Author Contributions

Conceptualization, Y.L. and L.Q.; methodology, Y.L.; software, L.Q.; validation, Y.L., L.Q. and B.Q.; formal analysis, Y.L.; investigation, L.Q.; resources, Y.L.; data curation, L.Q.; writing—original draft preparation, L.Q.; writing—review and editing, Y.L., L.Q. and B.Q.; visualization, Y.L.; supervision, B.Q.; project administration, Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Fundamental Research Funds for the Central Universities, grant number ZY20220201, the Liaoning Provincial Education Department Scientific Research-Youth “Nurturing” Project, grant number 2020JYT06, the Funded by Science and Technology Project of Hebei Education Department, grant number QN2023146, the Langfang Municipal Science and Technology Plan Project, grant number 2022013091, and the Natural Science Foundation of Liaoning Province, grant number 2021-BS-278, Educational Research and Teaching Reform Project of Institute of Disaster Prevention, grant number JY2023A08.

Figure 1.

Dispersion curve of the layered pipe structure.

Figure 1.

Dispersion curve of the layered pipe structure.

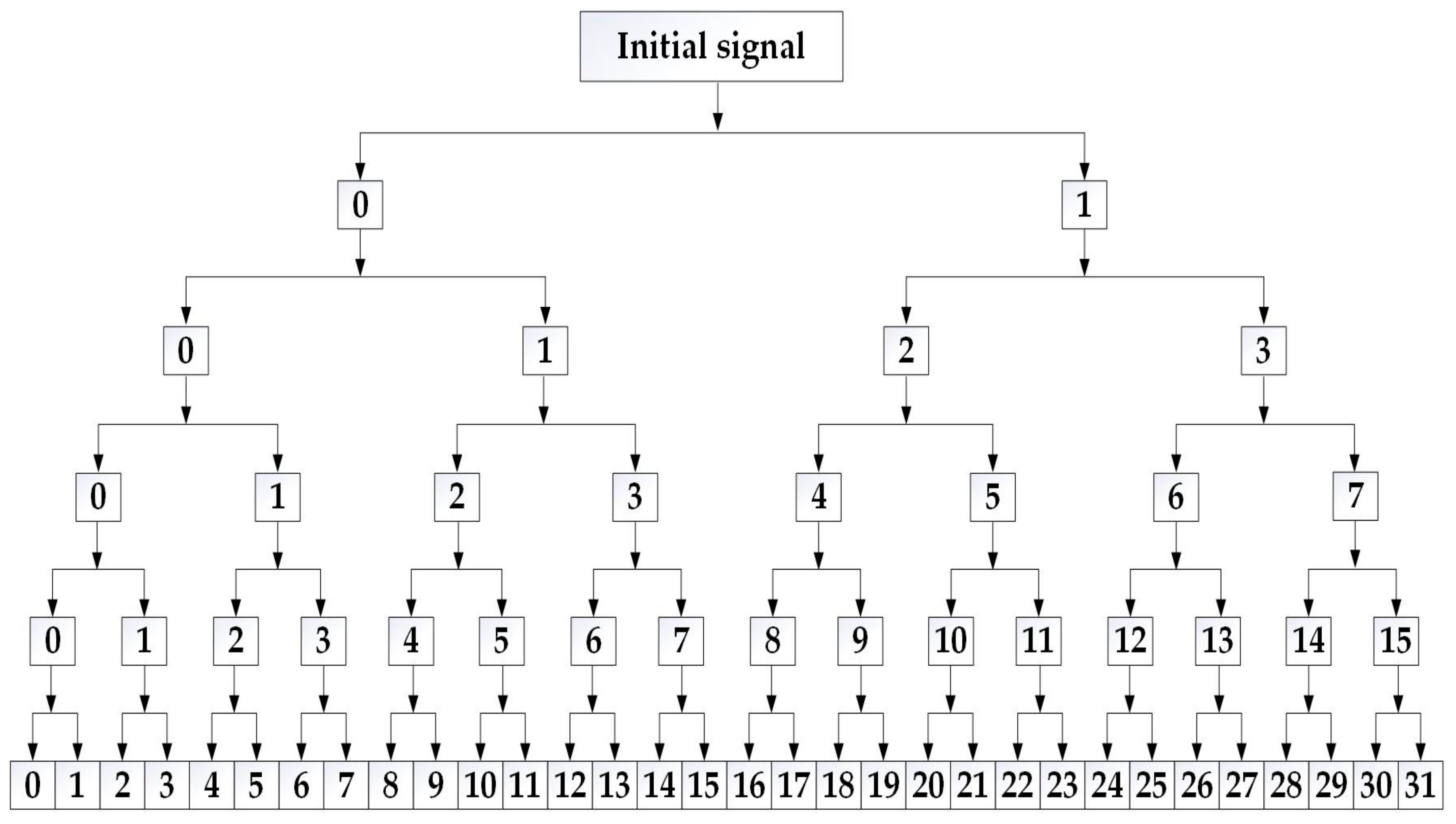

Figure 2.

Wavelet packet decomposition tree at level 5.

Figure 2.

Wavelet packet decomposition tree at level 5.

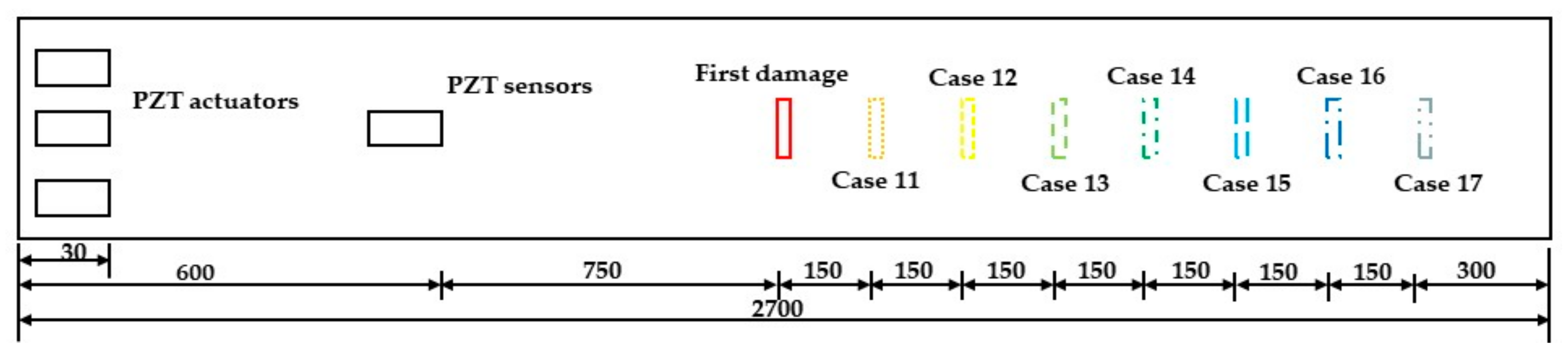

Figure 3.

Schematic diagram of circumferential defects.

Figure 3.

Schematic diagram of circumferential defects.

Figure 4.

Schematic of double defects with the same circumferential position in the pipeline structure.

Figure 4.

Schematic of double defects with the same circumferential position in the pipeline structure.

Figure 5.

Defect layout diagram for dual defects in pipeline structures at different circumferential positions.

Figure 5.

Defect layout diagram for dual defects in pipeline structures at different circumferential positions.

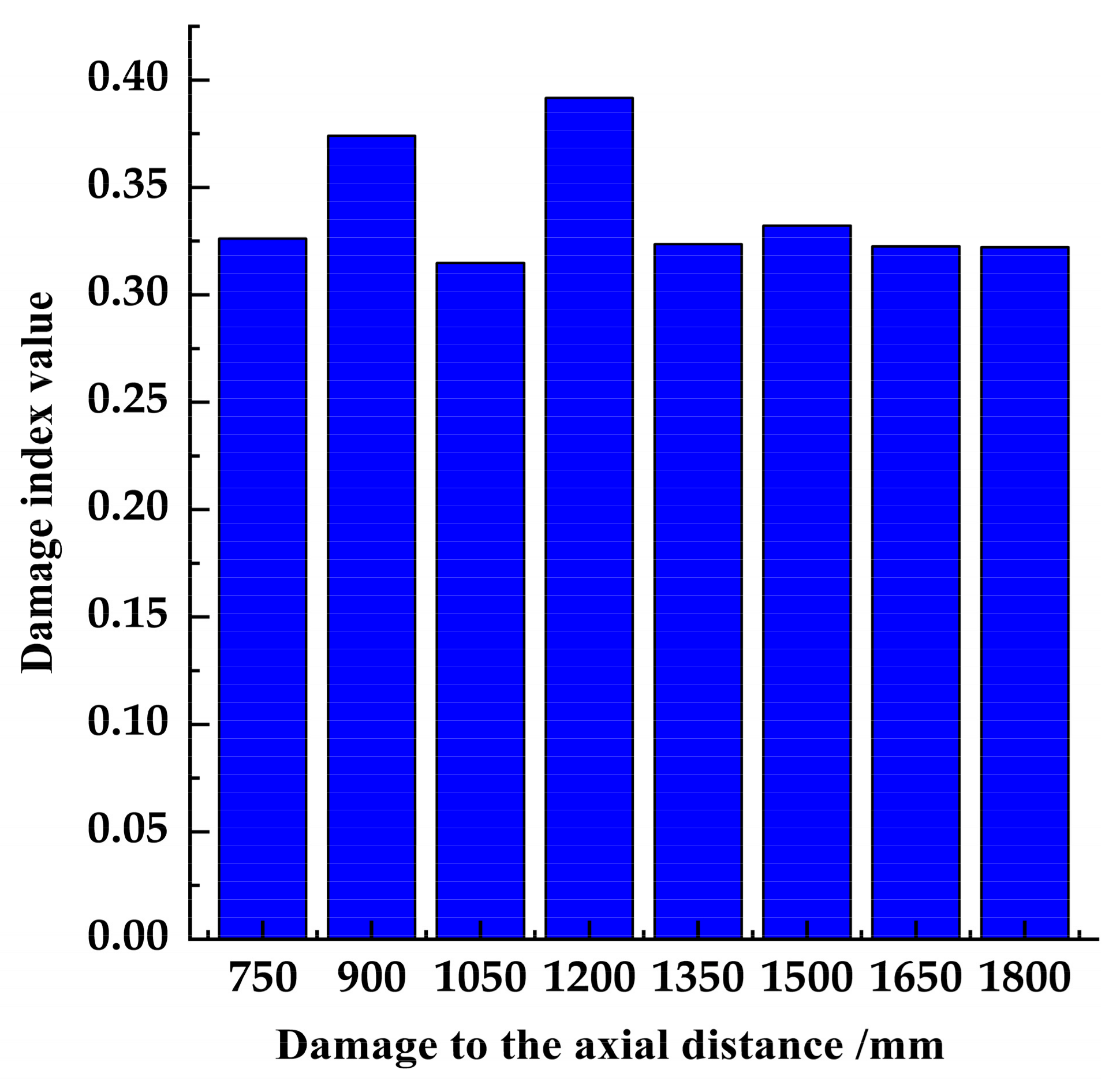

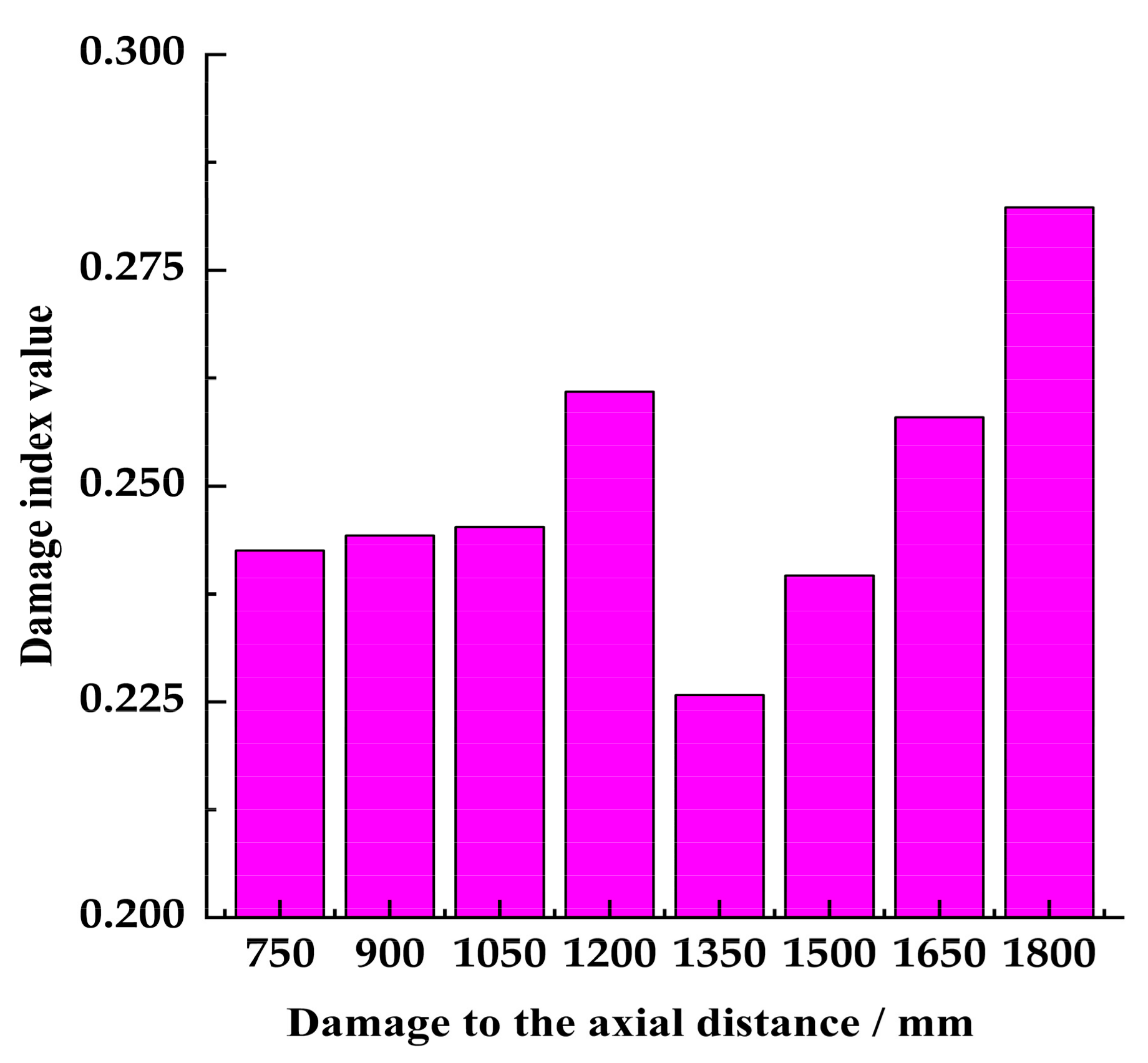

Figure 6.

Two-dimensional damage index matrix for pipeline structures with dual defects at the same circumferential position 4. 4 The axial distance of damage in the figure is the distance between the second defect and the piezoelectric element sensor, with the first defect always located at a position 750 mm away from the piezoelectric element sensor. The axial distance between the second defect and the piezoelectric element sensor was set as 750 mm, such that the position of the first defect overlapped with that of the second defect, meaning that there was only one defect in the pipeline structure.

Figure 6.

Two-dimensional damage index matrix for pipeline structures with dual defects at the same circumferential position 4. 4 The axial distance of damage in the figure is the distance between the second defect and the piezoelectric element sensor, with the first defect always located at a position 750 mm away from the piezoelectric element sensor. The axial distance between the second defect and the piezoelectric element sensor was set as 750 mm, such that the position of the first defect overlapped with that of the second defect, meaning that there was only one defect in the pipeline structure.

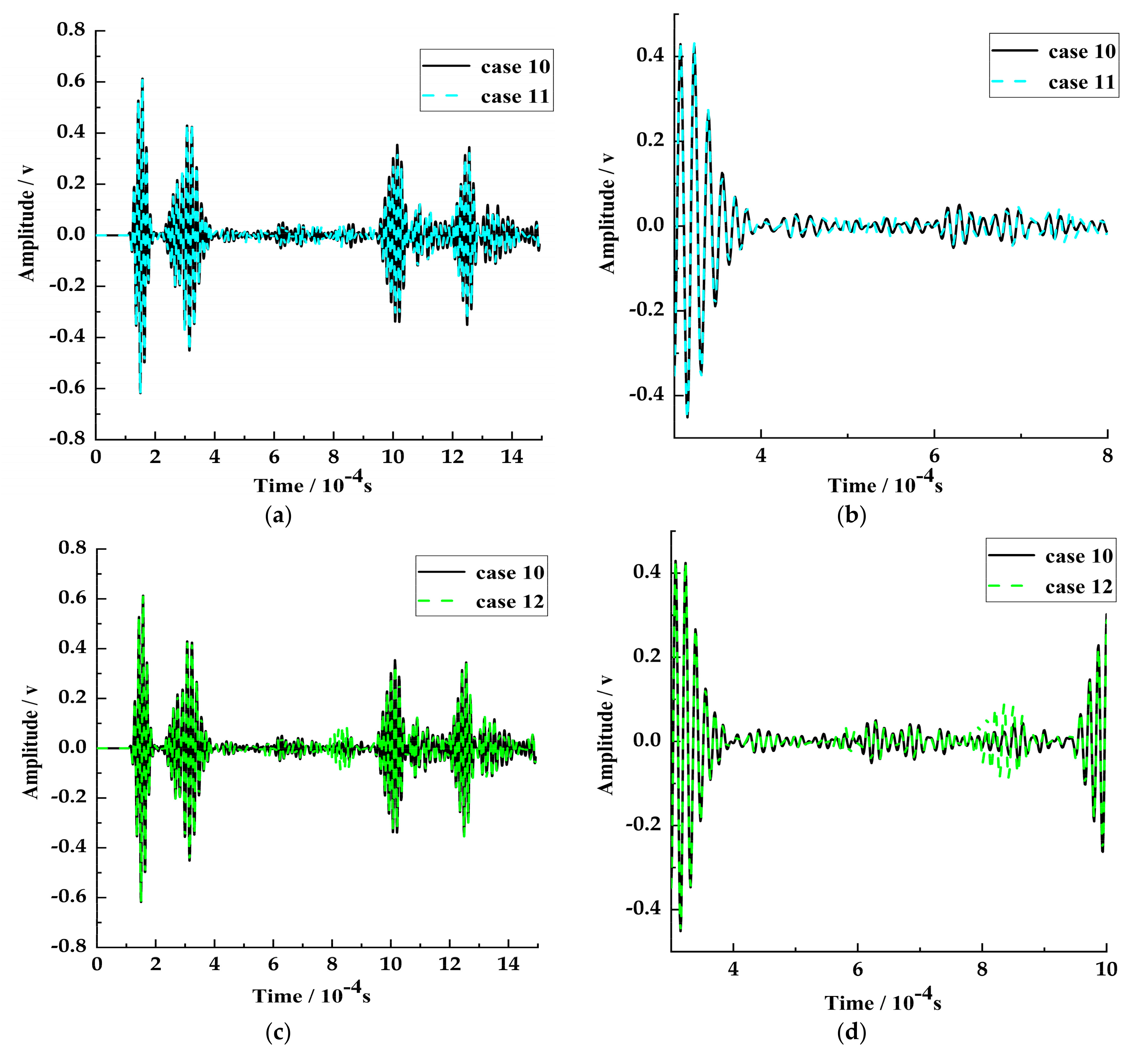

Figure 7.

Time-domain comparison plots for the operating conditions: (a) comparison of the piezoelectric time-domain signals between case 10 and case 11, (b) the partial detailed diagrams of case 10 and case 11, (c) comparison of the piezoelectric time-domain signals between case 10 and case 12, and (d) the partial detailed diagrams of case 10 and case 12.

Figure 7.

Time-domain comparison plots for the operating conditions: (a) comparison of the piezoelectric time-domain signals between case 10 and case 11, (b) the partial detailed diagrams of case 10 and case 11, (c) comparison of the piezoelectric time-domain signals between case 10 and case 12, and (d) the partial detailed diagrams of case 10 and case 12.

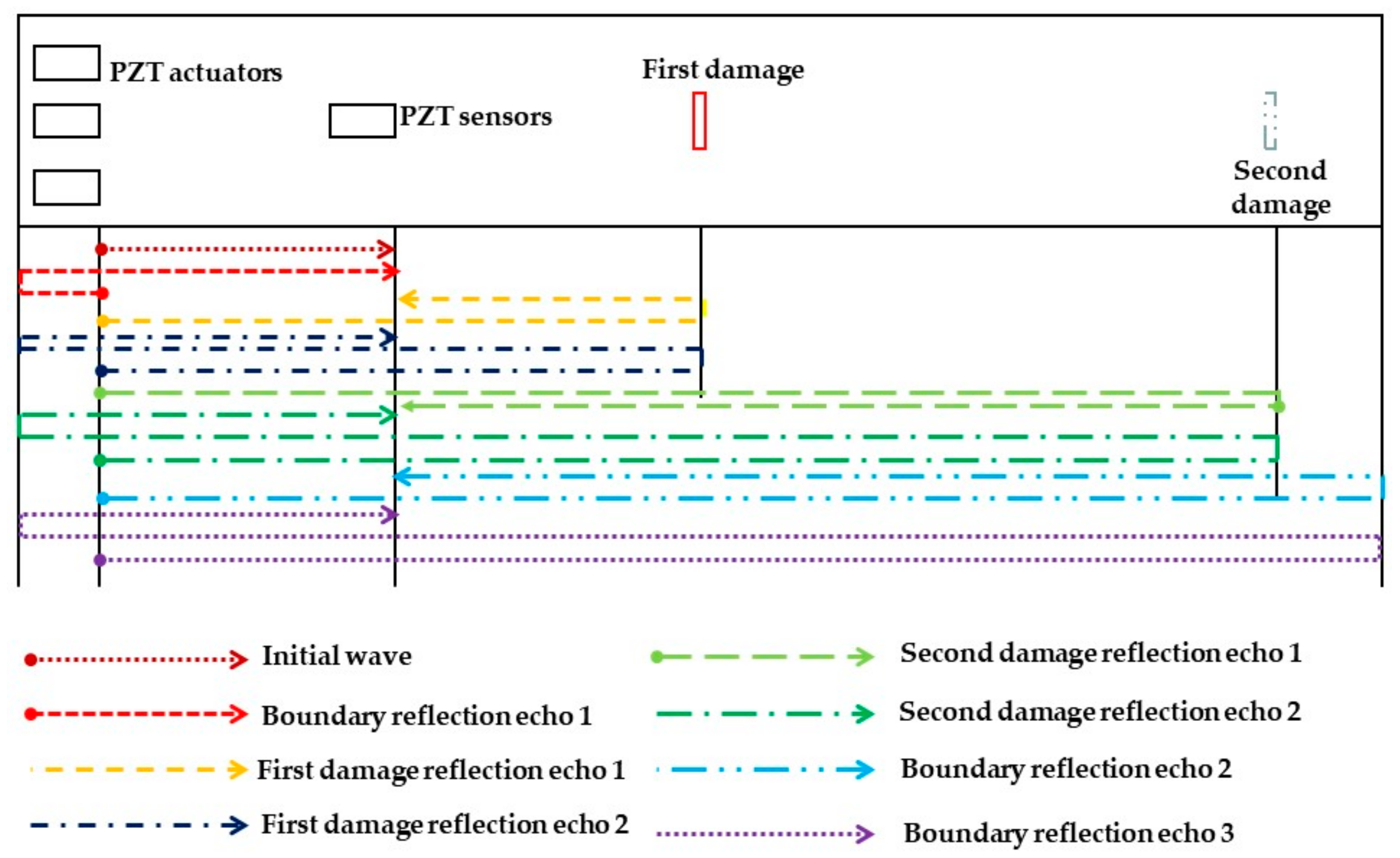

Figure 8.

The propagation mechanism of guided waves in pipeline structures with dual defects.

Figure 8.

The propagation mechanism of guided waves in pipeline structures with dual defects.

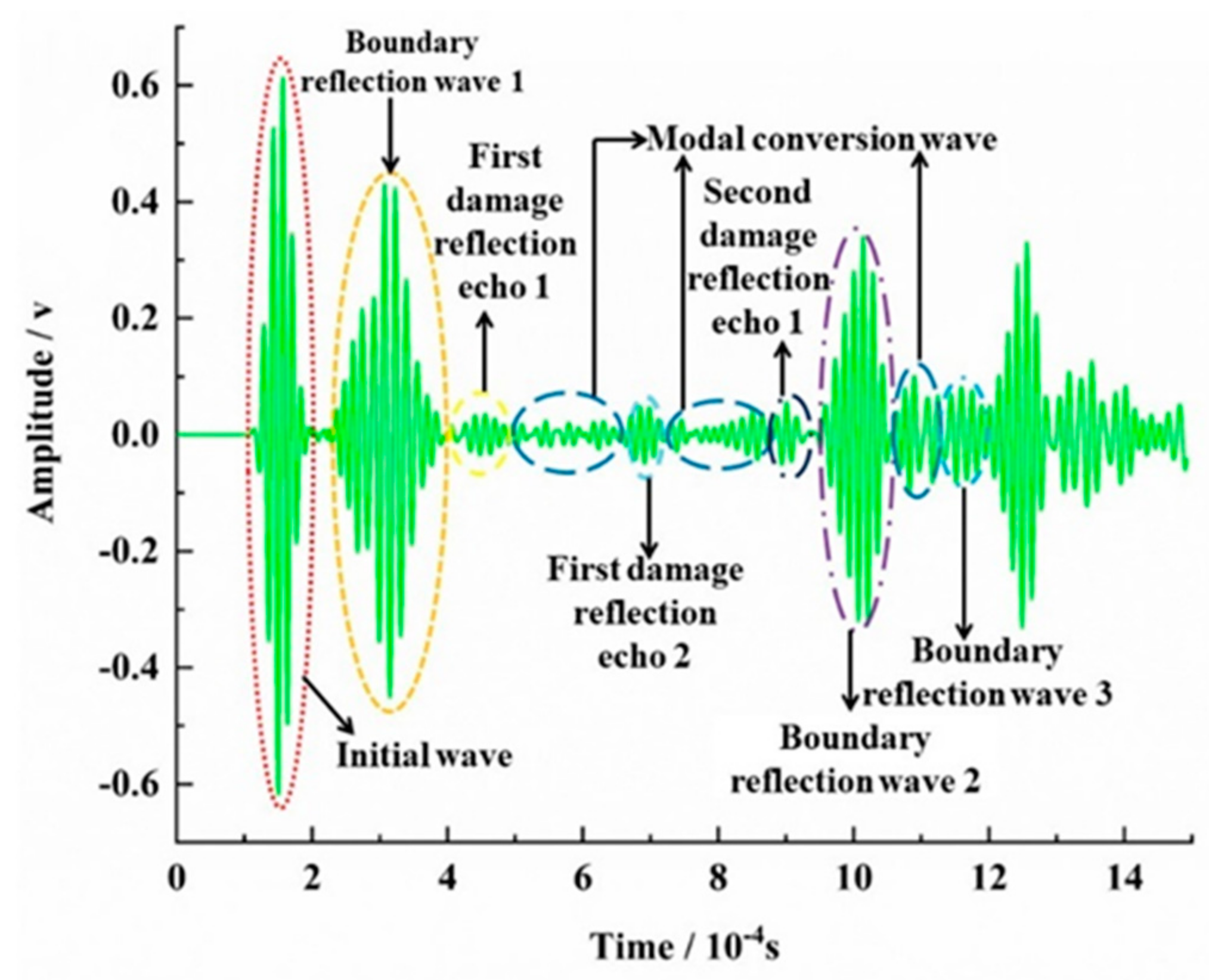

Figure 9.

Sensor signal diagram.

Figure 9.

Sensor signal diagram.

Figure 10.

The two-dimensional damage index matrix for dual defects in pipeline structures with different circumferential positions 6. 6 The axial distance of the damage shown in the figure refers to the distance between the second defect and the piezoelectric element sensor. The first damage is always located at 750 mm from the piezoelectric element sensor.

Figure 10.

The two-dimensional damage index matrix for dual defects in pipeline structures with different circumferential positions 6. 6 The axial distance of the damage shown in the figure refers to the distance between the second defect and the piezoelectric element sensor. The first damage is always located at 750 mm from the piezoelectric element sensor.

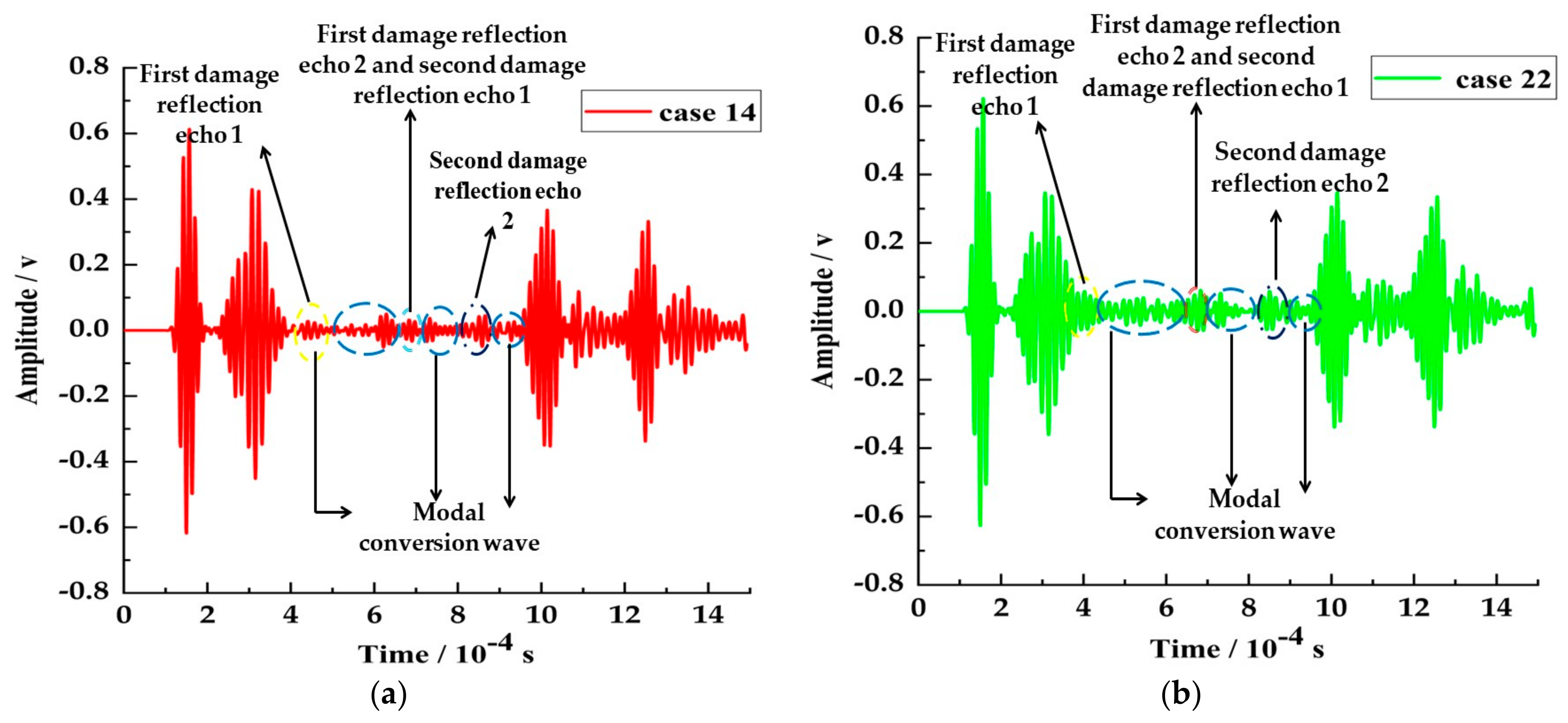

Figure 11.

Piezoelectric time domain comparison 7: (a) piezoelectric time domain diagram of case 14, (b) piezoelectric time domain diagram of case 22, (c) piezoelectric time domain comparison between case 14 and case 22, (d) piezoelectric temporal domain local amplification diagram. 7 For case 14 and case 22, the reflection echo 2 of the first defect, and the reflection echo 1 of the second defect propagated the same distance in the pipeline, so the two wave packets completely overlapped at this time.

Figure 11.

Piezoelectric time domain comparison 7: (a) piezoelectric time domain diagram of case 14, (b) piezoelectric time domain diagram of case 22, (c) piezoelectric time domain comparison between case 14 and case 22, (d) piezoelectric temporal domain local amplification diagram. 7 For case 14 and case 22, the reflection echo 2 of the first defect, and the reflection echo 1 of the second defect propagated the same distance in the pipeline, so the two wave packets completely overlapped at this time.

Figure 12.

The comparison of the damage index matrices for pipeline structures 8. 8 The axial distance of the damage in the figure refers to the axial distance between the second defect and the piezoelectric element sensor. As the single-layered pipeline structure had only one defect, the axial distance of the damage refers to the axial distance between the damage and the piezoelectric element sensor.

Figure 12.

The comparison of the damage index matrices for pipeline structures 8. 8 The axial distance of the damage in the figure refers to the axial distance between the second defect and the piezoelectric element sensor. As the single-layered pipeline structure had only one defect, the axial distance of the damage refers to the axial distance between the damage and the piezoelectric element sensor.

Figure 13.

Radial schematic diagram of the layered pipeline structure.

Figure 13.

Radial schematic diagram of the layered pipeline structure.

Figure 14.

Experimental system for layered pipeline structures.

Figure 14.

Experimental system for layered pipeline structures.

Table 1.

The pipeline structure material properties.

Table 1.

The pipeline structure material properties.

| | Type of

Structure | Internal Diameter/mm | Outer Diameter/mm | Wall Thickness/mm | Density/kg·m−3 | Modulus of Elasticity/Pa | Poisson Ratio | Tube Length/m |

|---|

| Material Properties | |

|---|

| Steel tube | 68 | 76 | 4 | 7850 | 2.1 × 1011 | 0.32 | 2.7 |

| Rigid polyurethane foam | 76 | 136 | 20 | 80 | 7.8 × 108 | 0.25 | 2.1 |

| High-density polyethylene | 136 | 140 | 2 | 946 | 5.52 × 108 | 0.4 | 2.1 |

Table 2.

Single defect model case for the pipeline structure 1.

Table 2.

Single defect model case for the pipeline structure 1.

| Case | Damage Axial Distance/mm |

|---|

| case 1 | 0 |

| case 2 | 750 |

| case 3 | 900 |

| case 4 | 1050 |

| case 5 | 1200 |

| case 6 | 1350 |

| case 7 | 1500 |

| case 8 | 1650 |

| case 9 | 1800 |

Table 3.

Meshing of the finite element model 2.

Table 3.

Meshing of the finite element model 2.

| Structure Name | Element Type | Grid Size/mm | Number of Grids |

|---|

| piezoelectric element | C3D8E | 12 | 20 |

| structural layer | C3D20R | 5 | 49,674 |

| insulation layer | C3D20R | 5 | 107,520 |

| anticorrosive layer | C3D20R | 5 | 36,960 |

Table 4.

Operational parameters of the finite element model with the same circumferential position in pipeline structural health monitoring 3.

Table 4.

Operational parameters of the finite element model with the same circumferential position in pipeline structural health monitoring 3.

| Case | First Defect Axial Distance/mm | Second Defect

Axial Distance/mm | Spacing of

Damage/mm |

|---|

| case 10 | 750 | 750 | 0 |

| case 11 | 750 | 900 | 150 |

| case 12 | 750 | 1050 | 300 |

| case 13 | 750 | 1200 | 450 |

| case 14 | 750 | 1350 | 600 |

| case 15 | 750 | 1500 | 750 |

| case 16 | 750 | 1650 | 900 |

| case 17 | 750 | 1800 | 1050 |

Table 5.

Finite element model operating conditions for different circumferential positions.

Table 5.

Finite element model operating conditions for different circumferential positions.

| Case | First Defect Axial Distance/mm | Second Defect Axial Distance/mm | Spacing of Damage/mm | Double Defect Relative Circumferential Position Change/° |

|---|

| case 18 | 750 | 750 | 0 | 90 |

| case 19 | 750 | 900 | 150 | 90 |

| case 20 | 750 | 1050 | 300 | 90 |

| case 21 | 750 | 1200 | 450 | 90 |

| case 22 | 750 | 1350 | 600 | 90 |

| case 23 | 750 | 1500 | 750 | 90 |

| case 24 | 750 | 1650 | 900 | 90 |

| case 25 | 750 | 1800 | 1050 | 90 |

Table 6.

Comparison of the times at which the piezoelectric element sensors received the wave packets 5.

Table 6.

Comparison of the times at which the piezoelectric element sensors received the wave packets 5.

| | Receiving Time/s | Refection Echoes 1 of First Defect/s | Reflection Echoes 2 of First Defect /s | Refection Echoes 1 of Second Defect/s | Reflection Echoes 2 of Second Defect/s |

|---|

| Case | |

|---|

| case 10 | 4.07 × 10−4 | 6.37 × 10−4 | 4.07 × 10−4 | 6.37 × 10−4 |

| case 11 | 4.07 × 10−4 | 6.37 × 10−4 | 4.65 × 10−4 | 7.14 × 10−4 |

| case 12 | 4.07 × 10−4 | 6.37 × 10−4 | 5.22 × 10−4 | 7.72 × 10−4 |

Table 7.

The comparison between the finite element simulation, and the theoretical calculation, for the second defect.

Table 7.

The comparison between the finite element simulation, and the theoretical calculation, for the second defect.

| Case | Time of Dissemination/s | Finite Element Simulation Propagation Velocity/m·s−1 | The Second Defect Theoretical Damage Distance/m | The Second Defect Finite Element Simulation Damage Distance/m | Error/% |

|---|

| case 17 | 7.3 × 10−4 | 5191 | 1.8 | 1.895 | 4 |

Table 8.

Comparison of the damage index values for single and double defects, based on the damage index value.

Table 8.

Comparison of the damage index values for single and double defects, based on the damage index value.

| PD/mm | Description of

Features | Reasons |

|---|

| | , overlap of reflection echoes and increase in pulse width. , reflection echoes gradually separate from each other, but the mode conversion wave still overlaps with the reflection echoes. |

| | , complete separation of reflection echoes.On the other hand, the reflection echoes of the damage have a longer propagation distance and lower waveform amplitude. |

Table 9.

Comparison of damage index values based on different circumferential positions.

Table 9.

Comparison of damage index values based on different circumferential positions.

| Content of Influence | PD/mm | Performance | Reasons |

|---|

| I value

|

| | Changing the circumferential position caused a phase difference, which led to a decrease in the overall waveform amplitude. |

| The trend of I |

| was cyclical | , the phase difference caused the reflection echoes to cancel out or reinforce each other. |

| showed a decreasing trend followed immediately by an increasing trend | In addition to an increase in l, the phase difference also played a role. |

| both showed an increasing trend | The damage echo of the damage gradually separated, and the pulse width of the waveform increased. |

| showed a slow downward trend | , the reflection echoes were completely separated, and the amplitude of the waveform decreased. |

| showed a rapid upward trend | The phase difference caused the overlap of the waveform between the reflection echoes of the defect and the boundary reflection echoes. |

Table 10.

Experimental conditions.

Table 10.

Experimental conditions.

| Condition Name | First Defect Axial Distance/mm | Second Defect Axial Distance/mm | Spacing of Damage/mm | Double Defect Relative Circumferential Position Change/° |

|---|

| case 5 | 0 | 1200 | 0 | 0 |

| case 8 | 0 | 1650 | 0 | 0 |

| case 13 | 750 | 1200 | 450 | 0 |

| case 16 | 750 | 1650 | 900 | 0 |

| case 21 | 750 | 1200 | 450 | 90 |

| case 24 | 750 | 1650 | 900 | 90 |

Table 11.

Comparison between the experimental and simulation results.

Table 11.

Comparison between the experimental and simulation results.

| Case | Source | Damage Index Value | Error/% |

|---|

| case 13 | Experiment | 0.39323 | 0.4 |

| Finite element simulation | 0.39166 |

| case 21 | Experiment | 0.25878 | 0.82 |

| Finite element simulation | 0.26093 |

Table 12.

Comparison of single and double damage based on experimental damage index values.

Table 12.

Comparison of single and double damage based on experimental damage index values.

| PD/mm | Case | The Number of Defects and Their Relative Circumferential Position | Damage Index Value | Relationship between the Magnitude of the Damage Index Value |

|---|

| case 5 | Single defect | 0.32987 | |

| case 13 | Double defect 0° | 0.39323 |

| case 21 | Double defect 90° | 0.25878 |

| case 8 | Single defect | 0.33861 | |

| case 16 | Double defect 0° | 0.32174 |

| case 24 | Double defect 90° | 0.25985 |