Experimental Evaluation of the Factors That Influence Cylindrical Water Projection Devices against IEDs

Abstract

:1. Introduction

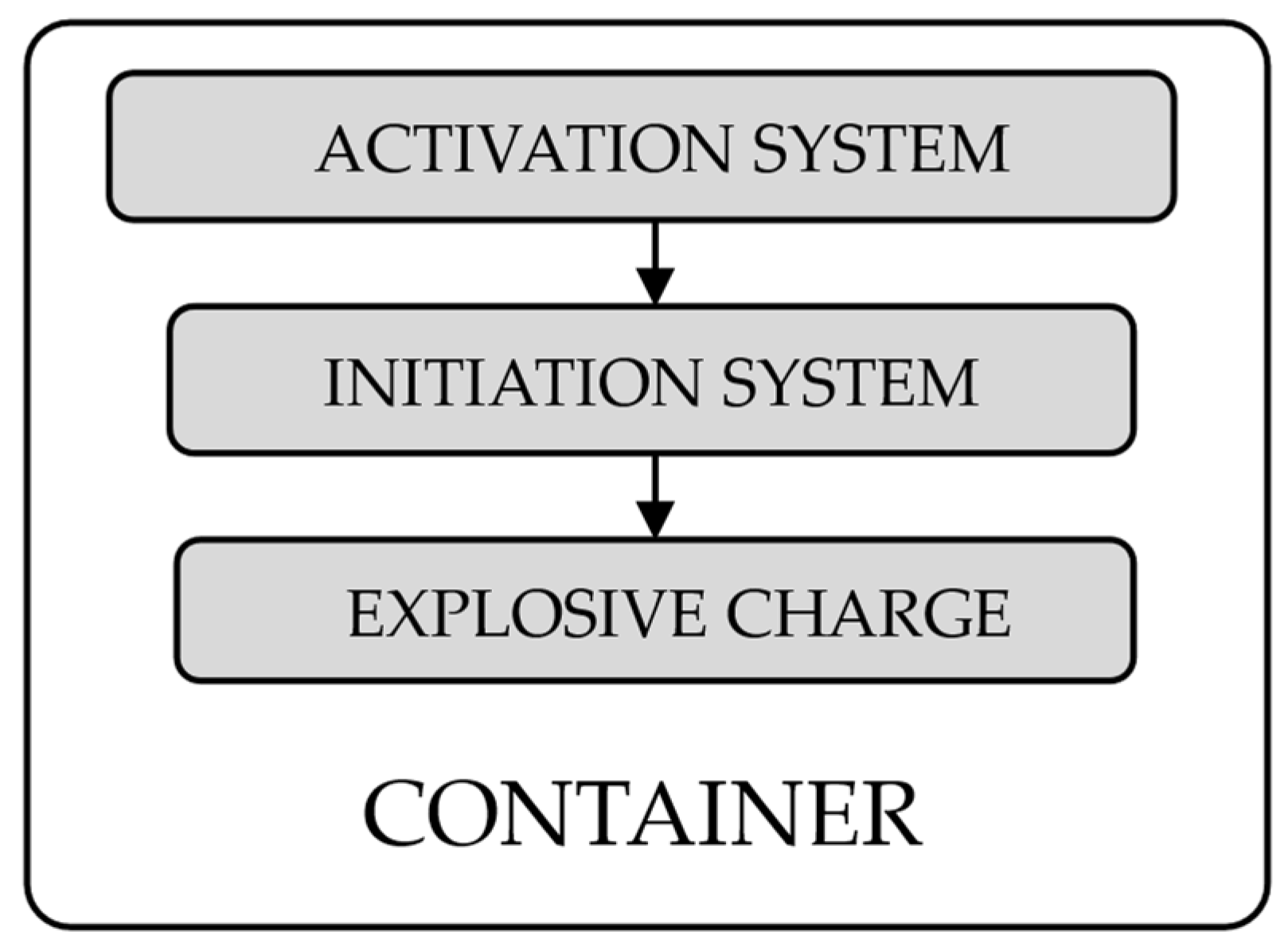

2. Materials and Methods

2.1. Methodology

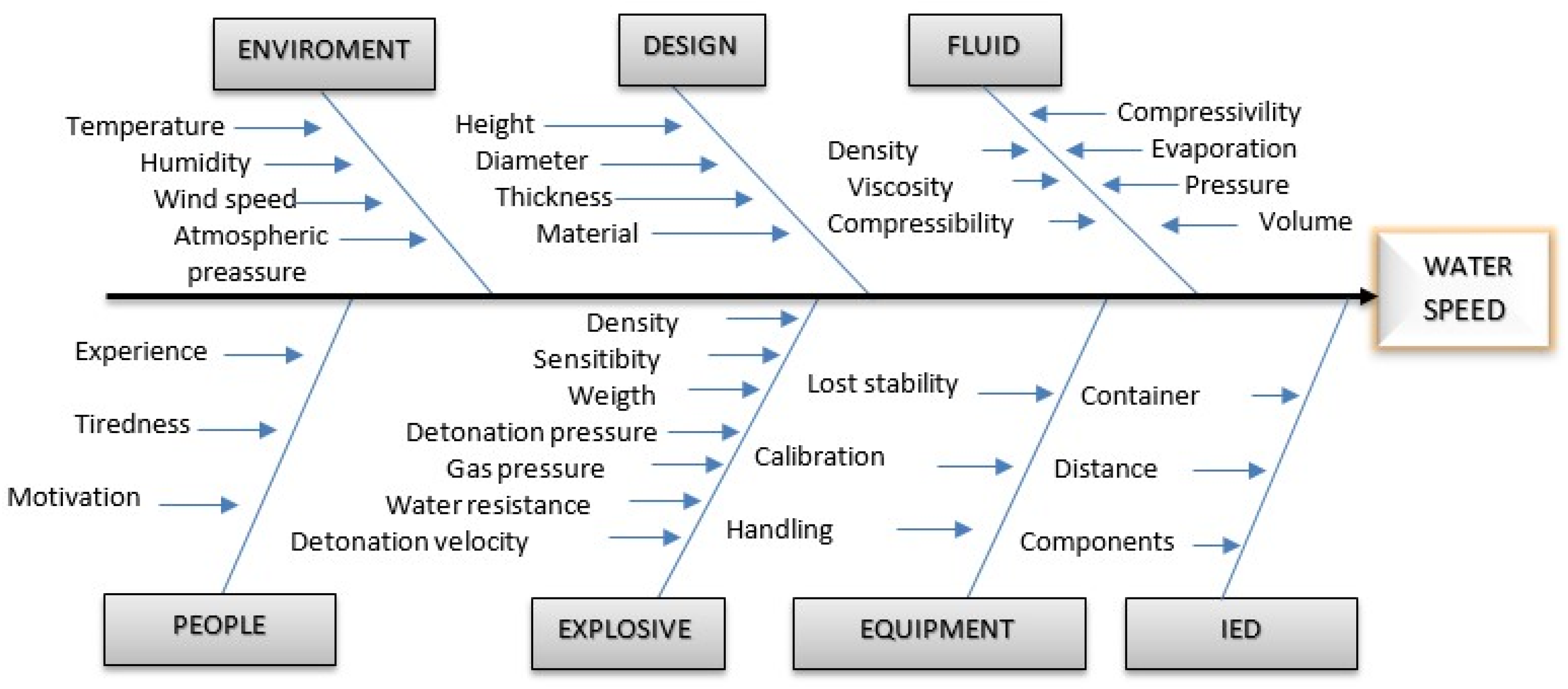

2.2. Selection of the Response Variable, the Factors, and the Levels of Each Factor

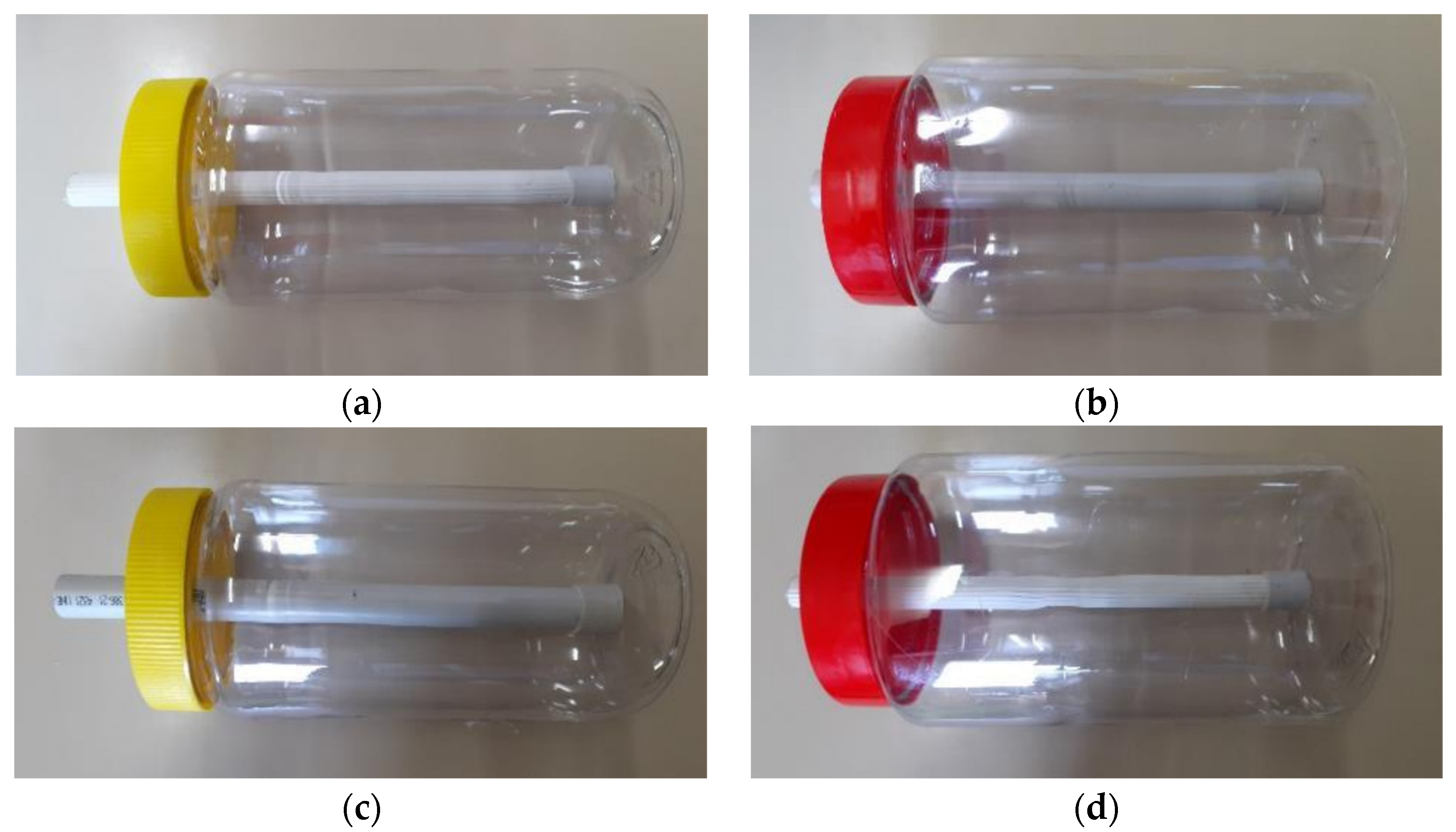

2.2.1. Factors Related to the Design of the Device

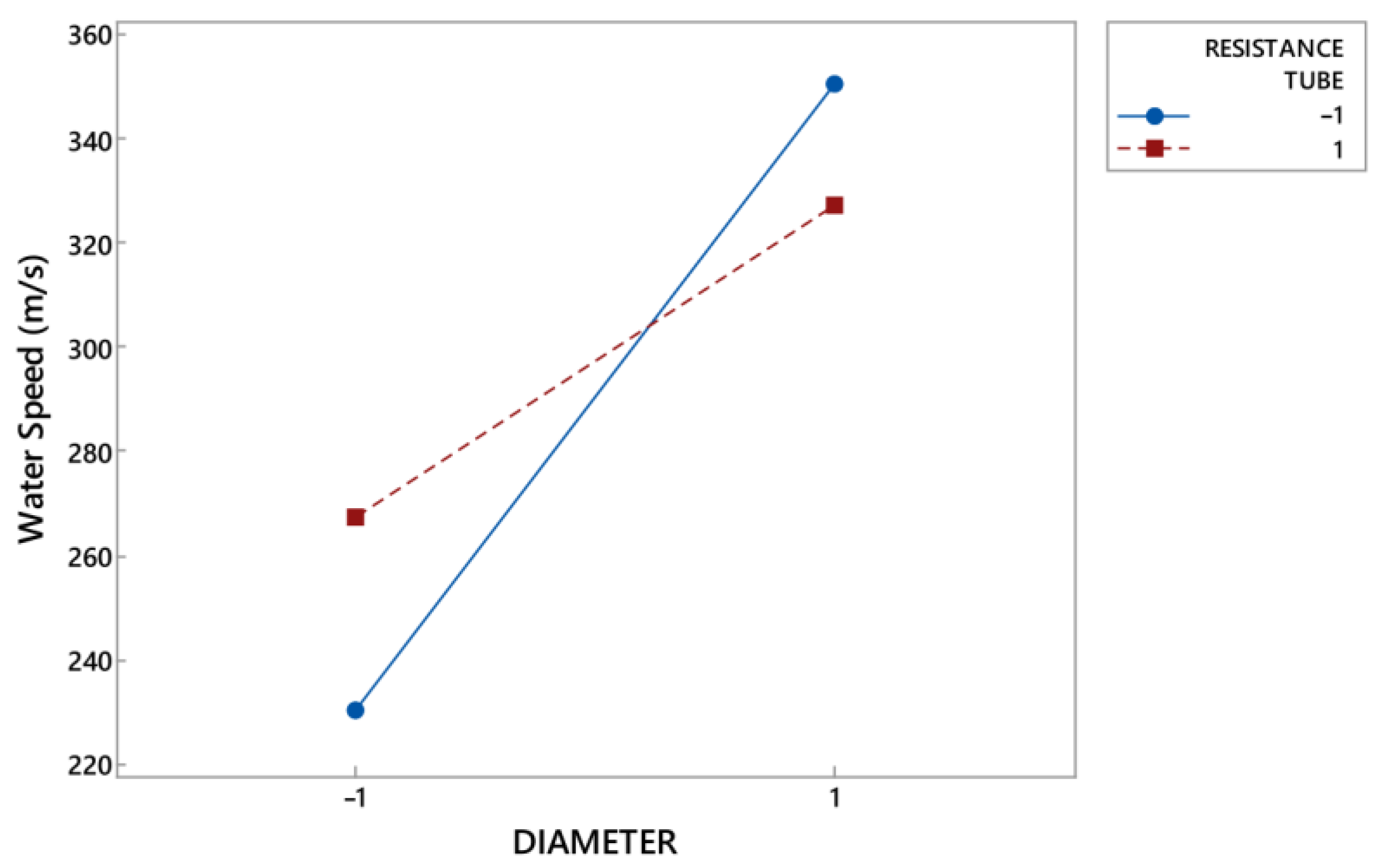

- The diameter of the cylinder (in order to observe the influence of the mass of water related to the amount of explosive), using two diameters, 105 mm and 85 mm;

- The material of the inner tube (two materials of different resistance are used to observe their effects on the speed of the projected liquid)—on the one hand, an inner tube of polyvinyl chloride (PVC) and another of polypropylene (PP).

2.2.2. Factors Related to the Fluid

2.2.3. Factors Related to the Explosive

2.2.4. Factors Related to the IED

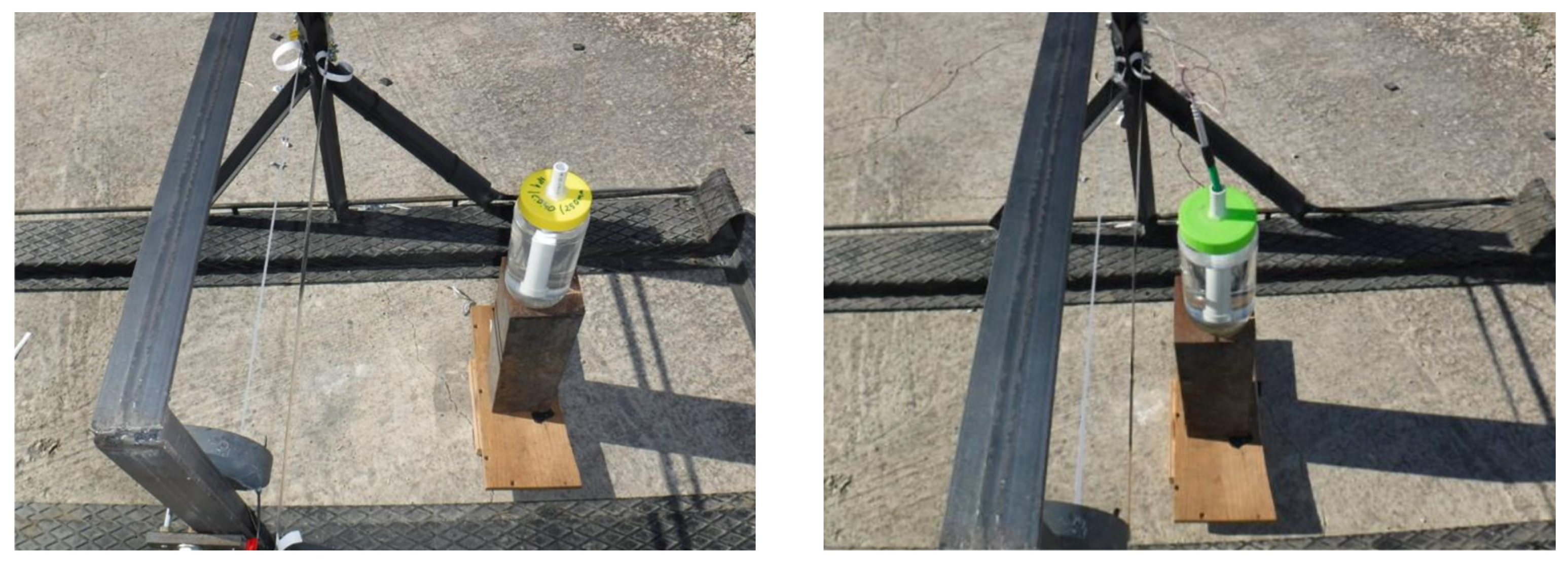

2.3. Experimental Setup

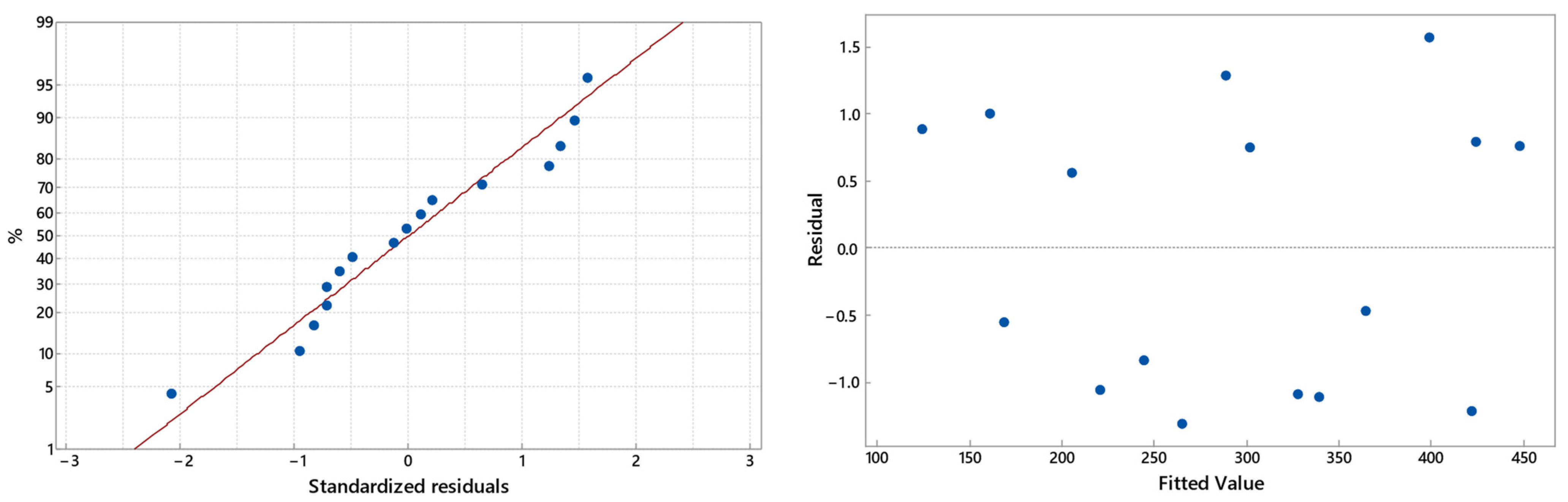

3. Results and Discussion

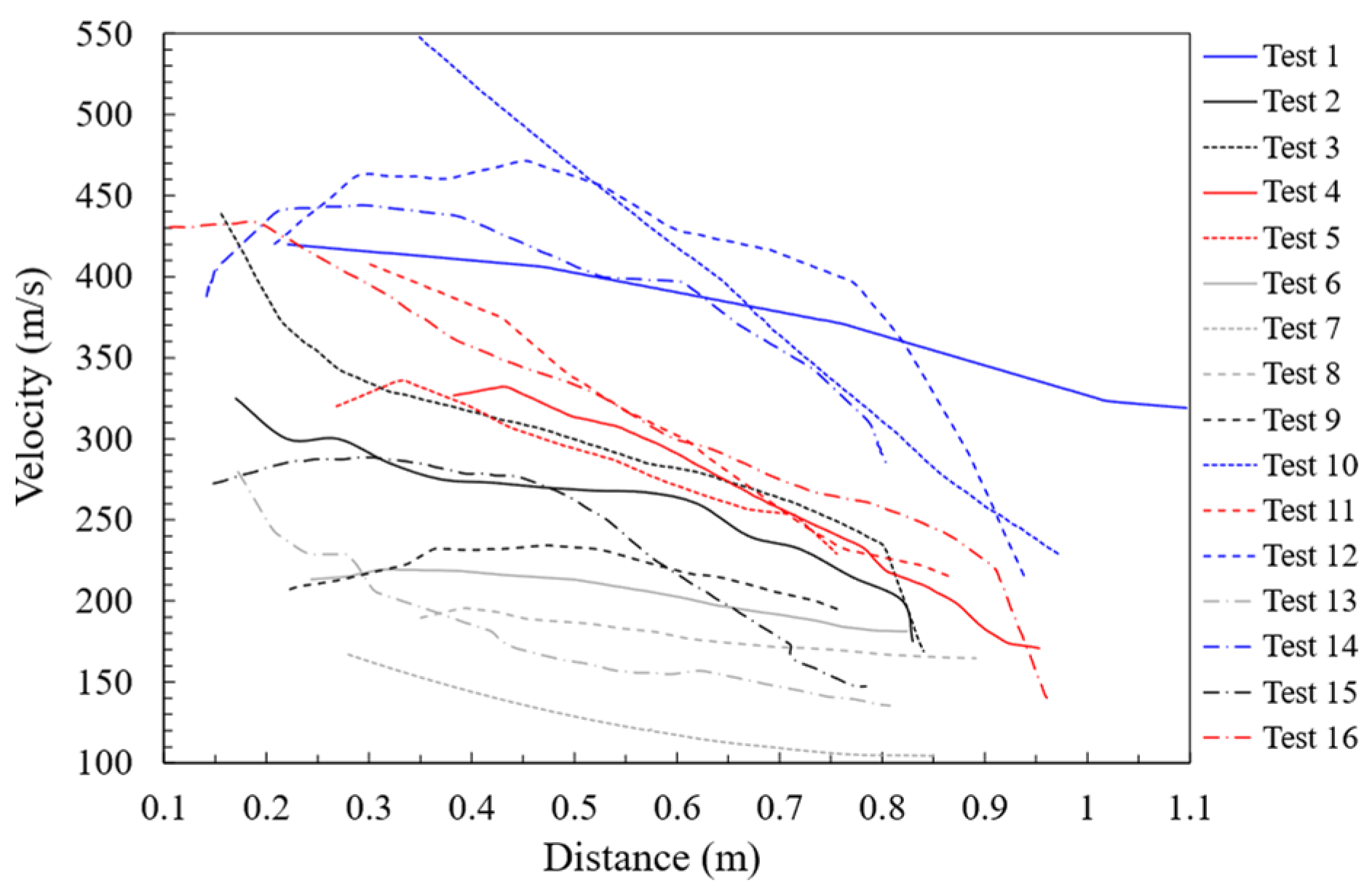

3.1. Experimental Tests

3.2. Discussion

Regression Equation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Institute for Economics and Peace. Trends in Terrorism; Institute for Economics and Peace: Sydney, Australia, 2018. [Google Scholar]

- United Nations Mine Action Service (UNMAS) United Nation Improvised Explosive Device Disposal Standars. 2018. Available online: https://unmas.org/sites/default/files/un_iedd_standards.pdf (accessed on 10 December 2022).

- Centro Superior de Estudios de la Defensa Nacional. La Seguridad Frente Artefactos Explosivos. 2009. Available online: https://tienda.boe.es/detail.php?id=9788497815314 (accessed on 10 December 2022).

- Africa Center for Strategic Studies. 2021. Available online: https://africacenter.org/spotlight/drones-and-violent-nonstate-actors-in-africa/ (accessed on 15 December 2022).

- Gil, E.A. El Futuro Del Terrorismo Nuclear En La Táctica De Los Actores Individuales. Revista Insituto Español Estudios Estratégicos 2018, 12, 46–76. [Google Scholar]

- Liu, J.-q.; Gu, W.-b.; Lu, M.; Xu, H.-m.; Wu, S.-z. Formation of explosively formed penetrator with fins and its flight. Def. Technol. 2014, 10, 119–123. [Google Scholar] [CrossRef] [Green Version]

- Alford, S. Explosives. EEUU Patent US 9,322,624 B2, 26 April 2016. Available online: https://patents.justia.com/patent/9322624 (accessed on 10 December 2022).

- Cherry, C.R. Fluid-filled bomb-disrupting apparatus and method. U.S. Patent US6269725B1, 2001. [Google Scholar]

- Geneva International Centre For Humanitarian Demining. Improvised Explosive Device Clearance Good Practice Guide; Geneva International Centre For Humanitarian Demining: Geneve, Switzerland, 2020. [Google Scholar]

- Enache, C.; Trană, E.; Rotariu, T.; Rotariu, A.; Ţigănescu, V.T.; Zecheru, T. Numerical Simulation and Experimental Tests on Explosively-Induced Water Jet Phenomena. Propellants Explos. Pyrotech. 2016, 41, 1020–1028. [Google Scholar] [CrossRef]

- Radomski, M. Stability Conditions and Interior Ballistics of Recoilless Projected Water Disruptor. Propellants Explos. Pyrotech. 2014, 39, 916–921. [Google Scholar] [CrossRef]

- Parate, B.A.; Chandel, S.; Shekhar, H. An experimental and numerical aproach characterisation of power cartridge for water-jet application. Defecnce Technol. 2018, 14, 683–690. [Google Scholar] [CrossRef]

- Petrenko, O. Investigation of Formation and Applications of High-Speed Liquid; Digital Commons New Jersey Institute of Technology: Newark, NJ, USA, 2007. [Google Scholar]

- Petrenco, O.; Geskin, E.; Semko, A.N. Mechanics of powder hydro cannon for imcompresible fluid. In Proceedings of the 2005 WJRA American Waterjet Conference, Houston, TX, USA, 21–23 August 2005. [Google Scholar]

- Cliff, E. What is Total Quality Control? The Japanese Way; Defensa, M.D., Ed.; Prentice Hall: Hoboken, NJ, USA, 1985; pp. 38–47. [Google Scholar]

- Montgomery, D.C.; Runger, G.C. Applied Statistics and Probability for Engineers; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Whitcom, P.J. DOE Simplified: Practical Tools for Effective Experimentation; Productivity Inc.: Portland, OR, USA, 2007. [Google Scholar]

- Mongomery, D. Statistical Quality Control: A Modern Introduction, 7th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Engel, T.; Reid, P. Physical Chemistry; Pearson: Harlow, UK, 2014. [Google Scholar]

- Semko, A.N.; Rusanova, O.A.; Kazak, O.V.; Beskrovnaya, M.V.; Vinogradov, S.A.; Gricina, I.N. The use of pulsed high-speed liquid jet for putting out gas blow-out. Int. J. Multiphysics 2015, 9, 9–20. [Google Scholar] [CrossRef]

- Lide, D.R. Handbook of Chemistry and Physics, 90th ed.; Crc Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Alonso, J.B.; Herbert, H. Perforación y Voladuras de Rocas en Minería; Universidad Politécnica de Madrid: Madrid, Spain, 2013. [Google Scholar]

- Locking, P. TNT equivalence, berthelot theory and the traulz lead block test. In Proceedings of the 32nd International Symposium on Ballistics, Reno, NV, USA, 8–13 May 2022. [Google Scholar]

- TEMA Starter—Aostechnologies. Available online: https://www.aostechnologies.com/high-speed-cameras/software-solutions/tema-starter/ (accessed on 27 September 2021).

- Minitab Web Site. Available online: http://www.support.minitab.com (accessed on 27 September 2021).

| ID. | 2⁰ | 2¹ | 2² | 2³ | 2⁴ | Test Matrix | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 4 | 8 | 16 | ||||||

| Factors | Factors | |||||||||

| A | B | C | D | E | A | B | C | D | ABCD = E | |

| 0 | 0 | 0 | 0 | 0 | 0 | −1 | −1 | −1 | −1 | 1 |

| 1 | 1 | 0 | 0 | 0 | 0 | 1 | −1 | −1 | −1 | −1 |

| 2 | 0 | 1 | 0 | 0 | 0 | −1 | 1 | −1 | −1 | −1 |

| 3 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | −1 | −1 | 1 |

| 4 | 0 | 0 | 1 | 0 | 0 | −1 | −1 | 1 | −1 | −1 |

| 5 | 1 | 0 | 1 | 0 | 0 | 1 | −1 | 1 | −1 | 1 |

| 6 | 0 | 1 | 1 | 0 | 0 | −1 | 1 | 1 | −1 | 1 |

| 7 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | −1 | −1 |

| 8 | 0 | 0 | 0 | 1 | 0 | −1 | −1 | −1 | 1 | −1 |

| 9 | 1 | 0 | 0 | 1 | 0 | 1 | −1 | −1 | 1 | 1 |

| 10 | 0 | 1 | 0 | 1 | 0 | −1 | 1 | −1 | 1 | 1 |

| 11 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | −1 | 1 | −1 |

| 12 | 0 | 0 | 1 | 1 | 0 | −1 | −1 | 1 | 1 | 1 |

| 13 | 1 | 0 | 1 | 1 | 0 | 1 | −1 | 1 | 1 | −1 |

| 14 | 0 | 1 | 1 | 1 | 0 | −1 | 1 | 1 | 1 | −1 |

| 15 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 |

| Order Num. | Diameter (mm) | Mass of Explosive (g/m) | Density of Water (kg/L) | Inner Tube Resistance (Material) | Distance (cm) |

|---|---|---|---|---|---|

| 1 | 86 | 40 | 1.16 | PVC | 55 |

| 2 | 86 | 20 | 1.00 | PP | 40 |

| 3 | 86 | 20 | 1.16 | PVC | 40 |

| 4 | 105 | 40 | 1.00 | PVC | 55 |

| 5 | 105 | 40 | 1.16 | PVC | 40 |

| 6 | 105 | 20 | 1.2 | PP | 40 |

| 7 | 105 | 20 | 1.00 | PVC | 40 |

| 8 | 105 | 20 | 1.00 | PP | 55 |

| 9 | 86 | 20 | 1.00 | PVC | 55 |

| 10 | 86 | 40 | 1.00 | PP | 55 |

| 11 | 105 | 40 | 1.16 | PP | 55 |

| 12 | 86 | 40 | 1.00 | PVC | 40 |

| 13 | 105 | 20 | 1.16 | PVC | 55 |

| 14 | 86 | 40 | 1.16 | PP | 40 |

| 15 | 86 | 20 | 1.16 | PP | 55 |

| 16 | 105 | 40 | 1.00 | PP | 40 |

| Material | Specification |

|---|---|

| Polyethylene terephthalate (PET) plastic container. | 160 mm high × 105 mm in diameter, and screw cap. |

| PET plastic container. | 160 mm high × 86 mm in diameter, and screw cap. |

| PP inner tube. | 21 mm high × 12 mm outer diameter. |

| PP inner tube. | 21 mm high × 15 mm outer diameter. |

| Hot silicone for sealing and assembly of the inner tube. | EVA resin, melting point 164 °F. |

| PVC cylinder to center the inner PP tube. | 15 mm × 15 mm diameter. |

| PVC cylinder to center the inner PP tube. | 15 mm × 19 mm diameter. |

| Detonating cord with PETN. | 40 and 20 g/m. |

| Instant insensitive electric detonators. | 7 mm diameter 68 mm height, with lead trinitroresorcinate and tetracene. |

| Distilled water. | Density: .00 g·cm−3 at 20 °C. |

| A saturated solution of sodium chloride in water. | Density: g·cm−3 at 20 °C. |

| Test N. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| V (m/s) | 396.2 | 273.8 | 316.2 | 304.4 | 318.3 | 217.5 | 143.0 | 182.5 |

| Test N. | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| V (m/s) | 226.2 | 441.6 | 315.4 | 364.1 | 156.5 | 432.6 | 237.4 | 354.8 |

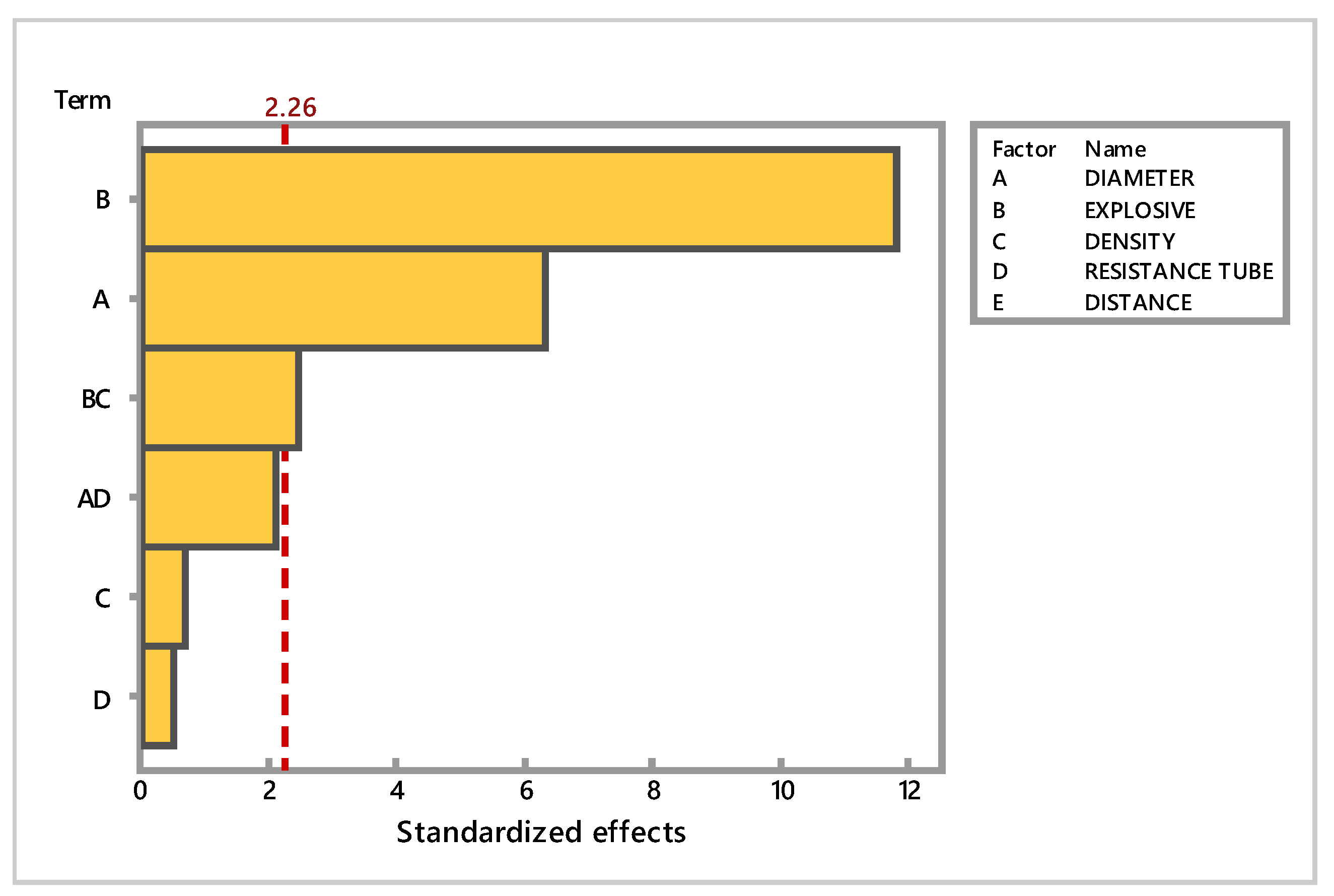

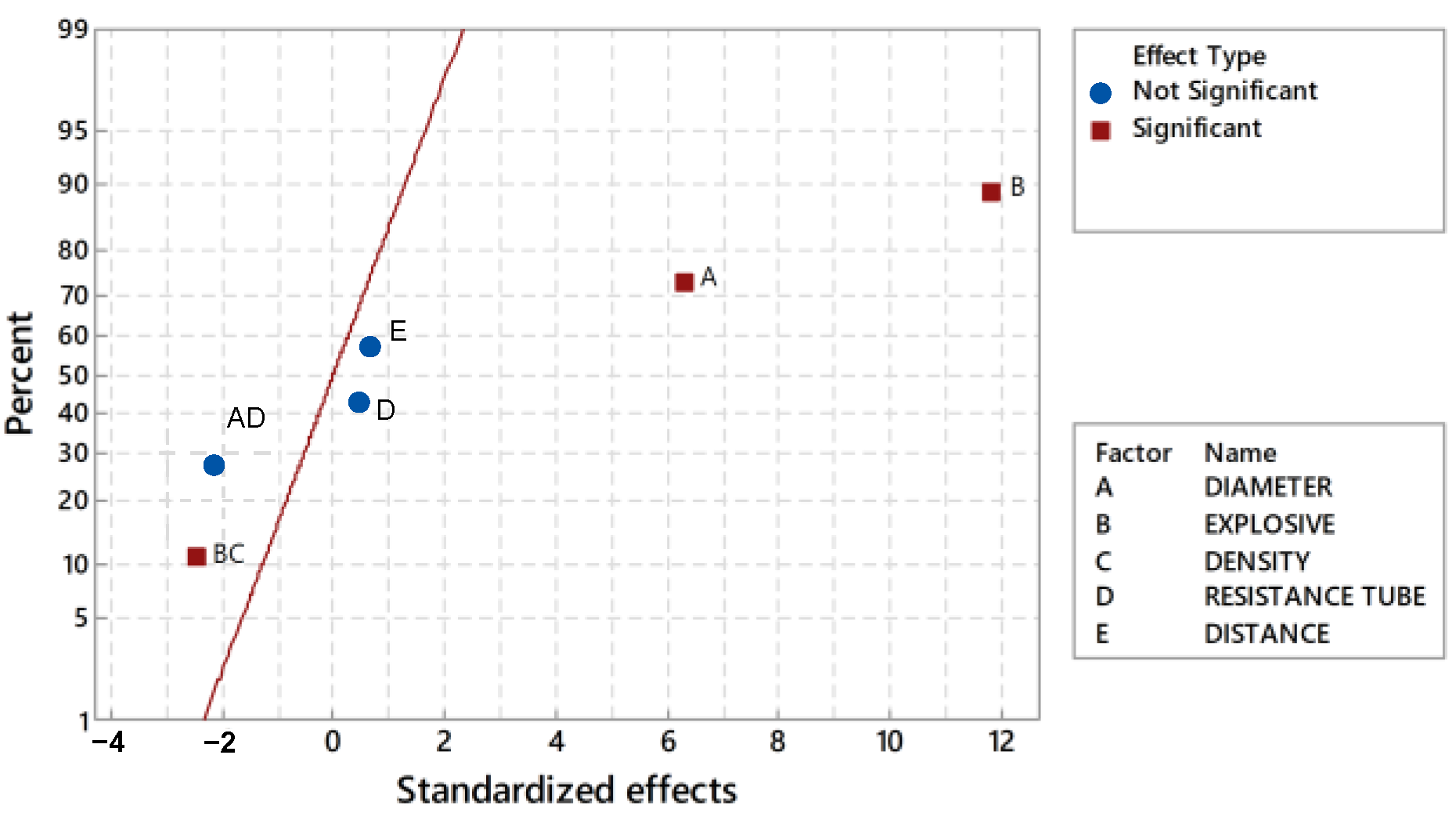

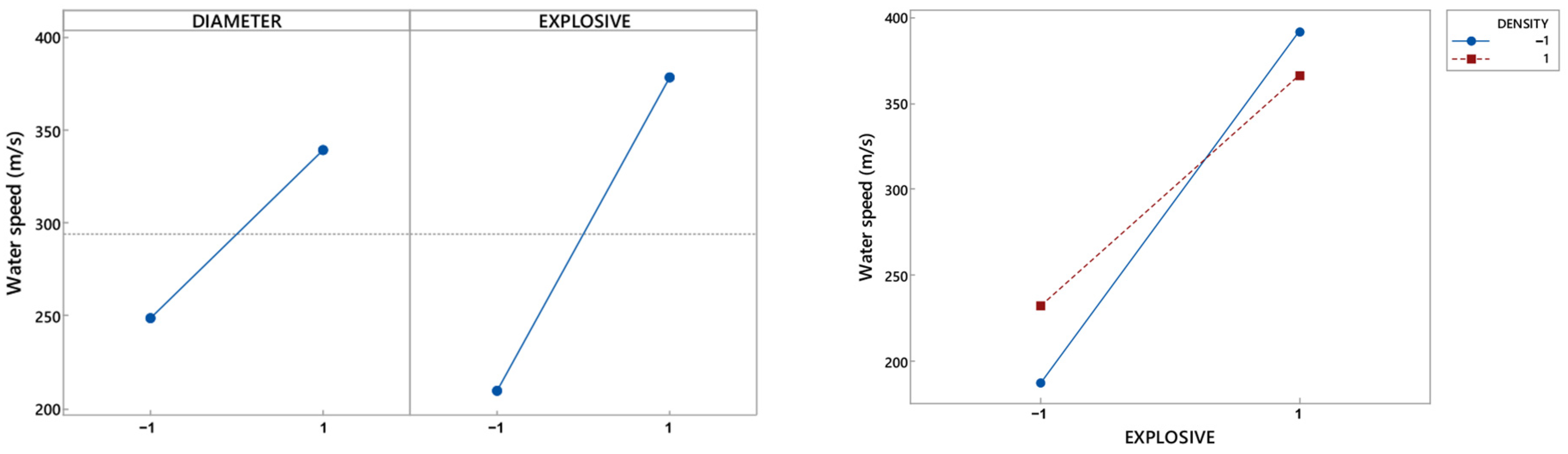

| Df | Adj. SS | Adj. MS | F-Value | p-Value | |

|---|---|---|---|---|---|

| ▪ Model | 6 | 155,366 | 25,894 | 31.83 | 0.000 |

| ▪ Linear | 4 | 146,836 | 36,709 | 45.12 | 0.000 |

| ▪ Diameter | 1 | 32,416 | 32,416 | 39.85 | 0.000 |

| ▪ Explosive Specific Mass | 1 | 113,876 | 113,876 | 139.97 | 0.000 |

| ▪ Density | 1 | 356 | 356 | 0.44 | 0.525 |

| ▪ Resistance Inner Tube | 1 | 188 | 188 | 0.23 | 0.642 |

| ▪ Two-Way Interaction | 2 | 8530 | 4265 | 5.24 | 0.031 |

| ▪ Diameter/Resistance Inner Tube | 1 | 3629 | 3629 | 4.46 | 0.064 |

| ▪ Explosive Specific Mass/Density | 1 | 4901 | 4901 | 6.02 | 0.036 |

| ▪ Error | 9 | 7322 | 814 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ródenas-García, J.F.; Otón-Martínez, R.A.; Sancho-Val, J.; de Francisco Ortiz, O.; Jiménez Pacheco, R.; Gil Garnacho, I. Experimental Evaluation of the Factors That Influence Cylindrical Water Projection Devices against IEDs. Appl. Sci. 2023, 13, 1167. https://doi.org/10.3390/app13021167

Ródenas-García JF, Otón-Martínez RA, Sancho-Val J, de Francisco Ortiz O, Jiménez Pacheco R, Gil Garnacho I. Experimental Evaluation of the Factors That Influence Cylindrical Water Projection Devices against IEDs. Applied Sciences. 2023; 13(2):1167. https://doi.org/10.3390/app13021167

Chicago/Turabian StyleRódenas-García, José F., Ramón A. Otón-Martínez, Joaquín Sancho-Val, Oscar de Francisco Ortiz, Roberto Jiménez Pacheco, and Iván Gil Garnacho. 2023. "Experimental Evaluation of the Factors That Influence Cylindrical Water Projection Devices against IEDs" Applied Sciences 13, no. 2: 1167. https://doi.org/10.3390/app13021167

APA StyleRódenas-García, J. F., Otón-Martínez, R. A., Sancho-Val, J., de Francisco Ortiz, O., Jiménez Pacheco, R., & Gil Garnacho, I. (2023). Experimental Evaluation of the Factors That Influence Cylindrical Water Projection Devices against IEDs. Applied Sciences, 13(2), 1167. https://doi.org/10.3390/app13021167