Utility of Ultrasonic Pulse Velocity for Estimating the Overall Mechanical Behavior of Recycled Aggregate Self-Compacting Concrete

Abstract

1. Introduction

2. Materials and Methods

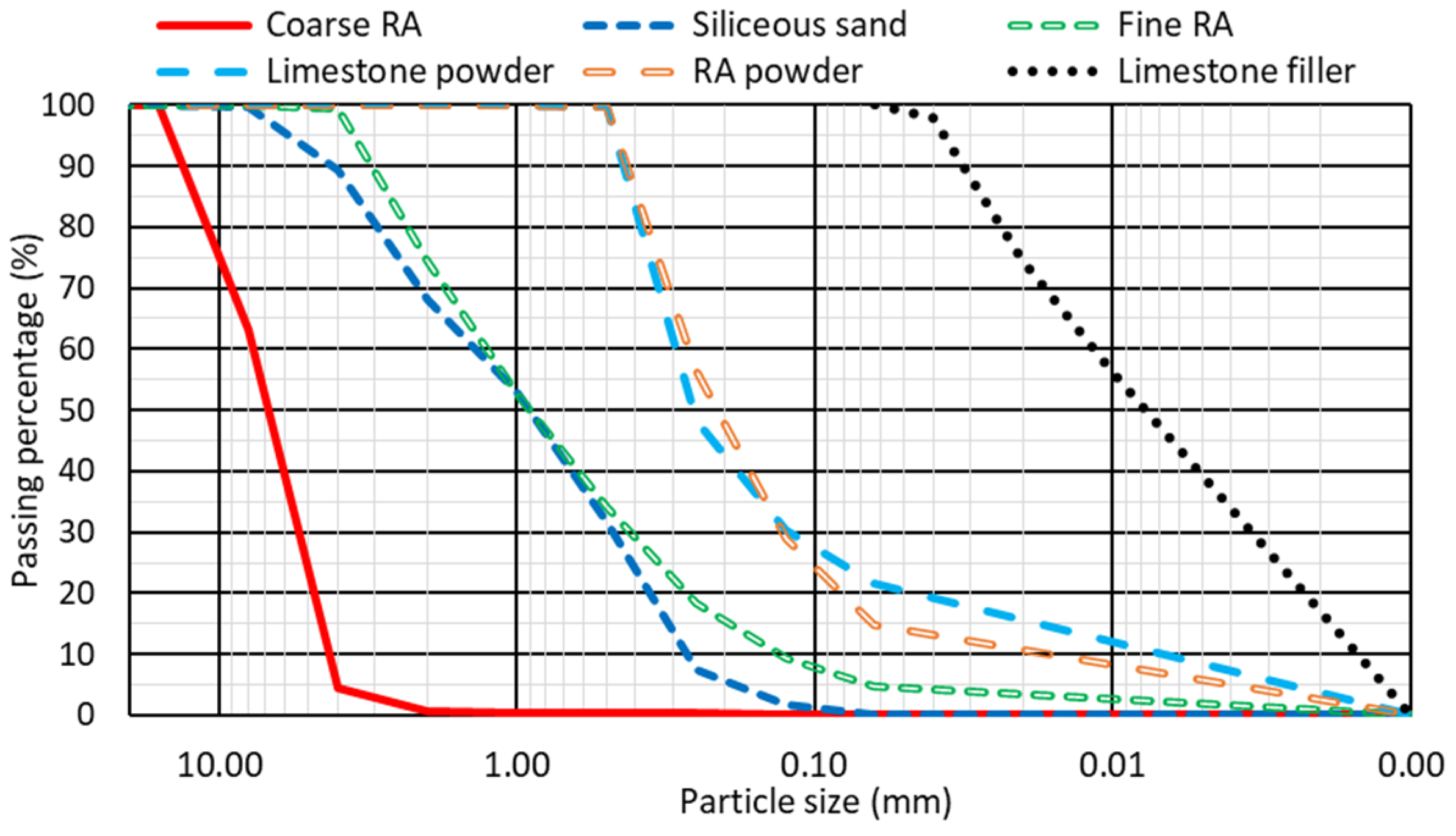

2.1. SCC Raw Materials

2.2. SCC Mix Design

- All the mixes incorporated the same amount of coarse RA, cement, and admixtures.

- The amount of water was increased when increasing the fine RA content or adding RA powder to balance their high-water absorption levels (Table 1), so that the effective water-to-cement ratio was equal to 0.40 in all mixes. The effective-water-to-cement ratio was calculated according to the 15-min water absorption levels (Table 1), as the mixing process of SCC lasted for 15 min.

- The use of larger-sized aggregate powders (limestone powder 0/0.5 mm and RA powder 0/0.5 mm) required increased amounts of aggregate powder compared to the mixes made with limestone filler <0.063 mm, proportionally adjusting the amount of fine aggregate. This action was necessary to achieve the fine particle content for the required slump flow [38].

- Aggregate powder: Limestone Filler (F); Limestone powder (L); RA powder (R).

- Percentage content of fine RA: 0% fine RA (0); 50% fine RA (50); 100% fine RA (100).

2.3. Experimental Plan

3. Results and Discussion: Experimental Tests

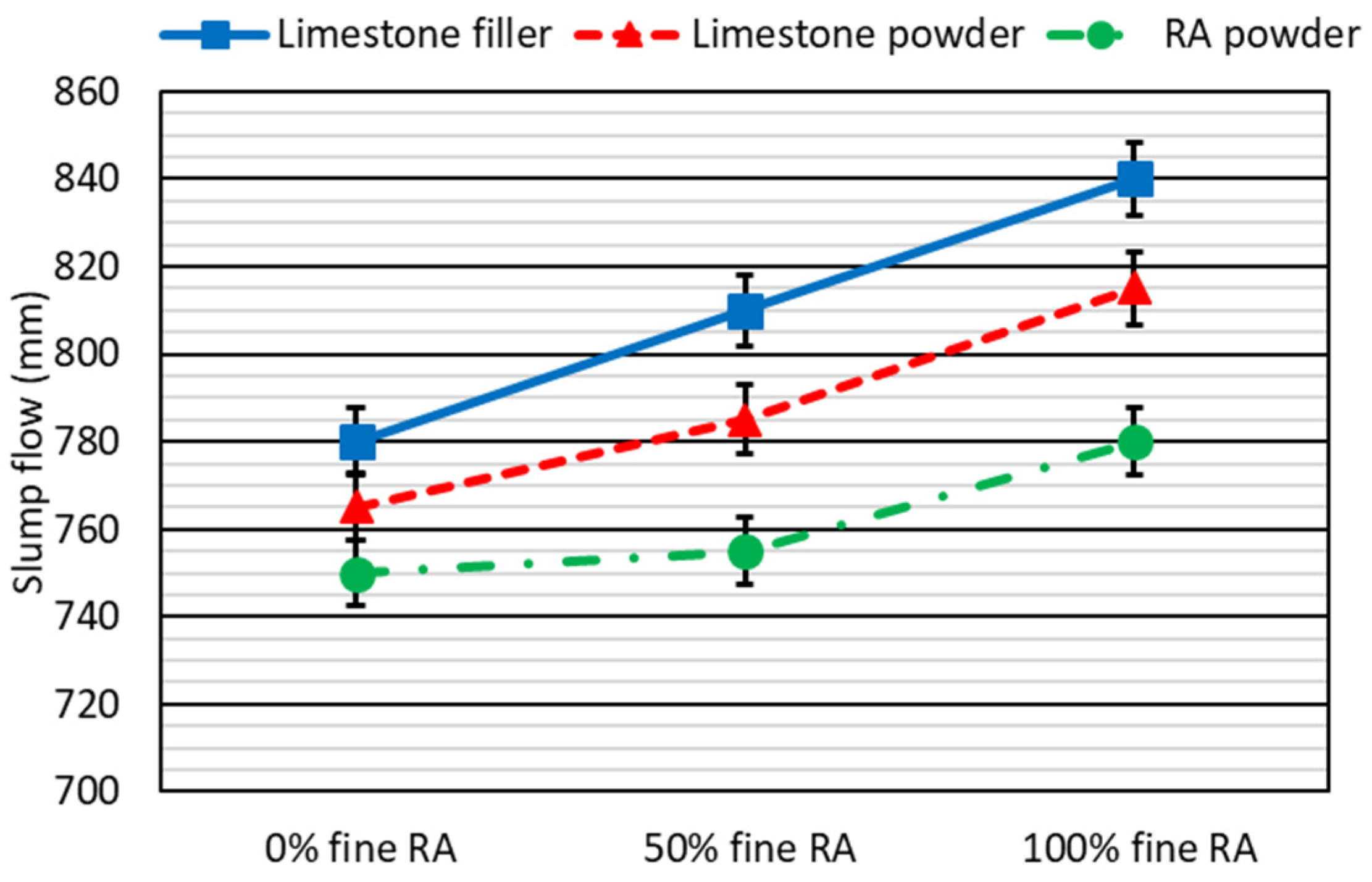

3.1. Fresh Performance: Slump Flow

3.2. Mechanical Performance

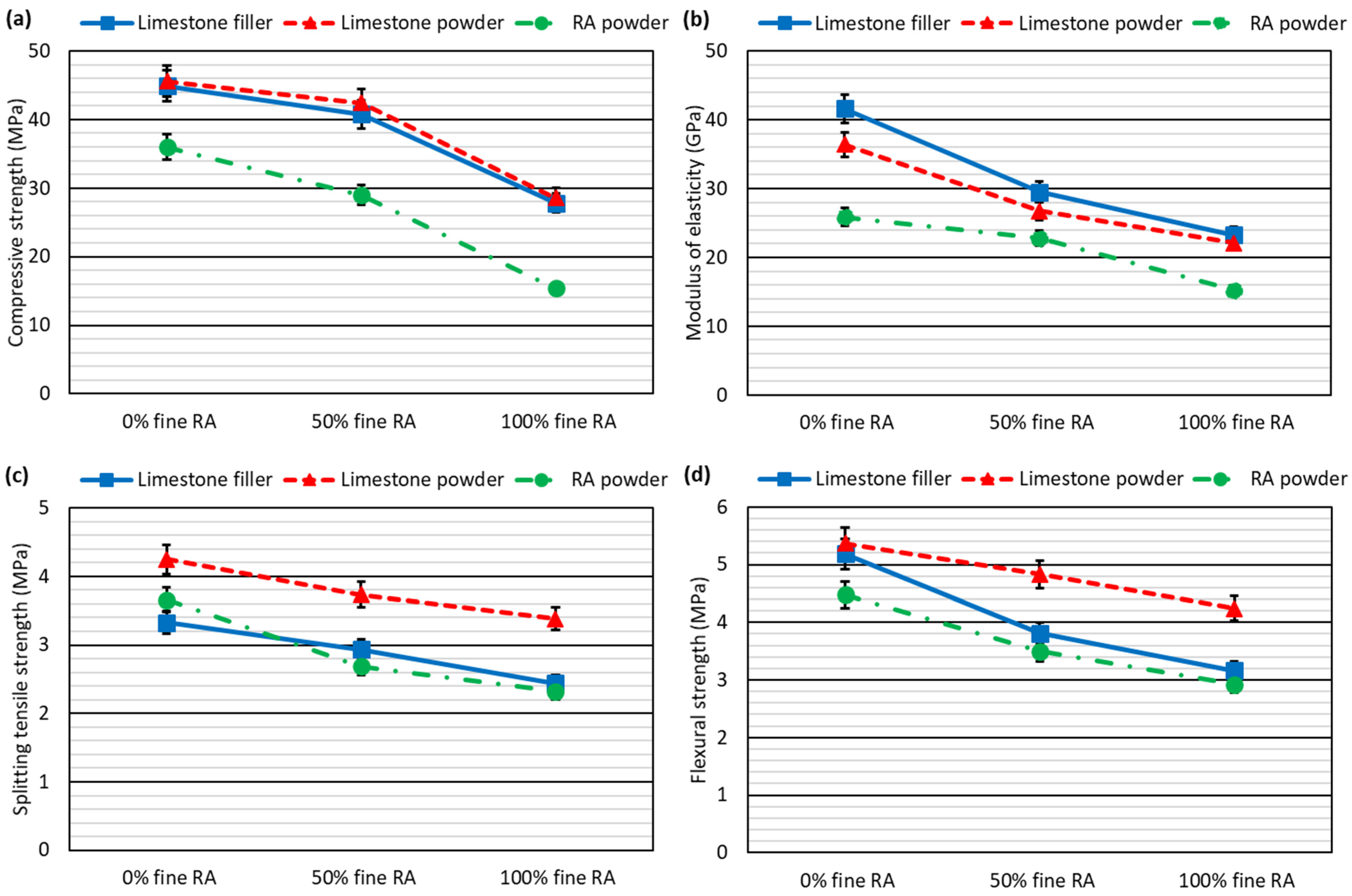

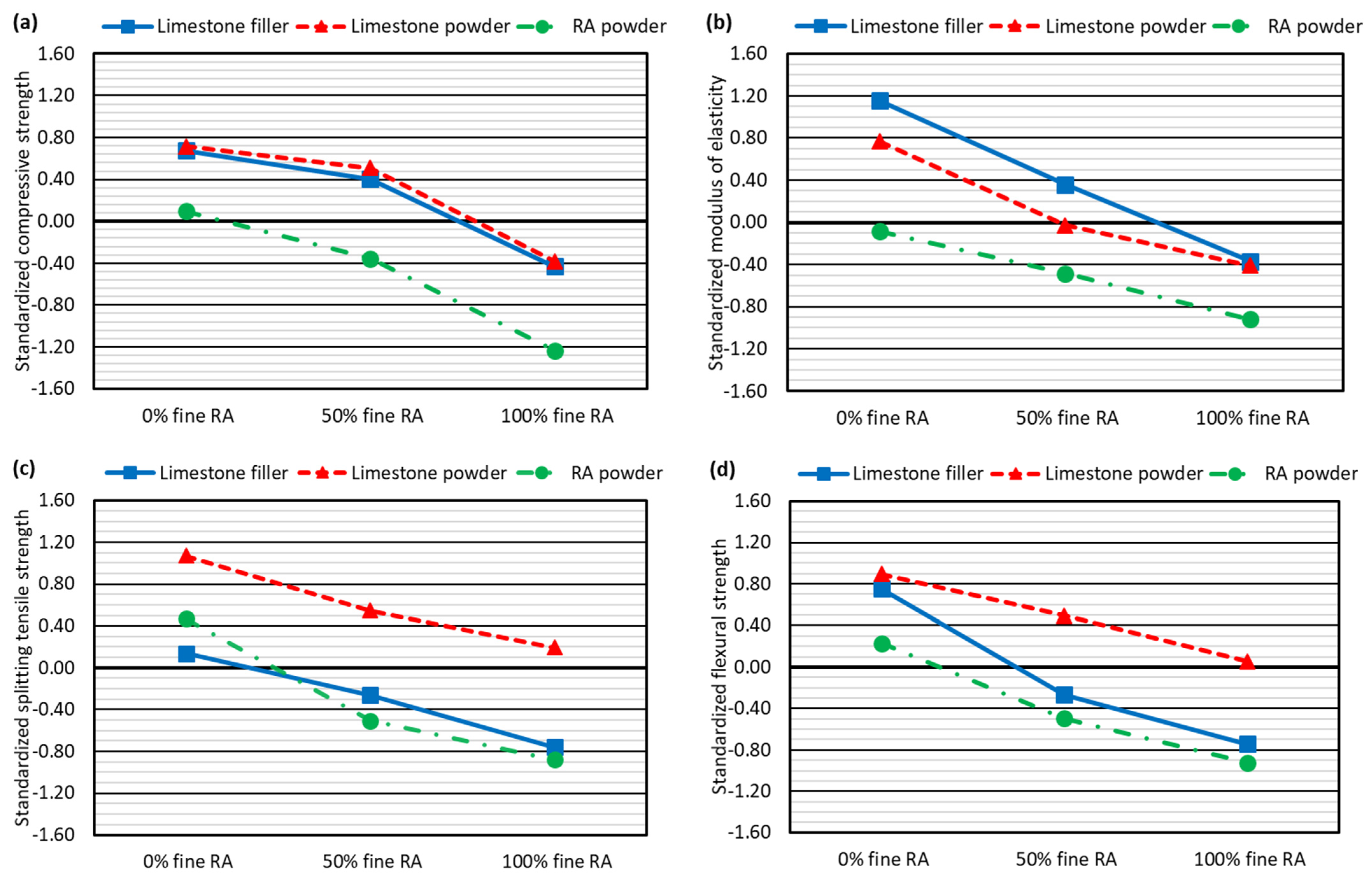

- On the one hand, the addition of fine RA led to a decrease in all mechanical properties, with an average reduction of 30–40% when using 100% fine RA. This decrease was almost linear for the properties dependent on bending-tensile behavior (splitting tensile strength and flexural strength, Figure 3c,d). On the contrary, the decrease in compressive strength and the modulus of elasticity for a 50% fine RA content was less than expected, considering the values obtained for 100% fine RA (Figure 3a,b). It showed the mainly negative effects of small amounts of fine RA on the bending-tensile behavior of SCC, which was already worse than that of vibrated concrete, due to its higher fines content [51]. Increased porosity and weakening of the interfacial transition zones caused by the fine RA explained this worsening of the mechanical performance [22,27].

- On the other hand, limestone powder provided the best results for strength-related properties and especially in those properties dependent on bending-tensile behavior. As found in other studies, this aggregate powder contributed to a compact and high-quality cementitious matrix [48]. The use of RA powder yielded the worst mechanical results and in the same way as fine RA, its presence explained a similar yet more pronounced strength behavior in the concrete [50,51]. Thus, a compressive strength of only 15.4 MPa was obtained when combining 100% fine RA and RA powder.

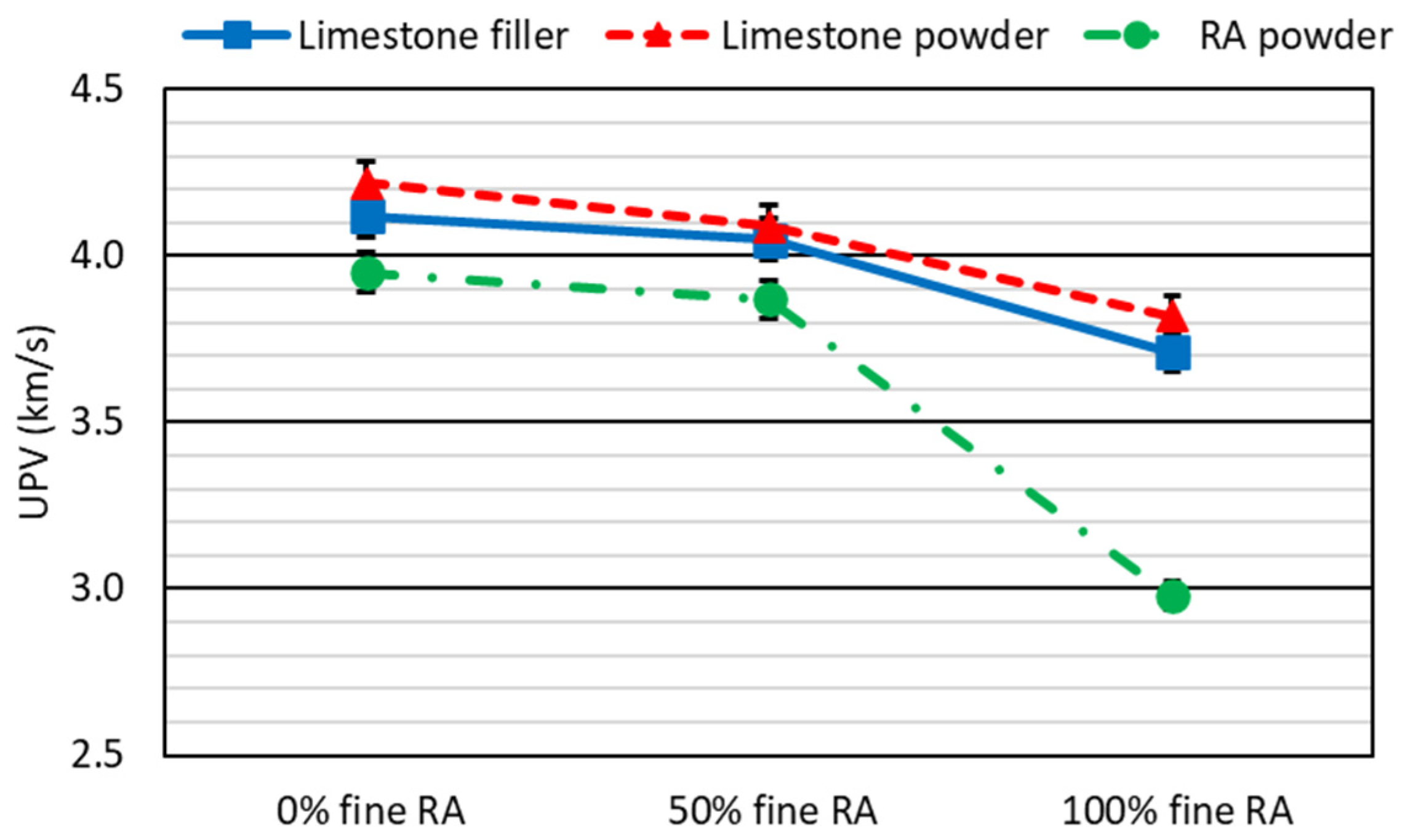

3.3. Ultrasonic Pulse Velocity (UPV)

4. Results and Discussion: Statistical Approach

4.1. Correlation Analysis

4.2. Simple-Regression Analysis

4.3. Multiple-Regression Analysis

4.3.1. Standardization

- A standardized value between 0.00 and 0.50 indicates that the property is above the mean and within the confidence interval.

- A value greater than 0.50 shows that the property is above the upper limit of the confidence interval.

- A value between −0.50 and 0.00 indicates that the property is below the mean, but within the 95% confidence interval.

- A value below −0.50 shows that the property is below the lower limit of the 95% confidence interval.

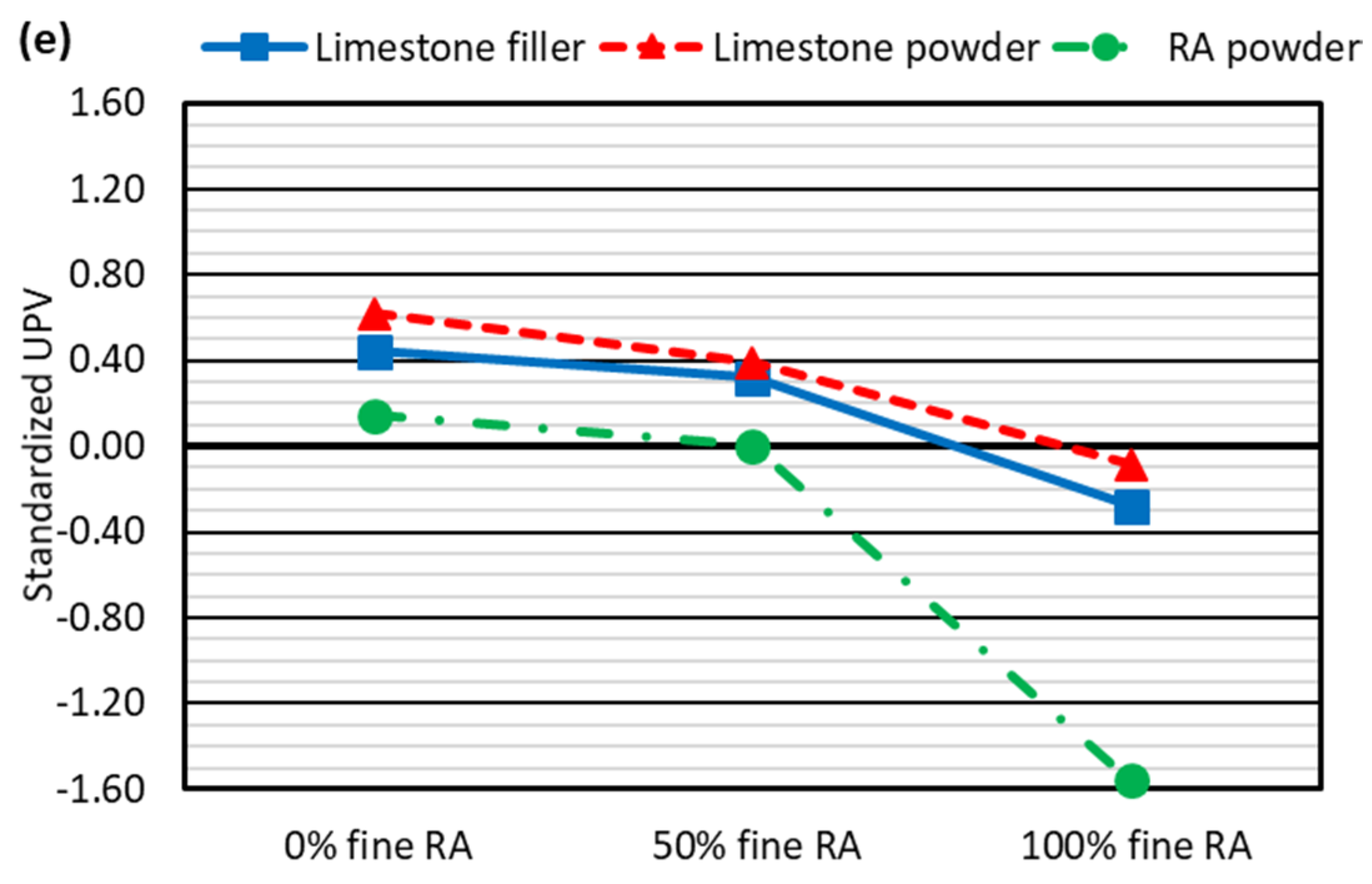

- The compressive-behavior-related mechanical properties (compressive strength and modulus of elasticity), as well as the UPV of the mixes made with up to 50% fine RA and limestone (both types) presented values that were in general higher than the mean value (standardized values over zero).

- The mixtures with limestone and fine natural aggregates (0% RA) were the ones that exceeded the upper limit of the 95% confidence interval (standardized values over 0.5).

- The standardized values for those mixes made with 100% fine RA were lower than the mean value and the lower limit of the 95% confidence interval (standardized values under −0.5).

- For the properties related to bending-tensile behavior (splitting tensile strength and flexural strength), only limestone powder 0/0.5 mm led to properties above the mean value in all cases (positive standardized values).

- The use of RA powder together with 0% fine RA led to standardized values very close to 0.00 for all the properties that were studied, which caused the increase in fine RA content to yield values that were clearly below the mean. Furthermore, when 100% fine RA was added, they were clearly below the 95% confidence interval (standardized values under −0.5).

4.3.2. Model Development

- On the one hand, two mechanical properties had a negative sign, i.e., a negative contribution to the UPV value. One of these properties was the modulus of elasticity, which offset the value of compressive strength. The other one was flexural strength, which counteracted the value of splitting tensile strength. As a result, it can be affirmed that the UPV value is a weighting of the mean of the properties related to compressive behavior, compressive strength, and modulus of elasticity, and of the mean of the properties related to bending-tensile behavior, which are splitting tensile strength and flexural strength.

- On the other hand, the weight of splitting tensile strength and flexural strength, properties related to bending-tensile behavior, had a negligible weight compared to the properties related to compressive behavior; results that are in line with the correlations and the accuracy of the simple-regression models presented in previous sections.

4.3.3. Model Applicability and Utility

4.3.4. Analysis of Other Studies: Validation

5. Conclusions

- UPV was strongly correlated with all the mechanical properties, although the mechanical properties related to compressive behavior (compressive strength and modulus of elasticity) presented a higher correlation. The dependence of UPV on mechanical properties was fundamentally monotonic.

- In line with the correlation analysis, the best-fitting simple-regression model for all mechanical properties was an inverse square-root model (potential model). However, the estimation accuracy obtained for splitting tensile strength and flexural strength was lower than those for compressive strength and modulus of elasticity.

- The mechanical properties related to bending-tensile behavior (splitting tensile strength and flexural strength) had practically no percentage influence on the UPV value when developing linear-combination multiple-regression models through standardized properties. Furthermore, their forced introduction reduced the estimation accuracy. Therefore, the development of multiple-regression models that linked UPV readings with splitting tensile strength and flexural strength was not adequate.

- Relating UPV readings, compressive strength, and modulus of elasticity values of SCC containing RA was feasible through multiple regression, either through individual treatment of each mechanical property (Equation (6)) or as the mean value of compressive behavior (Equation (7)). Thus, both mechanical properties can be estimated from the UPV readings when one of them is known.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, H.; Nie, X.; Gan, S.; Zhao, Y.; Qiu, H. Interfacial imperfection detection for steel-concrete composite structures using NDT techniques: A state-of-the-art review. Eng. Struct. 2021, 245, 112778. [Google Scholar] [CrossRef]

- Yumnam, M.; Gupta, H.; Ghosh, D.; Jaganathan, J. Inspection of concrete structures externally reinforced with FRP composites using active infrared thermography: A review. Constr. Build. Mater. 2021, 310, 125265. [Google Scholar] [CrossRef]

- Colla, C.; Grüner, F.; Dieruf, B. SMOOHS, Smart Monitoring of Historic Structures. D5.1-Part1: Report on Test Methods and Former Test Results; MPA Universität Stuttgart: Stuttgart, Germany, 2010. [Google Scholar]

- Varzaneh, A.S.; Naderi, M. In situ evaluation of the mechanical properties of pozzolanic concrete containing fibers. J. Crit. Rev. 2020, 7, 545–554. [Google Scholar] [CrossRef]

- Torres, J.; Andrade, C.; Sánchez, J. Initiation period of corrosion by chloride ion according to EHE 08 in cracked concrete elements. Inf. Constr. 2020, 72, e331. [Google Scholar] [CrossRef]

- Anaya, P.; Rodríguez, J.; Andrade, C.; Martín-Pérez, B.; Hombrados, C.L. Determination of wires transfer length in prestressed concrete members with different levels of corrosion. Inf. Constr. 2020, 72, 1–10. [Google Scholar] [CrossRef]

- D’Amato, M.; Luchin, G.; De Matteis, G. A Preliminary Study on Properties of A Weak Units–Strong Mortar Masonry: The Case Study of Matera Tufo Masonry (Italy). Int. J. Archit. Herit. 2022. [Google Scholar] [CrossRef]

- Zima, B.; Kędra, R. Evaluation of the resistance of steel–concrete adhesive connection in reinforced concrete beams using guided wave propagation. Arch. Civ. Mech. Eng. 2020, 20, 1. [Google Scholar] [CrossRef]

- Schuster, G.T. Resolution limits for crosswell migration and traveltime tomography. Geophys. J. Int. 1996, 127, 427–440. [Google Scholar] [CrossRef]

- Luchin, G.; Ramos, L.F.; D’Amato, M. Sonic Tomography for Masonry Walls Characterization. Int. J. Archit. Herit. 2020, 14, 589–604. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, Q.; Tan, Z.; Wang, L.; Li, Z.; Ma, G. Investigation of steel wire mesh reinforcement method for 3D concrete printing. Arch. Civ. Mech. Eng. 2021, 21, 24. [Google Scholar] [CrossRef]

- Qasrawi, H. Effect of the position of core on the strength of concrete of columns in existing structures. J. Build. Eng. 2019, 25, 100812. [Google Scholar] [CrossRef]

- Marcos, I.; San-José, J.T.; Garmendia, L.; Santamaría, A.; Manso, J.M. Central lessons from the historical analysis of 24 reinforced-concrete structures in northern Spain. J. Cult. Heritage 2016, 20, 649–659. [Google Scholar] [CrossRef]

- Jones, R. The non-destructive testing of concrete. Mag. Concr. Res. 1949, 1, 67–78. [Google Scholar] [CrossRef]

- Krautkrämer, J.; Krautkrämer, H. Ultrasonic Testing of Materials; Springer: Berlin/Heidelberg, Germany, 1996. [Google Scholar] [CrossRef]

- Jones, R. The ultrasonic testing of concrete. Ultrasonics 1963, 1, 78–82. [Google Scholar] [CrossRef]

- Washer, G.; Fuchs, P.; Graybeal, B.A.; Hartmann, J.L. Ultrasonic Testing of Reactive Powder Concrete. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2004, 51, 193–201. [Google Scholar] [CrossRef]

- Chiriatti, L.; François, P.; Mercado-Mendoza, H.; Apedo, K.L.; Fond, C.; Feugeas, F. Monitoring of the rebar-concrete bond structural health through ultrasonic measurements: Application to recycled aggregate concrete. J. Civ. Struct. Health Monit. 2020, 10, 595–607. [Google Scholar] [CrossRef]

- Çalışkan, A.; Demirhan, S.; Tekin, R. Comparison of different machine learning methods for estimating compressive strength of mortars. Constr. Build. Mater. 2022, 335, 127490. [Google Scholar] [CrossRef]

- Zhang, Y.; Aslani, F.; Lehane, B. Compressive strength of rubberized concrete: Regression and GA-BPNN approaches using ultrasonic pulse velocity. Constr. Build. Mater. 2021, 307, 124951. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Skaf, M.; Serrano-López, R.; Ortega-López, V. Models for compressive strength estimation through non-destructive testing of highly self-compacting concrete containing recycled concrete aggregate and slag-based binder. Constr. Build. Mater. 2021, 280, 122454. [Google Scholar] [CrossRef]

- Santos, S.; da Silva, P.R.; de Brito, J. Self-compacting concrete with recycled aggregates—A literature review. J. Build. Eng. 2019, 22, 349–371. [Google Scholar] [CrossRef]

- Nepomuceno, M.C.S.; Bernardo, L.F.A. Evaluation of self-compacting concrete strength with non-destructive tests for concrete structures. Appl. Sci. 2019, 9, 5109. [Google Scholar] [CrossRef]

- Nguyen, N.T.; Sbartaï, Z.-M.; Lataste, J.-F.; Breysse, D.; Bos, F. Assessing the spatial variability of concrete structures using NDT techniques—Laboratory tests and case study. Constr. Build. Mater. 2013, 49, 240–250. [Google Scholar] [CrossRef]

- Abdulhameed, A.A.; Hanoon, A.N.; Abdulhameed, H.A.; Banyhussan, Q.S.; Mansi, A.S. Push-out test of steel–concrete–steel composite sections with various core materials: Behavioural study. Arch. Civ. Mech. Eng. 2021, 21, 17. [Google Scholar] [CrossRef]

- Yu, F.; Li, X.; Song, J.; Fang, Y.; Qin, Y.; Bu, S. Experimental study on flexural capacity of PVA fiber-reinforced recycled concrete slabs. Arch. Civ. Mech. Eng. 2021, 21, 166. [Google Scholar] [CrossRef]

- Deresa, S.T.; Xu, J.; Demartino, C.; Heo, Y.; Li, Z.; Xiao, Y. A review of experimental results on structural performance of reinforced recycled aggregate concrete beams and columns. Adv. Struct. Eng. 2020, 23, 3351–3369. [Google Scholar] [CrossRef]

- Xu, J.J.; Chen, W.G.; Demartino, C.; Xie, T.Y.; Yu, Y.; Fang, C.F.; Xu, M. A Bayesian model updating approach applied to mechanical properties of recycled aggregate concrete under uniaxial or triaxial compression. Constr. Build. Mater. 2021, 301, 124274. [Google Scholar] [CrossRef]

- Faleschini, F.; Zanini, M.A.; Hofer, L. Reliability-based analysis of recycled aggregate concrete under carbonation. Adv. Civ. Eng. 2018, 2018, 4742372. [Google Scholar] [CrossRef]

- Xing, W.; Tam, V.W.; Le, K.N.; Hao, J.L.; Wang, J. Life cycle assessment of recycled aggregate concrete on its environmental impacts: A critical review. Constr. Build. Mater. 2022, 317, 125950. [Google Scholar] [CrossRef]

- Zhan, P.M.; Zhang, X.X.; He, Z.H.; Shi, J.Y.; Gencel, O.; Hai Yen, N.T.; Wang, G.C. Strength, microstructure and nanomechanical properties of recycled aggregate concrete containing waste glass powder and steel slag powder. J. Clean. Prod. 2022, 341, 130892. [Google Scholar] [CrossRef]

- Barra Bizinotto, M.; Faleschini, F.; Jiménez Fernández, C.G.; Aponte Hernández, D.F. Effects of chemical admixtures on the rheology of fresh recycled aggregate concretes. Constr. Build. Mater. 2017, 151, 353–362. [Google Scholar] [CrossRef]

- Etxeberria, M. Evaluation of eco-efficient concretes produced with fly ash and uncarbonated recycled aggregates. Materials 2021, 14, 7499. [Google Scholar] [CrossRef] [PubMed]

- Nobre, J.; Bravo, M.; de Brito, J.; Duarte, G. Durability performance of dry-mix shotcrete produced with coarse recycled concrete aggregates. J. Build. Eng. 2020, 29, 101135. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Ortega-López, V.; Skaf, M.; Khan, A.U.R.; Manso, J.M. Deformational behavior of self-compacting concrete containing recycled aggregate, slag cement and green powders under compression and bending: Description and prediction adjustment. J. Build. Eng. 2022, 54, 104611. [Google Scholar] [CrossRef]

- Carro-López, D.; González-Fonteboa, B.; De Brito, J.; Martínez-Abella, F.; González-Taboada, I.; Silva, P. Study of the rheology of self-compacting concrete with fine recycled concrete aggregates. Constr. Build. Mater. 2015, 96, 491–501. [Google Scholar] [CrossRef]

- Ouchi, M.; Hibino, M.; Sugamata, T.; Okamura, H. Quantitative evaluation method for the effect of superplasticizer in self-compacting concrete. Trans. Jpn. Concr. Inst. 2000, 22, 15–20. [Google Scholar]

- Okamura, H. Self-compacting high-performance concrete. Concr. Int. 1997, 19, 50–54. [Google Scholar]

- Ouchi, M.; Edamatsu, Y.; Ozawa, K.; Okamura, H. Simple evaluation method for interaction between coarse aggregate and mortar’s particles in self-compacting concrete. Trans. Jpn. Concr. Inst. 1999, 21, 1–6. [Google Scholar]

- Revilla-Cuesta, V.; Ortega-López, V.; Skaf, M.; Fiol, F.; Manso, J.M. Why is the effect of recycled concrete aggregate on the compressive strength of self-compacting concrete not homogeneous? A bibliographic review. Inf. Constr. 2022, 74, e435. [Google Scholar] [CrossRef]

- Bier, T.A.; Rizwan, S.A. Ecological, economical and environmental aspects of self compacting concrete—Present and future. Int. J. Soc. Mater. Eng. Resour. 2014, 20, 12–16. [Google Scholar] [CrossRef]

- Singh, N.; Singh, S.P. Evaluating the performance of self compacting concretes made with recycled coarse and fine aggregates using non destructive testing techniques. Constr. Build. Mater. 2018, 181, 73–84. [Google Scholar] [CrossRef]

- Kazemi, M.; Madandoust, R.; de Brito, J. Compressive strength assessment of recycled aggregate concrete using Schmidt rebound hammer and core testing. Constr. Build. Mater. 2019, 224, 630–638. [Google Scholar] [CrossRef]

- Pazouki, G.; Pourghorban, A. Using a hybrid artificial intelligence method for estimating the compressive strength of recycled aggregate self-compacting concrete. Eur. J. Environ. Civ. Eng. 2022, 26, 5569–5593. [Google Scholar] [CrossRef]

- Abed, M.A.; Tayeh, B.A.; Abu Bakar, B.H.; Nemes, R. Two-year non-destructive evaluation of eco-efficient concrete at ambient temperature and after freeze-thaw cycles. Sustainability 2021, 13, 10605. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Ortega-López, V.; Faleschini, F.; Espinosa, A.B.; Serrano-López, R. Hammer rebound index as an overall-mechanical-quality indicator of self-compacting concrete containing recycled concrete aggregate. Constr. Build. Mater. 2022, 347, 128549. [Google Scholar] [CrossRef]

- EN-Euronorm Rue de Stassart, 36; Brussels, Belgium: European Committee for Standardization.

- Santamaría, A.; González, J.J.; Losáñez, M.M.; Skaf, M.; Ortega-López, V. The design of self-compacting structural mortar containing steelmaking slags as aggregate. Cem. Concr. Compos. 2020, 111, 103627. [Google Scholar] [CrossRef]

- EC-2 Eurocode 2: Design of Concrete Structures. Part 1-1: General Rules and Rules for Buildings; CEN (European Committee for Standardization): Brussels, Belgium, 2010.

- Wu, Y.; Liu, C.; Liu, H.; Hu, H.; He, C.; Song, L.; Huang, W. Pore structure and durability of green concrete containing recycled powder and recycled coarse aggregate. J. Build. Eng. 2022, 53, 104584. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Faleschini, F.; Pellegrino, C.; Skaf, M.; Ortega-López, V. Simultaneous addition of slag binder, recycled concrete aggregate and sustainable powders to self-compacting concrete: A synergistic mechanical-property approach. J. Mater. Res. Technol. 2022, 18, 1886–1908. [Google Scholar] [CrossRef]

- Ivanović, B.; Saha, A.; Stević, Ž.; Puška, A.; Zavadskas, E.K. Selection of truck mixer concrete pump using novel MEREC DNMARCOS model. Arch. Civ. Mech. Eng. 2022, 22, 173. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, H.; Liu, F.; Cheng, S.; Wang, B.; Yang, L. Effects of steel fibers and concrete strength on flexural toughness of ultra-high performance concrete with coarse aggregate. Case Stud. Constr. Mater. 2022, 17, e01170. [Google Scholar] [CrossRef]

- Llopis-Albert, C.; Toro, W.R.V.; Farhat, N.; Zamora-Ortiz, P.; Del Pozo, Á.F.P. A new method for time normalization based on the continuous phase: Application to neck kinematics. Mathematics 2021, 9, 3138. [Google Scholar] [CrossRef]

- Winkler, J.R.; Mitrouli, M.; Koukouvinos, C. The application of regularisation to variable selection in statistical modelling. J. Comput. Appl. Math. 2022, 404, 113884. [Google Scholar] [CrossRef]

- Fiol, F.; Thomas, C.; Muñoz, C.; Ortega-López, V.; Manso, J.M. The influence of recycled aggregates from precast elements on the mechanical properties of structural self-compacting concrete. Constr. Build. Mater. 2018, 182, 309–323. [Google Scholar] [CrossRef]

- Uygunoğlu, T.; Topçu, I.B.; Çelik, A.G. Use of waste marble and recycled aggregates in self-compacting concrete for environmental sustainability. J. Clean. Prod. 2014, 84, 691–700. [Google Scholar] [CrossRef]

| Aggregate | SSD Density (Mg/m3) 1 | 15-min Water Absorption (wt%) | 24-h Water Absorption (wt%) |

|---|---|---|---|

| Limestone filler | 2.77 | 0.37 | 0.54 |

| Limestone powder | 2.60 | 1.95 | 2.57 |

| RA powder | 2.31 | 6.32 | 7.95 |

| Siliceous sand | 2.58 | 0.18 | 0.25 |

| Fine RA | 2.37 | 5.77 | 7.36 |

| Coarse RA | 2.42 | 4.90 | 6.25 |

| Aggregate | F0 | F50 | F100 | L0 | L50 | L100 | R0 | R50 | R100 |

|---|---|---|---|---|---|---|---|---|---|

| Limestone filler | 165 | 165 | 165 | 0 | 0 | 0 | 0 | 0 | 0 |

| Limestone powder | 0 | 0 | 0 | 335 | 335 | 335 | 0 | 0 | 0 |

| RA powder | 0 | 0 | 0 | 0 | 0 | 0 | 305 | 305 | 305 |

| Siliceous sand | 1100 | 550 | 0 | 940 | 475 | 0 | 940 | 475 | 0 |

| Fine RA | 0 | 505 | 1010 | 0 | 435 | 865 | 0 | 435 | 865 |

| Coarse RA | 530 | 530 | 530 | 530 | 530 | 530 | 530 | 530 | 530 |

| Viscosity regulator | 2.30 | 2.30 | 2.30 | 2.30 | 2.30 | 2.30 | 2.30 | 2.30 | 2.30 |

| Plasticizer | 4.50 | 4.50 | 4.50 | 4.50 | 4.50 | 4.50 | 4.50 | 4.50 | 4.50 |

| Water | 185 | 210 | 235 | 185 | 210 | 235 | 200 | 220 | 245 |

| Cement | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Mechanical Property | Most Accurate Model | Linear Model | ||

|---|---|---|---|---|

| a | b | R2 (%) | R2 (%) | |

| Compressive strength | 21.353 | 194.252 | 97.91 | 87.51 |

| Modulus of elasticity | 23.404 | 208.482 | 90.31 | 62.54 |

| Splitting tensile strength | 25.383 | 31.679 | 64.86 | 53.94 |

| Flexural strength | 25.398 | 41.214 | 73.90 | 62.38 |

| Variable | Xmax | Xmin | Xm |

|---|---|---|---|

| Compressive strength (MPa) | 42.23 | 26.75 | 34.49 |

| Modulus of elasticity (GPa) | 33.31 | 20.58 | 27.01 |

| Splitting tensile strength (MPa) | 3.69 | 2.70 | 3.20 |

| Flexural strength (MPa) | 4.84 | 3.49 | 4.17 |

| UPV (km/s) | 4.15 | 3.58 | 3.87 |

| Variable | a | R2 (%) |

|---|---|---|

| Compressive strength | 0.933 | 87.52 |

| Modulus of elasticity | 0.769 | 80.43 |

| Splitting tensile strength | 0.730 | 53.86 |

| Flexural strength | 0.787 | 62.26 |

| Calculation Step | Value | |

|---|---|---|

| Known SCC properties | Compressive strength (MPa) 1 | 45.6 |

| UPV (km/s) | 4.22 | |

| Standardized properties | Compressive strength | 0.7177 |

| UPV | 0.6179 | |

| Standardized modulus of elasticity with Equation (6) | 0.8034 | |

| Standardized modulus of elasticity with Equation (7) | 0.6646 | |

| Modulus of elasticity with Equation (6) (GPa) (Equation (2) and Table 4) | 37.2 | |

| Modulus of elasticity with Equation (7) (GPa) (Equation (2) and Table 4) | 35.5 | |

| Modulus of elasticity: Experimental value (GPa) | See Figure 3b | 36.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Espinosa, A.B.; Revilla-Cuesta, V.; Skaf, M.; Faleschini, F.; Ortega-López, V. Utility of Ultrasonic Pulse Velocity for Estimating the Overall Mechanical Behavior of Recycled Aggregate Self-Compacting Concrete. Appl. Sci. 2023, 13, 874. https://doi.org/10.3390/app13020874

Espinosa AB, Revilla-Cuesta V, Skaf M, Faleschini F, Ortega-López V. Utility of Ultrasonic Pulse Velocity for Estimating the Overall Mechanical Behavior of Recycled Aggregate Self-Compacting Concrete. Applied Sciences. 2023; 13(2):874. https://doi.org/10.3390/app13020874

Chicago/Turabian StyleEspinosa, Ana B., Víctor Revilla-Cuesta, Marta Skaf, Flora Faleschini, and Vanesa Ortega-López. 2023. "Utility of Ultrasonic Pulse Velocity for Estimating the Overall Mechanical Behavior of Recycled Aggregate Self-Compacting Concrete" Applied Sciences 13, no. 2: 874. https://doi.org/10.3390/app13020874

APA StyleEspinosa, A. B., Revilla-Cuesta, V., Skaf, M., Faleschini, F., & Ortega-López, V. (2023). Utility of Ultrasonic Pulse Velocity for Estimating the Overall Mechanical Behavior of Recycled Aggregate Self-Compacting Concrete. Applied Sciences, 13(2), 874. https://doi.org/10.3390/app13020874