Effect of Polycarboxylate Admixture on the Performance of Fluorogypsum-Based Self-Leveling Material

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

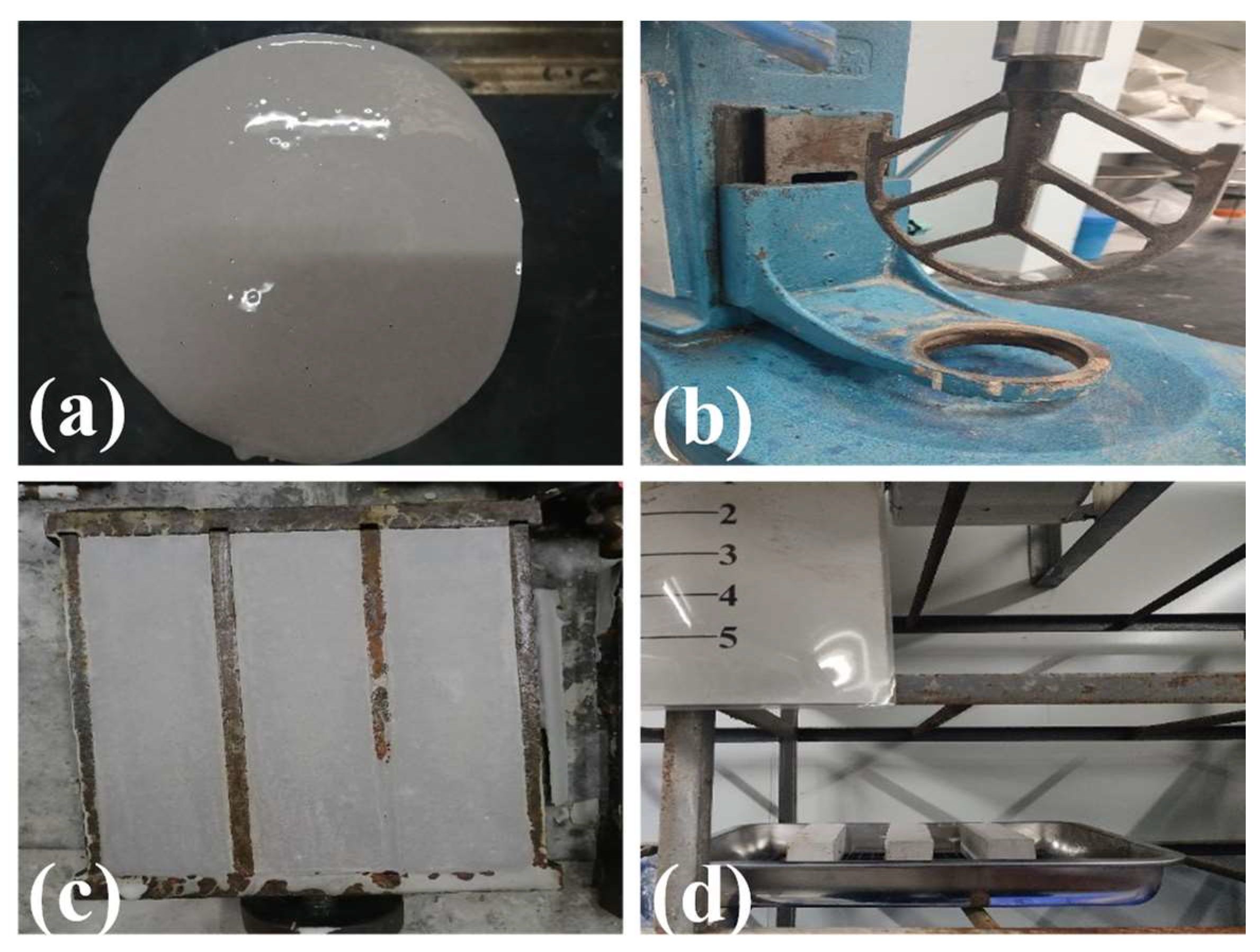

2.2. Mixing Ratio and Sample Preparation

2.3. Test Method

2.3.1. Setting Time

2.3.2. Fluidity

2.3.3. Flexural and Compressive Strength

2.3.4. XRD

2.3.5. TG-DSC

2.3.6. SEM

2.3.7. MIP Pore Structure Analysis

3. Results and Discussion

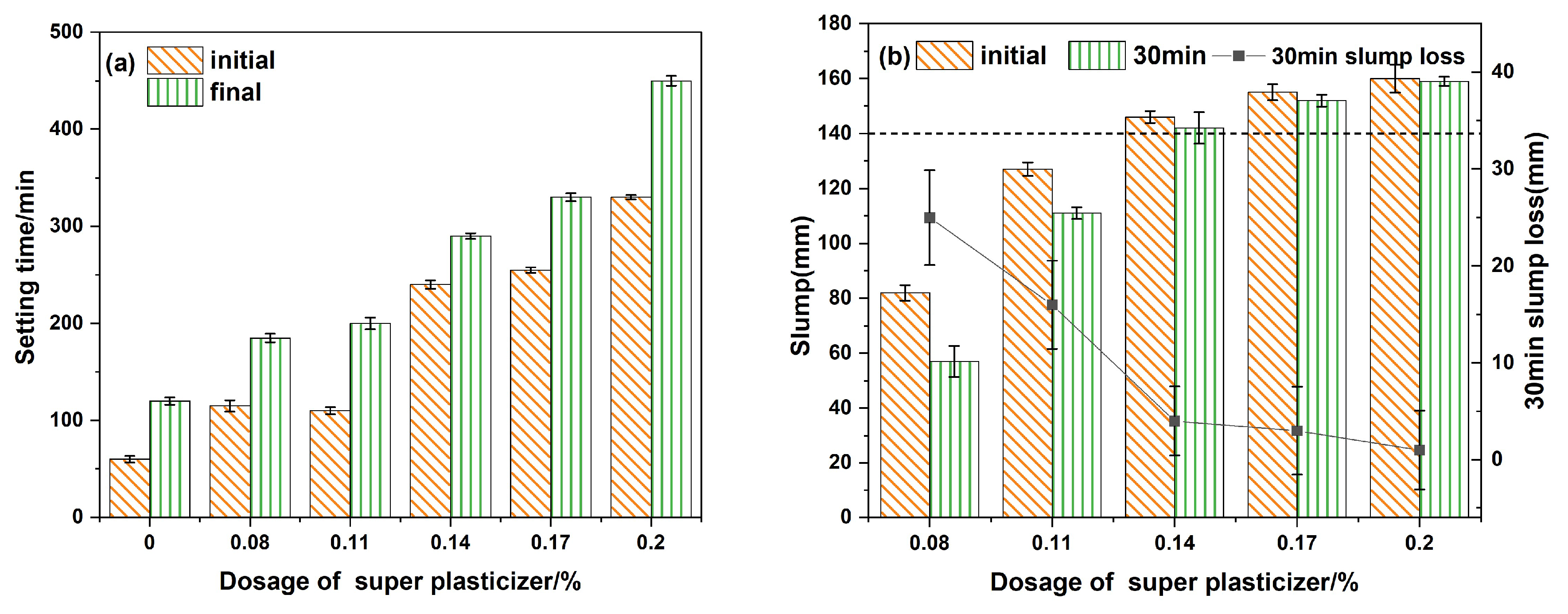

3.1. Setting Time and Fluidity

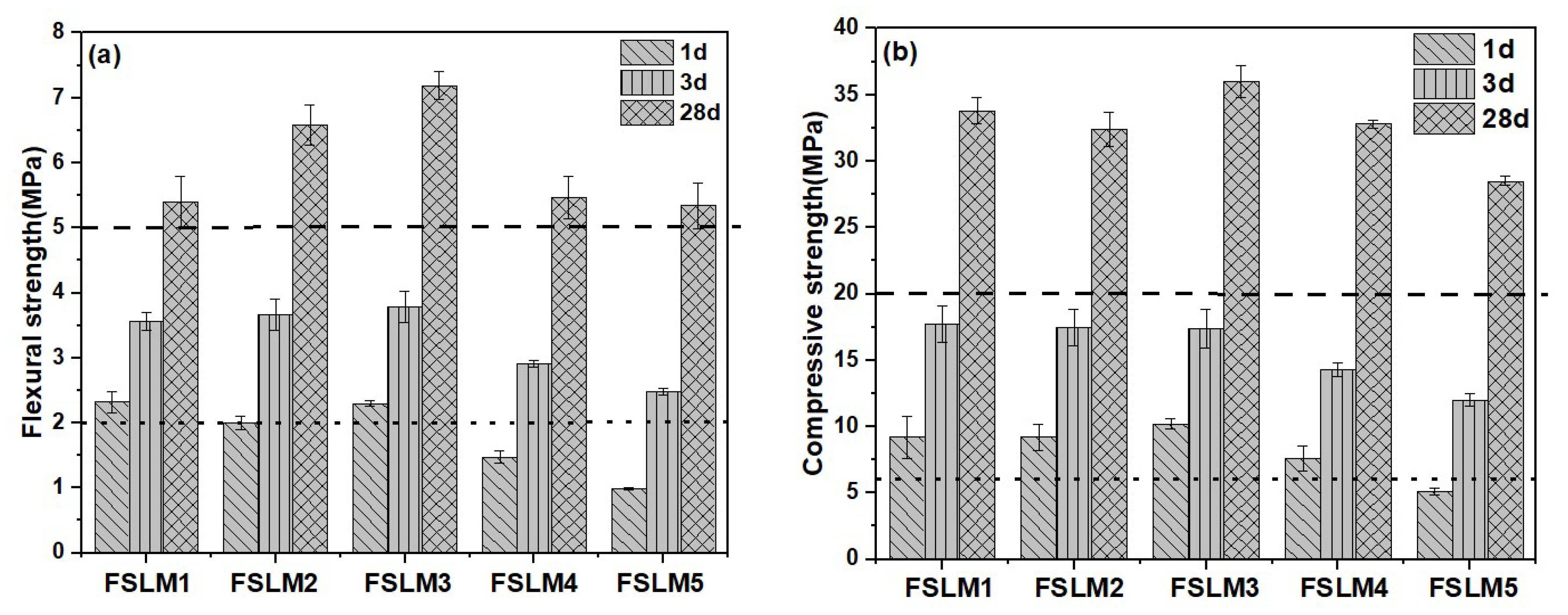

3.2. Strength

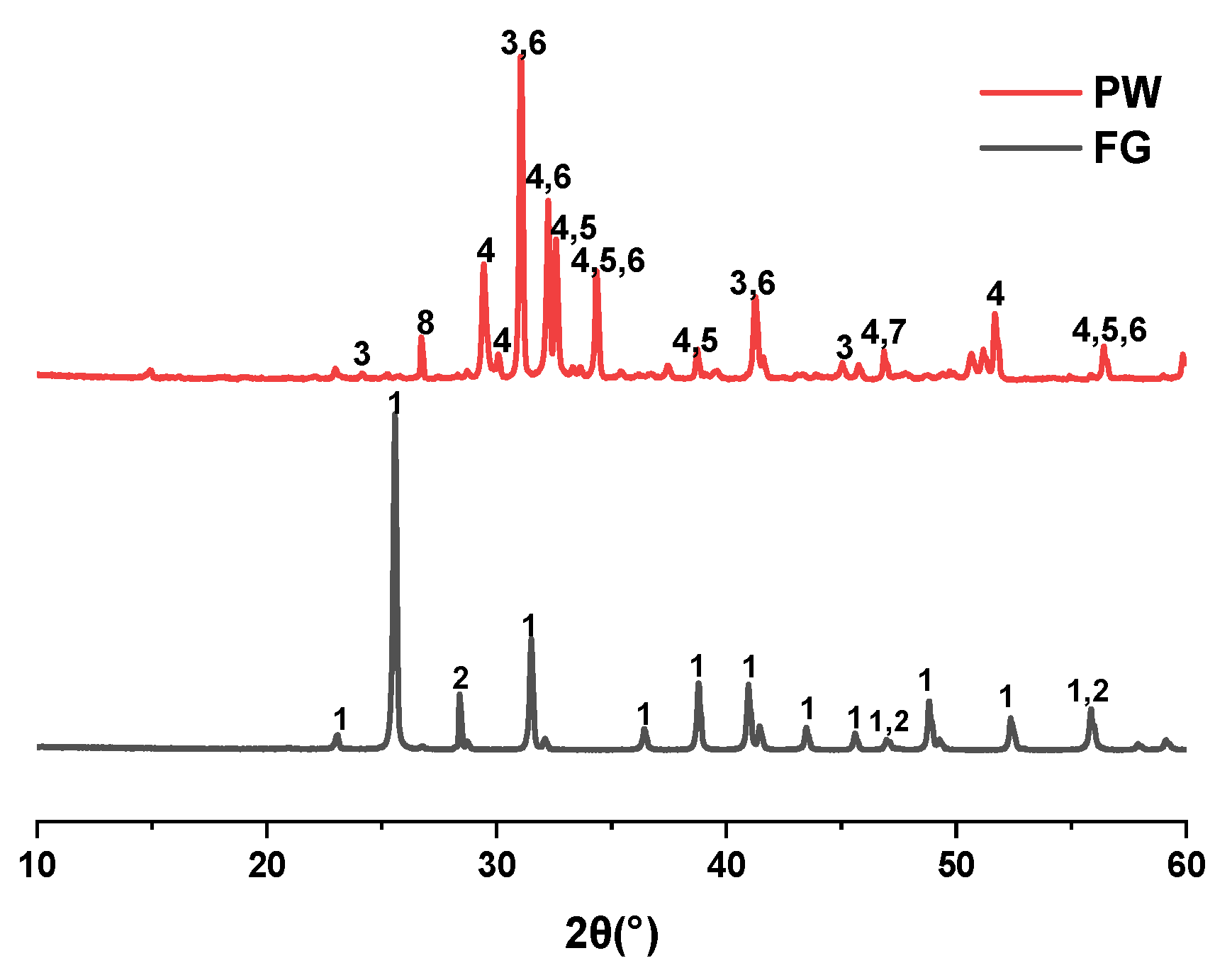

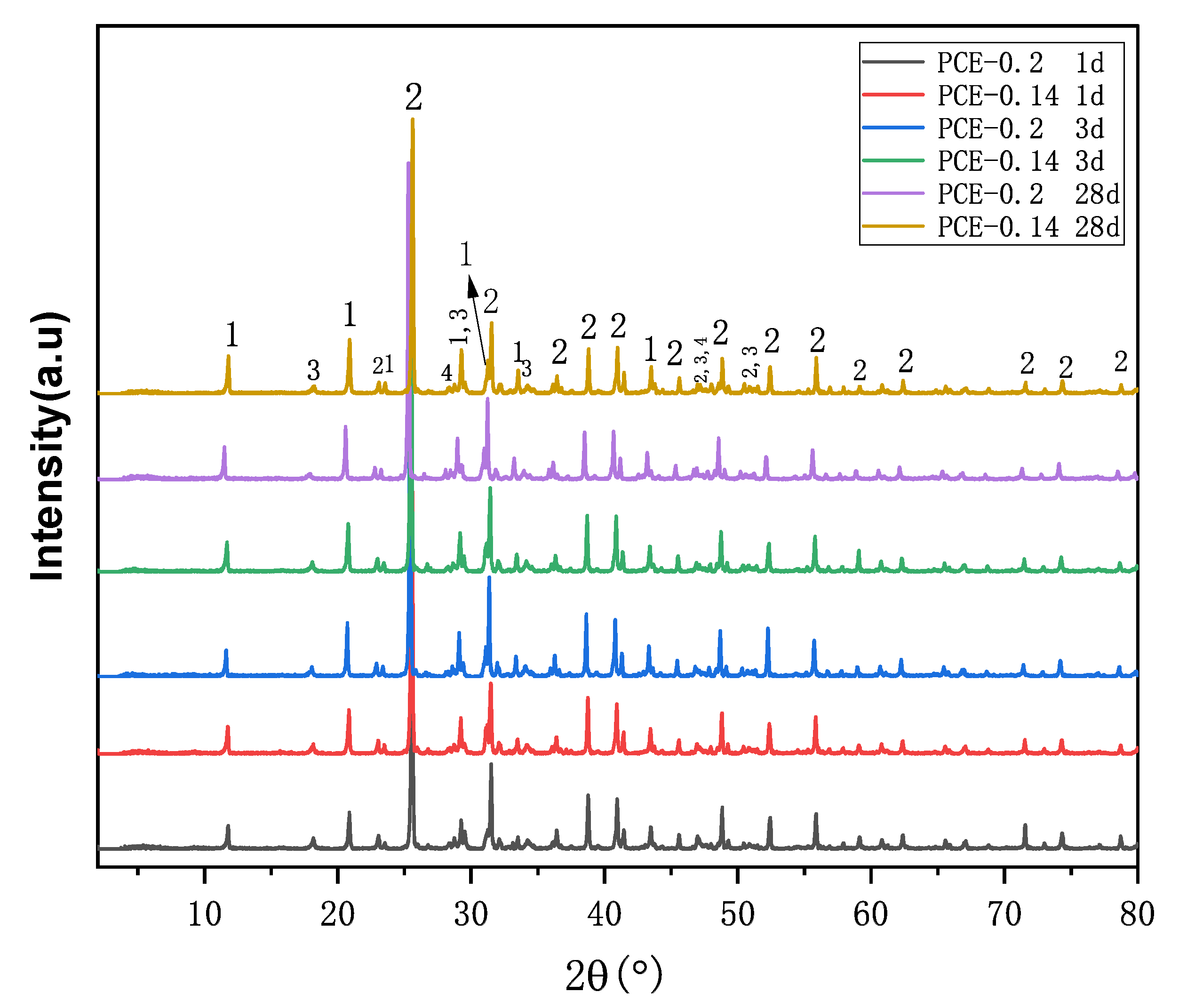

3.3. XRD

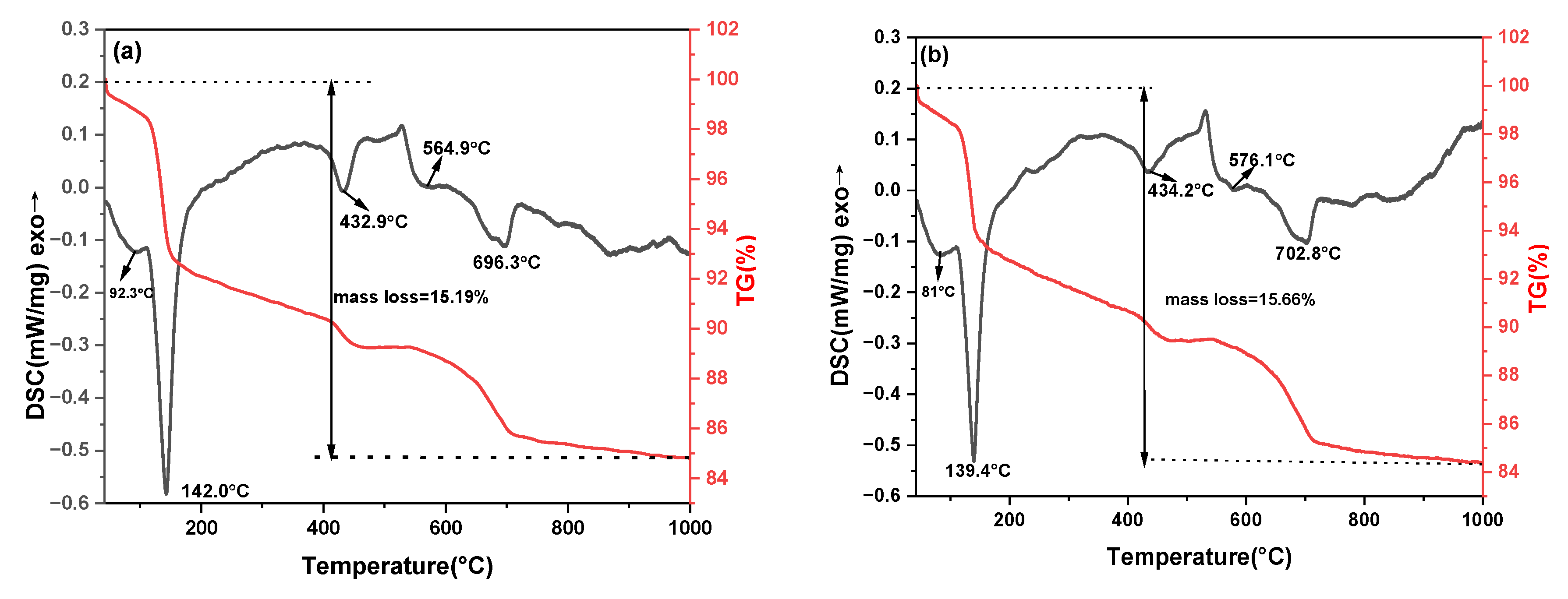

3.4. TG-DSC

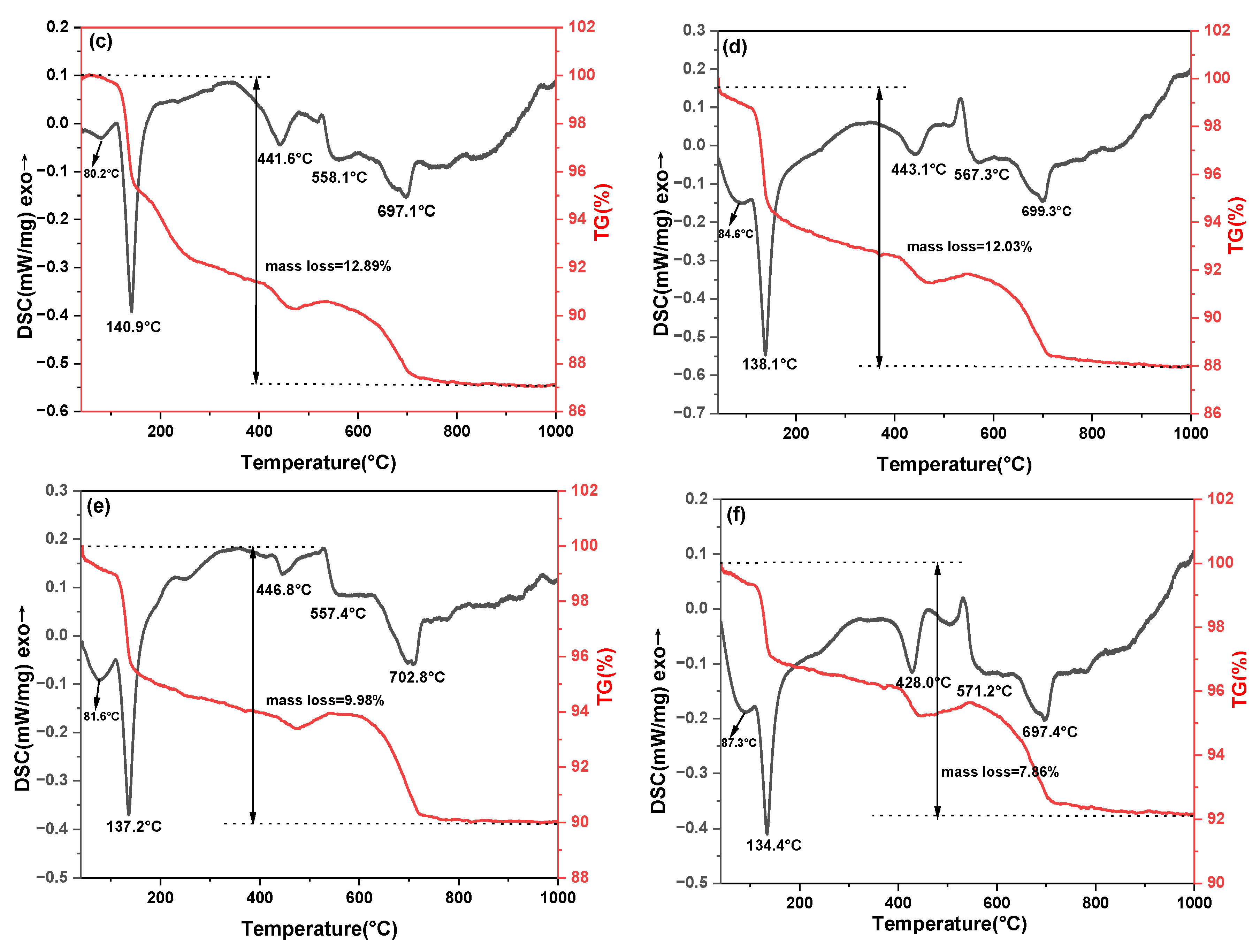

3.5. MIP

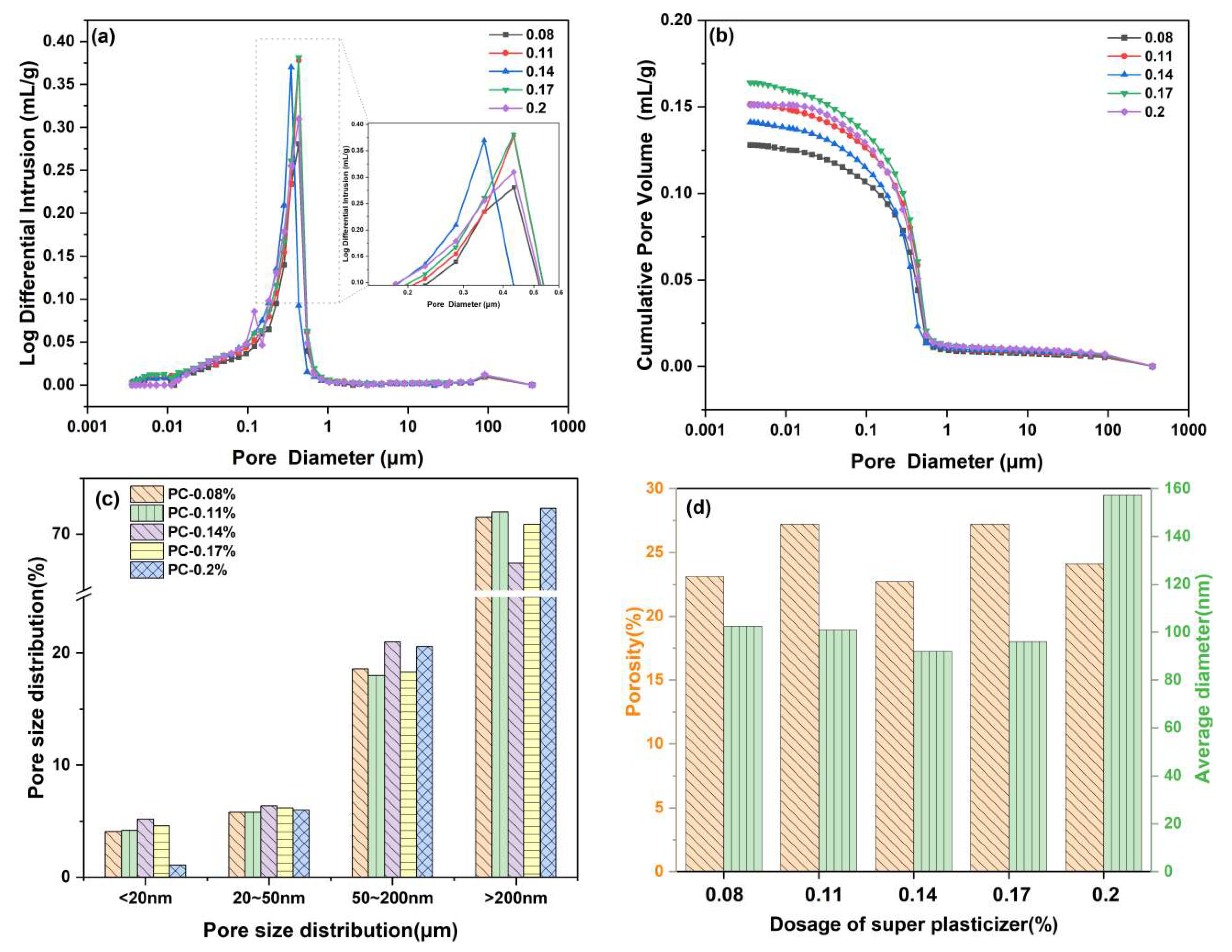

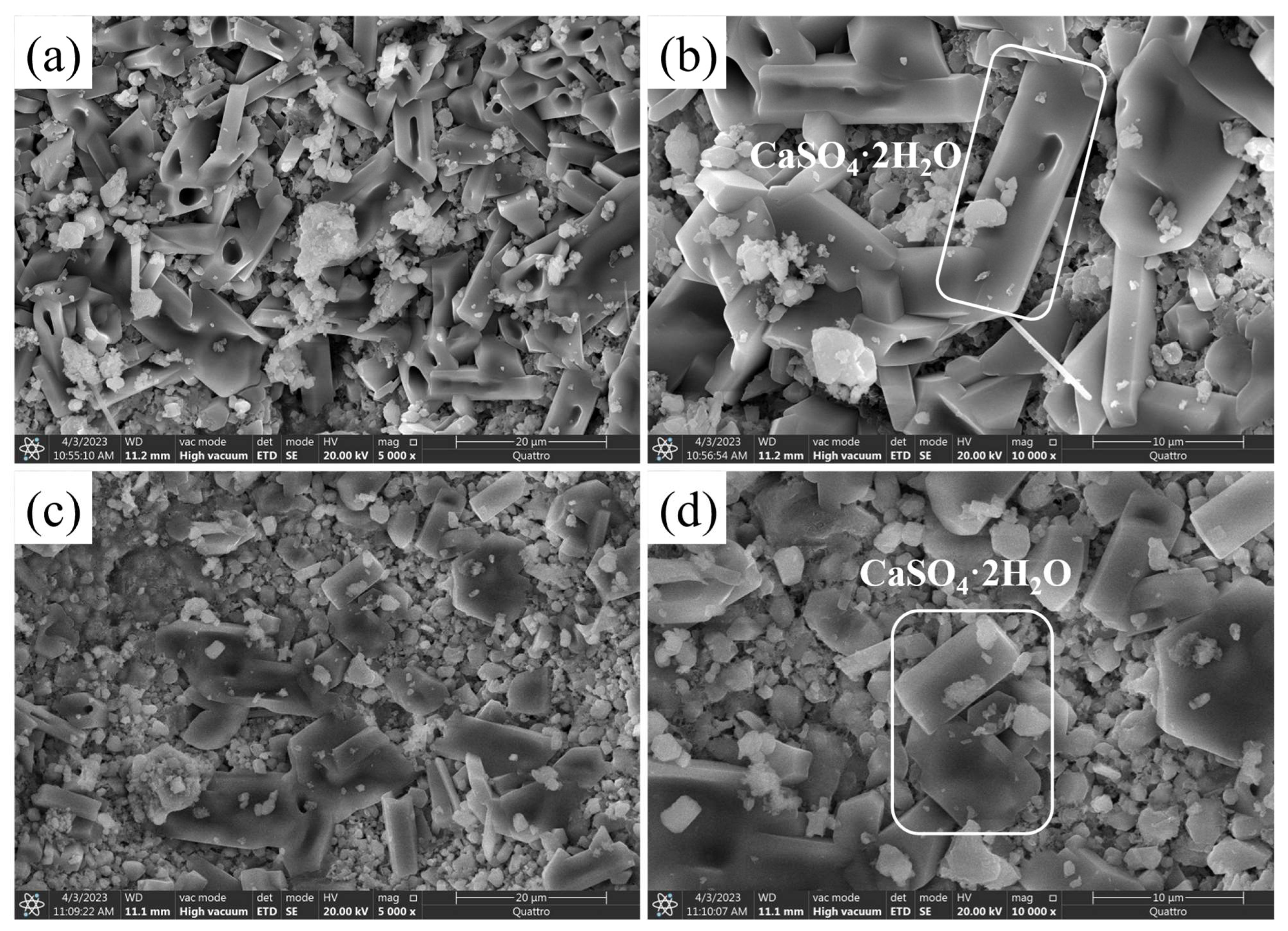

3.6. SEM

4. Conclusions

- Results showed that the optimal PCE doping level was 0.14%. By adding an appropriate dose of PCE, FSLM exhibits increased fluidity, and the 30 min slump of 142 mm and slump loss was reduced even at a lower water–cement ratio. FSLM prepared with 0.14% PCE demonstrates good performance and meets the main performance requirements outlined in JC/T 1023-2021 (gypsum-based self-leveling mortar).

- Optimal PCE doping leads to gypsum crystals with a larger aspect ratio and tighter intercrystalline lapping, improving the structural density and reducing porosity. This results in an optimized pore size distribution. However, excessive PCE hinders the above performances of fluorogypsum and thereby has a negative impact on strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FG | Fluorogypsum |

| PW | White Cement |

| PCE | Polycarboxylate Admixture |

| FLSM | Fluorogypsum-based Self-leveling Material |

| DF | Defoaming Agent |

| WR | Water-retaining Agent |

| XRD | X-ray Diffraction |

| TG-DSC | Thermogravimetric-Differential Scanning Calorimetry |

| MIP | Mercury intrusion porosimetry |

| SEM | Scanning Electron Microscope |

References

- Huang, X.; Jiang, M.; Zhao, X.; Tang, C. Mechanical properties and hydration mechanisms of high-strength fluorogypsum-blast furnace slag-based hydraulic cementitious binder. Constr. Build. Mater. 2016, 127, 137–143. [Google Scholar] [CrossRef]

- Singh, M.; Garg, M. Activation of fluorogypsum for building materials. J. Sci. Ind. Res. 2009, 68, 130–134. [Google Scholar]

- Wang, J.; Yang, X.; Yu, D. Modification of fluorgypsum as cement retarder. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2007, 22, 745–748. [Google Scholar] [CrossRef]

- Barnes, P.; Bensted, J. Structure and Performance of Cements; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Wang, Y.; Li, G.; Wang, F. Study of Fluorgypsum Modification. In Proceedings of the 2nd International Conference on Manufacturing Science and Engineering, Guilin, China, 9–11 April 2011; pp. 2086–2089. [Google Scholar]

- Zhou, M.; Zhang, W.; Hou, H.; Huang, X.; Wang, W. The Activation of Fluorgypsum with Slag Activator and the Fluorine Solidification Mechanics. J. Wuhan Univ. Technol. -Mater. Sci. Ed. 2011, 26, 1023–1026. [Google Scholar] [CrossRef]

- Anikanova, L.; Volkova, O.; Kudyakov, A.; Lotov, V.; Danilova, E.; Kurzina, I. On thermal effects of early structure formation of fluorogypsum composite binder. In Proceedings of the The XVII International Conference on Prospects of Fundamental Sciences Development, Tomsk, Russian, 21–24 April 2020; IOP Publishing: Bristol, UK, 2020; p. 012048. [Google Scholar]

- Singh, N.B. The activation effect of K2SO4 on the hydration of gypsum anhydrite, CaSO4 (II). J. Am. Ceram. Soc. 2005, 88, 196–201. [Google Scholar] [CrossRef]

- Escalante-Garcia, J.I.; Rios-Escobar, M.; Gorokhovsky, A.; Fuentes, A.F. Fluorgypsum binders with OPC and PFA additions, strength and reactivity as a function of component proportioning and temperature. Cem. Concr. Compos. 2008, 30, 88–96. [Google Scholar] [CrossRef]

- Fraire-Luna, P.E.; Escalante-Garcia, J.I.; Gorokhovsky, A. Composite systems fluorgypsum–blastfurnance slag–metakaolin, strength and microstructures. Cem. Concr. Res. 2006, 36, 1048–1055. [Google Scholar] [CrossRef]

- Bazaldua-Medellin, M.E.; Magallanes-Rivera, R.X.; Garcia, J.I.E. Composite hydraulic binders based on fluorgypsum: Reactions, properties and sustainability. J. Build. Eng. 2022, 53, 104590. [Google Scholar] [CrossRef]

- Magallanes-Rivera, R.X.; Escalante-García, J.I. Hemihydrate or waste anhydrite in composite binders with blast-furnace slag: Hydration products, microstructures and dimensional stability. Constr. Build. Mater. 2014, 71, 317–326. [Google Scholar] [CrossRef]

- Weng, R.; Liu, X. Fluorgypsum binders with fly ash, cement and activators, strength and microstructures. In Proceedings of the 2011 International Conference on Materials for Renewable Energy & Environment, Shanghai, China, 20–22 May 2011; pp. 887–891. [Google Scholar]

- Kovler, K. Strength and water absorption for gypsum-cement silica fume blends of improved performance. Adv. Cem. Res. 1998, 10, 81–92. [Google Scholar] [CrossRef]

- Garg, M.; Pundir, A. Investigation of properties of fluorogypsum-slag composite binders–hydration, strength and microstructure. Cem. Concr. Compos. 2014, 45, 227–233. [Google Scholar] [CrossRef]

- Huang, X.; Shi, Z.; Wang, Z.; Dong, J.; Wang, X.; Zhao, X. Microstructure and performances of sludge soil stabilized by fluorogypsum-based cementitious binder. Constr. Build. Mater. 2022, 325, 126702. [Google Scholar] [CrossRef]

- Jang, J.; Jang, J.; Barbato, M.; Gutierrez-Wing, M.T.; Rusch, K.A.; Jung, J. Effects of Fluorogypsum and Quicklime on Unconfined Compressive Strength of Kaolinite. J. Coast. Res. 2021, 114, 126–130. [Google Scholar] [CrossRef]

- Katsiadramis, N.J.; Sotiropoulou, A.B.; Pandermarakis, Z.G. Rheological and Mechanical Response Modifications for a Self-Leveling Mortar. In Proceedings of the 14th International Conference on Experimental Mechanics (ICEM14), Poitiers, France, 4–9 July 2010. [Google Scholar]

- Schaefer, C.O.; Cheriaf, M.; Rocha, J.C. Production of Synthetic Phosphoanhydrite and Its Use as a Binder in Self-Leveling Underlayments (SLU). Materials 2017, 10, 958. [Google Scholar] [CrossRef]

- Zhi, Z.; Ma, B.; Tan, H.; Guo, Y.; Jin, Z.; Yu, H.; Jian, S. Effect of Competitive Adsorption between Polycarboxylate Superplasticizer and Hydroxypropylmethyl Cellulose on Rheology of Gypsum Paste. J. Mater. Civ. Eng. 2018, 30, 04018141. [Google Scholar] [CrossRef]

- Wang, Q.; Jia, R. A novel gypsum-based self-leveling mortar produced by phosphorus building gypsum. Constr. Build. Mater. 2019, 226, 11–20. [Google Scholar] [CrossRef]

- Zhi, Z.; Huang, J.; Guo, Y.; Lu, S.; Ma, B. Effect of chemical admixtures on setting time, fluidity and mechanical properties of phosphorus gypsum based self-leveling mortar. Ksce J. Civ. Eng. 2017, 21, 1836–1843. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y.; Liu, J.; Miao, Y. Study on the Properties of Gypsum-based Self-leveling Mortar using Molybdenum Tailings. In Proceedings of the International Conference on Advances in Civil Engineering, Energy Resources and Environment Engineering (ACCESE), Changchun, China, 28–30 June 2019. [Google Scholar]

- Zhang, J.; Zhang, Y.; Liu, J.; Miao, Y.; Duan, S. Study on application of gypsum-based self-leveling mortar in floor heating backfill. In Proceedings of the 2019 2nd International Symposium on Traffic Transportation and Civil Architecture (ISTTCA 2019), Chengdu, China, 13–15 December 2019; IOP Conference Series: Materials Science and Engineering. IOP Publishing: Bristol, UK, 2020; p. 042010. [Google Scholar]

- Zhang, Y.; Yang, J.; Liu, Y.; Liu, B.; Zhao, F. Preparation of self-leveling mortar based on anhydrite-II phosphogypsum. In Proceedings of the 7th International Conference on Energy Technology and Materials Science (ICETMS 2021), Zhoushan, China, 27–29 September 2021; IOP Publishing: Bristol, UK, 2021; p. 012035. [Google Scholar]

- JC/T 1023-2021; Gypsum-Based Self-Leveling Mortar. Ministry of Industry and Information Technology: Beijing, China, 2021.

- Ma, B.; Lu, W.; Su, Y.; Li, Y.; Gao, C.; He, X. Synthesis of α-hemihydrate gypsum from cleaner phosphogypsum. J. Clean. Prod. 2018, 195, 396–405. [Google Scholar] [CrossRef]

- Jiang, G.; Wang, H.; Chen, Q.; Zhang, X.; Wu, Z.; Guan, B. Preparation of alpha-calcium sulfate hemihydrate from FGD gypsum in chloride-free Ca(NO3)2 solution under mild conditions. Fuel 2016, 174, 235–241. [Google Scholar] [CrossRef]

- Pundir, A.; Garg, M.; Singh, R. Evaluation of properties of gypsum plaster-superplasticizer blends of improved performance. J. Build. Eng. 2015, 4, 223–230. [Google Scholar] [CrossRef]

- Eve, S.; Gomina, M.; Hamel, J.; Orange, G. Investigation of the setting of polyamide fibre/latex-filled plaster composites. J. Eur. Ceram. Soc. 2006, 26, 2541–2546. [Google Scholar] [CrossRef]

- Rubio-Avalos, J.C.; Manzano-Ramírez, A.; Luna-Bárcenas, J.G.; Pérez-Robles, J.F.; Alonso-Gumán, E.M.; Contreras-García, M.E.; González-Hernández, J. Flexural behavior and microstructure analysis of a gypsum-SBR composite material. Mater. Lett. 2005, 59, 230–233. [Google Scholar] [CrossRef]

- Silva, D.B.P.; Lima, N.B.; Lima, V.M.E.; Estolano, A.M.L.; Nascimento, H.C.B.; Vilemen, P.; Padron-Hernandez, E.; Carneiro, A.M.P.; Lima, N.B.D.; Povoas, Y.V. Producing a gypsum-based self-leveling mortar for subfloor modified by polycarboxylate admixture (PCE). Constr. Build. Mater. 2023, 364, 130007. [Google Scholar] [CrossRef]

- Sakthieswaran, N.; Sophia, M. Effect of superplasticizers on the properties of latex modified gypsum plaster. Constr. Build. Mater. 2018, 179, 675–691. [Google Scholar] [CrossRef]

- Garg, M.; Pundir, A.; Singh, R. Modifications in water resistance and engineering properties of β-calcium sulphate hemihydrate plaster-superplasticizer blends. Mater. Struct. 2016, 49, 3253–3263. [Google Scholar] [CrossRef]

- Agarwal, S.K.; Masood, I.; Malhotra, S.K. Compatibility of superplasticizers with different cements. Constr. Build. Mater. 2000, 14, 253–259. [Google Scholar] [CrossRef]

- GB/T 17669.4-1999; Gypsum Plasters-Determination of Physical Properties of Pure Paste. The State Bureau of Quality and Technical Supervision: Beijing, China, 1999.

- Nicoleau, L.; Van Driessche, A.E.S.; Kellermeier, M. A kinetic analysis of the role of polymers in mineral nucleation. The example of gypsum. Cem. Concr. Res. 2019, 124, 105837. [Google Scholar] [CrossRef]

- Peng, J.; Qu, J.; Zhang, J.; Chen, M.; Wan, T. Adsorption characteristics of water-reducing agents on gypsum surface and its effect on the rheology of gypsum plaster. Cem. Concr. Res. 2005, 35, 527–531. [Google Scholar] [CrossRef]

- Fu, L.; Deng, Z.; Zhang, Y.; Zheng, B.; Yu, J. Effect of molecular structure of polycarboxylate superplasticizers on gypsum dispersion. Acta Polym. Sin. 2011, 3, 294–301. [Google Scholar] [CrossRef]

- Sebök, T.; Vondruska, M. Interaction of anhydrite and melamine-formaldehyde polycondensates in aqueous suspensions. Cem. Concr. Res. 2000, 30, 993–1003. [Google Scholar] [CrossRef]

- Cao, W.; Yi, W.; Yin, S.; Peng, J.; Li, J. A novel low-density thermal insulation gypsum reinforced with superplasticizers. Constr. Build. Mater. 2021, 278, 122421. [Google Scholar] [CrossRef]

- Chen, S.; Yuan, H. Characterization and optimization of eco-friendly cementitious materials based on titanium gypsum, fly ash, and calcium carbide residue. Constr. Build. Mater. 2022, 349, 128635. [Google Scholar] [CrossRef]

- Matschei, T.; Lothenbach, B.; Glasser, F.P. Thermodynamic properties of Portland cement hydrates in the system CaO–Al2O3–SiO2–CaSO4–CaCO3–H2O. Cem. Concr. Res. 2007, 37, 1379–1410. [Google Scholar] [CrossRef]

- Martinez-Aguilar, O.A.; Castro-Borges, P.; Escalante-Garcia, J.I. Hydraulic binders of Fluorgypsum-Portland cement and blast furnace slag, stability and mechanical properties. Constr. Build. Mater. 2010, 24, 631–639. [Google Scholar] [CrossRef]

- Ramadan, M.; Amin, M.S.; Waly, S.A.; Mohsen, A. Effect of high gamma radiation dosage and elevated temperature on the mechanical performance of sustainable alkali-activated composite as a cleaner product. Cem. Concr. Compos. 2021, 121, 104087. [Google Scholar] [CrossRef]

- Shwita, F.; El-Faramawy, N.; Ramadan, W.; Ramadan, M. Investigation of the mechanical properties, morphology and the attenuation behavior of gamma rays for OPC pastes mingled with two different glass wastes. Constr. Build. Mater. 2021, 313, 125475. [Google Scholar] [CrossRef]

- Li, Q.; He, C.; Zhou, H.; Xie, Z.; Li, D. Effects of polycarboxylate superplasticizer-modified graphene oxide on hydration characteristics and mechanical behavior of cement. Constr. Build. Mater. 2021, 272, 121904. [Google Scholar] [CrossRef]

- Selim, F.A.; Amin, M.S.; Ramadan, M.; Hazem, M.M. Effect of elevated temperature and cooling regimes on the compressive strength, microstructure and radiation attenuation of fly ash–cement composites modified with miscellaneous nanoparticles. Constr. Build. Mater. 2020, 258, 119648. [Google Scholar] [CrossRef]

- Ramadan, M.; El-Gamal, S.M.A.; Selim, F.A. Mechanical properties, radiation mitigation and fire resistance of OPC-recycled glass powder composites containing nanoparticles. Constr. Build. Mater. 2020, 251, 118703. [Google Scholar] [CrossRef]

- Essam, Y.; El-Faramawy, N.; Ramadan, W.; Ramadan, M. From dangerous wastes to green construction materials, as thermally stable-radiation blocker, in presence of meso-porous magnesia and alumina. J. Build. Eng. 2023, 66, 105896. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Y.; Guo, B.; Zhang, S.; Tong, Y.; Niu, D. Study on the Strength and Hydration Behavior of Sulfate-Resistant Cement in High Geothermal Environment. Materials 2022, 15, 2790. [Google Scholar] [CrossRef] [PubMed]

- Guan, B.; Ye, Q.; Zhang, J.; Lou, W.; Wu, Z. Interaction between α-calcium sulfate hemihydrate and superplasticizer from the point of adsorption characteristics, hydration and hardening process. Cem. Concr. Res. 2010, 40, 253–259. [Google Scholar] [CrossRef]

| CaO | SO3 | SiO2 | Al2O3 | MgO | K2O | Fe2O3 | BaO | Na2O | F | SrO | Others | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FG | 49.39 | 45.36 | 1.03 | 0.37 | 0.90 | 0.04 | 0.90 | 1.03 | - | 0.48 | 0.17 | 0.33 1 |

| PW | 65.55 | 3.17 | 21.59 | 1.95 | 6.35 | 0.63 | 0.26 | - | 0.29 | - | 0.05 | - |

| NO. | Cemented Material | PCE | WR | DF | ||

|---|---|---|---|---|---|---|

| K2SO4 | PW | FG | ||||

| FSLM1 | 1 | 8 | 92 | 0.08 | 0.02 | 0.06 |

| FSLM2 | 1 | 8 | 92 | 0.11 | 0.02 | 0.06 |

| FSLM3 | 1 | 8 | 92 | 0.14 | 0.02 | 0.06 |

| FSLM4 | 1 | 8 | 92 | 0.17 | 0.02 | 0.06 |

| FSLM5 | 1 | 8 | 92 | 0.20 | 0.02 | 0.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, L.; Xiong, S.; Wang, W.; Zhang, J.; Zeng, L. Effect of Polycarboxylate Admixture on the Performance of Fluorogypsum-Based Self-Leveling Material. Appl. Sci. 2023, 13, 12802. https://doi.org/10.3390/app132312802

Fan L, Xiong S, Wang W, Zhang J, Zeng L. Effect of Polycarboxylate Admixture on the Performance of Fluorogypsum-Based Self-Leveling Material. Applied Sciences. 2023; 13(23):12802. https://doi.org/10.3390/app132312802

Chicago/Turabian StyleFan, Li, Shuangyan Xiong, Wenting Wang, Jianxin Zhang, and Lu Zeng. 2023. "Effect of Polycarboxylate Admixture on the Performance of Fluorogypsum-Based Self-Leveling Material" Applied Sciences 13, no. 23: 12802. https://doi.org/10.3390/app132312802

APA StyleFan, L., Xiong, S., Wang, W., Zhang, J., & Zeng, L. (2023). Effect of Polycarboxylate Admixture on the Performance of Fluorogypsum-Based Self-Leveling Material. Applied Sciences, 13(23), 12802. https://doi.org/10.3390/app132312802