A New Approach of Well Productivity Evaluation for Fractured Buried Hill Gas Reservoirs Based on Imaging Logging Data

Abstract

:1. Introduction

2. Construction of Productivity Prediction Method of Reservoir

2.1. Construction of Fracture Effectiveness Index

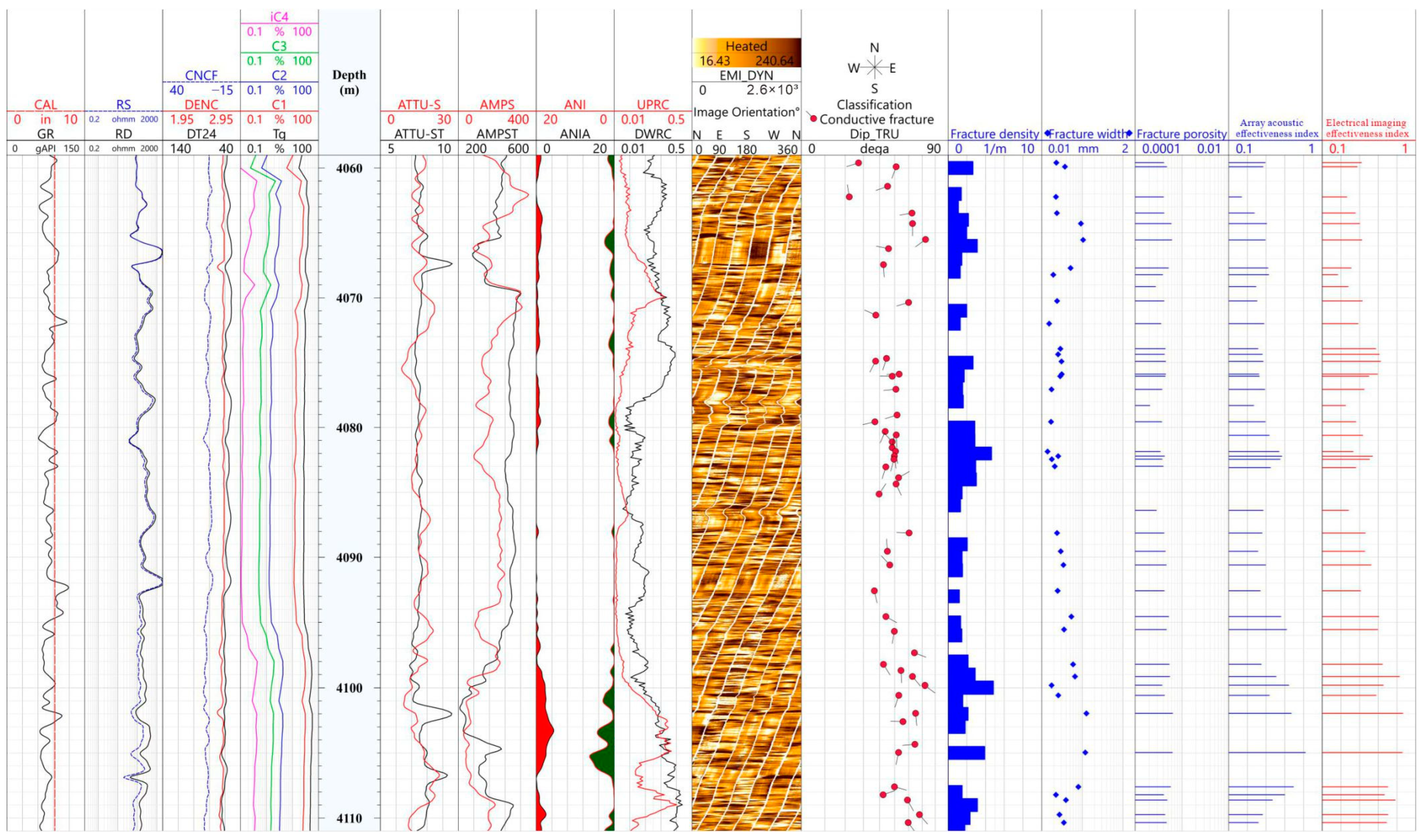

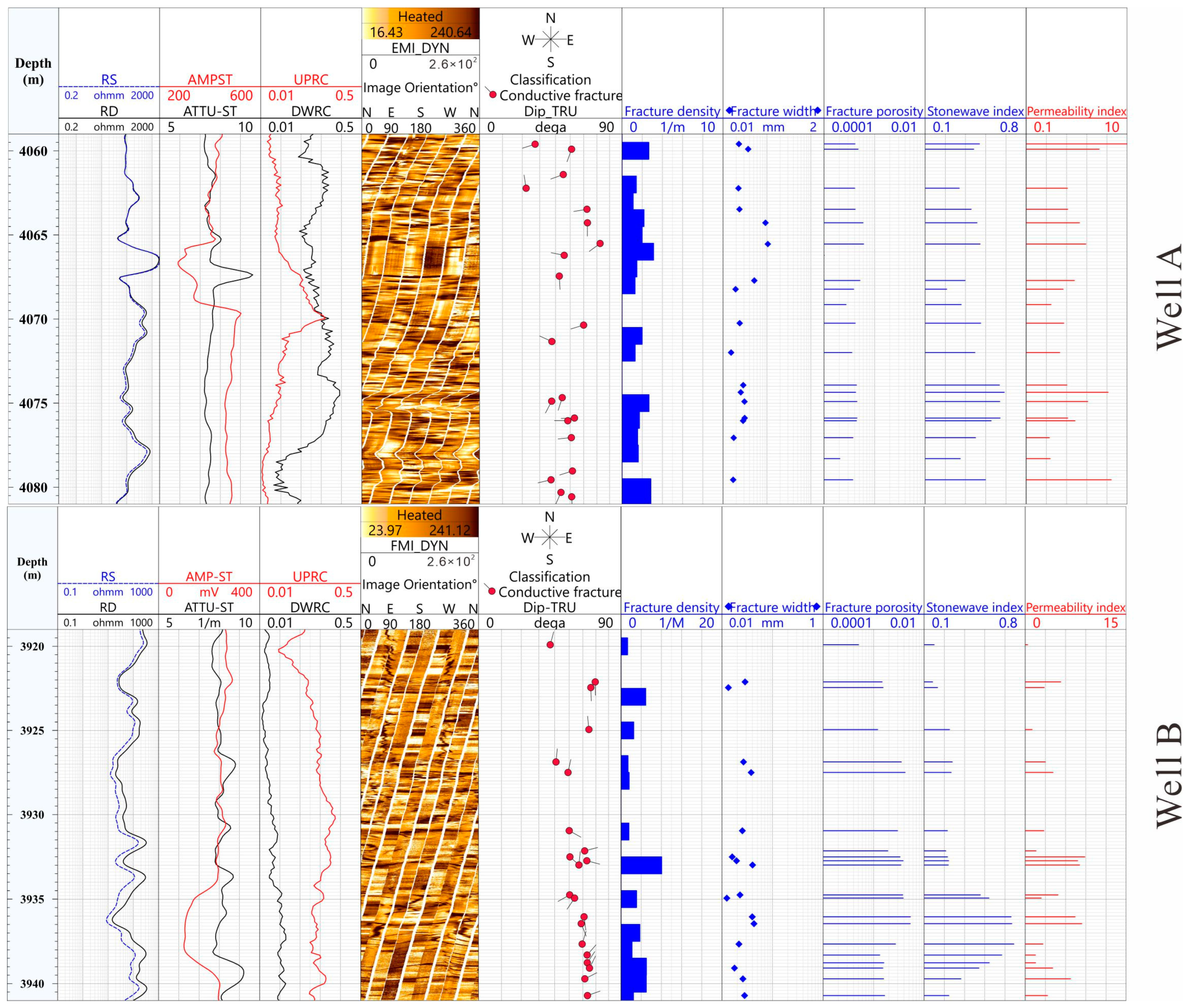

2.2. Calculation of Fracture Parameters

2.2.1. Fracture Density

2.2.2. Fracture Width

2.2.3. Fracture Porosity

2.3. Construction of Fracture Permeability Index

2.4. Construction of Productivity Coefficients

3. Application Examples

3.1. Calculation of Fracture Parameters

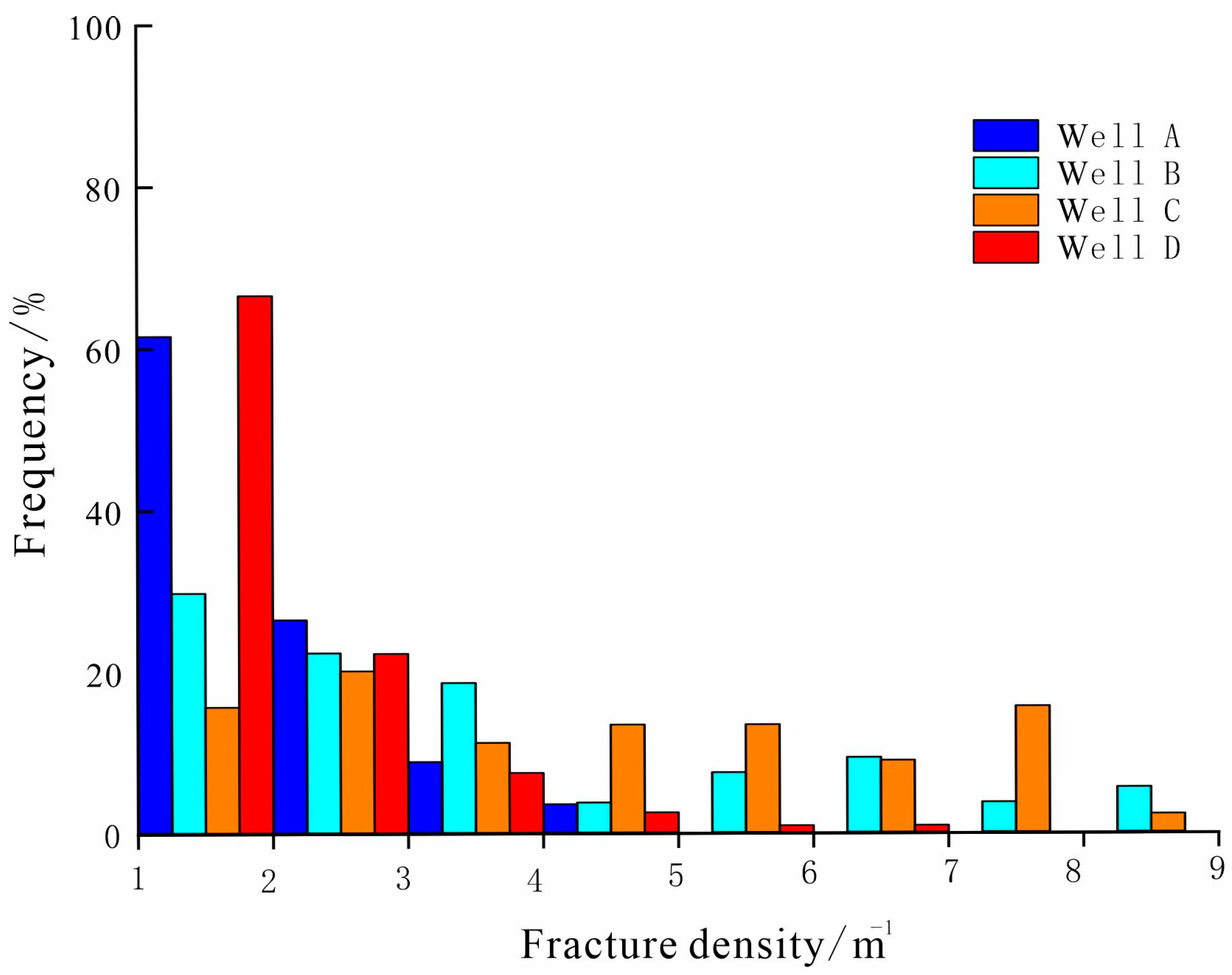

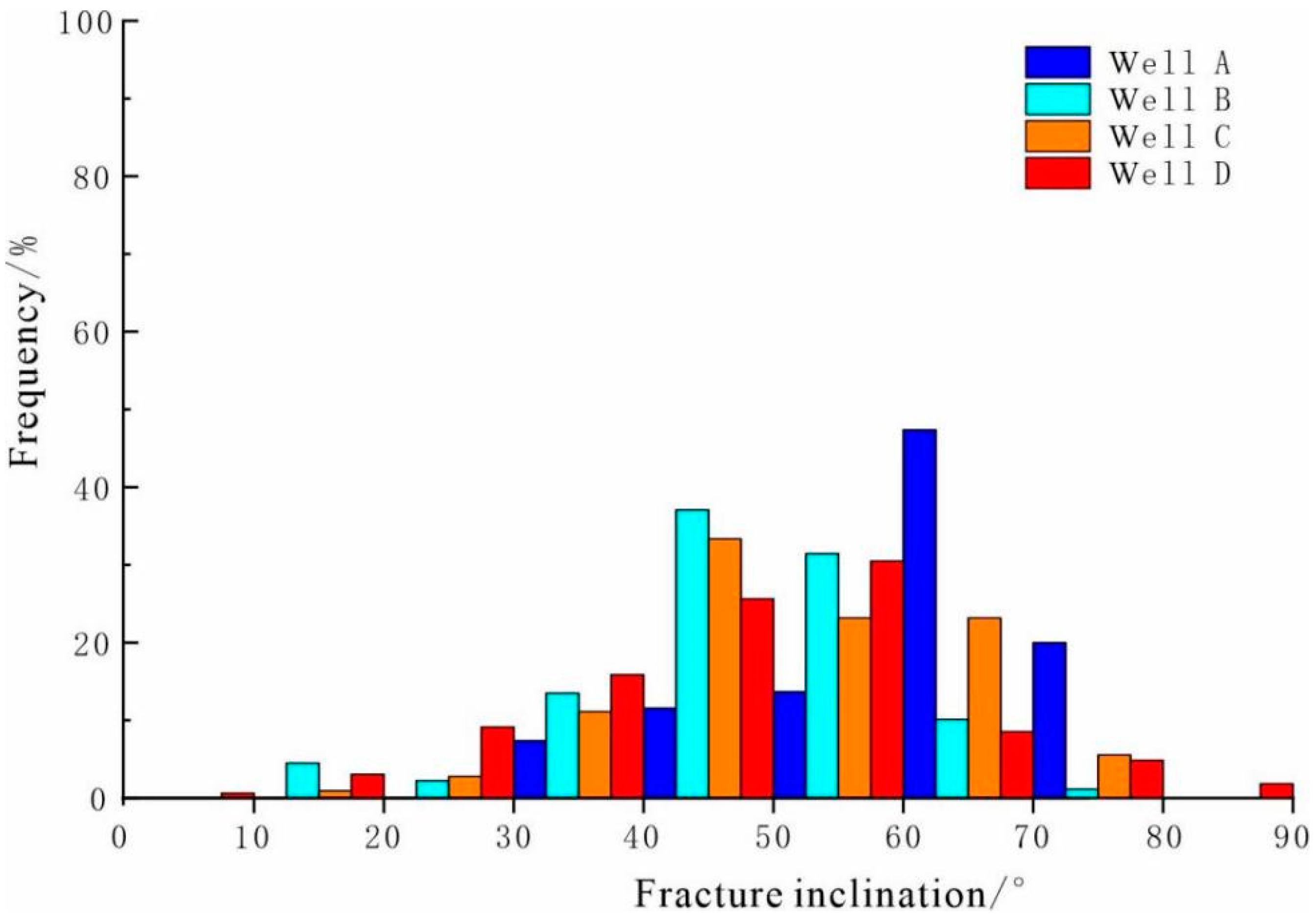

3.1.1. Fracture Density

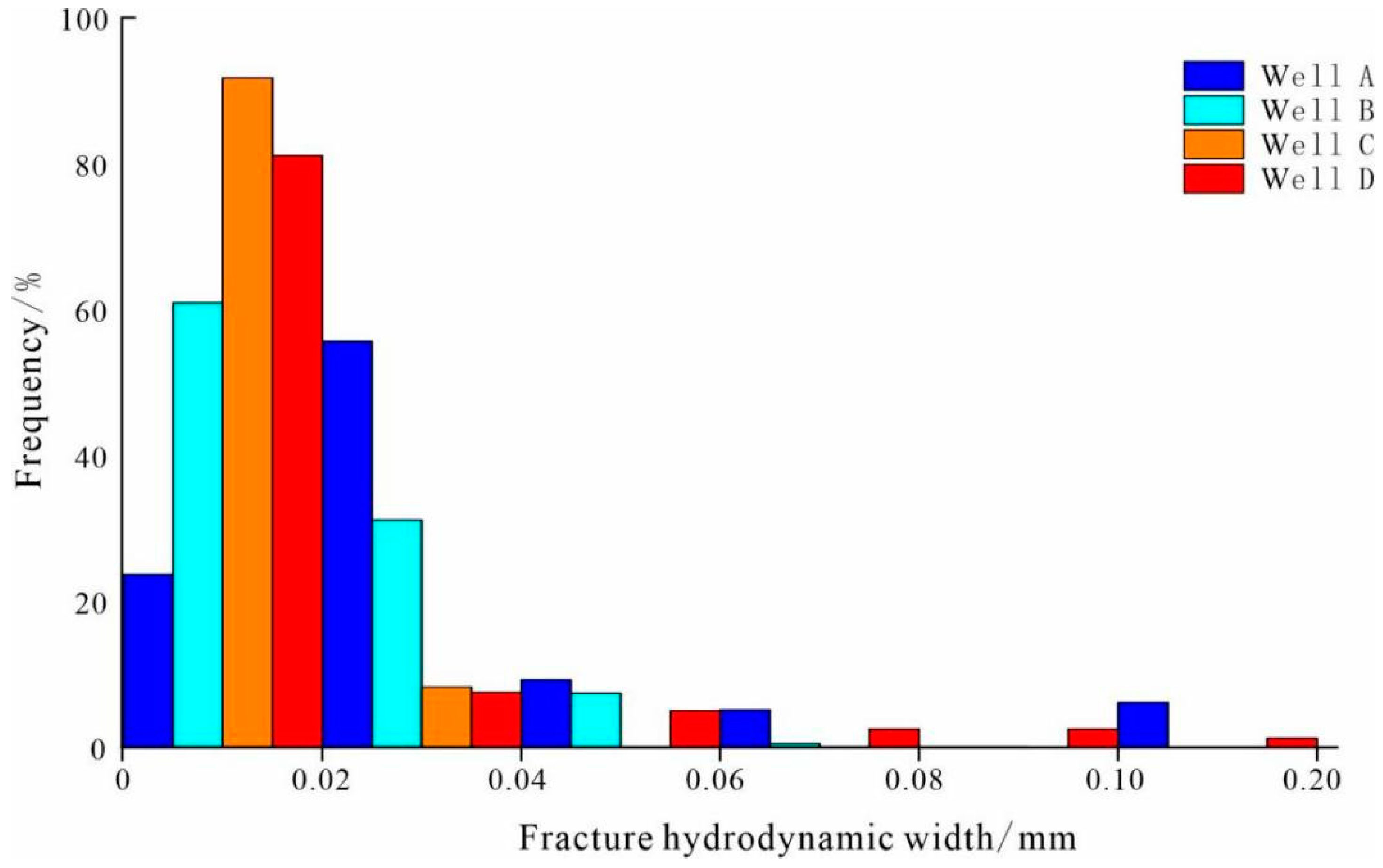

3.1.2. Fracture Width

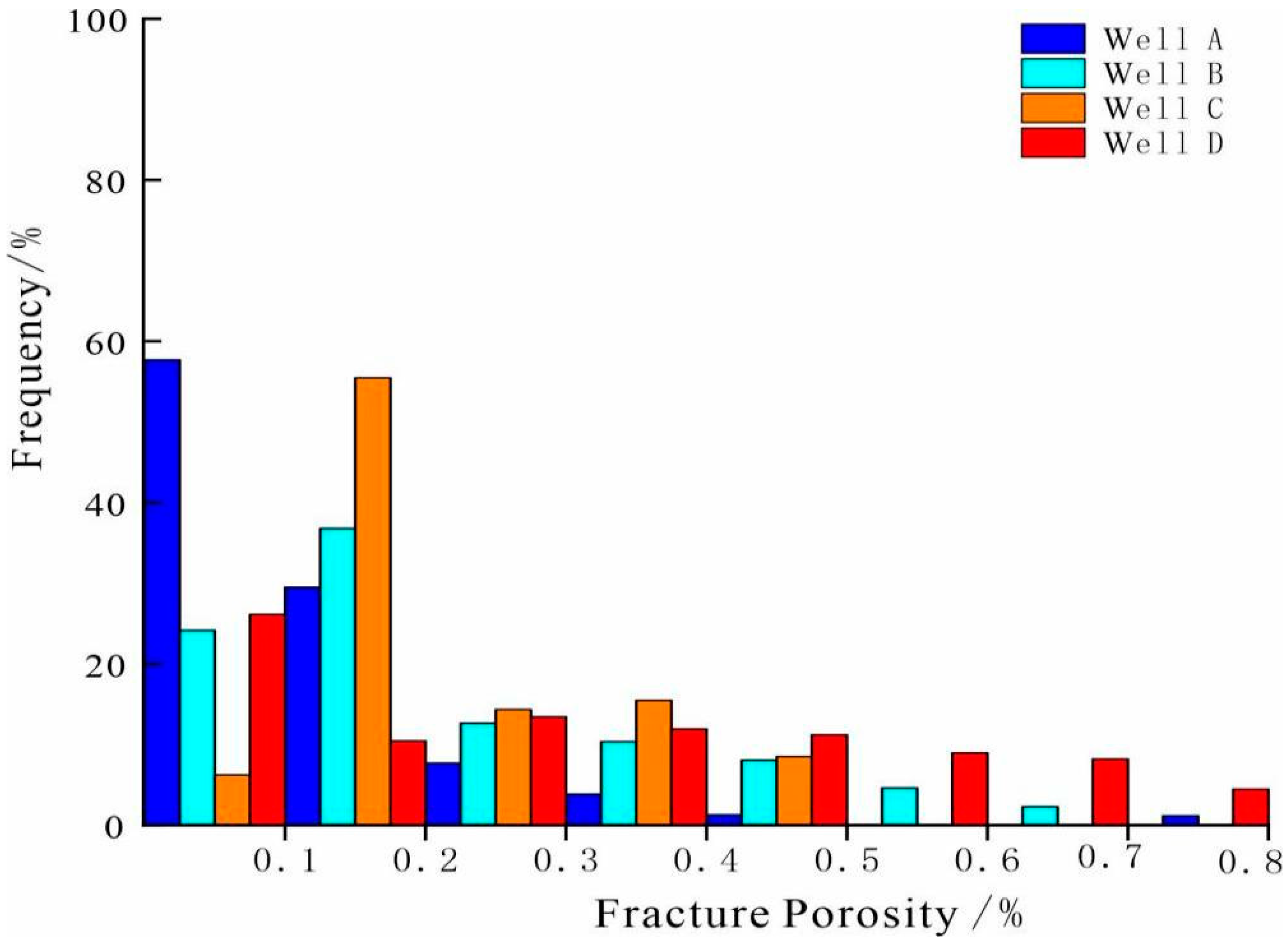

3.1.3. Fracture Porosity

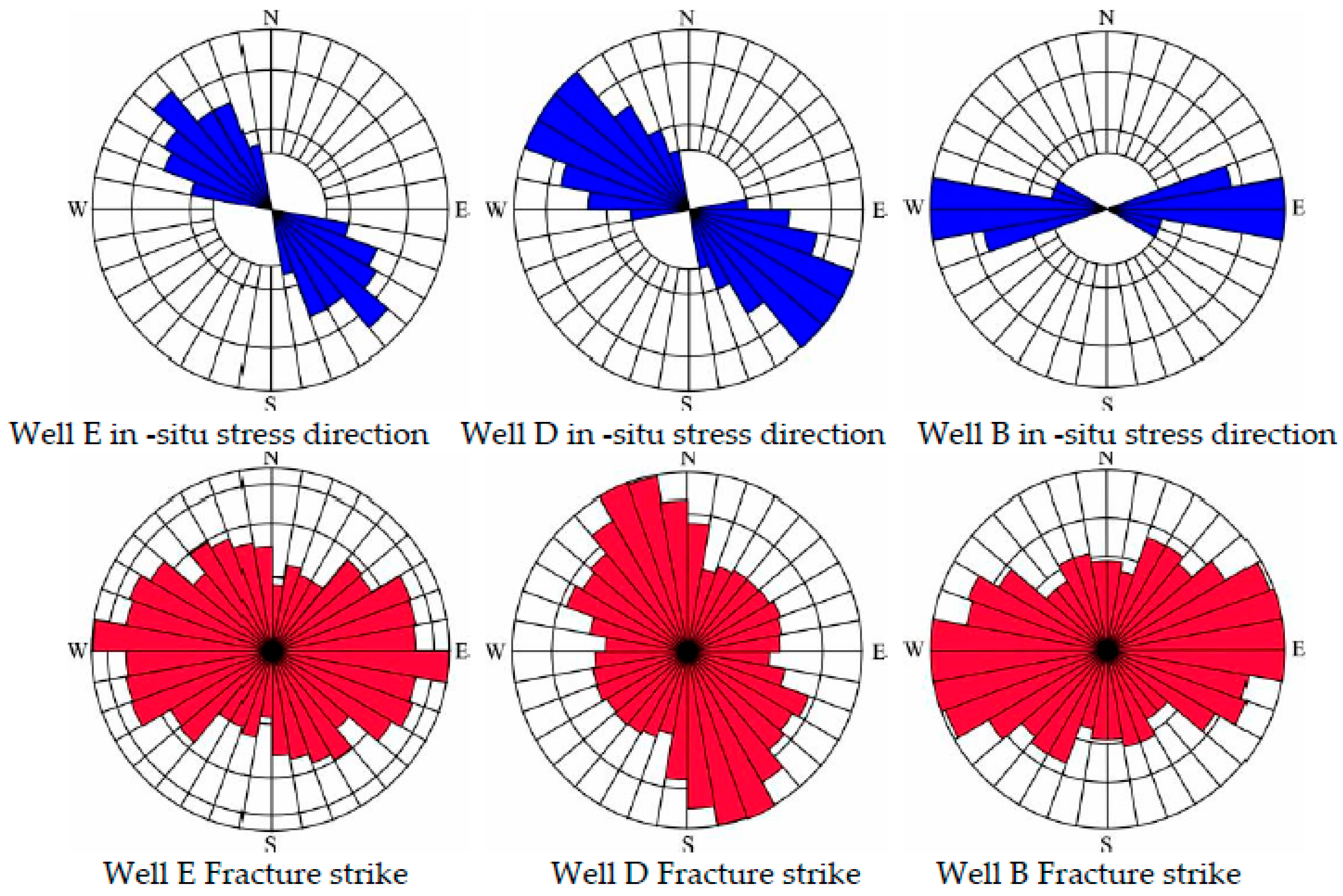

3.2. Evaluation of Fracture Effectiveness

3.3. Reservoir Permeability Evaluation

3.4. Well Productivity Evaluation

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Landes, K.K.; Amoruso, J.J.; Charlesworth, L.J., Jr.; Heany, F.; Lesperance, P.J. Petroleum resources in basement rocks. AAPG Bull. 1960, 44, 1682–1691. [Google Scholar]

- Pan, Z.X. Petroleum in basement rocks. AAPG Bull. 1982, 66, 1579–1643. [Google Scholar]

- Xu, C.G.; Du, X.F.; Liu, X.J.; Liu, W.; Hao, Y. Formation mechanism of high-quality deep burie-hill reservoir of Archaean metamorphic rocks and its significance in petroleum expolration in Bohai Sea area. Oil Gas Geol. 2020, 41, 235–247, 294. [Google Scholar]

- Hou, M.C.; Cao, H.Y.; Li, H.Y.; Chen, A.; Wei, A.; Chen, Y.; Wang, Y.; Zhou, X.; Ye, T. Characteristics and controlling factors of deep buried-hill reservoirs in the BZ19-6 structural belt, Bohai Sea area. Nat. Gas Ind. 2019, 39, 33–44. [Google Scholar] [CrossRef]

- Li, W.; Dou, L.R.; Wen, Z.G.; Zhang, G.; Cheng, D.; Du, Y.; Hu, Y. Buried-hill hydrocarbon genesis and accumulation process in Bongor Basin, Chad. Acta Petro-Lei Sin. 2017, 38, 1253–1262. [Google Scholar]

- Li, X.Y.; Qin, R.B. Method of Fracture Characterization and Productivity Prediction of 19-6 Buried-Hill Fractured Reservoirs, Bohai Bay Basin. Earth Sci. 2023, 48, 475–487. [Google Scholar]

- Ren, F.X.; Guo, Y.J.; Zhang, J.C.; Gu, T. Research on seismic response characteristics of fracture developed section of reservoirs inside the buried hill. Nat. Gas Geo-Sci. 2014, 25, 565–573. [Google Scholar]

- Al-Hussainy, R.; Ramey, H.J., Jr.; Crawford, P.B. The flow of real gases through porous media. J. Pet. Technol. 1966, 18, 624–636. [Google Scholar] [CrossRef]

- Teng, S.N.; Liang, J.W.; Li, Y.S.; Lei, G. One point method productivity prediction formula for low permeability gas reservoirs. XinJiang Pet. Geol. 2012, 33, 92–94. [Google Scholar]

- Sun, H.D.; Meng, G.R.; Cao, W.; Su, X.; Liang, Y.; Zhang, R.; Zhu, S.; Wang, S. Applicable conditions of the binomial pressure method and pressure-squared method for gas well deliverability evaluation. Nat. Gas Ind. 2020, 40, 69–75. [Google Scholar] [CrossRef]

- Kang, K.; Zhao, L.; Luo, X.B.; Zhang, L.; Wu, H. A new productivity evaluation method for fractured buried hill gas reservoirs and its application. China Offshore Oil Gas 2021, 33, 100–106. [Google Scholar]

- Zheng, X.R.; Li, X.B.; Li, X.L. New prediction method for fracture reservoir productivity. Fault-Block Oil Filed 2015, 22, 744–746+751. [Google Scholar]

- Li, Y.; Li, B.; Wang, Q.; Deng, X. Different equivalent simulation methods for fractured-vuggy carbonate gas condensate reservoirs. In Proceedings of the SPE Europec Featured at 79th EAGE Conference and Exhibition, Paris, France, 12–15 June 2017. [Google Scholar]

- Akbar, M.N.A.; Nemes, I.; Bihari, Z.; Soltész, H.; Bárány, Á.; Tóth, L.; Borka, S.; Ferincz, G. Naturally fractured carbonate reservoir characterization: A case study of a mature high-pour point oil field in Hungary. Petrophysics 2022, 63, 634–649. [Google Scholar] [CrossRef]

- Xu, S.N.; Cui, Y.J.; Lu, Y.L.; Xu, J.; Bie, X.; Han, Z. New quantitative calculation method for buried-hill reservoir productivity by rock mechanical parameters. Fault-Block Oil Filed 2017, 24, 674–677. [Google Scholar]

- Yang, F.; Zhu, C.Q.; Wang, X.H.; Qu, H.; Zhang, F.; Niu, X. A capacity prediction model for the low porosity fractured reservoirs in the Kuqa foreland basin, NW China. Pet. Explor. Dev. 2013, 40, 341–345. [Google Scholar] [CrossRef]

- Mao, Z.Q.; Li, J.F. Method and Model for Predicting Oil and Gas Reservoir Productivity. Acta Pet. Sin. 2000, 21, 58–61+3. [Google Scholar]

- Xie, Q.; Li, G.; Yang, X.; Peng, H. Evaluating the Degree of Tectonic Fracture Development in the Fourth Member of the Leikoupo Formation in Pengzhou, Western Sichuan, China. Energies 2023, 16, 1797. [Google Scholar] [CrossRef]

- Qu, H.Z.; Zhang, F.X.; Wang, Z.Y.; Yang, X.; Liu, H.; Ba, D.; Wang, X. Quantitative fracture evaluation method based on core-image logging: A case study of Cretaceous Bashijiqike Formation in ks2 well area, Kuqa depression, Tarim Basin, NW China. Pet. Explor. Dev. 2016, 43, 465–473. [Google Scholar] [CrossRef]

- Chen, Y.X.; Ren, X.F.; Mu, Y.; Chen, H.; Yu, B.; Yao, H.; Liu, L. Effectiveness evaluation method for tight carbonate reservoirs based on electrical imaging logging data. Well Logging Technol. 2020, 44, 49–54. [Google Scholar]

- Wu, W.; Shao, G.H.; Gui, P.F.; Zhang, Q.; Wei, H.; Li, G.; Ren, P. Fracture effectiveness evaluation and reservoir quality classification based on electrical imaging data: A case study of Cretaceous in Yaerxia Oilfield. Lithol. Reserv. 2019, 31, 102–108. [Google Scholar]

- Tan, L.H.; Zhang, G.Q.; Tan, Z.J.; Zhang, G.; Zhang, C.; Cai, M. Evaluation of metamorphic reservoir effectiveness by array acoustic logging data. Oil Geophys. Prospect. 2022, 57, 1464–1472+1263. [Google Scholar]

- Zhang, G.Q. Effectiveness evaluation of buried hill reservoirs based on acoustic amplitude quantification. Oil Geophys. Prospect. 2023, 58, 206–213+227. [Google Scholar]

- Tong, K.J.; Zhao, C.M.; Lyu, Z.B.; Zhang, Y.; Zheng, H.; Xu, S.; Wang, J.; Pan, L. Reservoir evaluation and fracture characterization of the metamorphic buried hill reservoir in Bohai Bay. Pet. Explor. Dev. 2012, 39, 56–63. [Google Scholar] [CrossRef]

- Wanniarachchi, W.A.M.; Ranjith, P.G.; Perera, M.S.A.; Rathnaweera, T.D.; Zhang, C.; Zhang, D.C. An integrated approach to simulate fracture permeability and flow characteristics using regenerated rock fracture from 3-D scanning: A numerical study. J. Nat. Gas Sci. Eng. 2018, 53, 249–262. [Google Scholar] [CrossRef]

- Chen, Y.B.; Zhang, C.G.; Cai, M.; Zhang, Z.T. Calculation model and application of fracture permeability based on Stoneley wave. Fault-Block Oil Filed 2022, 29, 609–613+640. [Google Scholar]

- Tang, J.; Zhang, C.G.; Cai, D.Y. Effectiveness evaluation of tight sandstone reservoir based on Stoneley wave characteristic parameters. J. Oil Gas Technol. 2013, 35, 79–85. [Google Scholar]

- Sibbit, A.M.; Faivre, O. The dual laterolog response in fractured rocks. In Proceedings of the SPWLA 26th Annual Logging Symposium, Dallas, TX, USA, 17–20 June 1985. [Google Scholar]

- Shang, S.G.; Gao, K.C.; Gao, Q.Y.; Ma, J.X.; Wangm, P.C. Influence of fracture development on seepage characteristics of low-porosity rocks. Sci. Technol. Eng. 2023, 23, 9809–9819. [Google Scholar]

- Cui, Y.; Wang, Z.; Xu, F.; Han, R.; Qi, X. Analysis of Fracture Formation Characteristics of Igneous Rock Based on Stoneley Wave and Electrical Imaging Logging. J. Jilin Univ. (Earth Sci. Ed.) 2022, 52, 624–632. [Google Scholar]

| Productivity Coefficient | Effectiveness Index | Permeability Index | |

|---|---|---|---|

| high-yield well | >100 | <0.5 | <0.4 |

| Middle-yield well | 10–100 | 0.5–0.7 | 0.4–0.7 |

| Low-yield well | <10 | >0.7 | >0.7 |

| Well Name | Difference in Deep and Shallow Resistivity | Fracture Density 1/m | Fracture Length m/m2 | Shear Wave Amplitude Ratio | Effectiveness Index | Productivity Coefficient |

|---|---|---|---|---|---|---|

| B well | 2.87 | 0.78 | 1.83 | 0.47 | <0.5 | 219.3 |

| D well | 2.49 | 0.49 | 1.64 | 0.65 | 0.5–0.7 | 58.2 |

| E well | 2.17 | 0.34 | 1.18 | 0.82 | >0.7 | 2.8 |

| Well Name | Productivity Coefficient | Effectiveness Index | Permeability Index | Angle ° | Percentage of Unfilled Fractures % |

|---|---|---|---|---|---|

| B well | 219.3 | <0.5 | <0.4 | 0 | 45 |

| D well | 58.2 | 0.5–0.7 | 0.4–0.7 | <30 | 33 |

| E well | 2.8 | >0.7 | >0.7 | >30 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, H.; Chen, P. A New Approach of Well Productivity Evaluation for Fractured Buried Hill Gas Reservoirs Based on Imaging Logging Data. Appl. Sci. 2023, 13, 12328. https://doi.org/10.3390/app132212328

Bi H, Chen P. A New Approach of Well Productivity Evaluation for Fractured Buried Hill Gas Reservoirs Based on Imaging Logging Data. Applied Sciences. 2023; 13(22):12328. https://doi.org/10.3390/app132212328

Chicago/Turabian StyleBi, Hongri, and Peng Chen. 2023. "A New Approach of Well Productivity Evaluation for Fractured Buried Hill Gas Reservoirs Based on Imaging Logging Data" Applied Sciences 13, no. 22: 12328. https://doi.org/10.3390/app132212328

APA StyleBi, H., & Chen, P. (2023). A New Approach of Well Productivity Evaluation for Fractured Buried Hill Gas Reservoirs Based on Imaging Logging Data. Applied Sciences, 13(22), 12328. https://doi.org/10.3390/app132212328