The Effect of Grouping Output Parameters by Quality Characteristics on the Predictive Performance of Artificial Neural Networks in Injection Molding Process

Abstract

:1. Introduction

2. Theoretical Background

2.1. Artificial Neural Networks

2.2. Backpropagation

2.3. Hyperparameters

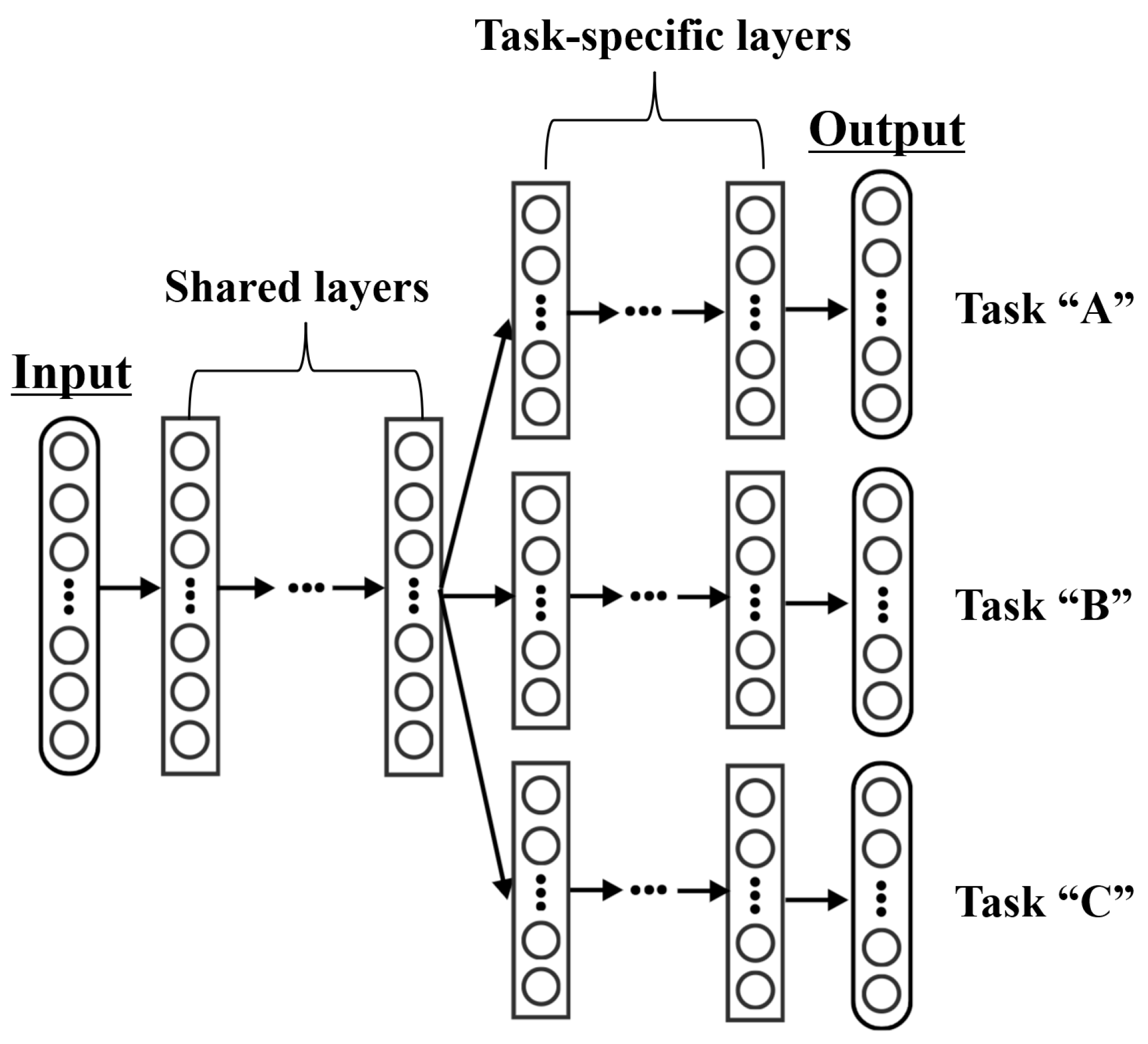

2.4. Multi-Task Learning

3. Experiment

3.1. Materials and Molding Equipment

3.2. Experimental Conditions

4. Neural Network Architectures and Implementation

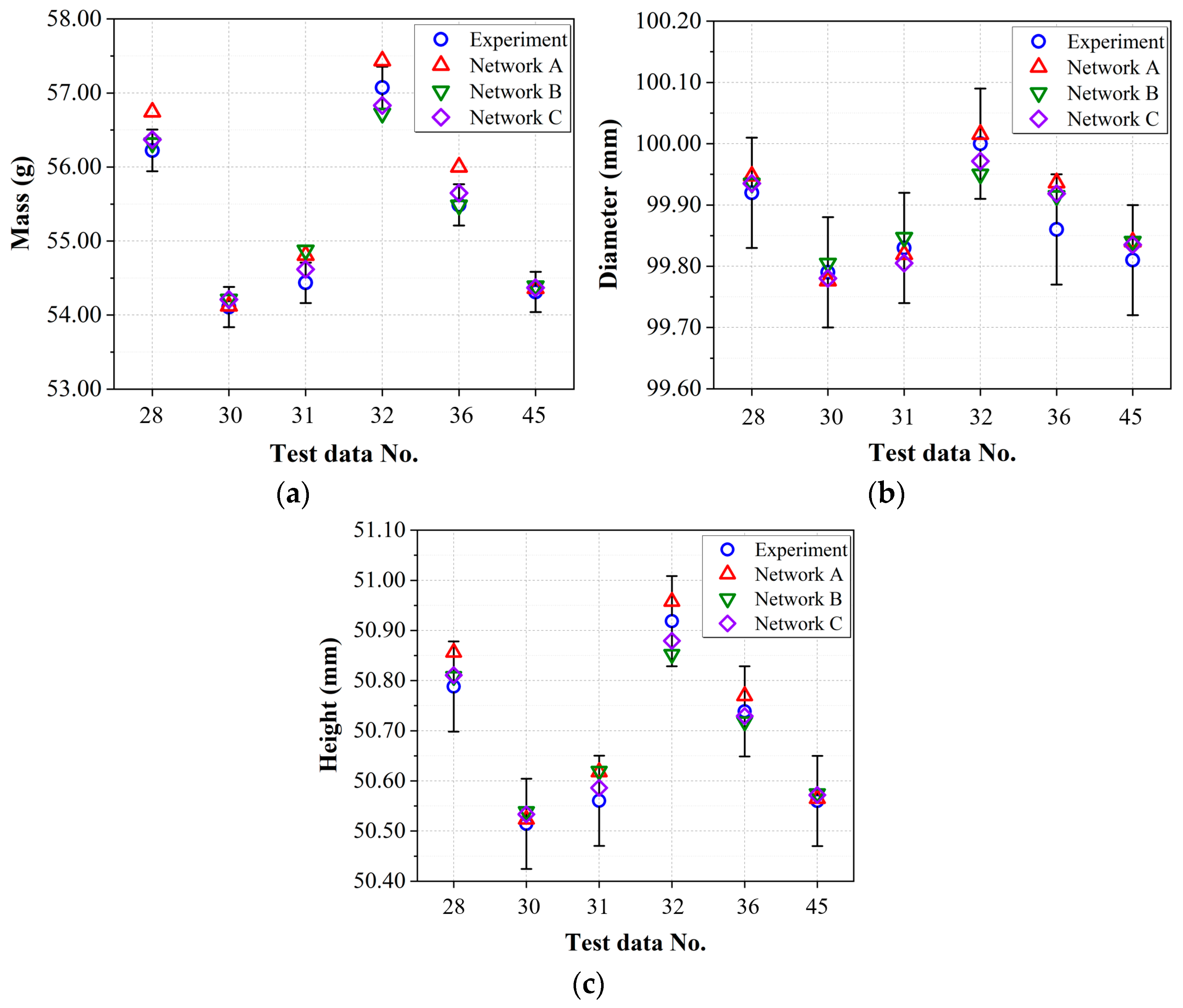

5. Results

6. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Exp. No. | Melt Temperature (°C) | Mold Temperature (°C) | Injection Speed (mm/s) | Packing Pressure (bar) | Packing Time (s) | Cooling Time (s) | Note |

|---|---|---|---|---|---|---|---|

| 1 | 200 | 40 | 40.0 | 150 | 6.0 | 38 | L27 |

| 2 | 200 | 40 | 40.0 | 150 | 12.0 | 48 | L27 |

| 3 | 200 | 40 | 40.0 | 150 | 18.0 | 58 | L27 |

| 4 | 200 | 50 | 70.0 | 200 | 6.0 | 38 | L27 |

| 5 | 200 | 50 | 70.0 | 200 | 12.0 | 48 | L27 |

| 6 | 200 | 50 | 70.0 | 200 | 18.0 | 58 | L27 |

| 7 | 200 | 60 | 100.0 | 250 | 6.0 | 38 | L27 |

| 9 | 200 | 60 | 100.0 | 250 | 18.0 | 58 | L27 |

| 10 | 220 | 40 | 70.0 | 250 | 6.0 | 48 | L27 |

| 11 | 220 | 40 | 70.0 | 250 | 12.0 | 58 | L27 |

| 12 | 220 | 40 | 70.0 | 250 | 18.0 | 38 | L27 |

| 13 | 220 | 50 | 100.0 | 150 | 6.0 | 48 | L27 |

| 14 | 220 | 50 | 100.0 | 150 | 12.0 | 58 | L27 |

| 15 | 220 | 50 | 100.0 | 150 | 18.0 | 38 | L27 |

| 16 | 220 | 60 | 40.0 | 200 | 6.0 | 48 | L27 |

| 17 | 220 | 60 | 40.0 | 200 | 12.0 | 58 | L27 |

| 18 | 220 | 60 | 40.0 | 200 | 18.0 | 38 | L27 |

| 19 | 240 | 40 | 100.0 | 200 | 6.0 | 58 | L27 |

| 20 | 240 | 40 | 100.0 | 200 | 12.0 | 38 | L27 |

| 21 | 240 | 40 | 100.0 | 200 | 18.0 | 48 | L27 |

| 22 | 240 | 40 | 40.0 | 250 | 6.0 | 58 | L27 |

| 23 | 240 | 50 | 40.0 | 250 | 12.0 | 38 | L27 |

| 24 | 240 | 50 | 40.0 | 250 | 18.0 | 48 | L27 |

| 25 | 240 | 60 | 70.0 | 150 | 6.0 | 58 | L27 |

| 26 | 240 | 60 | 70.0 | 150 | 12.0 | 38 | L27 |

| 27 | 240 | 60 | 70.0 | 150 | 18.0 | 48 | L27 |

| 28 | 214 | 55 | 82.7 | 204 | 16.3 | 52 | Random |

| 29 | 204 | 44 | 43.4 | 202 | 13.9 | 41 | Random |

| 30 | 203 | 46 | 93.6 | 205 | 13.7 | 45 | Random |

| 31 | 202 | 54 | 83.4 | 213 | 6.6 | 48 | Random |

| 32 | 206 | 43 | 61.6 | 221 | 6.9 | 39 | Random |

| 33 | 212 | 44 | 53.3 | 240 | 17.0 | 52 | Random |

| 34 | 212 | 51 | 90.8 | 224 | 6.1 | 48 | Random |

| 35 | 200 | 52 | 50.0 | 215 | 17.6 | 39 | Random |

| 36 | 229 | 51 | 46.2 | 153 | 11.7 | 45 | Random |

| 37 | 228 | 49 | 53.2 | 217 | 12.3 | 58 | Random |

| 38 | 222 | 51 | 63.7 | 167 | 8.7 | 51 | Random |

| 39 | 219 | 50 | 41.4 | 156 | 16.3 | 52 | Random |

| 40 | 228 | 46 | 96.5 | 154 | 16.7 | 57 | Random |

| 41 | 228 | 46 | 62.5 | 191 | 10.9 | 46 | Random |

| 42 | 219 | 42 | 98.4 | 237 | 17.9 | 41 | Random |

| 43 | 220 | 43 | 55.8 | 241 | 14.8 | 44 | Random |

| 44 | 233 | 42 | 50.8 | 198 | 13.5 | 55 | Random |

| 45 | 238 | 53 | 41.6 | 221 | 17.2 | 40 | Random |

| 46 | 234 | 48 | 68.2 | 222 | 8.8 | 41 | Random |

| 47 | 233 | 44 | 84.9 | 171 | 6.7 | 55 | Random |

| 48 | 234 | 43 | 56.9 | 176 | 11.1 | 48 | Random |

| 49 | 239 | 49 | 41.2 | 234 | 8.6 | 52 | Random |

| 50 | 240 | 49 | 76.1 | 241 | 6.4 | 51 | Random |

References

- Rosato, D.V.; Rosato, M.G. Injection Molding Handbook; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Fernandes, C.; Pontes, A.J.; Viana, J.C.; Gaspar-Cunha, A. Modeling and optimization of the injection-molding process: A review. Adv. Polym. Technol. 2018, 37, 429–449. [Google Scholar] [CrossRef]

- Shen, C.; Wang, L.; Li, Q. Optimization of injection molding process parameters using combination of artificial neural network and genetic algorithm method. J. Mater. Process. Technol. 2007, 183, 412–418. [Google Scholar] [CrossRef]

- Ozcelik, B.; Erzurumlu, T. Comparison of the warpage optimization in the plastic injection molding using ANOVA, neural network model and genetic algorithm. J. Mater. Process. Technol. 2006, 171, 437–445. [Google Scholar] [CrossRef]

- Yang, D.C.; Lee, J.H.; Yoon, K.H.; Kim, J.S. A study on the prediction of optimized injection molding condition using artificial neural network(ANN). Trans. Mater. Process. 2020, 4, 218–228. [Google Scholar] [CrossRef]

- Heinisch, J.; Lockner, Y.; Hopmann, C. Comparison of design of experiment methods for modeling injection molding experiments using artificial neural networks. J. Manuf. Process. 2021, 61, 357–368. [Google Scholar] [CrossRef]

- Michelucci, U.; Venturini, F. Multi-task learning for multi-dimensional regression: Application to luminescence sensing. Appl. Sci. 2019, 9, 4748. [Google Scholar] [CrossRef]

- Aggarwal, C. Neural Networks and Deep Learning; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning (Adaptive Computation and Machine Learning Series); MIT Press: Cambridge, MA, USA, 2017. [Google Scholar]

- Li, L.; Jamieson, K.; DeSalvo, G.; Rostamizadeh, A.; Talwalkar, A. Hyperband: A novel bandit-based approach to hyper-parameter optimization. J. Mach. Learn. Res. 2017, 18, 6765–6816. [Google Scholar] [CrossRef]

- Rudder, S. An overview of multi-task learning in deep neural networks. arXiv 2017, arXiv:1706.05098. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, Q. An overview of multi-task learning. Natl. Sci. Rev. 2018, 5, 30–43. [Google Scholar] [CrossRef]

- Caruana, R. Multitask Learning; Springer: Berlin/Heidelberg, Germany, 1997. [Google Scholar]

- Thung, K.H.; Wee, C.Y. A brief review on multi-task learning. Multimed. Tools Appl. 2018, 77, 29705–29725. [Google Scholar] [CrossRef]

- Kingma, D.P.; Ba, J. Adam: A method for stochastic optimization. arXiv 2014, arXiv:1412.6980. [Google Scholar] [CrossRef]

- ISO 20457:2018; Plastics Moulded Parts—Tolerances and Acceptance Conditions. ISO: Geneva, Switzerland, 2018.

- Lee, J.; Yang, D.; Yoon, K.; Kim, J. Effects of Input Parameter Range on the Accuracy of Artificial Neural Network Prediction for the Injection Molding Process. Polymers 2022, 14, 1724. [Google Scholar] [CrossRef]

| Conditions | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Melt temperature (°C) | 200 | 220 | 240 |

| Mold temperature (°C) | 40 | 50 | 60 |

| Injection speed (mm/s) | 40 | 70 | 100 |

| Packing pressure (bar) | 150 | 200 | 250 |

| Packing time (s) | 6.0 | 12.0 | 18.0 |

| Cooling time (s) | 38 | 48 | 58 |

| Hyperparameters | Range | Note |

|---|---|---|

| Seed number | 0–50 | Step size was 1 |

| Batch size | 16, 32, 64, … | Increased in multiples of 2 until it could cover the number of learning data |

| Optimizer | Adams [15] | Fixed |

| Learning rate | 0.0001–0.01 [15] | Step size was 0.0001 |

| Beta 1 | 0.1–1.0 [15] | Step size was 0.1 |

| Bata 2 | 0.9, 0.99, 0.999, 0.999 [15] | - |

| Number of neurons | 3–18 | Step size was 1 |

| Initializer | He normal (hidden layer) Xavier normal (output layer) | - |

| Activation function | Elu (hidden layer) Linear (output layer) | - |

| Drop number | 0.0–0.4 | Step size was 0.1 |

| Coefficient of L2 normalization | 0.001, 0.01, 0.1 | - |

| Hyperparameters | Network A | Network B | Network C |

|---|---|---|---|

| Seed number | 17 | 6 | 47 |

| Batch size | 16 | 16 | 32 |

| Optimizer | |||

| Learning rate | 0.0073 | 0.0051 | 0.0052 |

| Beta 1 | 0.6 | 0.3 | 0.1 |

| Bata 2 | 0.99 | 0.99 | 0.99 |

| Number of neurons | 17-13-8-7 | 17-15-13 (common layers) [5, 7] (mass, length layer) | 18-7-7 (common layers) [3, 5, 6] (mass, diameter, height layer) |

| Initializer | |||

| Activation function | |||

| Drop number | 0.0-0.3-0.1-0.1 | 0.03-0.00-0.00 (common layer) [0.2, 0.0] (mass, length layer) | 0.0-0.2-0.0 (common layers) [0.1, 0.4, 0.2] (mass, diameter, height layers) |

| Coefficient of L2 normalization | 0.01 | 0.001, 0.001 (mass, length) | 0.01, 0.001, 0.1 (mass, diameter, height) |

| Network | Total Normalized Test Data |

|---|---|

| A | |

| B | |

| C |

| Network | Mass | Diameter | Height |

|---|---|---|---|

| A | |||

| B | |||

| C |

| Network | Mass | Diameter | Height |

|---|---|---|---|

| A | |||

| B | |||

| C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Kim, J.; Kim, J. The Effect of Grouping Output Parameters by Quality Characteristics on the Predictive Performance of Artificial Neural Networks in Injection Molding Process. Appl. Sci. 2023, 13, 12876. https://doi.org/10.3390/app132312876

Lee J, Kim J, Kim J. The Effect of Grouping Output Parameters by Quality Characteristics on the Predictive Performance of Artificial Neural Networks in Injection Molding Process. Applied Sciences. 2023; 13(23):12876. https://doi.org/10.3390/app132312876

Chicago/Turabian StyleLee, Junhan, Jongsun Kim, and Jongsu Kim. 2023. "The Effect of Grouping Output Parameters by Quality Characteristics on the Predictive Performance of Artificial Neural Networks in Injection Molding Process" Applied Sciences 13, no. 23: 12876. https://doi.org/10.3390/app132312876

APA StyleLee, J., Kim, J., & Kim, J. (2023). The Effect of Grouping Output Parameters by Quality Characteristics on the Predictive Performance of Artificial Neural Networks in Injection Molding Process. Applied Sciences, 13(23), 12876. https://doi.org/10.3390/app132312876