Modeling Investigation of Groove Effect on the Multipactor of Dielectric-Loaded Coaxial Low-Pass Filters

Abstract

1. Introduction

2. Modeling and Simulation Methods

2.1. Design of the Verification Device

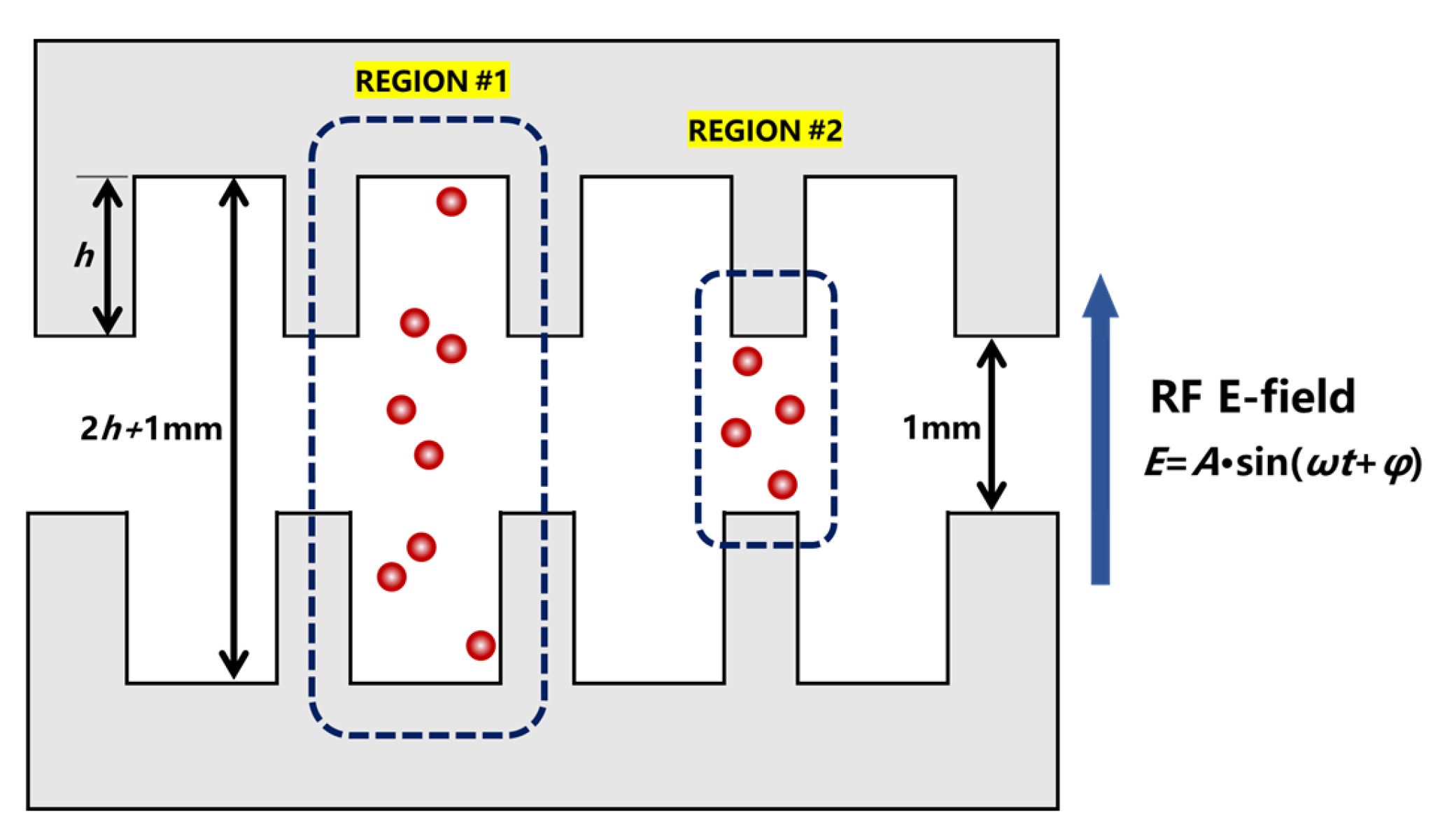

2.2. Multipactor Simulation for the SCLPF with Flat Dielectric Loaded

3. Simulation Verification

3.1. The Groove Effect on the Multipactor Threshold

3.2. The Effect of Groove Number on the Multipactor Threshold

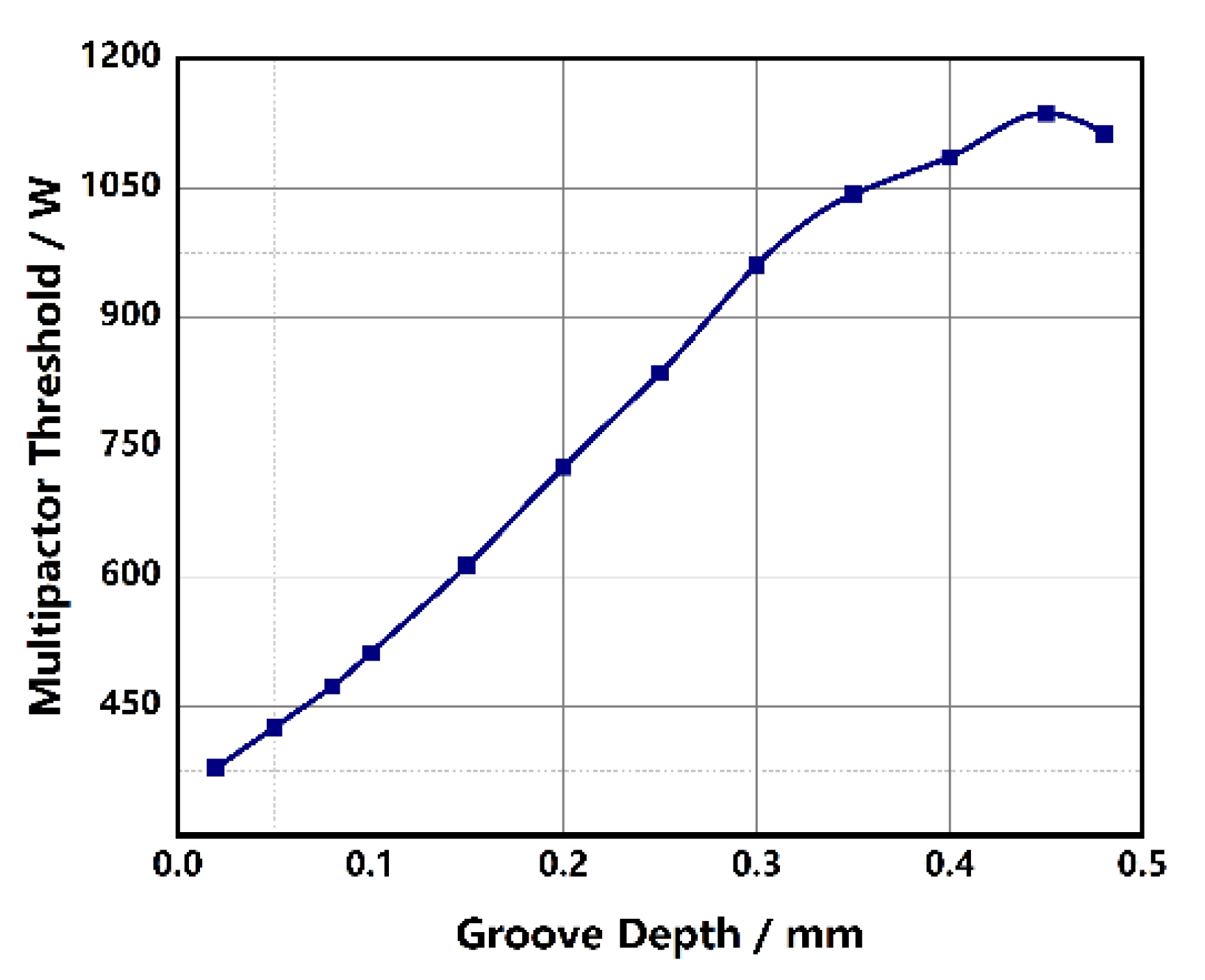

3.3. The Effect of Groove Depth on the Multipactor Threshold

3.4. The Effect of Multiple Factors on the Multipactor Threshold

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vaughan, J.R.M. Multipactor. IEEE Trans. Electron Devices 1988, 35, 1172–1180. [Google Scholar] [CrossRef]

- Lara, J.; Perez, F.; Alfonseca, M.; Galan, L.; Montero, I.; Roman, E.; Garcia-Baquero, D.R. Multipactor prediction for on-board spacecraft RF equipment with the MEST software tool. IEEE Trans. Plasma Sci. 2006, 34, 476–484. [Google Scholar] [CrossRef]

- Dong, Y.; Liu, Q.X.; Pang, J.; Zhou, H.J.; Dong, Z.W. Influence of secondary electron yield of material on two-sided multipactor discharge in cavity. Acta Phys. Sin. 2018, 67, 037901. [Google Scholar] [CrossRef]

- Raboso, D. Multipactor breakdown: Present status and where are we heading. In Proceedings of the 6th International Workshop on Multipactor Corona and Passive Intermodulation, Valencia, Spain, 1 September 2008. [Google Scholar]

- Chang, C.; Liu, Y.S.; Verboncoeur, J.; Chen, C.H.; Guo, L.T.; Li, S.; Wu, X.L. The effect of periodic wavy profile on suppressing window multipactor under arbitrary electromagnetic mode. Appl. Phys. Lett. 2015, 106, 014102. [Google Scholar] [CrossRef]

- Fil, N.; Belhaj, M.; Hillairet, J.; Puech, J. Multipactor threshold sensitivity to total electron emission yield in small gap waveguide structure and TEEY models accuracy. Phys. Plasmas 2016, 23, 123118. [Google Scholar] [CrossRef]

- Geng, R.L.; Padamsee, H.; Shemelin, V. Multipacting in a Rectangular Waveguide. In Proceedings of the 2001 Particle Accelerator Conference (Cat. No.01CH37268), Chicago, IL, USA, 18–22 June 2001; pp. 1228–1230. [Google Scholar] [CrossRef][Green Version]

- Riyopoulos, S. Multipactor with electric field retarding secondary emission. Phys. Plasmas 1998, 5, 305–311. [Google Scholar] [CrossRef]

- Hueso, J.; Vicente, C.; Gimeno, B.; Boria, V.E.; Marini, S.; Taroncher, M. Multipactor Effect Analysis and Design Rules for Wedge-Shaped Hollow Waveguides. IEEE Trans. Electron Devices 2010, 57, 3508–3517. [Google Scholar] [CrossRef]

- Wang, D.; He, Y.N.; Cui, W.Z. Secondary electron emission characteristics of TiN coatings produced by RF magnetron sputtering. J. Appl. Phys. 2018, 124, 053301. [Google Scholar] [CrossRef]

- Pimpec, F.L.; Kirby, R.E.; King, F.; Pivi, M. Properties of TiN and TiZrV thin film as a remedy against electron cloud. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2005, 551, 187–199. [Google Scholar] [CrossRef]

- Henrist, B.; Hilleret, N.; Scheuerlein, C.; Taborelli, M. The secondary electron yield of TiZr and TiZrV non-evaporable getter thin film coatings. Appl. Surf. Sci. 2001, 172, 95–102. [Google Scholar] [CrossRef]

- Le Pimpec, F.; Kirby, R.E.; King, F.K.; Pivi, M. The effect of gas ion bombardment on the secondary electron yield of TiN, TiCN and TiZrV coatings for suppressing collective electron effects in storage rings. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2006, 564, 44–50. [Google Scholar] [CrossRef]

- Pinto, P.C.; Calatroni, S.; Neupert, H.; Letant-Delrieux, D.; Edwards, P.; Chiggiato, P.; Taborelli, M.; Vollenberg, W.; Yin-Vallgren, C.; Colaux, J.L.; et al. Carbon coatings with low secondary electron yield. Vacuum 2013, 98, 29–36. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Xu, Y.H.; Zhang, Y.X.; Zhang, B.; Wei, W. Secondary electron emission characteristics of graphene films with copper substrate. Chin. Phys. C 2016, 40, 117003. [Google Scholar] [CrossRef]

- Cao, M.; Zhang, X.S.; Liu, W.H.; Wang, H.G.; Li, Y.D. Secondary electron emission of graphene-coated copper. Diam. Relat. Mater. 2017, 73, 199–203. [Google Scholar] [CrossRef]

- Ye, M.; He, Y.N.; Wang, R.; Hu, T.C.; Zhang, N.; Yang, J.; Cui, W.Z.; Zhang, Z.B. Suppression of secondary electron emission by micro-trapping structure surface. Acta Phys. Sin. 2014, 63, 147901. [Google Scholar] [CrossRef]

- Wang, D.; Ye, M.; Feng, P.; He, Y.N.; Cui, W.Z. An effective reduction on secondary electron emission yield of gold coated surfaces by laser etching. Acta Phys. Sin. 2019, 68, 067901. [Google Scholar] [CrossRef]

- Nistor, V.; González, L.A.; Aguilera, L.; Montero, I.; Galan, L.; Wochner, U.; Raboso, D. Multipactor suppression by micro-structured gold/silver coatings for space applications. Appl. Surf. Sci. 2014, 315, 445–453. [Google Scholar] [CrossRef]

- Valizadeh, R.; Malyshev, O.B.; Wang, S.; Zolotovskaya, S.A.; Gillespie, W.A.; Abdolvand, A. Low secondary electron yield engineered surface for electron cloud mitigation. Appl. Phys. Lett. 2014, 105, 231605. [Google Scholar] [CrossRef]

- Cummings, K.A.; Risbud, S.H. Dielectric materials for window applications. J. Phys. Chem. Solids 2000, 61, 551–560. [Google Scholar] [CrossRef]

- Vague, J.; Melgarejo, J.C.; Guglielmi, M.; Boria, V.E.; Anza, S.; Vicente, C.; Rocio, M.M.; Maria, M.; Benito, G.M.; Raboso, D. Multipactor Effect Characterization of Dielectric Materials for Space Applications. IEEE Trans. Microw. Theory Tech. 2018, 66, 3644–3655. [Google Scholar] [CrossRef]

- Li, Y.; Wang, D.; Yu, M.; He, Y.N.; Cui, W.Z. Experimental Verification of Multipactor Discharge Dynamics Between Ferrite Dielectric and Metal. IEEE Trans. Electron Devices 2018, 65, 4592–4599. [Google Scholar] [CrossRef]

- Zhu, X.; Guo, J.J.; Li, X.X.; Zhou, R.D.; Wang, D.; Zhao, W. Evolvement Investigation of Secondary Electron Emission for Ultrathin MgO Coatings Prepared by Atomic Layer Deposition. Appl. Sci. 2021, 11, 4801. [Google Scholar] [CrossRef]

- Cao, W.W.; Wang, B.; Yang, Y.; Zhu, B.L.; Guo, J.J.; Xu, P.; Bai, X.H.; Qin, J.J.; Wang, C.; Zhu, J.P.; et al. Secondary electron emission characteristics of the Al2O3/MgO double-layer structure prepared by atomic layer deposition. Ceram Int. 2021, 47, 9866–9872. [Google Scholar] [CrossRef]

- Suharyanto, Y.; Yamano, S.; Kobayashi, S.; Michizono, S.; Saito, Y. Secondary electron emission and surface charging evaluation of alumina ceramics and sapphire. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 72–78. [Google Scholar] [CrossRef]

- Wang, D.; Mao, Z.S.; Ye, Z.; Cai, Y.H.; Li, Y.; He, Y.N.; Qi, K.C.; Xu, Y.N.; Jia, Q.Q. Ultralow electron emission yield achieved on alumina ceramic surfaces and the application in multipactor suppression. J. Phys. D Appl. Phys. 2022, 55, 455301. [Google Scholar] [CrossRef]

- Meng, X.C.; Wang, D.; Cai, Y.H.; Ye, Z.; He, Y.N.; Xu, Y.N. Secondary electron emission suppression on alumina surface and its application in multipactor suppression. Acta Phys. Sin. 2023, 72, 107901. [Google Scholar] [CrossRef]

- Pivi, M.; King, F.K.; Kirby, R.E.; Raubenheimer, T.O.; Stupakov, G.; Le Pimpec, F. Sharp reduction of the secondary electron emission yield from grooved surfaces. J. Appl. Phys. 2008, 104, 104904. [Google Scholar] [CrossRef]

- Vague, J.J.; Asensio, I.; Coves, A.; San Blas, A.A.; Reglero, M.; Pantaleoni, A.V.; Raboso, D.; Baquero-Escudero, M.; Boria, V.E. Study of the Multipactor Effect in Groove Gap Waveguide Technology. IEEE Trans. Microw. Theory Tech. 2022, 70, 2566–2578. [Google Scholar] [CrossRef]

- Swanson, C.; Kaganovich, I.D. Modeling of reduced effective secondary electron emission yield from a velvet surface. J. Appl. Phys. 2016, 120, 213302. [Google Scholar] [CrossRef]

- Swanson, C.; Kaganovich, I.D. “Feathered” fractal surfaces to minimize secondary electron emission for a wide range of incident angles. J. Appl. Phys. 2017, 122, 043301. [Google Scholar] [CrossRef]

- Swanson, C.; Kaganovich, I.D. Modeling of reduced secondary electron emission yield from a foam or fuzz surface. J. Appl. Phys. 2018, 123, 023302. [Google Scholar] [CrossRef]

- Matthaei, G.; Young, L.; Jones, E.M. Microwave Filters, Impedance-Matching Networks, and Coupling Structures; Artech House: Norwood, MA, USA, 1980. [Google Scholar]

- David, M.P. Microwave Engineering, 4th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012. [Google Scholar]

- Automatic Optimization|CST. Available online: https://www.3ds.com/products-services/simulia/products/cst-studio-suite/optimization/ (accessed on 10 July 2023).

- Christopher, M.K.; Charlotte, B.; Hsueh-Yung, C. Multipaction Breakdown Simulation of Mated Coaxial Assemblies Utilizing Heterogeneous SEY Boundaries. In Proceedings of the International Workshop on Multipactor, Corona and Passive Intermodulation, Valencia, Spain, 19–21 October 2022. [Google Scholar]

- Stephen, A.S.; Preston, T.P. Measurement and Simulation of Partially-Unseated TNC Multipactor Thresholds. In Proceedings of the International Workshop on Multipactor, Corona and Passive Intermodulation, Valencia, Spain, 19–21 October 2022. [Google Scholar]

- Spark3D. Available online: https://www.3ds.com/products-services/simulia/products/spark3d/ (accessed on 10 July 2023).

- Guo, J.J.; Wang, D.; Xu, Y.T.; Zhu, X.P.; Wen, K.L.; Miao, G.H.; Cao, W.W.; Si, J.H.; Lu, M.; Guo, H.T. Secondary electron emission characteristics of Al2O3 coatings prepared by atomic layer deposition. AIP Adv. 2019, 9, 095303. [Google Scholar] [CrossRef]

- Cai, Y.H.; Wang, D.; Zhang, W.; He, Y.N. Seesaw-type modulation of secondary electron emission characteristics of polytetrafluoroethylene-MgO composite coating. J. Vac. Sci. Technol. B 2022, 40, 044001. [Google Scholar] [CrossRef]

- Hatch, A.J.; Williams, H.B. The secondary electron resonance mechanism of low-pressure high-frequency gas breakdown. J. Appl. Phys. 1958, 25, 417–423. [Google Scholar] [CrossRef]

| Groove Number | Aspect Ratio | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.1 | 0.2 | 0.4 | 0.5 | 0.8 | 1 | 1.6 | 3 | 3.5 | 3.9 | |

| 3 | 417.95 | 441.39 | 568.33 | |||||||

| 7 | / | 472.64 | / | 710.89 | 960.91 | 1132.79 | ||||

| 13 | / | 425.76 | / | 558.58 | 738.25 | 851.53 | 1095.24 | |||

| 20 | / | 415.61 | / | 509.37 | 628.88 | 718.72 | 984.30 | 1164.04 | ||

| 26 | 378.89 | 400.77 | / | 484.36 | / | / | 955.06 | / | 1160.10 | 1136.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, J.; Zhao, Y.; Zhou, W.; Sun, B.; Zhang, J.; Wang, D.; Liu, Y.; Sun, T.; Zhang, X.; Tie, W. Modeling Investigation of Groove Effect on the Multipactor of Dielectric-Loaded Coaxial Low-Pass Filters. Appl. Sci. 2023, 13, 8586. https://doi.org/10.3390/app13158586

Shi J, Zhao Y, Zhou W, Sun B, Zhang J, Wang D, Liu Y, Sun T, Zhang X, Tie W. Modeling Investigation of Groove Effect on the Multipactor of Dielectric-Loaded Coaxial Low-Pass Filters. Applied Sciences. 2023; 13(15):8586. https://doi.org/10.3390/app13158586

Chicago/Turabian StyleShi, Jincheng, Yuchao Zhao, Weixiang Zhou, Baichang Sun, Jinbo Zhang, Dongliang Wang, Ying Liu, Teng Sun, Xiangtian Zhang, and Weihao Tie. 2023. "Modeling Investigation of Groove Effect on the Multipactor of Dielectric-Loaded Coaxial Low-Pass Filters" Applied Sciences 13, no. 15: 8586. https://doi.org/10.3390/app13158586

APA StyleShi, J., Zhao, Y., Zhou, W., Sun, B., Zhang, J., Wang, D., Liu, Y., Sun, T., Zhang, X., & Tie, W. (2023). Modeling Investigation of Groove Effect on the Multipactor of Dielectric-Loaded Coaxial Low-Pass Filters. Applied Sciences, 13(15), 8586. https://doi.org/10.3390/app13158586