Dynamic Responses of a Coupled Tunnel with Large Span and Small Clear Distance under Blasting Load of the Construction of Transverse Passage

Abstract

:1. Introduction

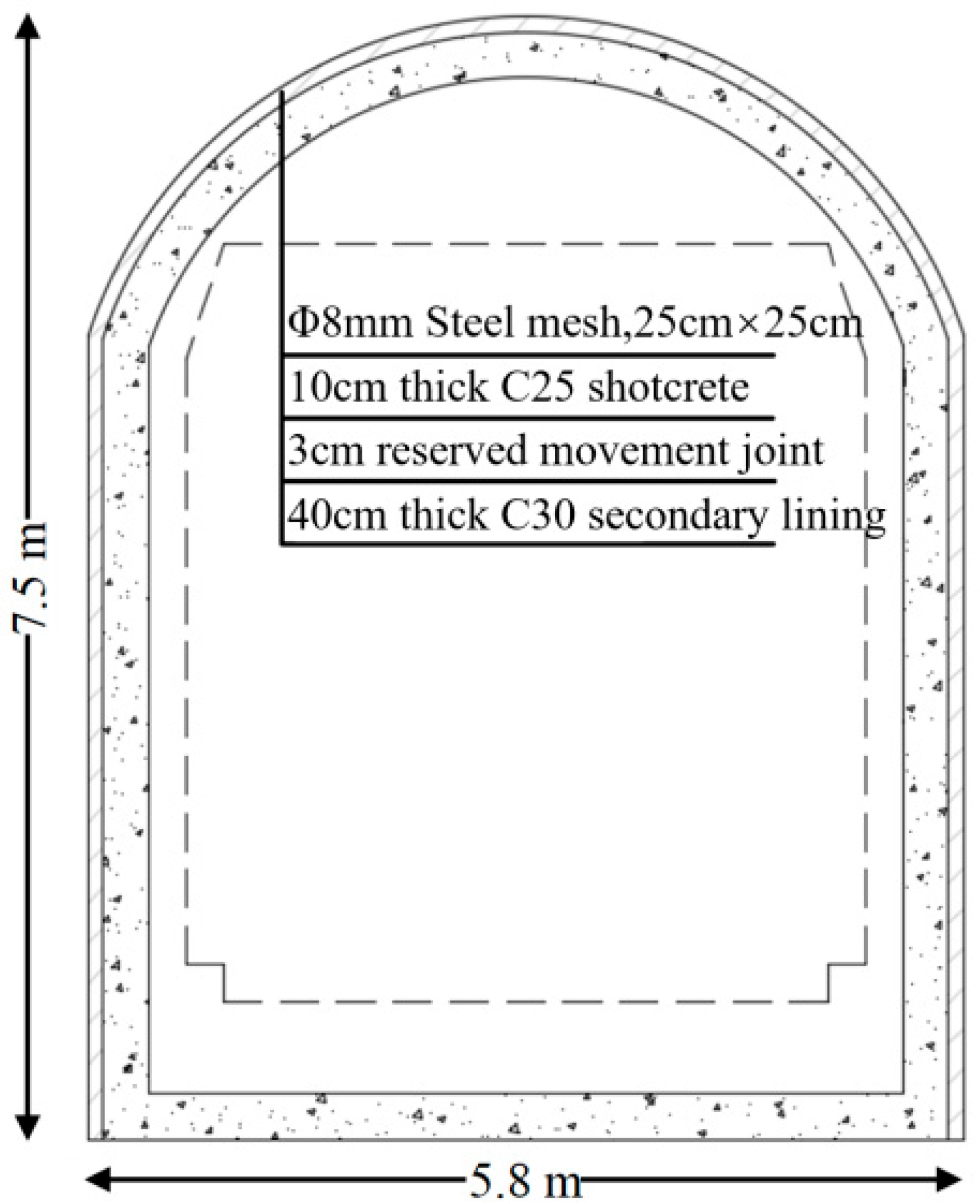

2. Overview of the Project

3. Numerical Computing Model

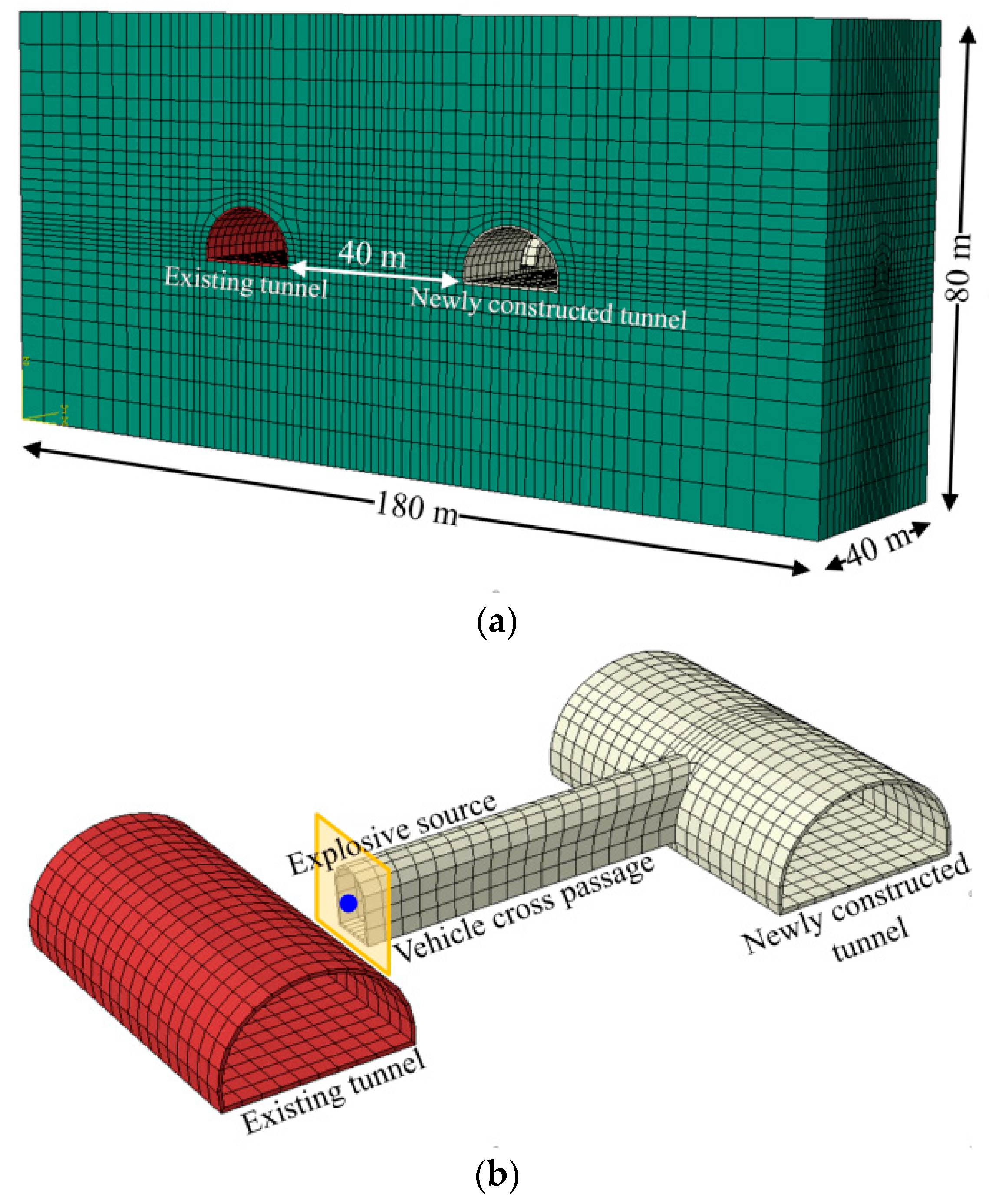

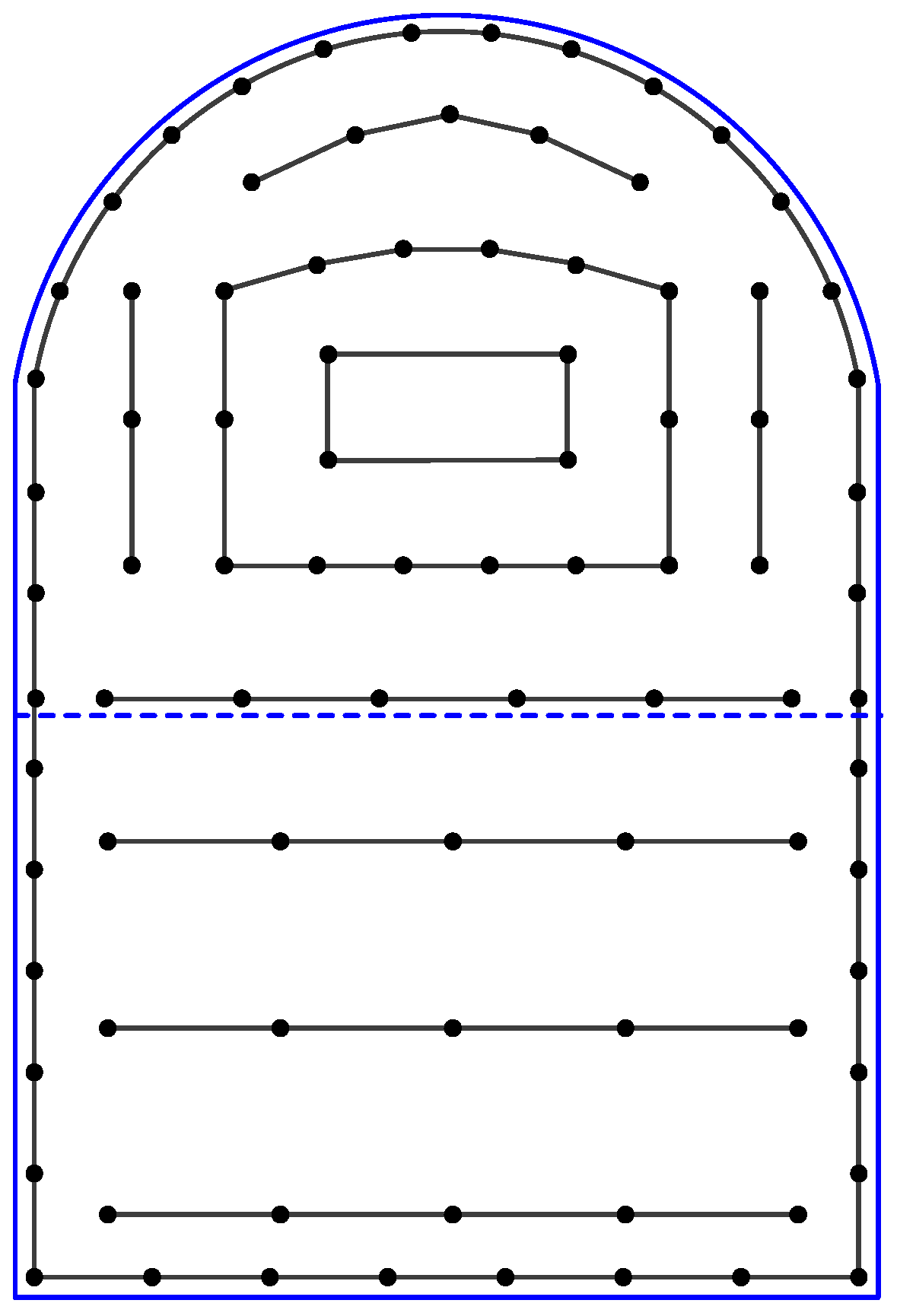

3.1. Model Establishment

3.1.1. Fundamental Model and Boundary Conditions

3.1.2. Computational Parameters

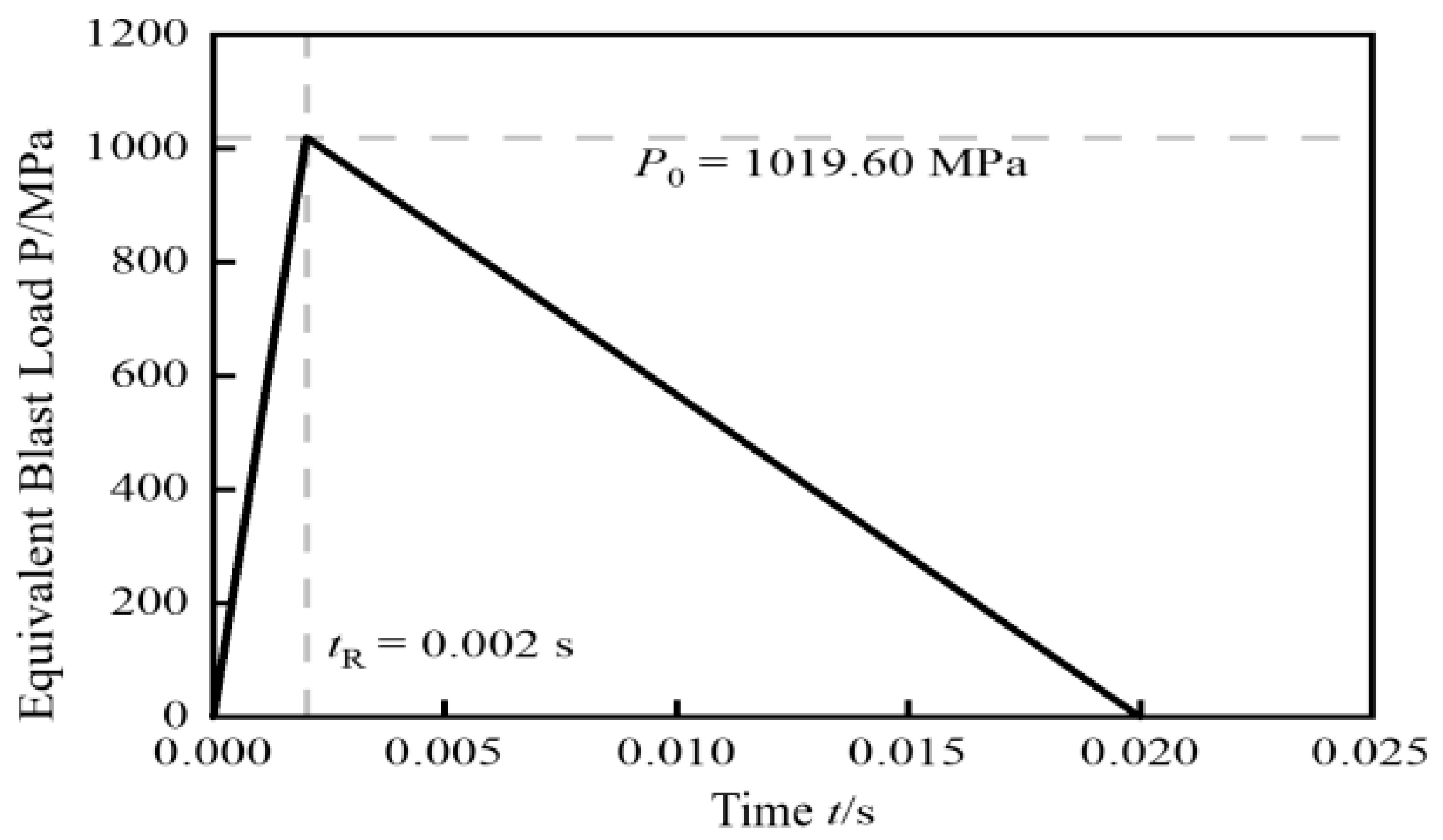

3.2. Simulation of Transverse Tunnel Blasting Construction

3.2.1. Construction Plan

3.2.2. Blasting Equivalent Load

4. Analysis of Results

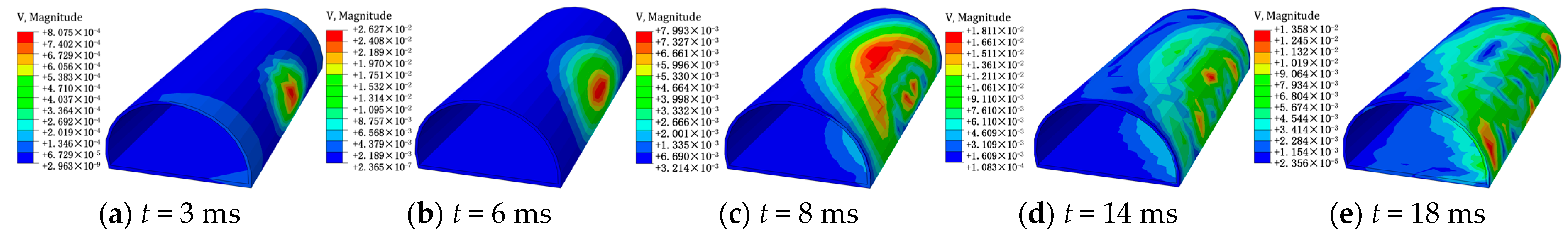

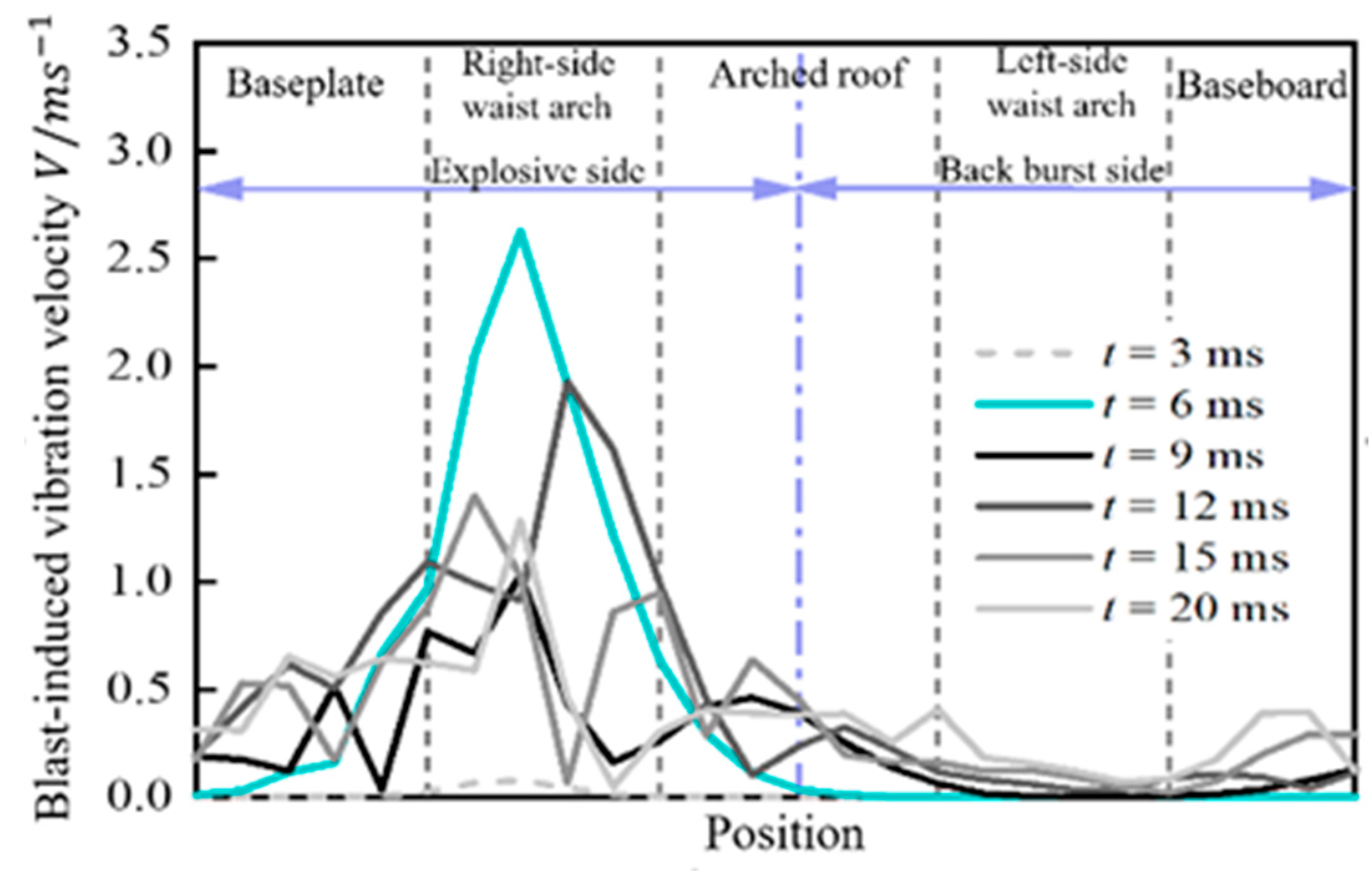

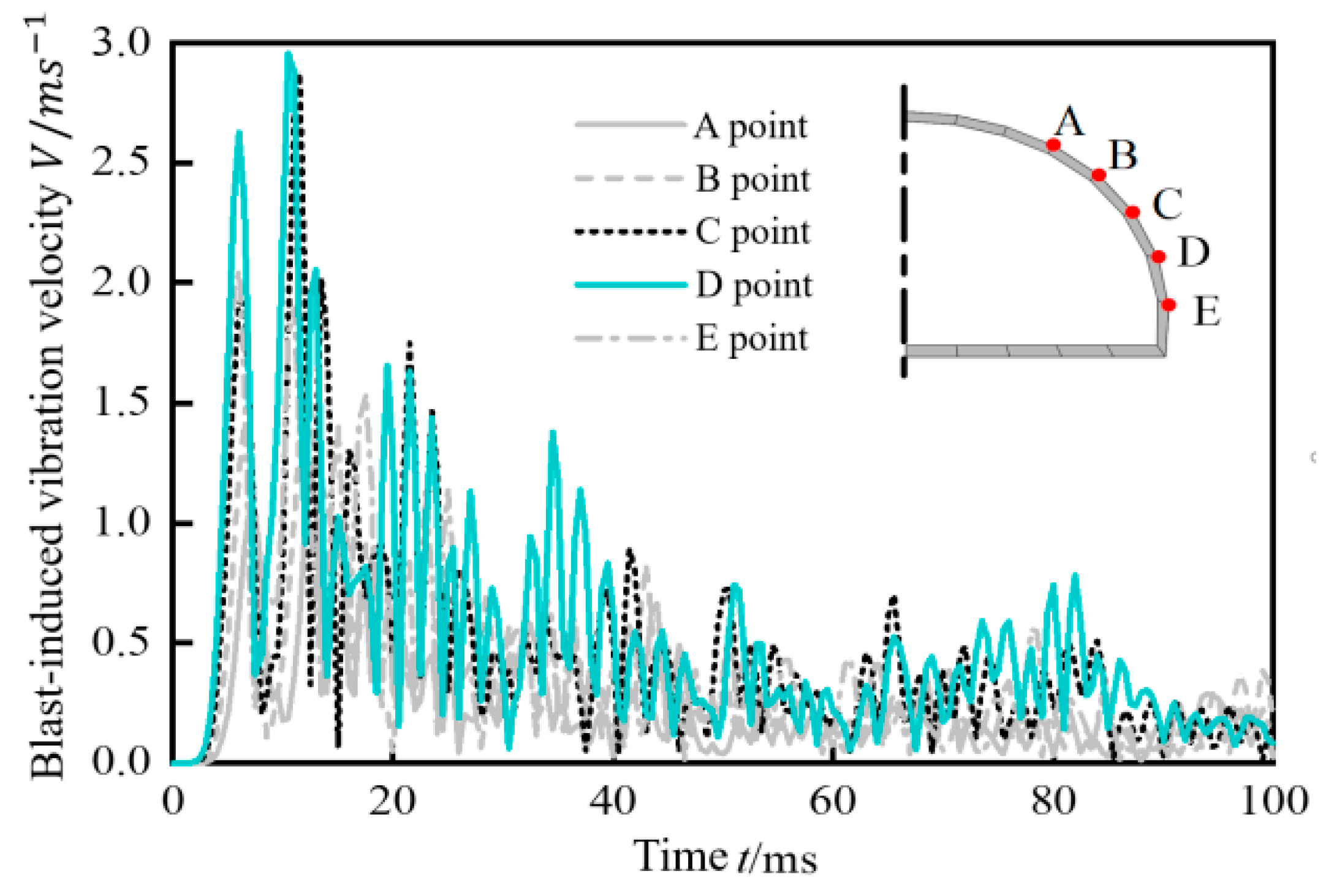

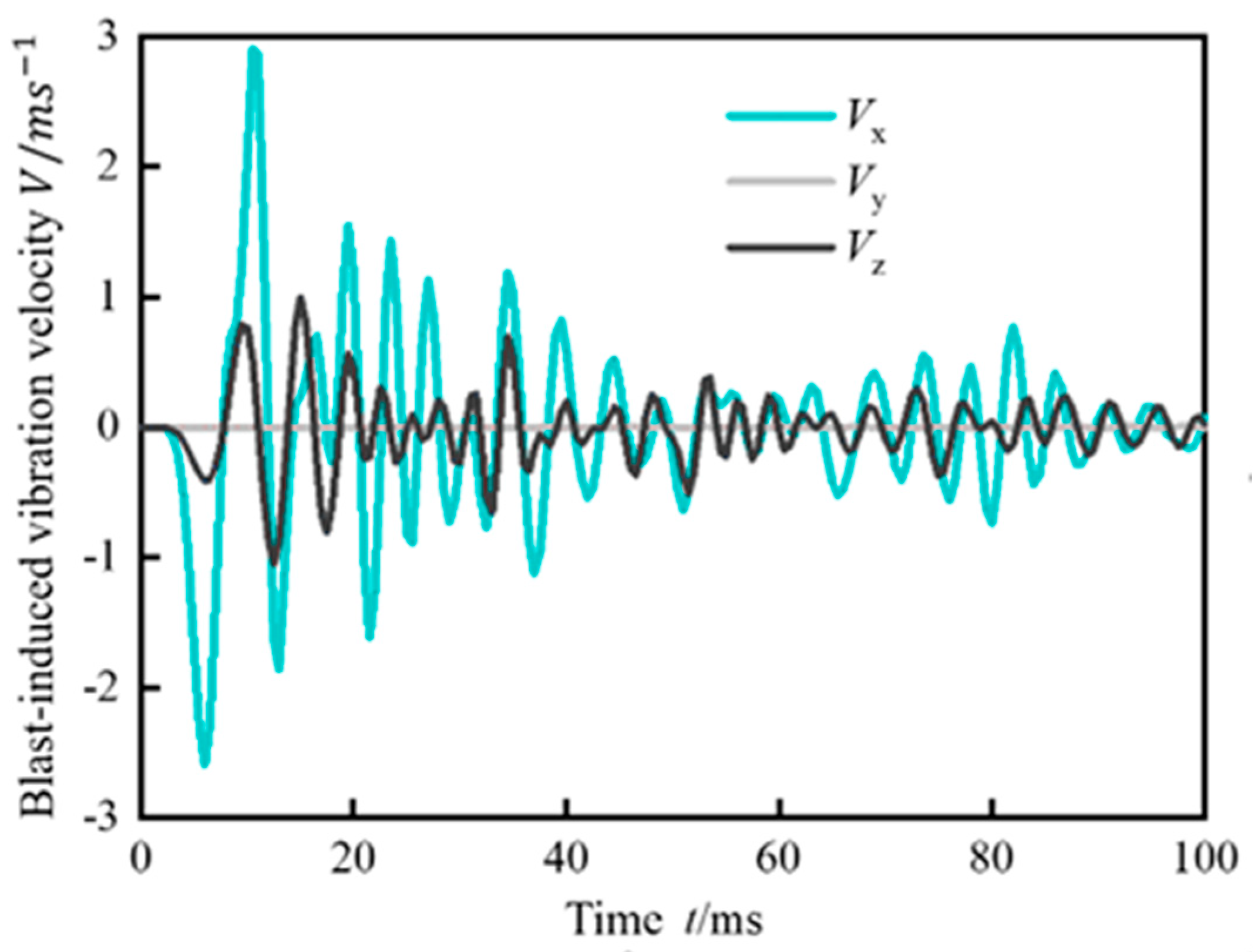

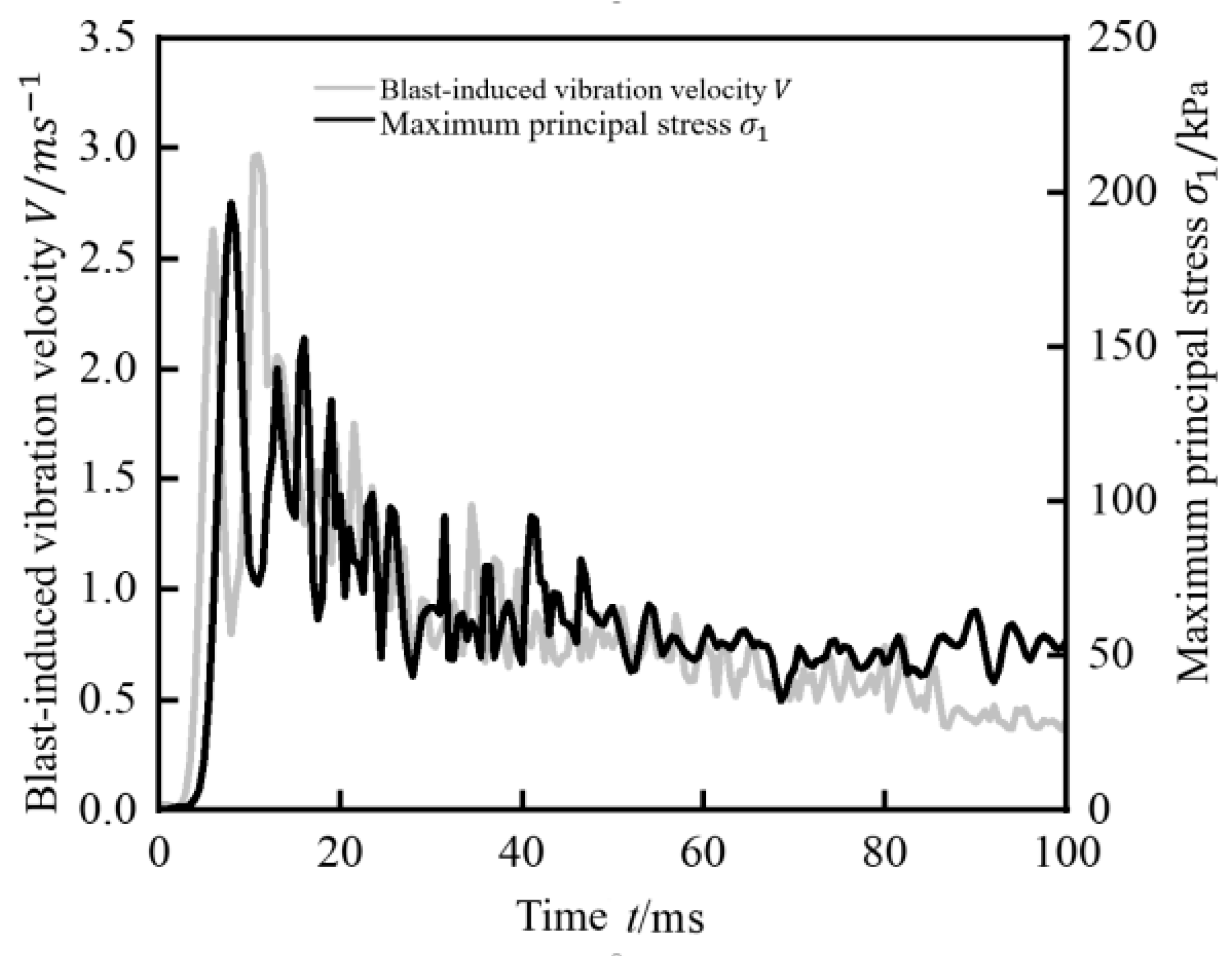

4.1. Vibration Velocity of the Existing Lining

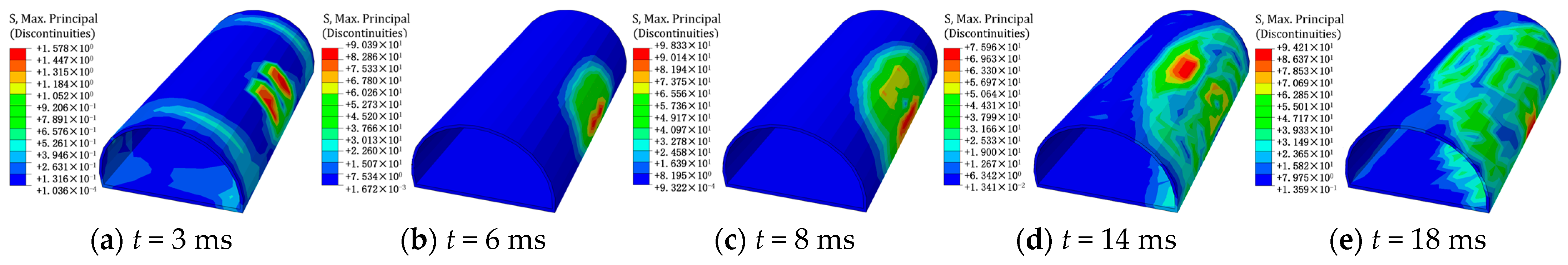

4.2. Stress on the Existing Lining

5. Exploring the Rational Clear Distance from the Excavation Face: A Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.C.; Lin, C.M.; Li, J.S.; Dong, Y.; Shen, Y. Development status and prospect of highway tunnel rehabilitation and expansion in China. Tunn. Constr. 2022, 42, 570–585. [Google Scholar]

- Huang, L.; Ma, J.; Lei, M.; Liu, L.; Lin, Y.; Zhang, Z. Soil-water inrush induced shield tunnel lining damage and its stabilization: A case study. Tunn. Undergr. Space Technol. 2020, 97, 103290. [Google Scholar] [CrossRef]

- Bai, G.Q.; Li, Z.H.; Zhang, T. Exploration and discussion on the setting of cross passages between new and old tunnels of highway reconstruction and extension project. Mod. Tunn. Technol. 2019, 56, 21–27. [Google Scholar]

- Clough, L.G.; Clubley, S.K. Steel column response to thermal and long duration blast loads inside an air blast tunnel. Struct. Infrastruct. Eng. 2019, 15, 1510–1528. [Google Scholar] [CrossRef]

- Sun, T.J.; Wang, W.; Luo, R.M. Influences of different lining structure defects on overall safety of tunnel structure. J. Archit. Civ. Eng. 2017, 34, 82–90. [Google Scholar]

- Wang, W.; Jiang, H.; Yuan, Q. Numerical analysis of dynamic response of existing lining under close tunnel blasting. Eng. Blasting 2022, 28, 33–39. [Google Scholar]

- Qian, Y.F.; Wang, X.H. Study on safety influence of blasting construction close to existing tunnel. J. Beijing Jiaotong Univ. 2014, 38, 90–96. [Google Scholar]

- Torano, J.; Rodríguez, R.; Diego, I.; Rivas, J.M.; Casal, M.D. FEM models including randomness and its application to the blasting vibrations prediction. Comput. Geotech. 2006, 33, 15–28. [Google Scholar] [CrossRef]

- Ma, J.; Chen, J.; Guan, J.; Lin, Y.; Chen, W.; Huang, L. Implementation of Johnson-Holmquist-Beissel model in four-dimensional lattice spring model and its application in projectile penetration. Int. J. Impact Eng. 2022, 170, 104340. [Google Scholar] [CrossRef]

- Xu, M.; Li, X.; Liu, T.; Luo, Y.; Huang, J.; Wang, G.; Gao, W. A study on hollow effect and safety design of deep crossing Caverns under blasting vibration. Tunn. Undergr. Space Technol. 2021, 111, 103866. [Google Scholar] [CrossRef]

- Blair, D.P. Blast vibration dependence on charge length, velocity of detonation and layered media. Int. J. Rock Mech. Min. Sci. 2014, 65, 29–39. [Google Scholar] [CrossRef]

- Wang, D.K.; Luo, J.J.; Gao, L.P. Analysis of reasonable spacing of large underground caverns based on blasting equivalent load. J. Cent. South Univ. 2022, 53, 2224–2233. [Google Scholar]

- Abuov, M.G.; Aitaliev, S.M.; Ermekov, T.M.; Zhanbyrbaev, N.B.; Kayupov, M.A. Studies of the effect of dynamic processes during explosive break-out upon the roof of mining excavations. Sov. Min. Sci. 1988, 24, 581–590. [Google Scholar] [CrossRef]

- Carter, J.P.; Booker, J.R. Sudden excavation of a long circular tunnel in elastic ground. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1990, 27, 129–132. [Google Scholar] [CrossRef]

- Lu, W.B.; Geng, X.; Chen, M.; Shu, D.Q.; Zhou, C.B. Study of selection of excavation procedure and contour blasting method for deep underground powerhouse. Chin. J. Rock Mech. Eng. 2011, 30, 1531–1539. [Google Scholar]

- Lu, W.; Yang, J.; Chen, M.; Zhou, C. Mechanism and equivalent numerical simulation of transient release of excavation load for deep tunnel. Chin. J. Rock Mech. Eng. 2011, 30, 1089–1096. [Google Scholar]

- Jun, H.U.; Zhong, L. Exploration for open-pit mine blasting load equivalent way. Met. Mine 2014, 43, 37–41. [Google Scholar]

- Chen, S.G.; Zhao, J.; Zhou, Y.X. UDEC modeling of a field explosion test. Fragblast 2000, 4, 149–163. [Google Scholar] [CrossRef]

- Luo, Y.; Yang, J.H.; Hu, D.R. Study on the Impact of Blasting Vibration on Surrounding Rock of Small Clearance Tunnels. Chin. J. Undergr. Space Eng. 2021, 17, 1309–1314. [Google Scholar]

- Zhang, C.F.; Qin, T.G.; Zhang, X. Study on Effect of Blasting Vibration on Underground Caverns. Blasting 2022, 39, 56–63. [Google Scholar]

- Wang, X.Q.; Huang, Y.B.; Peng, L.M.; Chen, J.W.; Lei, M.F. Study on full-time load function of tunnel blasting and its application. J. Railw. Sci. Eng. 2019, 16, 144–151. [Google Scholar]

- Gu, Y.; Liu, J.B.; Du, Y.X. 3D consistent viscous-spring artificial boundary and viscous-spring boundary element. Eng. Mech. 2007, 24, 31–37. [Google Scholar]

- JTG/T D70-2010; Guidelines for Design of Highway Tunnel. Ministry of Transport of the People’s Republic of China: Beijing, China; China Communications Publishing & Media Management Co., Ltd.: Beijing, China, 2010.

- GB 50010-2010; Code for Design of Concrete Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China, State Administration for Market Regulation: Beijing, China; Architecture & Building Press: Beijing, China, 2010.

- Ramadas, C.; Balasubramaniam, K.; Hood, A.; Joshi, M.; Krishnamurthy, C.V. Modelling of attenuation of Lamb waves using Rayleigh damping: Numerical and experimental studies. Compos. Struct. 2011, 93, 2020–2025. [Google Scholar] [CrossRef]

- Lin, Y.X.; Lai, Z.S.; Ma, J.J.; Huang, L.C.; Lei, M.F. A FDEM approach to study mechanical and fracturing responses of geo-materials with high inclusion contents using a novel reconstruction strategy. Eng. Fract. Mech. 2023, 282, 109171. [Google Scholar] [CrossRef]

- Lin, Y.; Yin, Z.Y.; Wang, X.; Huang, L. A systematic 3D simulation method for geomaterials with block inclusions from image recognition to fracturing modelling. Theor. Appl. Fract. Mech. 2021, 117, 103194. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, X.; Ma, J.; Huang, L. A finite-discrete element based appoach for modelling the hydraulic fracturing of rocks with irregular inclusions. Eng. Fract. Mech. 2022, 261, 108209. [Google Scholar] [CrossRef]

- JTG/T F60-2009; Technical Guidelines for Construction of Highway Tunnel. Ministry of Transport of the People’s Republic of China: Beijing, China; China Communications Publishing & Media Management Co., Ltd.: Beijing, China, 2009.

| Part | Blasthole Name | Blasting Caps per Blasthole | Blasthole Depth (m) | Number of Holes | Charge Weight per Blasthole (kg) | Explosive Amount per Blasthole (kg) | Advance per Round (m) | Blasthole Utilization Rate (%) | Total Charge Weight (kg) | Total Number of Blast Holes | Explosive Specific Consumption Rate (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Berm construction | Drift hole | 1 | 1.8 | 4 | 1.05 | 4.20 | 1.5 | 85 | 27.60 | 55 | 1.2 |

| Auxiliary hole | 3 | 1.7 | 14 | 0.75 | 10.50 | ||||||

| Auxiliary hole | 5 | 1.7 | 6 | 0.60 | 3.60 | ||||||

| Auxiliary hole | 7 | 1.7 | 5 | 0.60 | 3.00 | ||||||

| Peripheral hole | 9 | 1.7 | 20 | 0.45 | 0.90 | ||||||

| Bottom plate hole | 11 | 1.7 | 6 | 0.90 | 5.40 | ||||||

| Berm removal | Auxiliary hole | 1 | 1.7 | 5 | 0.75 | 3.75 | 1.5 | 88 | 16.65 | 33 | 0.7 |

| Auxiliary hole | 3 | 1.7 | 5 | 0.75 | 3.75 | ||||||

| Auxiliary hole | 5 | 1.7 | 5 | 0.75 | 3.75 | ||||||

| Peripheral hole | 7 | 1.7 | 18 | 0.45 | 5.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Liang, G.; Liang, Y.; Zhang, Z.; Xiao, C. Dynamic Responses of a Coupled Tunnel with Large Span and Small Clear Distance under Blasting Load of the Construction of Transverse Passage. Appl. Sci. 2023, 13, 8599. https://doi.org/10.3390/app13158599

Zhang W, Liang G, Liang Y, Zhang Z, Xiao C. Dynamic Responses of a Coupled Tunnel with Large Span and Small Clear Distance under Blasting Load of the Construction of Transverse Passage. Applied Sciences. 2023; 13(15):8599. https://doi.org/10.3390/app13158599

Chicago/Turabian StyleZhang, Wu, Guanglin Liang, Yu Liang, Zhongjie Zhang, and Chuanyu Xiao. 2023. "Dynamic Responses of a Coupled Tunnel with Large Span and Small Clear Distance under Blasting Load of the Construction of Transverse Passage" Applied Sciences 13, no. 15: 8599. https://doi.org/10.3390/app13158599

APA StyleZhang, W., Liang, G., Liang, Y., Zhang, Z., & Xiao, C. (2023). Dynamic Responses of a Coupled Tunnel with Large Span and Small Clear Distance under Blasting Load of the Construction of Transverse Passage. Applied Sciences, 13(15), 8599. https://doi.org/10.3390/app13158599