High-Frequency Harmonic Suppression Strategy and Modified Notch Filter-Based Active Damping for Low-Inductance HPMSM

Abstract

:1. Introduction

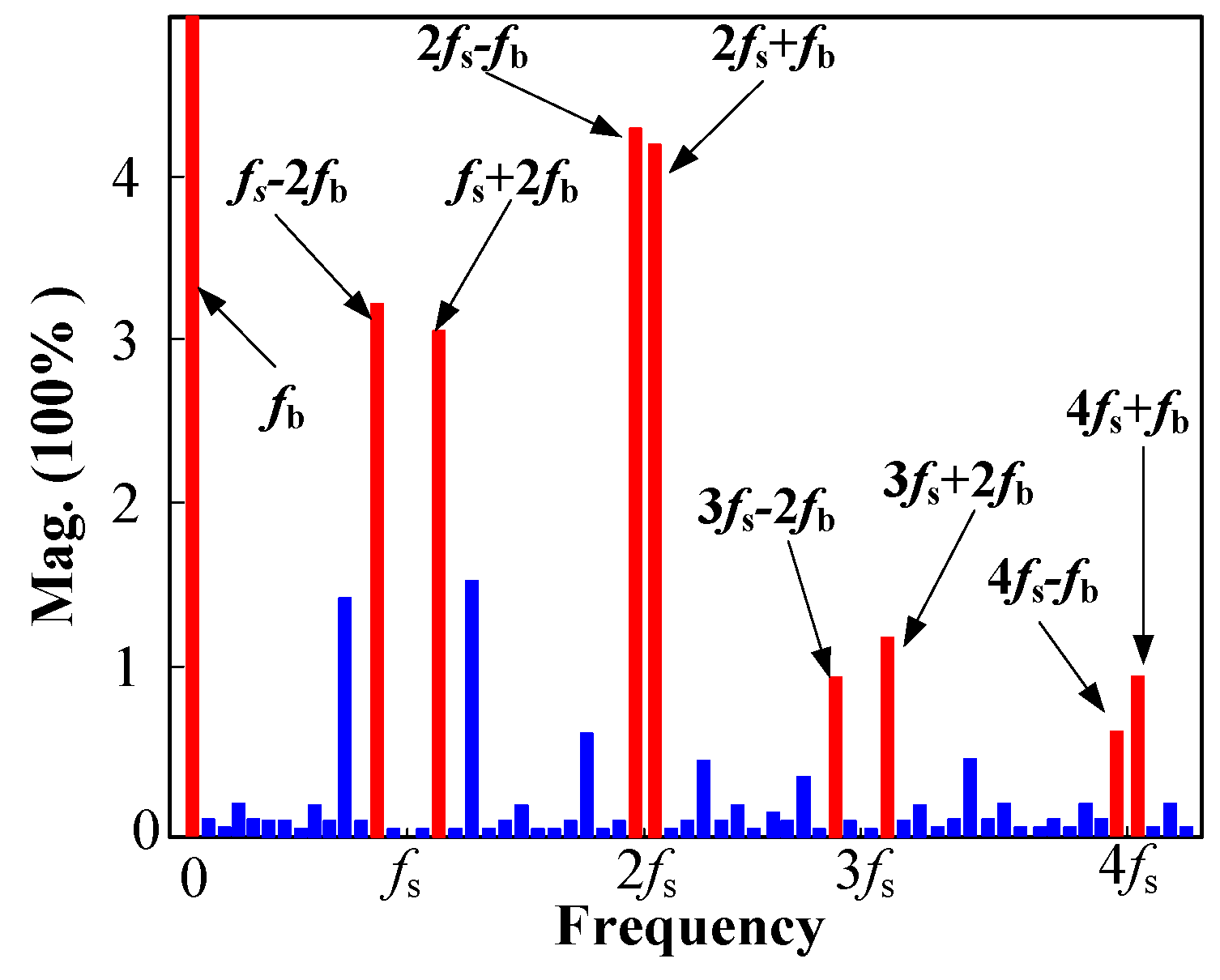

2. High-Frequency Current Harmonics Analysis of HPMSM

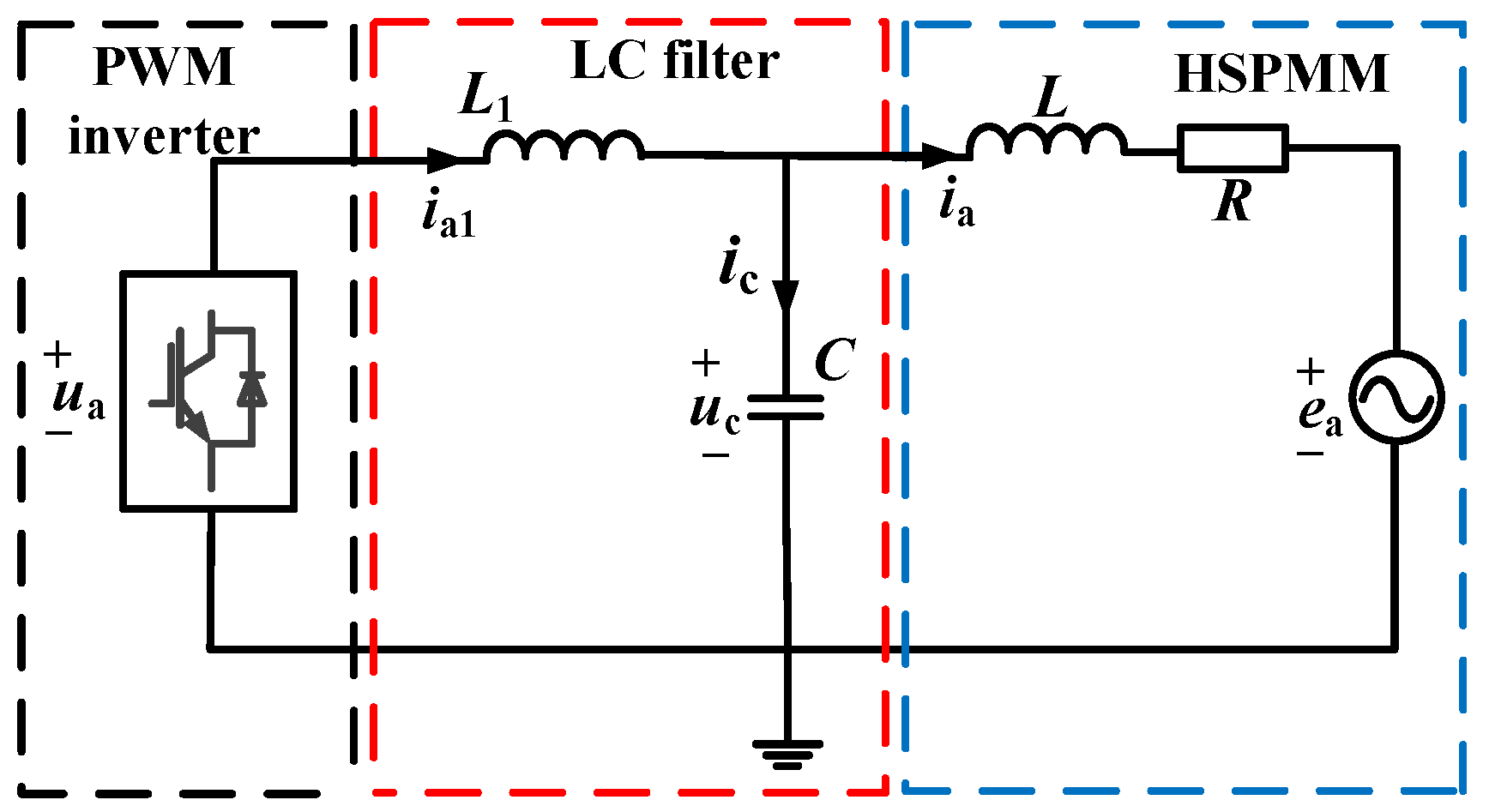

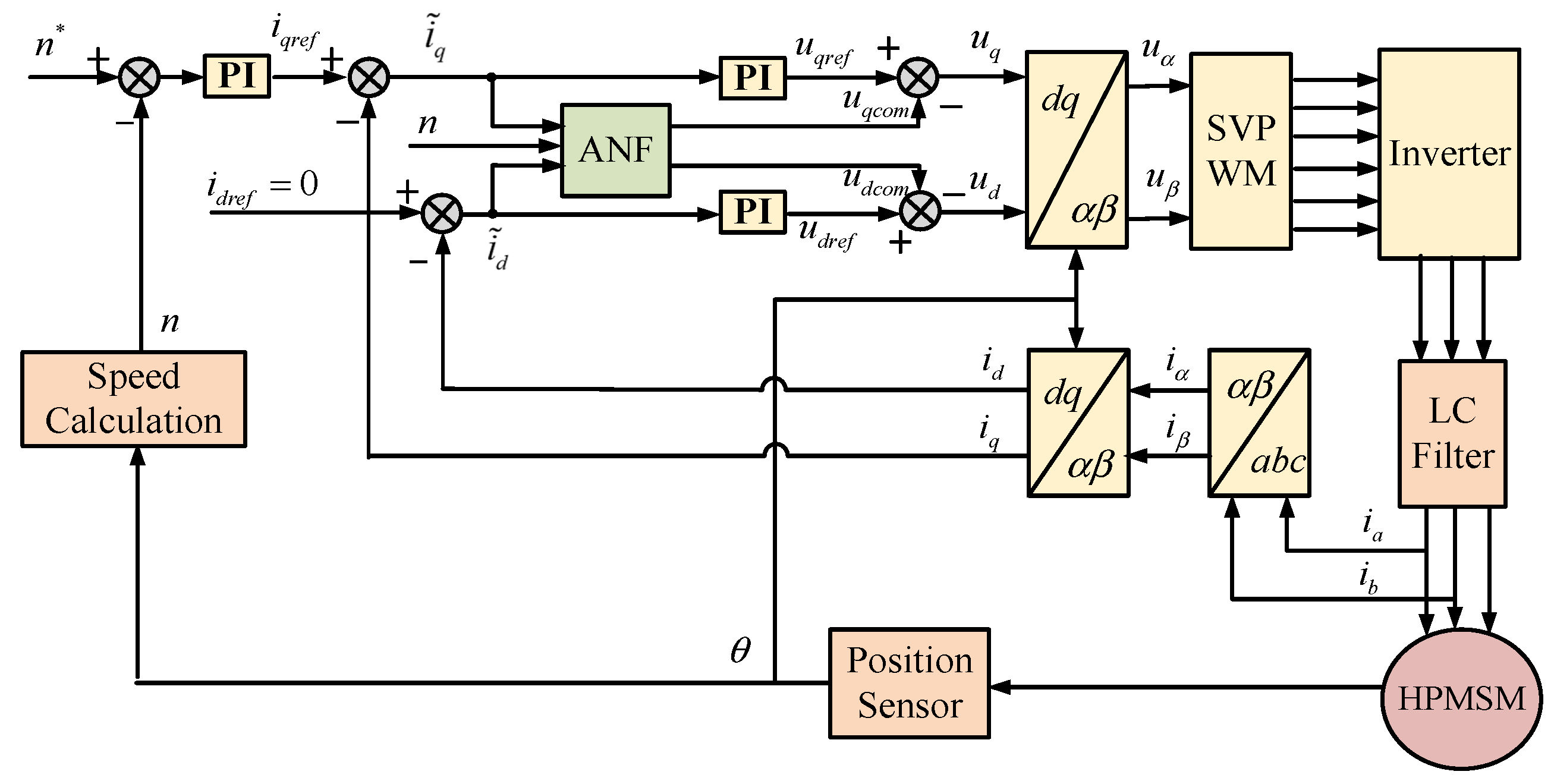

3. HPMSM System with Output LC Filter

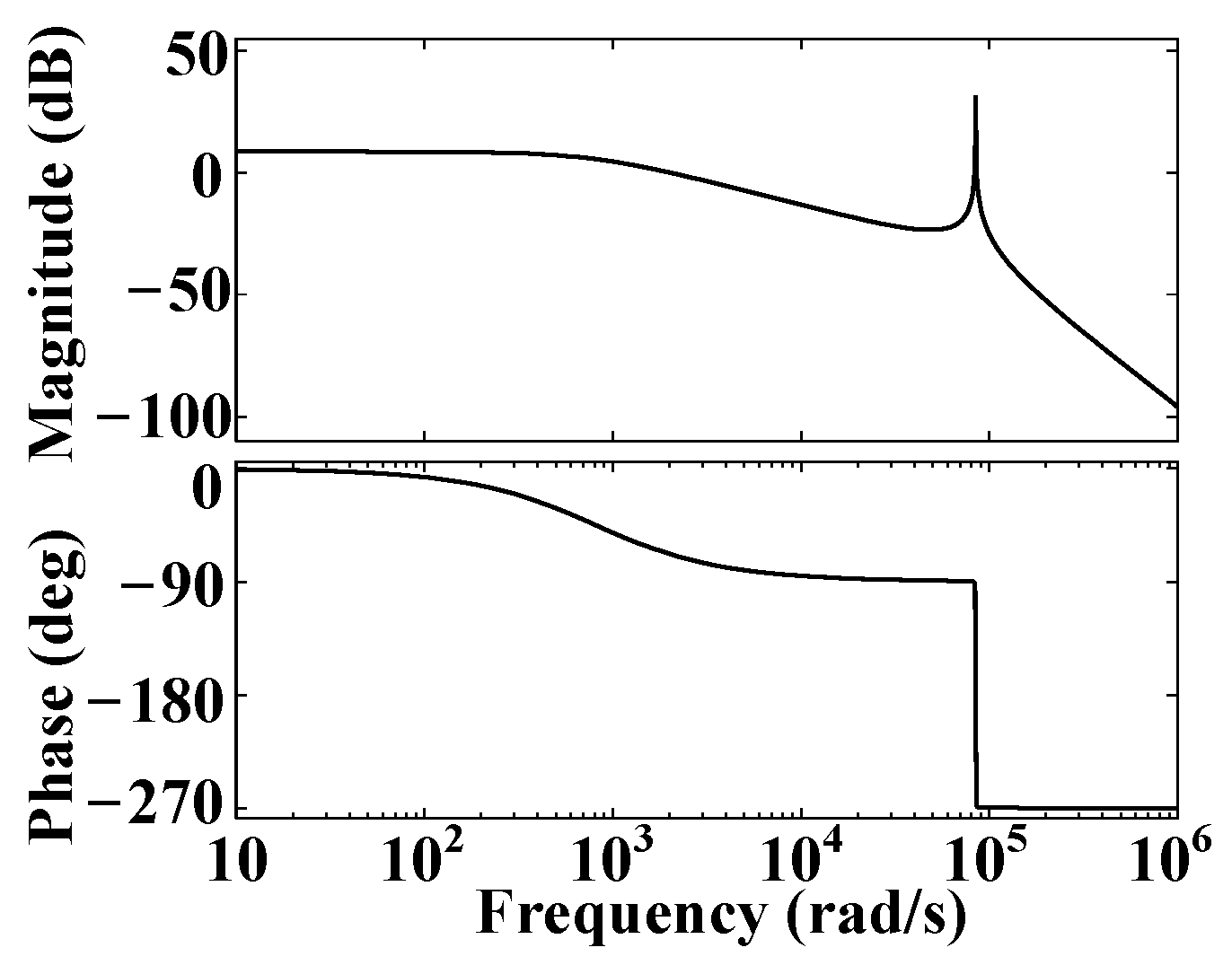

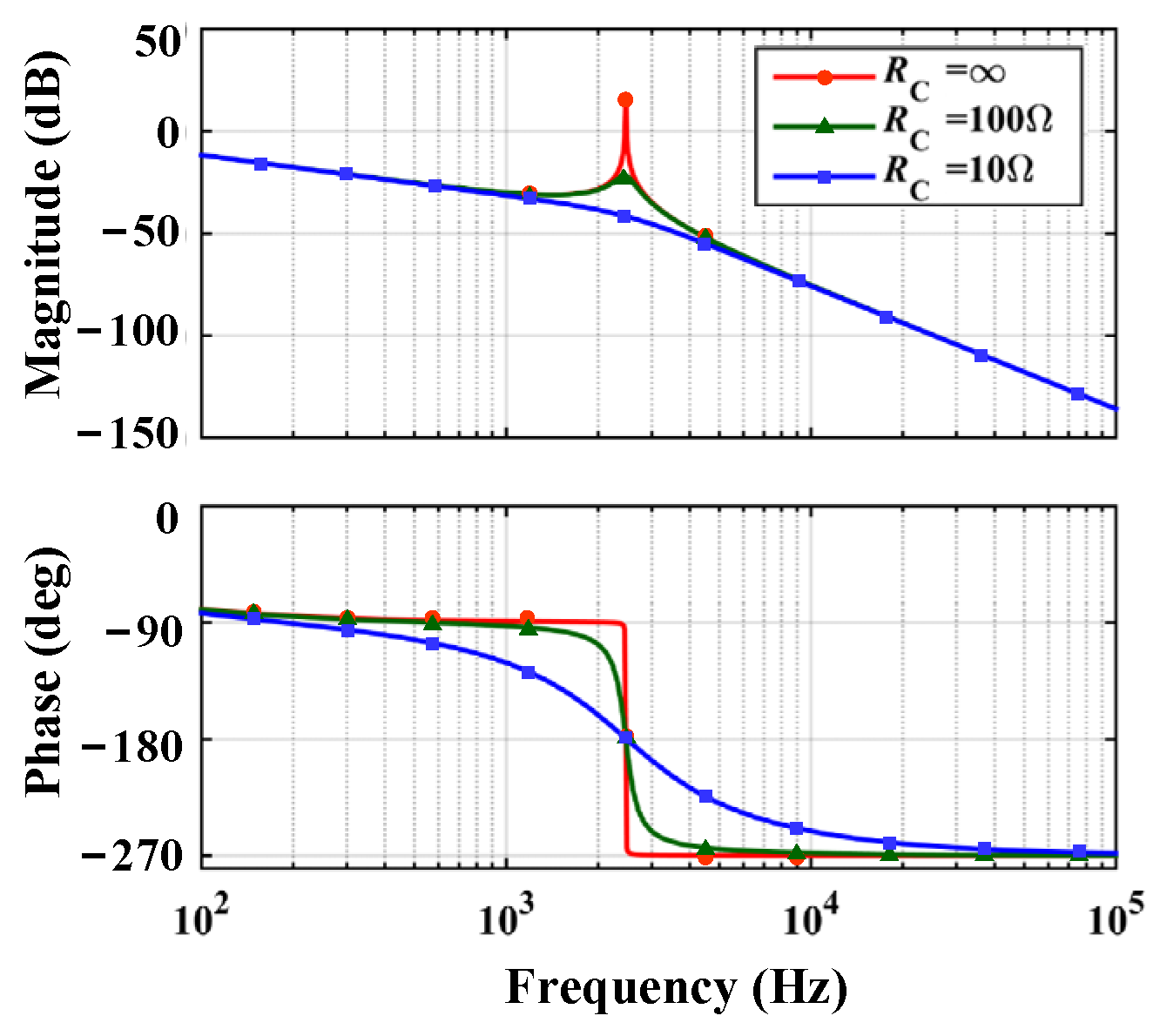

3.1. Passive Damping Method

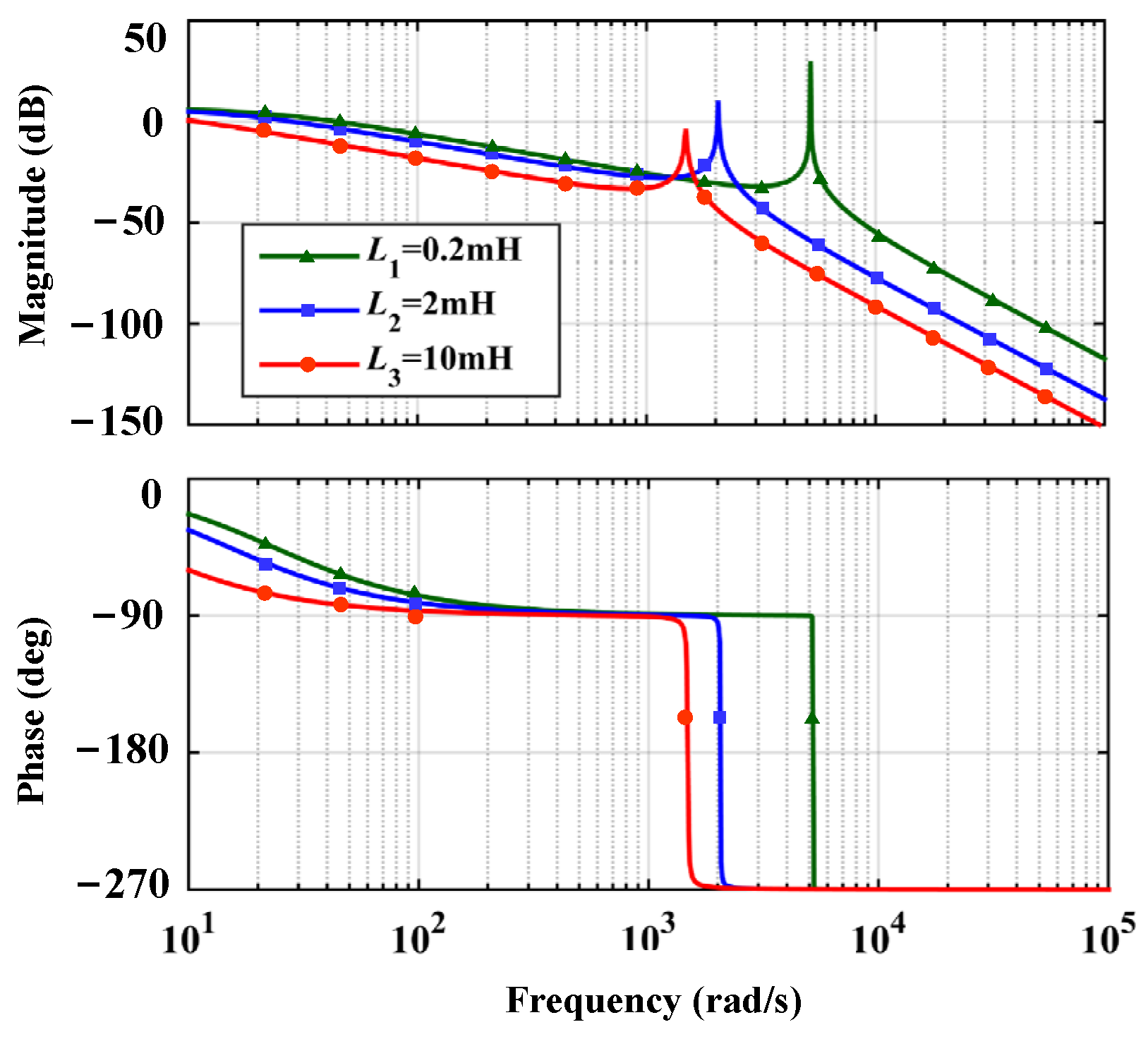

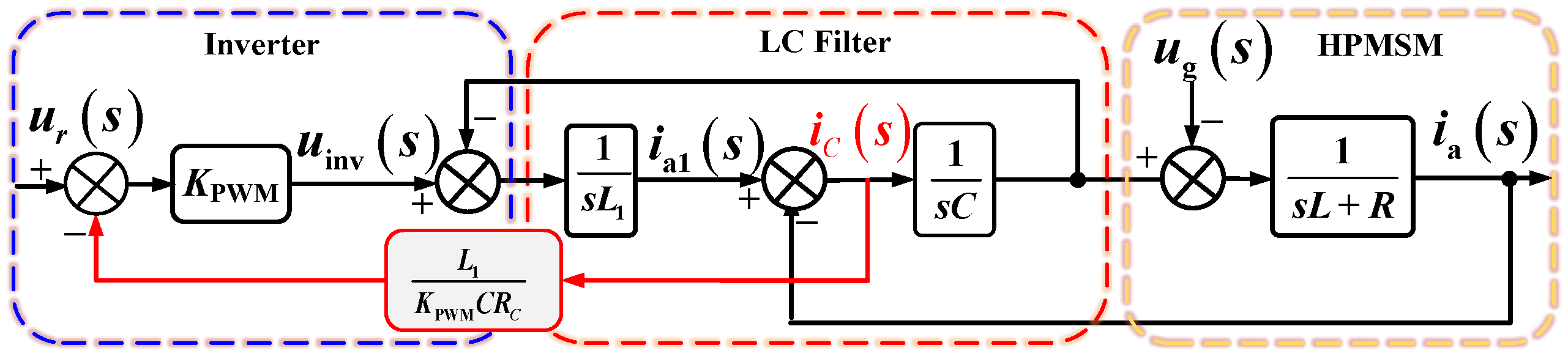

3.2. Traditional Active Damping Methods

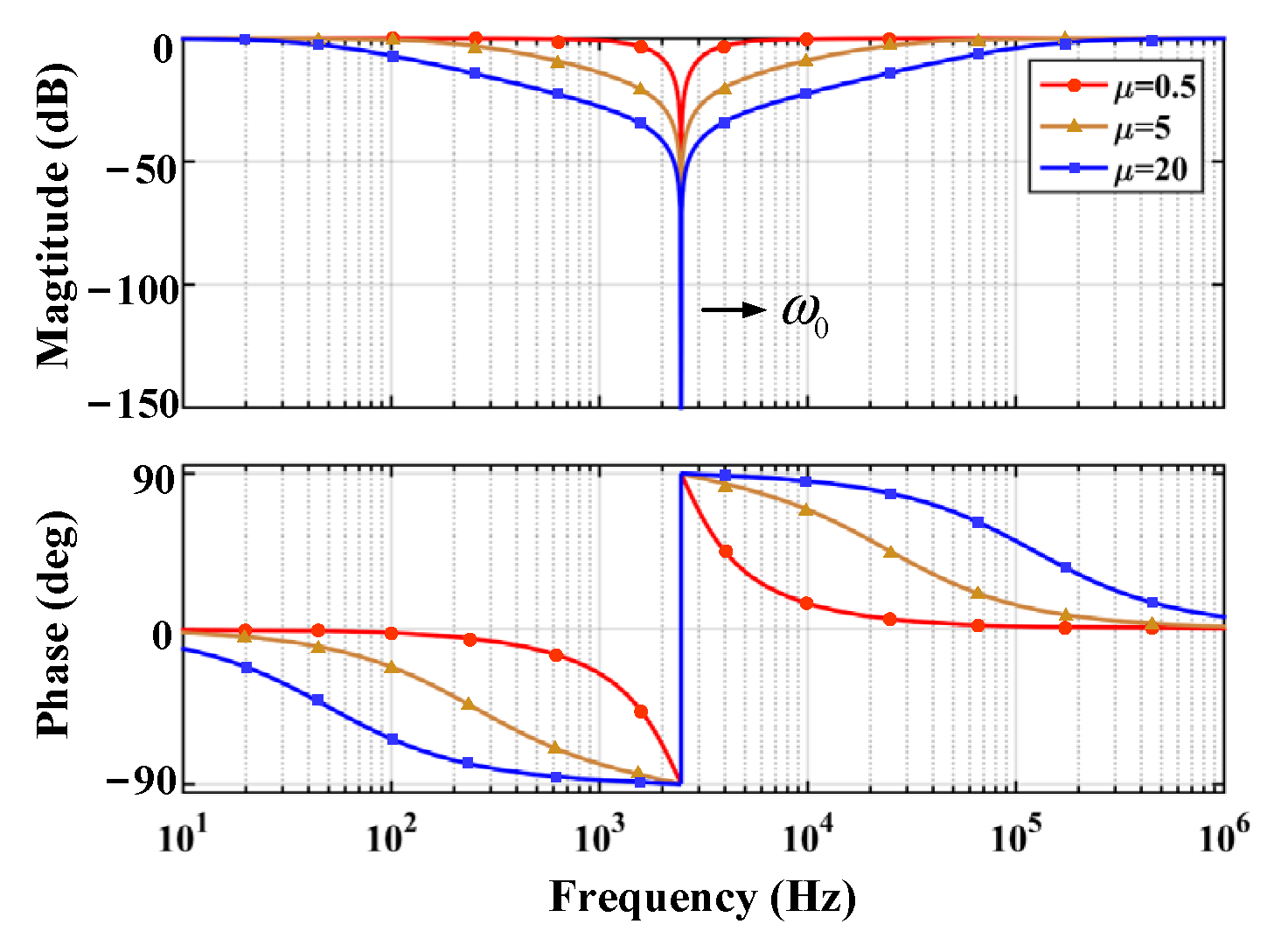

4. ANF Based Active Damping

4.1. ANF

4.2. Design of ANF with Frequency Adaption

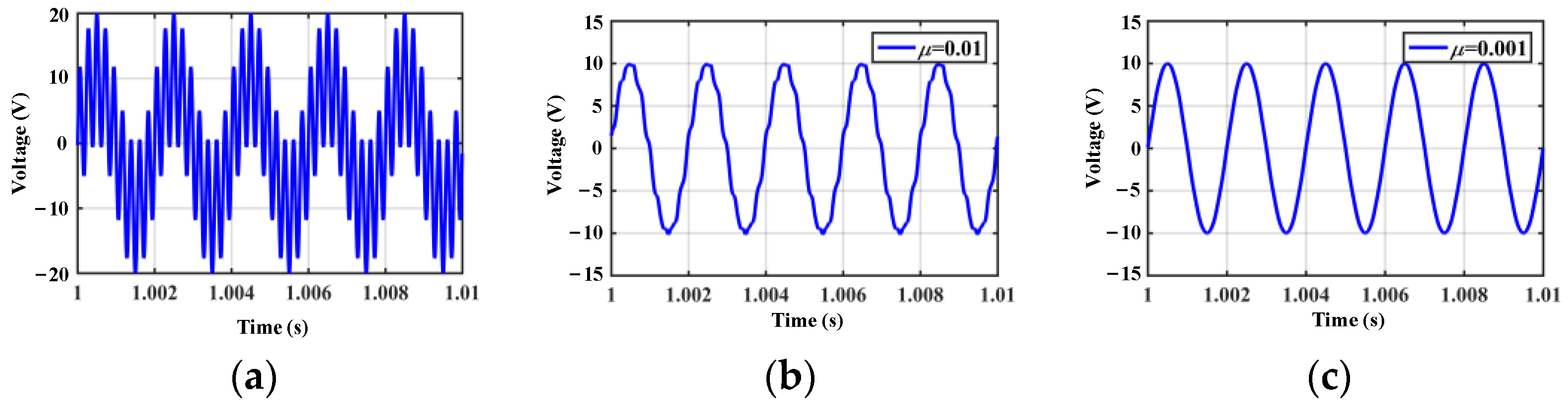

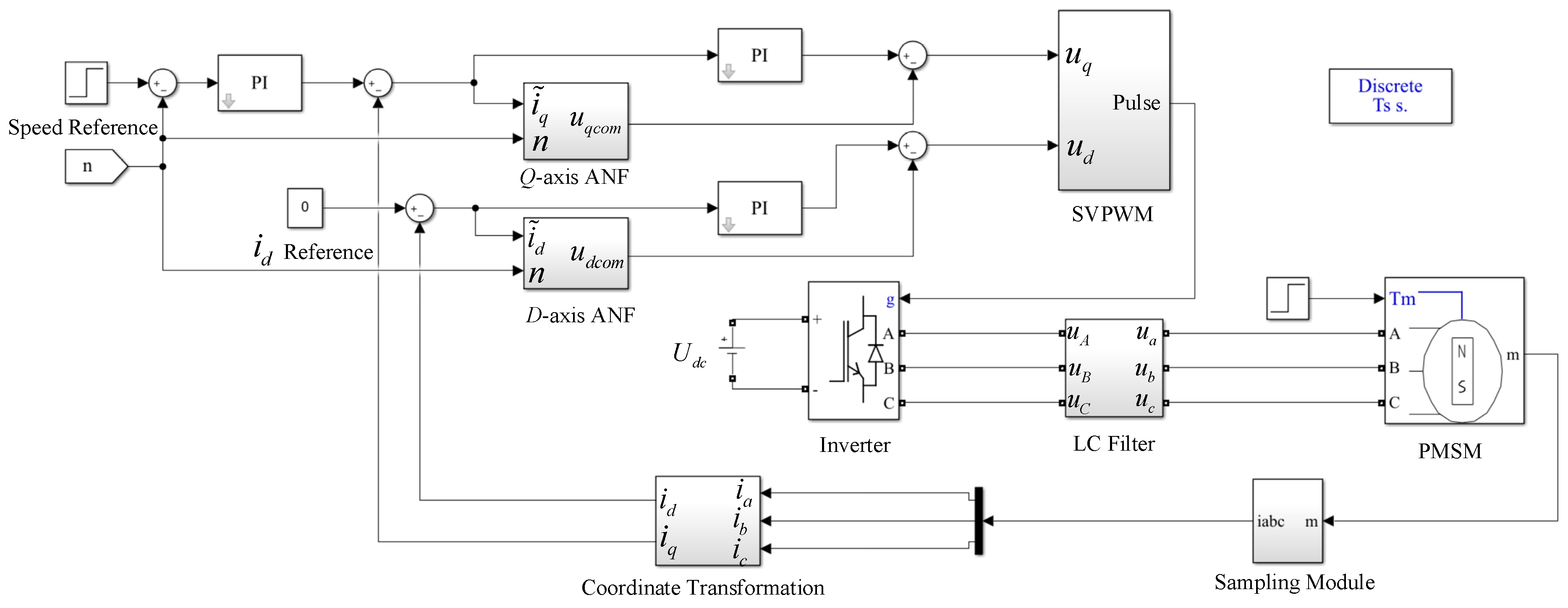

5. Simulation Analysis

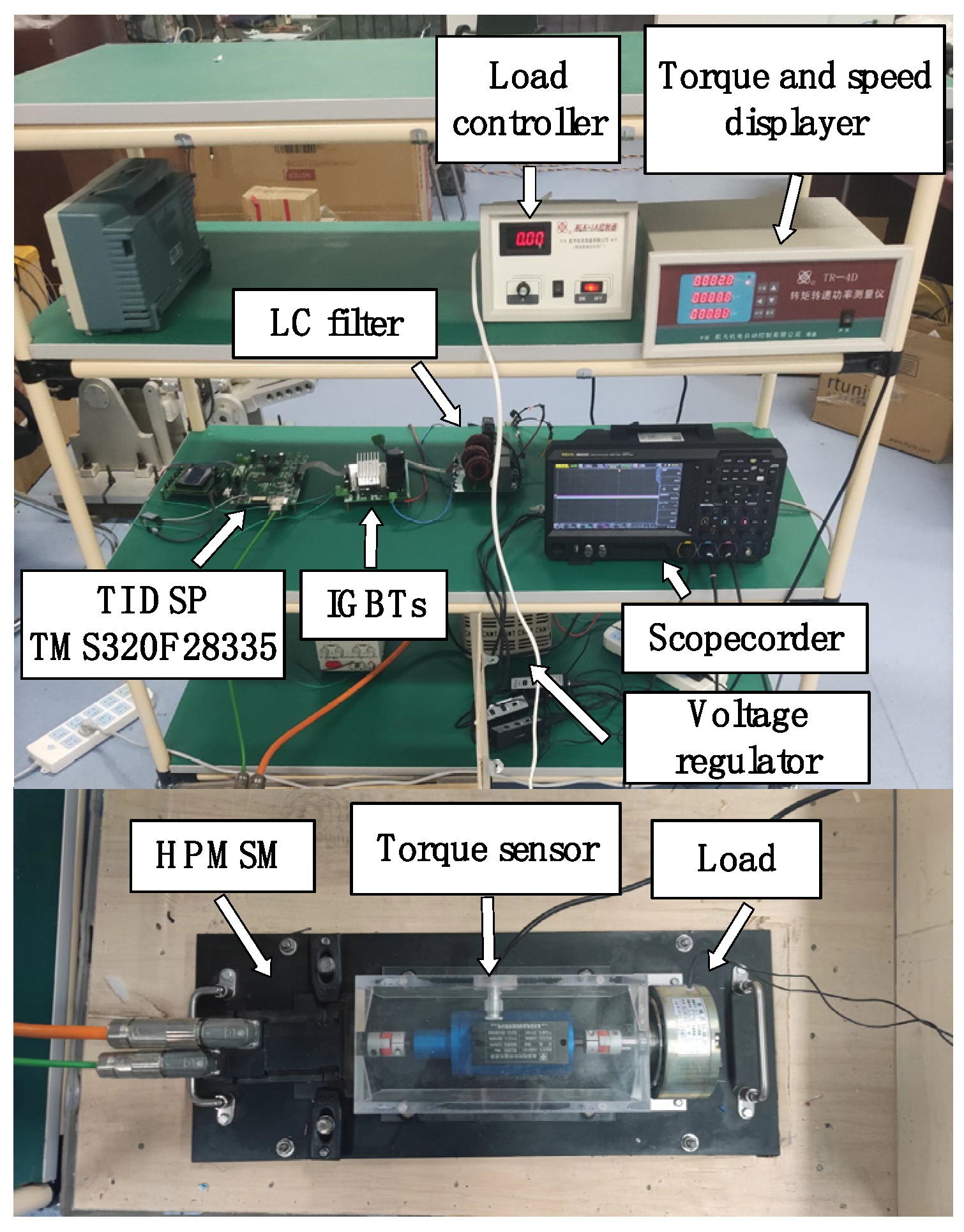

6. Experimental Verification

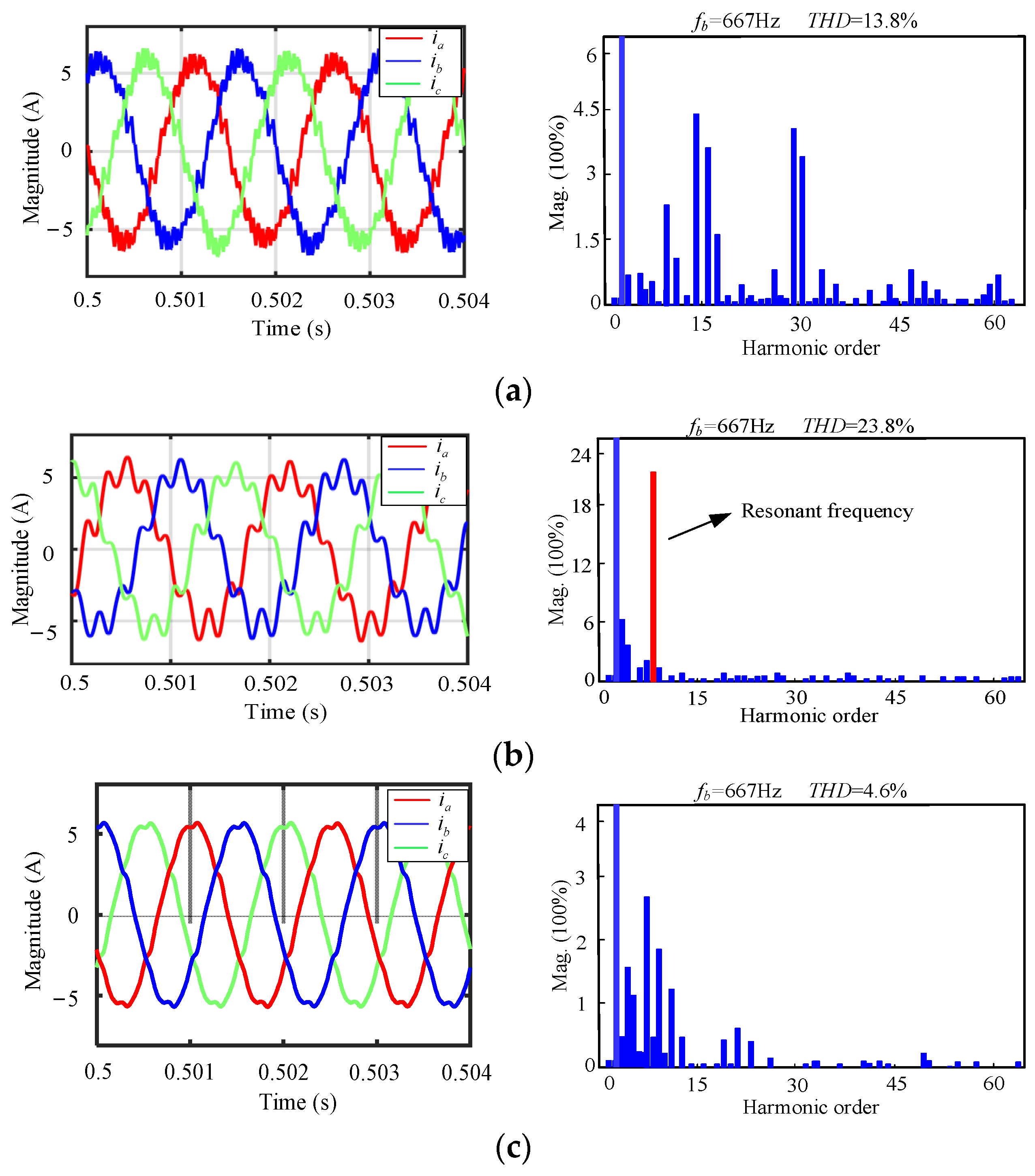

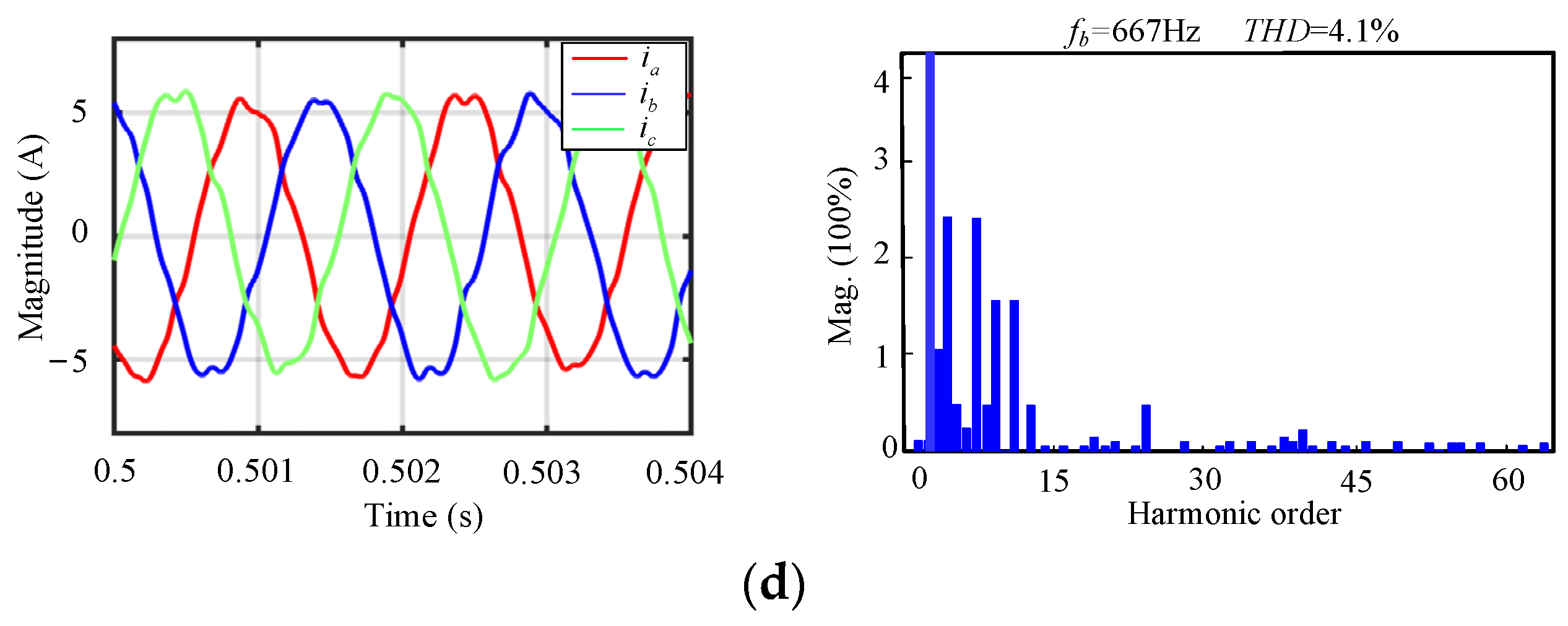

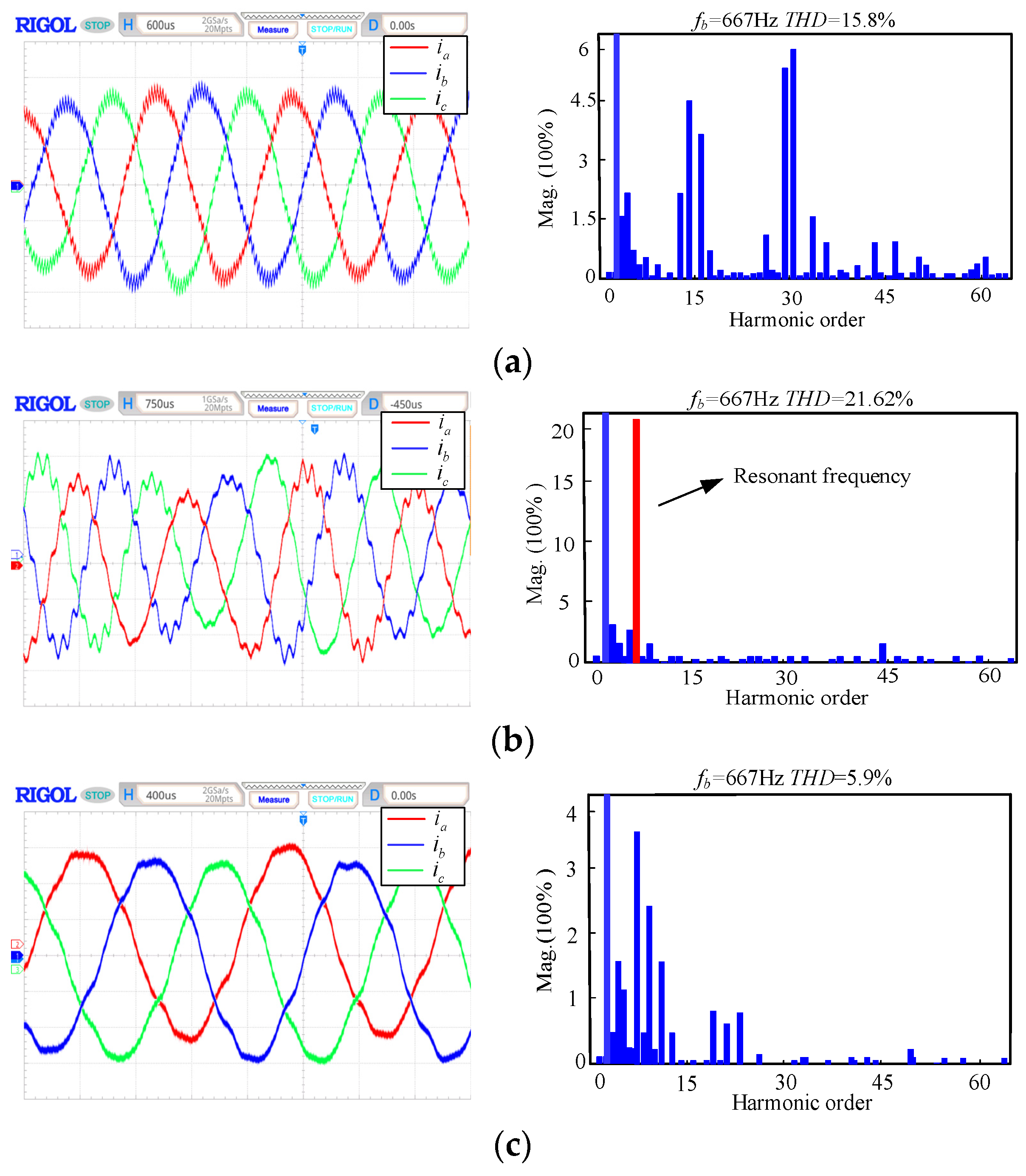

6.1. Harmonic Suppression Performance Tests

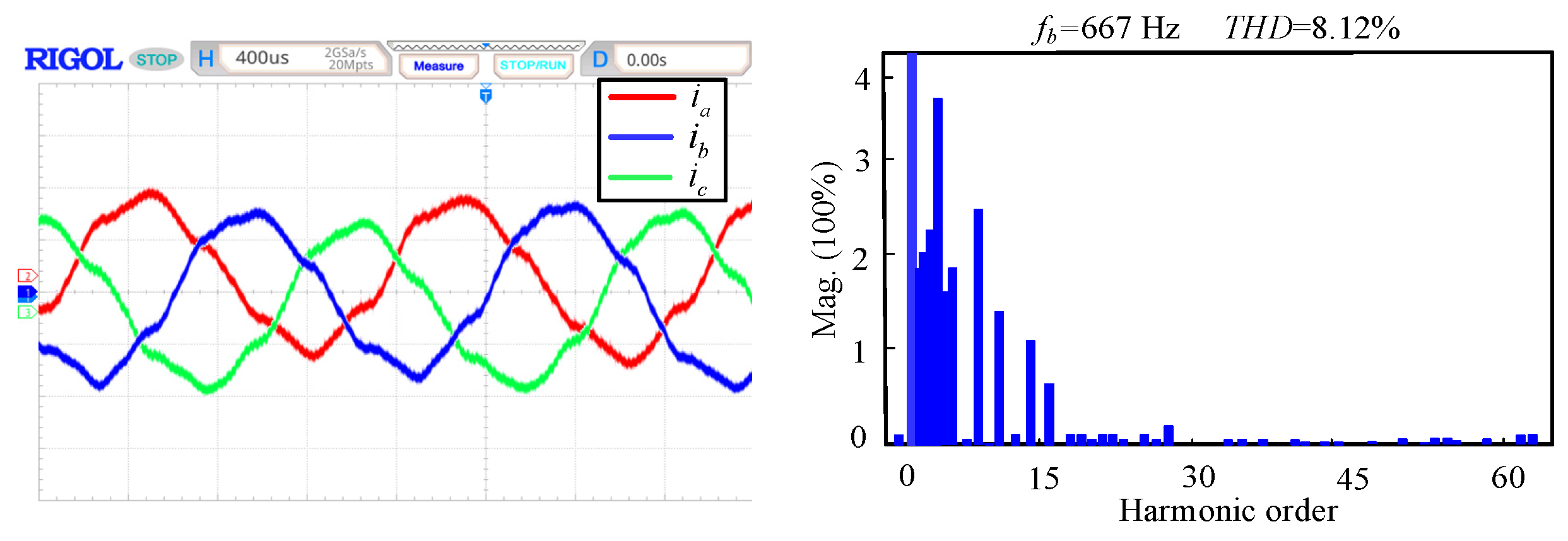

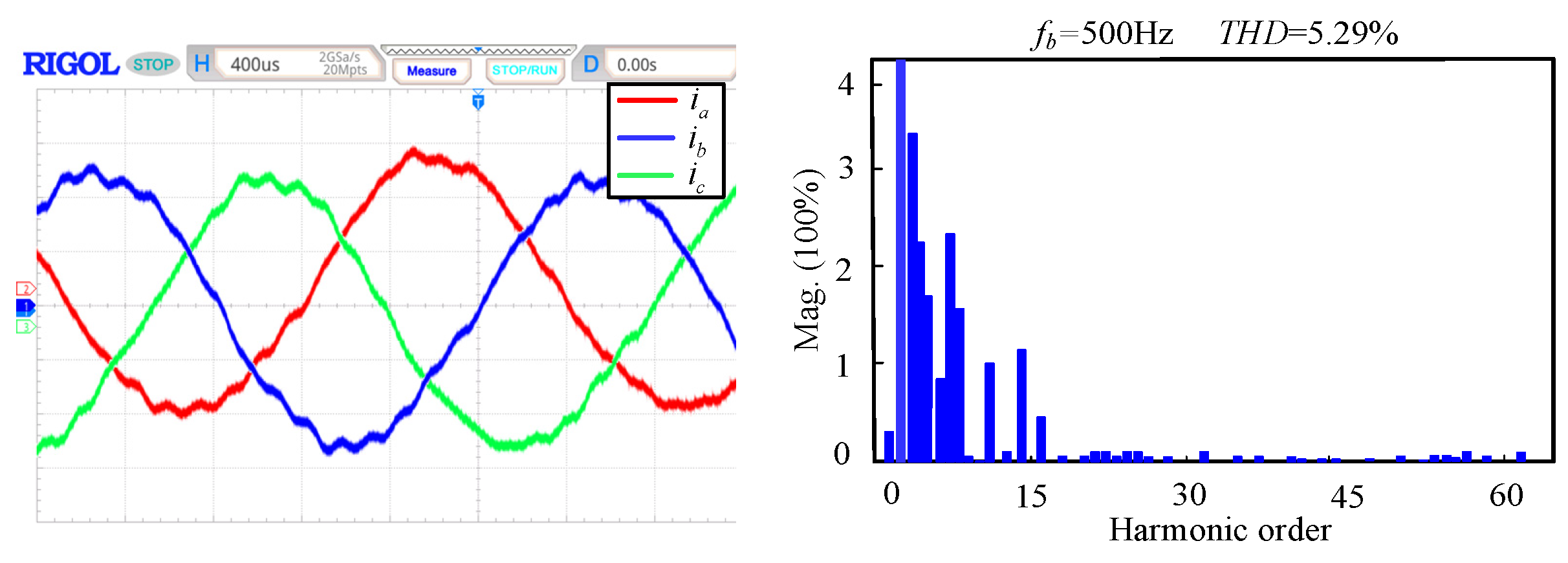

6.2. Frequency Adaptive Performance Tests

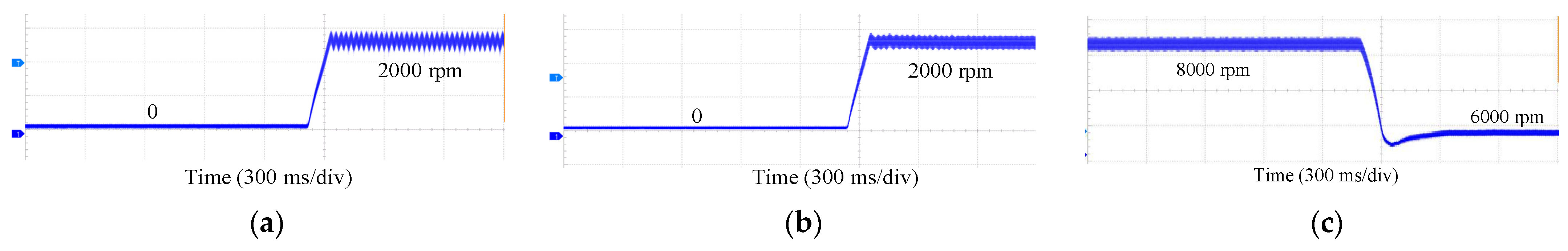

6.3. Speed Regulation Performance Tests

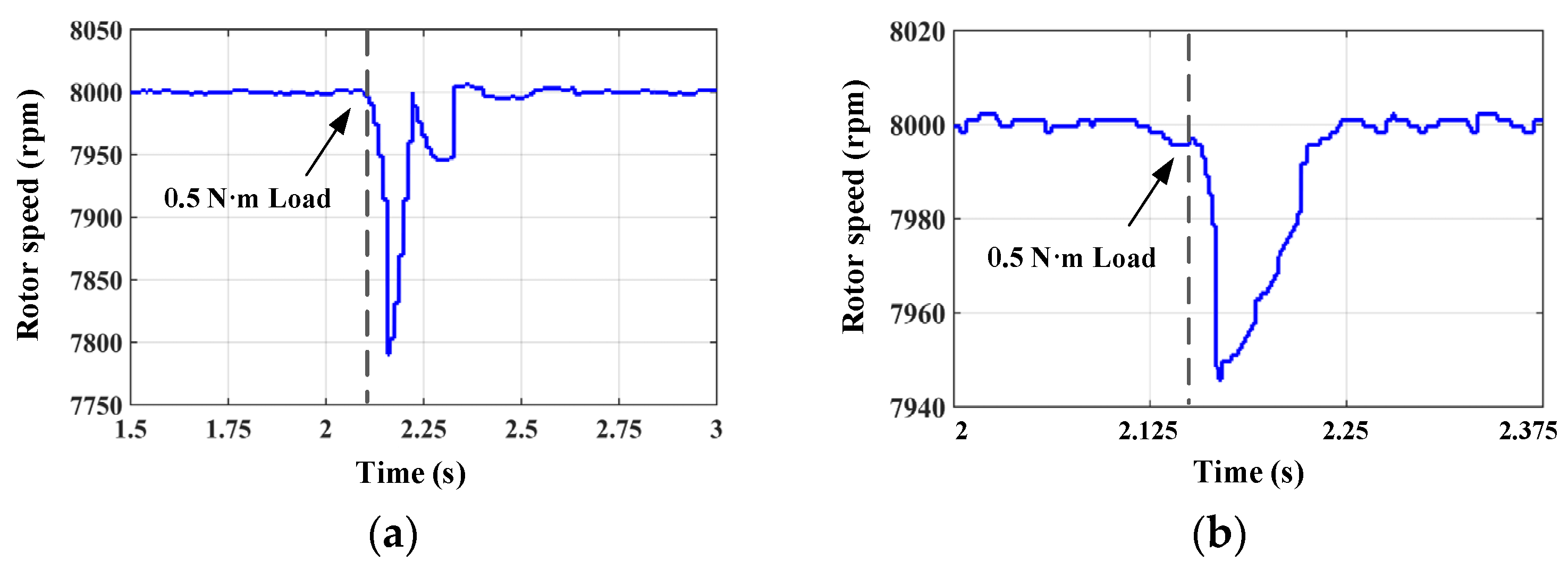

6.4. Load Disturbance Tests

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Choi, H.H.; Yun, H.M.; Kim, Y. Implementation of evolutionary fuzzy PID speed controller for PM synchronous motor. IEEE Trans. Ind. Informat. 2015, 11, 540–547. [Google Scholar] [CrossRef]

- Feng, G.; Lai, C.; Kar, N.C. Expectation-maximization particle-fifilter- and Kalman-fifilter-based permanent magnet temperature estimation for PMSM condition monitoring using high-frequency signal injection. IEEE Trans. Ind. Informat. 2017, 13, 1261–1270. [Google Scholar] [CrossRef]

- Liu, K.; Feng, J.; Guo, S.; Xiao, L.; Zhu, Z. Identifification of flflux linkage map of permanent magnet synchronous machines under uncertain circuit resistance and inverter nonlinearity. IEEE Trans. Ind. Informat. 2018, 14, 556–568. [Google Scholar] [CrossRef]

- Jing, R.; Ding, D.; Zhang, G.; Wang, Q.; Wang, G.; Xu, D. Active-Damping-Based Field-Weakening Control Strategy with Voltage Angle Regulation for High-Speed SPMSM Drive. IEEE Trans. Ind. Electron. 2024, 71, 1421–1431. [Google Scholar] [CrossRef]

- Dai, S.; Wang, J.B.; Sun, Z.; Chong, E. Transient performance improvement of deadbeat predictive current control of high-speed surface-mounted PMSM drives by online inductance identification. IEEE Trans. Ind. Electron. 2022, 69, 12358–12368. [Google Scholar] [CrossRef]

- Woo, J.-H.; Bang, T.-K.; Lee, H.-K.; Kim, K.-H.; Shin, S.-H.; Choi, J.-Y. Electromagnetic Characteristic Analysis of High-Speed Motors with Rare-Earth and Ferrite Permanent Magnets Considering Current Harmonics. IEEE Trans. Magn. 2021, 57, 20287784. [Google Scholar] [CrossRef]

- Gu, C.; Wang, X.; Deng, Z. Evaluation of Three Improved Space-Vector-Modulation Strategies for the High-Speed Permanent Magnet Motor Fed by a SiC/Si Hybrid Inverter. IEEE Trans. Power Electron. 2021, 36, 4399–4409. [Google Scholar] [CrossRef]

- Yaghoobi, J.; Zare, F.; Rathnayake, H. Current Harmonics Generated by Motor-Side Converter: New Standardizations. IEEE J. Emerg. Sel. Topics Power Electron. 2021, 9, 2868–2880. [Google Scholar] [CrossRef]

- Liang, W.; Wang, J.; Luk, P.C.-K.; Fang, W.; Fei, W. Analytical Modeling of Current Harmonic Components in PMSM Drive with Voltage-Source Inverter by SVPWM Technique. IEEE Trans. Energy Convers. 2014, 29, 673–680. [Google Scholar] [CrossRef]

- Millinger, J.; Wallmark, O.; Soulard, J. High-Frequency Characterization of Losses in Fully Assembled Stators of Slotless PM Motors. IEEE Trans. Ind. Appl. 2018, 54, 2265–2275. [Google Scholar] [CrossRef]

- Feng, G.D.; Lai, C.Y.; Kar, N.C. Practical testing solutions to optimal stator harmonic current design for PMSM torque ripple minimization using speed harmonics. IEEE Trans. Power Electron. 2018, 33, 5181–5191. [Google Scholar] [CrossRef]

- Zwyssig, C.; Duerr, M.; Hassler, D.; Kolar, J.W. An ultra-high-speed, 500,000 rpm, 1 kW electrical drive system. In Proceedings of the 2007 Power Conversion Conference, Nagoya, Japan, 2–5 April 2007; pp. 1577–1583. [Google Scholar]

- Wang, Z.; Chang, L. A DC voltage monitoring and control method for three-phase grid connected wind turbine inverters. IEEE Trans. Power Electron. 2008, 23, 1118–1125. [Google Scholar] [CrossRef]

- Liserre, M.; Blaabjerg, F.; Hansen, S. Design and control of an LCL-filter-based three-phase active rectifier. IEEE Trans. Ind. Appl. 2005, 41, 1281–1291. [Google Scholar] [CrossRef]

- Beres, R.N.; Wang, X.; Blaabjerg, F.; Liserre, M.; Bak, C.L. Optimal design of high-order passive-damped filters for grid-connected applications. IEEE Trans. Power Electron. 2016, 31, 2083–2098. [Google Scholar] [CrossRef]

- Wang, T.C.Y.; Ye, Z.; Sinha, G.; Yuan, X. Output filter design for a grid-interconnected three-phase inverter. In Proceedings of the IEEE 34th Annual Conference on Power Electronics Specialist, Acapulco, Mexico, 15–19 June 2003; Volume 2, pp. 779–784. [Google Scholar]

- Rockhill, A.A.; Liserre, M.; Teodorescu, R.; Rodriguez, P. Grid-filter design for a multimegawatt medium-voltage voltage-source inverter. IEEE Trans. Ind. Electron. 2011, 58, 1205–1217. [Google Scholar] [CrossRef]

- Tang, W.; Ma, K. Yubo Song Critical Damping Ratio to Ensure Design Efficiency and Stability of LCL Filters. IEEE Trans. Power Electron. 2021, 36, 315–325. [Google Scholar] [CrossRef]

- Peña-Alzola, R.; Liserre, M.; Blaabjerg, F.; Sebastián, R.; Dannehl, J.; Fuchs, F.W. Analysis of the passive damping losses in LCL-filter-based grid converters. IEEE Trans. Power Electron. 2013, 28, 2642–2646. [Google Scholar] [CrossRef]

- Li, S.; Lin, H. A Capacitor-Current-Feedback Positive Active Damping Control Strategy for LCL-Type Grid-Connected Inverter to Achieve High Robustness. IEEE Trans. Power Electron. 2022, 37, 6462–6474. [Google Scholar] [CrossRef]

- Wang, X.; Blaabjerg, F.; Loh, P. Virtual RC Damping of LCL Filtered Voltage Source Converters with Extended Selective Harmonic Compensation. IEEE Trans. Power Electron. 2015, 30, 4726–4737. [Google Scholar] [CrossRef]

- Blasko, V.; Kaura, V. A novel control to actively damp resonance in input LC filter of a three-phase voltage source converter. IEEE Trans. Ind. Appl. 1997, 33, 542–550. [Google Scholar] [CrossRef]

- Pena-Alzola, R.; Liserre, M.; Blaabjerg, F.; Sebastian, R.; Dannehl, J.; Fuchs, F.W. Systematic Design of the Lead-Lag Network Method for Active Damping in LCL-Filter Based Three Phase Converters. IEEE Trans. Ind. Inform. 2014, 10, 43–52. [Google Scholar] [CrossRef]

- Pena-Alzola, R.; Liserre, M.; Blaabjerg, F.; Ordonez, M.; Yang, Y. LCL-Filter Design for Robust Active Damping in Grid Connected Converters. IEEE Trans. Ind. Inform. 2014, 10, 2192–2203. [Google Scholar] [CrossRef]

- Dick, C.P.; Richter, S.; Rosekeit, M.; Rolink, J.; De Doncker, R.W. Active damping of LCL resonance with minimum sensor effort by means of a digital infinite impulse response filter. In Proceedings of the 2007 European Conference on Power Electronics and Applications, Aalborg, Denmark, 2–5 September 2007; pp. 1–8. [Google Scholar]

- Yang, L.; Yang, J.; Gao, M.; Chen, Y.; Zhang, X. A Systematic Approach via IIR Filters for Enhancing the Robustness of LCL-Type Shunt Active Power Filters to Grid Impedance. IEEE Trans. Ind. Appl. 2020, 56, 5095–5107. [Google Scholar] [CrossRef]

- Han, Y.; Li, Z.; Yang, P.; Wang, C.; Xu, L.; Guerrero, J.M. Analysis and Design of Improved Weighted Average Current Control Strategy for LCL-Type Grid-Connected Inverters. IEEE Trans. Energy Convers. 2017, 32, 941–952. [Google Scholar] [CrossRef]

- Liserre, M.; Dell’Aquilla, A.; Blaabjerg, F. Genetic algorithm based design of the active damping for a LCL-filter three-phase active rectifier. IEEE Trans. Power Electron. 2003, 19, 234–240. [Google Scholar]

- Dannehl, J.; Liserre, M.; Fuchs, F. Filter-based active damping of voltage source converters with LCL-filter. IEEE Trans. Ind. Electron. 2011, 58, 3623–3633. [Google Scholar] [CrossRef]

- Lyu, Z.; Wu, L. Resonant Frequency Deviation Analysis and Modified Notch Filter-Based Active Damping for SiC-Based PMSM Drive with Sine Wave Filter. IEEE Trans. Energy Convers. 2023, 38, 417–427. [Google Scholar] [CrossRef]

- Pillay, P.; Krishnan, R. Modeling, simulation, and analysis of permanent-magnet motor drives. I. The permanent-magnet synchronous motor drive. IEEE Trans. Ind. Appl. 1989, 25, 265–273. [Google Scholar] [CrossRef]

- Harnefors, L.; Pietilainen, K.; Gertmar, L. Torque-maximizing field-weakening control: Design, analysis, and parameter selection. IEEE Trans. Ind. Electron. 2001, 48, 161–168. [Google Scholar] [CrossRef]

- Lei, Y.; Jianqing, S.; Fei, X.; Chen, M.-L. Nonsingular terminal sliding-mode observer design for interior permanent magnet synchronous motor drive at very low-speed. Acta Phys. Sin. 2013, 62, 45–53. (In Chinese) [Google Scholar]

| Parameters | Symbol | Value |

|---|---|---|

| Power rating | Pn | 730 W |

| Pole pairs | Pn | 5 |

| Permanent magnetic linkage | 0.0509 Wb | |

| Rated speed | 10,000 rpm | |

| Rotor diameter | Dr | 28 mm |

| Stator resistance | Rb | 1.41 Ω |

| D-axis stator inductance | Ld | 0.8 mH |

| Q-axis stator inductance | Lq | 0.8 mH |

| Rotor inertia | J | 0.0005 kg·m2 |

| ANF step size | 0.02 | |

| Filter inductance | L1 | 0.3 mH |

| Filter capacitance | C | 4.7 F |

| Switching frequency | fs | 10 kHz |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Du, J.; Zhao, X.; Song, Y.; Wang, Y. High-Frequency Harmonic Suppression Strategy and Modified Notch Filter-Based Active Damping for Low-Inductance HPMSM. Appl. Sci. 2023, 13, 11309. https://doi.org/10.3390/app132011309

Liu Y, Du J, Zhao X, Song Y, Wang Y. High-Frequency Harmonic Suppression Strategy and Modified Notch Filter-Based Active Damping for Low-Inductance HPMSM. Applied Sciences. 2023; 13(20):11309. https://doi.org/10.3390/app132011309

Chicago/Turabian StyleLiu, Yifeng, Jinhua Du, Xiaodong Zhao, Yutong Song, and Yao Wang. 2023. "High-Frequency Harmonic Suppression Strategy and Modified Notch Filter-Based Active Damping for Low-Inductance HPMSM" Applied Sciences 13, no. 20: 11309. https://doi.org/10.3390/app132011309

APA StyleLiu, Y., Du, J., Zhao, X., Song, Y., & Wang, Y. (2023). High-Frequency Harmonic Suppression Strategy and Modified Notch Filter-Based Active Damping for Low-Inductance HPMSM. Applied Sciences, 13(20), 11309. https://doi.org/10.3390/app132011309