Gradation Influence on Crack Resistance of Stress-Absorbing Membrane Interlayer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Crumb-Rubber-Modified Asphalt

2.2. Aggregate

2.3. Asphalt Mixture

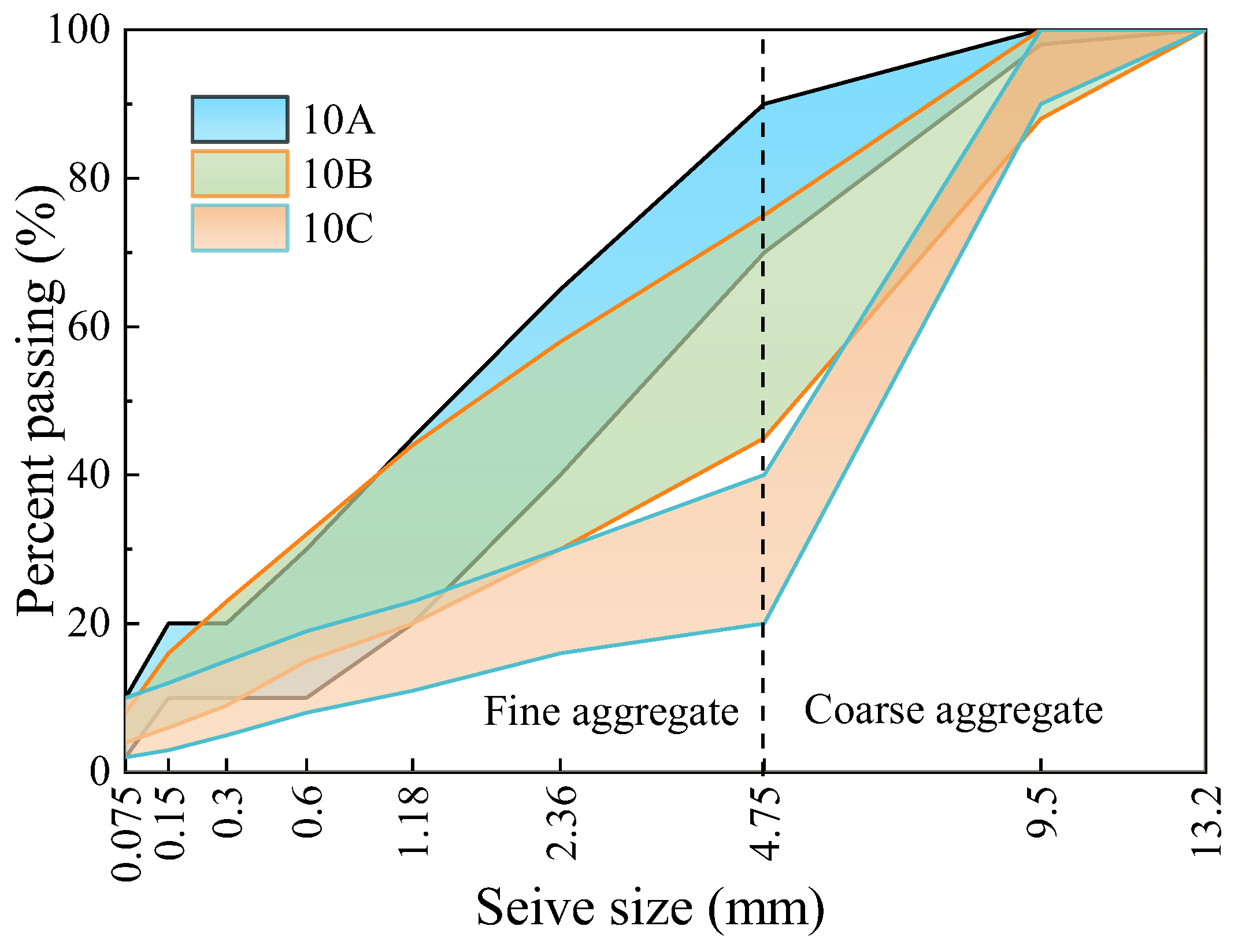

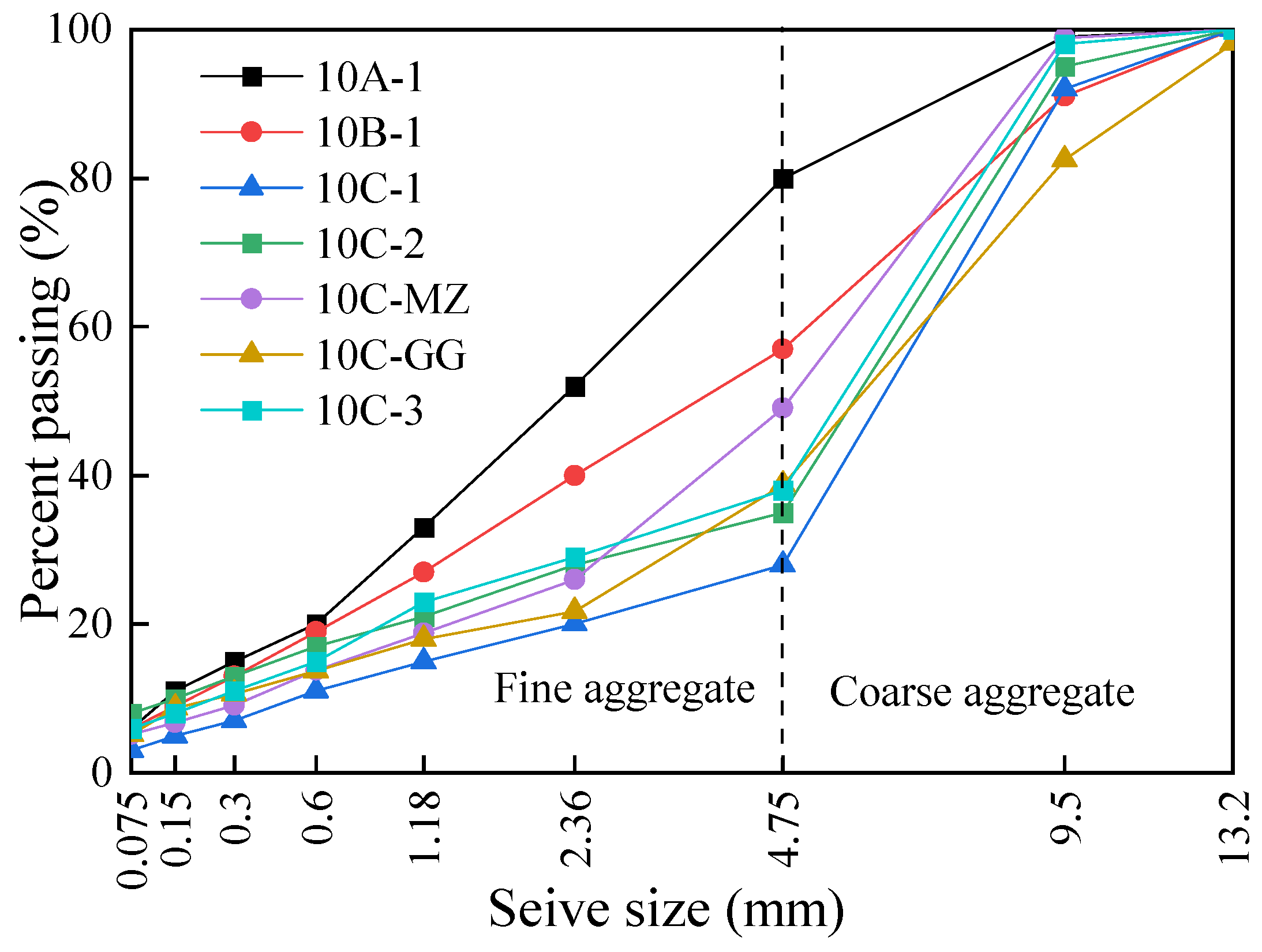

2.3.1. Gradation

- (a)

- Referring to the gradation range of CAM, it was named 10A, and one gradation was selected and named 10A-1.

- (b)

- Referring to the gradation range of JTG F40-2004 and DBJ/T13-147-2012, it was named 10B, and one gradation was selected and named 10B-1.

- (c)

- Referring to the gradation range of DB45/T 1098-2014 [32], DB 36/T 744-2013 [33], DG/TJ08-2109-2012 [34], DB11/T 916-2012 [35], DB13/T 1013-2009 [36], and DB14/T 160-2015 [37], it was named 10C, and three gradations were selected and named 10C-1, 10C-2, 10C-3. Referring to the specific engineering gradation of Minzu (MZ) Avenue and Guigang (GG) Expressway, two gradations were selected and named 10C-MZ and 10C-GG.

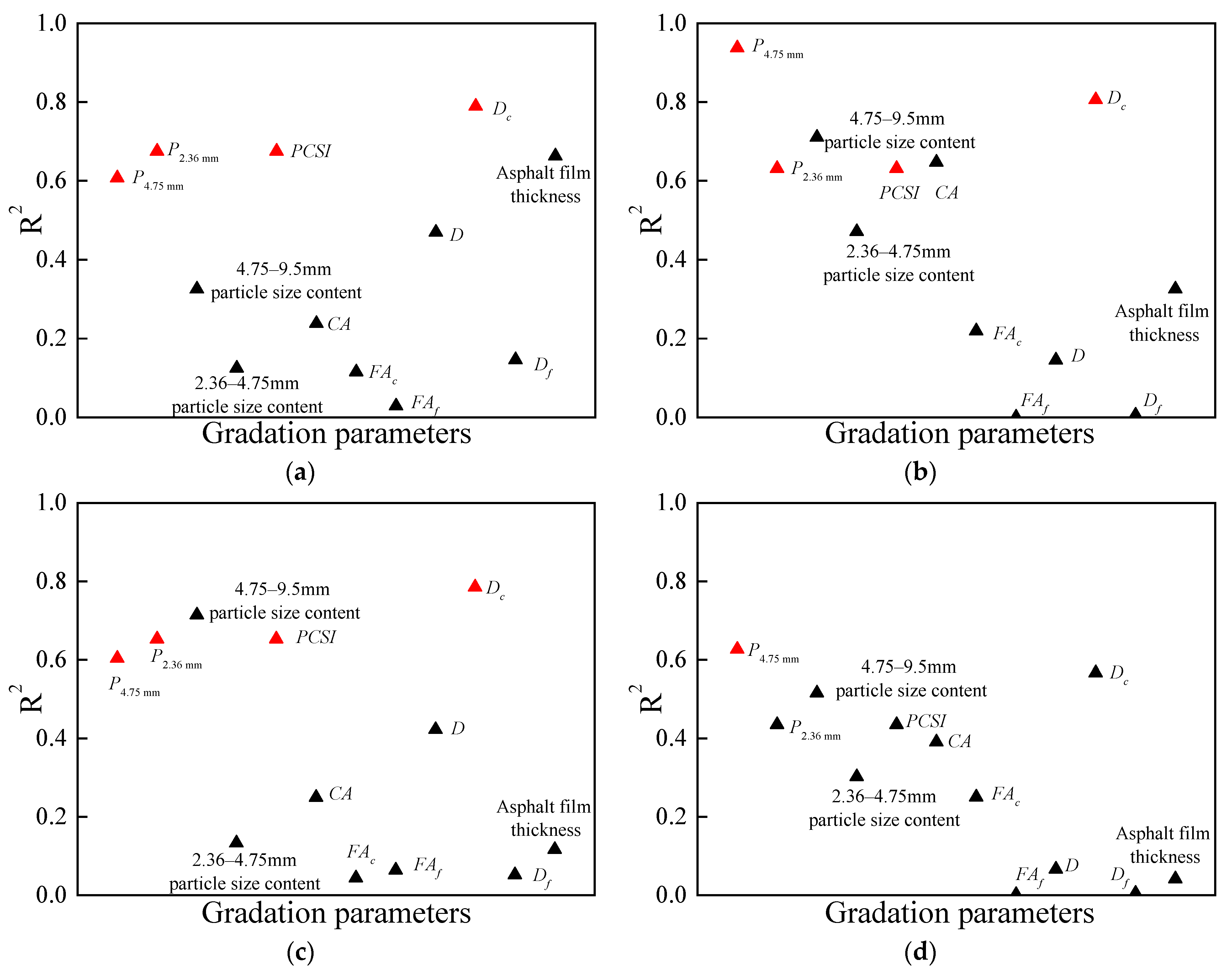

2.3.2. Gradation Evaluation Methods

- (a)

- Key sieve passing ratios. As shown in Figure 2, there is a large difference in the passing ratios at the 4.75 mm sieve among different gradations. According to JTG F40-2004 [28], the 10-type gradation uses the 2.36 mm sieve as the key sieve to distinguish between coarse and fine aggregates. The passing rates at the 4.75 mm and 2.36 mm sieves affect the voids in the mineral aggregate (VMA) and the air voids (VV) of the mixture, and VMA and VV affect the mixture properties. Therefore, P4.75mm and P2.36mm were selected as key sieve passing rates.

- (b)

- Key particle size aggregate content. The content of coarse aggregate above 2.36 mm affects the skeleton structure of the mixture and determines the initial voids in the mixture. Therefore, 4.75–9.5 mm and 2.36–4.75 mm were selected as key particle sizes.

- (c)

- The primary control sieve index (PCSI) [39]where PCSI is the difference in percentage passing between the given gradation and the point on the maximum density line at the primary control sieve; P is the passage ratio of the corresponding sieve, %; d is the maximum nominal particle size, mm; the primary control sieve (PCS) is 0.22 × d, mm; PPCS,MDL is the passage ratio of the maximum density curve at PCS, taken as 47%, %.

- (d)

- Parameters of the Bailey methodwhere CA is the coarse aggregate ratio; FAc is the fine aggregate coarse ratio; FAf is the fine aggregate fine ratio; the secondary control sieve (SCS) is 0.22 × PCS; the third control sieve (TCS) is 0.22 × TCS.

- (e)

- Fractal dimensionwhere D is the mass fractal dimension; k is the slope of the fitting line obtained by linear regression in the double logarithmic coordinates of the sieve size and the passing rate. When only the part above 2.36 mm or below is taken, the gradation fractal dimensions Dc and Df of coarse aggregate and fine aggregate can be calculated according to the fitting line, respectively.

2.4. Methods

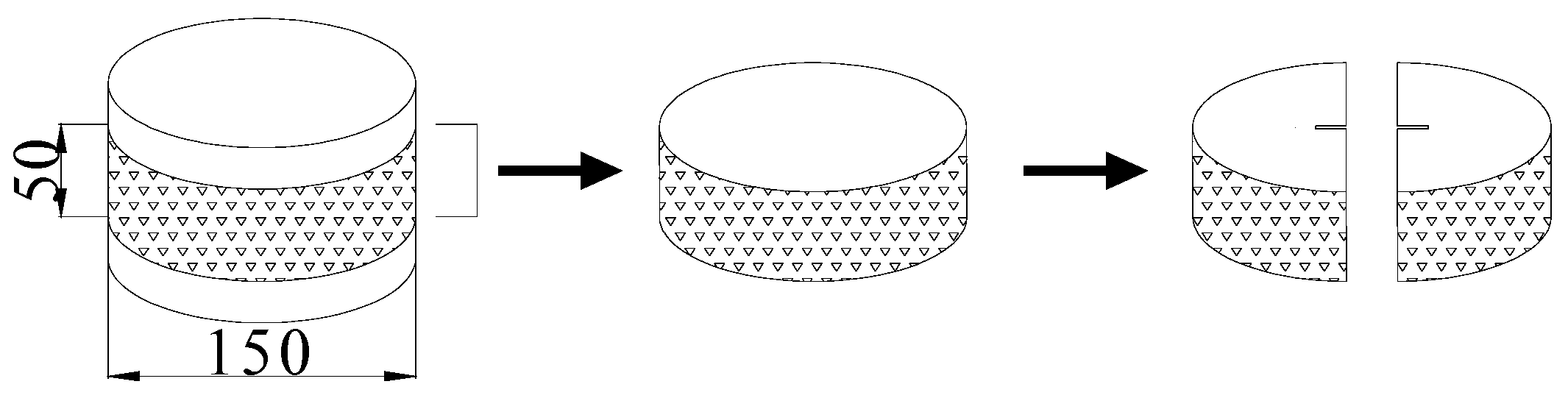

2.4.1. BBT

2.4.2. LT-SCB Test

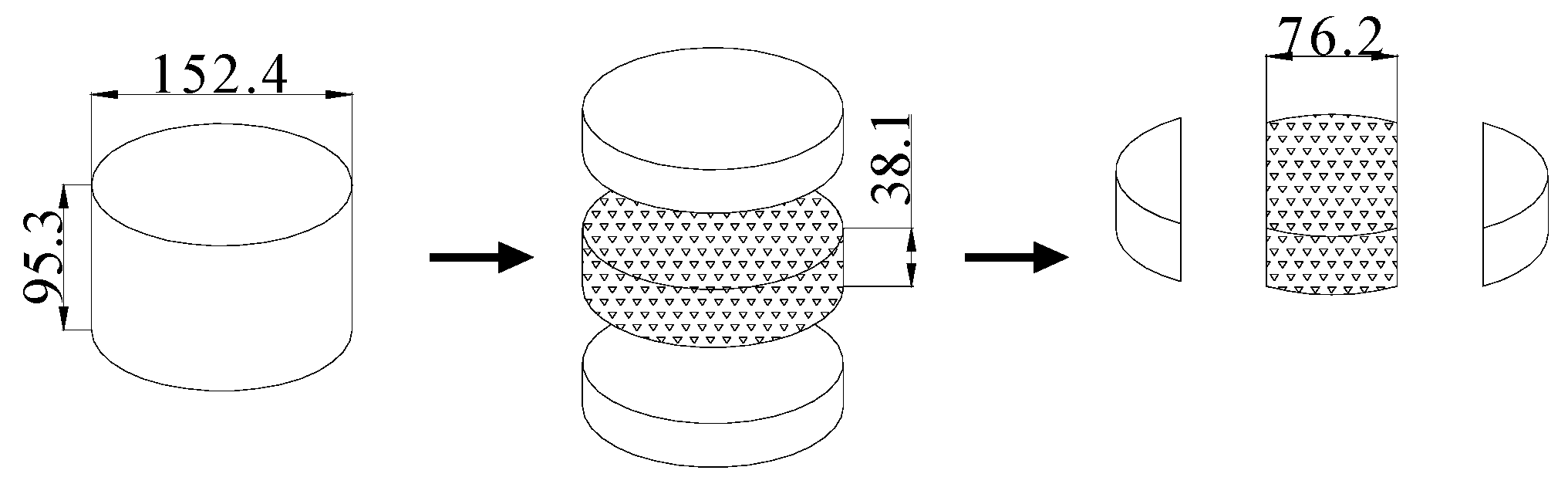

2.4.3. CE-SCB Test

2.4.4. OT

3. Results and Discussion

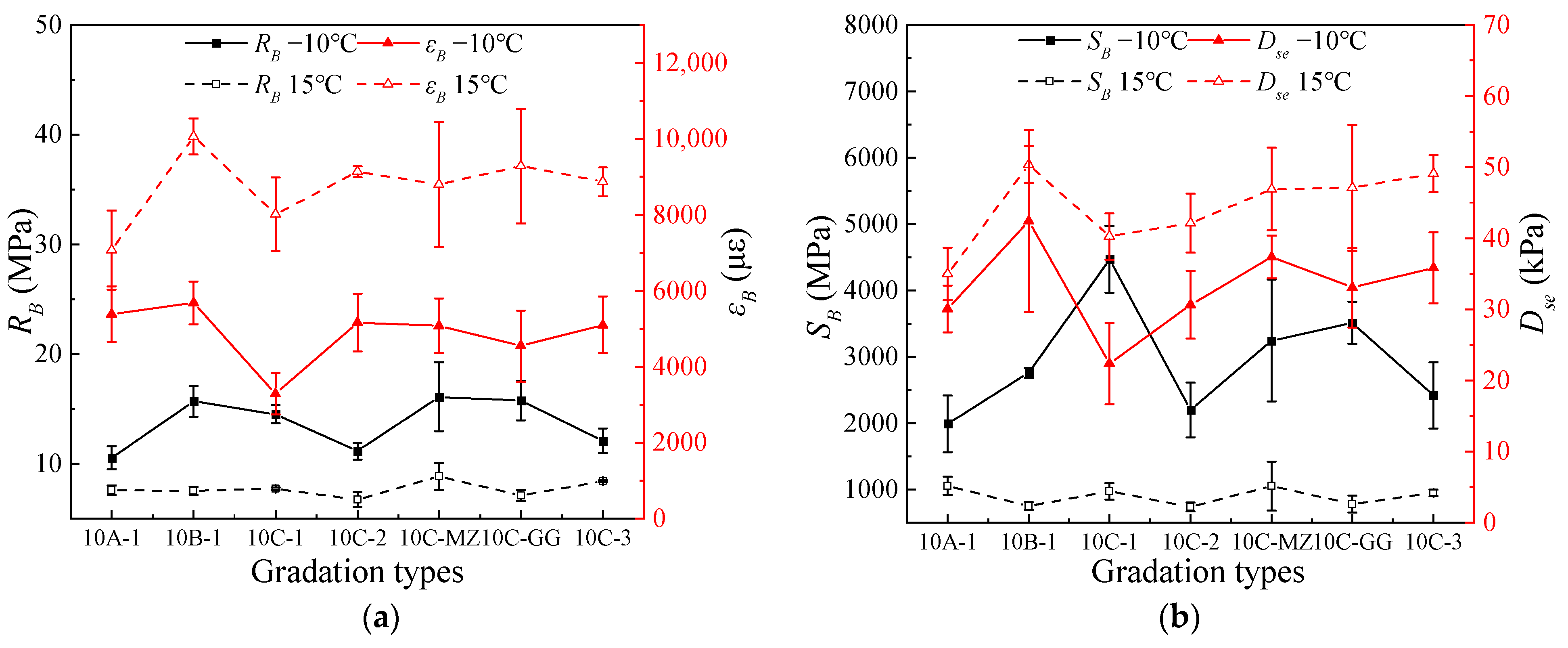

3.1. BBT

3.2. LT-SCB Test

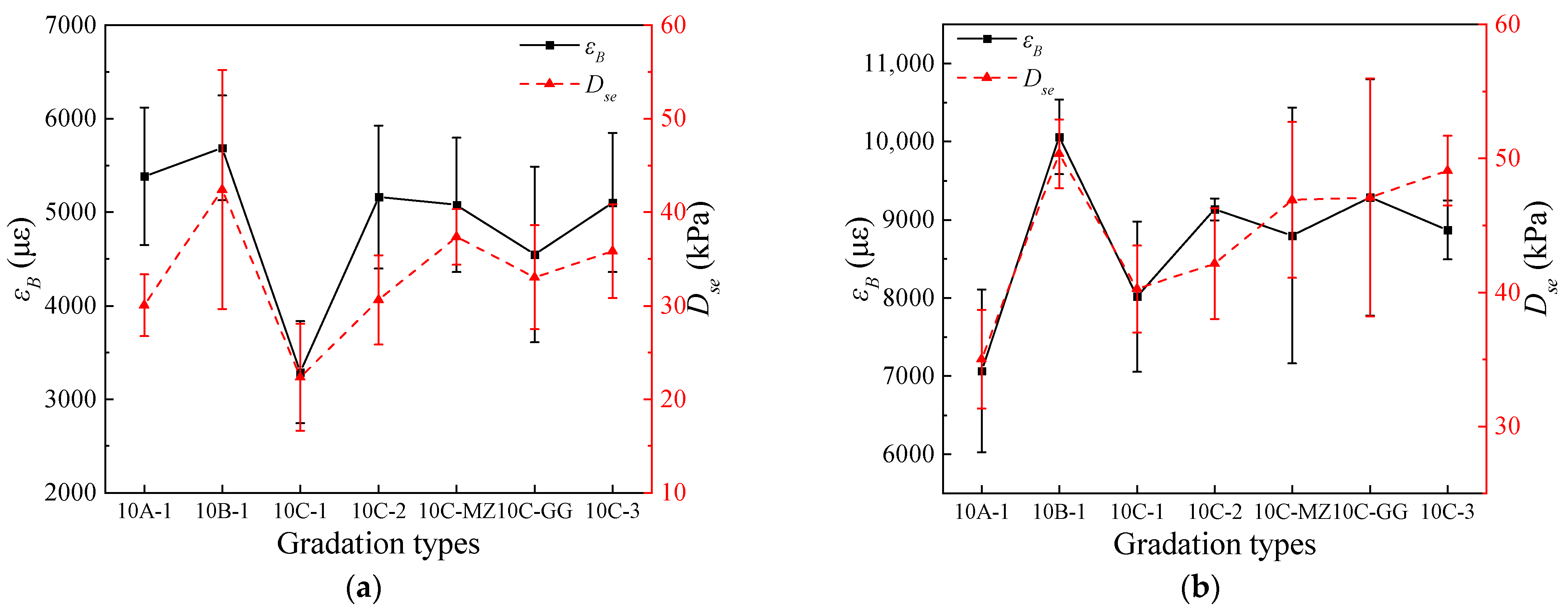

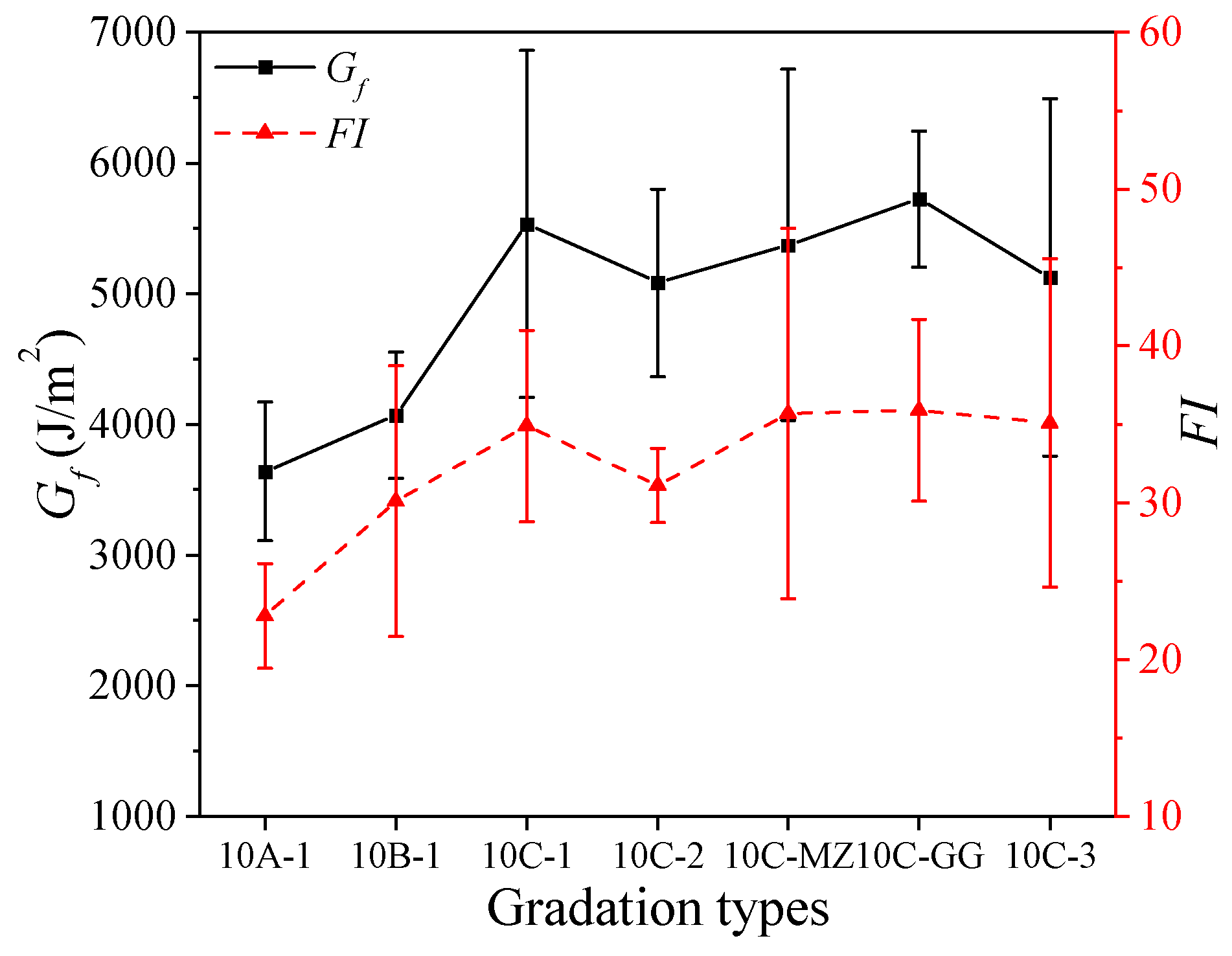

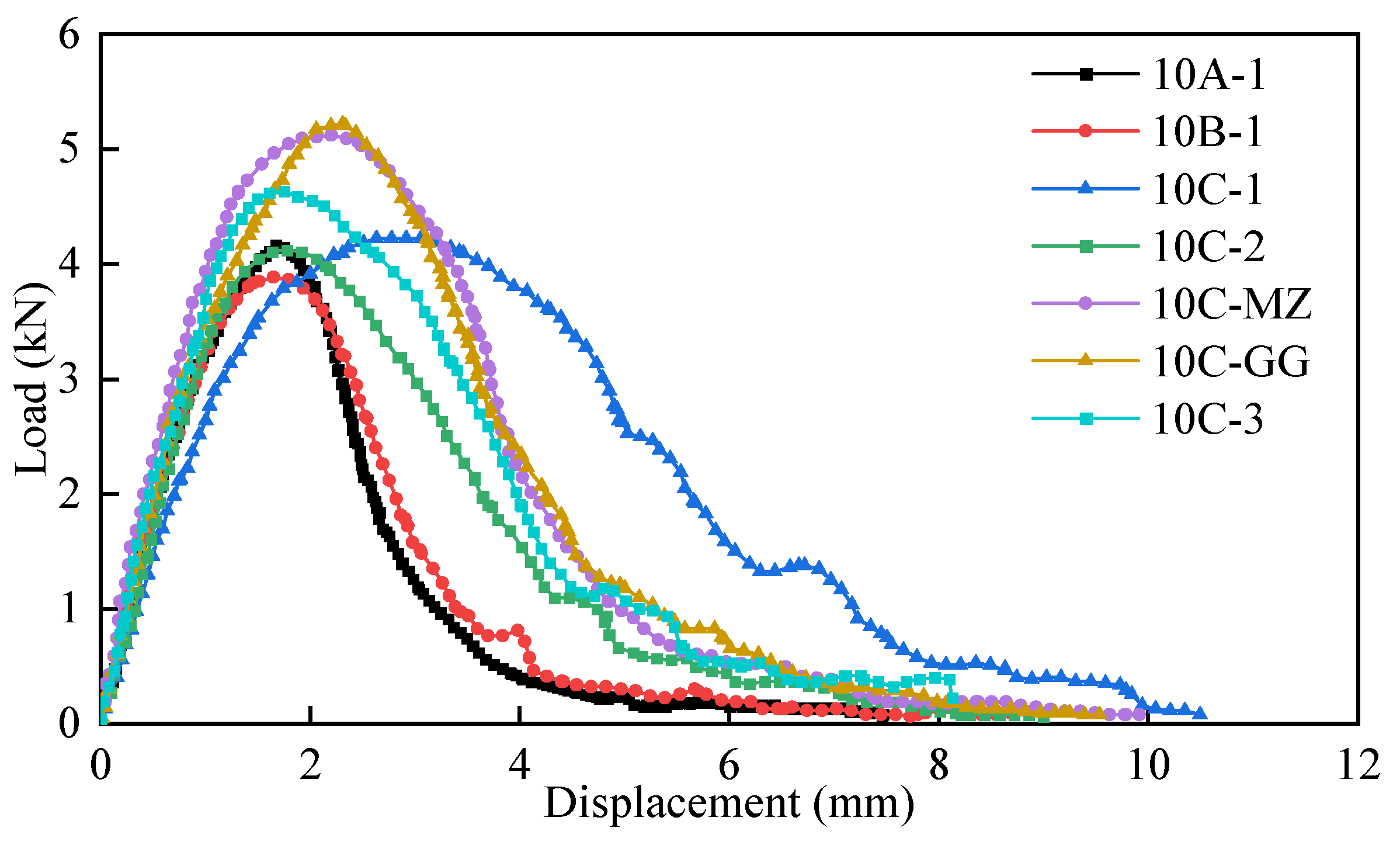

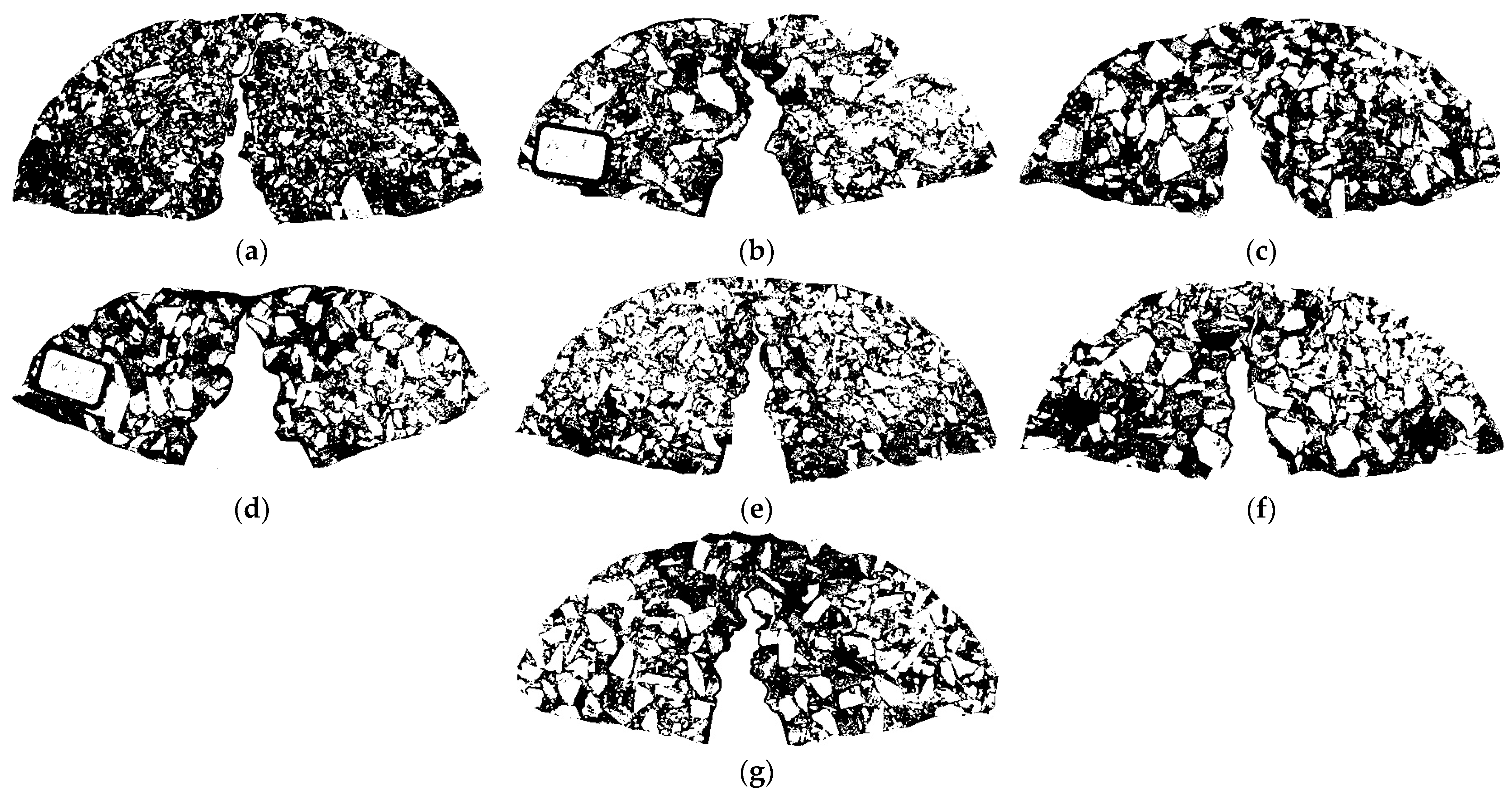

3.3. CE-SCB Test

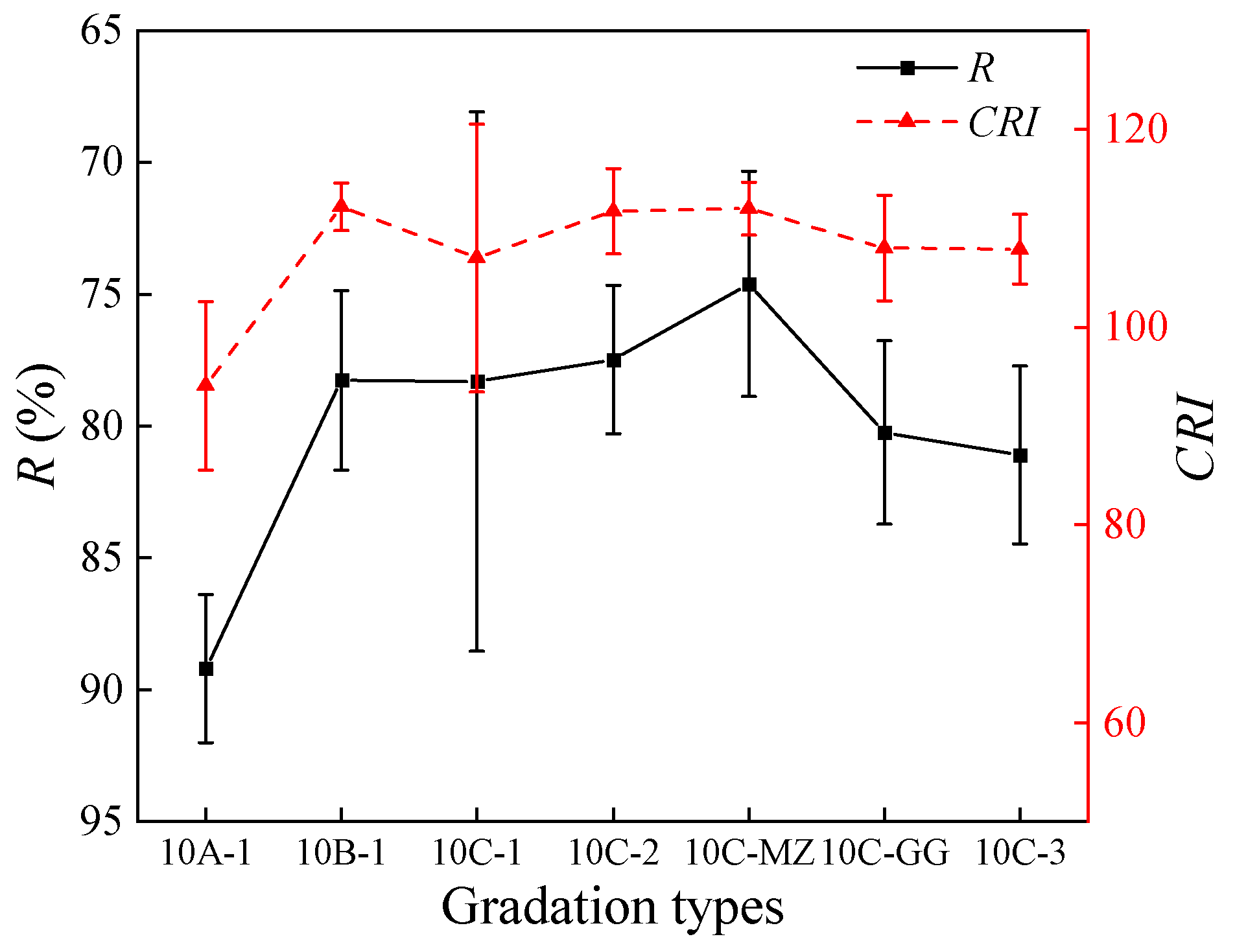

3.4. OT

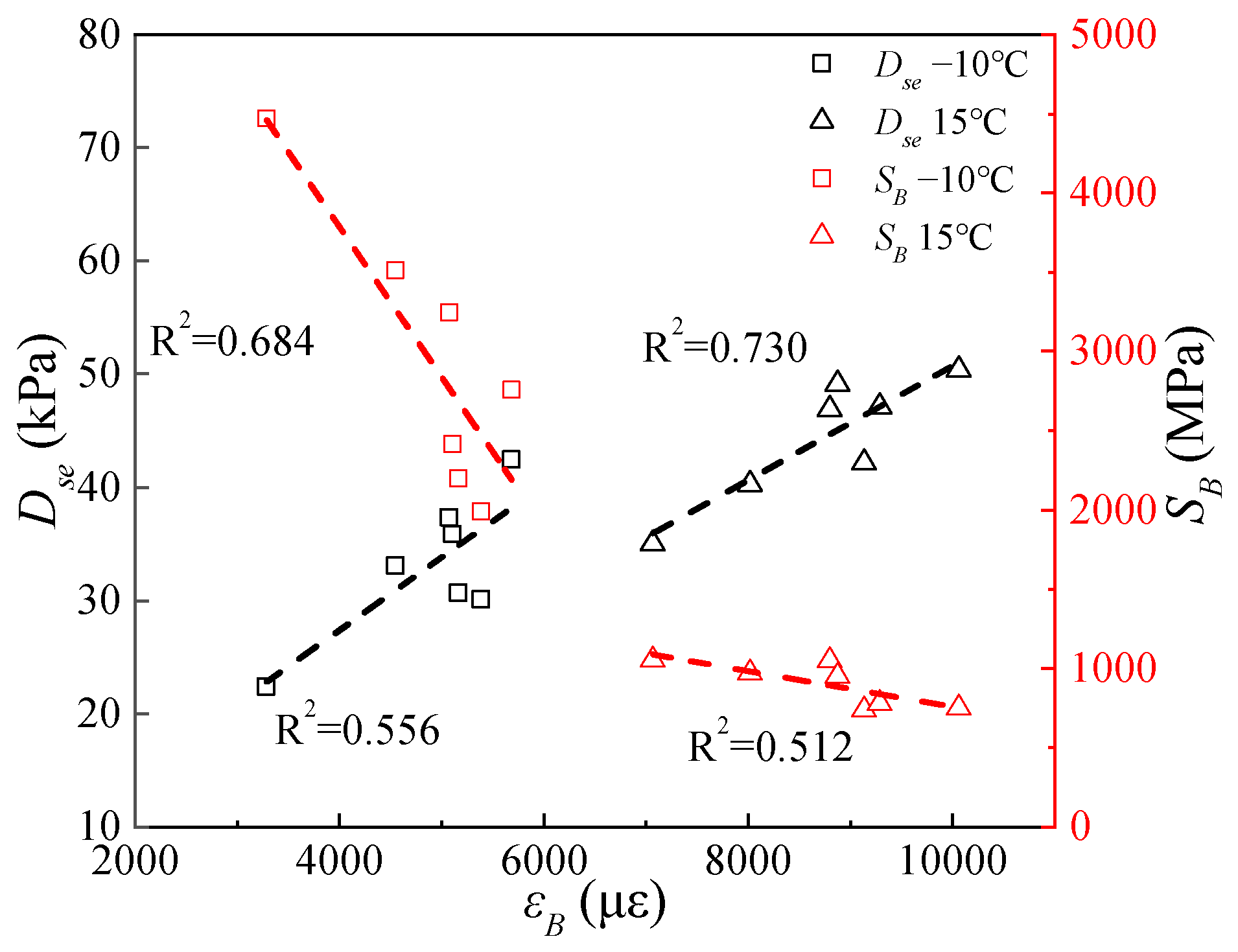

3.5. Relevance of Evaluation Methods

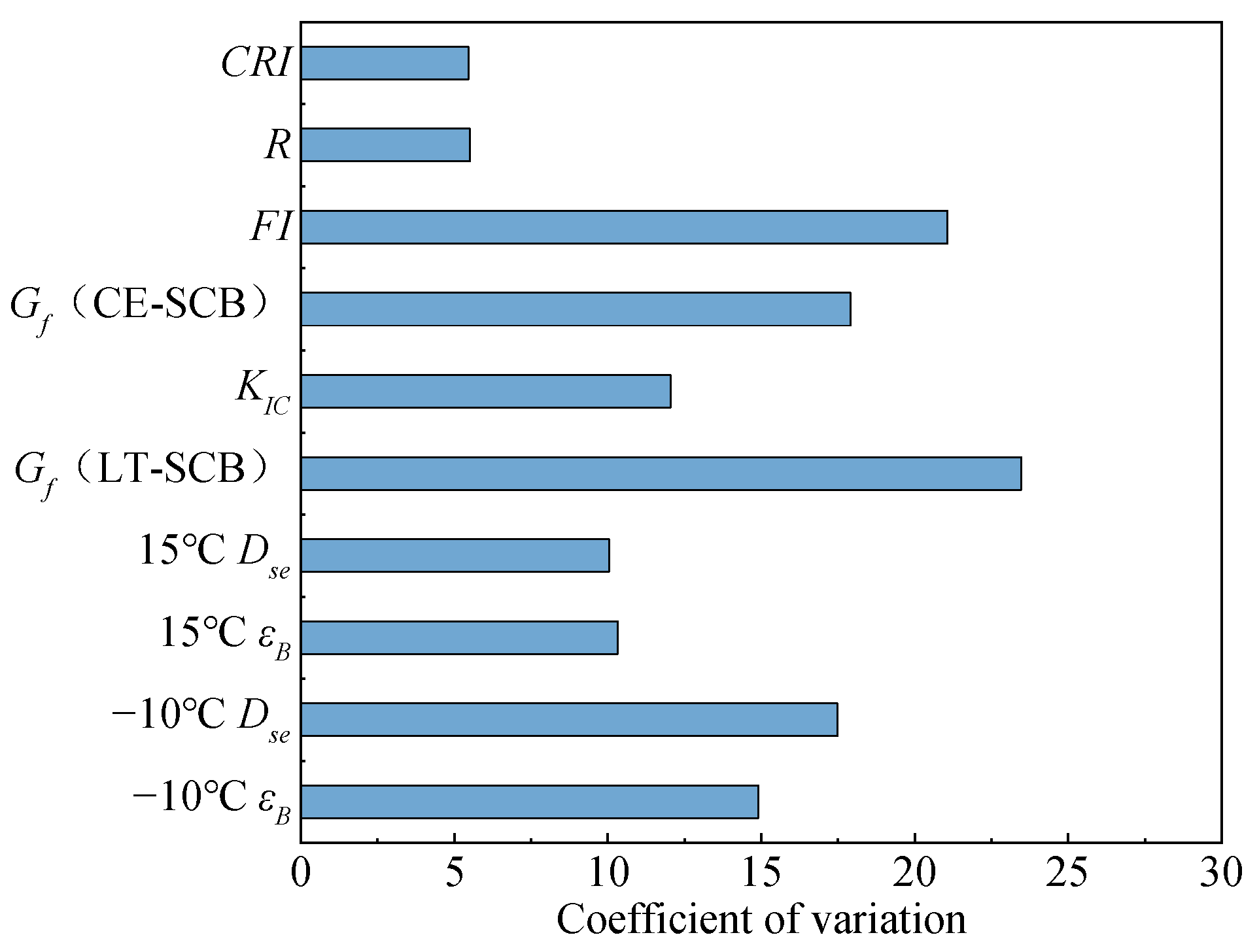

3.5.1. Dispersion of Tests

3.5.2. Distinction of Tests

3.5.3. Correlation of Tests

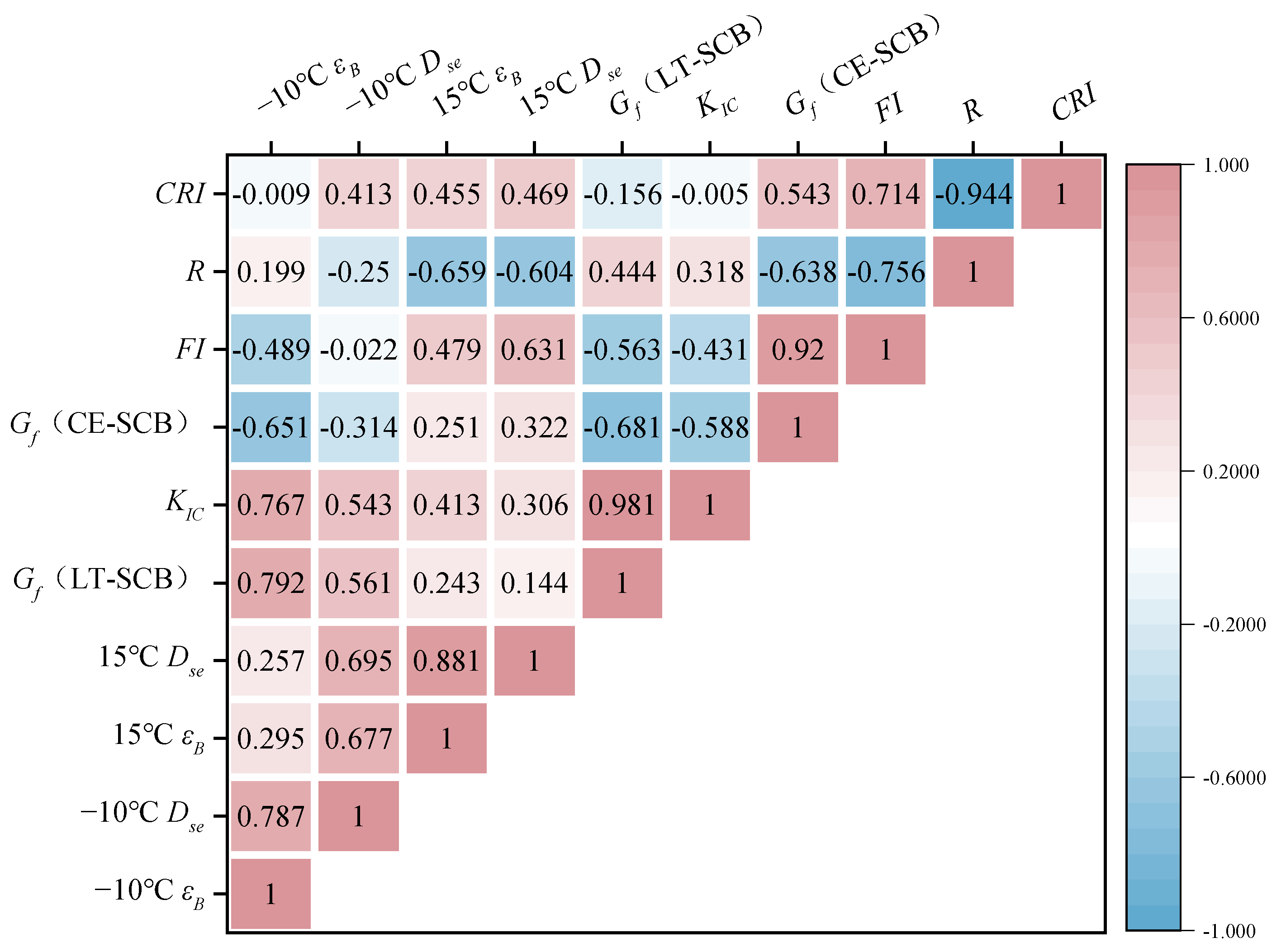

- (a)

- The −10 °C BBT had a good positive correlation with the LT-SCB test. The correlation coefficients between their parameters were all greater than 0.5, indicating that the flexural fatigue resistance and the low-temperature crack resistance of the asphalt mixture were consistent under low-temperature conditions. The higher the toughness of the asphalt mixture, the higher its deformation and load dissipation, and the higher its crack resistance.

- (b)

- The 15 °C BBT had a poor correlation with other tests. The correlation coefficients between their parameters were mainly less than 0.5, indicating that the flexural fatigue resistance of the asphalt mixture at room temperature was different from other types of cracking resistance.

- (c)

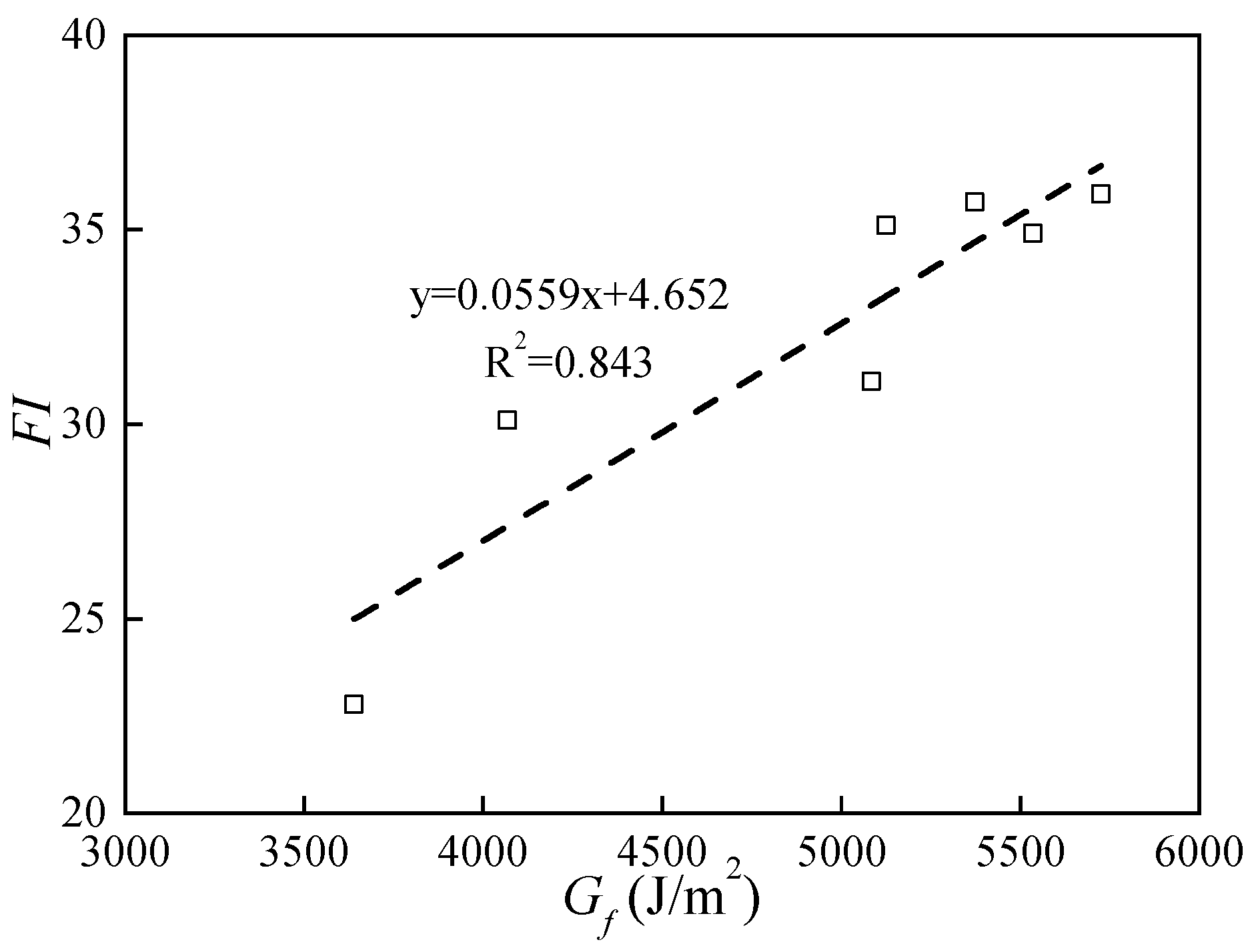

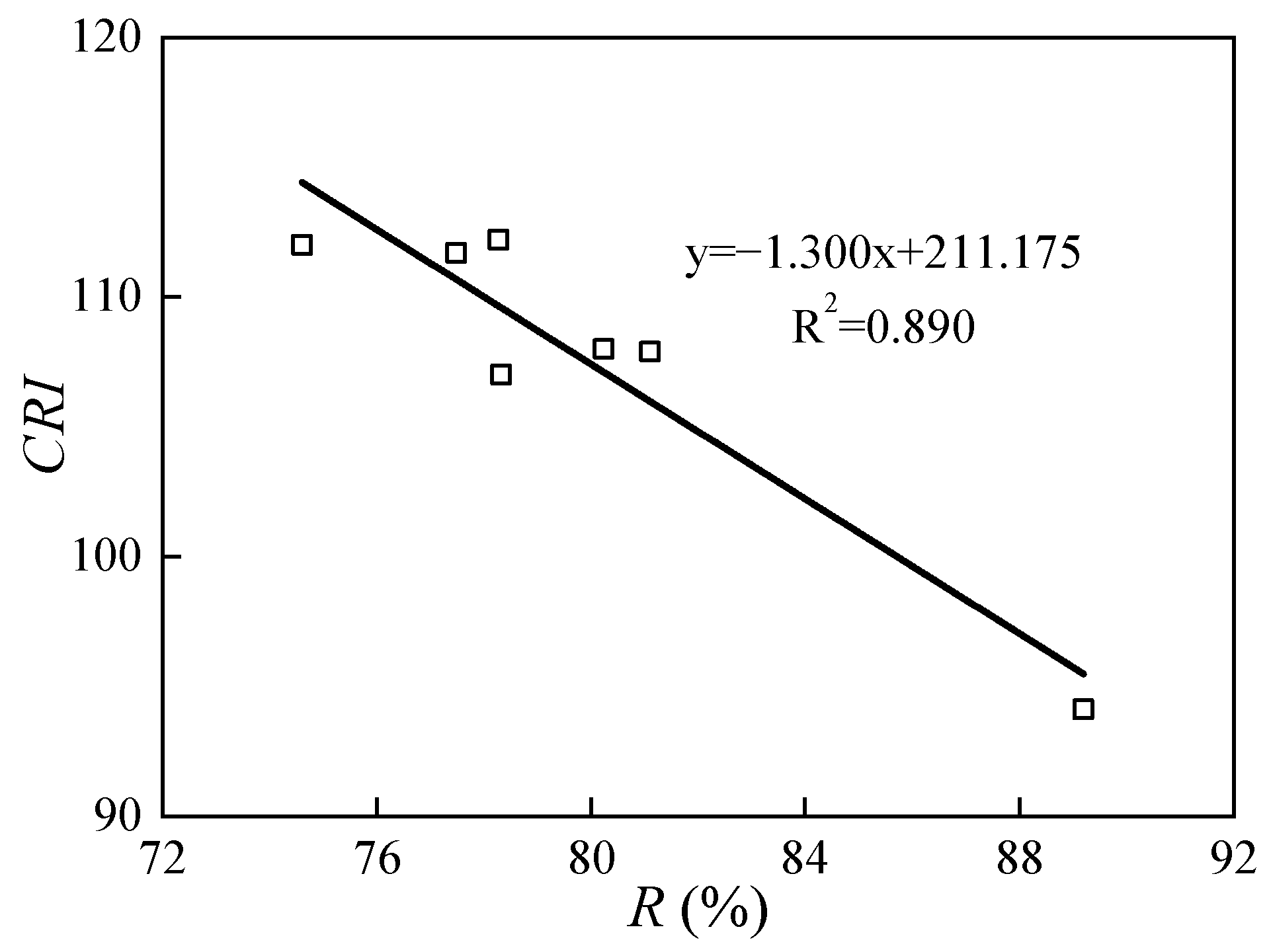

- The CE-SCB test had a good correlation with the OT. The correlation coefficients between the Gf, FI, and the R and CRI were −0.638, 0.543, and −0.756, 0.714, respectively. These values indicated that the Gf of the asphalt mixture increased as the R decreased. The FI and CRI characterized the load decay and the crack growth rate after peak load. The higher the FI and CRI, the slower the load decay and the crack growth, and the higher the crack resistance.

- (d)

- The −10 °C BBT, LT-SCB, CE-SCB, and OT tests had some degree of negative correlation. For example, the correlation coefficient between the Gf of the LT-SCB test and the Gf of the CE-SCB test was −0.681, which implies that the asphalt mixture with higher energy consumption at low-temperature cracking was less prone to cracking, while the asphalt mixture with lower energy consumption at crack expansion after cracking had faster crack development. This indicated that the cracking mechanism of asphalt mixtures under different conditions was different and that different types of tests should be considered comprehensively in performance evaluation.

4. Conclusions

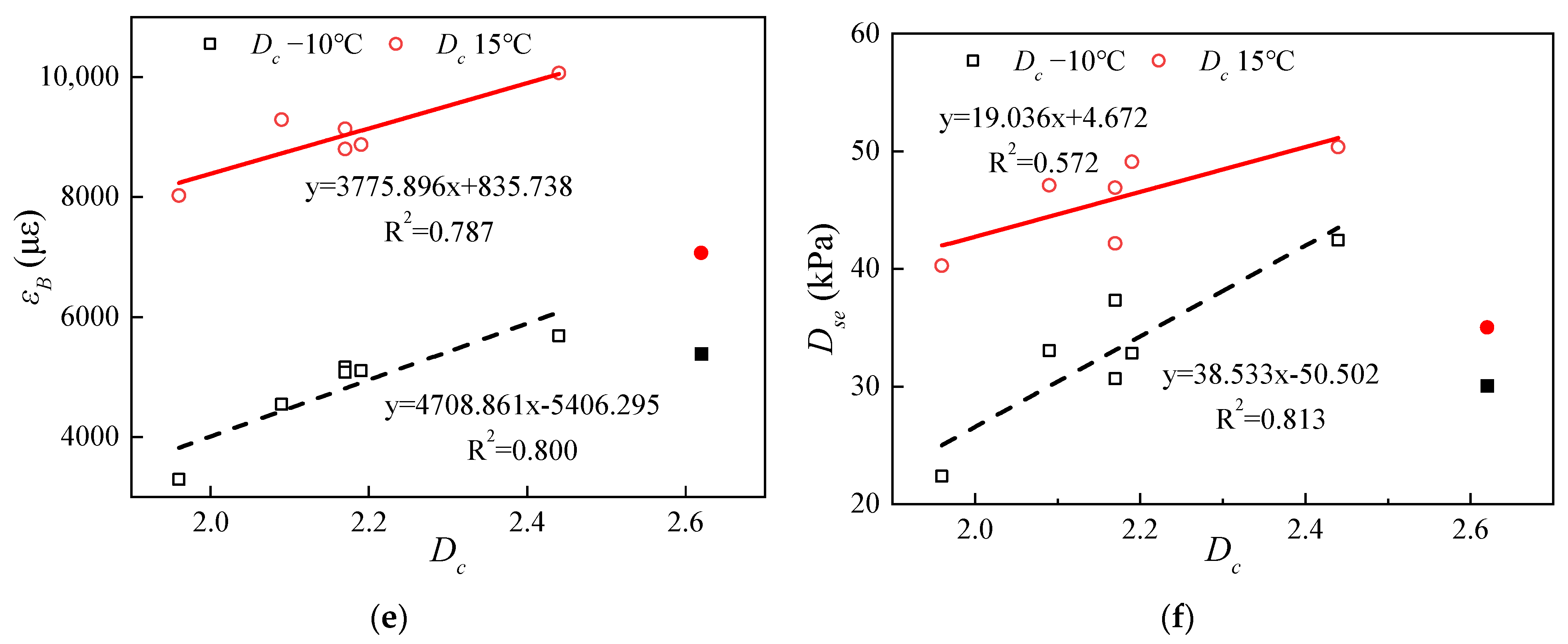

- The AR-SAMI with different gradations showed different performance in different tests, with a maximum difference of 56.07%. The AR-SAMI of 10B gradation had the best performance in the BBT, while the AR-SAMI of 10A and 10B gradation had the best performance in the LT-SCB test. The AR-SAMI of 10C gradation had the best performance in the CE-SCB test, and the AR-SAMI of 10B and 10C gradation had good performance in the OT.

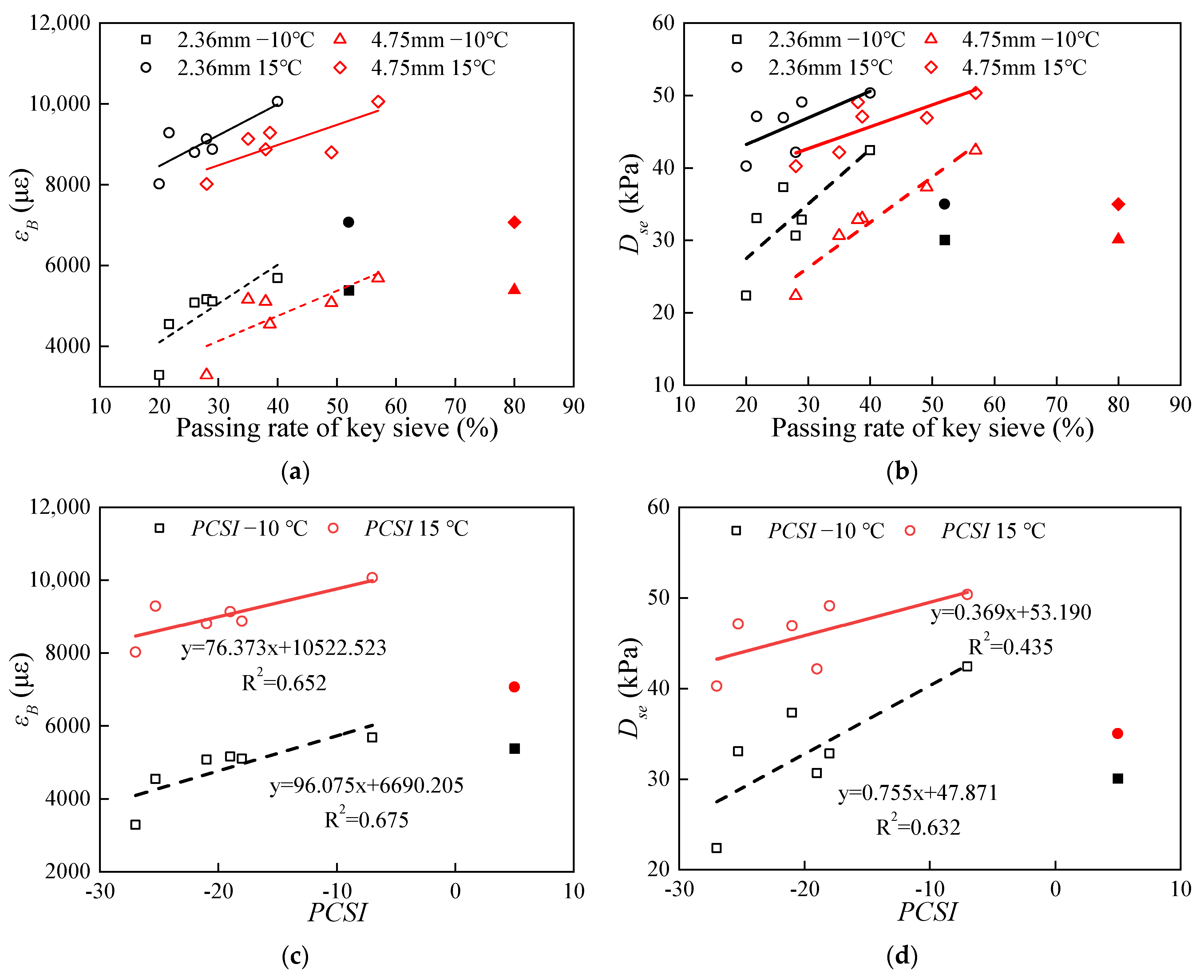

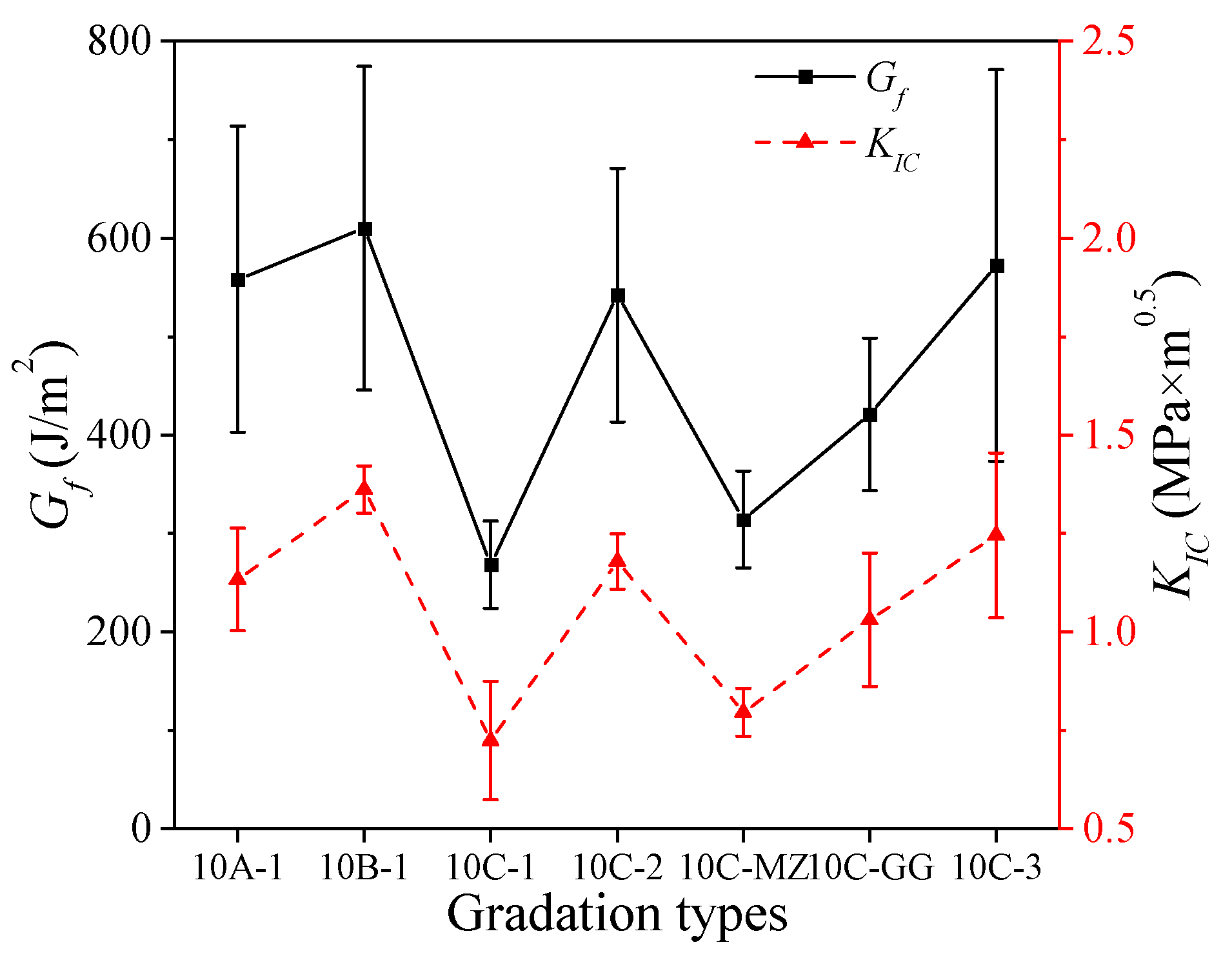

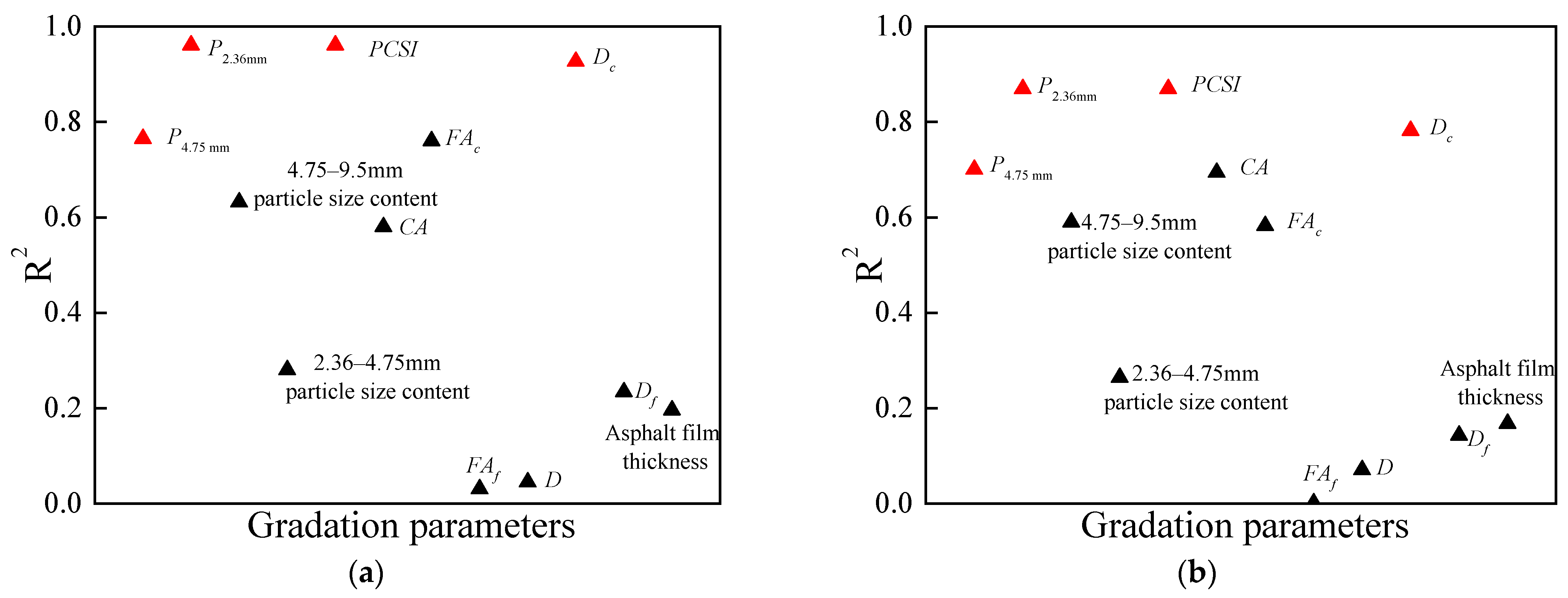

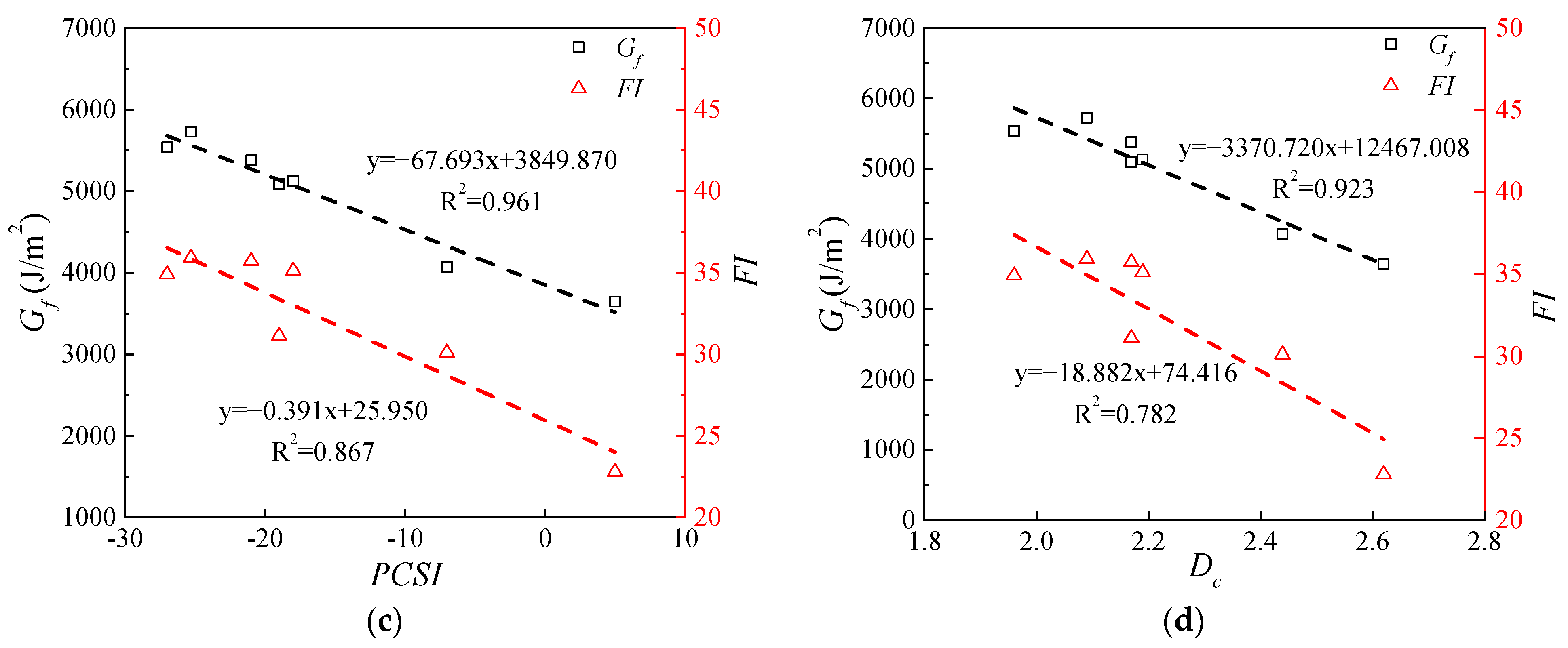

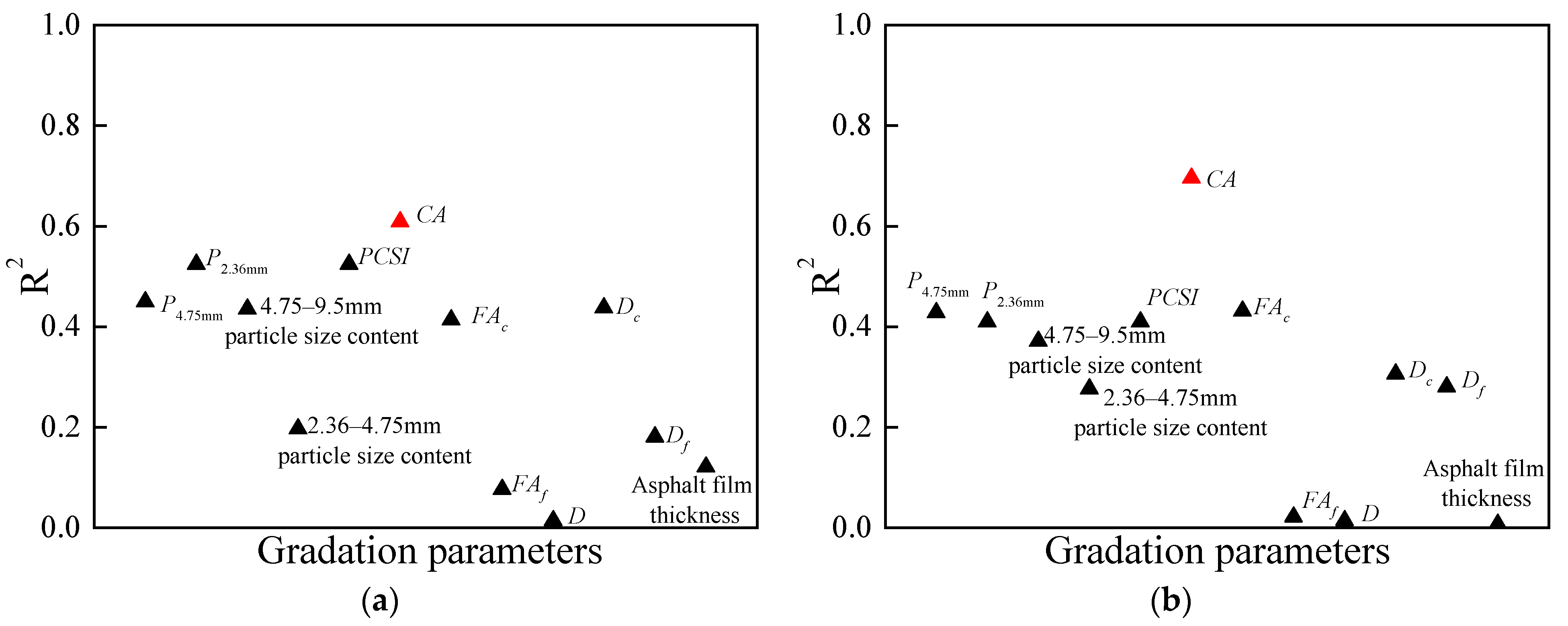

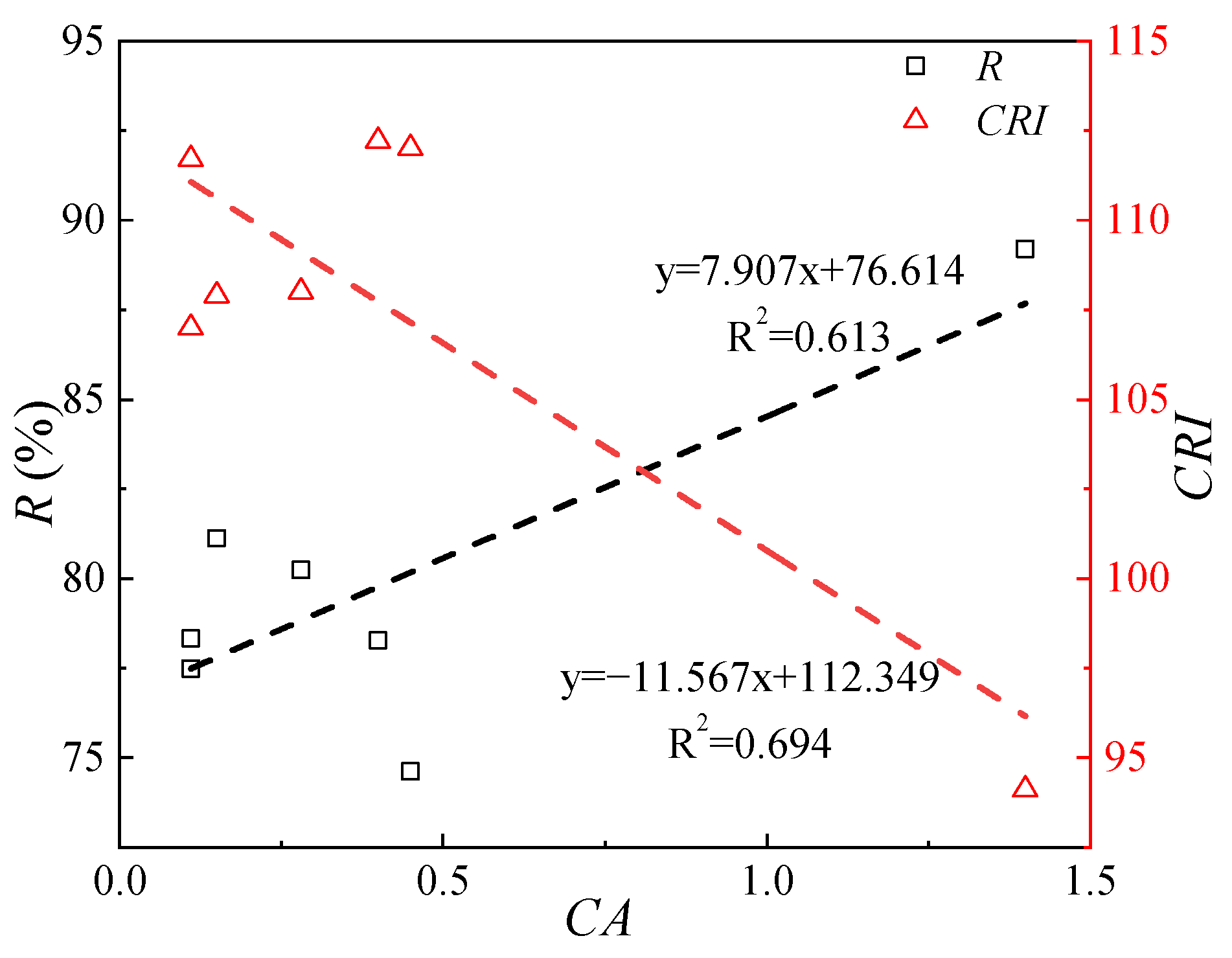

- The different tests were influenced by different parameters. The performance of the AR-SAMI in the BBT improved with the increase of the P4.75mm and P2.36mm, PCSI, and Dc. However, the performance of the AR-SAMI in the CE-SCB test deteriorated with the increase of these parameters. The performance of the AR-SAMI in the LT-SCB test improved with the increase of the asphalt film thickness, while the performance of the AR-SAMI in the OT worsened with the increase of the CA.

- The stress absorption performance of asphalt mixtures consisted of two aspects: crack resistance and crack expansion resistance. These two aspects were inversely related to each other, meaning that a mixture with better crack resistance did not necessarily have better crack expansion resistance.

- The −10 °C BBT, LT-SCB, CE-SCB, and OT tests could be used to evaluate the stress absorption performance, but they reflected different aspects of performance. It was recommended to use the −10 °C BBT and CE-SCB tests as the evaluation methods of stress absorption performance. The εB and Dse of the −10 °C BBT and the Gf and FI of the CE-SCB test were recommended as the evaluation indicators.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oshone, M.; Dave, E.V.; Sias, J.E. Asphalt mix fracture energy based reflective cracking performance criteria for overlay mix selection and design for pavements in cold climates. Constr. Build. Mater. 2019, 211, 1025–1033. [Google Scholar] [CrossRef]

- Wang, X.; Zhong, Y. Reflective crack in semi-rigid base asphalt pavement under temperature-traffic coupled dynamics using XFEM. Constr. Build. Mater. 2019, 214, 280–289. [Google Scholar] [CrossRef]

- Idris, I.I.; Sadek, H.; Hassan, M. State-of-the-Art Review of the Evaluation of Asphalt Mixtures’ Resistance to Reflective Cracking in Laboratory. J. Mater. Civ. Eng. 2020, 32, 3120004. [Google Scholar] [CrossRef]

- Rith, M.; Lee, S.W. Development of cohesive-zone-based prediction model for reflective cracking in asphalt overlay. Int. J. Pavement Eng. 2022, 23, 1050–1059. [Google Scholar] [CrossRef]

- Zeng, Z.; Guo, Y.; Li, P.; Shen, A.; Zhai, C. Performance research of fiber-reinforced asphalt rubber as a stress-absorbing membrane interlayer. J. Adhes. Sci. Technol. 2021, 35, 2047–2063. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, Z.; Luo, Y. Material Composition Design and Anticracking Performance Evaluation of Asphalt Rubber Stress-Absorbing Membrane Interlayer (AR-SAMI). Hindawi 2018, 2018, 8560604. [Google Scholar] [CrossRef]

- Chen, Y.; Lopp, G.; Roque, R. Effects of an Asphalt Rubber Membrane Interlayer on Pavement Reflective Cracking Performance. J. Mater. Civ. Eng. 2013, 25, 1936–1940. [Google Scholar] [CrossRef]

- Wargo, A.; Safavizadeh, S.A.; Kim, Y.R. Comparing the Performance of Fiberglass Grid with Composite Interlayer Systems in Asphalt Concrete. Transp. Res. Record 2017, 2631, 123–132. [Google Scholar] [CrossRef]

- Deng, H.L.; Fu, X.Y.; Gao, W.X.; Ni, T.T.; Chen, K.J. Research on New Technology to Control Highway Semi-Rigid Base Asphalt Pavement Cracks. Adv. Mater. Res. 2011, 194, 1632–1638. [Google Scholar] [CrossRef]

- Ogundipe, O.M.; Thom, N.; Collop, A. Investigation of crack resistance potential of stress absorbing membrane interlayers (SAMIs) under traffic loading. Constr. Build. Mater. 2013, 38, 658–666. [Google Scholar] [CrossRef]

- Ogundipe, O.M.; Thom, N.H.; Collop, A.C. Evaluation of performance of stress-absorbing membrane interlayer (SAMI) using accelerated pavement testing. Int. J. Pavement Eng. 2013, 14, 569–578. [Google Scholar] [CrossRef]

- Li, Z.Z.; Chen, S.F.; Liao, W.D.; Yuan, R.X. Lab Simulation Study on Anti-Cracking Performance of Asphalt Concrete Overlays for Fatigue. Adv. Mater. Res. 2012, 510, 478–483. [Google Scholar] [CrossRef]

- Pan, R.; Li, Y. Effect of warm mix rubber modified asphalt mixture as stress absorbing layer on anti-crack performance in cold region. Constr. Build. Mater. 2020, 251, 118985. [Google Scholar] [CrossRef]

- Baghel, R.S.; Kasu, S.R.; Chandrappa, A.K. Effect of dual and new generation wide-base tire assembly on inverted pavements. J. Road Eng. 2022, 2, 124–136. [Google Scholar] [CrossRef]

- Yu, B.; Lu, Q.; Yang, J. Evaluation of anti-reflective cracking measures by laboratory test. Int. J. Pavement Eng. 2013, 14, 553–560. [Google Scholar] [CrossRef]

- Asadi, S.; Shafabakhsh, G. Experimental and statistical investigation on the performance of asphalt overlays reinforced with geocomposite in controlling the reflective cracks under different loadings and temperatures. SN Appl. Sci. 2023, 5, 202. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Ahmadi, S. Reflective cracking reduction by a comparison between modifying asphalt overlay and sand asphalt interlayer: An experimental evaluation. Int. J. Pavement Eng. 2021, 22, 192–200. [Google Scholar] [CrossRef]

- Zhang, Q. Effect of Grading Type on the Performance of Warm-Mix Rubber-Asphalt Mixture. IOP Conf. Ser. Earth Environ. Sci. 2020, 526, 12152. [Google Scholar] [CrossRef]

- Tran, N.T.; Takahashi, O. Effect of aggregate gradation on the cracking performance of wearing course mixtures. Constr. Build. Mater. 2017, 152, 520–528. [Google Scholar] [CrossRef]

- Germann, F.P.; Lytton, R.L. Methodology for Predicting the Reflection Cracking Life of Asphalt Concrete Overlays; Report No. 207-5; Texas State Department of Highways and Public Transportation: Austin, TX, USA, 1979.

- Zhou, F.; Hu, S.; Chen, D.H.; Scullion, T. Overlay Tester: Simple Performance Test for Fatigue Cracking. Transp. Res. Rec. J. Transp. Res. Board 2007, 2001, 1–8. [Google Scholar] [CrossRef]

- Wang, S.; Yan, K.; Ge, D.; Hong, Z. Laboratory research on the performance of stress-absorption interlayer (SAI) of waste tire rubber and amorphous ploy alpha olefin modified asphalt. Constr. Build. Mater. 2019, 223, 830–840. [Google Scholar] [CrossRef]

- Liu, J.Y.; Zhang, L.J.; Kou, B.; Shen, P. The Environment-Friendly High-Elasticity Asphalt Mixture Using as Stress Absorbing Layer. Adv. Mater. Res. 2012, 490, 3753–3761. [Google Scholar] [CrossRef]

- Zhou, F.; Newcomb, D.; Gurganus, C.; Banihashemrad, S.; Park, E.S.; Sakhaeifaran, M.; Lytton, R.L. Experimental Design for Field Validation of Laboratory Tests to Assess Cracking Resistance of Asphalt Mixtures; NCHRP Final Report 9-57; Transportation Research Board National Research Council: Washington, WA, USA, 2016; p. 103. [Google Scholar]

- CJJ/T273-2019; Rubber Asphalt Pavement Technical Standard. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2019.

- JT/T 798-2011; Asphalt Rubber for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- JTG F40-2004I; Technical Specifications for Construction of Highway Asphalt Pavement. Ministry of Transport of the People’s Republic of China: Beijing, China, 2004.

- Bischoff, D.L. Evaluation of Strata® Reflective Crack Relief System; Cost Effectiveness; Wisconsin Department of Transportation, Division of Transportation Systems Development, Bureau of Technical Services, Materials Management Section: Madison, WI, USA, 2007.

- Blomberg, J.M. Superpave Overlay of Sand Anti-Fracture Layer Over PCCP. In Concrete Pavements; Department of Transportation: Jefferson City, MO, USA, 2000. [Google Scholar]

- Scullion, T. Technical Bulletin on Design and Construction of Crack Attenuating Mixes (CAM); Texas Transportation Institute: College Station, TX, USA, 2010. [Google Scholar]

- DB45/T 1098-2014; Technical Specification for Construction of Asphalt Rubber Pavement. Guangxi Zhuang Autonomous Region Bureau: Nanning, China, 2014.

- DB 36/T 744-2013; Technical Specifications for Waste Tire Rubber Asphalt Pavement Construction. Jiangxi Provincial Bureau of Quality and Technical Supervision: Nanchang, China, 2013.

- DG/TJ08-2109-2012; Technical Code for Asphalt Rubber Pavement. Shanghai Urban-Rural Construction and Transportation Commission: Shanghai, China, 2012.

- DB11/T 916-2012; Technical specifications for asphalt rubber. Beijing Municipal Bureau of Quality and Technical Supervision: Beijing, China, 2012.

- DB13/T 1013-2009; Technical standard for tire crumb asphalt rubber and asphalt rubber hot mixture. Hebei Provincial Bureau of Quality and Technical Supervision: Shijiazhuang, China, 2009.

- DB 14/T 160-2015; Technical specification for highway modified asphalt pavement construction. Shanxi Provincial Bureau of Quality and Technical Supervision: Taiyuan, China, 2015.

- DBJ/T13-147-2012; Specification for Construction Technology of Stabilized Rubber Modified Asphalt Pavement. Fujian Provincial Department of Housing and Urban Rural Development: Fuzhou, China, 2012.

- Leiva, F.; West, R.C. Using the Primary Control Sieve Index to Define Gradation Type and as a Factor Related to Asphalt Mixture Properties; National Center for Asphalt Technology: Auburn, AL, USA, 2021.

- AASHTO TP 105-13; Standard Method of Test for Determining the Fracture Energy of Asphalt Mixtures Using the Semicircular Bend Geometry (SCB). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019; p. 13.

- EN 12697-44; Bituminous Mixtures-Test Methods for Hot Mix Asphalt-Part 44: Crack Propagation by Semi-Circular Bending Test. NSAI: Dublin, Ireland, 2010.

- AASHTO TP 124-16; Standard Method of Test for Determining the Fracture Potential of Asphalt Mixtures Using Semicircular Bend Geometry (SCB) at Intermediate Temperature. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2016.

- Tex-248-F; Texas Department of Transportation Test Procedure for Overlay Test. Texas Department of Transportation: Austin, TX, USA, 2017; pp. 1–13.

| Physical Properties | Unit | Value | Technical Requirement [26] | Standard [27] |

|---|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s) | 0.1 mm | 39.3 | 30~70 | T 0604 |

| Ductility (5 °C, 5 cm/min) | cm | 11.6 | >5 | T 0605 |

| Softening point | °C | 75.5 | >65 | T 0606 |

| Brookfield viscosity (180 °C) | Pa·s | 2.51 | 2.0~5.0 | T 0625 |

| Elastic recovery rate (25 °C) | % | 94.0 | >60 | T 0662 |

| Aggregate Types | Technical Index | Units | Value | Technical Requirement [28] | Standard [27] | |

|---|---|---|---|---|---|---|

| Coarse aggregate | Crushing value | % | 17 | ≤26 | T 0316 | |

| Apparent relative gravity | 13.2 mm | - | 2.705 | ≥2.60 | T 0304 | |

| 9.5 mm | 2.735 | |||||

| 4.75 mm | 2.63 | |||||

| Bulk specific gravity | 13.2 mm | - | 2.676 | - | T 0304 | |

| 9.5 mm | 2.654 | |||||

| 4.75 mm | 2.611 | |||||

| Water absorption | 13.2 mm | % | 0.41 | ≤2.0 | T 0304 | |

| 9.5 mm | 1.11 | |||||

| 4.75 mm | 0.27 | |||||

| Los Angeles abrasion loss | 10–20 mm | % | 15.6 | ≤30 | T 0317 | |

| 5–10 mm | 20.1 | |||||

| 3–5 mm | 18.7 | |||||

| Flat and elongated particles content | 10–20 mm | % | 13.2 | ≤15 | T 0312 | |

| 5–10 mm | 10.9 | ≤15 | ||||

| 3–5 mm | 7.5 | ≤20 | ||||

| Adhesional degree with aggregate | - | 5 | ≥4 | T 0616 | ||

| Fine aggregate | Bulk specific gravity | - | 2.62 | - | T 0304 | |

| water absorption | % | 0.27 | - | T 0304 | ||

| Apparent specific gravity | - | 2.622 | ≥2.50 | T 0304 | ||

| Sand equivalent | % | 69 | ≥60 | T 0334 | ||

| Angularity (flow time method) | s | 32.2 | ≥30 | T 0345 | ||

| Gradations Types | Optimal Asphalt–Aggregate Ratio/% | Theoretical Maximum Relative Density of Asphalt Mixture | Bulk Volume Relative Density of Asphalt Mixture | VV/% | VMA/% | VFA/% | Stability/kN | Flow Value/mm | FB | Asphalt Film Thickness/μm |

|---|---|---|---|---|---|---|---|---|---|---|

| 10A-1 | 6.95 | 2.394 | 2.333 | 2.5 | 16.82 | 85.15 | 9.48 | 2.87 | 0.94 | 10.06 |

| 10B-1 | 6.10 | 2.425 | 2.364 | 2.5 | 15.11 | 83.41 | 8.65 | 2.76 | 1.08 | 9.70 |

| 10C-1 | 7.49 | 2.381 | 2.333 | 2.5 | 17.64 | 85.66 | 7.66 | 3.14 | 0.45 | 21.24 |

| 10C-2 | 6.55 | 2.410 | 2.343 | 2.5 | 15.93 | 84.38 | 7.81 | 3.33 | 1.35 | 9.71 |

| 10C-MZ | 7.49 | 2.377 | 2.316 | 2.5 | 17.70 | 85.90 | 7.05 | 4.07 | 0.88 | 15.28 |

| 10C-GG | 7.00 | 2.403 | 2.340 | 2.5 | 16.65 | 85.00 | 6.84 | 2.87 | 0.93 | 9.53 |

| 10C-3 | 6.46 | 2.409 | 2.350 | 2.5 | 15.78 | 84.18 | 7.84 | 3.78 | 1.02 | 11.51 |

| Gradation Types | 10A-1 | 10B-1 | 10C-1 | 10C-2 | 10C-MZ | 10C-GG | 10C-3 | |

|---|---|---|---|---|---|---|---|---|

| Key sieve aggregate content (%) | 4.75–9.5 mm | 19 | 34 | 64 | 60 | 49.7 | 43.8 | 60 |

| 2.36–4.75 mm | 28 | 17 | 8 | 7 | 23.1 | 17 | 9 | |

| P4.75mm | 80 | 57 | 28 | 35 | 49.1 | 38.7 | 38 | |

| P2.36mm | 52 | 40 | 20 | 28 | 26 | 21.7 | 29 | |

| PCSI | 5 | −7 | −27 | −19 | −21 | −25.3 | −18 | |

| CA | 1.4 | 0.4 | 0.11 | 0.11 | 0.45 | 0.28 | 0.15 | |

| FAc | 0.38 | 0.48 | 0.55 | 0.61 | 0.53 | 0.63 | 0.52 | |

| FAf | 0.55 | 0.47 | 0.45 | 0.59 | 0.49 | 0.64 | 0.53 | |

| D | 2.44 | 2.45 | 2.35 | 2.52 | 2.4 | 2.46 | 2.45 | |

| Dc | 2.62 | 2.44 | 1.96 | 2.17 | 2.17 | 2.09 | 2.19 | |

| Df | 2.42 | 2.46 | 2.42 | 2.64 | 2.52 | 2.57 | 2.52 | |

| Test Name | Crack Resistance | Crack Expansion Resistance |

|---|---|---|

| BBT | √ | |

| LT-SCB test | √ | |

| CE-SCB test | √ | |

| OT | √ |

| Gradation Parameters | P4.75mm | P2.36mm | PCSI | Dc | CA | Asphalt Film Thickness |

|---|---|---|---|---|---|---|

| BBT | √ | √ | √ | √ | ||

| LT-SCB test | √ | |||||

| CE-SCB test | √ | √ | √ | √ | ||

| OT | √ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Xiao, X.; Tian, S.; Liu, J.; Peng, W.; Wang, B.; Liu, S. Gradation Influence on Crack Resistance of Stress-Absorbing Membrane Interlayer. Appl. Sci. 2023, 13, 11276. https://doi.org/10.3390/app132011276

Li P, Xiao X, Tian S, Liu J, Peng W, Wang B, Liu S. Gradation Influence on Crack Resistance of Stress-Absorbing Membrane Interlayer. Applied Sciences. 2023; 13(20):11276. https://doi.org/10.3390/app132011276

Chicago/Turabian StyleLi, Ping, Xuan Xiao, Shuaituan Tian, Junbin Liu, Wenju Peng, Bin Wang, and Shende Liu. 2023. "Gradation Influence on Crack Resistance of Stress-Absorbing Membrane Interlayer" Applied Sciences 13, no. 20: 11276. https://doi.org/10.3390/app132011276

APA StyleLi, P., Xiao, X., Tian, S., Liu, J., Peng, W., Wang, B., & Liu, S. (2023). Gradation Influence on Crack Resistance of Stress-Absorbing Membrane Interlayer. Applied Sciences, 13(20), 11276. https://doi.org/10.3390/app132011276