Image-Based Structural Health Monitoring: A Systematic Review

Abstract

1. Introduction

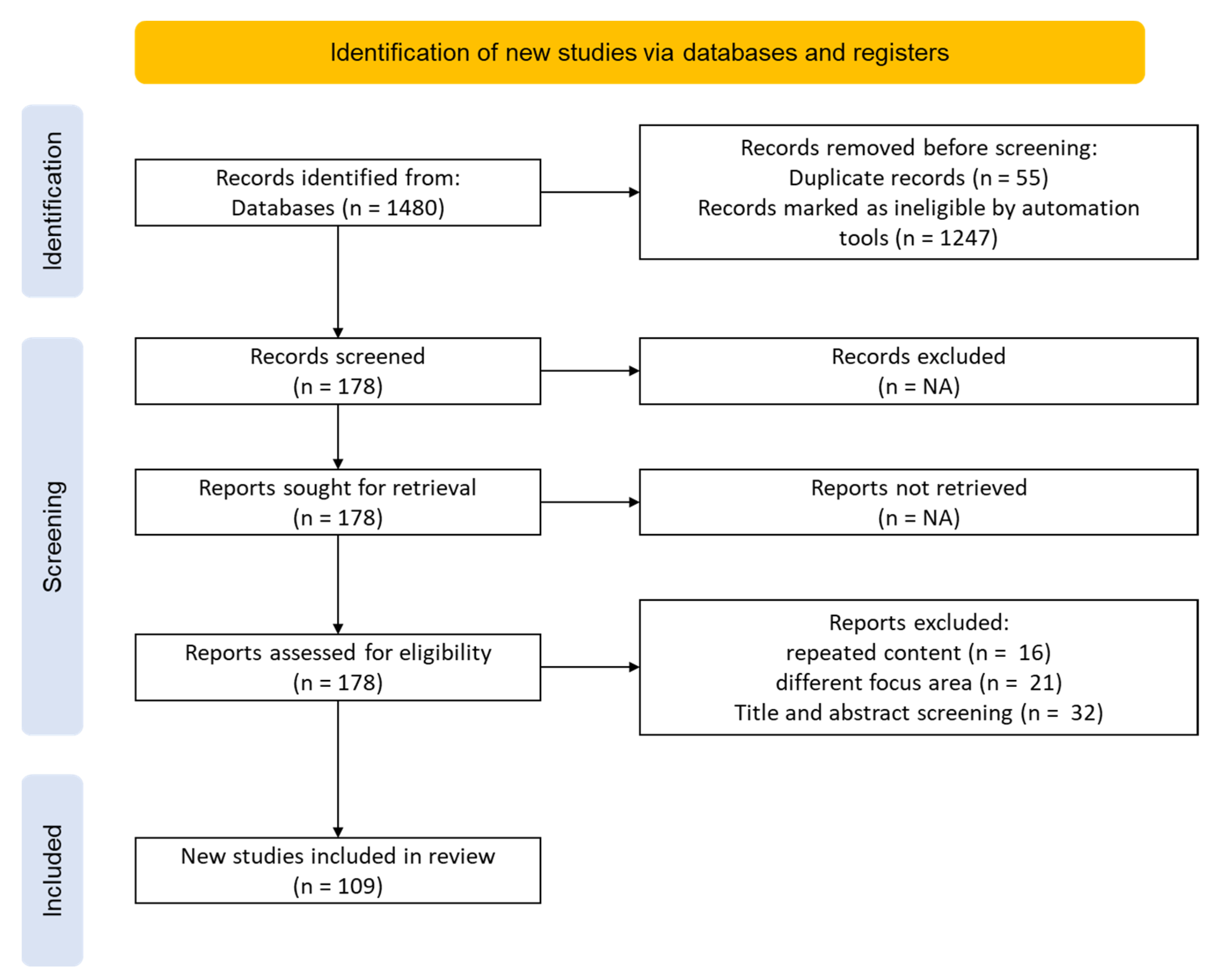

2. Materials and Methods

- RQ1:

- “What are the thematic purposes and implementation of image-based SHM and how to successfully employ them?”

- RQ2

- “If image-based SHM systems and devices are tailored to fit the requirements set before their implementation, what are its distinct and frontline features?”

- RQ3:

- “What are the innovations that solve difficulties expected in image-based monitoring?”

- Period (Inclusion: 2001–2023; Exclusion: Documents before 2001)

- Language must be English (Inclusion: translated version is available; Exclusion: translated version is not available)

- Type of document or literature (Inclusion: Articles, Conference Papers, Reviews, Book Chapters, Conference Reviews; Exclusion: Otherwise)

- Accessibility (Inclusion: Full-text available (In cases where access to the included journal is unavailable, the copy of the manuscript is requested directly from the authors); Exclusion: Otherwise)

- Relevance to RQs (Exclusion: Not relevant to at least two RQs)

3. Results

4. Discussion

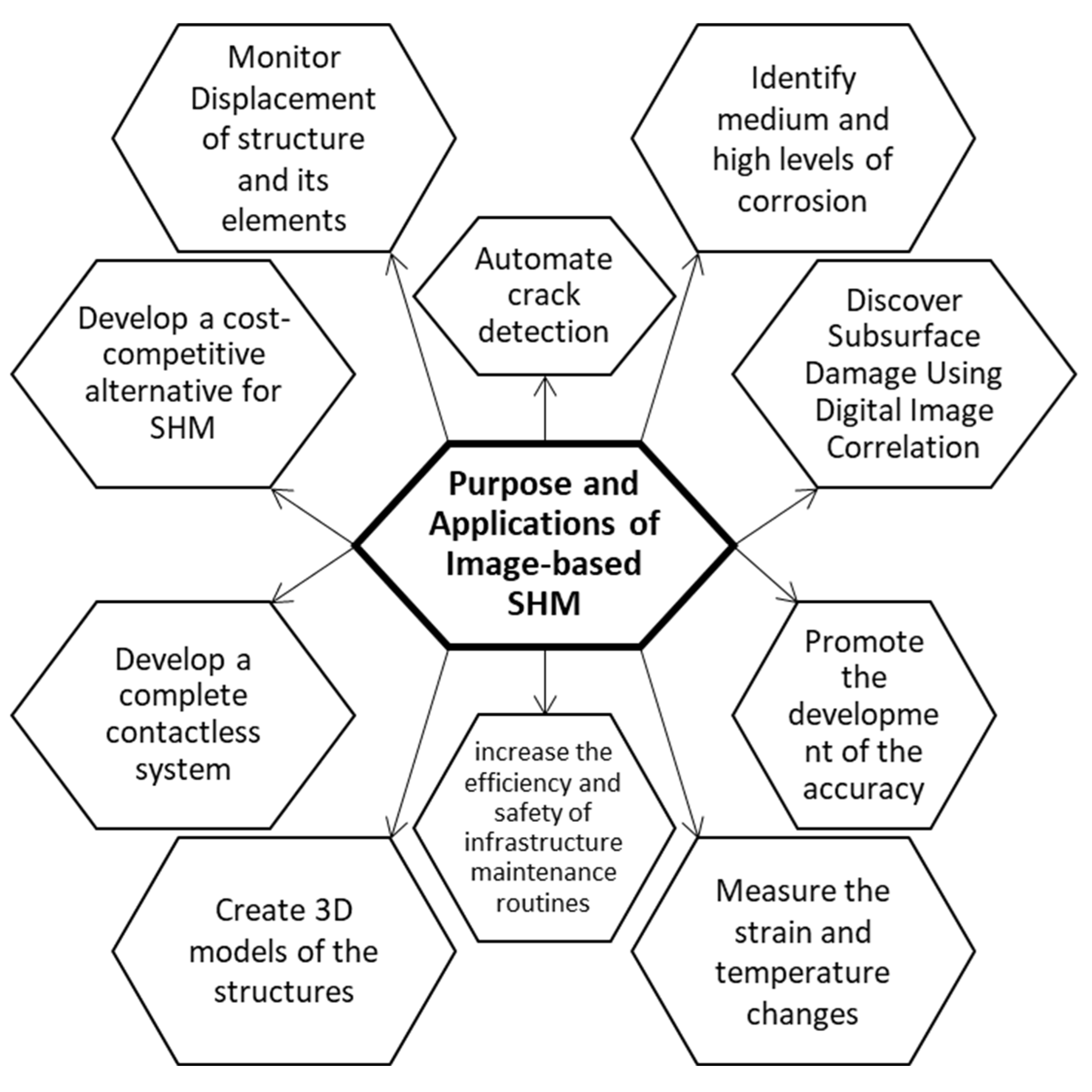

4.1. Purpose and Applications of Image-Based Structural Health Monitoring

4.1.1. To Identify and Discover

4.1.2. To Measure and Monitor

4.1.3. To Automate and Increase Efficiency

4.1.4. To Promote Development, and Create 3D Models

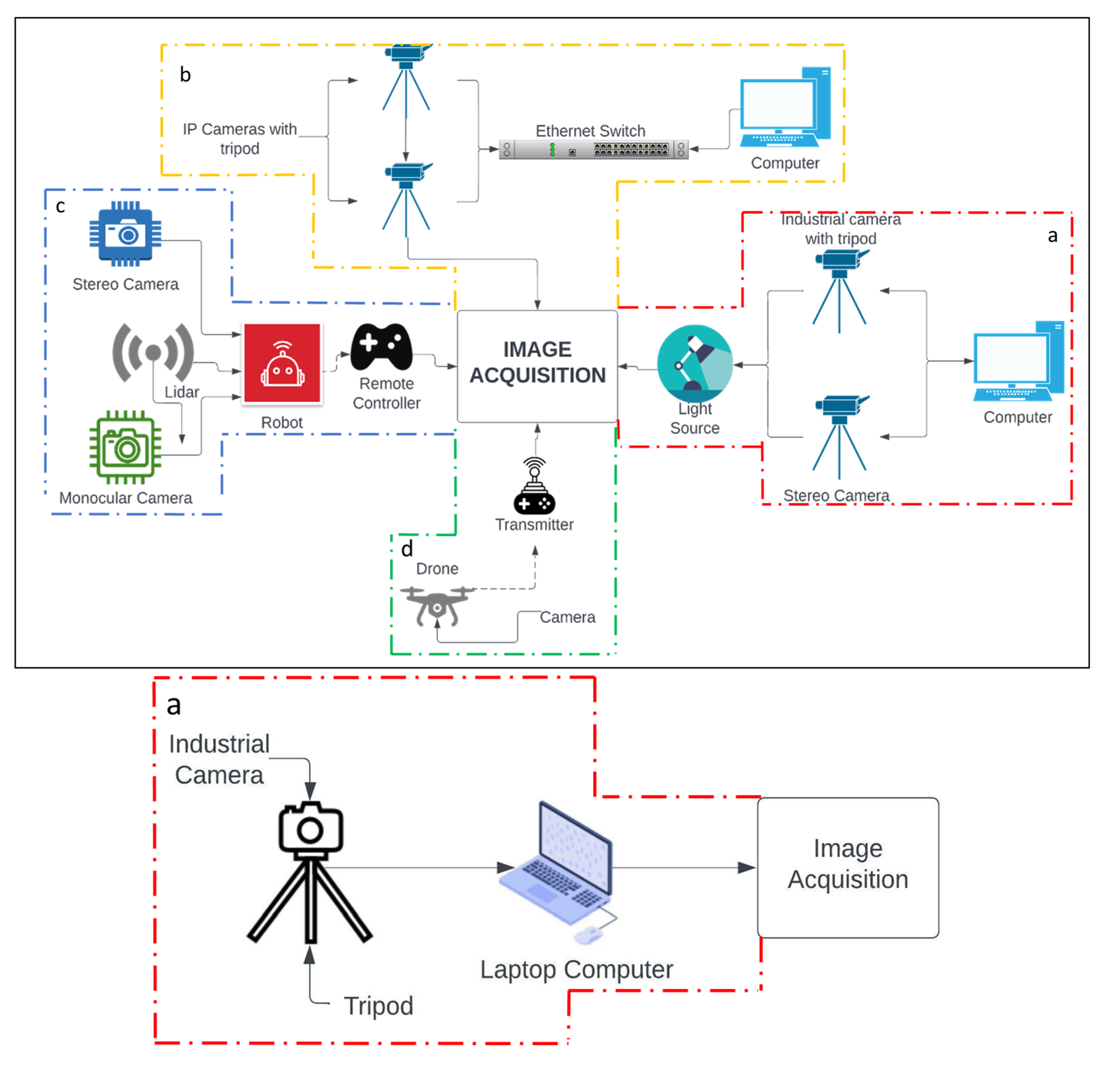

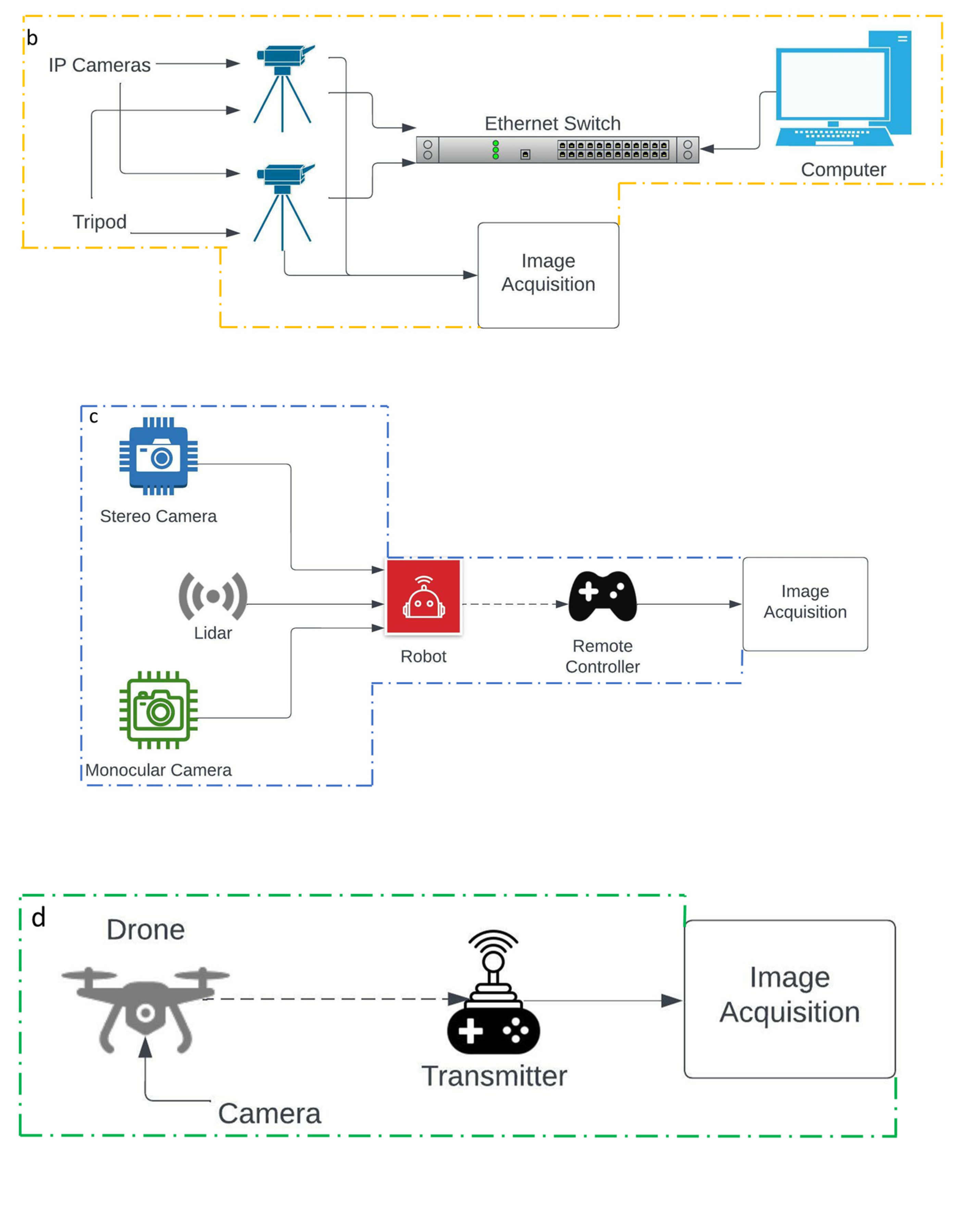

4.2. Implementation of Image-Based Devices and Systems

4.2.1. 2D Vision System for DIC

4.2.2. 3D Vision System for Digital Image Correlation

4.2.3. Novel Inspection System Using Inspection Robot

4.2.4. UAV Photogrammetry for Displacement Monitoring

4.3. Roles and Importance of Components and Parameters

4.3.1. Digital Image Correlation

4.3.2. Detection and Sizing of Deep and Multiple Damages

4.3.3. Pilotless Operations

4.3.4. Long-Term Applications

4.4. Issues on Image-Based SHM

4.4.1. Limited Range

- Hardware components of a camera. Each lens will vary in how much it magnifies the image (video).

- Atmosphere and weather. Even under ideal conditions, the air you are viewing through contains molecules that impair the image by obstructing light transmission. Moisture, rain, snow, dirt, and fog lessen visual contrast, while air turbulence caused by thermal fluctuations throughout the scene causes image distortions.

- Pixels Per Meter (PPM). A number that indicates the number of identifiable pixels over a 1 m width at a certain distance from the camera. PPM is an objective assessment of detail that takes into consideration the camera’s lens, resolution, and sensor size.

- Angle of View (AOV). The focal length of the lens in proportion to the sensor size determines AOV. Longer lenses or smaller sensors generate narrower fields of vision, whereas shorter lenses or bigger sensors produce broader fields of view.

- Sensor resolution. The amount of detail inside a camera’s field of vision is determined by this factor.

4.4.2. Broad-Scale of Natural Frequencies to Be Utilized

4.4.3. Difficulty in Securing High-Quality Devices, Use of Advanced Types of Sensors, Determining Enough Quantities of Sensors for a Strategic Location

4.4.4. Automation

4.4.5. Other Issues

4.5. Applications for Innovation

- ○

- Digital Camera Detection SHM

- ○

- Eyeglass Augmented Reality SHM

- ○

- Flashlight to Image SHM

- ○

- Numerical simulations

- ○

- Big Data Analysis in Image-based SHM

4.6. Guidelines and Prerequisites

4.6.1. Creation of Threshold

4.6.2. Mandatory Video-Image Sensor

4.6.3. Eradication of Multiple Sensors and Expanding of Storage of Data

- How are the features generated?

- What is the best number of features to use?

- Having adopted the appropriate features, for the specific task, how does one design the classifier?

- How can one assess the performance of the designed classifier?

- What is the classification error rate? This is the task of the system evaluation stage.

4.6.4. Application of Digital Image Correlation on Moving Loads

4.6.5. New Algorithms for Grayscale and Colored Images

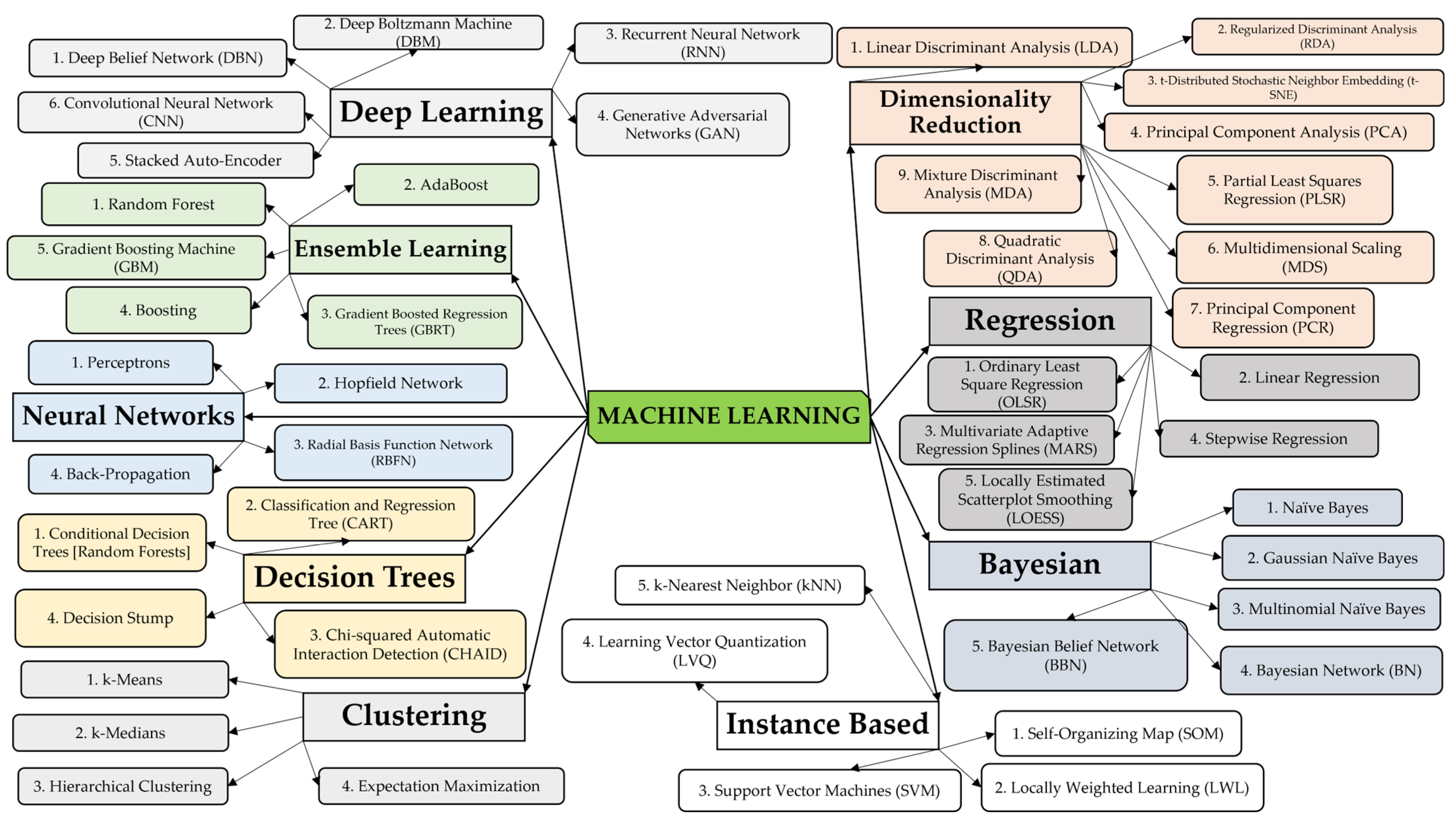

Convolutional Neural Networks (CNNs)

Long Short-Term Memory Networks (LSTMs)

Recurrent Neural Networks (RNNs)

Generative Adversarial Networks (GANs)

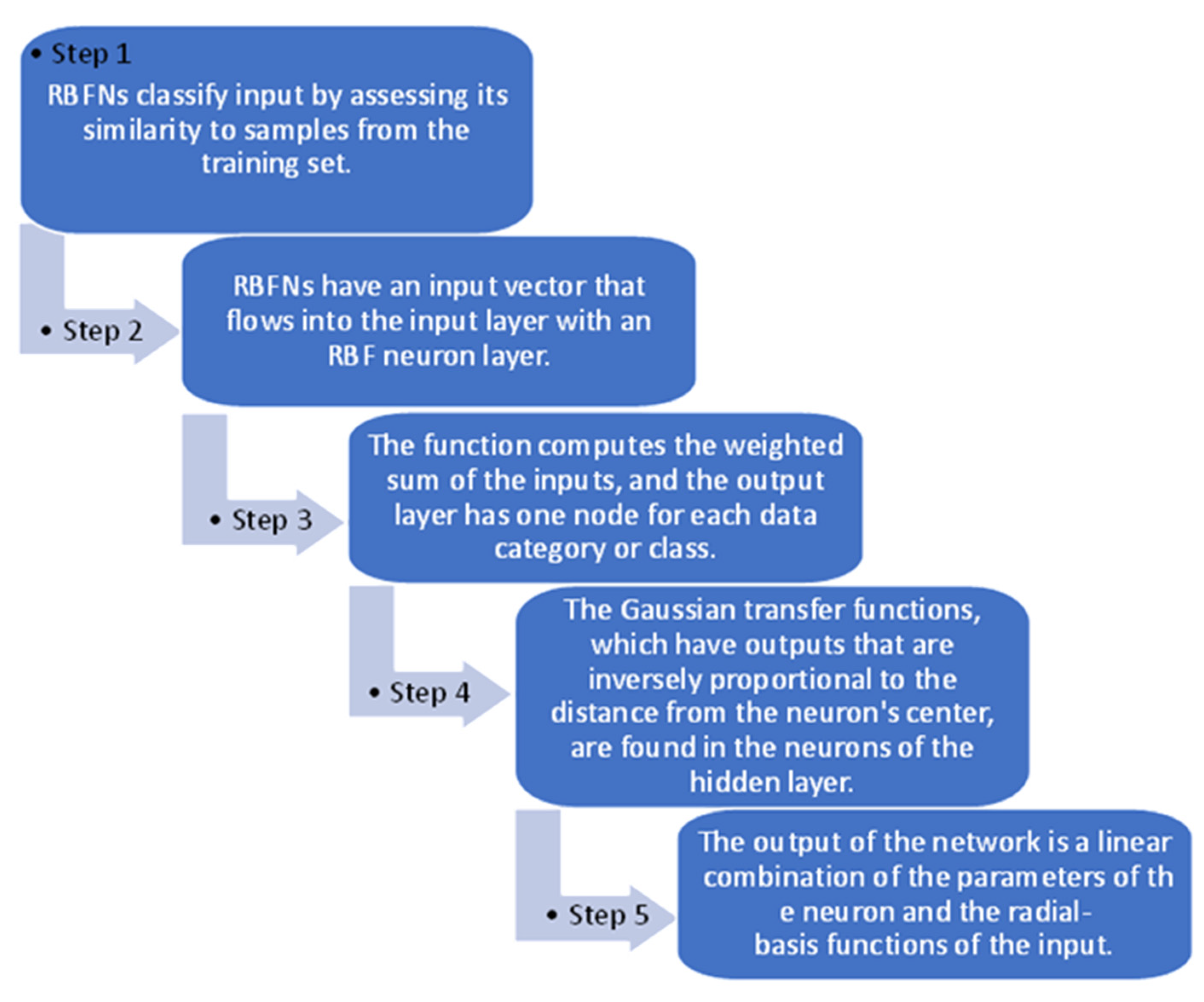

Radial Basis Function Networks (RBFNs)

5. Conclusions

- Devices and systems are not commercially available because there is no single absolute method for Image-based SHM. One must design their own that is tailored to their specific needs. These needs include, but are not limited to: the monitoring of displacement of structures and their elements; the automation of crack detection; the identification of medium and high levels of corrosion; the discovery of subsurface damage; the promotion of development; the measurement of strain and temperature changes; increasing efficiency; the creation of 2D and 3D models; the development of complete contactless approaches and methods through machine learning and autonomous systems; and the development of cost-competitive alternatives.

- Image acquisition is carried out using: IP cameras connected to a computer on an ethernet switch; industrial and stereo cameras equipped with a light source for better image quality; drones with cameras controlled by a transmitter; and remote-controlled robots with stereo and monocular cameras.

- In image-based SHM, the collection, treatment, and storage of data vary. DIC, a computer vision tool, is well-known for: its ability to disclose deformation patterns on structures; analyzing deflection produced by static loads; measuring the seismic response of structures; and comparing external displacement fields between damaged and non-damaged circumstances.

- Deep and multiple damages can be detected using faster R-CNN, end-to-end defect detection network, guided wave imaging, and convolutional neural network.

- Unmanned aerial vehicles can be used to perform in-construction and in-service condition monitoring, allowing for life-cycle monitoring and the assessment of the structure.

- We presented the typical challenges in image-based SHM that future researchers and implementers may face. The solutions for these issues and the concept map for machine learning applications on big data analysis in image-based SHM were highlighted in Section 4.4 and Section 4.5 of this study.

- In Section 4.6 of this work, the answer to the question: “How should image-based SHM be implemented, and what are the requirements for success?” is given.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 2D | Two-Dimensional | IP | Image Processing |

| 3D | Three-Dimensional | LSTMs | Long Short-Term Memory Networks |

| AOV | Angle of View | MDPI | Multidisciplinary Digital Publishing Institute |

| ASCE | The American Society of Civil Engineers | ML | Machine Learning |

| ANN | Artificial Neural Networks | MUAV | Multirotor Unmanned Aerial Vehicles |

| CIS | Civil Infrastructure Systems | NDT | Non-Destructive Testing |

| CNN | Convolutional Neural Networks | PPM | Pixels Per Meter |

| CV | Computer Vision | RBFNs | Radial Basis Function Networks |

| DAS | Delay-And-Sum | R-CNN | Region-based Convolutional Neural Network |

| DIC | Digital Image Correlation | RQ | Research Question |

| DL | Deep Learning | SHM | Structural Health Monitoring |

| EDDN | End-to-end Defect Detection Network | SURF | Speeded-Up Robust Features |

| GANs | Generative Adversarial Networks | UAVs | Unmanned Aerial Vehicles |

| GWI | Guided Waves Imaging | UIL | Unit Influence Line |

| IEEE | Institute of Electrical Engineers | ||

| IOP | Institute of Physics |

References

- Azimi, M.; Eslamlou, A.; Pekcan, G. Data-Driven Structural Health Monitoring and Damage Detection through Deep Learning: State-of-the-Art Review. Sensors 2020, 20, 2778. [Google Scholar] [CrossRef]

- Bao, Y.; Chen, Z.; Wei, S.; Xu, Y.; Tang, Z.; Li, H. The State of the Art of Data Science and Engineering in Structural Health Monitoring. Engineering 2019, 5, 234–242. [Google Scholar] [CrossRef]

- Li, H.-N.; Ren, L.; Jia, Z.-G.; Yi, T.-H.; Li, D.-S. State-of-the-Art in Structural Health Monitoring of Large and Complex Civil Infrastructures. J. Civ. Struct. Health Monit. 2016, 6, 3–16. [Google Scholar] [CrossRef]

- Achenbach, J.D. Structural Health Monitoring—What Is the Prescription? Mech. Res. Commun. 2009, 36, 137–142. [Google Scholar] [CrossRef]

- Sumitro, S.; Wang, M.L. Sustainable Structural Health Monitoring System. Struct. Control Health Monit. 2005, 12, 445–467. [Google Scholar] [CrossRef]

- Cha, Y.-J.; Choi, W.; Büyüköztürk, O. Deep Learning-Based Crack Damage Detection Using Convolutional Neural Networks: Deep Learning-Based Crack Damage Detection Using CNNs. Comput. Aided Civ. Infrastruct. Eng. 2017, 32, 361–378. [Google Scholar] [CrossRef]

- Roussel, M.; Glisic, B.; Lau, J.M.; Fong, C.C. Long-Term Monitoring of High-Rise Buildings Connected by Link Bridges. J. Civ. Struct. Health Monit. 2014, 4, 57–67. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M.Q. Experimental Validation of Cost-Effective Vision-Based Structural Health Monitoring. Mech. Syst. Signal Process. 2017, 88, 199–211. [Google Scholar] [CrossRef]

- Bianchi, E.; Hebdon, M. Visual Structural Inspection Datasets. Autom. Constr. 2022, 139, 104299. [Google Scholar] [CrossRef]

- Khuc, T.; Catbas, F.N. Completely Contactless Structural Health Monitoring of Real-Life Structures Using Cameras and Computer Vision: Structural Health Monitoring Using Computer Vision. Struct. Control Health Monit. 2016, 24, e1852. [Google Scholar] [CrossRef]

- Sankarasrinivasan, S.; Balasubramanian, E.; Karthik, K.; Chandrasekar, U.; Gupta, R. Health Monitoring of Civil Structures with Integrated UAV and Image Processing System. Procedia Comput. Sci. 2015, 54, 508–515. [Google Scholar] [CrossRef]

- Sajedi, S.O.; Liang, X. Uncertainty-assisted Deep Vision Structural Health Monitoring. Comput. Aided Civ. Infrastruct. Eng. 2021, 36, 126–142. [Google Scholar] [CrossRef]

- Zhou, H.; Xu, C.; Tang, X.; Wang, S.; Zhang, Z. A Review of Vision-Laser-Based Civil Infrastructure Inspection and Monitoring. Sensors 2022, 22, 5882. [Google Scholar] [CrossRef] [PubMed]

- Salman, M.; Mathavan, S.; Kamal, K.; Rahman, M. Pavement Crack Detection Using the Gabor Filter. In Proceedings of the 16th International IEEE Conference on Intelligent Transportation Systems (ITSC 2013), The Hague, Netherlands, 6–9 October 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 2039–2044. [Google Scholar]

- Zou, Q.; Cao, Y.; Li, Q.; Mao, Q.; Wang, S. CrackTree: Automatic Crack Detection from Pavement Images. Pattern Recognit. Lett. 2012, 33, 227–238. [Google Scholar] [CrossRef]

- Koch, C.; Brilakis, I. Pothole Detection in Asphalt Pavement Images. Adv. Eng. Inform. 2011, 25, 507–515. [Google Scholar] [CrossRef]

- Fu, J.; Zhu, X.; Li, Y. Recognition Of Surface Defects On Steel Sheet Using Transfer Learning. arXiv 2019. [Google Scholar] [CrossRef]

- Nishikawa, T.; Yoshida, J.; Sugiyama, T.; Fujino, Y. Concrete Crack Detection by Multiple Sequential Image Filtering: Concrete Crack Detection by Image Processing. Comput. Aided Civ. Infrastruct. Eng. 2012, 27, 29–47. [Google Scholar] [CrossRef]

- Abu Dabous, S.; Zeiada, W.; Zayed, T.; Al-Ruzouq, R. Sustainability-Informed Multi-Criteria Decision Support Framework for Ranking and Prioritization of Pavement Sections. J. Clean. Prod. 2020, 244, 118755. [Google Scholar] [CrossRef]

- Lydon, D.; Lydon, M.; Taylor, S.; Del Rincon, J.M.; Hester, D.; Brownjohn, J. Development and Field Testing of a Vision-Based Displacement System Using a Low Cost Wireless Action Camera. Mech. Syst. Signal Process. 2019, 121, 343–358. [Google Scholar] [CrossRef]

- Kuhn, V.N.; Drews, P.L.J.; Gomes, S.C.P.; Cunha, M.A.B.; da Botelho, S.S.C. Automatic Control of a ROV for Inspection of Underwater Structures Using a Low-Cost Sensing. J. Braz. Soc. Mech. Sci. Eng. 2014, 37, 361–374. [Google Scholar] [CrossRef]

- Lei, B.; Ren, Y.; Wang, N.; Huo, L.; Song, G. Design of a New Low-Cost Unmanned Aerial Vehicle and Vision-Based Concrete Crack Inspection Method. Struct. Health Monit. 2020, 19, 1871–1883. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, H.; Wang, S.; Xu, C.; Lv, Y. Design and Research of Low-Cost and Self-Adaptive Terrestrial Laser Scanning for Indoor Measurement Based on Adaptive Indoor Measurement Scanning Strategy and Structural Characteristics Point Cloud Segmentation. Adv. Civ. Eng. 2022, 2022, 5681771. [Google Scholar] [CrossRef]

- Grosso, A.E.D. Structural Health Monitoring: Research and Practice. In Proceedings of the SMAR 2013 the 2nd Conference on Smart Monitoring, Assessment and Rehabilitation of Civil Structures, Istanbul, Türkiye, 9–11 September 2013; pp. 1–8. [Google Scholar]

- Swartz, M.K. PRISMA 2020: An Update. J. Pediatr. Health Care 2021, 35, 351. [Google Scholar] [CrossRef]

- Power, J. Systematic Reviews in Engineering Education: A Catalyst for Change. Eur. J. Eng. Educ. 2021, 46, 1163–1174. [Google Scholar] [CrossRef]

- Balali, A.; Yunusa-Kaltungo, A.; Edwards, R. A Systematic Review of Passive Energy Consumption Optimisation Strategy Selection for Buildings through Multiple Criteria Decision-Making Techniques. Renew. Sustain. Energy Rev. 2013, 171, 113013. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Syst. Rev. 2021, 10, 89. [Google Scholar] [CrossRef]

- Ratan, S.; Anand, T.; Ratan, J. Formulation of Research Question—Stepwise Approach. J. Indian Assoc. Pediatr. Surg. 2019, 24, 15. [Google Scholar] [CrossRef]

- Kishore, J.; Vasundhra, S.; Anand, T. Formulation of a Research Question. Indian J. Med. Spec. 2011, 2, 184–188. [Google Scholar] [CrossRef]

- Carrera-Rivera, A.; Ochoa, W.; Larrinaga, F.; Lasa, G. How-to Conduct a Systematic Literature Review: A Quick Guide for Computer Science Research. MethodsX 2022, 9, 101895. [Google Scholar] [CrossRef]

- Zou, Z.; Qin, Z.; Li, Y.; Liu, Q. Study on a Health Monitoring and Defect Imaging Technology of Special Equipment That Is Based on Optical Fiber Ultrasonic Sensing. Opt. Fiber Technol. 2021, 61, 102393. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M.Q. Computer Vision for SHM of Civil Infrastructure: From Dynamic Response Measurement to Damage Detection—A Review. Eng. Struct. 2018, 156, 105–117. [Google Scholar] [CrossRef]

- Ngeljaratan, L.; Moustafa, M.A. Structural Health Monitoring and Seismic Response Assessment of Bridge Structures Using Target-Tracking Digital Image Correlation. Eng. Struct. 2020, 213, 110551. [Google Scholar] [CrossRef]

- Mitra, M.; Gopalakrishnan, S. Guided Wave Based Structural Health Monitoring: A Review. Smart Mater. Struct. 2016, 25, 053001. [Google Scholar] [CrossRef]

- Sun, Z.; Chang, C.C. Statistical Wavelet-Based Method for Structural Health Monitoring. J. Struct. Eng. 2004, 130, 1055–1062. [Google Scholar] [CrossRef]

- Hera, A.; Hou, Z. Application of Wavelet Approach for ASCE Structural Health Monitoring Benchmark Studies. J. Eng. Mech. 2004, 130, 96–104. [Google Scholar] [CrossRef]

- Croxford, A.J.; Wilcox, P.D.; Drinkwater, B.W.; Konstantinidis, G. Strategies for Guided-Wave Structural Health Monitoring. Proc. R. Soc. A Math. Phys. Eng. Sci. 2007, 463, 2961–2981. [Google Scholar] [CrossRef]

- Im, S.B.; Hurlebaus, S.; Kang, Y.J. Summary Review of GPS Technology for Structural Health Monitoring. J. Struct. Eng. 2013, 139, 1653–1664. [Google Scholar] [CrossRef]

- Ye, X.W.; Dong, C.Z.; Liu, T. A Review of Machine Vision-Based Structural Health Monitoring: Methodologies and Applications. J. Sens. 2016, 2016, 7103039. [Google Scholar] [CrossRef]

- Moreno-Gomez, A.; Perez-Ramirez, C.A.; Dominguez-Gonzalez, A.; Valtierra-Rodriguez, M.; Chavez-Alegria, O.; Amezquita-Sanchez, J.P. Sensors Used in Structural Health Monitoring. Arch. Comput. Methods Eng. 2018, 25, 901–918. [Google Scholar] [CrossRef]

- Bremer, K.; Wollweber, M.; Weigand, F.; Rahlves, M.; Kuhne, M.; Helbig, R.; Roth, B. Fibre Optic Sensors for the Structural Health Monitoring of Building Structures. Procedia Technol. 2016, 26, 524–529. [Google Scholar] [CrossRef]

- Farrar, C.R.; Park, G.; Allen, D.W.; Todd, M.D. Sensor Network Paradigms for Structural Health Monitoring. Struct. Control Health Monit. 2006, 13, 210–225. [Google Scholar] [CrossRef]

- Sony, S.; Laventure, S.; Sadhu, A. A Literature Review of Next-Generation Smart Sensing Technology in Structural Health Monitoring. Struct. Control Health Monit. 2019, 26, e2321. [Google Scholar] [CrossRef]

- Tokognon, C.A.; Gao, B.; Tian, G.Y.; Yan, Y. Structural Health Monitoring Framework Based on Internet of Things: A Survey. IEEE Internet Things J. 2017, 4, 619–635. [Google Scholar] [CrossRef]

- Scuro, C.; Sciammarella, P.F.; Lamonaca, F.; Olivito, R.S.; Carni, D.L. IoT for Structural Health Monitoring. IEEE Instrum. Meas. Mag. 2018, 21, 4–14. [Google Scholar] [CrossRef]

- Dizaji, M.S.; Alipour, M.; Harris, D.K. Subsurface Damage Detection and Structural Health Monitoring Using Digital Image Correlation and Topology Optimization. Eng. Struct. 2021, 230, 111712. [Google Scholar] [CrossRef]

- Sangirardi, M.; Altomare, V.; De Santis, S.; de Felice, G. Detecting Damage Evolution of Masonry Structures through Computer-Vision-Based Monitoring Methods. Buildings 2022, 12, 831. [Google Scholar] [CrossRef]

- Fioriti, V.; Roselli, I.; Tatì, A.; Romano, R.; De Canio, G. Motion Magnification Analysis for Structural Monitoring of Ancient Constructions. Measurement 2018, 129, 375–380. [Google Scholar] [CrossRef]

- Wadhwa, N.; Rubinstein, M.; Durand, F.; Freeman, W.T. Phase-Based Video Motion Processing. ACM Trans. Graph. 2013, 32, 1–10. [Google Scholar] [CrossRef]

- Fioriti, V.; Roselli, I.; Cataldo, A.; Forliti, S.; Colucci, A.; Baldini, M.; Picca, A. Motion Magnification Applications for the Protection of Italian Cultural Heritage Assets. Sensors 2022, 22, 9988. [Google Scholar] [CrossRef]

- do Cabo, C.T.; Valente, N.A.; Mao, Z. Motion Magnification for Optical-Based Structural Health Monitoring. In Proceedings of the Health Monitoring of Structural and Biological Systems IX, Online, 23 April–8 May 2020; Fromme, P., Su, Z., Eds.; SPIE: Bellingham, WA, USA, 2020; p. 83. [Google Scholar]

- do Cabo, C.T.; Valente, N.A.; Mao, Z. A Comparative Analysis of Imaging Processing Techniques for Non-Invasive Structural Health Monitoring. IFAC-PapersOnLine 2022, 55, 150–154. [Google Scholar] [CrossRef]

- Glisic, B.; Inaudi, D. Fibre Optic Methods for Structural Health Monitoring; John Wiley & Sons: Chichester, UK; Hoboken, NJ, USA, 2007; ISBN 9780470061428. [Google Scholar]

- Glisic, B.; Inaudi, D.; Kronenberg, P.; Vurpillot, S. Dam Monitoring Using Long SOFO Sensor. In Proceedings of the Hydropower into Next Century, Gmunden, Austria, 18–19 October 1999. [Google Scholar]

- Glisic, B.; Badoux, M.; Jaccoud, J.-P.; Inaudi, D.; Sa, S. Monitoring a Subterranean Structure with the Sofo System. Tunn. Manag. Int. Mag. 2000, 2, 22–27. [Google Scholar]

- Inaudi, D.; Casanova, N.; Sa, S.; Steinmann, G.; Mathier, J.-F.; Martinola, G. SOFO: Tunnel Monitoring with Fiber Optic Sensors. Reducing Risk Tunn. Des. Constr. 2000, 12, 7–8. [Google Scholar]

- Barros, F.; Aguiar, S.; Sousa, P.J.; Cachaço, A.; Tavares, P.J.; Moreira, P.M.G.P.; Ranzal, D.; Cardoso, N.; Fernandes, N.; Fernandes, R.; et al. Displacement Monitoring of a Pedestrian Bridge Using 3D Digital Image Correlation. Procedia Struct. Integr. 2022, 37, 880–887. [Google Scholar] [CrossRef]

- Kim, B.; Cho, S. Automated Vision-Based Detection of Cracks on Concrete Surfaces Using a Deep Learning Technique. Sensors 2018, 18, 3452. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Kang, F.; Li, J.; Ma, C. Structural Health Monitoring and Inspection of Dams Based on UAV Photogrammetry with Image 3D Reconstruction. Autom. Constr. 2021, 130, 103832. [Google Scholar] [CrossRef]

- Yuan, C.; Xiong, B.; Li, X.; Sang, X.; Kong, Q. A Novel Intelligent Inspection Robot with Deep Stereo Vision for Three-Dimensional Concrete Damage Detection and Quantification. Struct. Health Monit. 2022, 21, 788–802. [Google Scholar] [CrossRef]

- Martini, A.; Tronci, E.M.; Feng, M.Q.; Leung, R.Y. A Computer Vision-Based Method for Bridge Model Updating Using Displacement Influence Lines. Eng. Struct. 2022, 259, 114129. [Google Scholar] [CrossRef]

- Winkler, J.; Fischer, G.; Georgakis, C.T. Measurement of Local Deformations in Steel Monostrands Using Digital Image Correlation. J. Bridge Eng. 2014, 19, 04014042. [Google Scholar] [CrossRef]

- Acikgoz, S.; DeJong, M.J.; Soga, K. Sensing Dynamic Displacements in Masonry Rail Bridges Using 2D Digital Image Correlation. Struct. Control Health Monit. 2018, 25, e2187. [Google Scholar] [CrossRef]

- Curt, J.; Capaldo, M.; Hild, F.; Roux, S. An Algorithm for Structural Health Monitoring by Digital Image Correlation: Proof of Concept and Case Study. Opt. Lasers Eng. 2022, 151, 106842. [Google Scholar] [CrossRef]

- Barros, F.; Aguiar, S.; Sousa, P.J.; Cachaço, A.; Ramos, N.V.; Tavares, P.J.; Moreira, P.M.G.P.; Xu, M.; Santos, L.O.; Franco, E. Displacement Monitoring of Crossbeams in an Airport Runway Extension Using Digital Image Correlation. Procedia Struct. Integr. 2022, 37, 159–166. [Google Scholar] [CrossRef]

- Hild, F.; Roux, S. Digital Image Correlation: From Displacement Measurement to Identification of Elastic Properties—A Review. Strain 2006, 42, 69–80. [Google Scholar] [CrossRef]

- Sutton, M.A. Computer Vision-Based, Noncontacting Deformation Measurements in Mechanics: A Generational Transformation. Appl. Mech. Rev. 2013, 65, 050802. [Google Scholar] [CrossRef]

- Cha, Y.-J.; Choi, W.; Suh, G.; Mahmoudkhani, S.; Büyüköztürk, O. Autonomous Structural Visual Inspection Using Region-Based Deep Learning for Detecting Multiple Damage Types: Autonomous SHM Using Deep Faster R-CNN. Comput. Aided Civ. Infrastruct. Eng. 2018, 33, 731–747. [Google Scholar] [CrossRef]

- Lv, X.; Duan, F.; Jiang, J.; Fu, X.; Gan, L. Deep Metallic Surface Defect Detection: The New Benchmark and Detection Network. Sensors 2020, 20, 1562. [Google Scholar] [CrossRef]

- Miorelli, R.; Fisher, C.; Kulakovskyi, A.; Chapuis, B.; Mesnil, O.; D’Almeida, O. Defect Sizing in Guided Wave Imaging Structural Health Monitoring Using Convolutional Neural Networks. NDT E Int. 2021, 122, 102480. [Google Scholar] [CrossRef]

- Akbar, M.A.; Qidwai, U.; Jahanshahi, M.R. An Evaluation of Image-Based Structural Health Monitoring Using Integrated Unmanned Aerial Vehicle Platform. Struct. Control Health Monit. 2019, 26, e2276. [Google Scholar] [CrossRef]

- Khuc, T.; Nguyen, T.A.; Dao, H.; Catbas, F.N. Swaying Displacement Measurement for Structural Monitoring Using Computer Vision and an Unmanned Aerial Vehicle. Measurement 2020, 159, 107769. [Google Scholar] [CrossRef]

- Zaurin, R.; Catbas, F.N. Integration of Computer Imaging and Sensor Data for Structural Health Monitoring of Bridges. Smart Mater. Struct. 2010, 19, 015019. [Google Scholar] [CrossRef]

- Su, J.-Z.; Xia, Y.; Chen, L.; Zhao, X.; Zhang, Q.-L.; Xu, Y.-L.; Ding, J.-M.; Xiong, H.-B.; Ma, R.-J.; Lv, X.-L.; et al. Long-Term Structural Performance Monitoring System for the Shanghai Tower. J. Civ. Struct. Health Monit. 2013, 3, 49–61. [Google Scholar] [CrossRef]

- Park, S.W.; Park, H.S.; Kim, J.H.; Adeli, H. 3D Displacement Measurement Model for Health Monitoring of Structures Using a Motion Capture System. Measurement 2015, 59, 352–362. [Google Scholar] [CrossRef]

- Chen, C.-C.; Wu, W.-H.; Tseng, H.-Z.; Chen, C.-H.; Lai, G. Application of Digital Photogrammetry Techniques in Identifying the Mode Shape Ratios of Stay Cables with Multiple Camcorders. Measurement 2015, 75, 134–146. [Google Scholar] [CrossRef]

- Chen, D.Q.; Mocker, M.; Preston, D.S.; Teubner, A. Information Systems Strategy: Reconceptualization, Measurement, and Implications. MIS Q. 2010, 34, 233. [Google Scholar] [CrossRef]

- Malik, H.; Khattak, K.S.; Wiqar, T.; Khan, Z.H.; Altamimi, A.B. Low Cost Internet of Things Platform for Structural Health Monitoring. In Proceedings of the 2019 22nd International Multitopic Conference (INMIC), Islamabad, Pakistan, 29–30 November 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–7. [Google Scholar]

- Stabile, T.A.; Giocoli, A.; Perrone, A.; Palombo, A.; Pascucci, S.; Pignatti, S. A New Joint Application of Non-Invasive Remote Sensing Techniques for Structural Health Monitoring. J. Geophys. Eng. 2012, 9, S53–S63. [Google Scholar] [CrossRef]

- Pieraccini, M.; Fratini, M.; Parrini, F.; Atzeni, C.; Bartoli, G. Interferometric Radar vs. Accelerometer for Dynamic Monitoring of Large Structures: An Experimental Comparison. NDT E Int. 2008, 41, 258–264. [Google Scholar] [CrossRef]

- Gentile, C.; Bernardini, G. Output-Only Modal Identification of a Reinforced Concrete Bridge from Radar-Based Measurements. NDT E Int. 2008, 41, 544–553. [Google Scholar] [CrossRef]

- Yeum, C.M.; Dyke, S.J. Vision-Based Automated Crack Detection for Bridge Inspection: Vision-Based Automated Crack Detection for Bridge Inspection. Comput. Aided Civ. Infrastruct. Eng. 2015, 30, 759–770. [Google Scholar] [CrossRef]

- Hiasa, S.; Birgul, R.; Catbas, F.N. Infrared Thermography for Civil Structural Assessment: Demonstrations with Laboratory and Field Studies. J. Civ. Struct. Health Monit. 2016, 6, 619–636. [Google Scholar] [CrossRef]

- Saravanan, G.; Yamuna, G. Real Time Implementation of Image Enhancement Based on 2D-DWT. Procedia Comput. Sci. 2016, 87, 105–110. [Google Scholar] [CrossRef]

- Tharwat, M.; Mohamed, N.; Mongy, T. Image Enhancement Using MCNP5 Code and MATLAB in Neutron Radiography. Appl. Radiat. Isot. 2014, 89, 30–36. [Google Scholar] [CrossRef]

- The MathWorks Inc. (MATLAB). Academic Use (R2010a); The MathWorks Inc.: Natick, MA, USA, 2022. [Google Scholar]

- Tian, L.; Pan, B. Remote Bridge Deflection Measurement Using an Advanced Video Deflectometer and Actively Illuminated LED Targets. Sensors 2016, 16, 1344. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.-W.; Jeon, B.-G.; Kim, N.-S.; Park, J.-C. Vision-Based Monitoring System for Evaluating Cable Tensile Forces on a Cable-Stayed Bridge. Struct. Health Monit. 2013, 12, 440–456. [Google Scholar] [CrossRef]

- Pallarés, F.J.; Betti, M.; Bartoli, G.; Pallarés, L. Structural Health Monitoring (SHM) and Nondestructive Testing (NDT) of Slender Masonry Structures: A Practical Review. Constr. Build. Mater. 2021, 297, 123768. [Google Scholar] [CrossRef]

- Khuc, T.; Catbas, F.N. Vision-Based for Bridge Structural Health Monitoring and Identification. In Proceedings of the SMAR 2015-Third Conference on Smart Monitoring, Assessment and Rehabilitation of Civil Structures, Antalya, Türkiye, 7–9 September 2015; pp. 1–9. [Google Scholar]

- Singh, P.; Ahmad, U.F.; Yadav, S. Structural Health Monitoring and Damage Detection through Machine Learning Approaches. E3S Web Conf. 2020, 220, 01096. [Google Scholar] [CrossRef]

- Oliveros-Esco, J.; Gracia-Villa, L.; López-Mesa, B. 2D Image-Based Crack Monitoring: An Affordable, Sufficient and Non-Invasive Technique for the Democratization of Preventive Conservation of Listed Buildings. Herit. Sci. 2022, 10, 146. [Google Scholar] [CrossRef]

- Napolitano, R.; Liu, Z.; Sun, C.; Glisic, B. Combination of Image-Based Documentation and Augmented Reality for Structural Health Monitoring and Building Pathology. Front. Built Environ. 2019, 5, 50. [Google Scholar] [CrossRef]

- Ozer, E.; Feng, M.Q. Structural Health Monitoring. In Start-Up Creation; Elsevier: Amsterdam, The Netherlands, 2020; pp. 345–367. ISBN 9780128199466. [Google Scholar]

- Wei, H.; Li, J.; Wang, F.; Zheng, J.; Tao, Y.; Zhang, Y. Numerical Investigation on Fracture Evolution of Asphalt Mixture Compared with Acoustic Emission. Int. J. Pavement Eng. 2022, 23, 3481–3491. [Google Scholar] [CrossRef]

- Gong, J.; Nie, Z.; Zhu, Y.; Liang, Z.; Wang, X. Exploring the Effects of Particle Shape and Content of Fines on the Shear Behavior of Sand-Fines Mixtures via the DEM. Comput. Geotech. 2019, 106, 161–176. [Google Scholar] [CrossRef]

- Wang, L.; Yao, Y.; Li, J.; Tao, Y.; Liu, K. Review of Visualization Technique and Its Application of Road Aggregates Based on Morphological Features. Appl. Sci. 2022, 12, 10571. [Google Scholar] [CrossRef]

- Chernov, A.V.; Savvas, I.K.; Alexandrov, A.A.; Kartashov, O.O.; Polyanichenko, D.S.; Butakova, M.A.; Soldatov, A.V. Integrated Video and Acoustic Emission Data Fusion for Intelligent Decision Making in Material Surface Inspection System. Sensors 2022, 22, 8554. [Google Scholar] [CrossRef]

- Gulgec, N.S.; Shahidi, G.S.; Matarazzo, T.J.; Pakzad, S.N. Current Challenges with BIGDATA Analytics in Structural Health Monitoring. In Structural Health Monitoring & Damage Detection, Conference Proceedings of the Society for Experimental Mechanics Series; Niezrecki, C., Ed.; Springer International Publishing: Cham, Switzerland, 2017; Volume 7, pp. 79–84. ISBN 9783319541082. [Google Scholar]

- Raghupathi, W.; Raghupathi, V. Big Data Analytics in Healthcare: Promise and Potential. Health Inf. Sci. Syst. 2014, 2, 3. [Google Scholar] [CrossRef] [PubMed]

- Schumacher, T.; Shariati, A. Monitoring of Structures and Mechanical Systems Using Virtual Visual Sensors for Video Analysis: Fundamental Concept and Proof of Feasibility. Sensors 2013, 13, 16551–16564. [Google Scholar] [CrossRef]

- McGinnis, M.J.; Barbachyn, S.; Kurama, Y.C. Application of multiple digital image correlation sensors in earthquake engineering. In Proceedings of the 10th National Conference in Earthquake Engineering, Anchorage, AK, USA, 21–25 July 2014. [Google Scholar]

- Wu, X.; Zhu, X.; Wu, G.-Q.; Ding, W. Data Mining with Big Data. IEEE Trans. Knowl. Data Eng. 2014, 26, 97–107. [Google Scholar] [CrossRef]

- Taylor, R.C. An Overview of the Hadoop/MapReduce/HBase Framework and Its Current Applications in Bioinformatics. BMC Bioinform. 2010, 11, S1. [Google Scholar] [CrossRef] [PubMed]

- Dean, J.; Ghemawat, S. MapReduce: Simplified Data Processing on Large Clusters. Commun. ACM 2008, 51, 107–113. [Google Scholar] [CrossRef]

- Donoho, D.L. Compressed Sensing. IEEE Trans. Inf. Theory 2006, 52, 1289–1306. [Google Scholar] [CrossRef]

- He, K.; Gkioxari, G.; Dollar, P.; Girshick, R. Mask R-CNN. In Proceedings of the 2017 IEEE International Conference on Computer Vision (ICCV), Venice, Italy, 22–29 October 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 2980–2988. [Google Scholar]

- Mosalam, K.; Muin, S.; Gao, Y. New directions in structural health monitoring. NED Univ. J. Res. 2019, 2, 77–112. [Google Scholar] [CrossRef]

- Sun, L.; Shang, Z.; Xia, Y.; Bhowmick, S.; Nagarajaiah, S. Review of Bridge Structural Health Monitoring Aided by Big Data and Artificial Intelligence: From Condition Assessment to Damage Detection. J. Struct. Eng. 2020, 146, 04020073. [Google Scholar] [CrossRef]

- Ding, Z.; Li, J.; Hao, H. Structural Damage Identification by Sparse Deep Belief Network Using Uncertain and Limited Data. Struct. Control Health Monit. 2020, 27, e2522. [Google Scholar] [CrossRef]

- Rafiei, M.H.; Khushefati, W.H.; Demirboga, R.; Adeli, H. Supervised Deep Restricted Boltzmann Machine for Estimation of Concrete. ACI Mater. J. 2017, 114, 237–244. [Google Scholar] [CrossRef]

- Narazaki, Y.; Hoskere, V.; Hoang, T.A.; Spencer Jr, B.F. Automated Bridge Component Recognition Using Video Data. arXiv 2018, arXiv:1806.06820. [Google Scholar]

- Goodfellow, I.; Pouget-Abadie, J.; Mirza, M.; Xu, B.; Warde-Farley, D.; Ozair, S.; Courville, A.; Bengio, Y. Generative Adversarial Networks. arXiv 2014, arXiv:1406.2661. [Google Scholar] [CrossRef]

- Pathirage, C.S.N.; Li, J.; Li, L.; Hao, H.; Liu, W.; Wang, R. Development and Application of a Deep Learning–Based Sparse Autoencoder Framework for Structural Damage Identification. Struct. Health Monit. 2019, 18, 103–122. [Google Scholar] [CrossRef]

- Li, S.; Sun, L. Detectability of Bridge-Structural Damage Based on Fiber-Optic Sensing through Deep-Convolutional Neural Networks. J. Bridge Eng. 2020, 25, 04020012. [Google Scholar] [CrossRef]

- Hastie, T.; Tibshirani, R.; Buja, A. Flexible Discriminant Analysis by Optimal Scoring. J. Am. Stat. Assoc. 1994, 89, 1255–1270. [Google Scholar] [CrossRef]

- Natekin, A.; Knoll, A. Gradient Boosting Machines, a Tutorial. Front. Neurorobot. 2013, 7. [Google Scholar] [CrossRef]

- Friedman, J.H. Greedy Function Approximation: A Gradient Boosting Machine. Ann. Statist. 2001, 29, 1189–1232. [Google Scholar] [CrossRef]

- Zuo, K.; Bu, S.; Zhang, W.; Hu, J.; Ye, Z.; Yuan, X. Fast Sparse Flow Field Prediction around Airfoils via Multi-Head Perceptron Based Deep Learning Architecture. Aerosp. Sci. Technol. 2022, 130, 107942. [Google Scholar] [CrossRef]

- Heravi, O.E.; Ghalehnovi, M.; Entezami, A. Application of Hopfield Neural Network to Structural Health Monitoring. In Proceedings of the 6th International Conference on Acoustics & Vibration (ISAV2016), Tehran, Iran, 7–8 December 2016. [Google Scholar]

- Zang, C.; Friswell, M.I.; Imregun, M. Structural Health Monitoring and Damage Assessment Using Measured FRFs from Multiple Sensors, Part II: Decision Making with RBF Networks. Key Eng. Mater. 2003, 245–246, 141–148. [Google Scholar] [CrossRef]

- Li, S.; Wang, W.; Lu, B.; Du, X.; Dong, M.; Zhang, T.; Bai, Z. Long-Term Structural Health Monitoring for Bridge Based on Back Propagation Neural Network and Long and Short-Term Memory. Struct. Health Monit. 2022, 147592172211223. [Google Scholar] [CrossRef]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Lewis, R.J. An Introduction to Classification and Regression Tree (CART) Analysis. In Proceedings of the Annual Meeting of the Society for Academic Emergency Medicine, San Francisco, CA, USA, 22–25 May 2000. [Google Scholar]

- Zeng, J.; Roussis, P.C.; Mohammed, A.S.; Maraveas, C.; Fatemi, S.A.; Armaghani, D.J.; Asteris, P.G. Prediction of Peak Particle Velocity Caused by Blasting through the Combinations of Boosted-CHAID and SVM Models with Various Kernels. Appl. Sci. 2021, 11, 3705. [Google Scholar] [CrossRef]

- Ranasinghe, K.; Sabatini, R.; Gardi, A.; Bijjahalli, S.; Kapoor, R.; Fahey, T.; Thangavel, K. Advances in Integrated System Health Management for Mission-Essential and Safety-Critical Aerospace Applications. Prog. Aerosp. Sci. 2022, 128, 100758. [Google Scholar] [CrossRef]

- Salehi, H.; Burgueño, R. Emerging Artificial Intelligence Methods in Structural Engineering. Eng. Struct. 2018, 171, 170–189. [Google Scholar] [CrossRef]

- Dasgupta, S.; Frost, N.; Moshkovitz, M.; Rashtchian, C. Explainable K-Means and k-Medians Clustering. arXiv 2020, arXiv:2002.12538. [Google Scholar]

- Louiset, R.; Gori, P.; Dufumier, B.; Houenou, J.; Grigis, A.; Duchesnay, E. UCSL: A Machine Learning Expectation-Maximization Framework for Unsupervised Clustering Driven by Supervised Learning. arXiv 2021. [Google Scholar] [CrossRef]

- Entezami, A.; Shariatmadar, H.; Mariani, S. Structural Health Monitoring for Condition Assessment Using Efficient Supervised Learning Techniques. In Proceedings of the 6th International Electronic Conference on Sensors and Applications, Online, 15–30 November 2019; MDPI: Basel, Switzerland, 2019; p. 17. [Google Scholar]

- Fan, J.; Feng, Y.; Tong, X. A Road to Classification in High Dimensional Space: The Regularized Optimal Affine Discriminant: Regularized Optimal Affine Discriminant. J. R. Stat. Soc. Ser. B Stat. Methodol. 2012, 74, 745–771. [Google Scholar] [CrossRef]

- Rogovschi, N.; Kitazono, J.; Grozavu, N.; Omori, T.; Ozawa, S. T-Distributed Stochastic Neighbor Embedding Spectral Clustering. In Proceedings of the 2017 International Joint Conference on Neural Networks (IJCNN), Anchorage, AK, USA, 14–19 May 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1628–1632. [Google Scholar]

- Mishra, S.; Sarkar, U.; Taraphder, S.; Datta, S.; Swain, D.; Saikhom, R.; Panda, S.; Laishram, M. Multivariate Statistical Data Analysis- Principal Component Analysis (PCA). Int. J. Livest. Res. 2017, 7, 60–78. [Google Scholar] [CrossRef]

- Chen, C.; Cao, X.; Tian, L. Partial Least Squares Regression Performs Well in MRI-Based Individualized Estimations. Front. Neurosci. 2019, 13, 1282. [Google Scholar] [CrossRef]

- Hubert, M.; Branden, K.V. Robust Methods for Partial Least Squares Regression. J. Chemom. 2003, 17, 537–549. [Google Scholar] [CrossRef]

- Sen, D.; Erazo, K.; Zhang, W.; Nagarajaiah, S.; Sun, L. On the Effectiveness of Principal Component Analysis for Decoupling Structural Damage and Environmental Effects in Bridge Structures. J. Sound Vib. 2019, 457, 280–298. [Google Scholar] [CrossRef]

- Lin, J.-W. Repetitive Model Refinement for Structural Health Monitoring Using Efficient Akaike Information Criterion. Smart Struct. Syst. 2015, 15, 1329–1344. [Google Scholar] [CrossRef]

- Entezami, A.; Sarmadi, H.; Behkamal, B.; Mariani, S. Big Data Analytics and Structural Health Monitoring: A Statistical Pattern Recognition-Based Approach. Sensors 2020, 20, 2328. [Google Scholar] [CrossRef]

- Crawford, J.; Hughes, C.E.; Lykoudis, S. Alternative Least Squares Methods for Determining the Meteoric Water Line, Demonstrated Using GNIP Data. J. Hydrol. 2014, 519, 2331–2340. [Google Scholar] [CrossRef]

- Xi, P.S.; Ye, X.W.; Jin, T.; Chen, B. Structural Performance Monitoring of an Urban Footbridge. Struct. Monit. Maint. 2018, 5, 129–150. [Google Scholar] [CrossRef]

- Put, R.; Xu, Q.S.; Massart, D.L.; Vander Heyden, Y. Multivariate Adaptive Regression Splines (MARS) in Chromatographic Quantitative Structure–Retention Relationship Studies. J. Chromatogr. A 2004, 1055, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.L.; Deng, N.W.; Liu, Q.S. Optimization Study of Stepwise Regression and Partial Least Squares Regression Models for Dam Security Monitoring. Appl. Mech. Mater. 2014, 578–579, 1101–1107. [Google Scholar] [CrossRef]

- Jacoby, W.G. Loess:: A nonparametric, graphical tool for depicting relationships between variables. Elect. Stud. 2000, 19, 577–613. [Google Scholar] [CrossRef]

- Addin, O.; Sapuan, S.M.; Mahdi, E.; Othman, M. A Naïve-Bayes Classifier for Damage Detection in Engineering Materials. Mater. Des. 2007, 28, 2379–2386. [Google Scholar] [CrossRef]

- Jahromi, A.H.; Taheri, M. A Non-Parametric Mixture of Gaussian Naive Bayes Classifiers Based on Local Independent Features. In Proceedings of the 2017 Artificial Intelligence and Signal Processing Conference (AISP), Shiraz, Iran, 25–26 October 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 209–212. [Google Scholar]

- Kaushik, K.; Bhardwaj, A.; Dahiya, S.; Maashi, M.S.; Al Moteri, M.; Aljebreen, M.; Bharany, S. Multinomial Naive Bayesian Classifier Framework for Systematic Analysis of Smart IoT Devices. Sensors 2022, 22, 7318. [Google Scholar] [CrossRef]

- Tubaldi, E.; Turchetti, F.; Ozer, E.; Fayaz, J.; Gehl, P.; Galasso, C. A Bayesian Network-based Probabilistic Framework for Updating Aftershock Risk of Bridges. Earthq. Eng. Struct. Dyn. 2022, 51, 2496–2519. [Google Scholar] [CrossRef]

- Vagnoli, M.; Remenyte-Prescott, R.; Andrews, J. A Bayesian Belief Network Method for Bridge Deterioration Detection. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2021, 235, 338–355. [Google Scholar] [CrossRef]

- Saraee, M.; Vahid Moosavi, S.; Rezapour, S. Application of Self Organizing Map (SOM) to Model a Machining Process. J. Manuf. Technol. Manag. 2011, 22, 818–830. [Google Scholar] [CrossRef]

- Reyes, O.; Cano, A.; Fardoun, H.M.; Ventura, S. A Locally Weighted Learning Method Based on a Data Gravitation Model for Multi-Target Regression. Int. J. Comput. Intell. Syst. 2018, 11, 282. [Google Scholar] [CrossRef]

- Cervantes, J.; Garcia-Lamont, F.; Rodríguez-Mazahua, L.; Lopez, A. A Comprehensive Survey on Support Vector Machine Classification: Applications, Challenges and Trends. Neurocomputing 2020, 408, 189–215. [Google Scholar] [CrossRef]

- Parini; Mawengkang, H.; Efendi, S. Hybrid Learning Vector Quantization (LVQ) Algorithm on Face Recognition Using Webcam. IOP Conf. Ser. Mater. Sci. Eng. 2018, 420, 012126. [Google Scholar] [CrossRef]

- Huang, S.; Huang, M.; Lyu, Y. An Improved KNN-Based Slope Stability Prediction Model. Adv. Civ. Eng. 2020, 2020, 8894109. [Google Scholar] [CrossRef]

- Sony, S.; Dunphy, K.; Sadhu, A.; Capretz, M. A Systematic Review of Convolutional Neural Network-Based Structural Condition Assessment Techniques. Eng. Struct. 2021, 226, 111347. [Google Scholar] [CrossRef]

- Hall, D.L.; Llinas, J. An Introduction to Multisensor Data Fusion. Proc. IEEE 2000, 85, 6–23. [Google Scholar] [CrossRef]

- Dong, C.-Z.; Catbas, F.N. A Review of Computer Vision–Based Structural Health Monitoring at Local and Global Levels. Struct. Health Monit. 2021, 20, 692–743. [Google Scholar] [CrossRef]

- Kralovec, C.; Schagerl, M. Review of Structural Health Monitoring Methods Regarding a Multi-Sensor Approach for Damage Assessment of Metal and Composite Structures. Sensors 2020, 20, 826. [Google Scholar] [CrossRef] [PubMed]

- Di Sante, R. Fibre Optic Sensors for Structural Health Monitoring of Aircraft Composite Structures: Recent Advances and Applications. Sensors 2015, 15, 18666–18713. [Google Scholar] [CrossRef] [PubMed]

- Xia, D.-H.; Song, S.; Tao, L.; Qin, Z.; Wu, Z.; Gao, Z.; Wang, J.; Hu, W.; Behnamian, Y.; Luo, J.-L. Review-Material Degradation Assessed by Digital Image Processing: Fundamentals, Progresses, and Challenges. J. Mater. Sci. Technol. 2020, 53, 146–162. [Google Scholar] [CrossRef]

- Santosh, K.; Das, N.; Ghosh, S. Deep Learning: A Review. In Deep Learning Models for Medical Imaging; Elsevier: Amsterdam, The Netherlands, 2022; pp. 29–63. ISBN 9780128235041. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Payawal, J.M.G.; Kim, D.-K. Image-Based Structural Health Monitoring: A Systematic Review. Appl. Sci. 2023, 13, 968. https://doi.org/10.3390/app13020968

Payawal JMG, Kim D-K. Image-Based Structural Health Monitoring: A Systematic Review. Applied Sciences. 2023; 13(2):968. https://doi.org/10.3390/app13020968

Chicago/Turabian StylePayawal, John Mark Go, and Dong-Keon Kim. 2023. "Image-Based Structural Health Monitoring: A Systematic Review" Applied Sciences 13, no. 2: 968. https://doi.org/10.3390/app13020968

APA StylePayawal, J. M. G., & Kim, D.-K. (2023). Image-Based Structural Health Monitoring: A Systematic Review. Applied Sciences, 13(2), 968. https://doi.org/10.3390/app13020968