The Influence of Mechanical, Physical and Chemical Influences on Protective Clothing

Abstract

1. Introduction

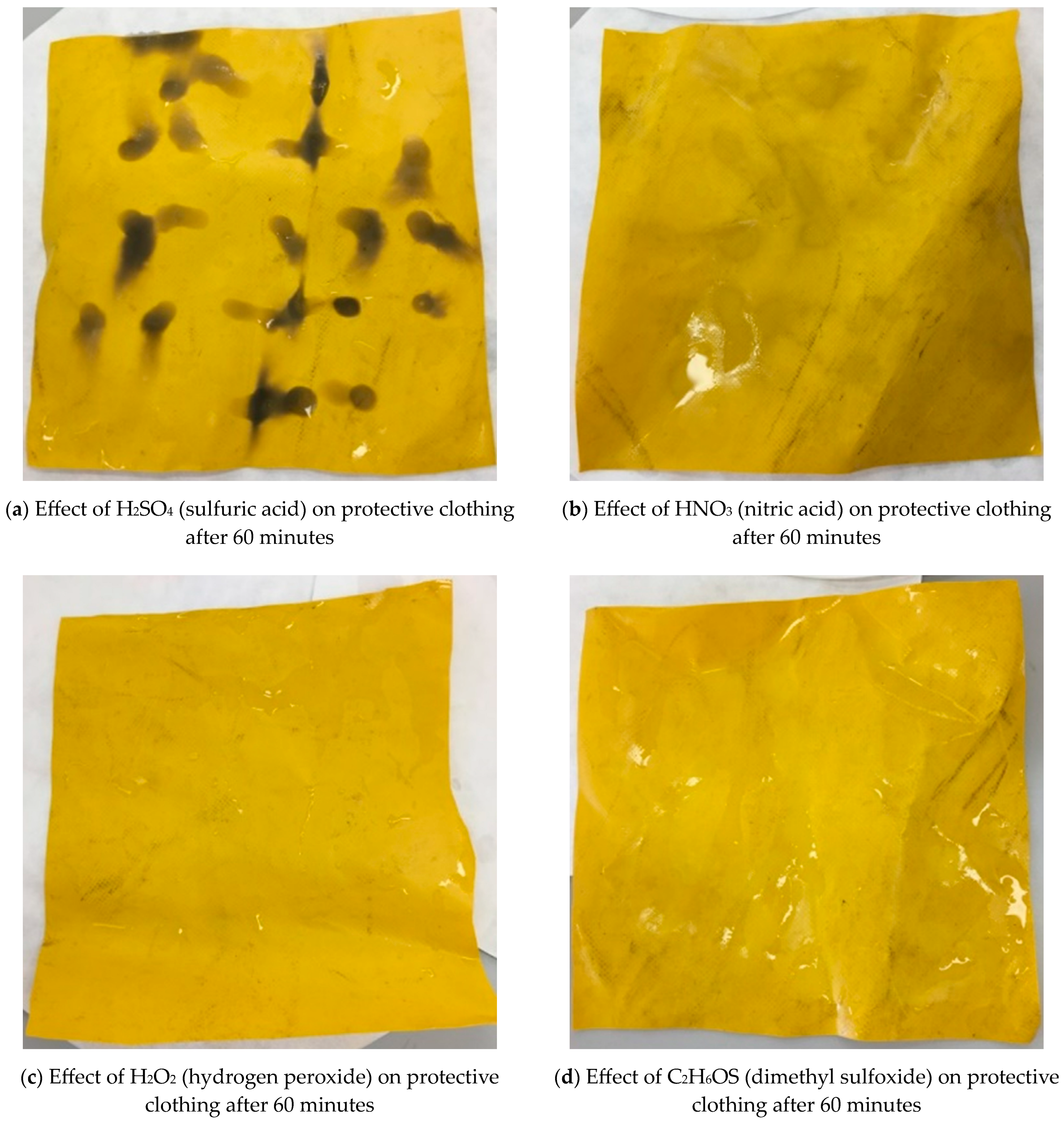

2. Materials and Methods

2.1. Preparation of Chemical-Resistant Garment Samples for Chemical Application

2.2. Preparation of Samples for Exposure of Protective Clothing to UV Radiation and Prolonged Exposure to Elevated Temperature

2.3. Testing Methodology

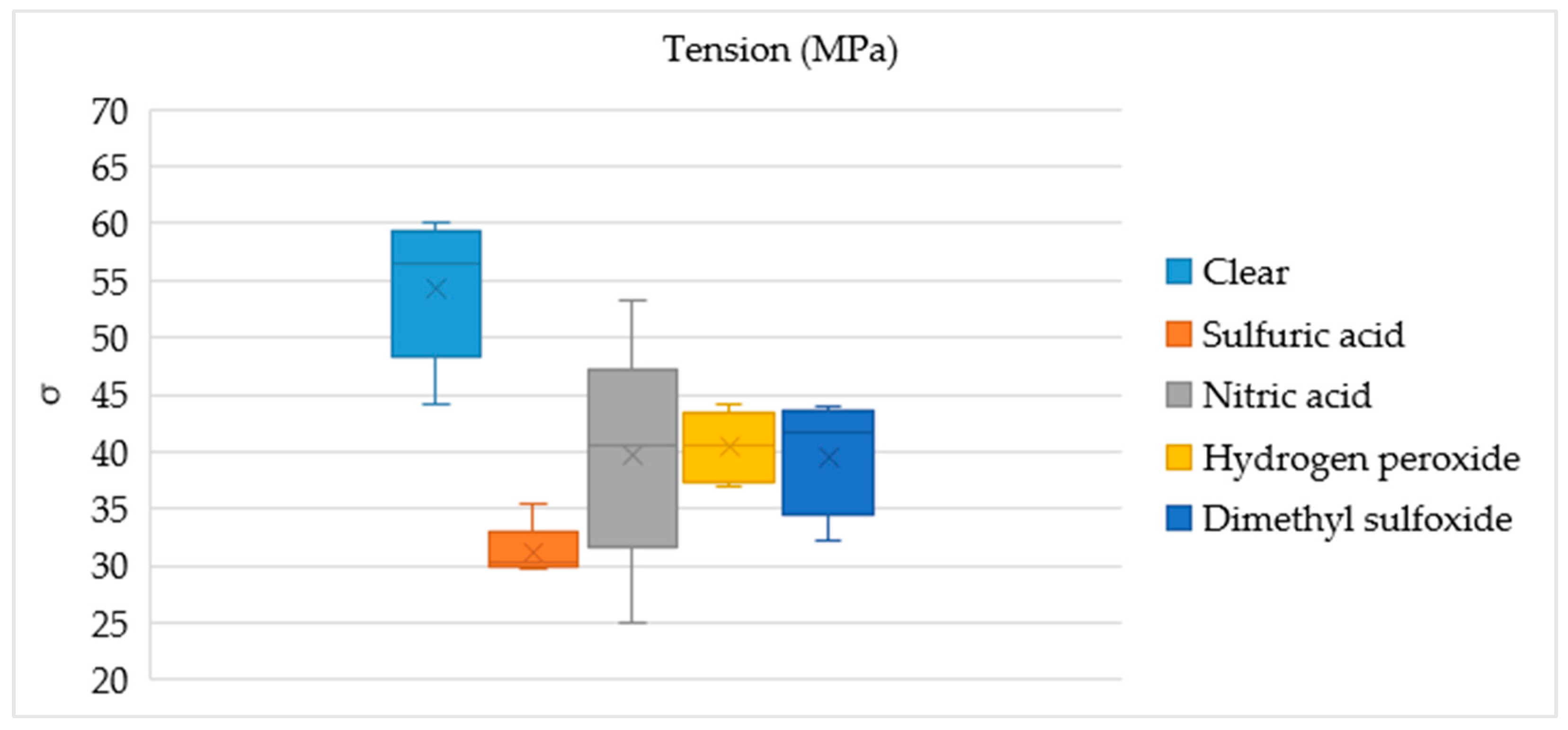

- σ—Mechanical stress (MPa);

- F—Power (N);

- S—Area (m2).

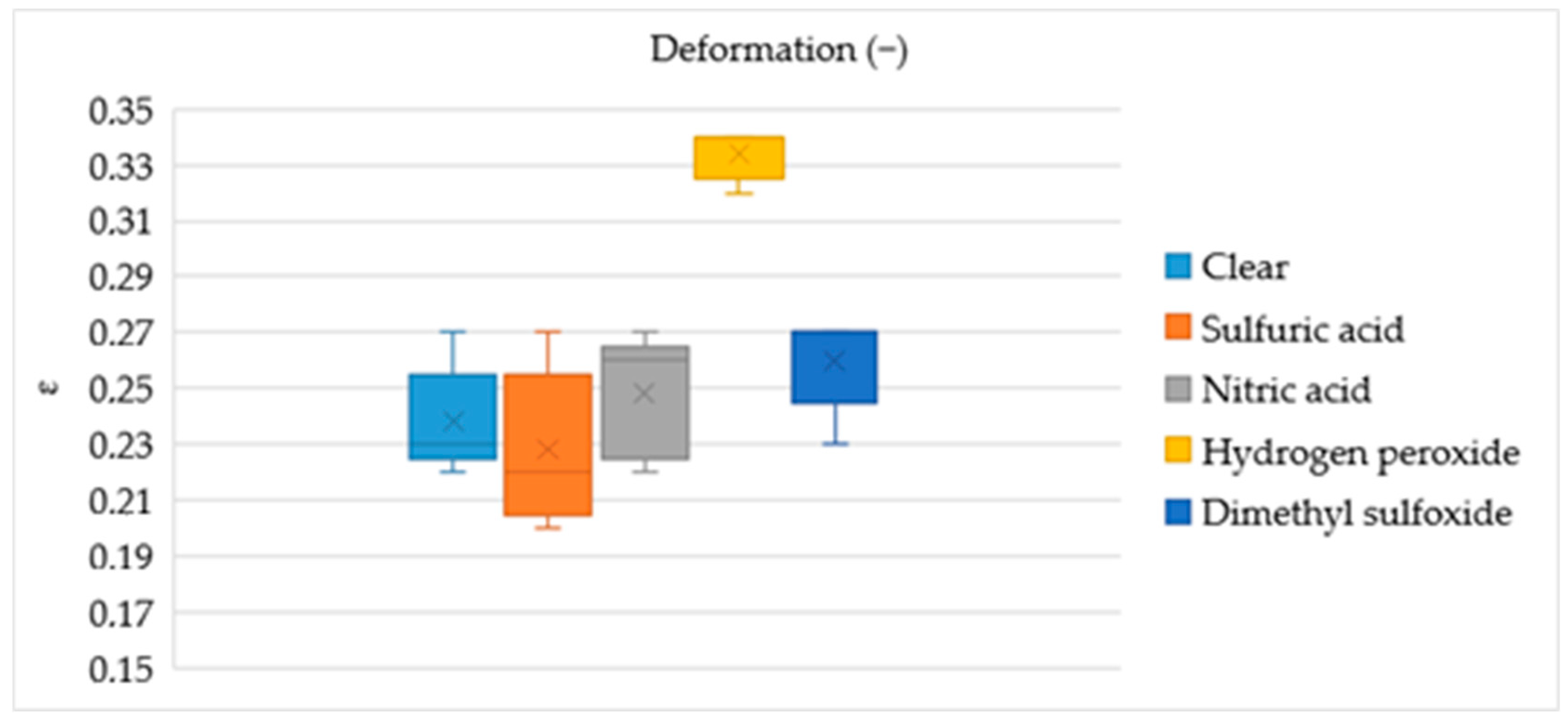

- ε—Relative deformation (−);

- ∆l—Length increment after loading (m);

- l—Length increment before loading (m).

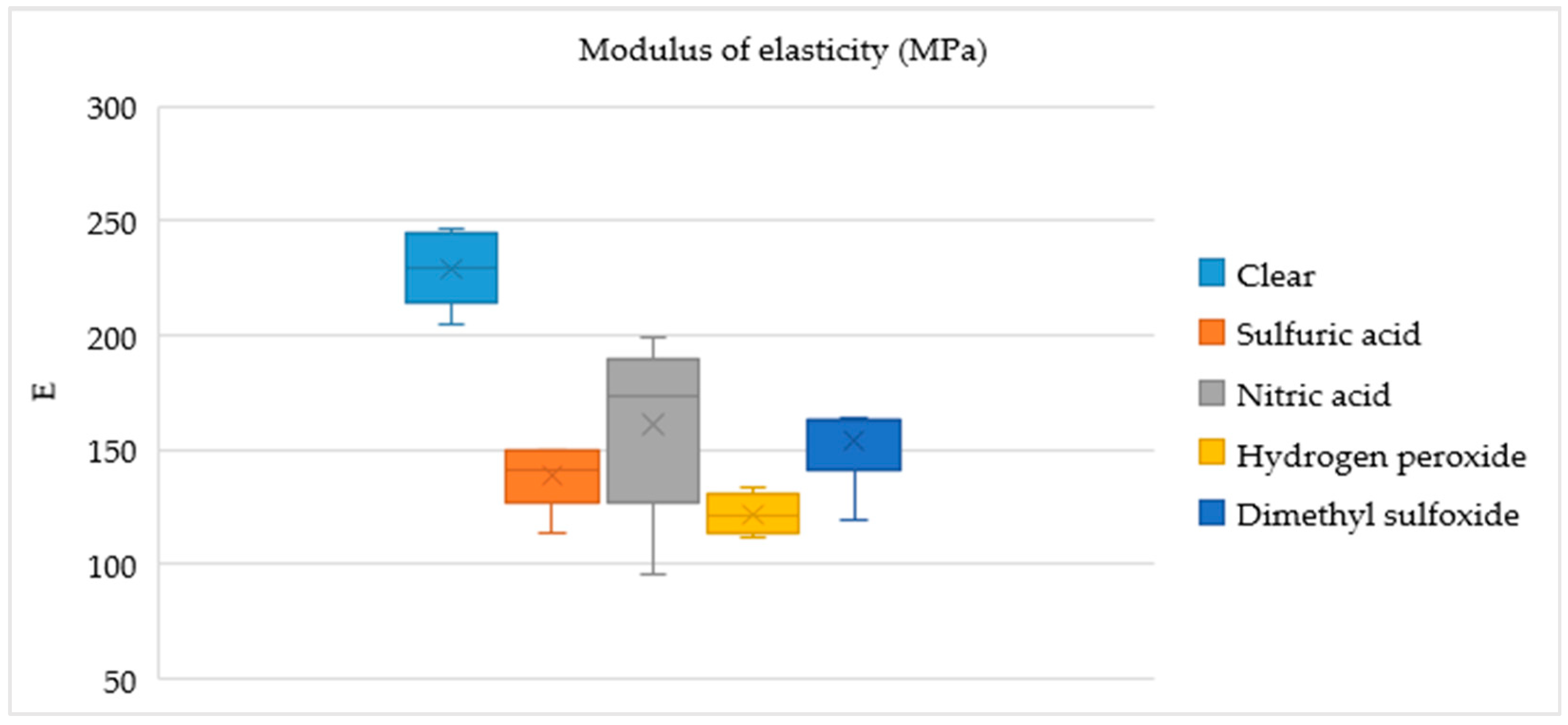

- E—Tensile modulus of elasticity, also Young’s modulus (MPa);

- σ—Mechanical stress (MPa);

- ε—Stress-induced deformation (−).

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pigatto, P.D.; Ronchi, A.; Guzzi, G. Chemical Exposure, Risk of Multiple Chemical Sensitivity, and Occupational Safety. Saf. Health Work 2020, 11, 383–384. [Google Scholar] [CrossRef] [PubMed]

- Crespo, J.P.; Canon, R.L.; Puchol, A.S. The Author Response: Risk of Multiple Chemical Sensitivity in Laboratory Workers. Saf. Health Work. 2018, 9, 473–478. [Google Scholar] [CrossRef]

- Instruction No. 70/2003 Is an Instruction of the President of the Fire and Rescue Corps of Slovak Republic; Fire and Rescue Corps of Slovak Republic: Bratislava, Slovak, 2003.

- Strahan, K.; Watson, S.J. The protective action decision model: When householders choose their protective response to wildfire. J. Risk Res. 2019, 22, 1602–1623. [Google Scholar] [CrossRef]

- Sundarrajan, S.; Chandrasekaran, A.R.; Ramakrishna, S. An update on nanomaterials based textiles for protection and decontamination. J. Am. Ceram. Soc. 2010, 93, 3955–3975. [Google Scholar] [CrossRef]

- Rissanen, S.; Rintamaki, H. Thermal responses and physiological strain in men wearing impermeable and semipermeable protective clothing in the cold. Ergonomics 1997, 40, 141–150. [Google Scholar] [CrossRef]

- Lee, S.; Kay Obendorf, S. Developing protective textile materials as barriers to liquid penetration using melt-electrospinning. J. Appl. Polym. Sci. 2006, 102, 3430–3437. [Google Scholar] [CrossRef]

- Song, G.; Wang, F. Firefighters’ Clothing and Equipment: Performance, Protection, and Comfort, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar] [CrossRef]

- EN 469:2020; Protective Clothing for Firefighters—Performance Requirements for Protective Clothing for Firefighting Activities. European Parliament: Strasbourg, France, 2020.

- EN 15384:2020; Protective Clothing for Firefighters—Laboratory Test Methods and Performance Requirements for Wildland Firefighting Clothing. European Parliament: Strasbourg, France, 2020.

- EN 16689:2017; Protective Clothing for Firefighters—Performance Requirements for Protective Clothing for Technical Rescue. European Parliament: Strasbourg, France, 2017.

- EN 1486:2007; Protective Clothing for Fire-Fighters—Test Methods and Requirements for Reflective Clothing for Specialized Fire-Fighting. European Parliament: Strasbourg, France, 2007.

- PN-EN 1486:2009; Protective Clothing for Firefighters—Laboratory Test Methods and Requirements for Reflecting Thermal Radiation Clothing for Specialized Firefighting. European Parliament: Strasbourg, France, 2009.

- EN 13911:2017; Protective Clothing for Firefighters. Requirements and Test Methods for Fire Hoods for Firefighters. European Parliament: Strasbourg, France, 2017.

- EN 443:2008; Helmets for Firefighting in Buildings and Other Structures. European Parliament: Strasbourg, France, 2008.

- EN 16471:2014; Firefighters Helmets—Helmets for Wildland Fire Fighting. European Parliament: Strasbourg, France, 2014.

- EN 16473:2014; Firefighters Helmets. Helmets for Technical Rescue. European Parliament: Strasbourg, France, 2014.

- EN 659:2003+A1:2008; Protective Gloves for Firefighters. European Parliament: Strasbourg, France, 2008.

- EN 15090:2012; Footwear for Firefighters. European Parliament: Strasbourg, France, 2012.

- EN 14458:2018; Personal Eye-Equipment—High Performance Visors Intended only for Use with Protective Helmets. European Parliament: Strasbourg, France, 2018.

- Hoque, M.S.; Dolez, P.I. Aging of high-performance fibers used in firefighters’ protective clothing: State of the knowledge and path forward. J. Appl. Polym. Sci. 2023, 140, e54255. [Google Scholar] [CrossRef]

- Mazari, A.; Mazari, F.B.; Naeem, J.; Havelka, A.; Marahatta, P. Impact of ultraviolet radiation on thermal protective performance and comfort properties of firefighter protective clothing. Ind. Textila 2022, 73, 54–56. [Google Scholar] [CrossRef]

- Schreuder-Gibson, H.L.; Truong, Q.; Walker, J.E.; Owens, J.R.; Wander, J.D.; Jones, W.E., Jr. Chemical and biological protection and detection in fabrics for protective clothing. MRS Bull. 2003, 28, 574–578. [Google Scholar] [CrossRef]

- Hao, X.; Zhang, J.; Guo, Y. Study of new protective clothing against SARS using semi-permeable PTFE/PU membrane. Eur. Polym. J. 2004, 40, 673–678. [Google Scholar] [CrossRef]

- Mandal, S.; Song, G.; Grover, I.B. Modeling of hot water and steam protective performance of fabrics used in Firefighters’ clothing. Fire Mater. 2021, 46, 463–475. [Google Scholar] [CrossRef]

- Rivin, D.; Meermeier, G.; Schneider, N.S.; Vishnyakov, A.; Neimark, A.V. Simultaneous transport of water and organic molecules through polyelectrolyte membranes. J. Phys. Chem. B 2004, 108, 8900–8909. [Google Scholar] [CrossRef]

- Rother, M.; Barmettler, J.; Reichmuth, A.; Araujo, J.V.; Rytka, C.; Glaied, O.; Pieles, U.; Bruns, N. Self-sealing and puncture resistant breathable membranes for water-evaporation applications. Adv. Mater. 2015, 27, 6620–6624. [Google Scholar] [CrossRef] [PubMed]

- Operating Manual Vautex Elite S, Vautex Elite S Expert Chemical Protective Suit Type 1a EN 943—1:2002. [Internet]. MSA AUER GmbH, Berlin, 2021. Available online: http://s7d9.scene7.com/is/content/minesafetyappliances/Vautex%20Elite_S_operating%20manual%20-%20GB (accessed on 18 December 2021).

- Vishnyakov, A.; Neimark, A.V. Molecular dynamics simulation of nanoscale distribution and mobility of water and dimethylmethylphosphonate in sulfonated polystyrene. J. Phys. Chem. B 2008, 112, 14905–14910. [Google Scholar] [CrossRef] [PubMed]

- Koros, W.; Fleming, G.; Jordan, S.; Kim, T.H.; Hoehn, H.H. Polymeric membrane materials for solution diffusion based permeation separations. Prog. Polym. Sci. 1988, 13, 339–401. [Google Scholar] [CrossRef]

- Fornasiero, F. Water vapor transport in carbon nanotube membranes and application in breathable and protective fabrics. Curr. Opin. Chem. Eng. 2017, 16, 1–8. [Google Scholar] [CrossRef]

- Gimenes, M.L.; Liu, L.; Feng, X. Sericin/poly (vinyl alcohol) blend membranes for pervaporation separation of ethanol/water mixtures. J. Membr. Sci. 2007, 295, 71–79. [Google Scholar] [CrossRef]

- Yip, N.Y.; Tiraferri, A.; Phillip, W.A.; Schiffman, J.D.; Elimelech, M. High performance thin-film composite forward osmosis membrane. Environ. Sci. Technol. 2010, 44, 3812–3818. [Google Scholar] [CrossRef]

- Khalil, E. A Technical Overview on Protective Clothing against Chemical Hazards. figshar e. J. Contrib. 2015. [Google Scholar] [CrossRef]

- Czabán, C.; Jackovics, P.; Kis, G. Application of the safety through organizational learning methodology for the post analysis of an adverse event during a search and rescue operation. Int. J. Occup. Saf. Ergon. 2021, 27, 308–315. [Google Scholar] [CrossRef]

- Jackovics, P. Analysis with applied statistics of the safety use of rope rescue equipment. Int. J. Occup. Saf. Ergon. 2020, 26, 762–771. [Google Scholar] [CrossRef] [PubMed]

- Gašpercová, S.; Marková, I.; Vandlíčková, M.; Osvaldová, L.M.; Svetlík, J. Effect of Protective Coatings on Wooden Elements Exposed to a Small Ignition Initiator. Appl. Sci. 2023, 13, 3371. [Google Scholar] [CrossRef]

- Makovicka Osvaldova, L.; Markova, I.; Jochim, S.; Bares, J. Experimental Study of Straw-Based Eco-Panel Using a Small Ignition Initiator. Polymers 2021, 13, 1344. [Google Scholar] [CrossRef]

- Soltes, V.; Kubas, J.; Velas, A.; Michalík, D. Occupational Safety of Municipal Police Officers: Assessing the Vulnerability and Riskiness of Police Officers’ Work. Int. J. Environ. Res. Public Health 2021, 18, 5605. [Google Scholar] [CrossRef] [PubMed]

- Mitrenga, P.; Ďaďová, A. Identification of Risk Business Sectors and Causes of Risks in Micro and Small Enterprises Based on the State of Occupational Safety and Health in Slovak Republic. Trilobit, 2022. Available online: http://trilobit.fai.utb.cz/Data/Articles/PDF/3c96f265-2d9e-40cb-bcfb-8ab56f1ad297.pdf (accessed on 20 July 2023).

- Kubás, J.; Bugánová, K.; Polorecká, M.; Petrlová, K.; Stolínová, A. Citizens’ Preparedness to Deal with Emergencies as an Important Component of Civil Protection. Int. J. Environ. Res. Public Health 2022, 19, 830. [Google Scholar] [CrossRef]

- Makka, K.; Kampova, K.; Lovecek, T.; Bernatik, A.; Rehak, D.; Ondrejka, R. Prevention and mitigation of injuries and damages arising from the activity of subliminal enterprises: A case study in Slovakia. J. Loss Prev. Process Ind. 2021, 70, 104410. [Google Scholar] [CrossRef]

- Strelcova, S.; Janasova, D.; Simak, L. Risk management at Slovak enterprises: An empirical Study. Econ. Ann.-XXI 2018, 174, 58–62. [Google Scholar] [CrossRef]

- Buganová, K.; Hudáková, M.; Šimíčková, J.; Mošková, E. Disparities in the Implementation of Risk Management in the SMEs. Systems 2023, 11, 71. [Google Scholar] [CrossRef]

- Buganova, K.; Luskova, M.; Hudakova, M. Early Warning System in Crisis Management. In Proceedings of the 2nd International Conference on Physical Education and Society Management (ICPESM), Singapore, 21–22 April 2013; Volume 9, pp. 218–223. [Google Scholar]

- Titko, M.; Ristvej, J.; Zamiar, Z. Population Preparedness for Disasters and Extreme Weather Events as a Predictor of Building a Resilient Society: The Slovak Republic. Int. J. Environ. Res. Public Health 2021, 18, 2311. [Google Scholar] [CrossRef]

- Ristvej, J.; Sokolová, L.; Starackova, J.; Ondrejka, R.; Lacinak, M. Experiences with implementation of information systems within preparation to deal with crisis situations in terms of crisis management and building resilience in the Slovak Republic. In Proceedings of the 2017 International Carnahan Conference on Security Technology (ICCST), Madrid, Spain, 23–26 October 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Krzemińska, S.; Szewczyńska, M. PAH contamination of firefighter protective clothing and cleaning effectiveness. Fire Saf. J. 2022, 131, 103610. [Google Scholar] [CrossRef]

- Chang, T.Y.; Lu, H.P.; Luor, T.Y.; Chang, P.W. Weighting of Firefighting Turnout Gear Risk Factors According to Expert Opinion. Sustainability 2022, 14, 7040. [Google Scholar] [CrossRef]

- Chen, Q.; Zheng, R.; Fu, B.; Yang, X.; Lin, J.; Fan, J. Comparison of standards for chemical protective clothing on performance requirements and measurements. J. Ind. Text. 2022, 51, 1815S–1858S. [Google Scholar] [CrossRef]

- Li, C.; Shen, Y.; Liu, L.; Tong, M.; Li, F. Test Evaluation of Thermal Protection Performance of Flame-Retardant Protective Clothing. In Man-Machine-Environment System Engineering: Proceedings of the 21st International Conference on MMESE, Beijing, China, 23–25 October 2021; Long, S., Dhillon, B.S., Eds.; Lecture Notes in Electrical Engineering; Springer: Singapore, 2022; Volume 800. [Google Scholar] [CrossRef]

- Makovicka Osvaldova, L.; Petho, M. Occupational Safety and Health During Rescue Activities. In Proceedings of the 6th International Conference on Applied Human Factors and Ergonomics (AHFE 2015) and the Affiliated Conferences, AHFE 2015, Las Vegas, NV, USA, 26–30 July 2015; Volume 3, pp. 4287–4293. [Google Scholar]

- He, J.; Sun, L.; Lu, Y. Effects of Radiant Heat and Frictional Abrasion on Thermal Protective Performance of Clothing Against High Pressurized Steam. Cloth. Text. Res. J. 2023, 41, 125–138. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osvaldová, L.M.; Kubás, J.; Hollá, K.; Klouda, K.; Bátrlová, K. The Influence of Mechanical, Physical and Chemical Influences on Protective Clothing. Appl. Sci. 2023, 13, 9123. https://doi.org/10.3390/app13169123

Osvaldová LM, Kubás J, Hollá K, Klouda K, Bátrlová K. The Influence of Mechanical, Physical and Chemical Influences on Protective Clothing. Applied Sciences. 2023; 13(16):9123. https://doi.org/10.3390/app13169123

Chicago/Turabian StyleOsvaldová, Linda Makovická, Jozef Kubás, Katarína Hollá, Karel Klouda, and Kateřina Bátrlová. 2023. "The Influence of Mechanical, Physical and Chemical Influences on Protective Clothing" Applied Sciences 13, no. 16: 9123. https://doi.org/10.3390/app13169123

APA StyleOsvaldová, L. M., Kubás, J., Hollá, K., Klouda, K., & Bátrlová, K. (2023). The Influence of Mechanical, Physical and Chemical Influences on Protective Clothing. Applied Sciences, 13(16), 9123. https://doi.org/10.3390/app13169123