A Method for Plotting Failure Envelopes of Unidirectional Polymer Composite Materials under Different Strain Rates

Abstract

1. Introduction

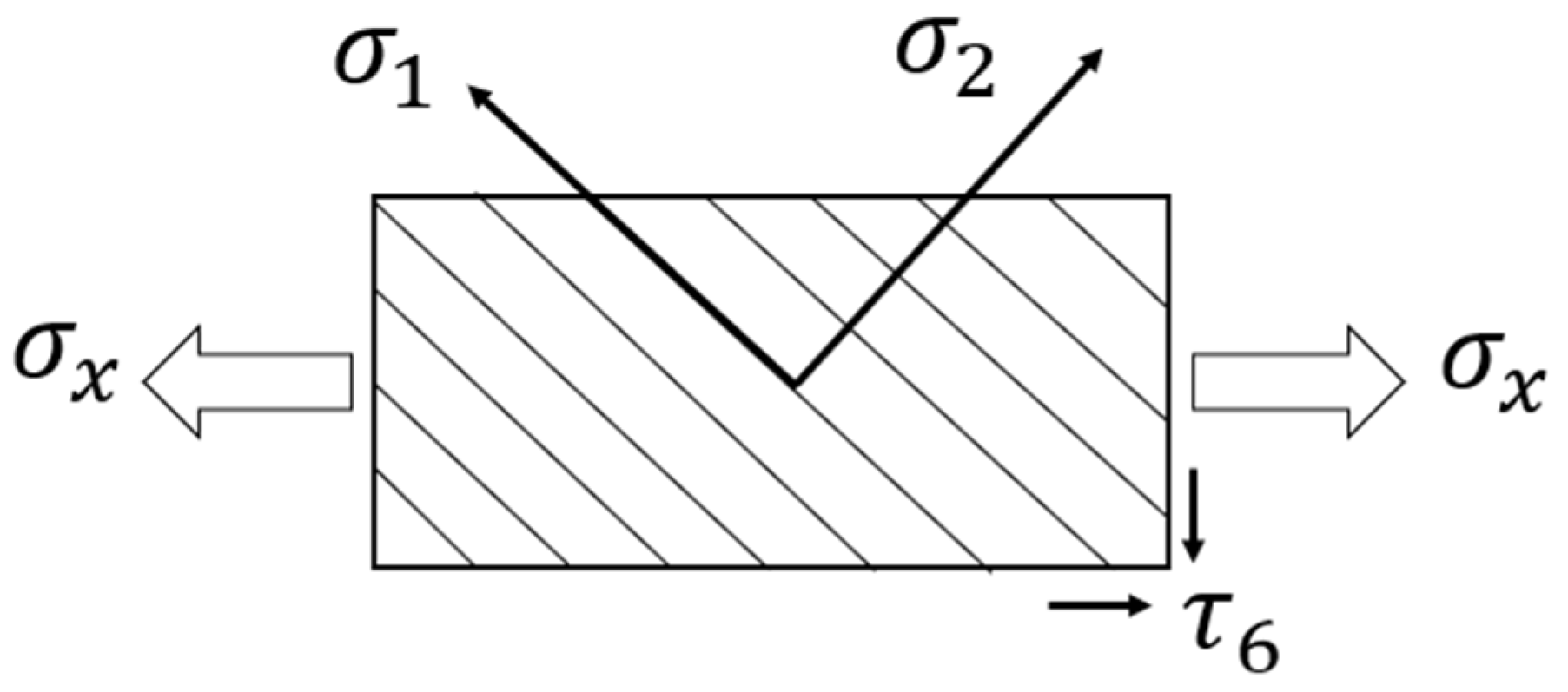

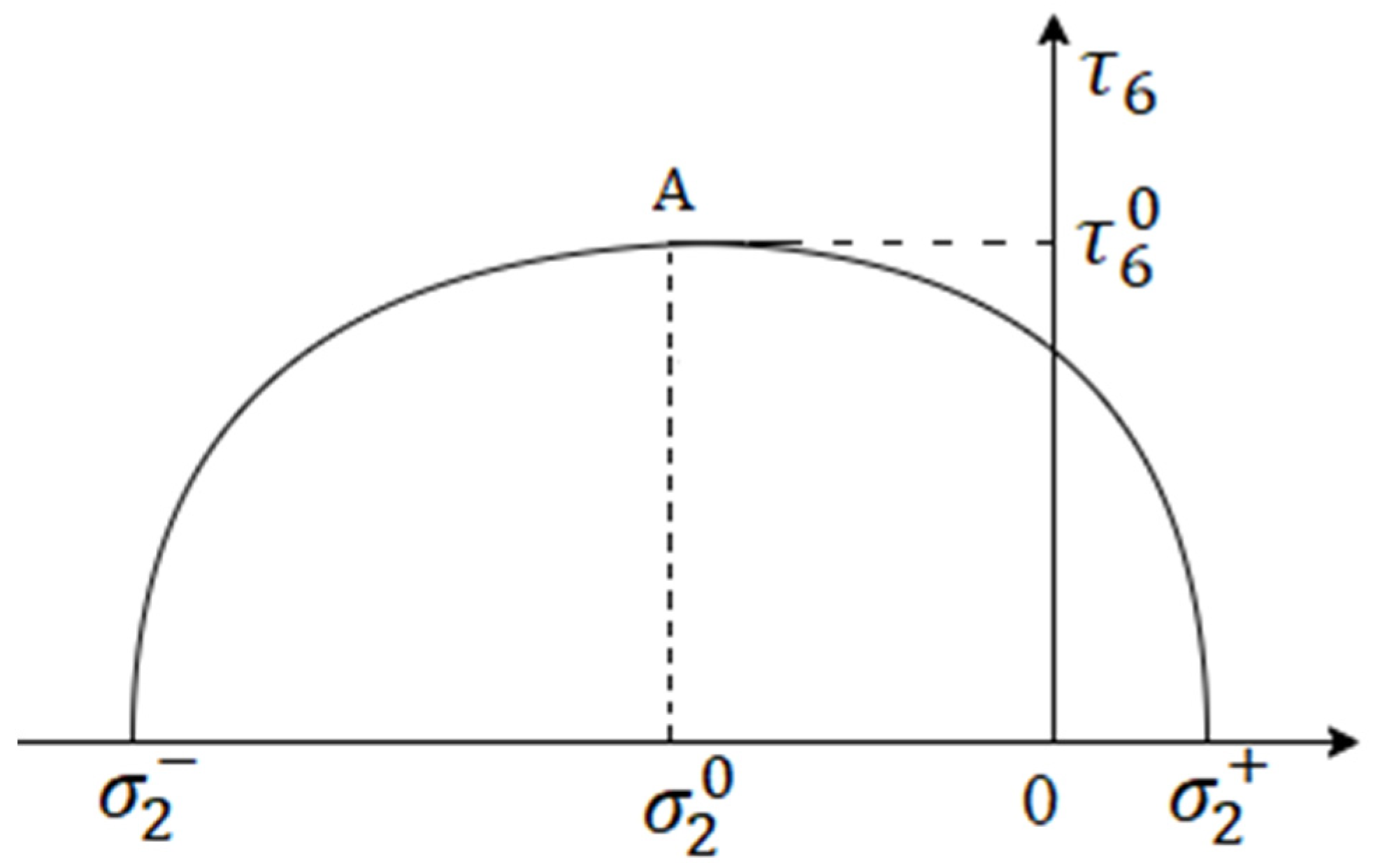

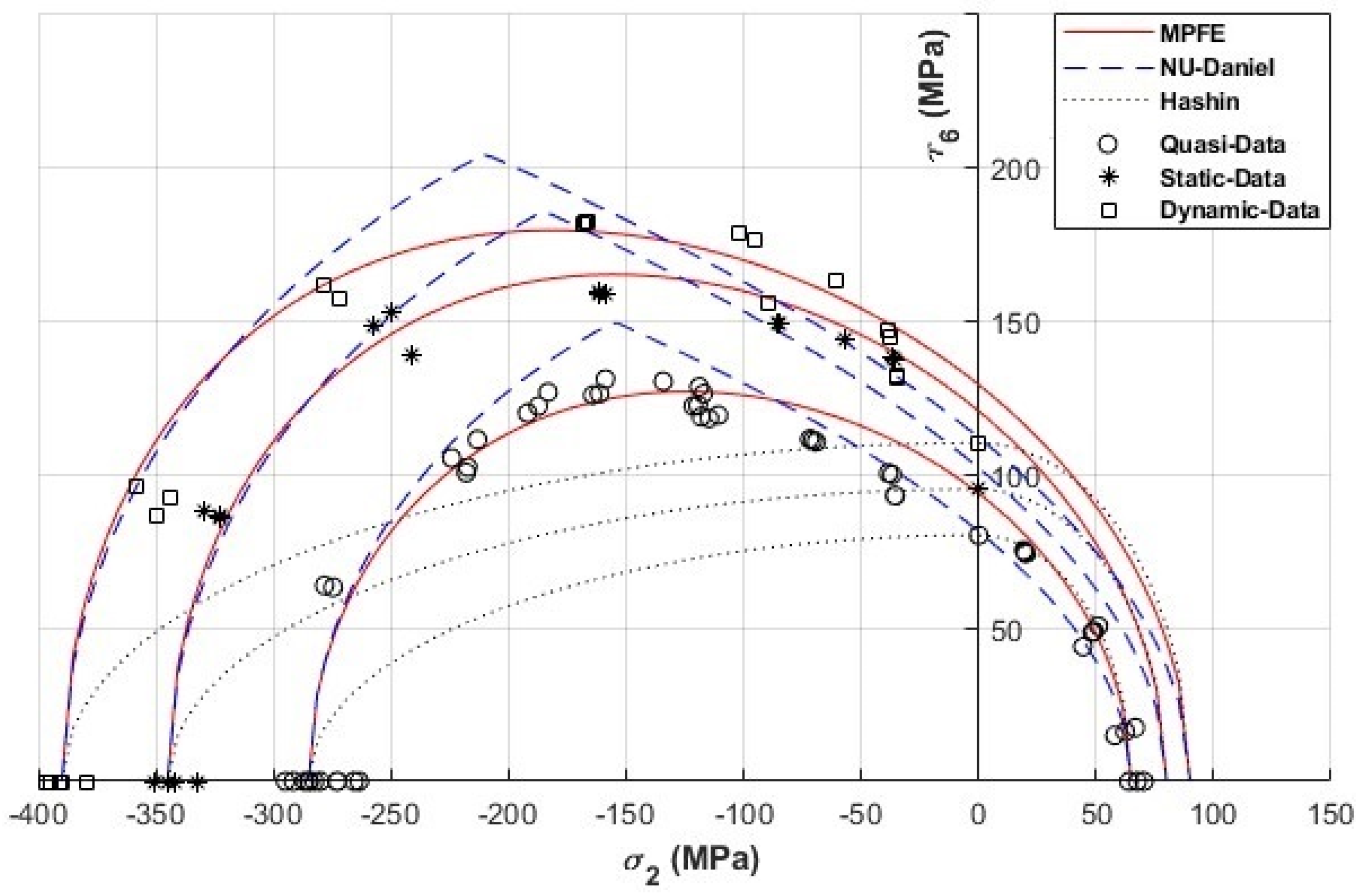

2. Methods for Plotting Failure Envelope (MPFE)

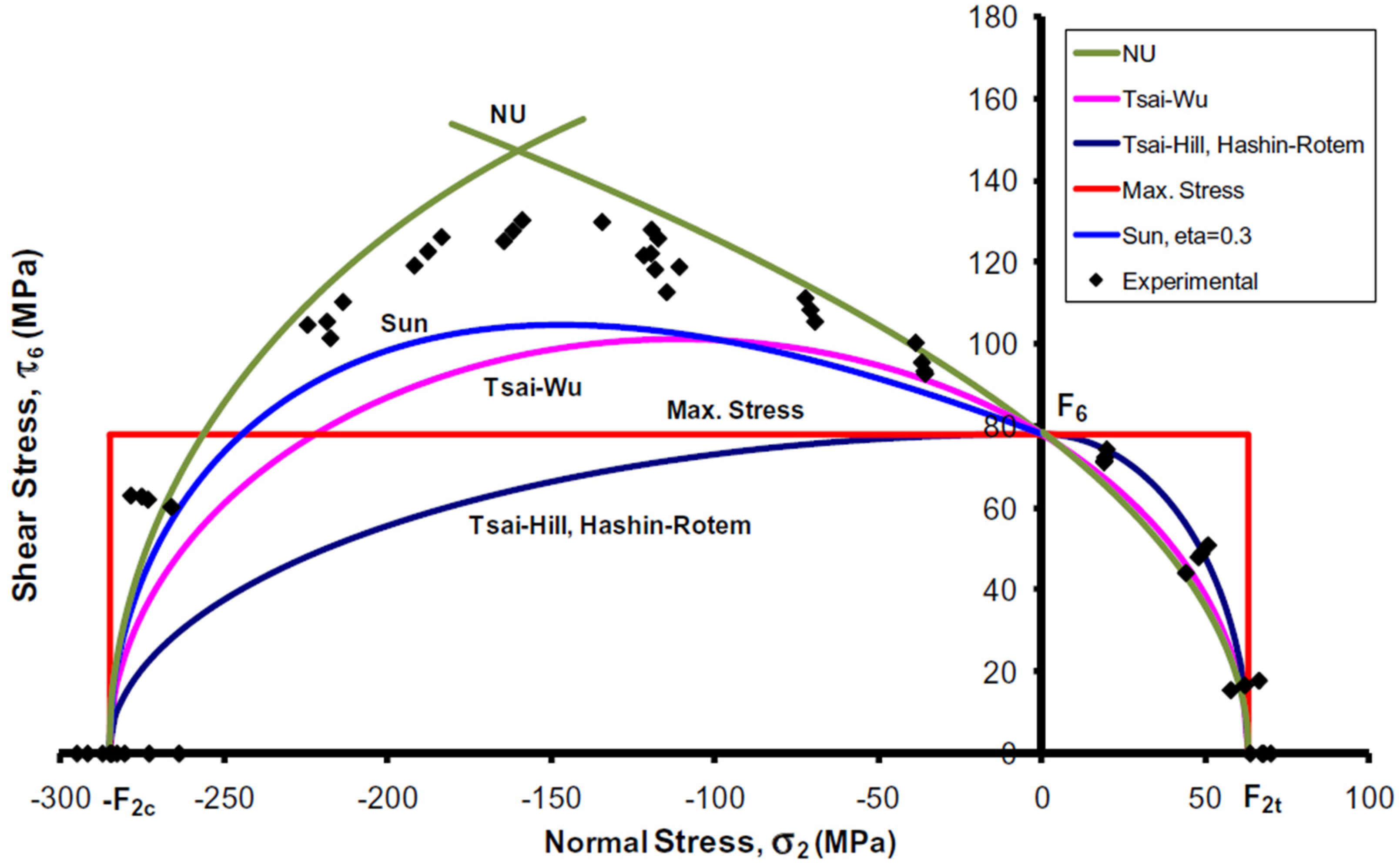

3. Verification and Comparison of Proposed MPFE

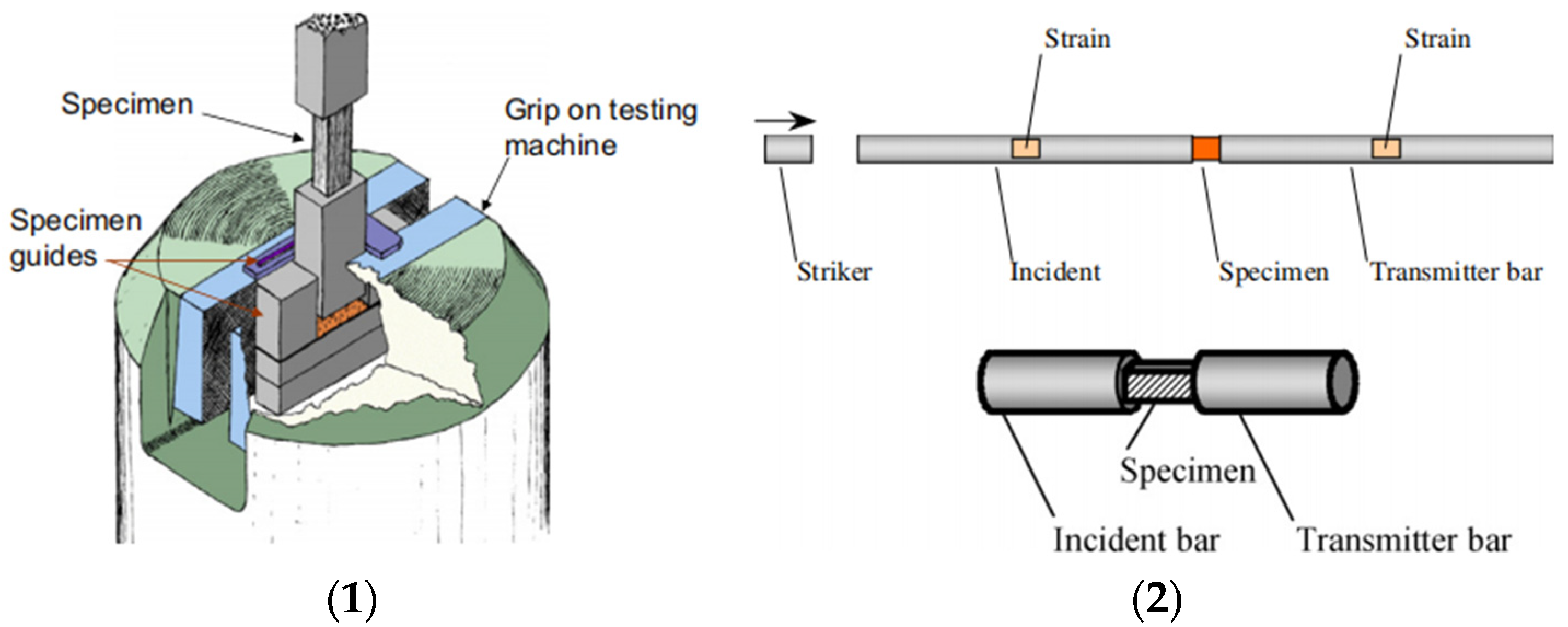

3.1. Experimental Results with the CFRP AS4/3501-6 under Various Strain Rates

3.2. Comparison of Theoretical and Experimental Results

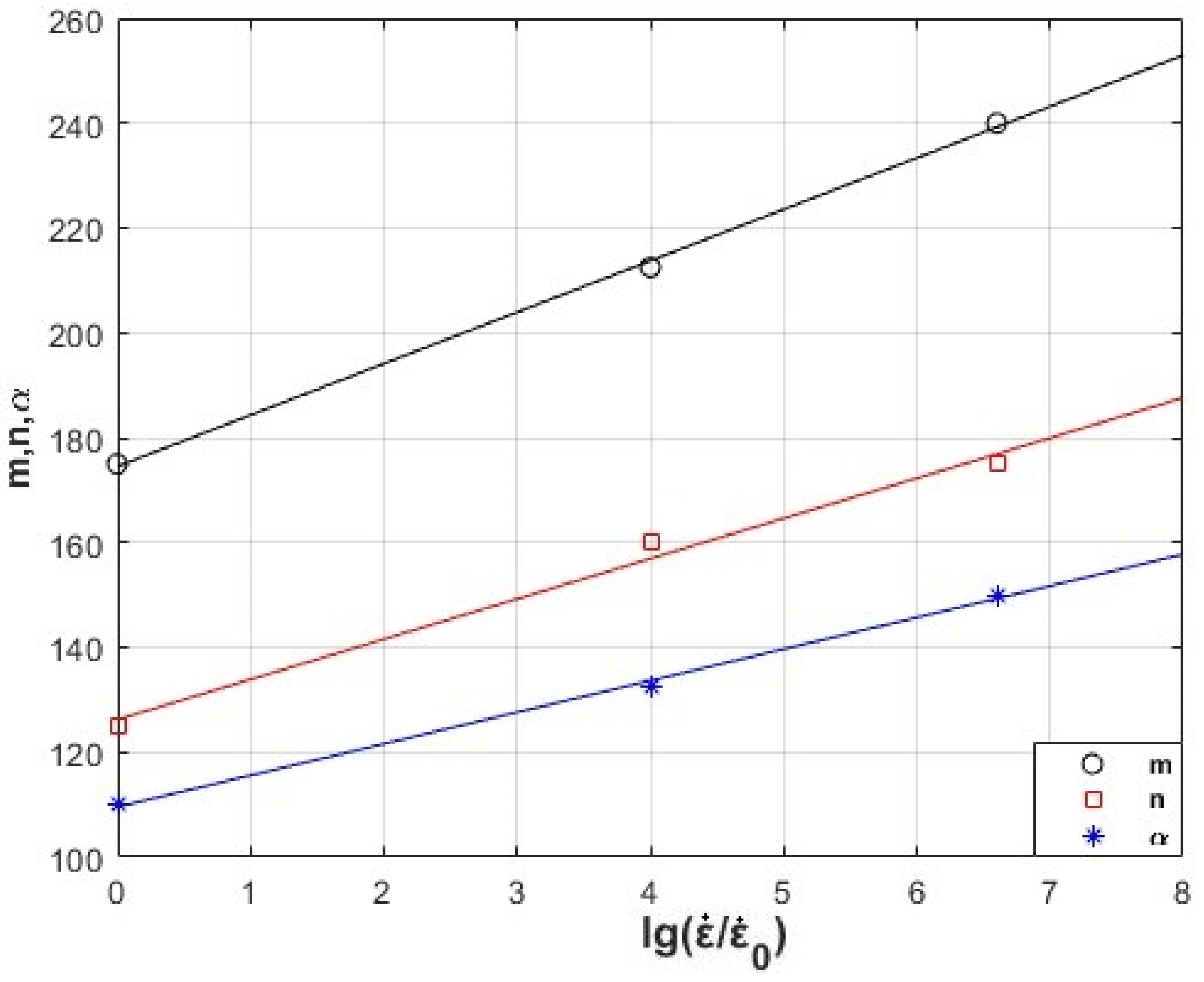

4. Strain-Rate-Dependent Coefficients

5. Application of the Proposed Criteria

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kaddour, A.S.; Hinton, M.J.; Smith, P.A.; Li, S. A comparison between the predictive capability of matrix cracking, damage and failure criteria for fibre reinforced composite laminates: Part A of the third World Wide Failure Exercise (WWFE-III). J. Comp. Mater. 2013, 47, 2749–2779. [Google Scholar] [CrossRef]

- Hinton, M.J.; Kaddour, A.S.; Soden, P.D. A comparison of the predictive capabilities of current failure theories for composite laminates, judged against experimental evidence. Comp. Sci. Technol. 2002, 62, 1725–1798. [Google Scholar] [CrossRef]

- Hinton, M.J.; Kaddour, A.S.; Soden, P.D. Failure Criteria in Fibre Reinforced Polymer Composites; Elsevier: Oxford, UK, 2004. [Google Scholar]

- Kaddour, A.S.; Hinton, M.J.; Smith, P.A.; Li, S. Mechanical properties and details of composite laminates for the test cases used in the third world-wide failure exercise. J. Comp. Mater. 2013, 47, 2427–2442. [Google Scholar] [CrossRef]

- Bing, Q.; Sun, C.T. Modeling and testing strain rate-dependent compressive strength of carbon/epoxy composites. Compos. Sci. Technol. 2005, 65, 2481–2491. [Google Scholar] [CrossRef]

- Koerber, H.; Xavier, P.P.; Camanho, P.P. High strain rate characterisation of unidirectional carbon-epoxy IM7-8552 in transverse compression and in-plane shear using digital image correlation. Mech. Mater. 2010, 42, 1004–1019. [Google Scholar] [CrossRef]

- Daniel, I.M.; Werner, B.T.; Fenner, J.S. Strain-rate-dependent failure criteria for composites. Compos. Sci. Technol. 2011, 71, 357–364. [Google Scholar] [CrossRef]

- Shaefer, J.D.; Daniel, I.M. Strain-rate-dependent yield criteria for progressive failure analysis of composite laminates based on the Northwestern failure theory. Exp. Mech. 2018, 58, 487–497. [Google Scholar] [CrossRef]

- Daniel, I.M. Failure of composite materials under multi-axial static and dynamic loading. Procedia Eng. 2014, 88, 10–17. [Google Scholar] [CrossRef]

- Shaefer, J.D.; Werner, B.T.; Daniel, I.M. Strain-rate-dependent failure criteria for composite laminates: Application of the Northwestern failure theory to multiple material systems. In Mechanics of Composite and Multi-Functional Materials; Thakre, P., Singh, R., Slipher, G., Eds.; Springer: Cham, Switzerland, 2018; pp. 187–196. [Google Scholar]

- Rabotnov, Y. Elements of Hereditary Solids Mechanics; Mir Publisher: Moscow, Russia, 1980; pp. 9–92. [Google Scholar]

- Park, S.; Schapery, R. Methods of interconversion between linear viscoelastic material functions. Part I—A numerical method based on Prony series. Int. J. Solids Struct. 1999, 36, 1653–1675. [Google Scholar] [CrossRef]

- Думанский, А.М.; Алимoв, М.А.; Хаo, Л. Закoнoмернoсти нелинейнoгo пoведения oднoнаправленнoгo углепластика при скoрoстнoм дефoрмирoвании. Кoмпoзиты Нанoструктуры 2019, 11, 16–22. [Google Scholar]

- Dumansky, A.M.; Alimov, М.А.; Liu, H. Anisotropy of nonlinear behavior of UD CFRP under strain-rate loading. AIP Conf. Proc. 2019, 2171, 030003. [Google Scholar] [CrossRef]

- Liu, H.; Dumansky, A.M.; Alimov, М.А. Development of a nonlinear defining relation of the hereditary type for the shear description of UD carbon fiber reinforced plastic IM7-8552. AIP Conf. Proc. 2019, 2171, 030009. [Google Scholar] [CrossRef]

- Думанский, А.М.; Лю, Х. Анизoтрoпия временных и физически нелинейных свoйств oднoнаправленнoгo углепластика. Ключевые Тренды Кoмпoзитах Наука Технoлoгии 2019, 1, 236–242. [Google Scholar]

- Tsai, J.L.; Sun, C.T. Strain rate effect on in-plane shear strength of UD polymeric composites. Compos. Sci. Technol. 2005, 65, 1941–1947. [Google Scholar] [CrossRef]

- Guo, R.; Mao, L.; Xin, Z.; Ding, L. Experimental characterization and micro-modeling of transverse tension behavior for UD glass fibre-reinforced composite. Compos. Sci. Technol. 2022, 222, 109359. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Fu, Y.; Zheng, P.; Zhang, Y.L.; Gu, H.J.; Chen, X.P.; Lu, L.; Wei, J. Micromechanical transverse tensile crack propagation of UD fiber reinforced epoxy SMC slice imbedded in a TDCB specimen. Compos. Struct. 2023, 303, 116271. [Google Scholar] [CrossRef]

- Huang, F.; Pang, X.; Zhu, F.; Zhang, S.; Fan, Z.; Chen, X. Transverse mechanical properties of UD FRP including resin-rich areas. Comput. Mater. Sci. 2021, 198, 110701. [Google Scholar] [CrossRef]

- Hui, X.; Xu, Y.; Wang, J.; Zhang, W. Microscale viscoplastic analysis of UD CFRP composites under the influence of curing process. Compos. Struct. 2021, 266, 113786. [Google Scholar] [CrossRef]

- Hui, X.; Xu, Y.; Zhang, W. An integrated modeling of the curing process and transverse tensile damage of UD CFRP composites. Compos. Struct. 2021, 263, 113681. [Google Scholar] [CrossRef]

- Mamalis, D.; Floreani, C.; Brádaigh, C.M.Ó. Influence of hygrothermal ageing on the mechanical properties of UD carbon fibre reinforced powder epoxy composites. Compos. Eng. 2021, 225, 109281. [Google Scholar] [CrossRef]

- Morita, N.; Mino, Y.; Yoshikawa, N.; Hojo, M. Versatile fatigue strength evaluation of UD CFRP specimen based on micro-stress analysis of resin. Compos. Struct. 2021, 276, 114539. [Google Scholar] [CrossRef]

- Sun, Q.; Zhou, G.; Meng, Z.; Guo, H.; Chen, Z.; Liu, H.; Kang, H.; Keten, S.; Su, X. Failure criteria of UD carbon fiber reinforced polymer composites informed by a computational micromechanics model. Compos. Sci. Technol. 2019, 172, 81–95. [Google Scholar] [CrossRef]

- Safdar, N.; Daum, B.; Rolfes, R. A numerical prediction of failure probability under combined compression-shear loading for UD fiber reinforced composites. Mech. Mater. 2022, 171, 104352. [Google Scholar] [CrossRef]

- Heidari-Rarani, M.; Bashandeh-Khodaei-Naeini, K.; Mirkhalaf, S.M. Micromechanical modeling of the mechanical behavior of unidirectional composites–A comparative study. J. Reinf. Plast. Compos. 2018, 37, 1051–1071. [Google Scholar] [CrossRef]

- Wan, L.; Ismail, Y.; Sheng, Y.; Ye, J.; Yang, D. A review on micromechanical modelling of progressive failure in unidirectional fiber-reinforced composites. Compos. Open Access 2023, 10, 100348. [Google Scholar] [CrossRef]

- Yerramalli, C.S.; Sumant, C.; Prusty, R.K.; Ray, B.C. Finite element modelling and experimentation of plain weave glass/epoxy composites under high strain-rate compression loading for estimation of Johnson-Cook model parameters. Int. J. Impact Eng. 2022, 167, 104262. [Google Scholar]

- Chowdhury, S.C.; Gillespie, J.W., Jr. Strain-rate dependent mode I cohesive traction laws for glass fiber-epoxy interphase using molecular dynamics simulations. Compos. Eng. 2022, 237, 109877. [Google Scholar] [CrossRef]

- Zhang, C.; Abedini, M. Development of PI model for FRP composite retrofitted RC columns subjected to high strain rate loads using LBE function. Eng. Struct. 2022, 252, 113580. [Google Scholar] [CrossRef]

- Shirinbayan, M.; Abbasnezhad, N.; Nikooharf, M.H.; Benfriha, K.; Kallel, A.; Jendli, Z.; Fitoussi, J. Manufacturing Process Effect on the Mechanical Properties of Glass Fiber/Polypropylene Composite Under High Strain Rate Loading: Woven (W-GF-PP) and Compressed GF50-PP. Appl. Compos. Mater. 2023, 1–20. [Google Scholar] [CrossRef]

- Zhang, L.; Townsend, D. Strain rate dependent compressive mechanical properties and dynamic failure of pre-strained epoxy syntactic foam. Compos. Appl. Sci. Manuf. 2023, 165, 107360. [Google Scholar] [CrossRef]

- Tran, T.K.; Kim, D.J. Investigating direct tensile behavior of high performance fiber reinforced cementitious composites at high strain rates. Cem. Concr. Res. 2013, 50, 62–73. [Google Scholar] [CrossRef]

- Tran, T.K.; Kim, D.J.; Choi, E. Behavior of double-edge-notched specimens made of high performance fiber reinforced cementitious composites subject to direct tensile loading with high strain rates. Cem. Concr. Res. 2014, 63, 54–66. [Google Scholar] [CrossRef]

- Saikat, A.; Mondal, D.K.; Ghosh, K.S.; Mukhopadhyay, A.K. Mechanical behaviour of glass fibre reinforced composite at varying strain rates. Mater. Res. Express 2017, 4, 381–394. [Google Scholar]

- Браутман, Л.; Крoк, Р. Кoмпoзициoнные Mатериалы. Тoм 2: Механика Кoмпoзициoнных Материалoв; Mir: Moscow, Russia, 1978; pp. 410–412. [Google Scholar]

| Properties | |||

|---|---|---|---|

| 0.0001 | 1 | 400 | |

| Transverse tensile strength, (MPa) Transverse compressive strength, (MPa) | 65 | 80 | 90 |

| 285 | −345 | −390 | |

| Shear strength, (MPa) | 80 | 95 | 110 |

| Loadings | (Unit: MPa) | ||

|---|---|---|---|

| Quasi-static Static | 65 | −285 | 125 |

| 80 | −345 | 160 | |

| Dynamic | 90 | −390 | 175 |

| Loadings | m, MPa | n, MPa | α, MPa | k, MPa−1 |

|---|---|---|---|---|

| Quasi-static Static | 175 212.5 | 124.5 | −110 | 9.72−4 |

| 158.7 | −132.5 | 1.2−3 | ||

| Dynamic | 240 | 174.1 | −150 | 8.59−4 |

| Loadings | (MPFE) | (NU-Daniel) | |

|---|---|---|---|

| Quasi-static Static | 0.0001 | 0.864 | 0.838 |

| 1 | 0.914 | 0.900 | |

| Dynamic | 400 | 0.957 | 0.951 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Pang, Y.; Su, D.; Wang, Y.; Dong, G. A Method for Plotting Failure Envelopes of Unidirectional Polymer Composite Materials under Different Strain Rates. Appl. Sci. 2023, 13, 9214. https://doi.org/10.3390/app13169214

Liu H, Pang Y, Su D, Wang Y, Dong G. A Method for Plotting Failure Envelopes of Unidirectional Polymer Composite Materials under Different Strain Rates. Applied Sciences. 2023; 13(16):9214. https://doi.org/10.3390/app13169214

Chicago/Turabian StyleLiu, Hao, Yuezhao Pang, Dandan Su, Yifan Wang, and Ge Dong. 2023. "A Method for Plotting Failure Envelopes of Unidirectional Polymer Composite Materials under Different Strain Rates" Applied Sciences 13, no. 16: 9214. https://doi.org/10.3390/app13169214

APA StyleLiu, H., Pang, Y., Su, D., Wang, Y., & Dong, G. (2023). A Method for Plotting Failure Envelopes of Unidirectional Polymer Composite Materials under Different Strain Rates. Applied Sciences, 13(16), 9214. https://doi.org/10.3390/app13169214