014, 25, 094010. [Google Scholar] [CrossRef]

- Uchiyama, K.; Murakami, H.; Katsuki, A.; Sajima, T. Development of a Sharp-Tipped L-Shaped Stylus for Measurement of Nanoscale Sidewall Features. Int. J. Autom. Technol. 2022, 16, 489–496. [Google Scholar] [CrossRef]

- Murakami, H.; Murakami, H.; Katsuki, A.; Sajima, T.; Uchiyama, K. Development of a two-step stylus with elastic hinge for microstructure measurement to improve sensitivity and vibration characteristics. Precis. Eng. 2023, 80, 72–81. [Google Scholar] [CrossRef]

- Murakami, H.; Katsuki, A.; Sajima, T.; Fukuda, M. Reduction of Liquid Bridge Force for 3D Microstructure Measurements. Appl. Sci. 2016, 6, 153. [Google Scholar] [CrossRef]

- Okuyama, K.M.H.; Morooka, S. Fine Particle Engineering; Ohmsha: Tokyo, Japan, 1992; pp. 32–40. [Google Scholar]

- Uchiyama, H.M.K.; Katsuki, A.; Sajima, T.; Yamamoto, R.N.T.; Fujiyoshi, K. Fabrication of a fiber probe using a CO2 laser for microstructure measurement: High functionality and durability test. Procedia CIRP 2018, 77, 513–516. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murakami, H.; Uchiyama, K.; Katsuki, A.; Sajima, T.; Fujiyoshi, K. Development of a High-Function Fiber Stylus for Microstructure Measurement with Water-Repellent and Antistatic Coatings. Appl. Sci. 2023, 13, 1260. https://doi.org/10.3390/app13031260

Murakami H, Uchiyama K, Katsuki A, Sajima T, Fujiyoshi K. Development of a High-Function Fiber Stylus for Microstructure Measurement with Water-Repellent and Antistatic Coatings. Applied Sciences. 2023; 13(3):1260. https://doi.org/10.3390/app13031260

Chicago/Turabian StyleMurakami, Hiroshi, Kosuke Uchiyama, Akio Katsuki, Takao Sajima, and Kunitaka Fujiyoshi. 2023. "Development of a High-Function Fiber Stylus for Microstructure Measurement with Water-Repellent and Antistatic Coatings" Applied Sciences 13, no. 3: 1260. https://doi.org/10.3390/app13031260

APA StyleMurakami, H., Uchiyama, K., Katsuki, A., Sajima, T., & Fujiyoshi, K. (2023). Development of a High-Function Fiber Stylus for Microstructure Measurement with Water-Repellent and Antistatic Coatings. Applied Sciences, 13(3), 1260. https://doi.org/10.3390/app13031260