Development and Investigation of the Hysteretic Behavior of an X-Shaped Metal Damper with an Oblique Angle

Abstract

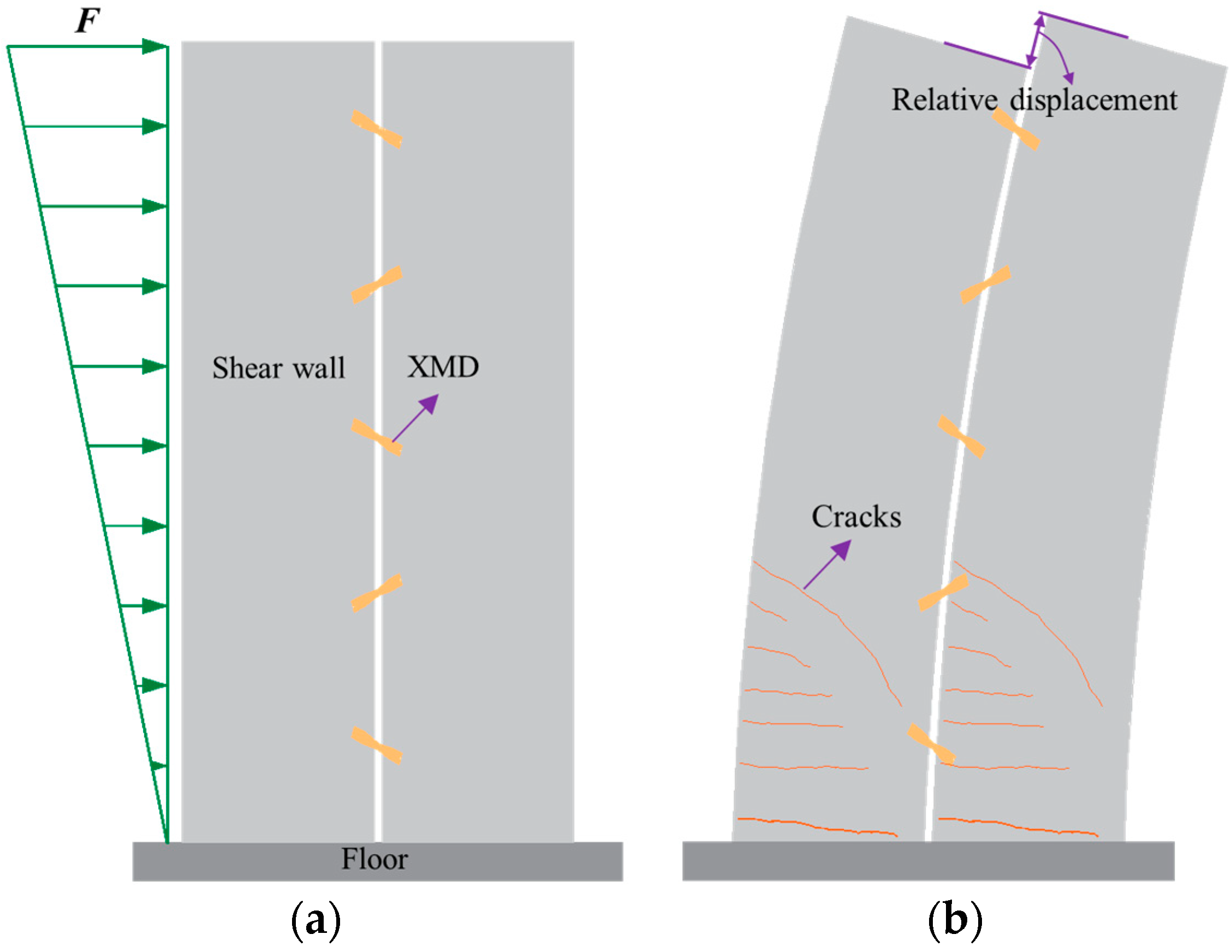

:1. Introduction

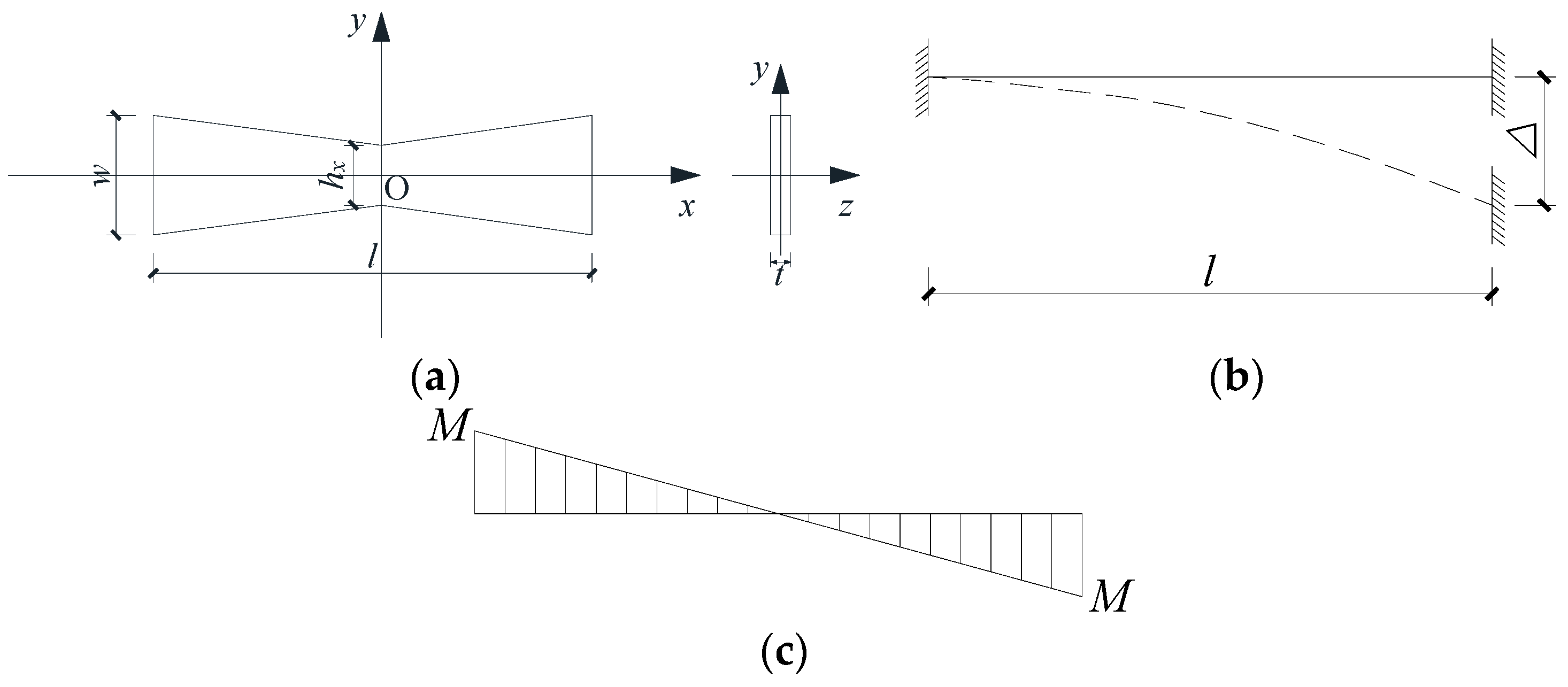

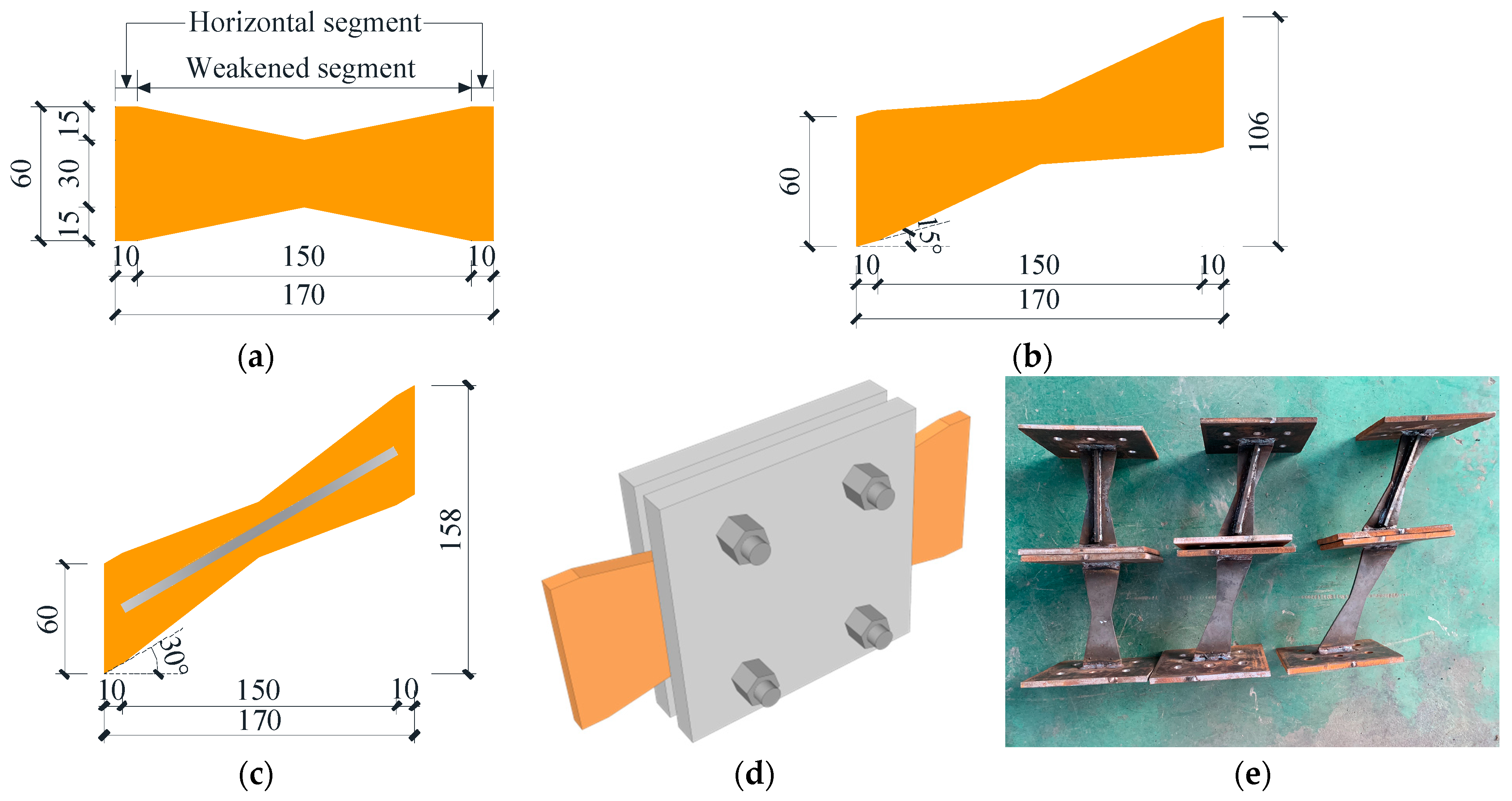

2. Damper Shape Selection

3. Cyclic Loading Tests

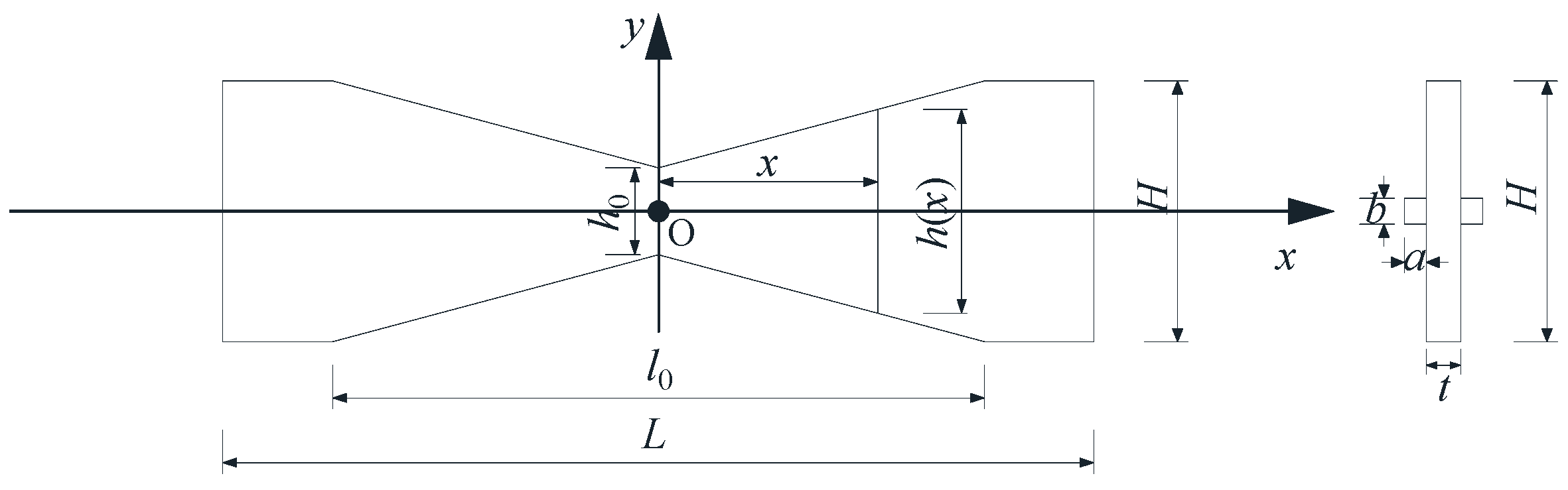

3.1. Specimen Design

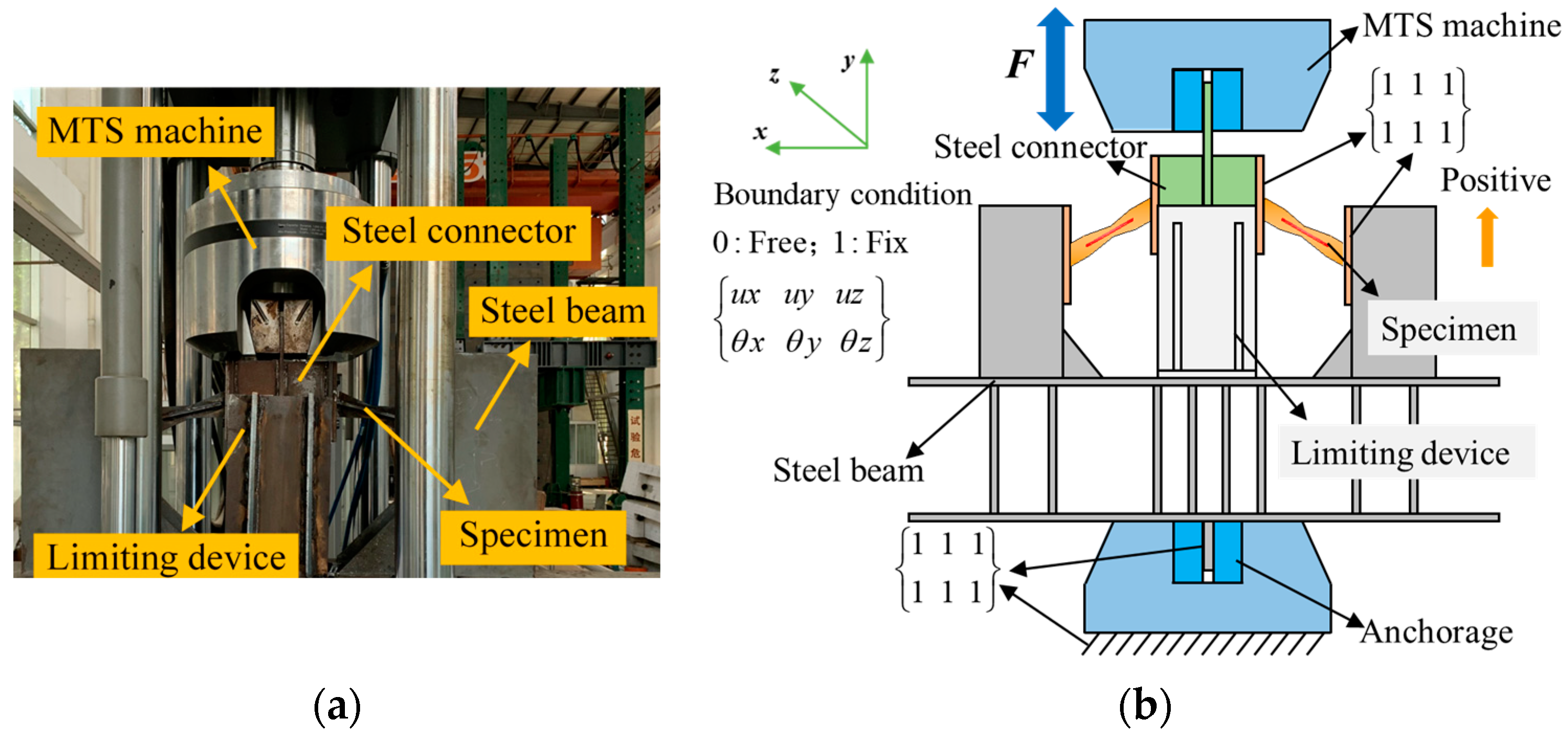

3.2. Test Setup and Procedure

4. Results and Discussions

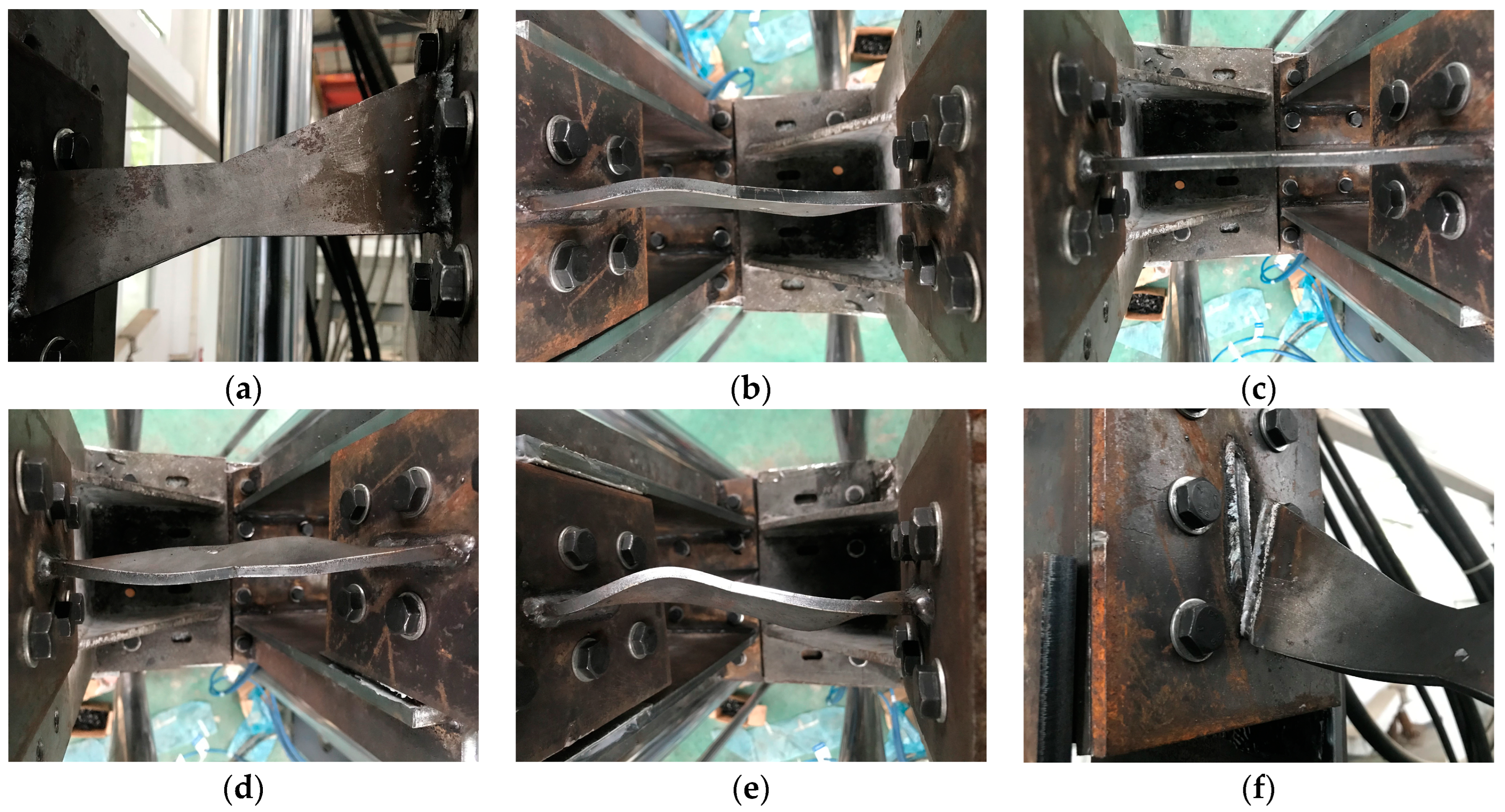

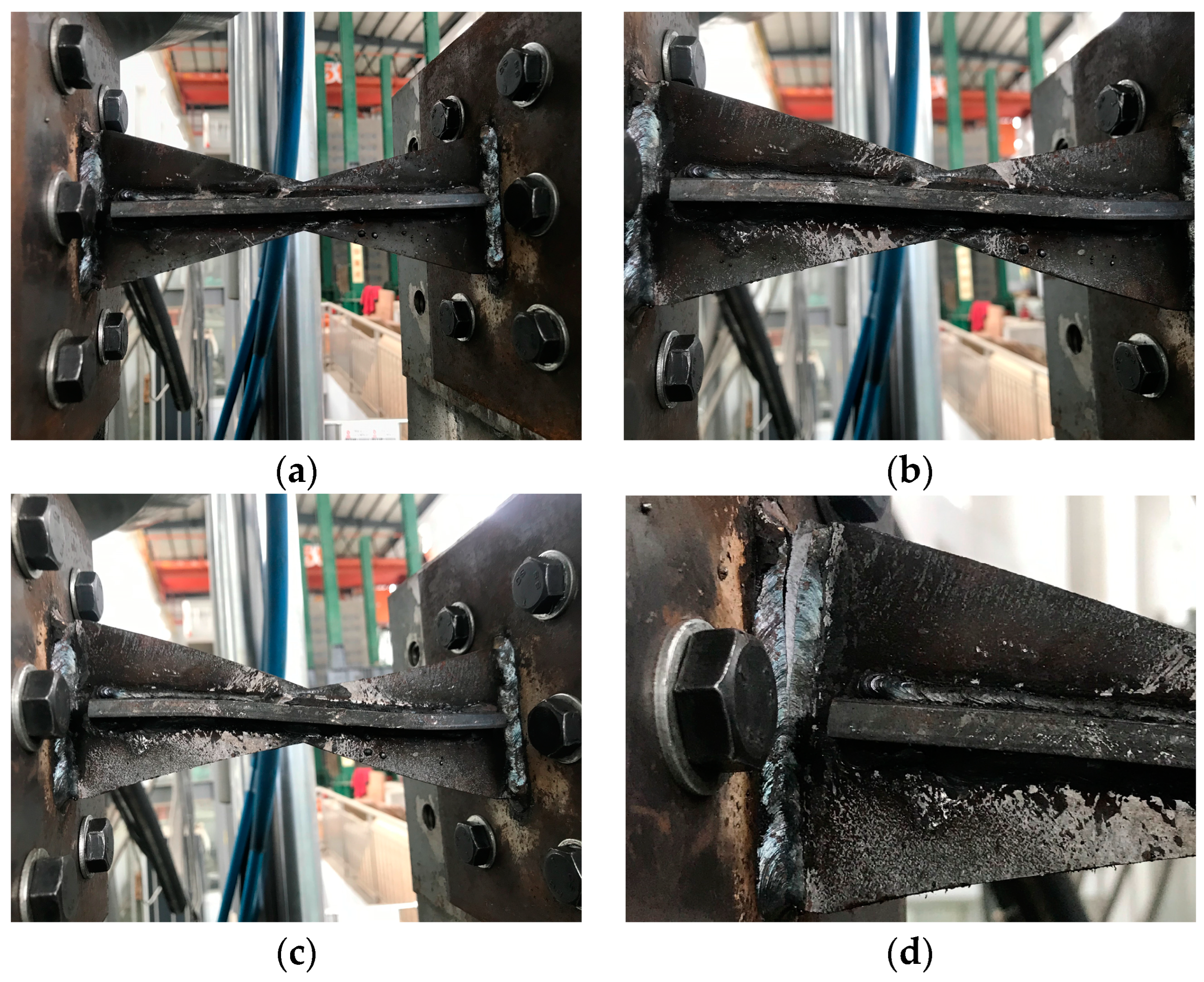

4.1. Failure Modes

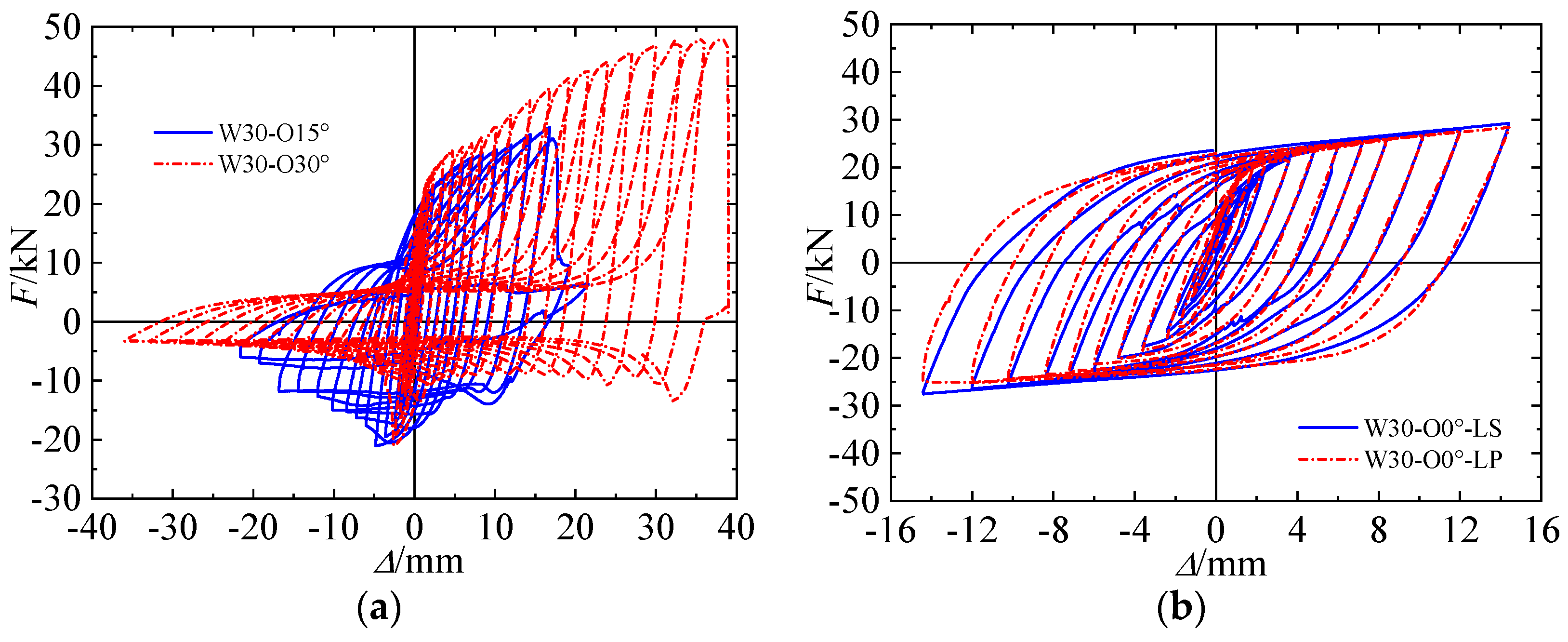

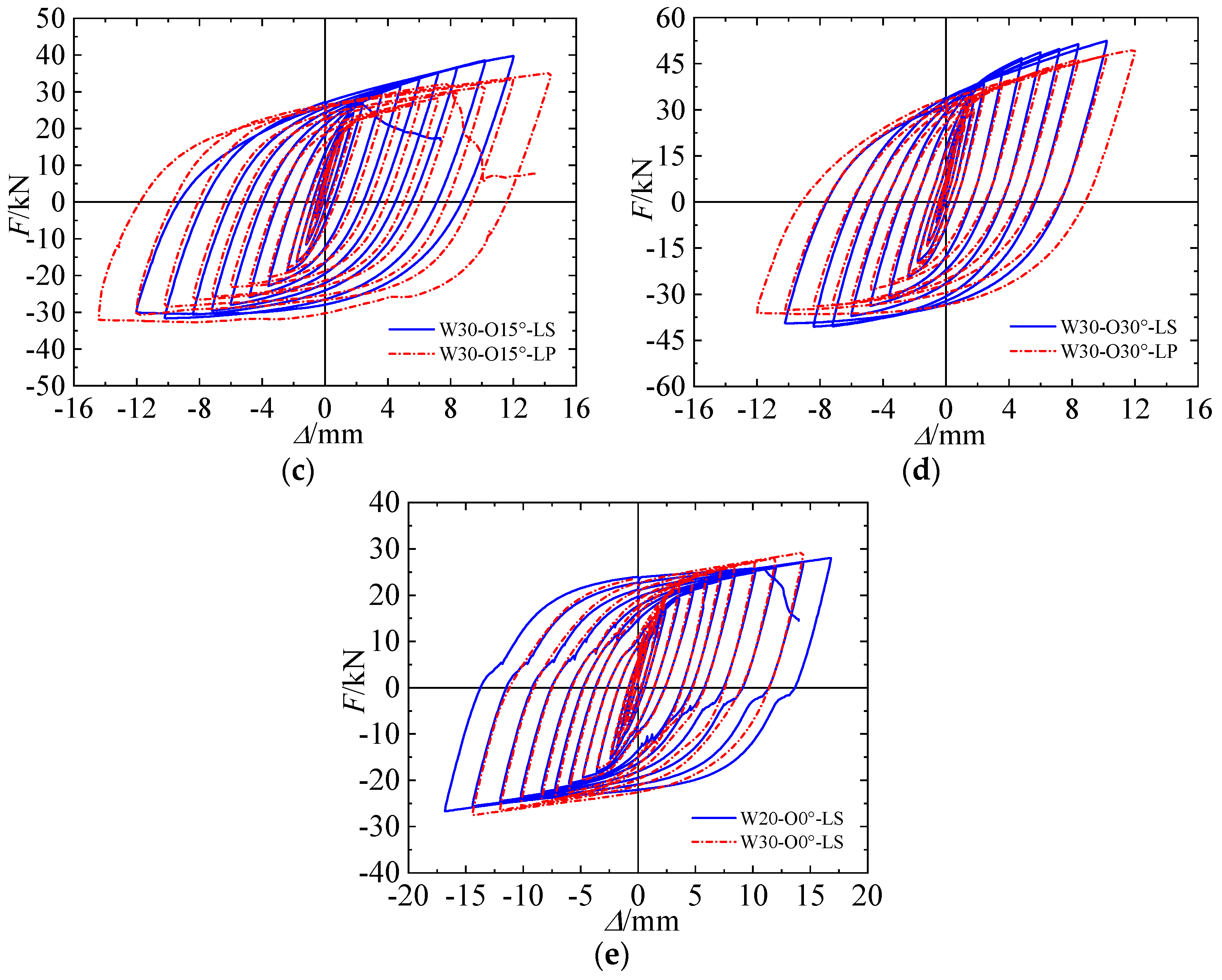

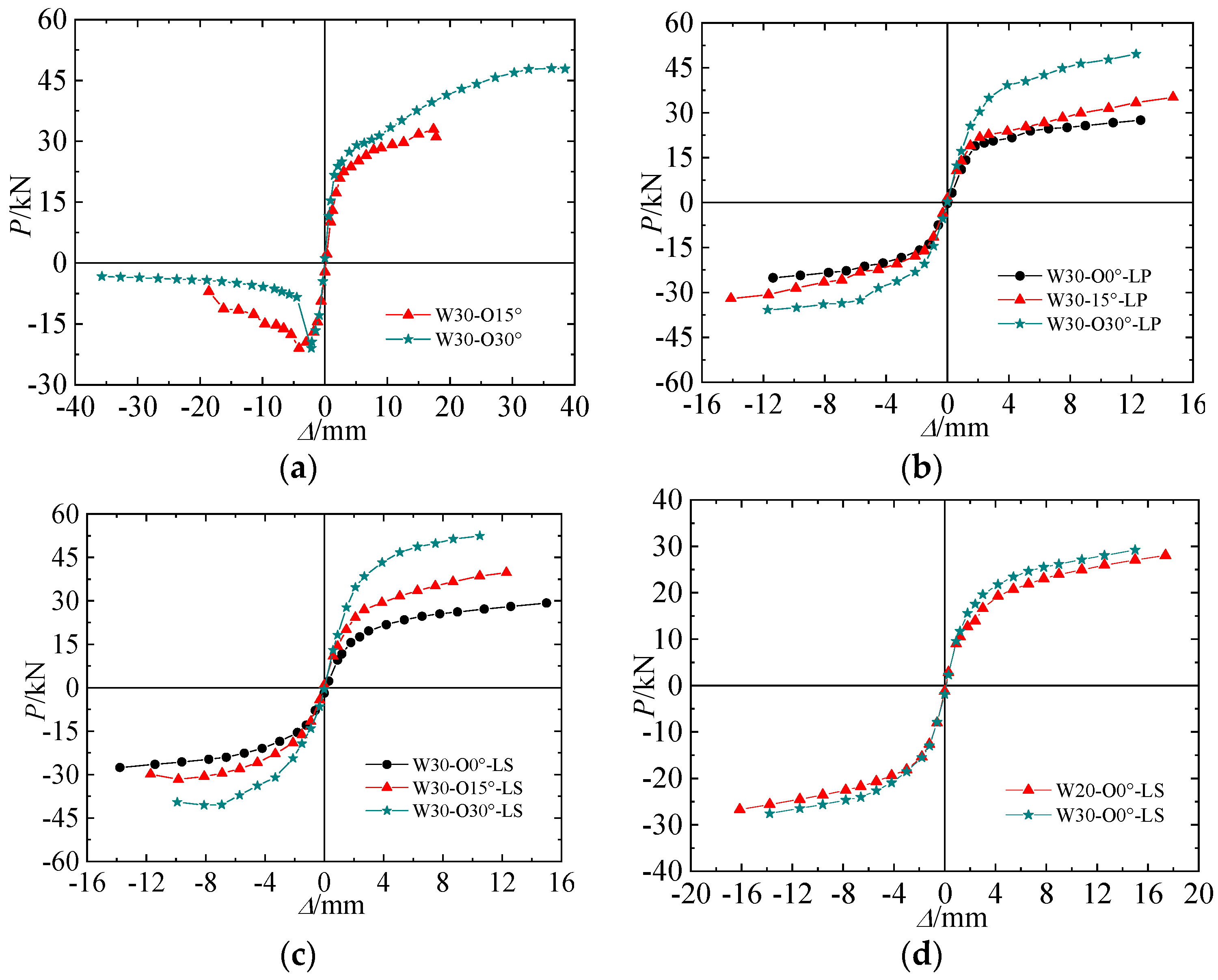

4.2. Hysteretic Behavior

4.3. Skeleton Curves

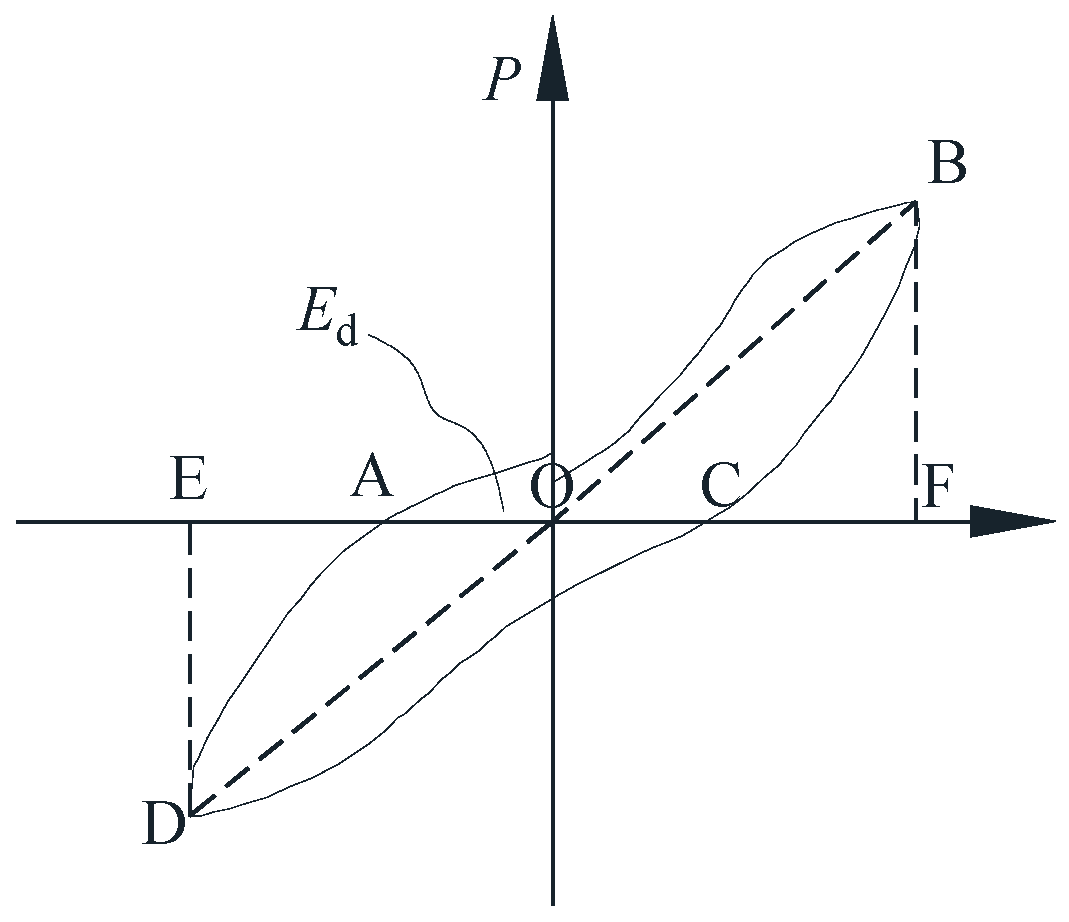

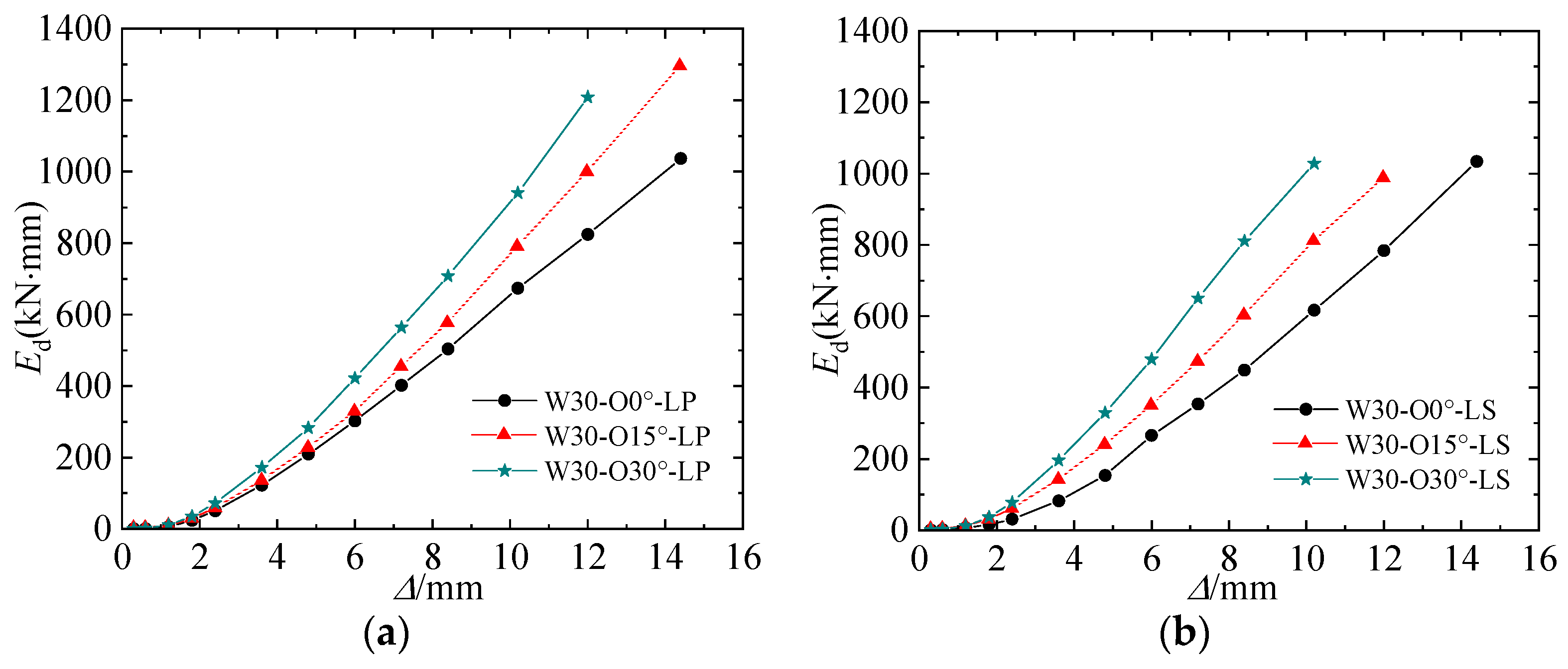

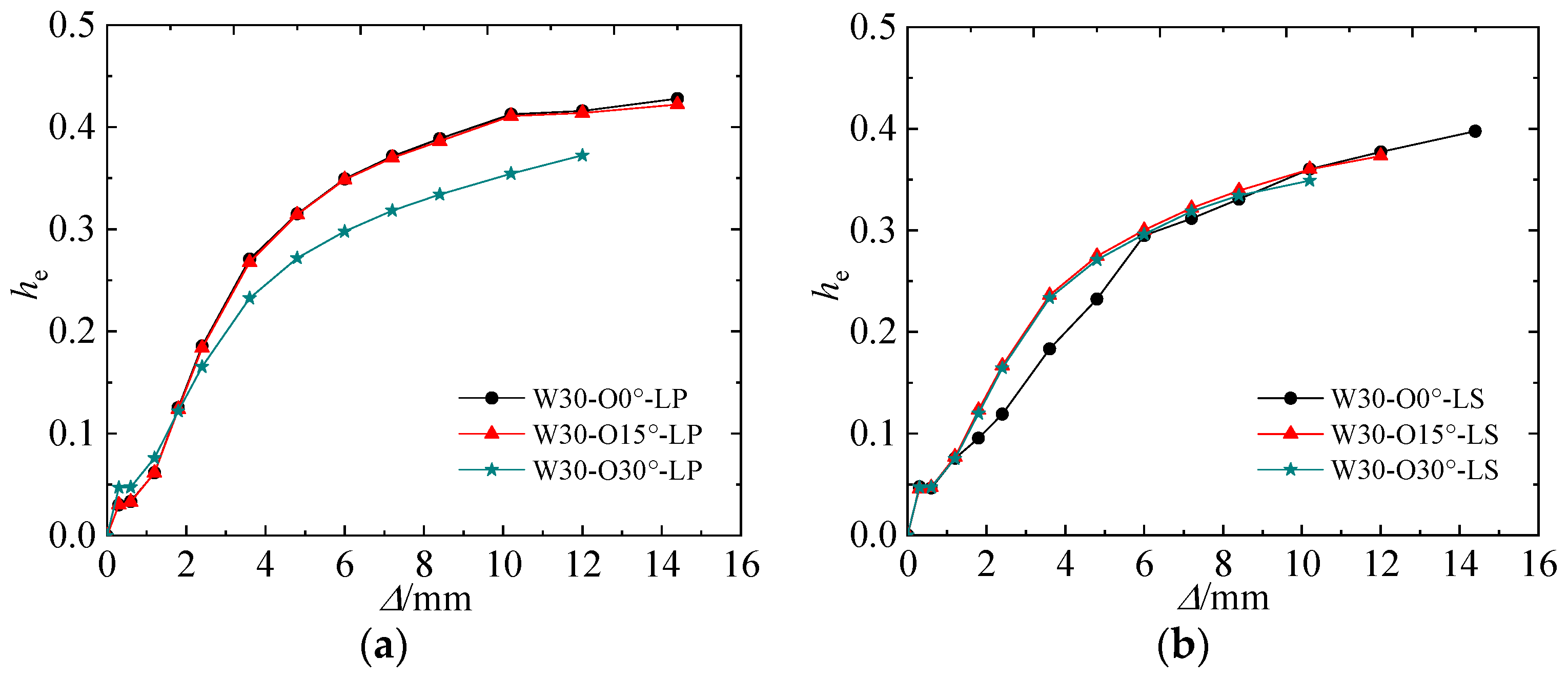

4.4. Energy Dissipation

5. Theoretical Analysis

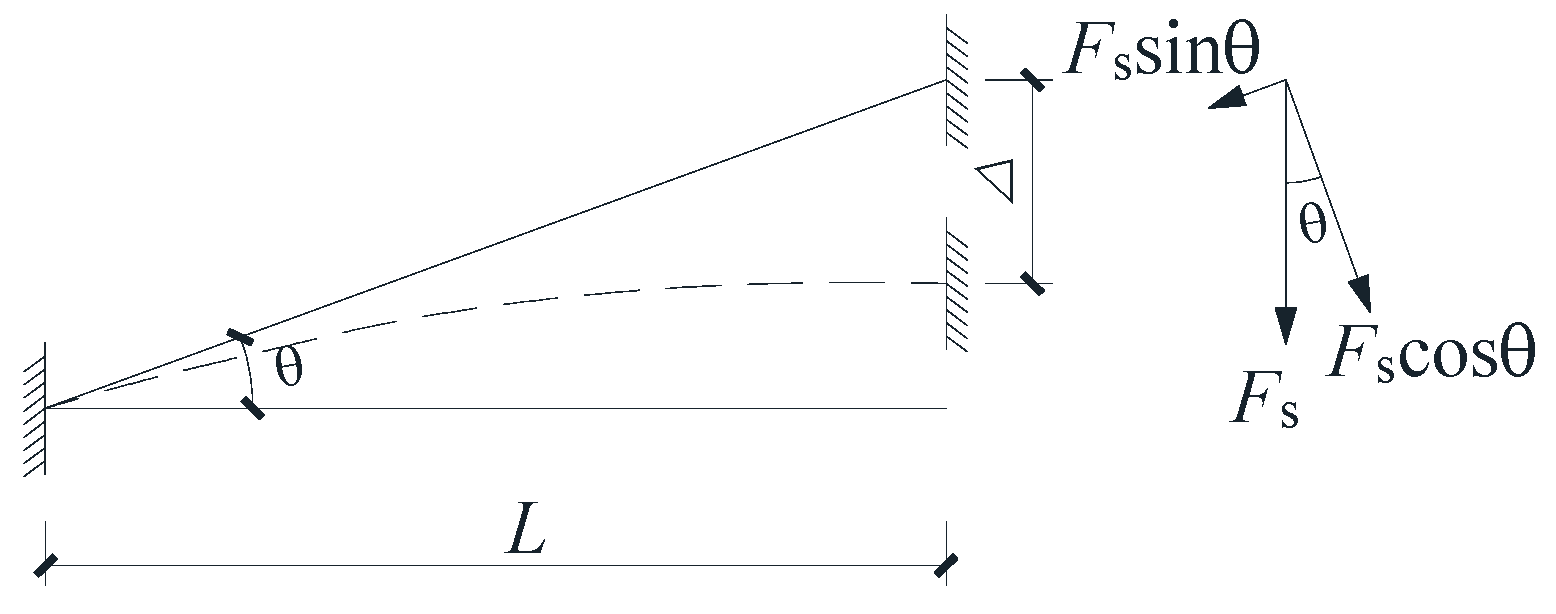

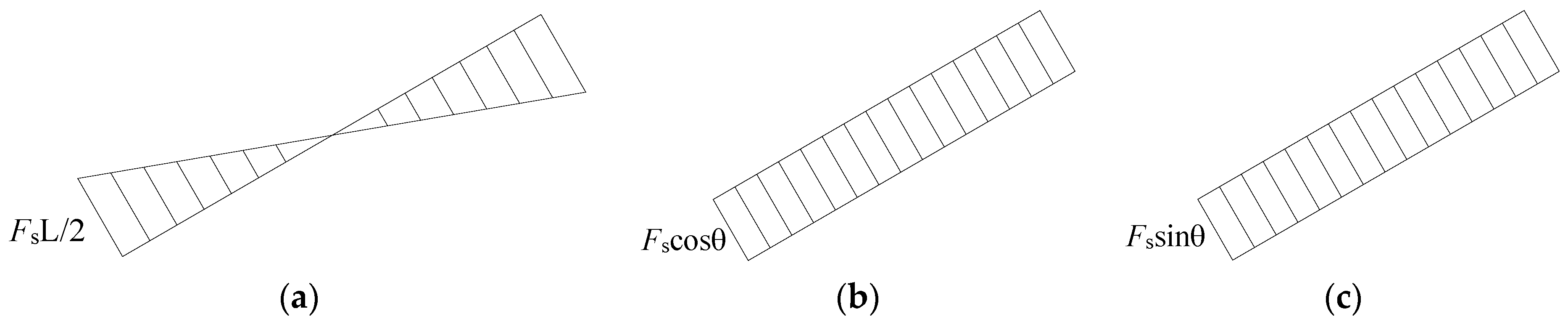

5.1. Elastic Stiffness Calculation Method

5.2. Comparison of Test and Theoretical Results

6. The Finite Element Analysis of Specimens

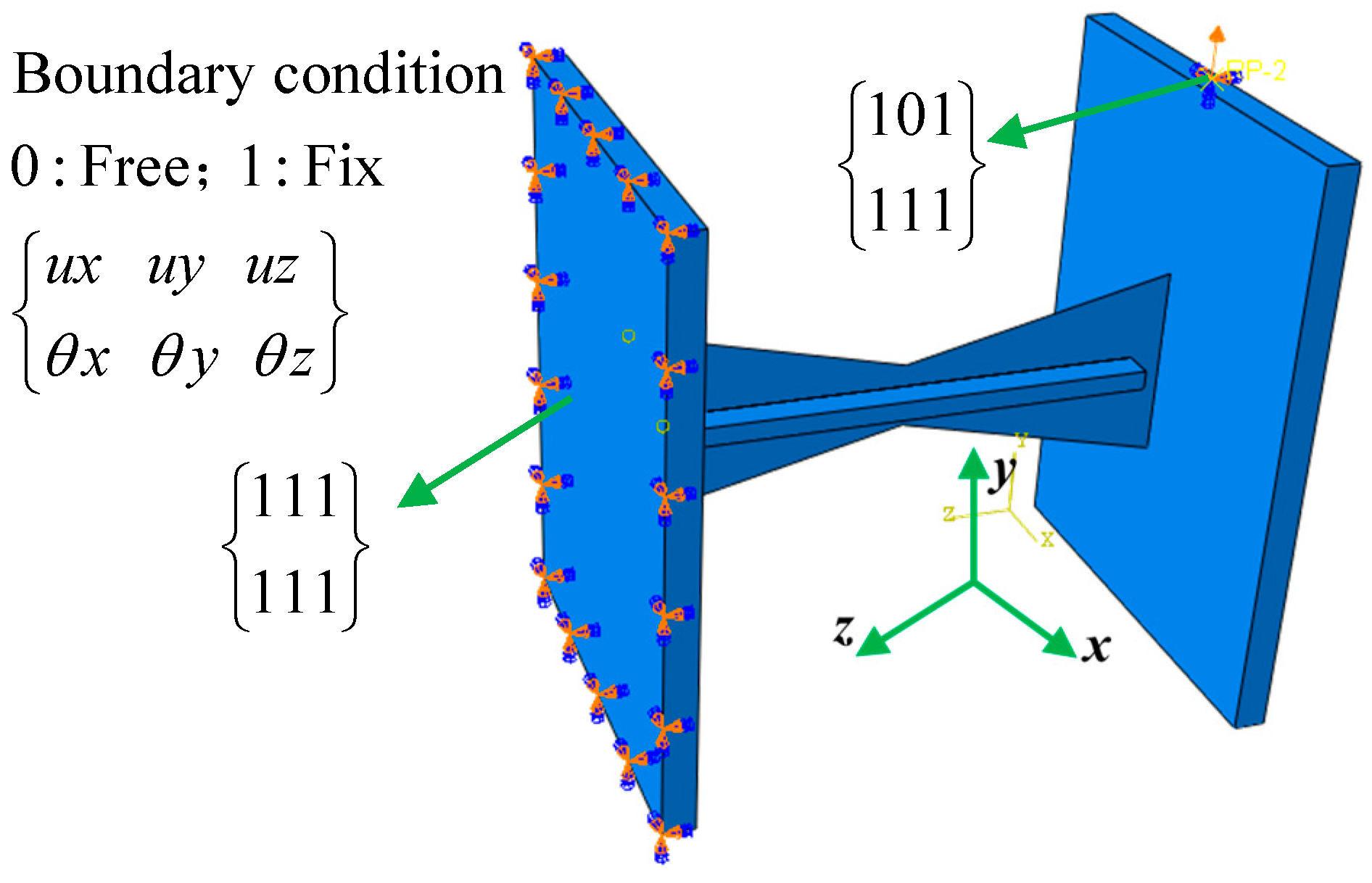

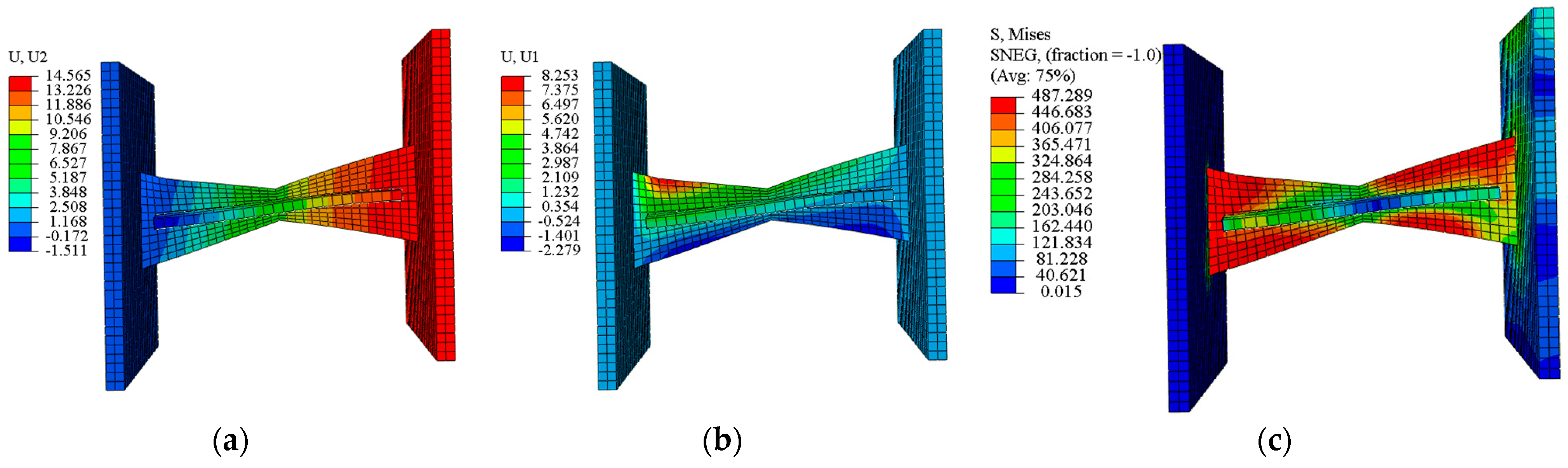

6.1. FEA Model

6.2. Material Properties of Steel

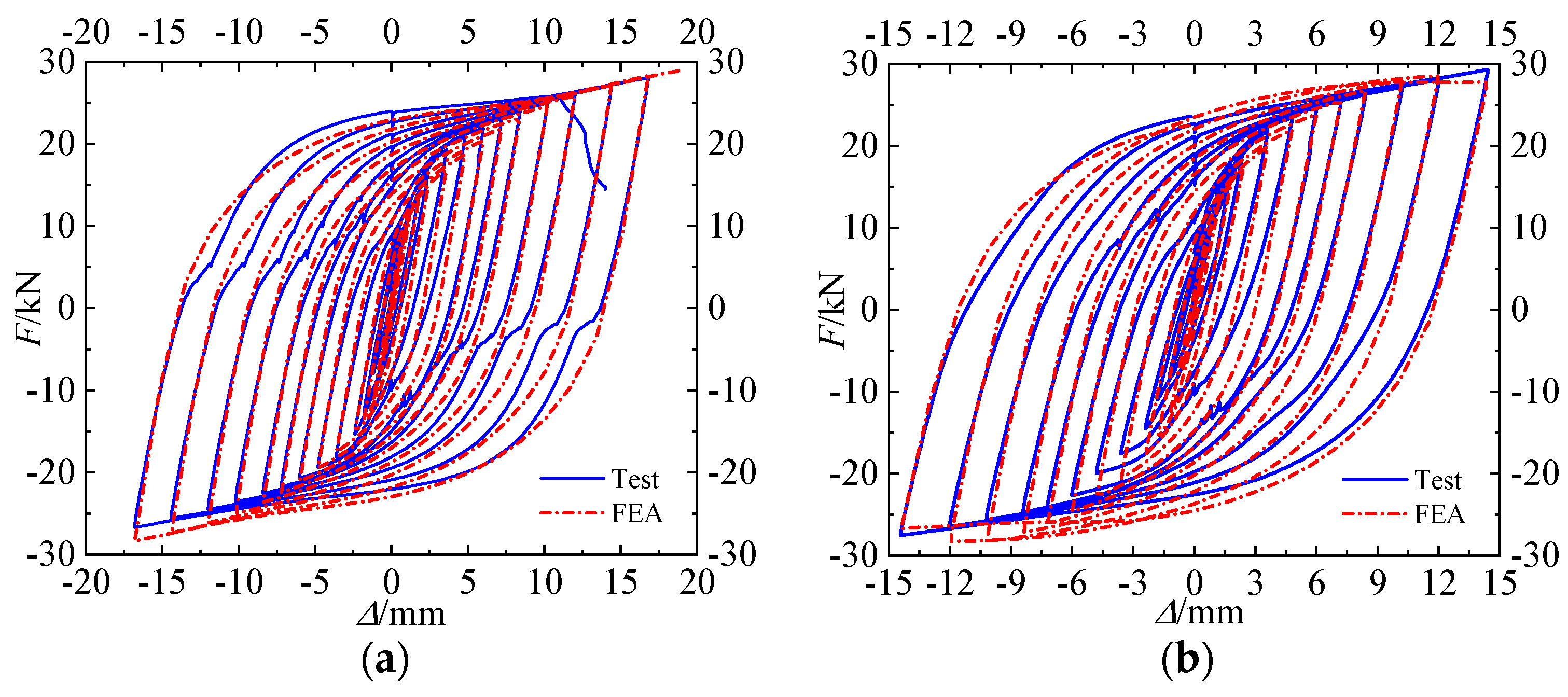

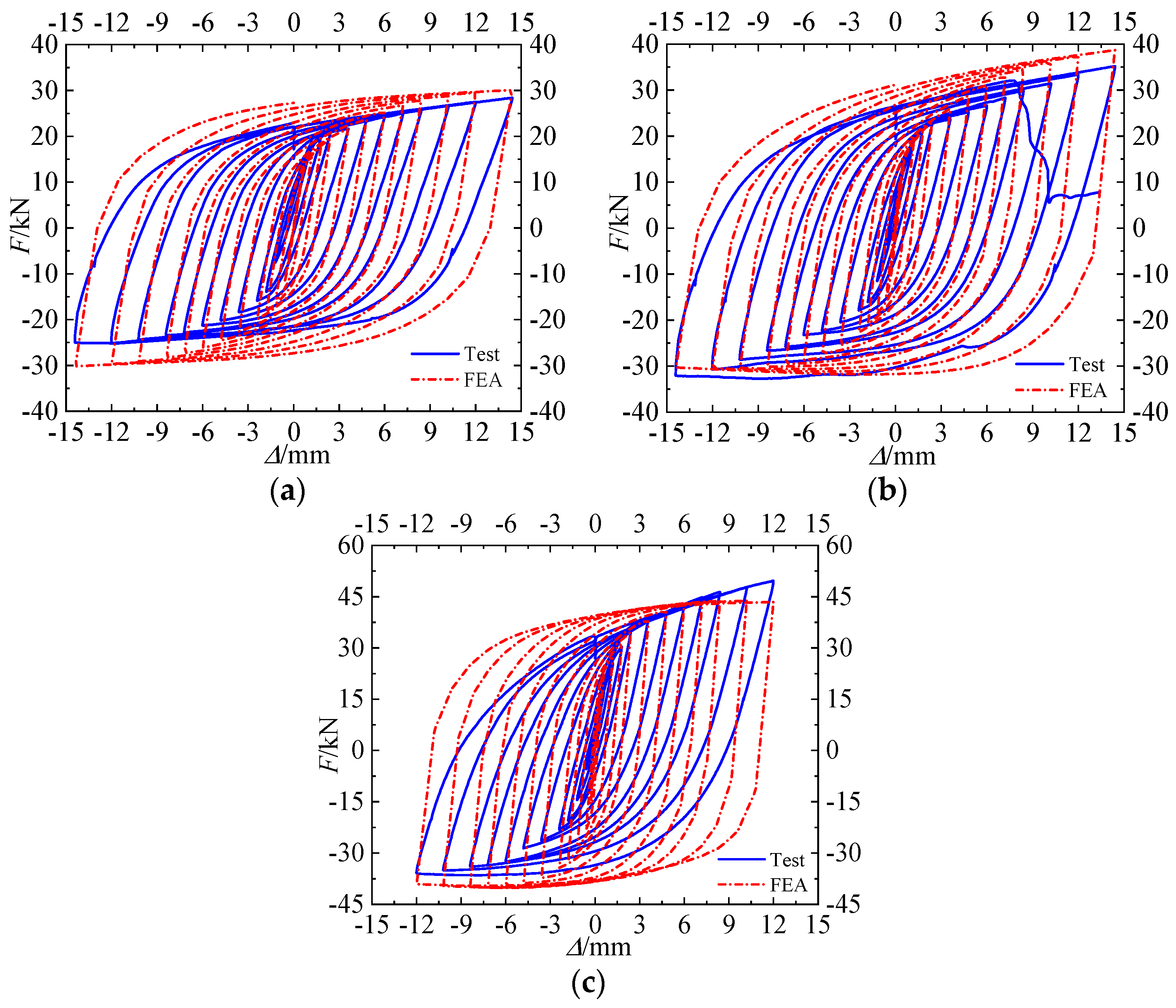

6.3. Comparison of Test and Numerical Results

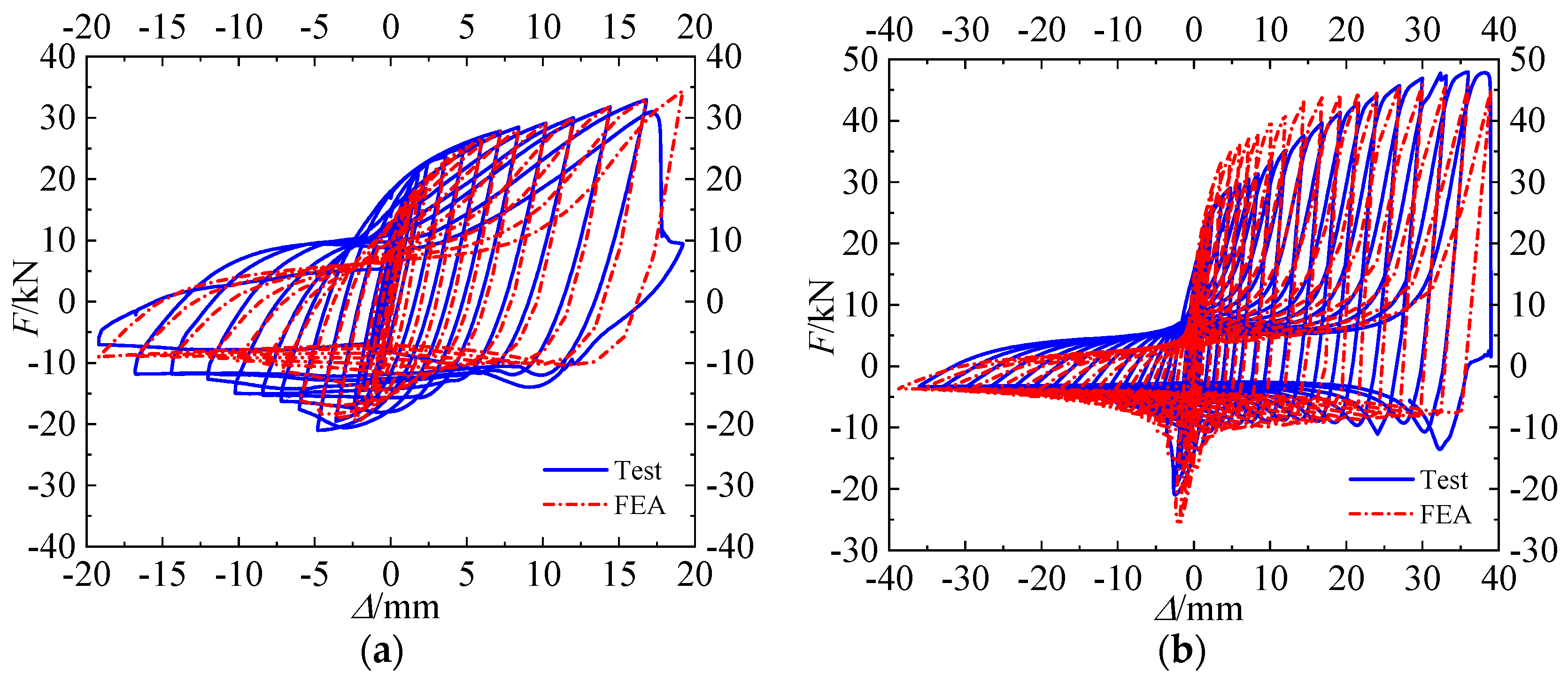

6.3.1. Specimens with Stiffening Ribs

6.3.2. Specimens with Cover Plates

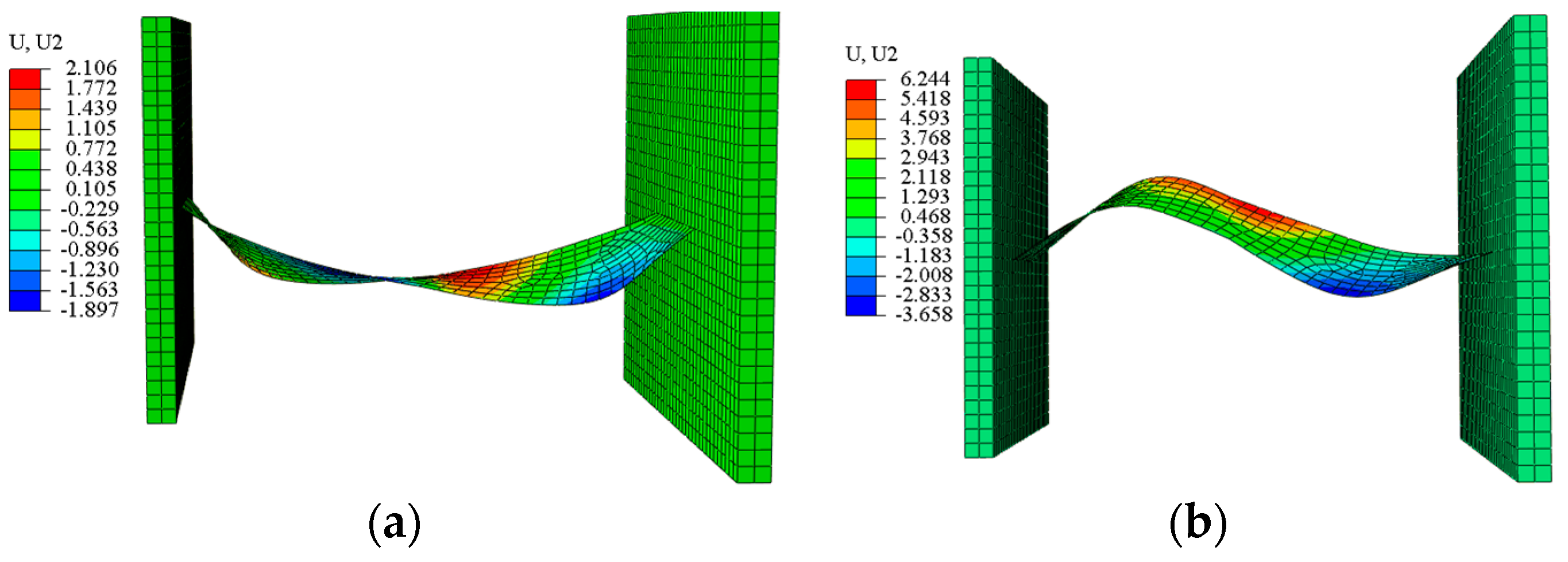

6.3.3. Specimens without Buckling-Restrained Devices

6.4. Potential Improvements

7. Conclusions

- In the initial loading stage, parallelogram hysteretic loops were observed in specimens W30-O15° and W30-O30° before reaching the critical buckling load of X-shaped metal plates. After that, obvious buckling behavior was found as specimens were mainly in compression and shear in the negative direction. On the contrary, the tensile behavior of X-shaped metal plates would eliminate the out-of-plane deformation.

- The stiffening ribs and cover plates can effectively constrain the out-of-plane deformation of X-shaped steel plates. However, due to the tensile and shear behavior of specimens in the positive direction, asymmetric hysteretic loops were also observed in specimens with oblique angles and buckling-restrained devices.

- The oblique angle could effectively improve the stiffness, strength, and energy dissipation of the XMD. When the oblique angle of the XMD with stiffening ribs increased from 0° to 30° at the applied displacement of 8.4 mm, the mean strengths and cumulative energy dissipation of specimens increased by about 80.77% and 80.57%, respectively. In addition, stiffening ribs with simple design details and higher strength were more suitable for application in engineering structures.

- A theoretical calculation method was proposed to predict the elastic stiffness of specimens with an oblique angle, and the theoretical elastic stiffness matched well with the tests results. Additionally, the relative deviation for all specimens was approximately 6%, indicating that the proposed method can effectively predict the elastic stiffness of the XMD with an oblique angle.

- The hysteretic behaviors of specimens with an oblique angle were predicted well using the proposed FEA model. For specimens with cover plates, the hysteretic loops of the proposed FEA model were fatter than those of test specimens due to the gap between X-shaped metal plates and cover plates.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, B.; Taucer, F.; Rossetto, T. Field investigation on the performance of building structures during the 12 May 2008 Wenchuan earthquake in China. Eng. Struct. 2009, 31, 1707–1723. [Google Scholar] [CrossRef]

- Weng, Y.K.; Pampanin, S. The seismic performance of RC buildings in the 22 February 2011 Christchurch earthquake. Struct. Concr. 2011, 12, 223–233. [Google Scholar]

- Xu, G.; Guo, T.; Li, A.Q.; Zhang, H.Y. Self-centering beam-column joints with variable stiffness for steel moment resisting frame. Eng. Struct. 2023, 278, 115526. [Google Scholar] [CrossRef]

- Xu, G.; Guo, T.; Li, A.Q. Self-centering rotational joints for seismic resilient steel moment resisting frame. J. Struct. Eng. 2023, 149, 04022245. [Google Scholar] [CrossRef]

- Xie, L.L.; Fan, Z.M.; Wang, X.Y.; Zeng, D.M.; Yang, C.T. Investigation on the resilience-based seismic design of isolated RC frame-shear wall structures. Eng. Mech. 2023, 40, 47–57. (In Chinese) [Google Scholar]

- Wu, M.; Liu, X.; Liu, H.T.; Du, X.L. Seismic performance of precast short-leg shear wall using a grouting sleeve connection. Eng. Struct. 2020, 208, 110338. [Google Scholar] [CrossRef]

- Dang, L.J.; Liang, S.T.; Zhu, X.J.; Zhang, M.; Song, Y.M. Seismic performance of precast concrete wall with vertical energy-dissipating connection. Struct. Des. Tall Spec. Build. 2021, 30, e1820. [Google Scholar] [CrossRef]

- Qian, J.R.; Peng, Y.Y.; Zhang, J.M.; Qin, H.; Li, J.S.; Liu, G.Q.; Zhao, F.D.; Li, L.R. Tests on seismic behavior of pre-cast shear walls with vertical reinforcements spliced by grout sleeves. Build. Struct. 2011, 41, 1–6. (In Chinese) [Google Scholar]

- Lew, M.; Naeim, F.; Carpenter, L.D.; Youssef, N.F.; Rojas, F.; Saragoni, G.R.; Adaros, M.S. The significance of the 27 February 2010 offshore maule, chile earthquake. Struct. Design Tall Spec. Build. 2010, 19, 826–837. [Google Scholar] [CrossRef]

- Kam, W.Y.; Pampanin, S.; Elwood, K. Seismic performance of reinforced concrete buildings in the 22 February Christchurch (Lyttleton) earthquake. New Zealand Soc. Earthq. Eng. 2011, 44, 239–279. [Google Scholar] [CrossRef]

- Pampanin, S. Reality-check and renewed challenges in earthquake engineering: Implementing low-damage structural systems- From theory to practice. J. Wuhan Inst. Phys. Educ. 2012, 45, 137–160. [Google Scholar]

- Jiang, X.Y.; Song, X.D.; Li, T.; Wu, K.X. Moment magnitudes of two large Turkish earthquakes on February 6, 2023 from long-period coda. Earthq. Sci. 2023, 36, 169–174. [Google Scholar] [CrossRef]

- Xu, G.; Li, A.Q. Seismic performance and design approach of unbonded post-tensioned precast sandwich wall structures with friction devices. Eng. Struct. 2020, 204, 110037. [Google Scholar] [CrossRef]

- Zhou, Y.; Deng, X.S.; Huang, W.H. Study on seismic control of structure with mixed lead rubber damper. Earthq. Eng. Eng. Vib. 1998, 18, 103–110. (In Chinese) [Google Scholar]

- Zhou, Y.; Li, D.B.; Shi, F.; Luo, W.L.; Deng, X.S. Experimental study on mechanical properties of the hybrid lead viscoelastic damper. Eng. Struct. 2021, 246, 113073. [Google Scholar] [CrossRef]

- Fang, X.J.; Zhou, Y.; Bi, K.M.; Hao, H.; Wang, T.Y. Experimental study on the cyclic behaviors of an innovative lead-viscoelastic coupling beam damper (LVCBD). J. Build. Eng. 2023, 64, 105596. [Google Scholar] [CrossRef]

- Bergman, D.M.; Goel, S.C. Evaluation of Cyclic Testing of Steel Plate Devices for Added Damping and Stiffness; Report No. UMCE87-10; The University of Michigan: Ann Arbor, MI, USA, 1987. [Google Scholar]

- Priestley, M.J.N. The PRESSS program-current status and proposed plans for Phase 3. PCI J. 1996, 41, 22–40. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, W.H.; Zhang, M.; Li, Y.J. A novel energy dissipation damper for multi-level earthquakes. J. Constr. Steel Res. 2022, 192, 107214. [Google Scholar] [CrossRef]

- Youssef, A.A.; Esfahani, M.R.; Zareian, M.S. Experimental evaluation of post-tensioned hybrid coupled shear wall system with TADAS steel dampers at the beam-wall interface. Structures 2023, 53, 1283–1299. [Google Scholar] [CrossRef]

- Yang, J.; Liang, S.T.; Zhu, X.J.; Dang, L.J.; Wang, W.K.; Zhou, S.Y. Development and performance research of an Xadas damper with a double-phased yield mechanism. Structures 2023, 24, 1420–1439. [Google Scholar] [CrossRef]

- Yang, J.; Liang, S.T.; Zhu, X.J.; Dang, L.J.; Shen, T.H.; Zhou, S.Y. Experimental and theoretical research on a shear-bending-metallic-damper with a double-phased yield mechanism. J. Constr. Steel Res. 2023, 203, 107839. [Google Scholar] [CrossRef]

- Kishiki, S.; Zheng, H.W.; Ishida, T.; Tatsumi, N.; Watanabe, A. Inspection of U-shaped steel dampers based on residual plastic deformation. Eng. Struct. 2021, 245, 112915. [Google Scholar] [CrossRef]

- Wang, B.; Zhu, S.Y. Superelastic SMA U-shaped Dampers with Self-centering Functions. Smart Mater. Struct. 2018, 27, 055003. [Google Scholar] [CrossRef]

- Shen, S.D.; Pan, P.; Miao, Q.S.; Li, W.F.; Gong, R.H. Test and analysis of reinforced concrete (RC) precast shear wall assembled using steel shear key (SSK). Earthq. Eng. Struct. Dyn. 2019, 48, 1595–1612. [Google Scholar] [CrossRef]

- Park, J.W.; Yoon, J.H.; Yoon, G.H.; Lim, Y.M. Effect of Dynamic Loading Conditions on Maximizing Energy Dissipation of Metallic Dampers. Appl. Sci. 2022, 12, 3086. [Google Scholar] [CrossRef]

- Lin, Y.; Yang, S.; Guan, D.Z.; Guo, Z.X. Modified strip model for indirect buckling restrained shear panel dampers. J. Constr. Steel Res. 2020, 175, 106371. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, Y.F.; Wu, W.H.; Yang, S.; Guo, Z.X.; Guan, D.Z.; Li, G.J. Experimental study on PSPC beam–Concrete encased CFST column frame installed with novel steel panel dampers. Eng. Struct. 2023, 288, 116211. [Google Scholar] [CrossRef]

- Wang, J.C.; Men, J.J.; Zhang, Q.; Fan, D.X.; Zhang, Z.Y.; Huang, C.H. Seismic performance evaluation of a novel shape-optimized composite metallic yielding damper. Eng. Struct. 2022, 268, 114714. [Google Scholar] [CrossRef]

- Guo, L.; Wang, J.F.; Wang, H.L. Seismic design and hybrid simulation test of existing concrete frames upgraded by metallic damper. Eng. Struct. 2023, 291, 116337. [Google Scholar] [CrossRef]

- Guan, D.Z.; Peng, Z.H.; Lin, Y.; Liu, J.B.; Zhang, L. Development and seismic performance of precast rocking walls with multiple steel energy dissipaters. Case Stud. Constr. Mater. 2023, 19, e02304. [Google Scholar] [CrossRef]

- Bedriñana, L.A.; Tani, M.; Kono, S.; Nishiyama, M. Seismic behavior of unbonded post-tensioned precast concrete walls with internal and external dampers. In Proceedings of the 17th World Conference on Earthquake Engineering, Sendai, Japan, 13–18 September 2020. [Google Scholar]

- Wang, B.; Zhu, S.Y.; Zhao, J.X.; Jiang, H.J. Earthquake resilient RC walls using shape memory alloy bars and replaceable energy dissipating devices. Smart Mater. Struct. 2019, 28, 065021. [Google Scholar] [CrossRef]

- Dang, L.J.; Liang, S.T.; Zhu, X.J.; Wang, Z.L.; Pang, R.; Yang, J. Development and seismic performance of precast concrete shear wall with vertical connectors subjected to cyclic loading. J. Earthq. Eng. 2023, 27, 2887–2918. [Google Scholar] [CrossRef]

- Dang, L.J.; Liang, S.T.; Zhu, X.J.; Pang, R.; Yang, J. Research on seismic behavior of unbonded post-tensioned concrete wall with vertical energy-dissipating connections. J. Build. Eng. 2021, 45, 103478. [Google Scholar] [CrossRef]

- Xu, Y.H.; Li, A.Q.; Zhen, H. Experimental study of mild steel dampers with parabolic shape. J. Build. Struct. 2011, 32, 202–209. (In Chinese) [Google Scholar]

- AISC Committee on Specifications. Specification for Structural Steel Buildings: ANSI/AISC 360-16; American Institute of Steel Construction: Chicago, IL, USA, 2016. [Google Scholar]

- Kenneth, M.L.; Chia, M.U.; Joel, T.L.; Anne, M.G. Fundamentals of Structural Analysis; McGraw-Hill Education: New York, NY, USA, 2018. [Google Scholar]

- GB 50010–2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2010. (In Chinese)

- Huo, L.F. Study on Seismic Performance of Slit Shear Wall Based on Metallic Damper. Master Thesis, School of Civil Engineering, Harbin Institute of Technology, Harbin, China, 2015. [Google Scholar]

- ABAQUS. ABAQUS Standard User’s Manual, Version 6.13; Dassault Systèmes Corp.: Providence, RI, USA, 2013. [Google Scholar]

- Yang, Y.F.; Hou, C.; Liu, M. Experimental study and numerical analysis of CFSST columns subjected to lateral cyclic loading. J. Struct. Eng. 2018, 144, 04018219. [Google Scholar] [CrossRef]

- Nip, K.H.; Gardner, L.; Davies, C.M.; Elghazouli, A.Y. Extremely low cycle fatigue tests on structural carbon steel and stainless steel. J. Constr. Steel Res. 2010, 66, 96–110. [Google Scholar] [CrossRef]

- Lin, Y.; Guo, Z.X.; Yang, S.; Guan, D. Development of duplex assembled I-shaped steel panel dampers. J. Constr. Steel Res. 2020, 174, 106267. [Google Scholar] [CrossRef]

| Specimen | Weakened Segment | Horizontal Segment | Thickness/mm | Angle | ||

|---|---|---|---|---|---|---|

| Length/mm | Width/mm | Length/mm | Width/mm | |||

| W30-O15° | 150 | 30 | 20 | 60 | 6 | 15° |

| W30-O30° | 150 | 30 | 20 | 60 | 6 | 30° |

| W20-O0°-LS | 150 | 20 | 20 | 60 | 6 | 0 |

| W30-O0°-LS | 150 | 30 | 20 | 60 | 6 | 0° |

| W30-O15°-LS | 150 | 30 | 20 | 60 | 6 | 15° |

| W30-O30°-LS | 150 | 30 | 20 | 60 | 6 | 30° |

| W30-O0°-LP | 150 | 30 | 20 | 60 | 6 | 0 |

| W30-O15°-LP | 150 | 30 | 20 | 60 | 6 | 15° |

| W30-O30°-LP | 150 | 30 | 20 | 60 | 6 | 30° |

| Specimen | Direction | Δ/mm | F/kN | Fm/kN | Ed/(kN·mm) | he |

|---|---|---|---|---|---|---|

| W30-O15° | Positive | 8.4 | 28.33 | 21.8 | 387.44 | 0.33 |

| Negative | −8.4 | −15.27 | ||||

| W30-O30° | Positive | 8.4 | 31.35 | 18.86 | 250.52 | 0.23 |

| Negative | −8.4 | −6.36 | ||||

| W20-O0°-LS | Positive | 8.4 | 23.95 | 23.25 | 405.12 | 0.33 |

| Negative | −8.4 | −22.56 | ||||

| W30-O0°-LS | Positive | 8.4 | 26.17 | 25.43 | 448.94 | 0.33 |

| Negative | −8.4 | −24.69 | ||||

| W30-O15°-LS | Positive | 8.4 | 36.58 | 33.62 | 601.35 | 0.34 |

| Negative | −8.4 | −30.65 | ||||

| W30-O30°-LS | Positive | 8.4 | 51.37 | 45.97 | 810.68 | 0.33 |

| Negative | −8.4 | −40.57 | ||||

| W30-O0°-LP | Positive | 8.4 | 25.71 | 24.56 | 503.78 | 0.39 |

| Negative | −8.4 | −23.41 | ||||

| W30-O15°-LP | Positive | 8.4 | 29.88 | 28.25 | 575.71 | 0.39 |

| Negative | −8.4 | −26.62 | ||||

| W30-O30°-LP | Positive | 8.4 | 46.4 | 40.19 | 708.3 | 0.33 |

| Negative | −8.4 | −33.99 |

| Specimen | Ke/(kN/mm) | Kt/(kN/mm) | Ke/Kt |

|---|---|---|---|

| W30-O15° | 13.23 | 15.09 | 0.88 |

| W30-O30° | 17.29 | 15.13 | 1.14 |

| W30-O0°-LP | 13.05 | 15.08 | 0.87 |

| W30-O15°-LP | 15.16 | 15.09 | 1.00 |

| W30-O30°-LP | 20.13 | 15.13 | 1.33 |

| W30-O0°-LS | 12.86 | 15.08 | 0.85 |

| W30-O15°-LS | 16.57 | 16.07 | 1.03 |

| W30-O30°-LS | 21.93 | 19.60 | 1.12 |

| σ|0/MPa | E/GPa | ν | C1 | γ1 | Q∞ | b |

|---|---|---|---|---|---|---|

| 316.11 | 200 | 0.3 | 62,105 | 1611 | 53 | 5 |

| Specimen | Δp/mm | Fe/kN | Fn/kN | Fn/Fe |

|---|---|---|---|---|

| W30-O15° | 12.00 | 21.18 | 19.66 | 0.93 |

| W30-O30° | 12.00 | 20.27 | 23.85 | 1.18 |

| W20-O0°-LS | 12.00 | 25.23 | 26.00 | 1.03 |

| W30-O0°-LS | 12.00 | 27.26 | 28.40 | 1.04 |

| W30-O15°-LS | 12.00 | 34.90 | 34.28 | 0.98 |

| W30-O30°-LS | 10.20 | 45.89 | 52.18 | 1.14 |

| W30-O0°-LP | 12.00 | 26.26 | 29.57 | 1.13 |

| W30-O15°-LP | 12.00 | 31.98 | 33.90 | 1.06 |

| W30-O30°-LP | 12.00 | 42.82 | 41.24 | 0.96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Dang, L.; Liang, S.; Zhang, M.; Yang, J.; Dai, X. Development and Investigation of the Hysteretic Behavior of an X-Shaped Metal Damper with an Oblique Angle. Appl. Sci. 2023, 13, 12464. https://doi.org/10.3390/app132212464

Zhu X, Dang L, Liang S, Zhang M, Yang J, Dai X. Development and Investigation of the Hysteretic Behavior of an X-Shaped Metal Damper with an Oblique Angle. Applied Sciences. 2023; 13(22):12464. https://doi.org/10.3390/app132212464

Chicago/Turabian StyleZhu, Xiaojun, Longji Dang, Shuting Liang, Ming Zhang, Jian Yang, and Xin Dai. 2023. "Development and Investigation of the Hysteretic Behavior of an X-Shaped Metal Damper with an Oblique Angle" Applied Sciences 13, no. 22: 12464. https://doi.org/10.3390/app132212464

APA StyleZhu, X., Dang, L., Liang, S., Zhang, M., Yang, J., & Dai, X. (2023). Development and Investigation of the Hysteretic Behavior of an X-Shaped Metal Damper with an Oblique Angle. Applied Sciences, 13(22), 12464. https://doi.org/10.3390/app132212464