1. Introduction

Korea is currently strengthening its green building roadmap. As part of this effort, we are striving to implement energy-saving measures with windows based on the “Energy-saving Design Standards” to minimize the energy demand for mandatory zero-energy buildings in the public sector by 2020 and the private sector by 2025 [

1]. Notably, office buildings account for 60–70% of the total energy consumed by the building sector, making energy savings in offices an increasingly important issue [

2,

3]. However, the development of smart envelope and Energy Management System (EMS)-linked technologies to reduce the cooling load of office buildings, which are the most thermally vulnerable parts when implementing zero-energy buildings, remains insufficient.

Building energy consumption is increasing globally, and office energy consumption is experiencing significant growth. Consequently, many studies are underway to reduce building cooling loads. Some studies focused on active awning systems [

4] and window systems using double skins [

5]. However, these efforts concentrated solely on reducing the cooling load by blocking solar radiation from reaching the building. Consequently, lighting energy consumption in office buildings is increasing. To minimize heat loss through windows in conventional buildings, it is essential to produce glass that can control the transmittance of visible light radiation artificially. The need for such technological advancement has become achievable recently, thanks to the progress in the development of thin-film materials with various functionalities and research on liquid crystal materials. One of these technologies is the use of variable transmittance glass, which can artificially adjust its transmittance based on the presence or absence of light or an electric field. Such glass can be broadly categorized into polymer-dispersed liquid crystal (PDLC) technology, vacuum sputter-coated electrochromic technology, and others, depending on the type of functional material used [

6,

7]. These advanced materials are being pursued as next-generation, high-performance, and high-value-added products. Various foreign companies and research institutions are investing substantial budgets in their development, alongside research on control methods. Therefore, in this study, we conducted research on the reduction of lighting and cooling energy consumption in zero-energy buildings through dimming control of a developed smart window system incorporating variable transmittance glass. To achieve this, the optimal dimming control algorithm has been derived and applied in simulations to analyze the energy consumption for lighting and cooling. The developed smart skin is a composite of suspended particle device (SPD) and lighting guide glass (LGG) technologies.

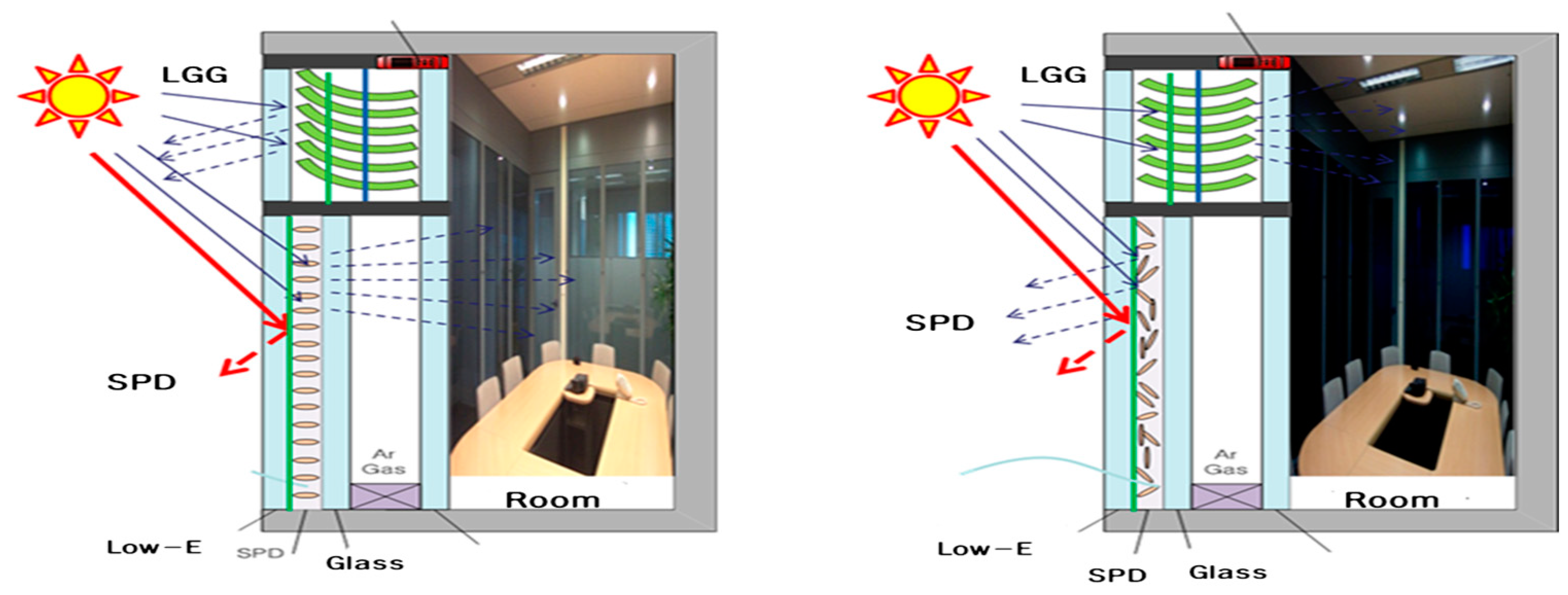

To address this issue, our study aimed to develop an active technology capable of reducing both cooling and lighting energy consumption by analyzing the correlation between cooling and lighting. Therefore, in this study, we developed a complex smart window by combining SPD glass [

8,

9] that can control light transmittance by actively responding to changes in indoor and outdoor environments, such as indoor temperature, illuminance, outdoor temperature, and solar radiation, with a LGG [

10] that is capable of actively controlling solar reflectance. In this case, SPD adjusts its transparency based on the external conditions of the building to minimize the building’s energy loss through heat, while LGG refracts sunlight to enhance the incoming light, thus conserving indoor lighting energy. The refractive index of LGG has been calculated using an algorithm to achieve the optimal value by adjusting its angle based on the elevation of the sun. In addition, we incorporated a dimming LED [

11] to maintain the indoor illuminance level and a controller to optimally control the complex smart window [

12,

13]. To achieve this, an optimal control algorithm and an EMS were developed using computer simulations [

14]. Subsequently, we experimentally measured the reduction in cooling and lighting loads in an office building [

15]. This study involved the development of a complex smart window system, the formulation of an SPD, LGG, and dimming LED control algorithm based on solar radiation in office building modeling using EnergyPlus and TRNSYS, and the design of a control algorithm in conjunction with a controller. Finally, we conducted a comparative experiment by installing tests and reference groups to measure energy consumption.

2. Materials and Methods

2.1. Development of Complex Smart Windows

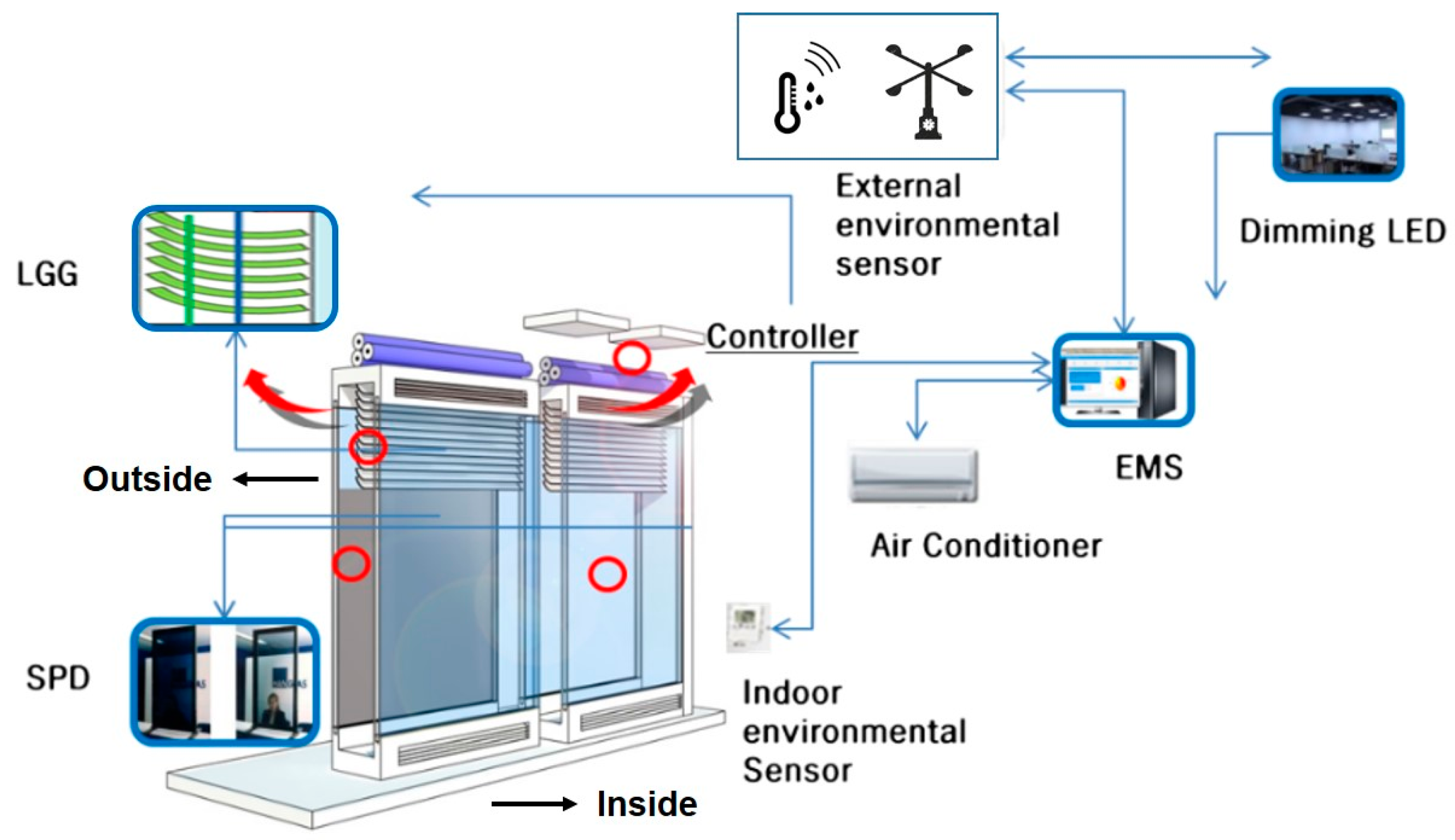

A complex smart window is a sophisticated building envelope that responds to the external environment and adjusts the conditions of the building envelope to optimize the indoor environment. It includes sensors for detecting the external environment (outside temperature, solar radiation) and internal environment (indoor temperature, illuminance), a computer program to respond to the central EMS of the building control system, an SPD and LGG, dimming LEDs, and a driving apparatus, among other components. Essentially, it functions as a smart skin for windows.

Figure 1 shows the configuration of a complex smart window.

Single-skin-shading and double-skin-type windows were developed [

16] considering wind pressure and watertight performance [

17,

18] to account for problems in strength and durability against external impacts depending on the location of the configuration. A complex smart window was combined with an SPD and LGG to maintain the indoor environment at optimal conditions. SPD reduces heat loss in a building by varying the transmittance according to the external conditions of the building [

19,

20]. LGG refracts light from the sun to increase the amount of light entering a building, thereby reducing the lighting energy in the building. An optimal control algorithm for driving the SPD and the LGG was developed using computer simulations. Additionally, the dimming LED was designed to interlock so that it would not affect the indoor working environment and change independently based on the variation in illumination intensity by blocking and distributing sunlight through the SPD and LGG. Furthermore, a controller was developed to interface with an EMS [

21] that monitors data and controls signals based on an optimal control algorithm in conjunction with the indoor and outdoor environments [

22,

23,

24].

Figure 2 shows the image of complex smart window operation.

2.2. Simulations

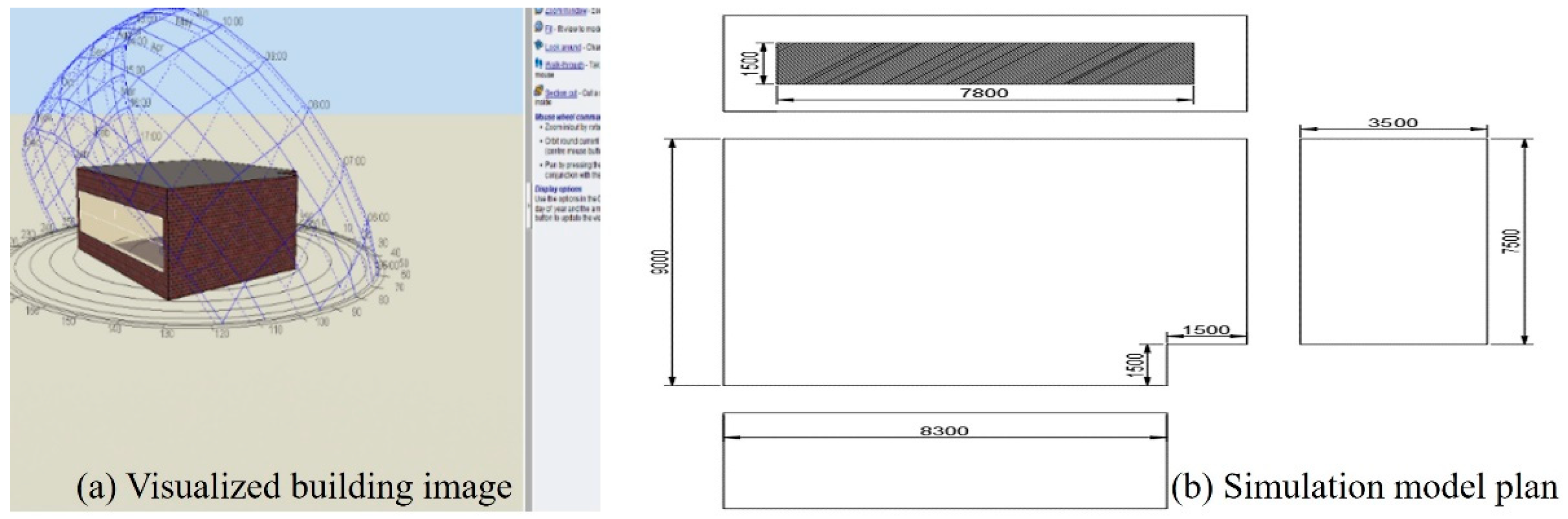

Transmittance and dimming controls for complex smart windows are required to effectively reduce the cooling load and lighting energy during the summer. Time-dependent transmittance control is necessary to achieve optimal control of complex smart windows. To establish the correlation between transmittance control and energy consumption, basic modeling was conducted on an office building located in Seoul, and the energy consumption was calculated using DesignBuilder (version 5.5.2.003).

Figure 3 shows the DesignBuilder simulation setup.

The simulated office building was located in Seoul, and a window was installed at a height of 1.5 m on the south-facing side of the building, which covered 50% of the total wall area.

Table 1 presents the details of the simulated buildings. For office dimming control, 700 lx was set as the standard for indoor illumination levels (range: 700–1500 lx). Regarding the SPD, a simulation was conducted by dividing the shading on the south-facing window into nine cases (with minimum and maximum shielding criteria of 0.1 and 0.9, respectively) to determine the appropriate SPD control method according to time. The weather data required for the analysis were based on the 2015 Seoul weather data provided by the Korean Meteorological Administration. A simulation was conducted for the baseline model, a model with the dimming control system was applied, and the dimming control system was applied to a general office building under natural light. All other conditions were kept constant. The results are summarized in

Figure 4. In this study, the function that controls the transmittance of the smart skin over time was determined using regression analysis. This function is proposed to be a function of time to optimize the cooling load and lighting energy by controlling the smart skin.

2.3. Pilot Plant

To develop the smart window system and algorithm, a pilot plant was built in the laboratory to monitor changes in cooling, heating, and room lighting loads according to changes in solar radiation. The collected data were used to develop control algorithms using machine learning techniques.

Figure 5 shows prototypes of the solar radiation blocking rate measuring device [

25], SPD production [

26], and smart window [

27], which were used to construct an actual pilot plant [

28,

29,

30].

2.4. Optimal Control Algorithm and Controller Development

In this study, the function that controls the permeability of the smart skin over time was calculated using regression analysis. Consequently, a time function that optimizes the cooling load and lighting energy by controlling the smart skin is proposed.

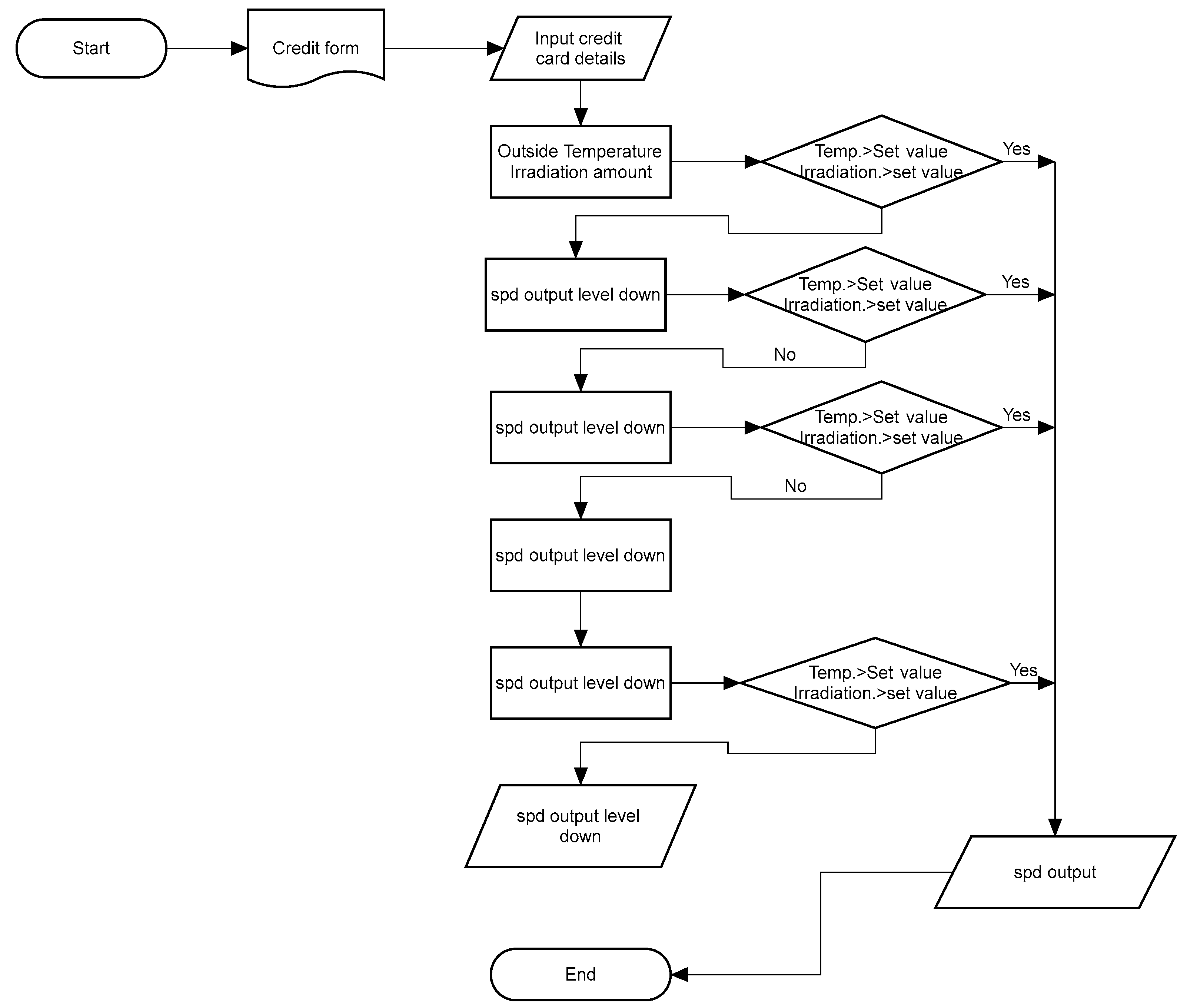

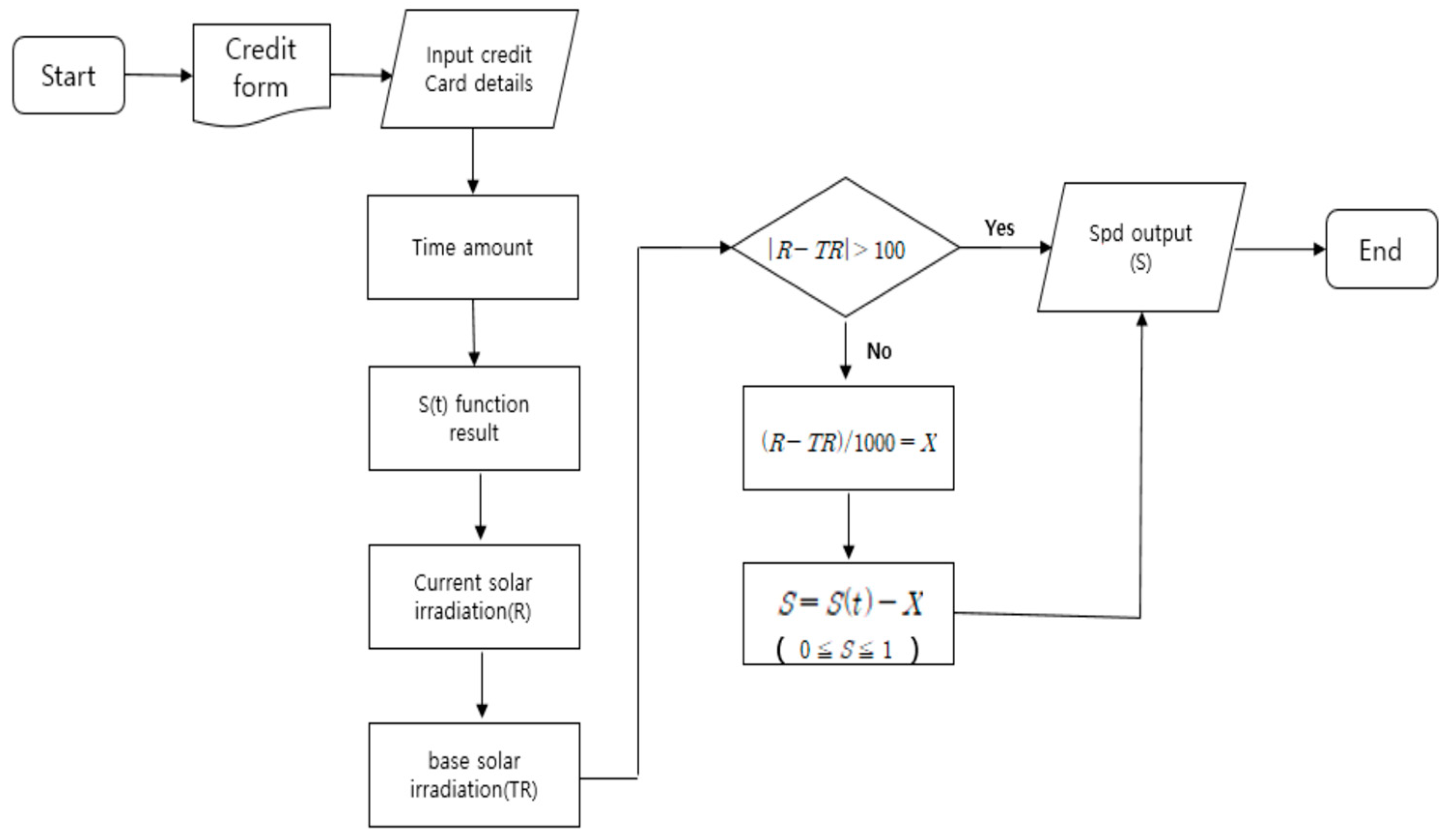

Different results were obtained when the direction of the building was changed to east, west, south, or north. Using this result, the smart skin control algorithm (implemented to achieve the maximum reduction of cooling and lighting loads in a zero-energy building) can be derived, as shown in

Figure 6. In the algorithm, the output level represents the temperature and irradiation amounts obtained from the sensor attached to the SPD. The SPD output is represented as a discrete value ranging from 0 to 1, with 1 indicating complete light blocking and 0 signifying transparent control allowing light transmission.

One disadvantage is that the effect of the change in insolation in real time cannot be fully considered through SPD and dimming control based solely on time. To address this limitation, precise, real-time control that considers the indoor environment is necessary. Therefore, a dependent logic considering the amount of insolation is proposed as follows:

where

In Equations (2) and (3),

S(

t) is a control value, and t is a variable representing time.

R represents the representative solar radiation, and

TR represents the hourly solar radiation. Equations (2) and (3) were used to supplement the control value in cases where the hourly insolation amount had a large error compared with the representative insolation amount. The following algorithm incorporates real-time insolation from the previous algorithm, resulting in a more accurate calculation of SPD values. Therefore, this algorithm allows for the calibration of SPD values, thereby improving the accuracy of SPD values for cloudy or rainy days. Finally, through algorithmic modeling, we were able to derive the optimal SPD transmittance and dimming values, and using these, we controlled the smart window.

Figure 7 shows a control method that considers real-time insolation.

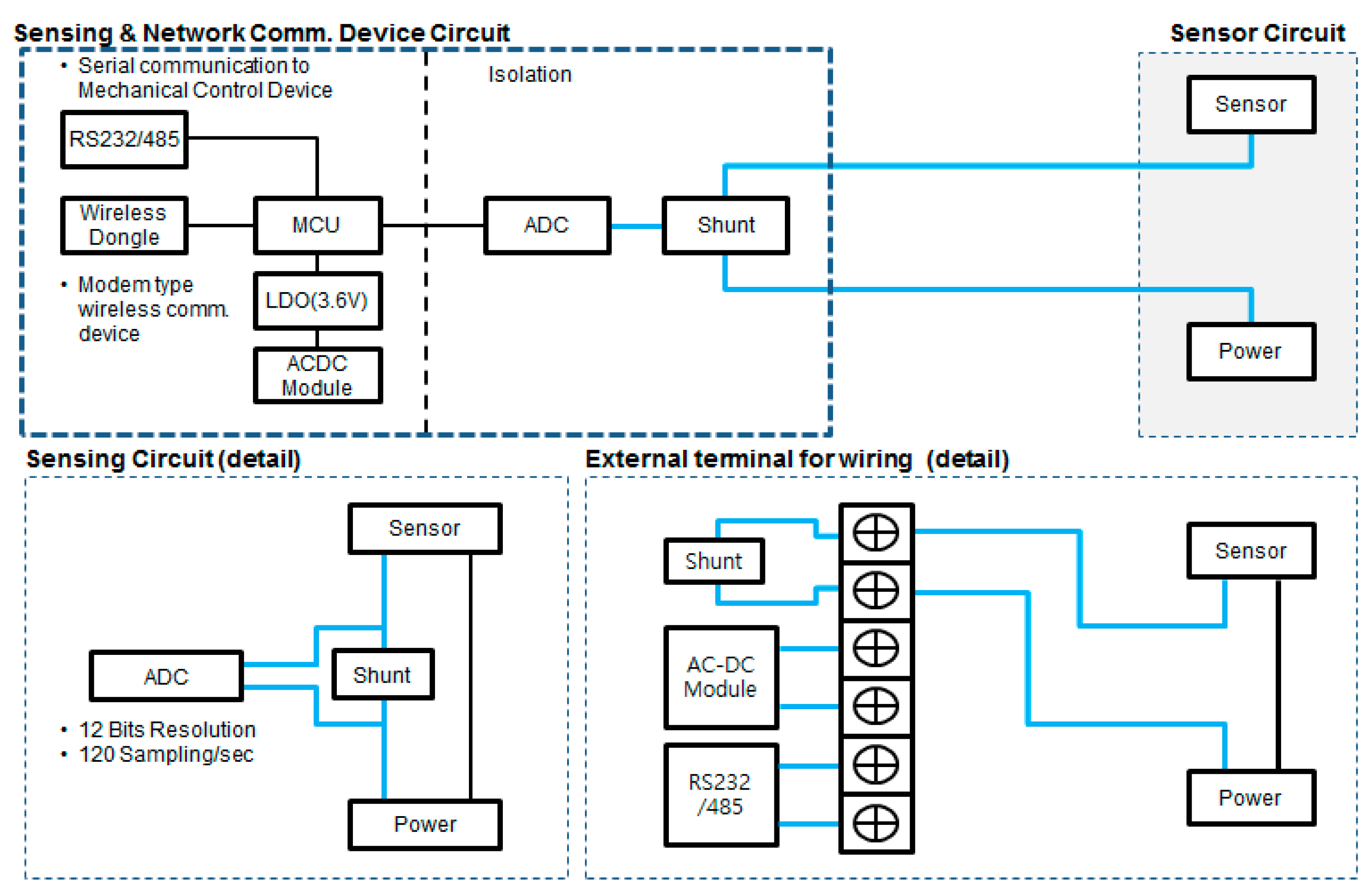

The development of hardware (HW) and firmware (FW) to control a complex smart window system in an office utilizes a LoRa-based wireless communication method to collect wireless sensor data. This supports LGG, SPD, and LED controls. The detailed hardware configuration is illustrated in

Figure 8.

2.5. Test Building Construction and Complex Smart Window Experiment

To reduce the lighting and cooling loads in a zero-energy building, a test room was established to conduct experiments on a complex smart window, and an optimal control method was developed that applies both dimming control and variable transmittance glasses. For the experiment, two identical rooms—the test and reference—were constructed with an EPS panel structure, each with an area of 12 m2.

The experimental setup is shown in

Figure 9. Smart skins with SPD and LGG were installed in the test room, whereas ordinary glasses were installed in the reference room. Their configurations are presented in

Table 2. Temperature, humidity, illuminance, and solar radiation sensors were installed in each room for monitoring purposes. The heating and cooling units were installed separately to monitor the cooling energy consumption using a meter.

3. Results

3.1. Effect of a Complex Smart Window

The difference in energy consumption between the test and reference rooms is shown below. Although the current control method exhibited a high-cooling effect in the summer, it was slightly effective or ineffective in meeting the load required for heating and cooling during the shoulder season. However, when the experiment was conducted, the energy-saving effect was confirmed to be significant.

3.2. Site Experiments

The goal of this study was to reduce lighting and cooling loads in a zero-energy building by testing a smart skin and implementing an optimal control method that incorporates both dimming control and variable transmittance glass. To achieve this, the sensor and meter values were monitored using the EMS. The monitoring period for this study was limited to June–September 2000. During the test period, the energy consumption of the test and reference rooms was compared. Focus was placed on data collected from 9 am to 6 pm. This timeframe was chosen to align with standard working hours in public buildings, and changes in indoor temperature as well as the energy consumption of air conditioners and lighting were closely monitored. The illuminance level was set to 500 lx in both the test and reference rooms. In the experimental site, the indoor temperature was controlled to approximately 25 °C, and the indoor illuminance was maintained at approximately 500 lx, which is the required illuminance level for office work in a public building. The illuminance level measurement location was set at a height of approximately 0.7 m in both the test and reference rooms, based on the height of the office desk.

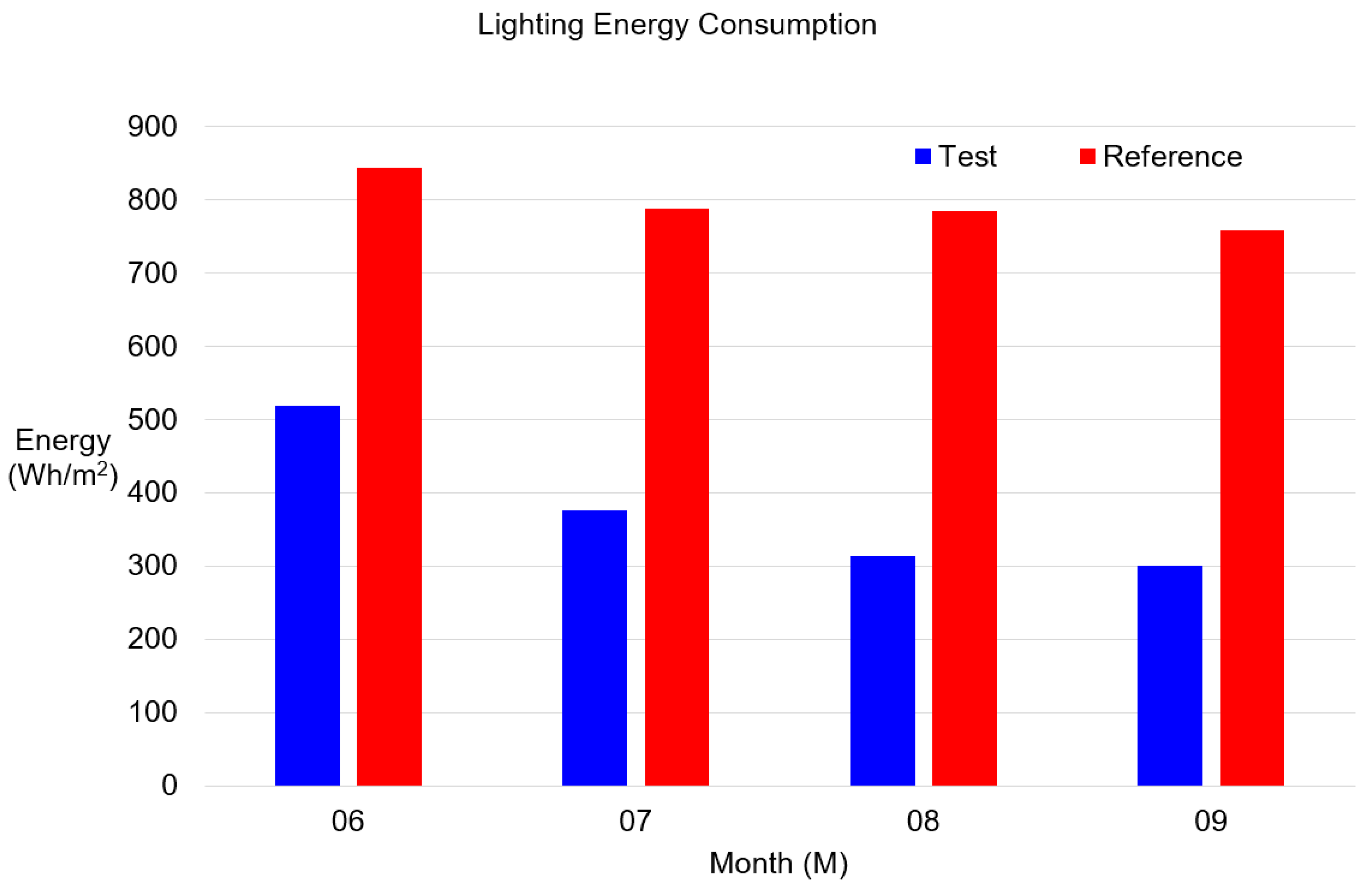

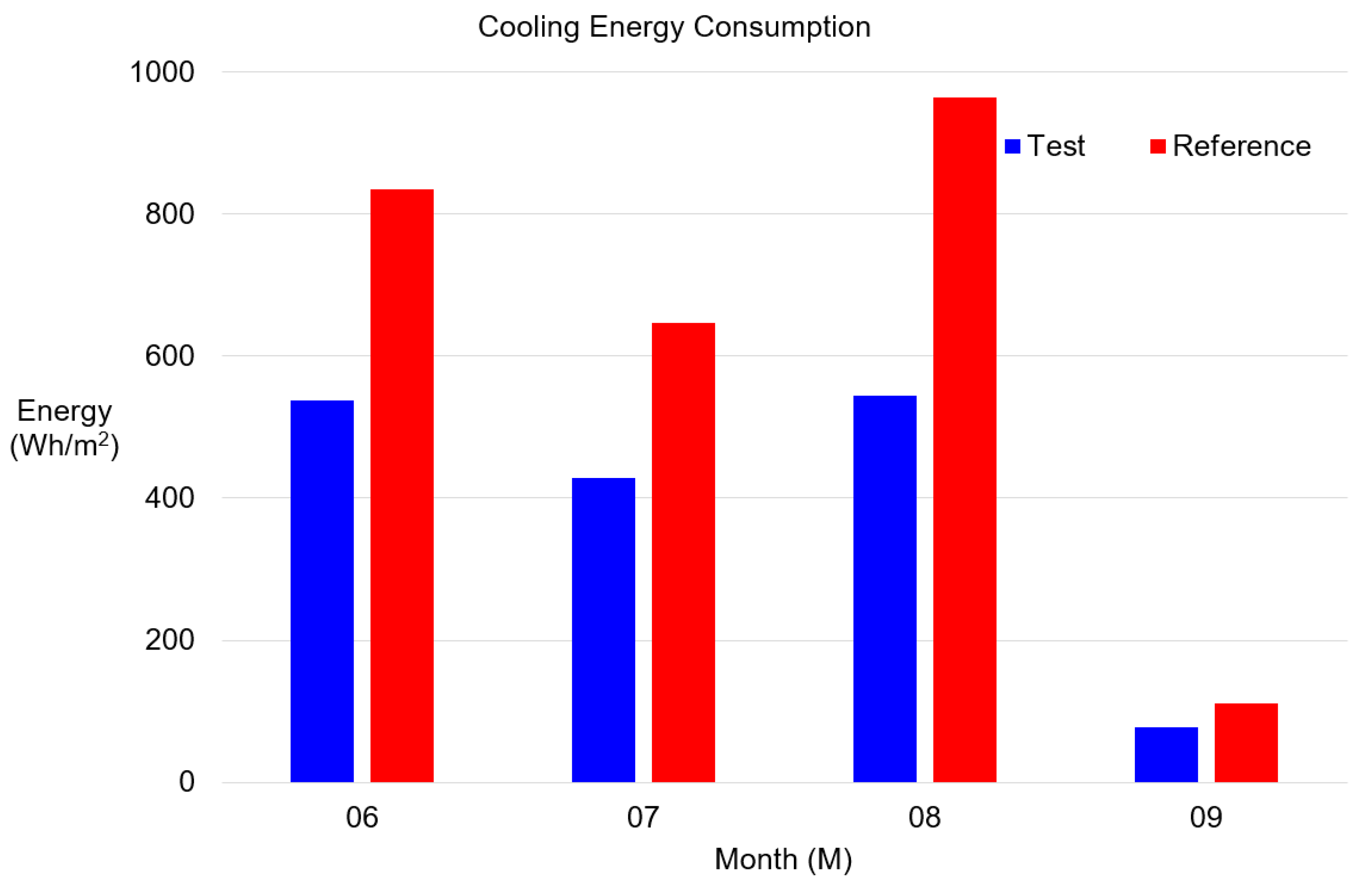

3.3. Comparison of Cooling and Lighting Energy Consumptions

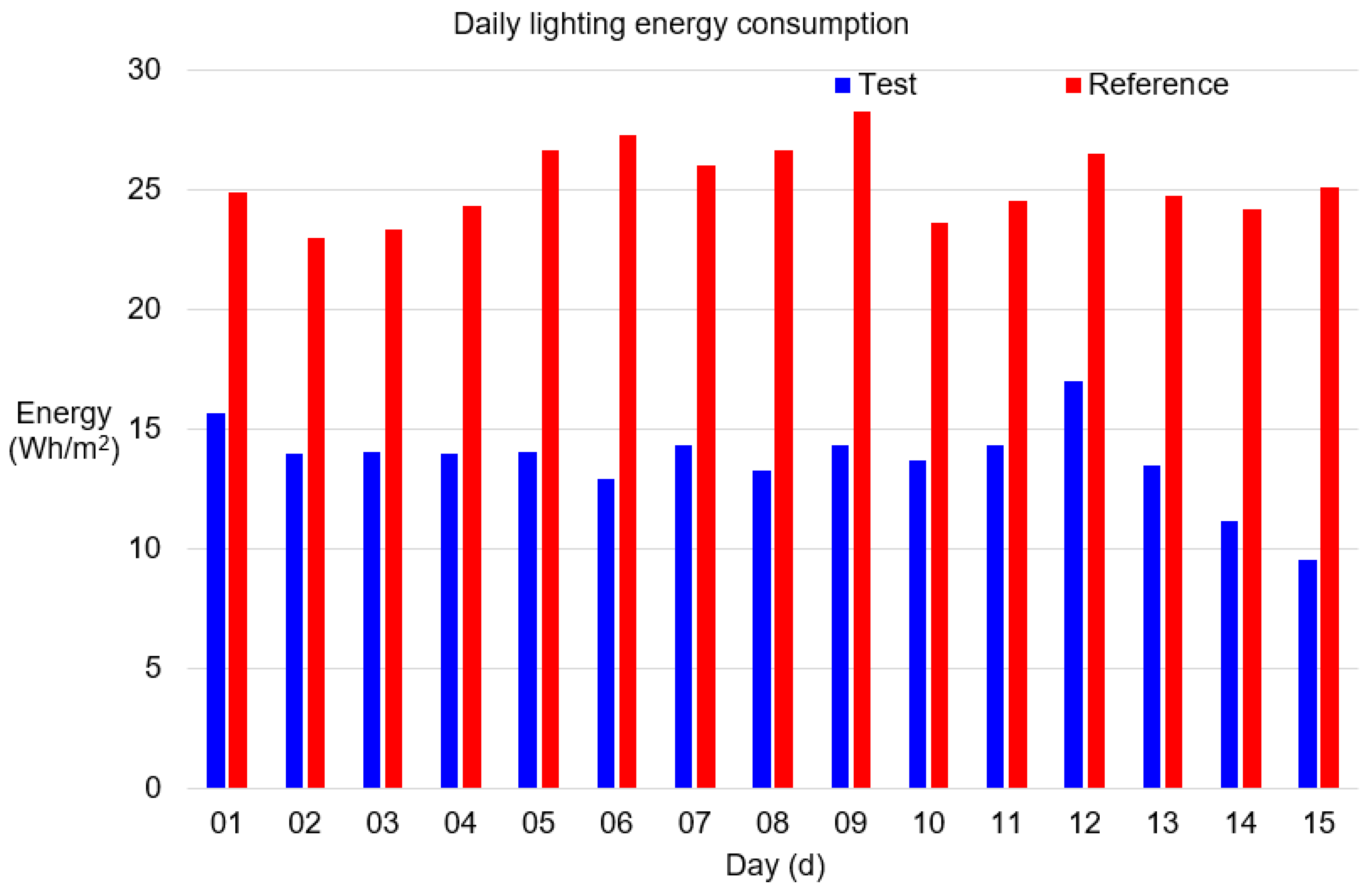

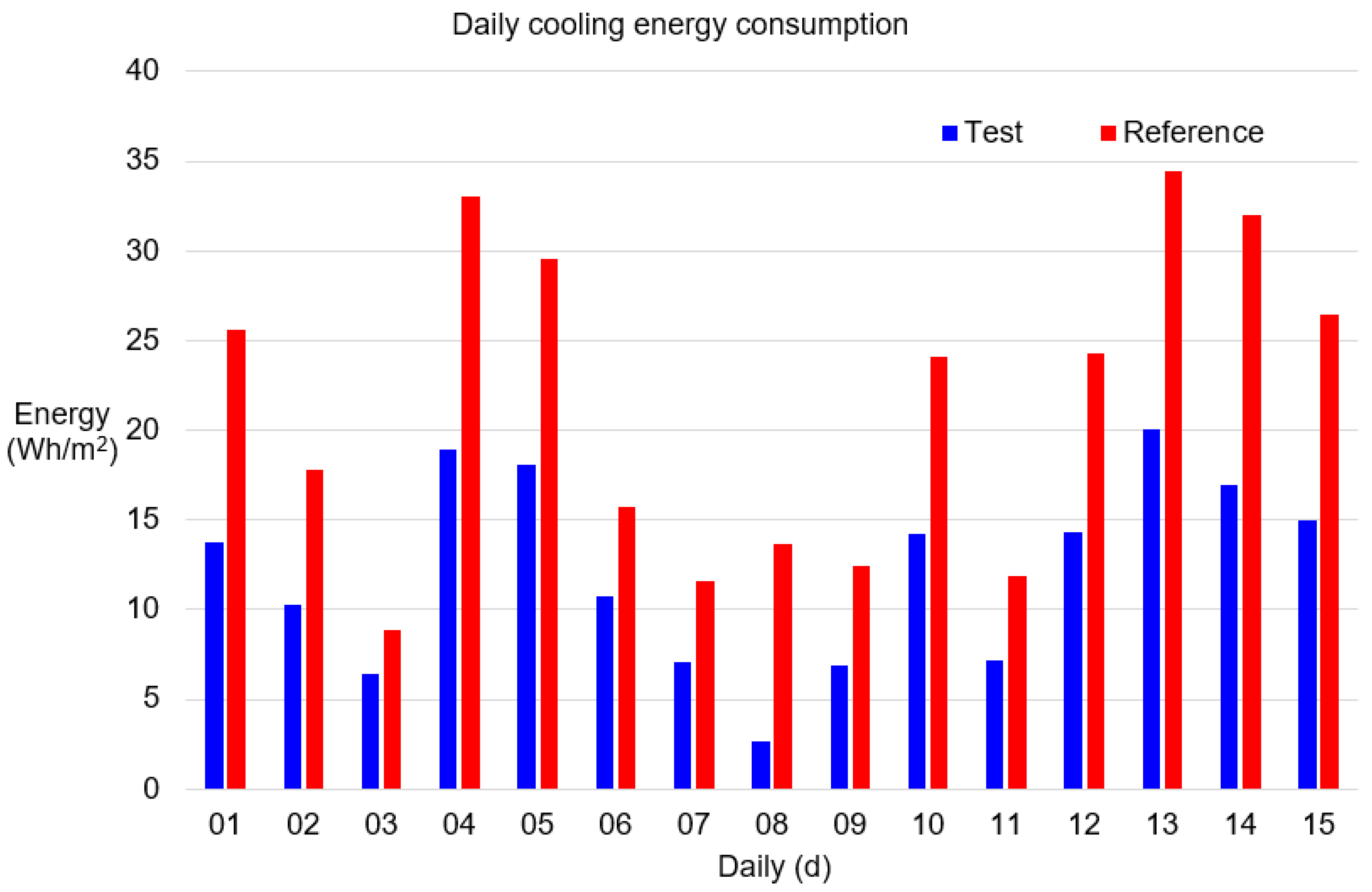

To reduce the cooling load and lighting energy in summer effectively, an experiment was conducted using a complex smart window combined with a dimming LED to maintain indoor illumination levels. For this purpose, we simulated the reduction of cooling and lighting loads through actual monitored SPD transmittance and dimming control. This window combines SPD glass, which actively responds to changes in indoor and outdoor environments and can control light transmittance, with LGG, which can actively control solar reflectance. The results of a comparative analysis of the energy consumption of the test and reference groups in the experiment using a complex smart window are shown in the following graph. In

Figure 10 and

Figure 11, the data for days 1 to 15 refer to the period from 1–15 August, which is when the cooling load is the highest during the summer season. Also, in

Figure 12 and

Figure 13, the monthly data include all days of the respective month.

Figure 9 displays the lighting energy consumption from 1–15 August, revealing that the Test group equipped with SPD and LGG generally exhibits lower consumption (<1.5 kWh).

Figure 11 presents cooling energy consumption, indicating larger daily variations due to external temperature influences rather than lighting, yet similarly, the Test group demonstrates lower cooling energy consumption, consistent with the lighting energy results.

Figure 12 and

Figure 13 depict lighting and cooling energy consumption from June to September. Overall, the Test group consistently exhibits lower energy consumption, and the highest reduction rate is observed in August, a period of heavy load.

The experiment yielded energy consumption under the same external and internal conditions, as shown in

Table 3. The cooling and lighting energy consumptions of the test room were 138.6 kWh and 124.1 kWh, respectively, whereas the cooling and lighting energy consumptions of the reference room were 219.8 kWh and 272.7 kWh, respectively. By applying smart skin, energy-efficient use was achieved in parallel with dimming control. By combining LGG and the dimer, the lighting load was reduced by 54.5% and the cooling energy consumption was reduced by approximately 36.9% compared with the reference room.

4. Discussion

Additional simulations were conducted (not mentioned in this study). In particular, after comparing the energy consumption of buildings with complex smart window systems based on the orientation of the office building and analyzing the differences, it was found that the highest energy savings occurred when the building faced south, whereas the lowest savings occurred when it faced north. The order of energy savings according to building direction was south, west, east, and north.

Furthermore, when comparing and simulating the amount of energy saved using different building envelope materials, such as reinforced concrete and brick, the energy-saving rate was found to be the same. However, when the window area differed from that of the wall, energy savings were proportional to the window area. Additionally, deep learning was applied to simulate the energy savings of a complex smart window system, and it was confirmed that a certain amount of energy consumption could be predicted.

In this study, to reduce cooling and lighting energy simultaneously, a complex smart window was developed by combining SPD glass, which is capable of controlling light transmittance by actively responding to changes in indoor and outdoor environments and outdoor air, with LGG, which can actively control solar reflectance. A dimming LED is also incorporated to maintain the required indoor illuminance level. Therefore, it is necessary to confirm the energy-saving effects associated with the use of this technology in various buildings. Additionally, based on this study, the developed smart window is considered effective in reducing lighting and cooling loads. However, from a long-term perspective, when applying smart skin technology, it is deemed necessary to install real-time sensors for detecting malfunctions in the SPD and LGG window systems and verifying their long-term effects.

5. Conclusions

In this study, a system was developed to reduce the lighting and cooling energy consumption in an office building during the summer period. Prior to the experiments, we developed a control algorithm to derive the optimal SPD transmittance and dimming values. The system simultaneously applied dimming control and smart skin with variable transmittance, and an optimal control method was devised to maximize energy savings. An experimental site was constructed to compare and study the actual energy consumption. The experimental period was from June to September, and the cooling period and lighting operation time were monitored from 9:00 am to 6:00 pm, aligned with the working hours of office workers. As a result of this study, it has been confirmed that the application of the developed complex smart window significantly reduces lighting and cooling loads during the summer season. The major findings are as follows:

- (1)

A complex smart window system was developed by combining SPD, LGG, and dimming LED to simultaneously reduce cooling and lighting loads and address the increasing energy consumption in offices during the summer period.

- (2)

An algorithm that can control the transmittance and dimming in parallel was developed to effectively control complex smart windows. The cooling load and lighting energy were optimized by determining a function that controlled the transmittance over time.

- (3)

To increase the effectiveness of the control and application of the complex smart window, an optimal control function was developed for each region using representative solar radiation data for each area. To control the complex smart window in an office, we developed HW and FW for the wireless controller using the LoRa-based wireless communication method, which supports LGG, SPD, and LED control.

- (4)

Based on experimentation, it was shown that energy efficiency can be achieved in parallel with dimming control when complex smart windows are used. By combining LGG and dimming, the lighting load was reduced by 54.5%.

- (5)

An experimental site was constructed to monitor the energy consumption in the test and reference rooms. In the test room with the smart skin system, the cooling energy consumption was reduced by approximately 36.9% compared with the reference room.

Author Contributions

Conceptualization, S.-K.H. and S.-H.C.; methodology, S.-K.H.; software, S.-K.H.; validation, S.-G.J. and S.-H.C.; investigation, S.-K.H.; data curation, S.-H.C.; writing—original draft preparation, S.-K.H.; writing—review and editing, S.-G.J.; visualization, S.-K.H.; supervision, S.-G.J.; funding acquisition, S.-K.H. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Korean Institute of Energy Technology Evaluation and Planning (KETEP) and the Ministry of Trade, Industry, and Energy (MOTIE) of the Republic of Korea (No. 2019271010015C). Additionally, this research was supported by the “Regional Innovation Strategy (RIS)” through the National Research Foundation of Korea (NRF), funded by the Ministry of Education (MOE) (2021RIS-004).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kim, S.H.; Kim, S.S.; Kim, K.W.; Cho, Y.H. A study on the proposes of energy analysis indicator by the window elements of office buildings in Korea. Energy Build. 2014, 73, 153–165. [Google Scholar] [CrossRef]

- Cappelletti, F.; Gasparella, A.; Romagnoni, P.; Baggio, P. Analysis of the influence of installation thermal bridges on windows performance: The case of clay block walls. Energy Build. 2011, 43, 1435–1442. [Google Scholar] [CrossRef]

- Adamus, J.; Pomada, M. Analysis of heat flow in composite structures used in window installation. Compos. Struct. 2018, 202, 127–135. [Google Scholar] [CrossRef]

- A New Wave in the Awning Industry Following a Paradigm Shift in Building Envelopes. 2016. Available online: http://www.todayenergy.kr (accessed on 3 July 2023).

- Seok, H.T.; Jo, J.H.; Kim, K.W. Establishing the Design Process of Double-Skin Façade Elements through Design Parameter Analysis. J. Asian Archit. Build. Eng. 2008, 8, 251–258. [Google Scholar] [CrossRef]

- Cupelli, D.; Nicoletta, F.P.; Manfredi, S.; Vivacqua, M.; Formoso, P.; De Filpo, G.; Chidichimo, G. Self-adjusting smart windows based on polymer-dispersed liquid crystals. Sol. Energy Mater. Sol. Cells 2009, 93, 2008–2012. [Google Scholar] [CrossRef]

- Karumuthil, S.C.; Ganesha, M.K.; Mondal, I.; Singh, A.K.; Kulkarni, G.U. Fabrication of dual-functional electrochromic smart window based on low-cost hybrid transparent electrode coated with a solution-processable polymer. J. Mater. Chem. A 2022, 10, 23265–23273. [Google Scholar] [CrossRef]

- Tsikaloudaki, K.; Theodosiou, T.H.; Laskos, K.; Bikas, D. Assessing cooling energy performance of windows for residential buildings in the Mediterranean zone. Energy Convers. Manag. 2012, 64, 335–343. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Duffy, A. Effect of sky conditions on light transmission through a suspended particle device switchable glazing. Sol. Energy Mater. Sol. Cells 2017, 160, 134–140. [Google Scholar] [CrossRef]

- Kischkoweit-Lopin, M. An overview of daylighting systems. Sol. Energy 2002, 73, 77–82. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, I.T.; Choi, A.S.; Sung, M. Evaluation of optimized PV power generation and electrical lighting energy savings from the PV blind-integrated daylight responsive dimming system using LED lighting. Sol. Energy 2014, 107, 746–757. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Properties, requirements and possibilities of smart windows for dynamic daylight and solar energy control in buildings: A state-of-the-art review. Sol. Energy Mater. Sol. Cells 2010, 94, 87–105. [Google Scholar] [CrossRef]

- Allen, K.; Connelly, K.; Rutherford, P.; Wu, Y. Smart windows—Dynamic control of building energy performance. Energy Build. 2017, 139, 535–546. [Google Scholar] [CrossRef]

- Beaudin, M.; Zareipour, H. Home energy management systems: A review of modelling and complexity. Renew. Sustain. Energy Rev. 2015, 45, 318–335. [Google Scholar] [CrossRef]

- Gago, E.J.; Muneer, T.; Knez, M.; Köster, H. Natural light controls and guides in buildings. Energy saving for electrical lighting, reduction of cooling load. Renew. Sustain. Energy Rev. 2015, 41, 1–13. [Google Scholar] [CrossRef]

- Cho, S.; Kim, S.H. Analysis of the performance of vacuum glazing in office buildings in Korea: Simulation and experimental studies. Sustainability 2017, 9, 936. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, Y.; Wilson, R. A review of thermal and optical characterisation of complex window systems and their building performance prediction. Appl. Energy 2018, 222, 729–747. [Google Scholar] [CrossRef]

- Dussault, J.M.; Gosselin, L. Office buildings with electrochromic windows: A sensitivity analysis of design parameters on energy performance, and thermal and visual comfort. Energy Build. 2017, 153, 50–62. [Google Scholar] [CrossRef]

- Li, C.; Tan, J.; Chow, T.T.; Qiu, Z. Experimental and theoretical study on the effect of window films on building energy consumption. Energy Build. 2015, 102, 129–138. [Google Scholar] [CrossRef]

- Fasi, M.A.; Budaiwi, I.M. Energy performance of windows in office buildings considering daylight integration and visual comfort in hot climates. Energy Build. 2015, 108, 307–316. [Google Scholar] [CrossRef]

- Ye, H.; Meng, X.; Xu, B. Theoretical discussions of perfect window, ideal near infrared solar spectrum regulating window and current thermochromic window. Energy Build. 2012, 49, 164–172. [Google Scholar] [CrossRef]

- Kumar, K.; Saboor, S.; Kumar, V.; Kim, K.H. Experimental and theoretical studies of various solar control window glasses for the reduction of cooling and heating loads in buildings across different climatic regions. Energy Build. 2018, 173, 326–336. [Google Scholar] [CrossRef]

- Ministry of Land, Transport and Maritime Affairs. Building Energy Conservation Design Standard; Ministry of Land, Transport and Maritime Affairs: Sejong-si, Republic of Korea, 2008.

- Ministry of Knowledge Economy. Energy Efficiency Equipment Operating Regulations; Ministry of Knowledge Economy: Seoul, Republic of Korea, 2012. [Google Scholar]

- Korea Agency for Technology and Standards, KS. Windows Set. 2015. Volume F3117. Available online: http://www.kats.go.kr/ (accessed on 3 July 2023).

- Korea Agency for Technology and Standards, KS. Standard Test Method for Thermal Resistance for Windows and Doors. 2017, Volume F2278. Available online: http://www.kats.go.kr/ (accessed on 3 July 2023).

- Korea Agency for Technology and Standards, KS. The Method of Air Tightness for Windows and Doors. 2018, Volume F2292. Available online: http://www.kats.go.kr/ (accessed on 3 July 2023).

- Korea Agency for Technology and Standards. Available online: http://www.kats.go.kr/ (accessed on 3 July 2023).

- Lawrence Berkeley National Laboratory. COMFEN. Available online: http://www.lbl.gov/ (accessed on 3 July 2023).

- Korea Agency for Energy. Available online: http://eep.energy.or.kr/ (accessed on 3 July 2023).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).