Pullout Behavior of a Polymeric Strap in Compacted Dry Granular Material

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

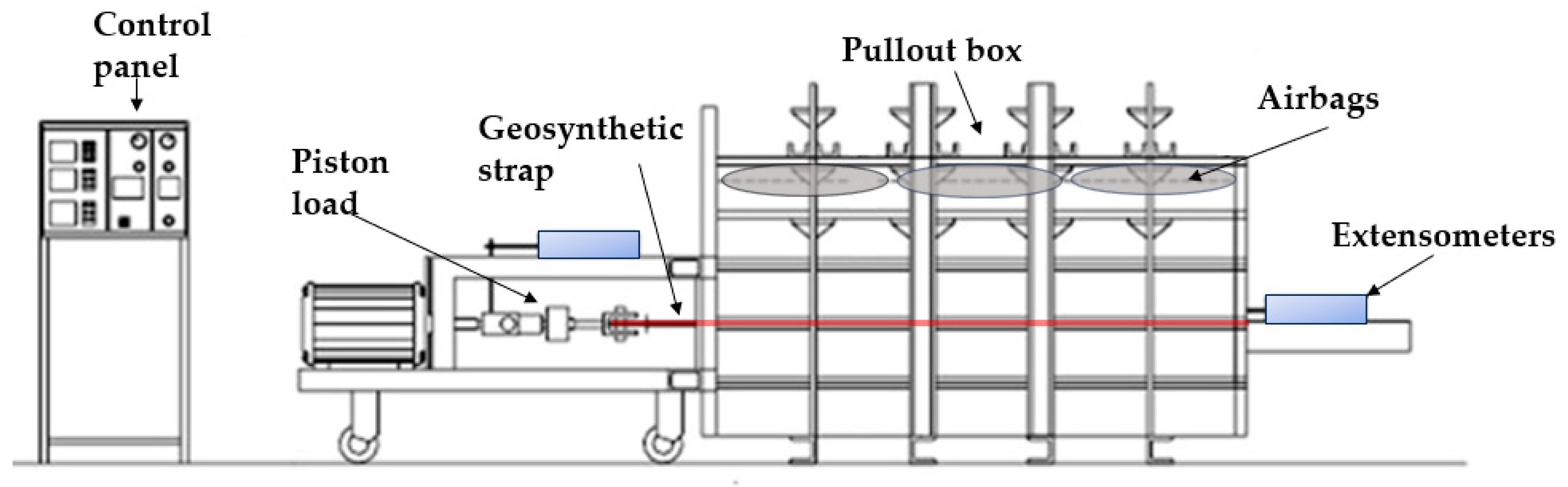

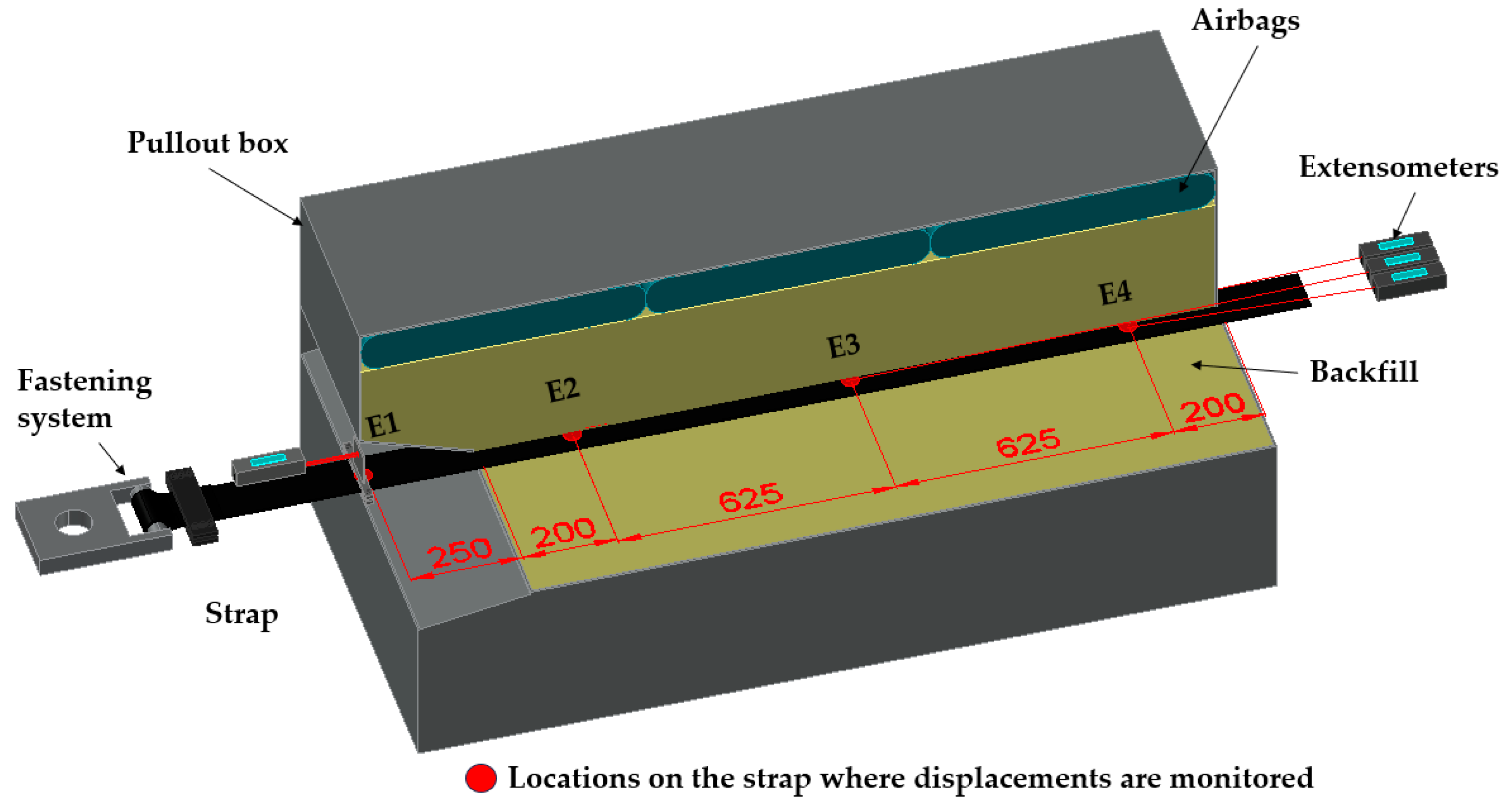

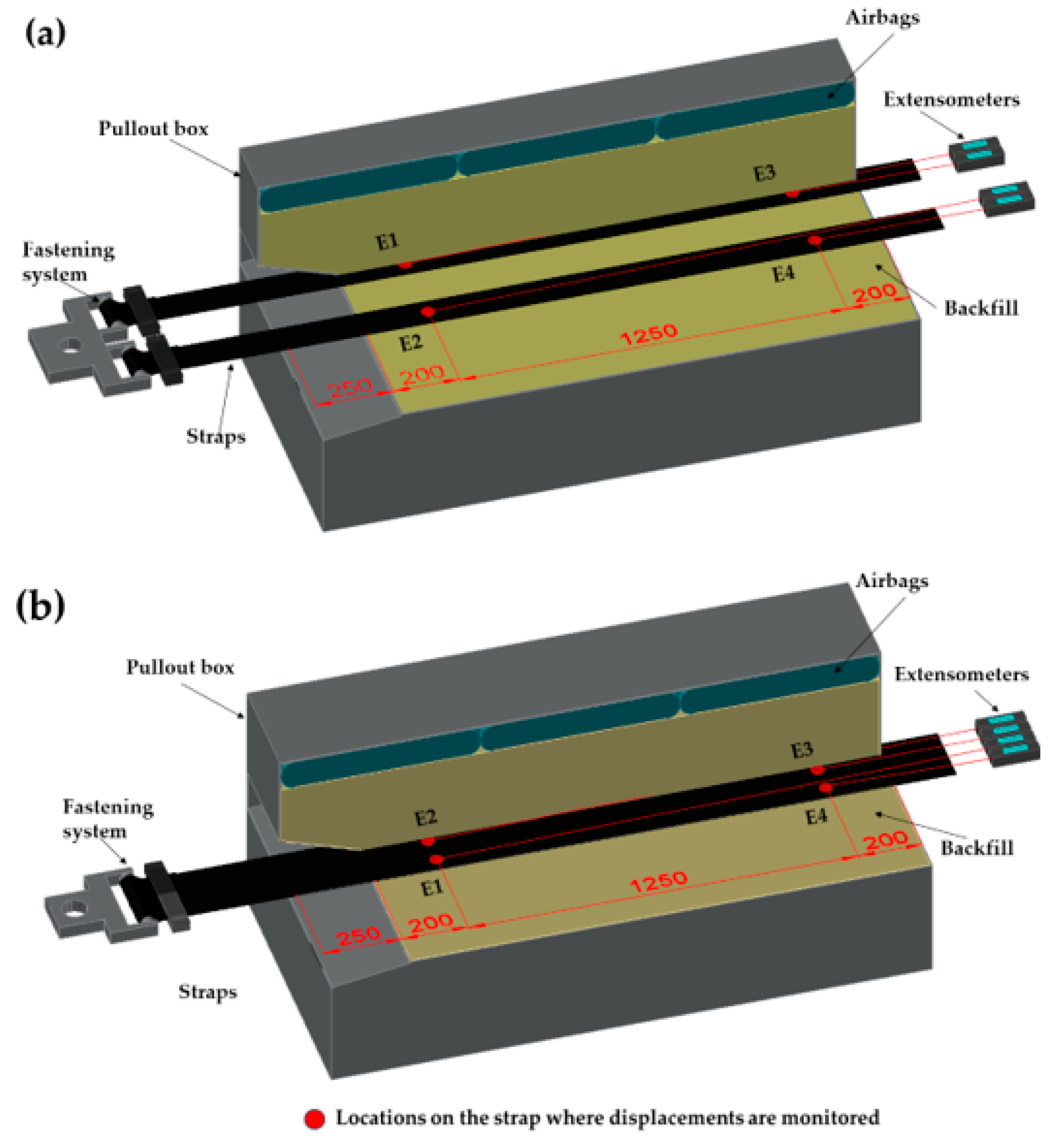

2.1. Testing Apparatus

2.2. Test Materials

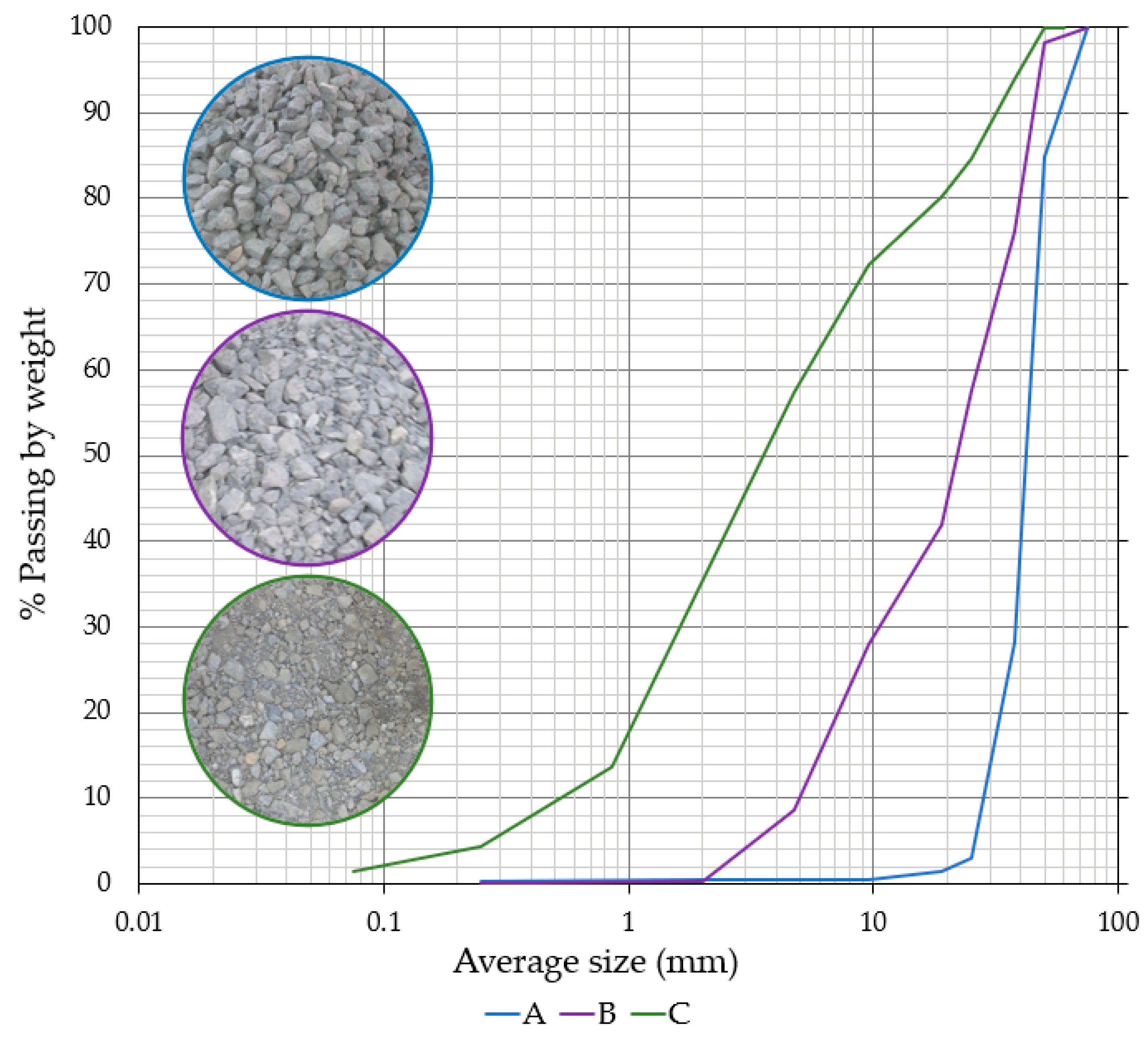

2.2.1. Backfill Material Properties

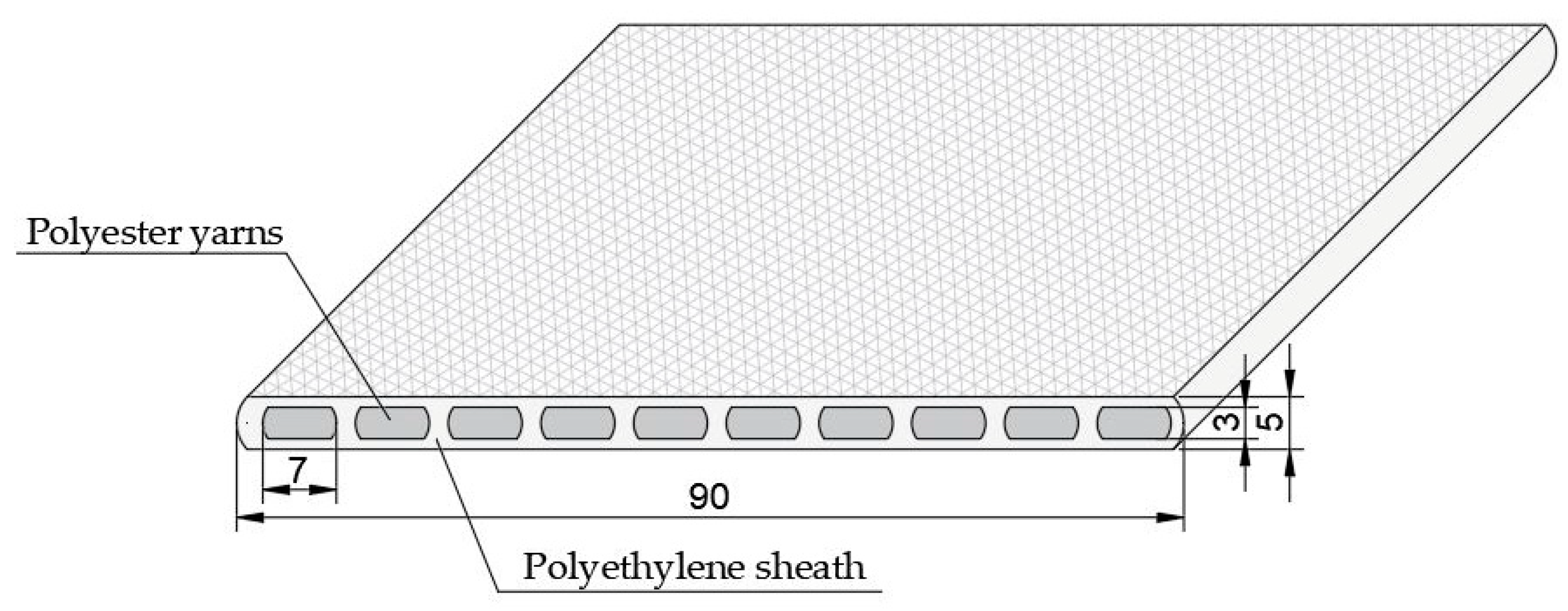

2.2.2. Geosynthetic Strap Properties

2.3. Sample Preparation and Test Procedure

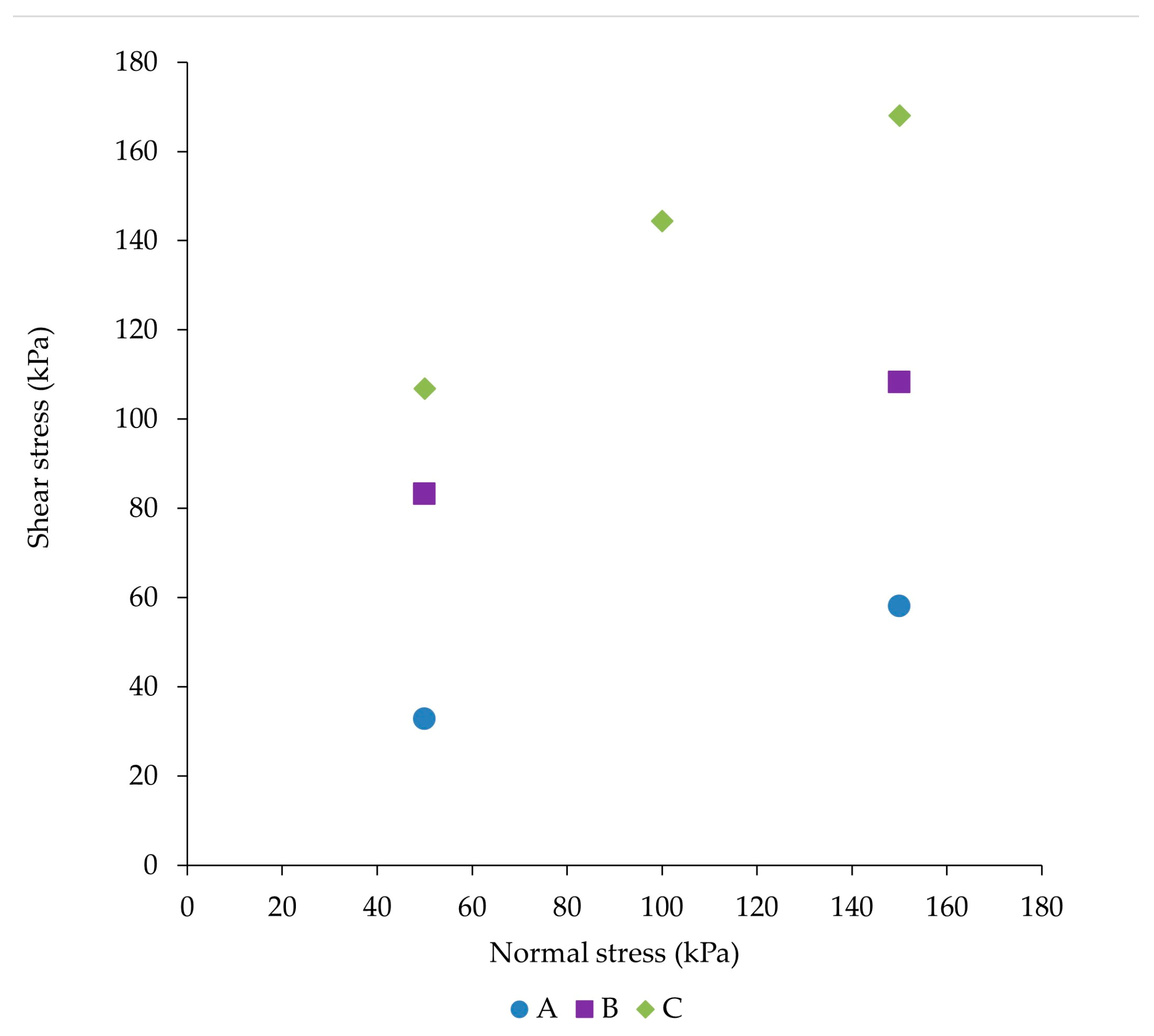

2.4. Interface Pullout Resistance for Polyester Strap and Crushed Stone

3. Results and Discussion

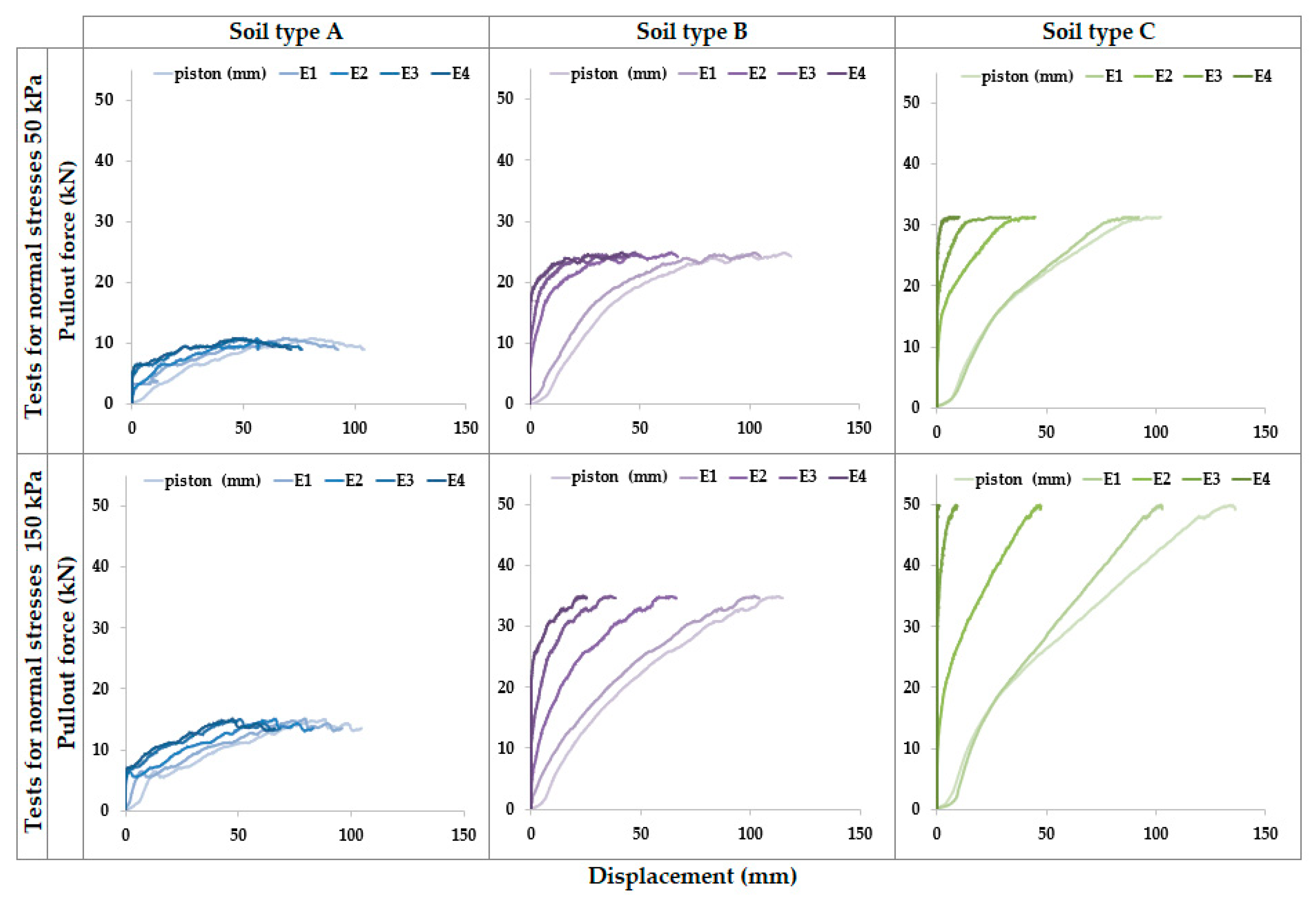

3.1. The Influence of the Grain Size Distribution of the Backfill Material and the Normal Stress on the Pullout Force of Geosynthetic Strap

3.2. The Stress–Strain Behavior of the Strap during the Pullout Tests

3.3. The Influence of Strap Interaction on the Pullout Resistance

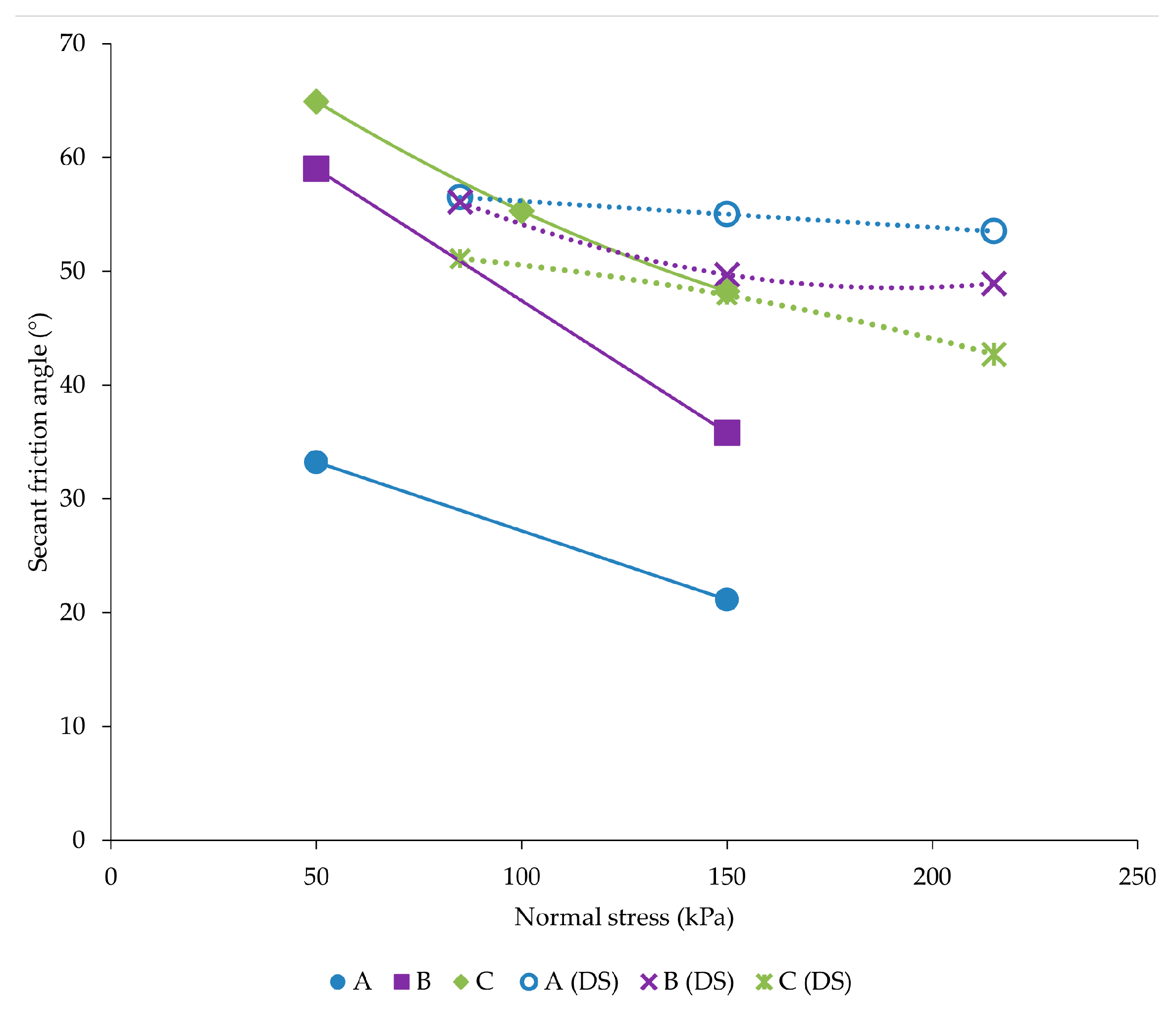

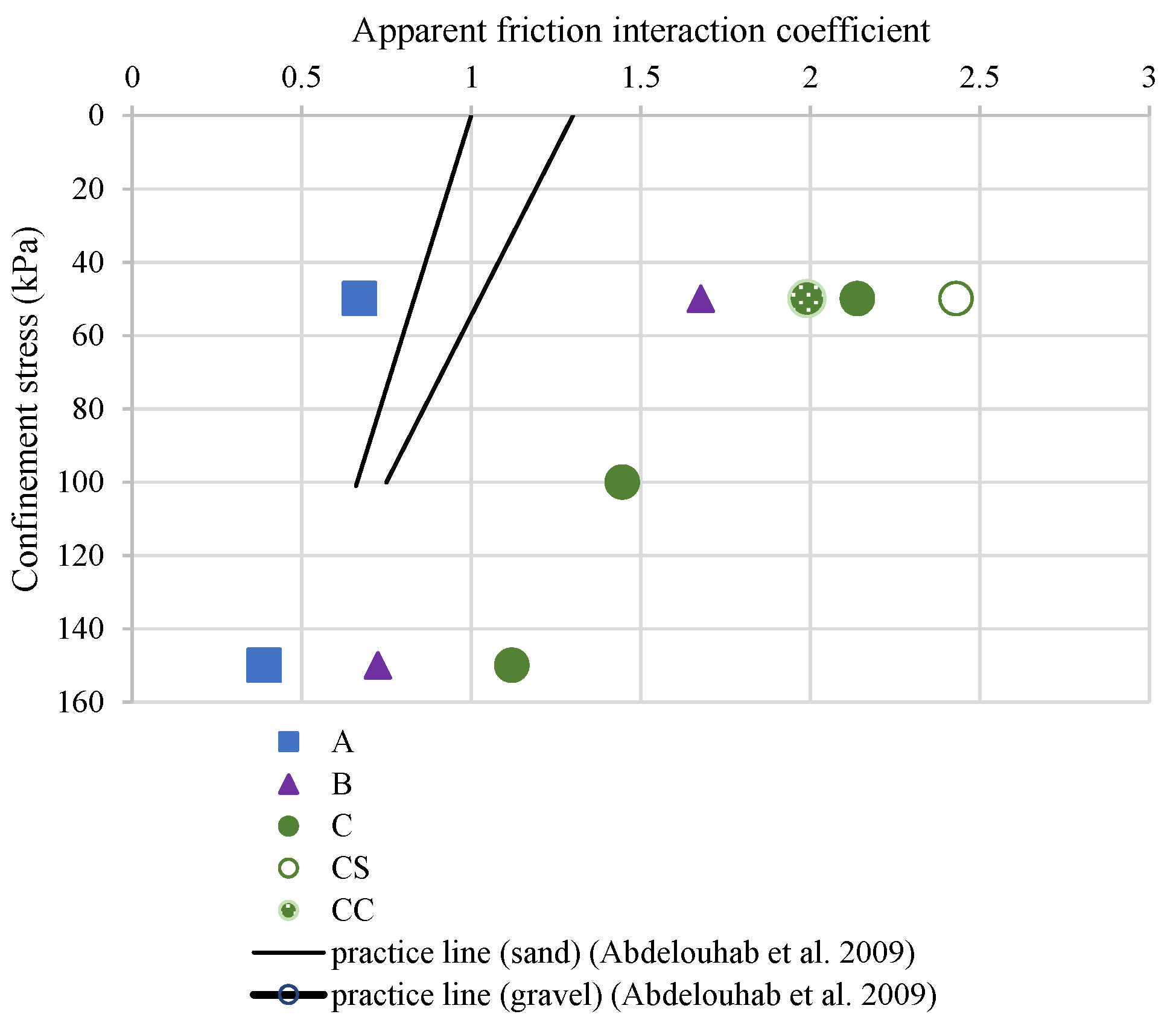

3.4. The Calculated Values of the Friction Interaction Coefficient

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Samtani, N.C.; Nowatzki, E.A. Mechanically Stabilizes Earth (MSE) Wall Fills—A Framework for Use of Local Available Sustainable Resources (LASAR); Publication No. FHWA-HIN-21-002; U.S. Department of Transportation, Federal Highway Administration: Washington, DC, USA, 2021.

- Herceg, V.; Klanfar, M.; Herceg, K.; Domitrović, D. Specific energy consumption of material handling by excavator in the quarrying of crushed stone. Rud.-Geol.-Naft. Zb. 2023, 38, 83–92. [Google Scholar] [CrossRef]

- Durukan, Z.; Tezcan, S.S. Cost analysis of reinforced soil walls. Geotext. Geomembr. 1992, 11, 29–43. [Google Scholar] [CrossRef]

- Singh, H.; Akhtar, S. A review on economical analysis of reinforced earth wall with different types of reinforcing materials. Int. J. Latest Technol. Eng. Manag. Appl. Sci. 2015, 4, 68–74. [Google Scholar]

- Basudhar, P.K.; Vashistha, A.; Deb, K.; Dey, A. Cost Optimization of Reinforced Earth Walls. Geotech. Geol. Eng. 2008, 26, 1–12. [Google Scholar] [CrossRef]

- AASHTO. Standard Specification for Highway Bridges, 17th ed.; AASHTO: Washington, DC, USA, 2002. [Google Scholar]

- FHWA-NHI-10-024: Design and Construction of Mechanically Stabilezed Earth Walls and Reinforced Soils Slope—Volume I; U.S. Departement of Transoirtation, Federal Highway Administration: Washington, DC, USA, 2009.

- Weldu, M.T. Pullout Resistance of MSE Wall Steel Strap Reinforcement in Uniform Aggregate. Master’s Thesis, University of Kansas, Lawrence, KS, USA, 24 November 2015. [Google Scholar]

- Bergado, D.T.; Chai, J.-C. Pullout force/displacement relationship of extensible grid reinforcements. Geotext. Geomembr. 1994, 13, 295–316. [Google Scholar] [CrossRef]

- Palmeira, E.M. Bearing force mobilisation in pull-out tests on geogrids. Geotext. Geomembr. 2004, 22, 481–509. [Google Scholar] [CrossRef]

- Suits, L.D.; Sheahan, T.; Lee, H.-S.; Bobet, A. Laboratory Evaluation of Pullout Capacity of Reinforced Silty Sands in Drained and Undrained Conditions. Geotech. Test. J. 2005, 28. [Google Scholar] [CrossRef]

- Minažek, K. Model Testing of Geogrid-Soil Interaction. Ph.D. Thesis, University of Zagreb, Faculty of Civil Engineering, Zagreb, Croatia, 20 December 2010. [Google Scholar]

- Lawson, W.; Jayawickrama, P.; Wood, T.; Surles, J. Pullout Resistance Factors for Steel Reinforcements Used in TxDOT MSE Walls. In Proceedings of the Geo-Congress 2013: Stability and Performance of Slopes and Embankments III, San Diego, CA, USA, 3–7 March 2013; ASCE: Reston, VA, USA, 2013; pp. 44–53. [Google Scholar] [CrossRef]

- Sukmak, K.; Sukmak, P.; Horpibulsuk, S.; Han, J.; Shen, S.-L.; Arulrajah, A. Effect of fine content on the pullout resistance mechanism of bearing reinforcement embedded in cohesive–frictional soils. Geotext. Geomembr. 2015, 43, 107–117. [Google Scholar] [CrossRef]

- Park, K.; Kim, D.; Park, J.; Na, H. The Determination of Pullout Parameters for Sand with a Geogrid. Appl. Sci. 2020, 11, 355. [Google Scholar] [CrossRef]

- Alfaro, M.C.; Hayashi, S.; Miura, N.; Watanabe, K. Pullout Interaction Mechanism of Geogrid Strip Reinforcement. Geosynth. Int. 1995, 2, 679–698. [Google Scholar] [CrossRef]

- Ochiai, H.; Otani, J.; Hayashic, S.; Hirai, T. The pull-out resistance of geogrids in reinforced soil. Geotext. Geomembr. 1996, 14, 19–42. [Google Scholar] [CrossRef]

- Moraci, N.; Gioffrè, D. A simple method to evaluate the pullout resistance of extruded geogrids embedded in a compacted granular soil. Geotext. Geomembr. 2006, 24, 116–128. [Google Scholar] [CrossRef]

- Palmeira, E.M. Soil–geosynthetic interaction: Modelling and analysis. Geotext. Geomembr. 2009, 27, 368–390. [Google Scholar] [CrossRef]

- Ezzein, F.M.; Bathurst, R.J. A new approach to evaluate soil-geosynthetic interaction using a novel pullout test apparatus and transparent granular soil. Geotext. Geomembr. 2014, 42, 246–255. [Google Scholar] [CrossRef]

- Lo, S. Pull-Out Resistance of Polyester Straps at Low Overburden Stress. Geosynth. Int. 1998, 5, 361–382. [Google Scholar] [CrossRef]

- Abdelouhab, A.; Dias, D.; Freitag, N. Physical and analytical modelling of geosynthetic strip pull-out behaviour. Geotext. Geomembr. 2010, 28, 44–53. [Google Scholar] [CrossRef]

- Pierozan, R.; Araujo, G.; Palmeira, E.; Romanel, C.; Zornberg, J. Interface pullout resistance of polymeric strips embedded in marginal tropical soils. Geotext. Geomembr. 2022, 50, 20–39. [Google Scholar] [CrossRef]

- Agarwal, A.; Ramana, G.; Datta, M.; Soni, N.K.; Satyakam, R. Pullout behaviour of polymeric strips embedded in mixed recycled aggregate (MRA) from construction & demolition (C&D) waste—Effect of type of fill and compaction. Geotext. Geomembr. 2023, 51, 405–417. [Google Scholar] [CrossRef]

- Lo, S.R. The influence of constrained dilatancy on pullout resistance of strap reinforcement. Geosynth. Int. 2003, 10, 47–55. [Google Scholar] [CrossRef]

- Sobhi, S.; Wu, J. An Interface Pullout Formula for Extensible Sheet Reinforcement. Geosynth. Int. 1996, 3, 565–582. [Google Scholar] [CrossRef]

- Cui, X.-Z.; Wang, Y.-L.; Liu, K.-W.; Wang, X.-Z.; Jin, Q.; Zhao, M.-L.; Cui, S.-Q. A simplified model for evaluating the hardening behaviour of sensor-enabled geobelts during pullout tests. Geotext. Geomembr. 2019, 47, 377–388. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.; Ferreira, F.; Lopes, M.d.L. Pullout Behaviour of Geogrids Embedded in a Recycled Construction and Demolition Material. Effects of Specimen Size and Displacement Rate. Sustainability 2020, 12, 3825. [Google Scholar] [CrossRef]

- Kvasnička, P.; Sorić, L.; Gradiški, K.; Marohnić, M. Mechanically stabilized earth wall—A case history. In Proceedings of the XV Danube-European Conference on Geotechnical Engineering, Vienna, Austria, 9–12 September 2014. [Google Scholar]

- Sorić, L.; Kvasnička, P.; Marohnić, M.; Gradiški, K.S. Trojica Reinforced Earth Wall—Back Analysis for the state Shortly after Construction. In Proceedings of the 6th Conference of Croatian Geotechnical Society, Zadar, Croatia, 17–19 October 2013. [Google Scholar]

- Gradiški, K.; Mulabdić, M.; Minažek, K. Selected results of determining the friction interaction coefficient between crushed stone and polyester strip. Rud.-Geol.-Naft. Zb. 2017, 32, 37–43. [Google Scholar] [CrossRef][Green Version]

- Abdelouhab, A.; Dias, D.; Freitag, N. Pull-out behaviour of geosynthetic strap reinforcements in coarse fill physical and analytical modelling. In Proceedings of the GIGSA GeoAfrica 2009 Conference, Cape Town, South Africa, 2–5 September 2009. [Google Scholar]

- Razzazan, S.; Keshavarz, A.; Mosallanezhad, M. Large-scale pullout testing and numerical evaluation of U-shape polymeric straps. Geosynth. Int. 2019, 26, 237–250. [Google Scholar] [CrossRef]

- Park, J.; Hong, G. Effective Length Prediction and Pullout Design of Geosynthetic Strips Based on Pullout Resistance. Materials 2021, 14, 6151. [Google Scholar] [CrossRef] [PubMed]

- ASTM D6706-01 (2001); Standard Test Method for Measuring Geosynthetic Pullout Resistance in Soil. ASTM International: West Conshohocken, PA, USA, 2001.

- Minažek, K.; Mulabdić, M. A review of soil and reinforcement interaction testing in reinforced soil by pullout test. Građevinar 2013, 65, 235–250. [Google Scholar] [CrossRef]

- Schlosser, F.; Bastick, M. Reinforced Earth. In Book Foundation Engineering Handbook, 2nd ed.; Fang, H.Y., Ed.; Springer Science Bussiness Media: New York, NY, US, 1991; pp. 778–795. [Google Scholar]

- AASHTO. LRFD Bridge Design Specifications, 9th ed.; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2020. [Google Scholar]

| Properties of Polymeric Strap | Soil Characteristic | Author and Reference Number | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. | Single | Double | Gap Width (mm) | Strap Width, bs (mm) | Strap Thickness (mm) | Tensile Strength per Strap (kN) | Surcharge Pressure (kPa) | Soil Type | Peak Friction Angle, φ | |

| 1 | ✓ | 85–90 | 4–6 | 20–30 20-30 30-50 | 26–95 15–100 15–100 | Well graded sandy gravel Well-graded, gravelly sand Well-graded sand | 40 40 38 | Lo [21] | ||

| 2 | ✓ | ✓ | 50 | 50 | 2 | / | 7–80 | Houston Rf sand | 38 | Abdelouhab et al. [22] |

| 3 | ✓ | ✓ | 50 | 50 | 2.5 | 47.5 | Coarse soil (0–31.5 mm) Fine sand (0.16–0.63 mm) | 36 36 | Abdelouhab et al. [32] | |

| 4 | ✓ | 90 | 5 | 100 | 50–150 | Crushed stone aggregate | 51 | Gradiški et al. [31] | ||

| 5 | ✓ | 90 | 3 | 75.4 | 20–160 | SP | 40 | Razzazan et al. [33] | ||

| 6 | ✓ | 40 | 1.8 | 21.6 | 5–400 | Sand SM–SP | 29.5 | Cui et al. [27] | ||

| 7 | ✓ | 50 | 50 | 4 | 50 | 12.5–50 | S100–L0 S75–L25 S50–L50 S0–L100 | 44 40 38 33 | Pierozzan et al. [23] | |

| 8 | ✓ | 40 | 50 | 3 | 50 | 20–80 | Mixed recycled aggregate Mixed recycled aggregate Sand from quarrying rock Fluvial sand | 53–41.5 50.1–40.5 49.5–38.7 42.1–37.6 | Agarwal et al. [24] | |

| Sample | |||

|---|---|---|---|

| Properties | A30/60 | B4/60 | C0/60 |

| Grain size range, D (mm) | 30–60 | 4–60 | 0–60 |

| Mean grain size, D50 (mm) | 40.1 | 20.2 | 6.5 |

| Uniformity coefficient, Cu (-) | 1.56 | 4.25 | 11.64 |

| Curvature coefficient, Cc (-) | 1.13 | 1.06 | 0.93 |

| Range of void ratio, emin–emax (-) | 0.54–0.62 | 0.37–0.59 | 0.27–0.46 |

| Friction angle, φ (°) | 55 | 49.7 | 47.9 |

| Dilatancy angle, ψ (°) | 21 | 17.11 | 9.8 |

| Sample | Normal Stress (kPa) | Strap | No. of Tests | |

|---|---|---|---|---|

| Label | Grain Size (mm) | |||

| A | 30–60 | 50 | single | 3 |

| 150 | single | 2 | ||

| B | 4–60 | 50 | single | 1 |

| 150 | single | 3 | ||

| C | 0–60 | 50 | single | 1 |

| 100 | single | 1 | ||

| 150 | single | 1 | ||

| 50 | two (200 mm apart) | 1 | ||

| two (close) | 1 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herceg, K.; Minažek, K.; Domitrović, D.; Horvat, I. Pullout Behavior of a Polymeric Strap in Compacted Dry Granular Material. Appl. Sci. 2023, 13, 8606. https://doi.org/10.3390/app13158606

Herceg K, Minažek K, Domitrović D, Horvat I. Pullout Behavior of a Polymeric Strap in Compacted Dry Granular Material. Applied Sciences. 2023; 13(15):8606. https://doi.org/10.3390/app13158606

Chicago/Turabian StyleHerceg, Karolina, Krunoslav Minažek, Dubravko Domitrović, and Ivan Horvat. 2023. "Pullout Behavior of a Polymeric Strap in Compacted Dry Granular Material" Applied Sciences 13, no. 15: 8606. https://doi.org/10.3390/app13158606

APA StyleHerceg, K., Minažek, K., Domitrović, D., & Horvat, I. (2023). Pullout Behavior of a Polymeric Strap in Compacted Dry Granular Material. Applied Sciences, 13(15), 8606. https://doi.org/10.3390/app13158606