Model-Based Adaptive Collaboration of Multi-Terminal Internal Force Tracking

Abstract

1. Introduction

- Based on the absolute relative motion strategy, we propose the time-varying force-tracking control mode and command internal force concept of a contact single-master–multi-slave terminal. Furthermore, the time-varying complex internal force working space is simplified and transformed according to the concept of command internal forces.

- A method for estimating the unknown stiffness and motion of the direction of multi-internal force commands is proposed. The suggested method is simple and robust to object stiffness, shape changes, and the uncertain motion of contact points.

- Based on the estimation of stiffness and motion in the command internal force direction, we use the uncertain motion and force of impedance model in the command internal force direction to track the formation method of the adaptive reference trajectory. This means that the force of the contact point measured by the force sensor and kinematics can stabilize the collaborative task without building a dynamic object model.

2. Model Establishment of a Multi-Terminal Clamping System

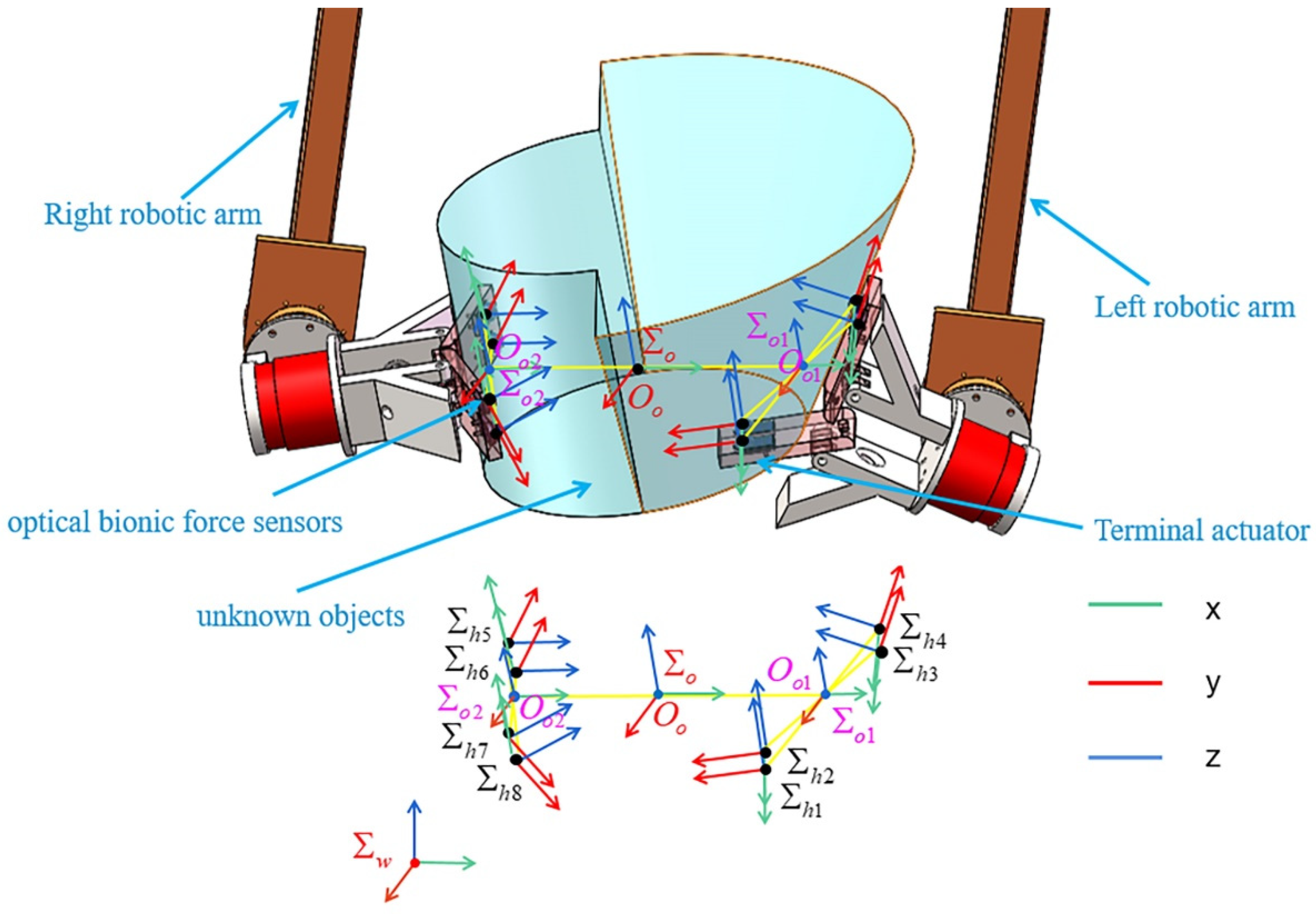

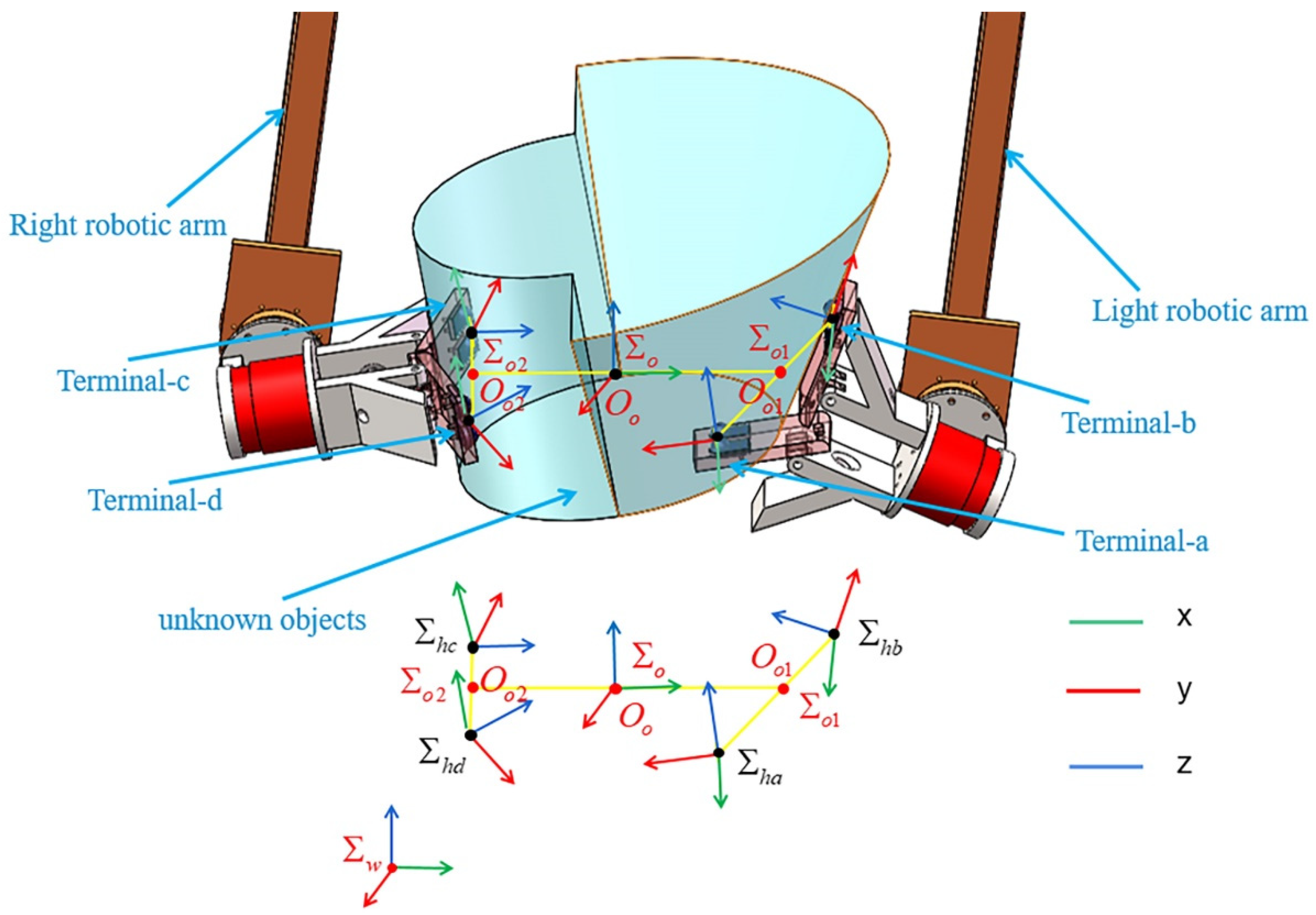

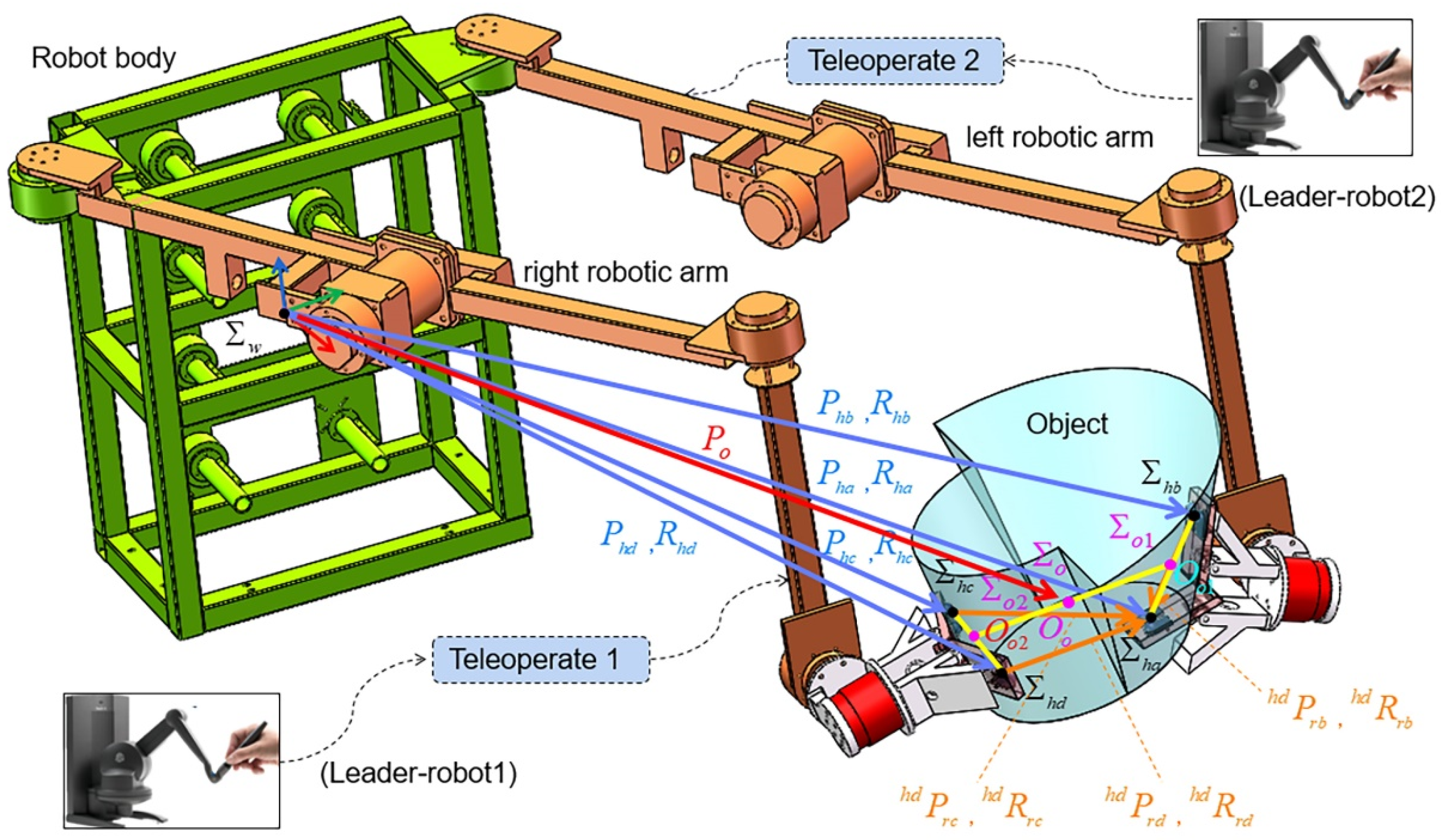

2.1. Formalizing the Workspace

- Vector composed of and .

- Force vectors of various parts of the system.

- Torque vector of each part of the system.

- A vector composed of vectors from multiple terminals.

- Origin of coordinate systems for various parts of the system.

- Translation velocity vector of various parts of the system.

- Position vectors of various parts of the system.

- Direction vectors of various parts of the system.

- Virtual rod vector from the coordinate origin of each terminal to the object coordinate origin .

- Angular velocity vectors of various parts of the system.

- Position, velocity, and force related to objects.

- Position, velocity, and force of the th virtual rod tip.

- Position, velocity, and force at the root of the virtual rod (at the th contact terminal).

- The position and speed of the root of the virtual rod (at the th slave terminal) after system simplification.

- Contact point or terminal serial number.

- Represents the simplified serial numbers of each slave terminal, .

- Relative (internal) position, velocity, and force.

- Generalized relative (internal) position, velocity, and force vectors.

- Measure of position, velocity, and force.

- Robot coordinate system .

- Simplified coordinate systems for each terminal .

- Simplified coordinate systems for each slave terminal .

- Remote operation enables each force-sensing contact point installed at the terminal to reach a reasonable, cooperative position on the object’s surface, and all contact points contact the object’s surface.

- The remote operation causes the four terminals to form an origin in the coordinate system , as illustrated in Figure 1, which is close to the object’s center of gravity.

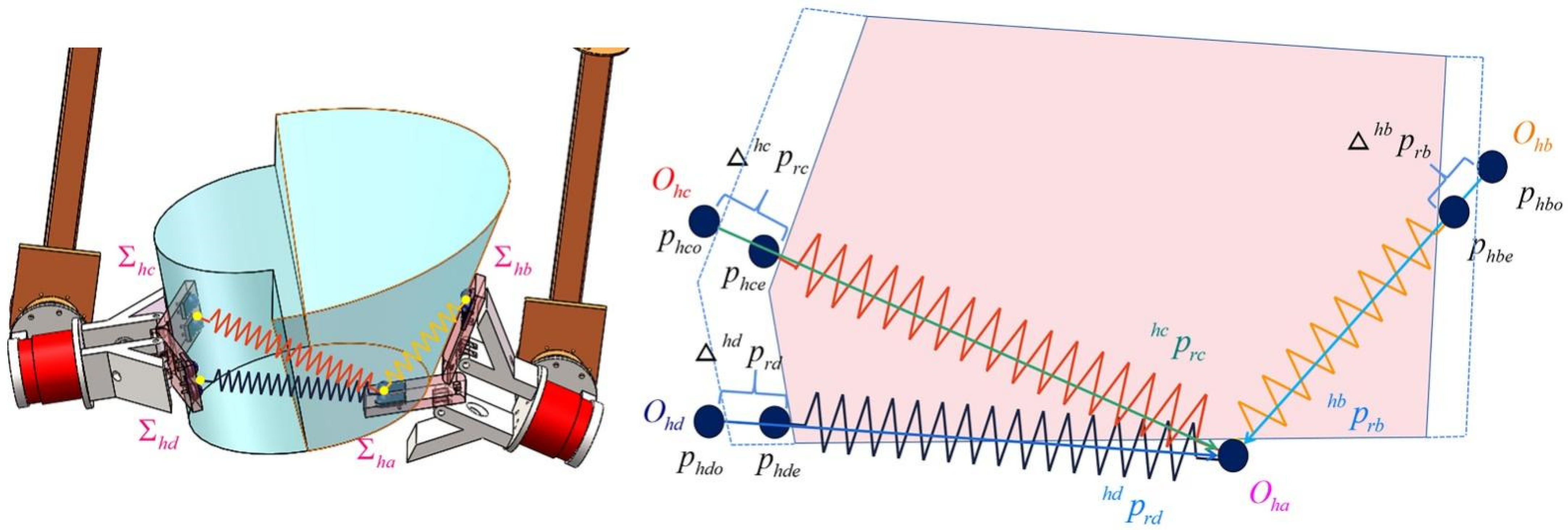

2.2. Simplification and Transformation of the Internal Force Space

- No torque vector is formed at a single contact point.

- No internal force is generated between two parallel contact points on a terminal.

- No internal torque is generated between all contact points, so only internal forces are involved in the control based on reference trajectories.

2.3. Absolute Relative Motion Control

3. Multi-Terminal Adaptive Motion

3.1. Problem Description

3.2. Unknown Motion Estimation of the Internal Command Force Direction

3.3. Tracking the Generation of Reference Trajectories of Expected Command Internal Forces

4. Experiments

4.1. Experimental Description

- The first manipulated object is softly wrapped, and its surface is soft and uneven.

- The second manipulated object is a container with a hard and flat surface.

4.2. Soft Package Manipulation Experiment

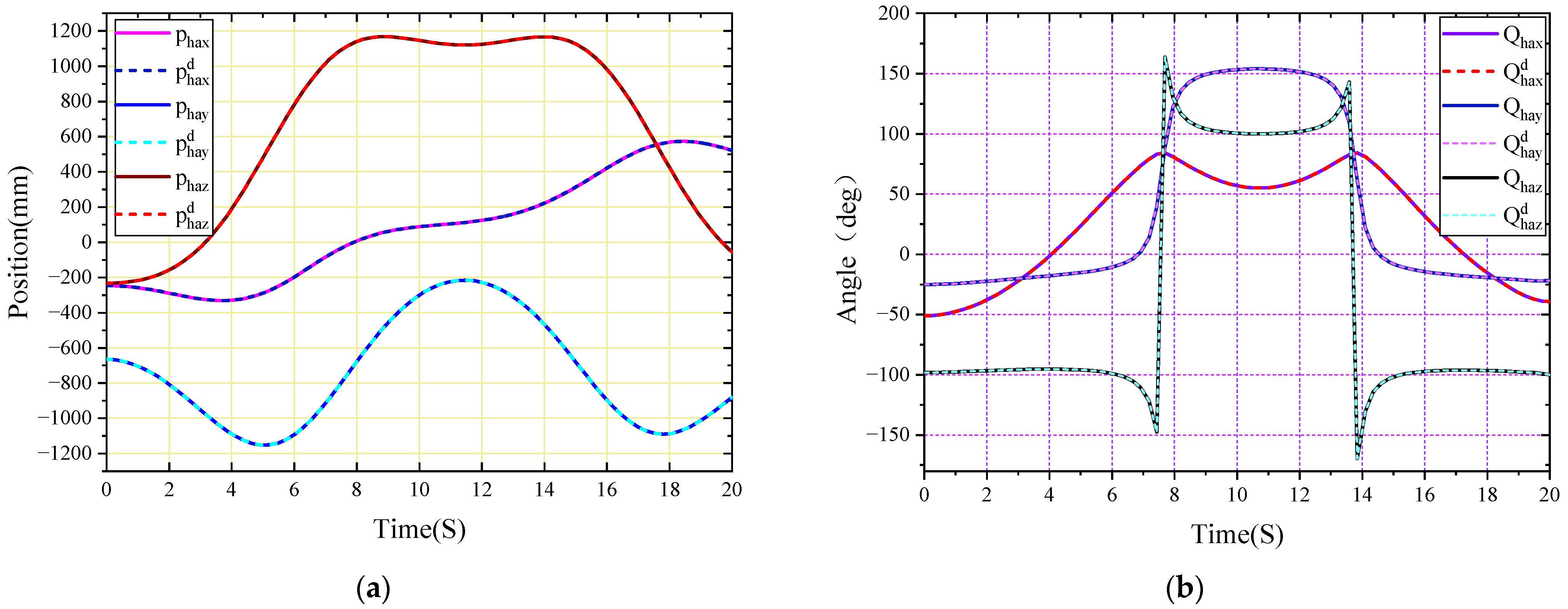

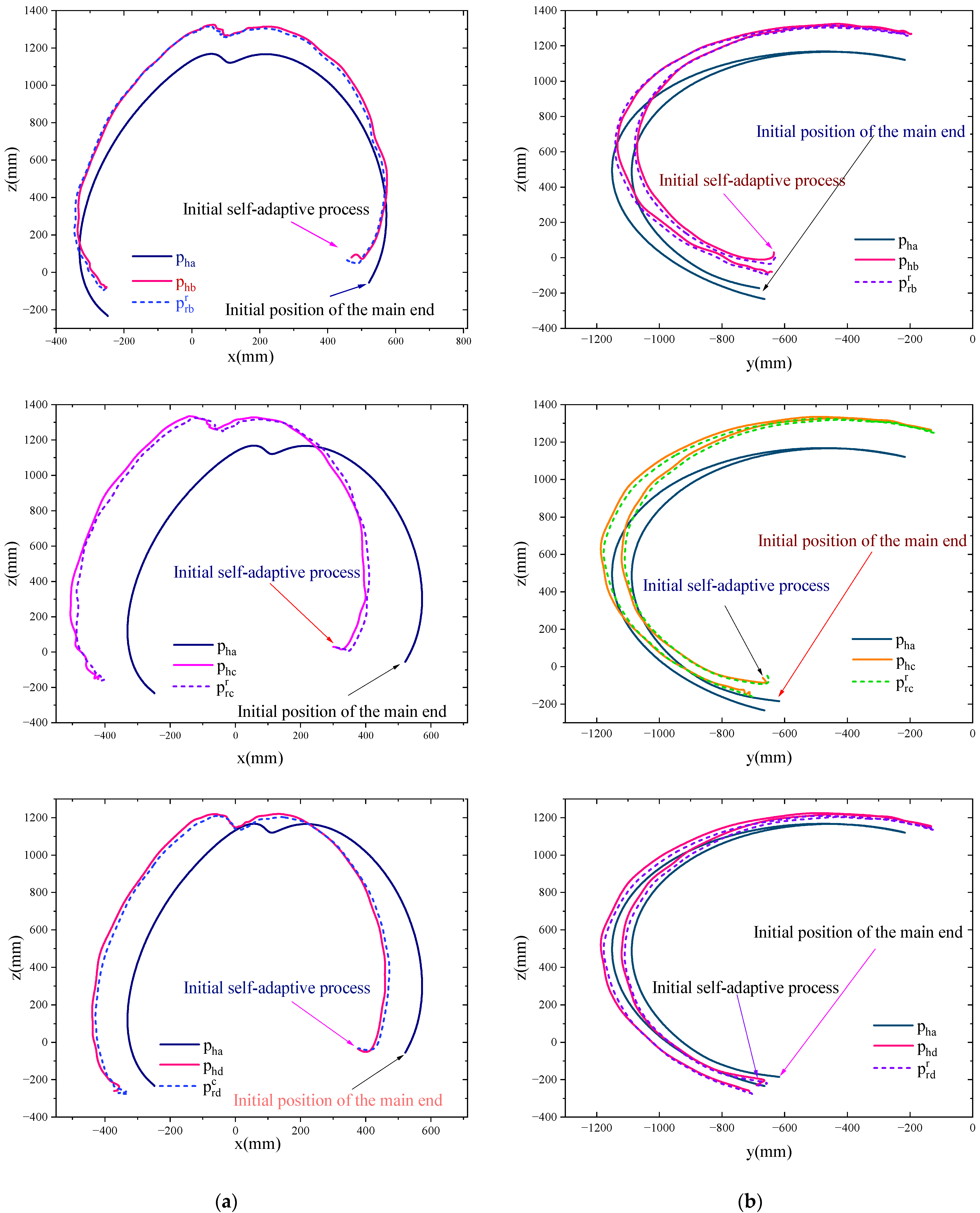

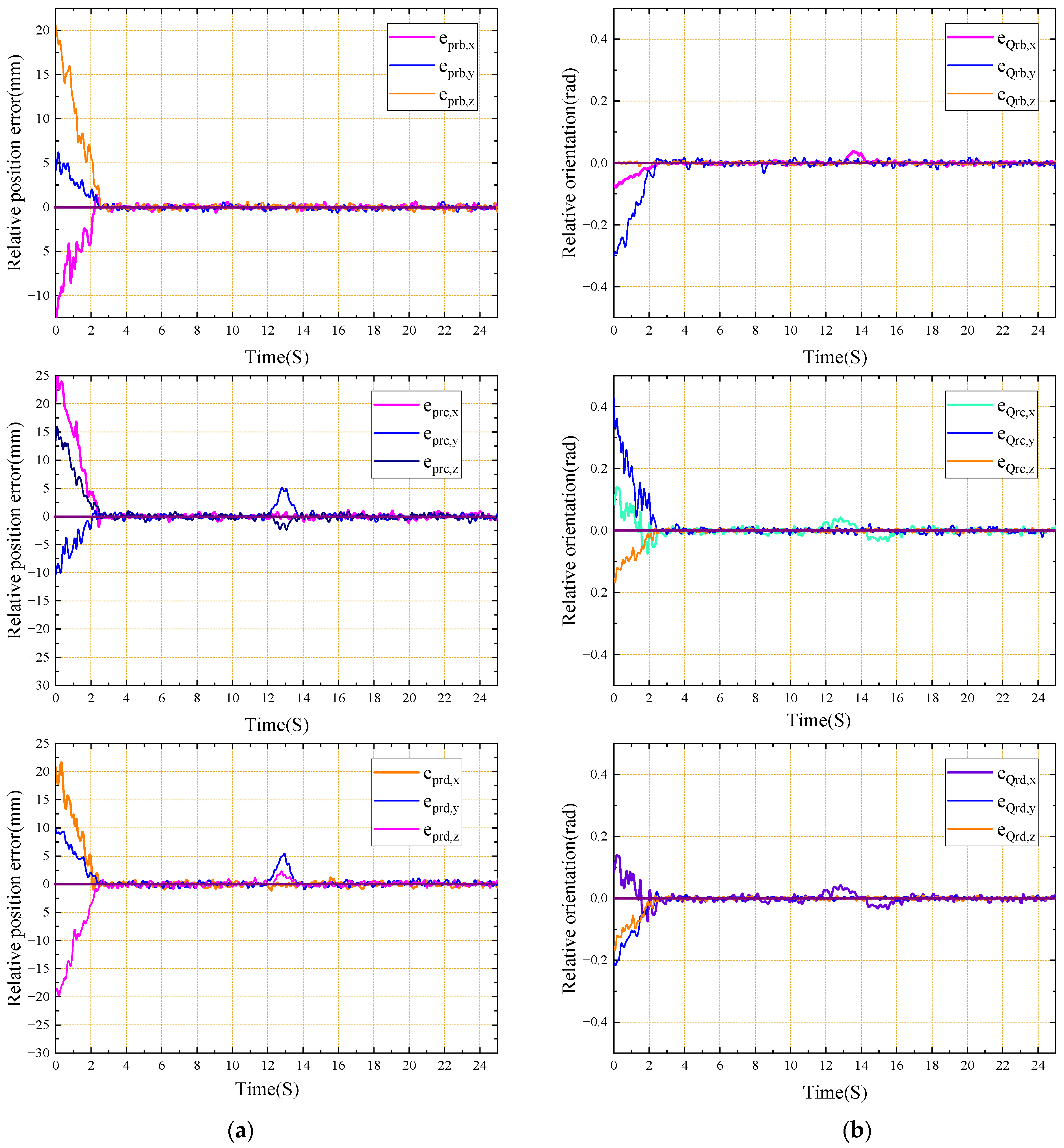

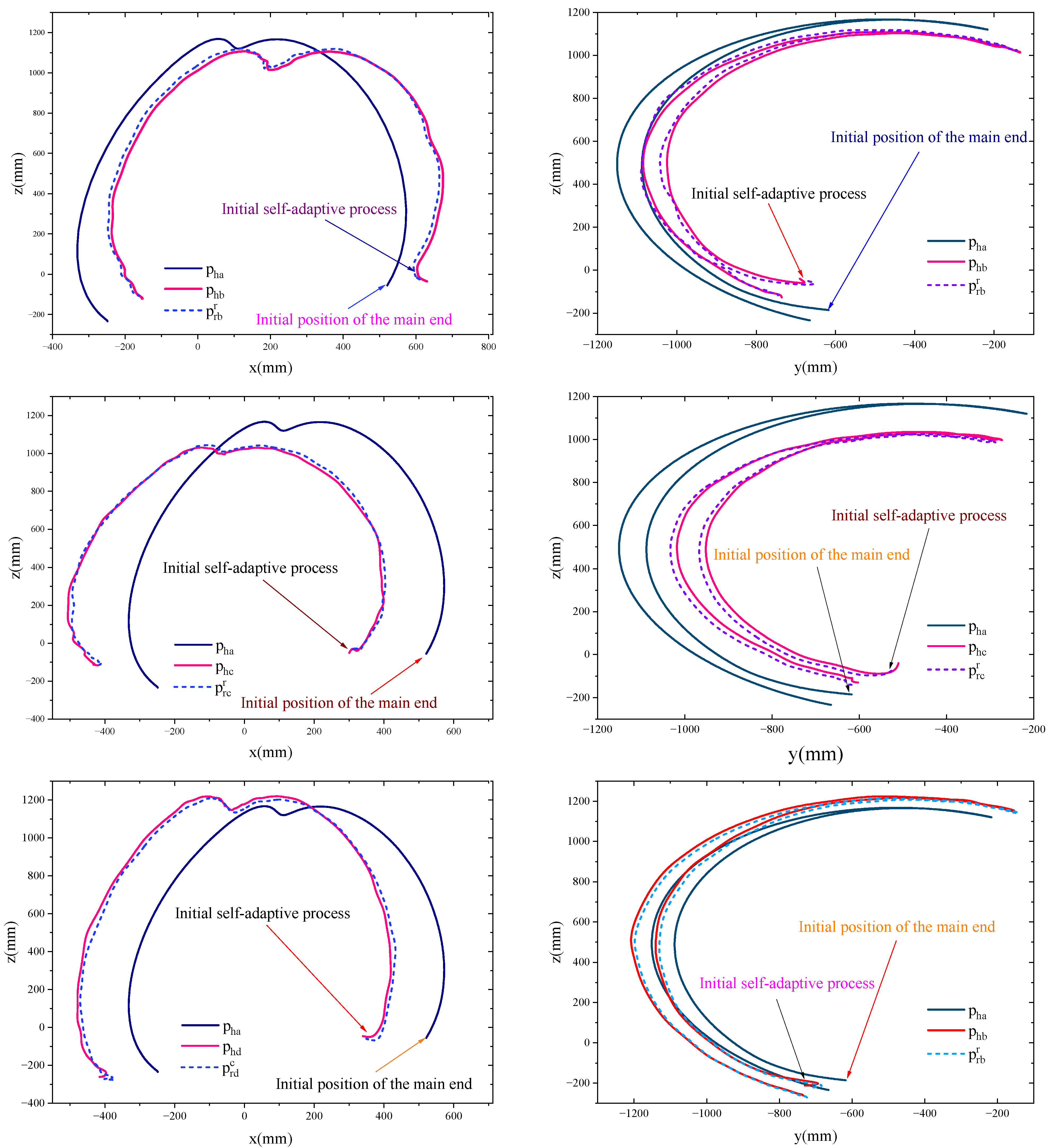

4.2.1. Motion Control Analysis

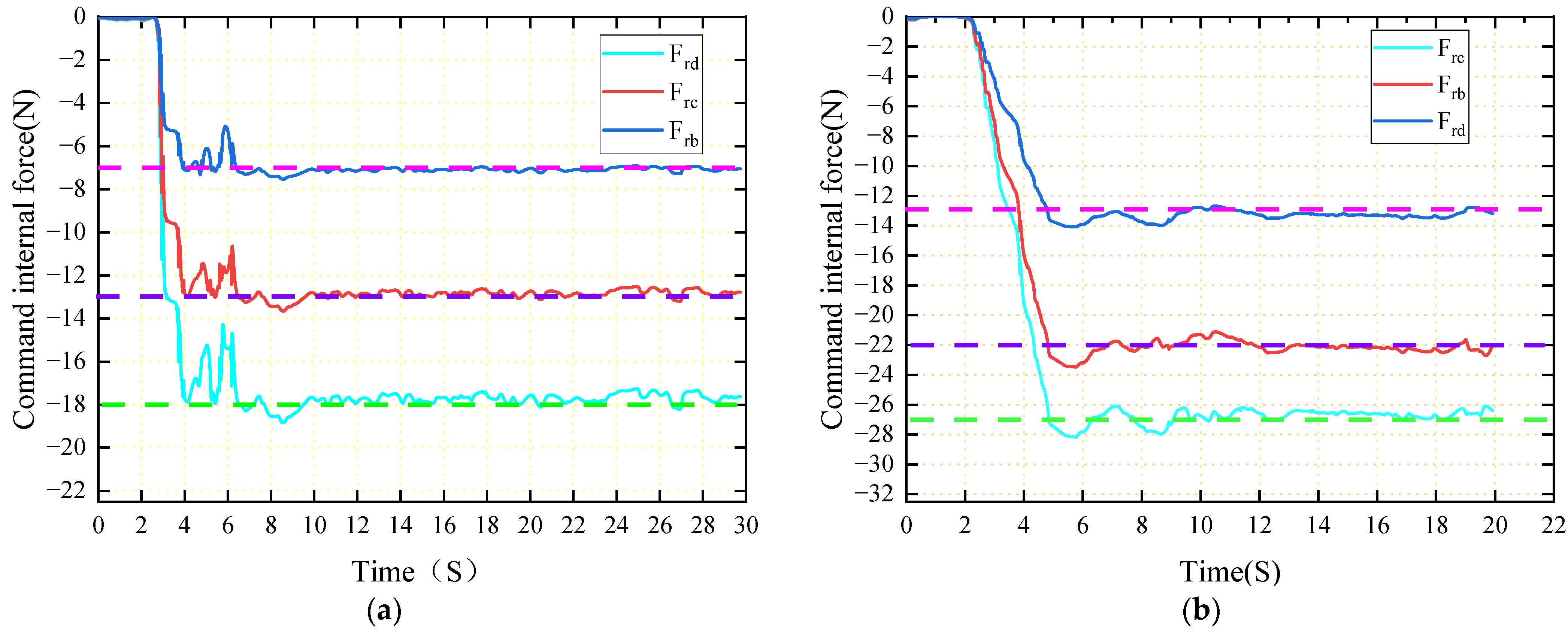

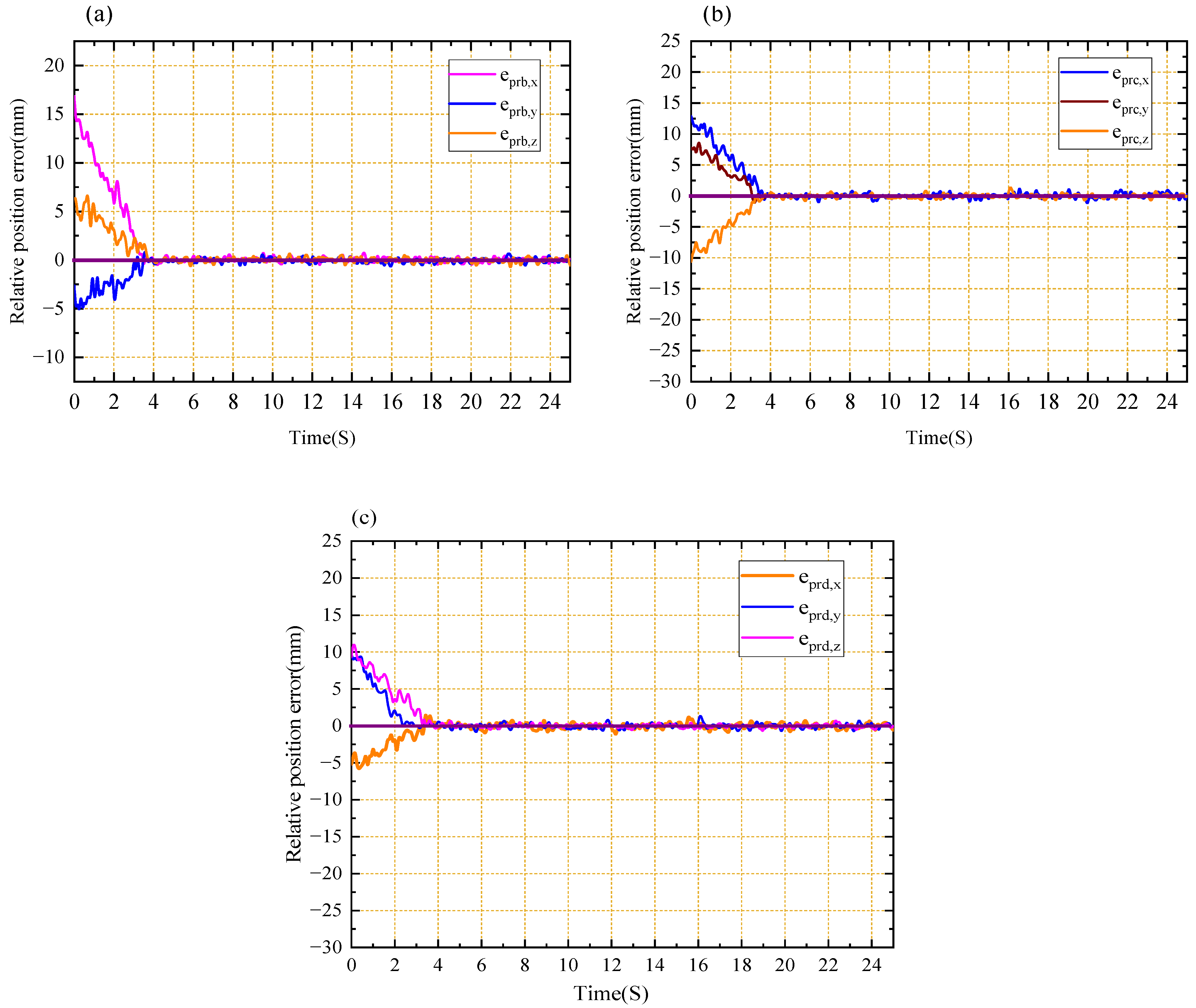

4.2.2. Internal Force Tracking Analysis

4.3. Manipulating Containers

- The proposed method effectively extracts and regulates holding lines for complex internal force spaces during multi-terminal force closure collaborations and maintains contact forces.

- The motion estimation in the proposed multi-terminal collaboration method is important for dealing with multi-terminal time-varying motion.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Coleshill, E.; Oshinowo, L.; Rembala, R.; Bina, B.; Rey, D.; Sindelar, S. Improving maintenance operations on the international space station. Acta Astronaut. 2009, 64, 869–874. [Google Scholar]

- Lee, Y.; Kim, S.; Park, J. A whole-body control framework based on the operational space formulation under inequality constraints via task-oriented optimization. IEEE Access 2021, 9, 39813–39826. [Google Scholar]

- Pfanne, M. Object-level impedance control for dexterous in-hand manipulation. IEEE Robot. Autom. Lett. 2020, 5, 2987–2994. [Google Scholar]

- Song, S.; Park, J.; Choi, Y.H. Dual-fingered stable grasping control for an optimal force angle. IEEE Trans. Robot. 2012, 28, 256–262. [Google Scholar]

- Galicki, M. Finite-time trajectory tracking control in a task space of robotic manipulators. Automatica 2016, 67, 165–170. [Google Scholar]

- Corradini, M.; Fossi, V.; Giantomassi, A. Minimal resource allocating networks for discrete time sliding mode control of robotic manipulators. IEEE Trans. Ind. Inform. 2012, 8, 733–745. [Google Scholar]

- Wang, H. Adaptive control of robot manipulators with uncertain kinematics and dynamics. IEEE Trans. Autom. Control 2017, 62, 948–954. [Google Scholar]

- Stephens, T.K.; Awasthi, C.; Kowalewski, T.M. Adaptive impedance control with setpoint force tracking for unknown soft environment interactions. In Proceedings of the 2019 IEEE 58th Conference on Decision and Control (CDC), Nice, France, 11–13 December 2019; pp. 1951–1958. [Google Scholar]

- Liu, T.; Yan, L.; Han, L.; Xu, W. Coordinated resolved motion control of dual-arm manipulators with closed chain. Int. J. Adv. Robot. Syst. 2016, 13, 80–94. [Google Scholar]

- Yan, L.; Yang, Y.; Xu, W.; Vijayakumar, S. Dual-arm coordinated motion planning and compliance control for capturing moving objects with large momentum. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems, Macau, China, 3–8 November 2019; Volume 713, pp. 7137–7144. [Google Scholar]

- Heck, D.; Saccon, A.; Wouw, N.; Nijmeijer, H. Guaranteeing stable tracking of hybrid position–force trajectories for a robot manipulator interacting with a stiff environment. Automatica 2016, 63, 235–247. [Google Scholar]

- Sun, D.; Liao, Q.; Stoyanov, Q.; Kiselev, A.; Loutfi, A. Bilateral telerobotic system using Type-2 fuzzy neural network based moving horizon estimation force observer for enhancement of environmental force compliance and human perception. Automatica 2019, 106, 358–373. [Google Scholar]

- Yang, G.; Wang, S.; Yang, J. Hybrid knowledge base for care robots. Int. J. Innov. Comput. Inf. Control 2021, 17, 335–343. [Google Scholar]

- Baigzadehnoe, B.; Rahmani, Z.; Khosravi, A.; Rezaie, B. On position/force tracking control problem of cooperative robot manipulators using adaptive fuzzy backstepping approach. ISA Ransactions 2017, 70, 432–446. [Google Scholar]

- Li, C.; Zhang, Z.; Xia, G.; Xie, X.; Zhu, Q. Efficient force control learning system for industrial robots based on variable impedance control. Sensors 2018, 18, 2539. [Google Scholar] [PubMed]

- Yang, Z.; Peng, J.; Liu, Y. Adaptive neural network force tracking impedance control for uncertain robotic manipulator based on nonlinear velocity observer. Neurocomputing 2019, 331, 263–280. [Google Scholar]

- Kaserer, D.; Gattringer, H.; Müller, A. Time Optimal Motion Planning and Admittance Control for Cooperative Grasping. Robot. Autom. Lett. 2020, 5, 2216–2223. [Google Scholar]

- Duan, J.; Gan, Y.; Chen, M.; Dai, X. Adaptive variable impedance control for dynamic contact force tracking in uncertain environment. Robot. Auton. Syst. 2018, 102, 54–65. [Google Scholar]

- Jiao, C.; Yu, L.; Su, X.; Wen, Y.; Dai, X. Adaptive hybrid impedance control for dual-arm cooperative manipulation with object uncertainties. Automatica 2022, 140, 110232. [Google Scholar]

- Garcia-Rodriguez, R.; Parra-Vega, V. In-hand manipulation of a circular object by soft finger-tips without angle measuring. Sci. China Inf. Sci. 2021, 64, 152209. [Google Scholar]

- Marwan, M.; Chyi, S.C.; Kwek, L.C. Comprehensive review on reaching and grasping of objects in robotics. Robotica 2021, 39, 1849–1882. [Google Scholar]

- Li, X.; Chen, Z.; Ma, C. Optimal grasp force for robotic grasping and in-hand manipulation with impedance control. Assem. Autom. 2021, 41, 208–220. [Google Scholar]

- Uchiyama, M.; Dauchez, P. Symmetric kinematic formulation and non-master/slave coordinated control of two-arm robots. Adv. Robot. 1993, 7, 361–383. [Google Scholar]

- Seraji, H.; Colbaugh, R. Force tracking in impedance control. Int. J. Robot. Res. 1997, 16, 97–117. [Google Scholar] [CrossRef]

| Module | Length (mm) | Width (mm) |

|---|---|---|

| Link 1 | 480 | |

| Link 2 | 480 | |

| Link 3 | 373.5 | |

| Link 4 | 126.5 | |

| Link 5 | 110.5 | |

| Link 6 | 54.5 | |

| Terminal | 100 | 50 |

| Sensor center distance | 25 | |

| Terminal axis spacing | 57 |

| Methods | Steady-State Force Error | Overshoot | Setting Time | Requirements for Stability Parameters | Applicability to Multi-Terminal Collaboration |

|---|---|---|---|---|---|

| Adaptive impedance control based on a reference trajectory | <1N | 15% | 5 s | Low | Strong |

| Pure motion control | 76% | 36 s | Non-convergence | ||

| Constant impedance control | <8 N | 43% | 16 s | Non-convergence | |

| Variable impedance control | <3 N | 32% | 13 s | High | Weak |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Dai, J.; Song, F. Model-Based Adaptive Collaboration of Multi-Terminal Internal Force Tracking. Appl. Sci. 2023, 13, 8672. https://doi.org/10.3390/app13158672

Wang Z, Dai J, Song F. Model-Based Adaptive Collaboration of Multi-Terminal Internal Force Tracking. Applied Sciences. 2023; 13(15):8672. https://doi.org/10.3390/app13158672

Chicago/Turabian StyleWang, Zhala, Jingmin Dai, and Fei Song. 2023. "Model-Based Adaptive Collaboration of Multi-Terminal Internal Force Tracking" Applied Sciences 13, no. 15: 8672. https://doi.org/10.3390/app13158672

APA StyleWang, Z., Dai, J., & Song, F. (2023). Model-Based Adaptive Collaboration of Multi-Terminal Internal Force Tracking. Applied Sciences, 13(15), 8672. https://doi.org/10.3390/app13158672