Experimental Investigation of Mechanical Properties of Clay–Cement Slurry Containing Graphene Oxide

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Device

2.2. Materials

2.2.1. Clay–Cement Slurry

2.2.2. Stratum Selection

2.3. Methods

2.3.1. Sample Preparation

2.3.2. Testing Procedures

3. Results

3.1. Performance Analysis of Grouting Reinforcement

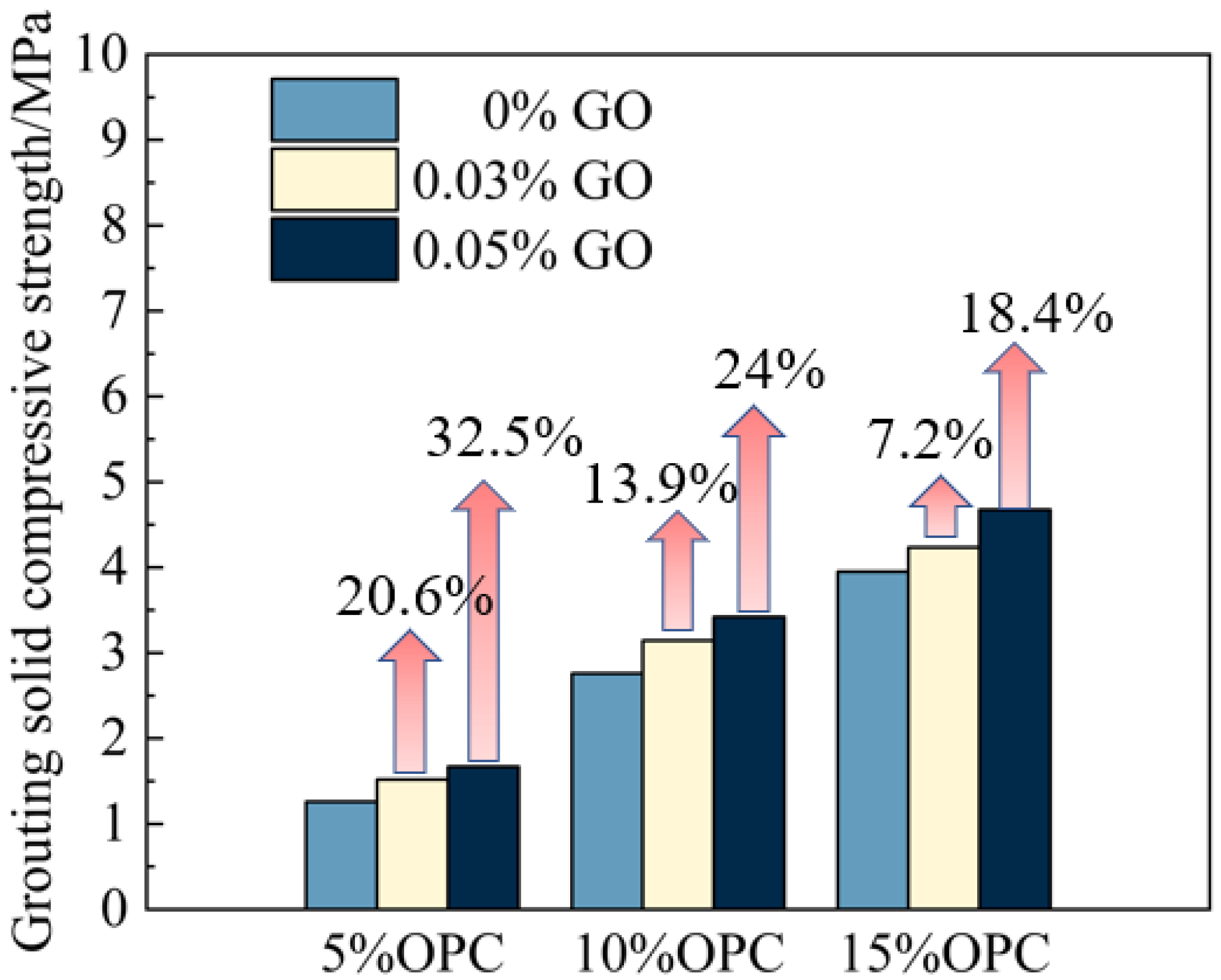

3.1.1. Uniaxial Compressive Strength

3.1.2. Shear Strength

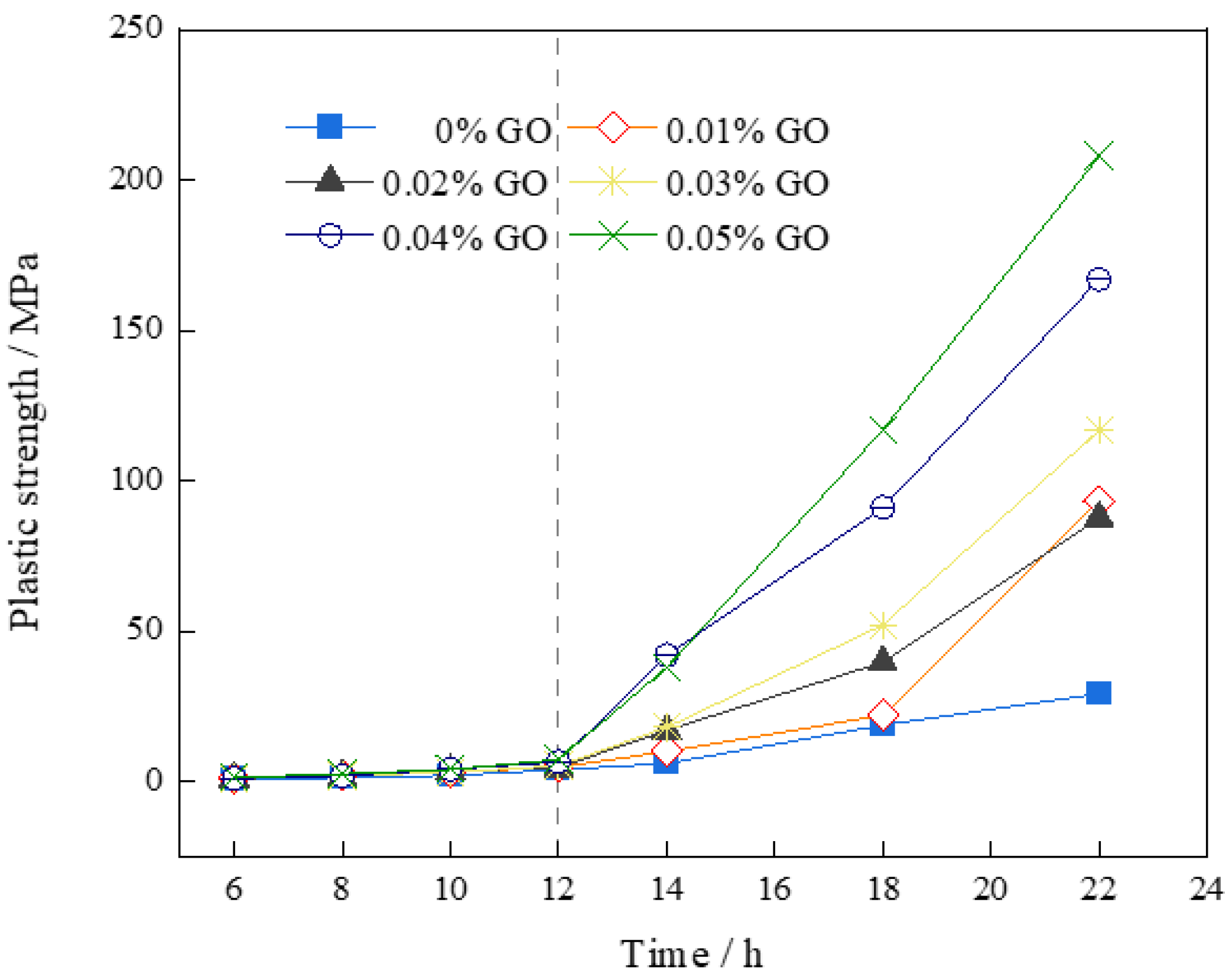

3.1.3. Plastic Strength of Slurry

3.2. Anti-Permeability Performance of Grouting Reinforcement

3.2.1. Range Analysis of Permeability Coefficient Test

3.2.2. Variance Analysis of Permeability Coefficient Test Results

3.2.3. Multiple Regression Analysis of Permeability Coefficient Influencing Factors

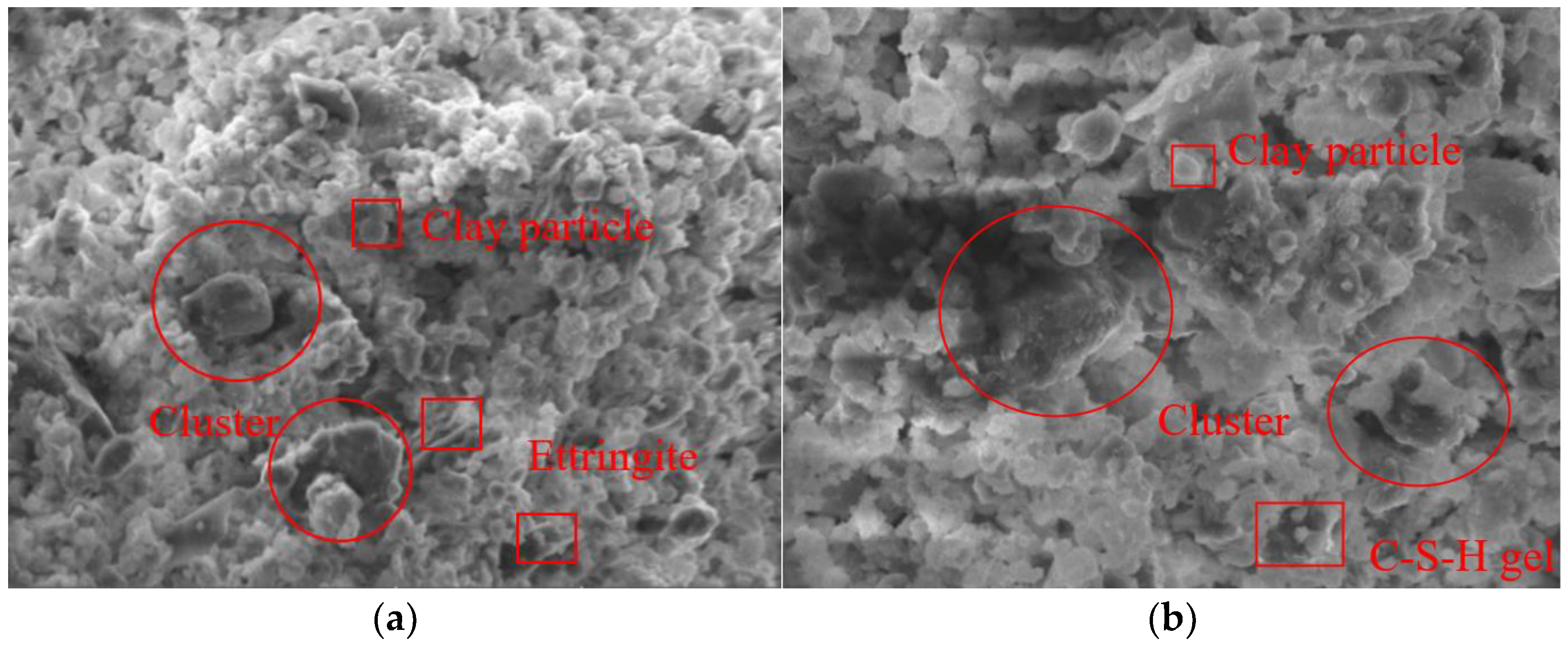

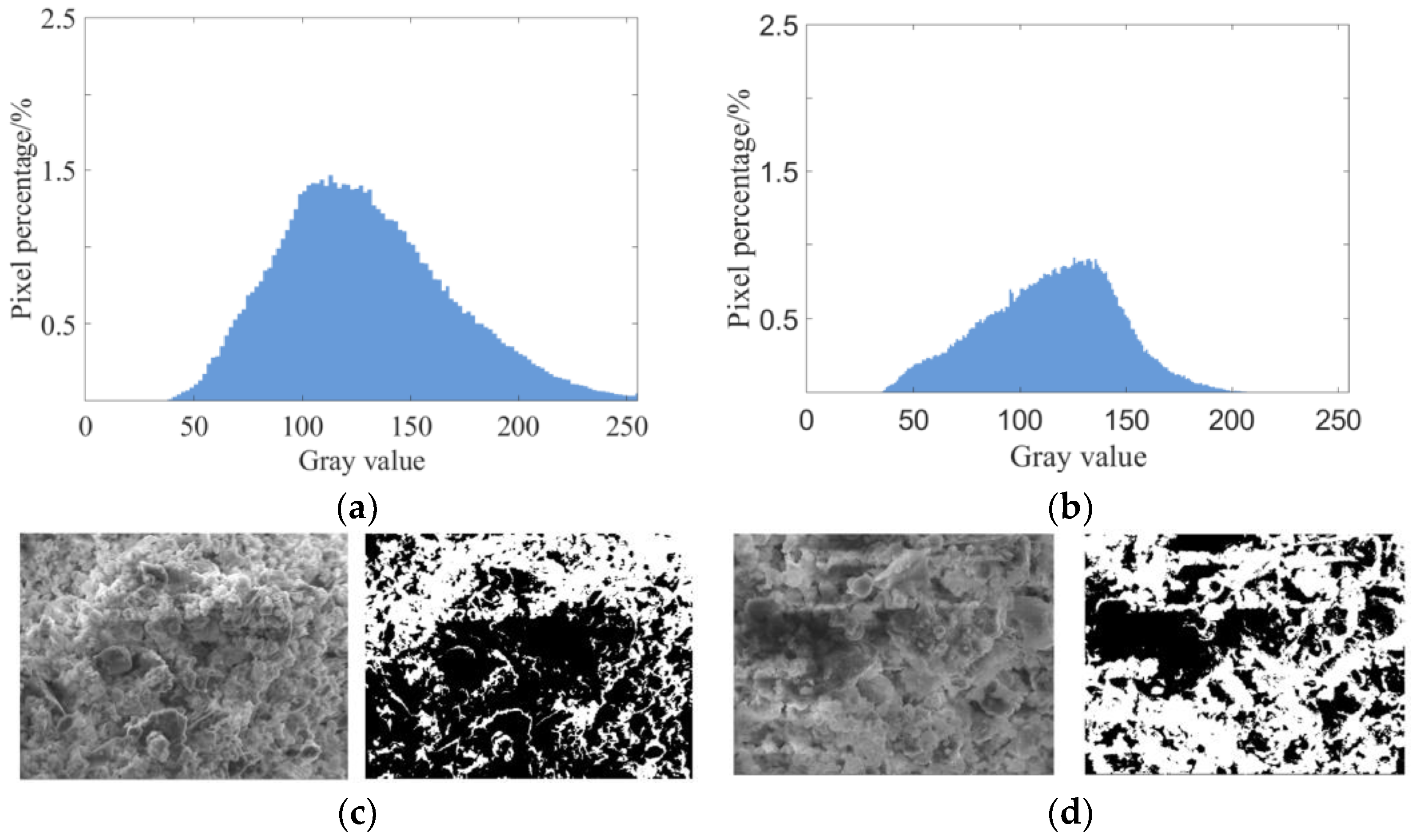

3.3. The Microstructural Characteristics of the Grout–Solid Interface

4. Conclusions

- (1)

- The addition of just 0.08wt% of industrial-grade oxidized graphene to reinforce fragmented gravel can increase the uniaxial compressive strength by 7.2% to 32.5% compared with traditional clay–cement slurries. This trend is observed across different mixing ratios. Increasing the content of oxidized graphene leads to higher uniaxial compressive and shear strengths, reaching a maximum near a 0.03% growth rate. Plastic strength slightly increases with the rise in oxidized graphene content within 12 h, but after 14 h, plastic strength is significantly enhanced. Industrial-grade oxidized graphene demonstrates a substantial effect on improving the mechanical properties of low-strength bound gravel, thus ensuring the safety of injection reinforcement.

- (2)

- Through orthogonal experiments, range analysis, variance analysis, and multiple regression analysis, it was determined that there is a strong correlation between the injection reinforcement body and three factors: OPC content, oxidized graphene (GO) content, and geological conditions. Among these factors, OPC content has the most significant impact on the permeability coefficient of the injection reinforcement body, followed by GO content, while geological conditions have the least influence. Industrial-grade oxidized graphene enhances the anti-seepage performance of the injection reinforcement body, contributes to early strength improvements, and ensures structural stability.

- (3)

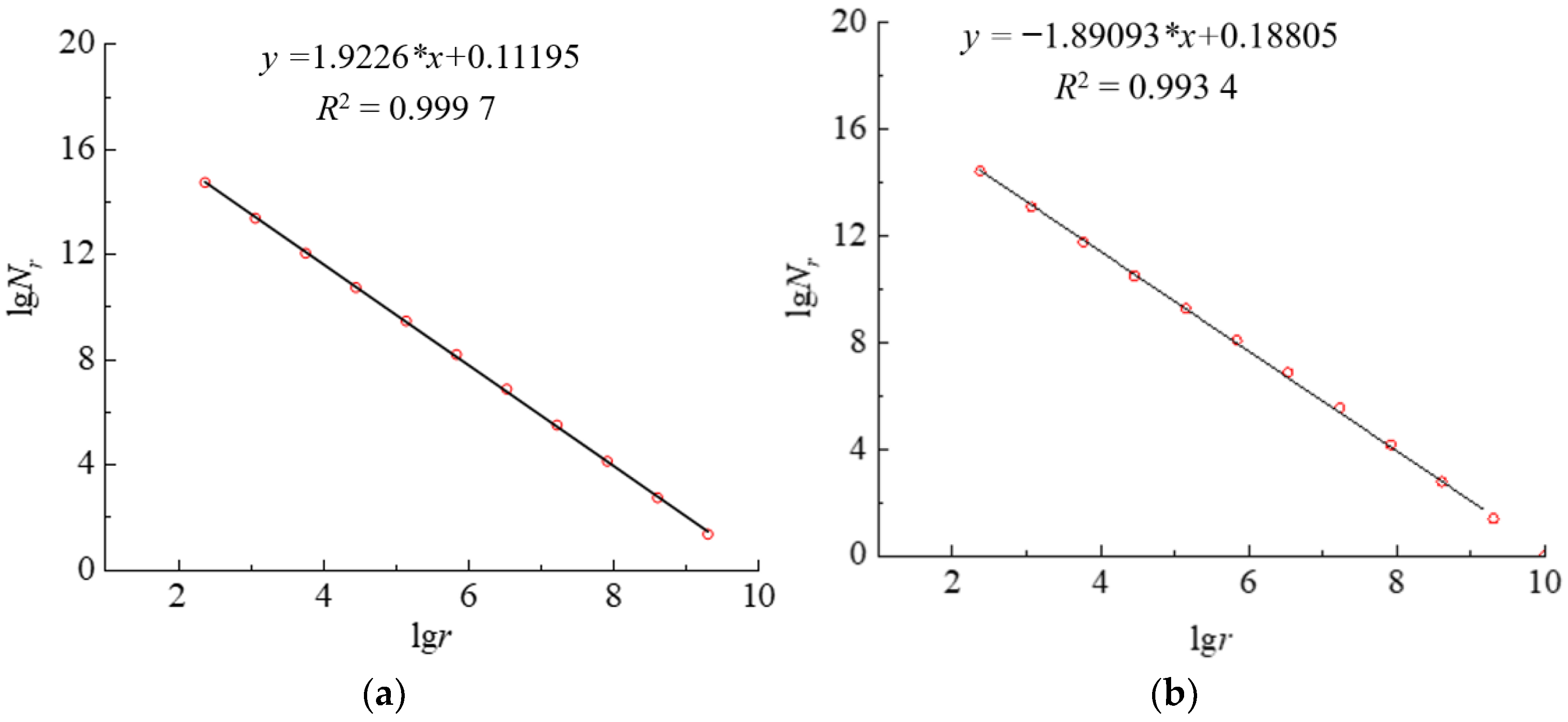

- SEM image characterization of the fractured surface further validates that the addition of oxidized graphene stimulates the formation of large-volume clay–cement particle aggregates, resulting in a dense aggregate skeleton, a mesh-like structure filled with clay particles, and a compact mineral structure. The GO-5 reinforcement exhibits advantages such as rational mineral composition, compact structure, and high interface bond strength compared with the GO-0 reinforcement. It guarantees excellent mechanical properties and long-term stability in water-rich environments. Calculation of the fractal box dimension shows that incorporating oxidized graphene into cement-based bonded materials can reduce the fractal box dimension of the fractured surface by 3% to 5%, confirming its role in enhancing the load-bearing capacity of specimens.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, G.; Cheng, X.S.; Zhou, H.Z. Resilient evaluation and control in geotechnical and underground engineering. China Civ. Eng. J. 2022, 55, 1–38. [Google Scholar]

- Xie, H.P. Research review of the state key research development program of China: Deep rock mechanics and mining theory. J. China Coal Soc. 2019, 5, 1283–1305. [Google Scholar]

- Zhang, H.W.; Jiang, H.; Liu, S.Q.; Zhao, Y.X.; Sun, X.P.; Ping, Q.; Liu, B.; Zhang, T. Mechanism of grouting diffusion and consolidation of rock mass based on D-Rb-C coupled model. J. China Coal Soc. 2023, 48, 1464–1475. [Google Scholar]

- Zhang, J.; Wang, C.; Li, Z.; Gao, Y.; Zhang, W. Experimental study on the engineering characteristics of red mud-based green high-performance grouting material. Chin. J. Rock Mech. Eng. 2022, 41, 3339–3352. [Google Scholar]

- Ma, J.; Sun, S.; Zhao, W.; Wang, L.; Ma, Y.; Liu, H.; Zhang, W.; Chen, H.; Chen, L.; Wei, Y. Review on China’s Traffic Tunnel Engineering Research: 2022. China J. Highw. Transp. 2022, 35, 1–40. [Google Scholar]

- Wang, Y.L.; Tang, H.Y.; Sun, J.X.; He, H.; Zhao, Y.J.; Wang, J.J. Effect of sodium sulfate and gypsum on performances of expansive grouting material with aluminum as expansion agent. Constr. Build. Mater. 2023, 394, 132212. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, P.; Yan, W. Grouting material development and dynamic grouting test of broken rock mass. J. Mater. Civ. Eng. 2022, 34, 04022072. [Google Scholar] [CrossRef]

- Yao, N.; Zhang, W.; Luo, B. Exploring on Grouting Reinforcement Mechanism of Expansive Slurry. Rock Mech. Rock Eng. 2023, 56, 4613–4627. [Google Scholar] [CrossRef]

- Liu, S.J.; Sun, J.Z.; Ding, Z.Y.; Zhang, J.W. Experimental Study on Performance of Graphene Oxide Modified Clay-cement Slurry. Met. Mine 2023, 3, 59–64. [Google Scholar]

- Zhang, Y.; Gao, G.R.; Gao, X.G. Theoretical analysis of clay-cement slurry diffusion mechanism considering time-dependent behavior of rheology parameters. Coal Eng. 2022, 5, 164–168. [Google Scholar]

- Yu, W.; Zhou, M.; Wan, X. Experimental study on physical properties of superfine cement grouting material. Front. Mater. 2022, 9, 1056135. [Google Scholar] [CrossRef]

- Mokhtar, M.M.; Abo-El-Enein, S.A.; Hassaan, M.Y. Mechanical performance, pore structure and micro-structural characteristics of graphene oxide nano platelets reinforced cement. Constr. Build. Mater. 2017, 138, 333–339. [Google Scholar] [CrossRef]

- Wang, K.; Li, S.C.; Yang, L.; Zhang, Q.S.; Li, Z.F.; Yuan, J.Q. Grouting Simulation Experiment on Reinforcement Characteristics of Completely Decomposed Granite. J. Tianjin Univ. Sci. Technol. 2017, 50, 1199–1209. [Google Scholar]

- Qian, Z.W.; Jiang, Z.Q.; Cao, L.W.; Sun, Q. Experiment study of penetration grouting model for weakly cemented porous media. Rock Soil Mech. 2013, 34, 139–142+147. [Google Scholar]

- Li, Z.P.; Zhang, L.Z.; Zhang, Q.S.; Liu, R.T.; Yang, W.D.; Chu, T.Y. Simulation test for permeation grouting reinforcement effect of sand layer. J. China Coal Soc. 2018, 43, 3488–3497. [Google Scholar]

- Feng, H.; Zhang, X.M.; Ou, X.F.; Zhang, C.; Jiang, J.; Guo, T.F.; Zhou, X.Y. Experimental Study on Geopolymer Grouting Material in Rapid Grouting Reinforcement of Fractured Rock. J. South China Univ. Technol. Nat. Sci. Ed. 2020, 48, 43–50. [Google Scholar]

- Newell, M.; Garcia-Taengua, E. Fresh and hardened state properties of hybrid graphene oxide/nanosilica cement composites. Constr. Build. Mater. 2019, 221, 433–442. [Google Scholar] [CrossRef]

- Peng, L.; Xu, Z.; Liu, Z.; Wei, Y.Y.; Sun, H.Y.; Li, Z.; Zhao, X.L.; Gao, C. An iron-based green approach to 1-h production of single-layer graphene oxide. Nat. Commun. 2015, 6, 5716. [Google Scholar]

- Luan, V.H.; Tien, H.N.; Hoa, L.T.; Hien, N.; Oh, E.; Chung, J.; Kim, E.J.; Choi, W.M.; Kong, B.; Hur, S.H. Synthesis of a highly conductive and large surface area graphene oxide hydrogel and its use in a supercapacitor. J. Mater. Chem. A 2012, 1, 208–211. [Google Scholar] [CrossRef]

- Sheshmani, S.; Fashapoyeh, M.A. Suitable Chemical Methods for Preparation of Graphene Oxide, Graphene and Surface Functionalized Graphene Nanosheets. Acta Chim. Slov. 2013, 60, 813–825. [Google Scholar]

- Li, Q.C.; He, C.; Zhou, H.; Xie, Z.Y.; Li, D.X. Effects of polycarboxylate superplasticizer-modified graphene oxide on hydration characteristics and mechanical behavior of cement. Constr. Build. Mater. 2021, 272, 121904. [Google Scholar] [CrossRef]

- Li, D.B.; Lei, P.B.; Zhang, H.C.; Liu, J.P.; Lu, W. Co-Effects of Graphene Oxide and Cement on Geotechnical Properties of Loess. Adv. Mater. Sci. Eng. 2021, 2021, 7429310. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, W.; Zhu, Z.D.; Li, N.; Pu, S.Y.; Wan, Y.; Huo, W.W. Triaxial mechanical characteristics and microscopic mechanism of graphene-modified cement stabilized expansive soil. Geotech. Eng. 2021, 26, 96–106. [Google Scholar] [CrossRef]

- Valizadeh, M.; Choobbasti, A.J. Evaluation of nano-graphene effect on mechanical behavior of clayey sand with microstructural and self-healing approach. J. Adhes. Sci. Technol. 2020, 34, 299–318. [Google Scholar] [CrossRef]

- Zhou, G.X.; Zhong, J.; Zhang, H.; Hu, X.Y.; Wu, J.L.; Koratkar, N.; Shi, X.M. Influence of releasing graphene oxide into a clayey sand: Physical and mechanical properties. RSC Adv. 2017, 7, 18060–18067. [Google Scholar] [CrossRef]

- Tong, T.; Fan, Z.; Liu, Q.; Wang, S.; Tan, S.; Yu, Q. Investigation of the effects of graphene and graphene oxide nanoplatelets on the micro- and macro-properties of cementitious materials. Constr. Build. Mater. 2016, 106, 102–114. [Google Scholar] [CrossRef]

- Lu, C.; Lu, Z.; Li, Z.; Leung, C.K. Effect of graphene oxide on the mechanical behavior of strain hardening cementitious composites. Constr. Build. Mater. 2016, 120, 457–464. [Google Scholar] [CrossRef]

- Pan, Z.; Wenhui, D.; Li, D.; Collins, F. Graphene Oxide Reinforced Cement and Concrete; Google Patents; Monash University: Melbourne, Australia, 2013. [Google Scholar]

- GB/T 1345-2005; The Test Sieving Method for Fineness of Cement. Standardization Administration of the People’s Republic of China: Beijing, China, 2005.

- Liu, S.J.; Sun, J.Z.; Zhang, J.W.; Xie, Z.D.; Yu, Z.J. Effect of Graphene Oxide on the Mechanical Property and Microstructure of Clay-Cement Slurry. Materials 2023, 16, 4294. [Google Scholar] [CrossRef]

- GB/T 17671-1999; Cement Mortar Strength Test Standard Cement Mortar Strength Test Method (ISO Method). Standardization Administration of the People’s Republic of China: Beijing, China, 1999.

- GB/T 1346-2011; Test Methods for Water Requirement of Normal Consistency, Setting Time and Soundness of the Portland Cements. Standardization Administration of the People’s Republic of China: Beijing, China, 2011.

- Gao, Y.; Jing, H.; Yu, Z.; Wu, J.; Yin, Q.; Fu, G. Experimental study on the mechanical properties of crushed stone cemented by graphene oxide and cement-based composite grouting materials. Chin. J. Rock Mech. Eng. 2022, 41, 1898–1909. [Google Scholar]

- Zhong, X.; Gao, G. Grouting Construction Manual, 1st ed.; China Coal Industry Publishing House: Beijing, China, 2013; pp. 41–42. [Google Scholar]

- Lu, S.; Sun, T.; Ma, Y.; Qiu, C.; Ding, H.; Liu, J. Regulation of grapheme oxide on microstructure of hydration crystals of cement composites and its impact on reinforcing toughness. Concrete 2013, 11, 105–112. [Google Scholar]

- Qi, M.; Pu, Y.D.; Yang, S.; Sheng, K.; Yun, X.Y. Effect of graphene oxide on the impermeability of cementitious capillary crystalline waterproofing. Acta Mater. Compos. Sin. 2023, 40, 1598–1610. [Google Scholar]

- Li, S.; Zhang, X.; Zhang, Q.; Sun, K.; Xu, X.; Zhang, W.; Li, H.; Liu, R.; Li, P. Research on mechanism of grout diffusion of dynamic grouting and plugging method in the water inrush of underground engineering. Chin. J. Rock Mech. Eng. 2011, 30, 2377–2396. [Google Scholar]

- Yuan, J.; Chen, W.; Huang, S. Experimental study on physico-mechanical properties of grouted completely weathered granite. Chin. J. Rock Mech. Eng. 2016, 35, 2876–2882. [Google Scholar]

- Wang, C.; Yang, C.; Heng, S.; Mao, H. CT test for evolution of mudstone fractures under compressive load. Rock Soil Mech. 2015, 36, 1591–1597. [Google Scholar]

- Gao, Y.; Jing, H.; Fu, G.; Zhao, Z.; Shi, X. Studies on combined effects of graphene oxide-fly ash hybrid on the workability, mechanical performance and pore structures of cementitious grouting under high W/C ratio. Constr. Build. Mater. 2021, 281, 122578. [Google Scholar] [CrossRef]

- Chen, S.J.; Li, C.Y.; Wang, Q.; Duan, W.H. Reinforcing mechanism of graphene at atomic level: Friction, crack surface adhesion and 2D geometry. Carbon 2017, 114, 557–565. [Google Scholar] [CrossRef]

- Mohammed, A.; Sanjayan, J.G.; Duan, W.H.; Nazari, A. Incorporating graphene oxide in cement composites: A study of transport properties. Constr. Build. Mater. 2015, 84, 341–347. [Google Scholar] [CrossRef]

- Li, S.J.; Li, D.; WU, L.; Cao, L.J. Meso-simulation and fractal characteristics for uniaxial compression test of inhomogeneous rock. J. China Coal Soc. 2014, 39, 849–854. [Google Scholar]

- Wang, Z.; Xiong, J.; Yang, Y.; Li, H. A flexible and robust threshold selection method. IEEE Trans. Circuits Syst. Video Technol. 2017, 28, 2220–2232. [Google Scholar] [CrossRef]

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Ai, T.; Zhang, R.; Zhou, H.W.; Pei, J.L. Box-counting methods to directly estimate the fractal dimension of a rock surface. Appl. Surf. Sci. 2014, 314, 610–621. [Google Scholar] [CrossRef]

- Wei, B.; Zhao, X.; Wang, L.; Hu, B.; Yu, L.; Tang, H. Analysis of gear surface morphology based on gray level co-occurrence matrix and fractal dimension. PLoS ONE 2019, 14, e0223825. [Google Scholar] [CrossRef] [PubMed]

| Cement | Property | Clay | Property | GO | Property |

|---|---|---|---|---|---|

| SiO2 | 21.32% | Water content | 3.7% | Suspension | 2 mg/mL |

| Al2O3 | 4.31% | Plastic limit | 24.2% | Diameter 3~8 nm | 95% |

| Fe2O3 | 3.38% | Liquid limit | 41.1% | Thickness < 3 nm | 90% |

| CaO | 61.26% | Plasticity index | 17.2 | Purity | 99% |

| MgO | 2.47% | Liquid index | −1.19 | - | - |

| SO2 | 2.55% | - | - | - | - |

| Number | OPC/(kg/m3) | GO/% | Sodium Silicate/mL/L |

|---|---|---|---|

| OPC-1-0 | 50 | 0 | 10 |

| OPC-1-1 | 50 | 0.03 | 10 |

| OPC-1-2 | 50 | 0.05 | 10 |

| OPC-2-0 | 100 | 0 | 10 |

| OPC-2-1 | 100 | 0.03 | 10 |

| OPC-2-2 | 100 | 0.05 | 10 |

| OPC-3-0 | 150 | 0 | 10 |

| OPC-3-1 | 150 | 0.03 | 10 |

| OPC-3-2 | 150 | 0.05 | 10 |

| Sample Group | Water Permeate/cm3 | Specimen Height/cm | Fracture Area/cm2 | Mean Water Level/cm | Time/s | Permeability Coefficient/ (cm/s) |

|---|---|---|---|---|---|---|

| I | 30.0 | 10 | 19.6 | 4.77 | 10 | 0.08 |

| II | 68.2 | 10 | 19.6 | 1.50 | 10 | 0.58 |

| III | 33.9 | 10 | 19.6 | 0.40 | 10 | 1.08 |

| Number | OPC/% | GO/% | Gradation |

| I | 30.0 | 10 | 19.6 |

| II | 68.2 | 10 | 19.6 |

| III | 33.9 | 10 | 19.6 |

| Number | /MPa | /s | m3 | Permeability Coefficient/ |

|---|---|---|---|---|

| 1-1 | 0.173 | 13 | 5.00 × 10−9 | 1.11 |

| 1-2 | 0.153 | 10 | 8.21 × 10−9 | 2.68 |

| 1-3 | 0.137 | 12 | 7.66 × 10−9 | 2.33 |

| 2-1 | 0.221 | 19 | 2.94 × 10−8 | 3.49 |

| 2-2 | 0.197 | 16 | 1.73 × 10−8 | 2.74 |

| 2-3 | 0.177 | 16 | 2.41 × 10−8 | 4.23 |

| 3-1 | 0.141 | 24 | 5.11 × 10−8 | 7.54 |

| 3-2 | 0.112 | 12 | 2.52 × 10−8 | 9.36 |

| 3-3 | 0.162 | 11 | 3.45 × 10−8 | 7.6 |

| Number | K/m·s−1 | ||

|---|---|---|---|

| OPC/% | GO/wt.% | n | |

| 6.12 | 12.14 | 14.70 | |

| 10.46 | 14.78 | 13.77 | |

| 24.50 | 14.16 | 12.61 | |

| 6.13 | 0.88 | 0.70 | |

| Source | Square of Deviance | Degree of Freedom | F-Value | p-Value |

|---|---|---|---|---|

| 1-1 | 0.173 | 13 | 5.00 × 10−9 | 1.11 |

| 1-2 | 0.153 | 10 | 8.21 × 10−9 | 2.68 |

| 1-3 | 0.137 | 12 | 7.66 × 10−9 | 2.33 |

| 2-1 | 0.221 | 19 | 2.94 × 10−8 | 3.49 |

| 2-2 | 0.197 | 16 | 1.73 × 10−8 | 2.74 |

| 2-3 | 0.177 | 16 | 2.41 × 10−8 | 4.23 |

| 3-1 | 0.141 | 24 | 5.11 × 10−8 | 7.54 |

| 3-2 | 0.112 | 12 | 2.52 × 10−8 | 9.36 |

| 3-3 | 0.162 | 11 | 3.45 × 10−8 | 7.6 |

| GO Content/% | Fractal Box Dimension | Fitting Degree |

|---|---|---|

| 0.00 | 1.9266 | 0.9997 |

| 0.01 | 1.8963 | 0.9995 |

| 0.02 | 1.8922 | 0.9973 |

| 0.03 | 1.7815 | 0.9981 |

| 0.04 | 1.8513 | 0.9992 |

| 0.05 | 1.8710 | 0.9947 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Liu, S.; Zhang, J.; Tian, Q.; Yu, Z.; Xie, Z. Experimental Investigation of Mechanical Properties of Clay–Cement Slurry Containing Graphene Oxide. Appl. Sci. 2023, 13, 8452. https://doi.org/10.3390/app13148452

Sun J, Liu S, Zhang J, Tian Q, Yu Z, Xie Z. Experimental Investigation of Mechanical Properties of Clay–Cement Slurry Containing Graphene Oxide. Applied Sciences. 2023; 13(14):8452. https://doi.org/10.3390/app13148452

Chicago/Turabian StyleSun, Jinze, Shujie Liu, Jiwei Zhang, Qinghao Tian, Zhijie Yu, and Zuodong Xie. 2023. "Experimental Investigation of Mechanical Properties of Clay–Cement Slurry Containing Graphene Oxide" Applied Sciences 13, no. 14: 8452. https://doi.org/10.3390/app13148452

APA StyleSun, J., Liu, S., Zhang, J., Tian, Q., Yu, Z., & Xie, Z. (2023). Experimental Investigation of Mechanical Properties of Clay–Cement Slurry Containing Graphene Oxide. Applied Sciences, 13(14), 8452. https://doi.org/10.3390/app13148452