Development of a Flexible Thin Wearable Device for Tuning Temperature, Humidity, and Surface Friction on Its Surface

Abstract

1. Introduction

2. Units for Changing Conditions

2.1. Functional Requirements

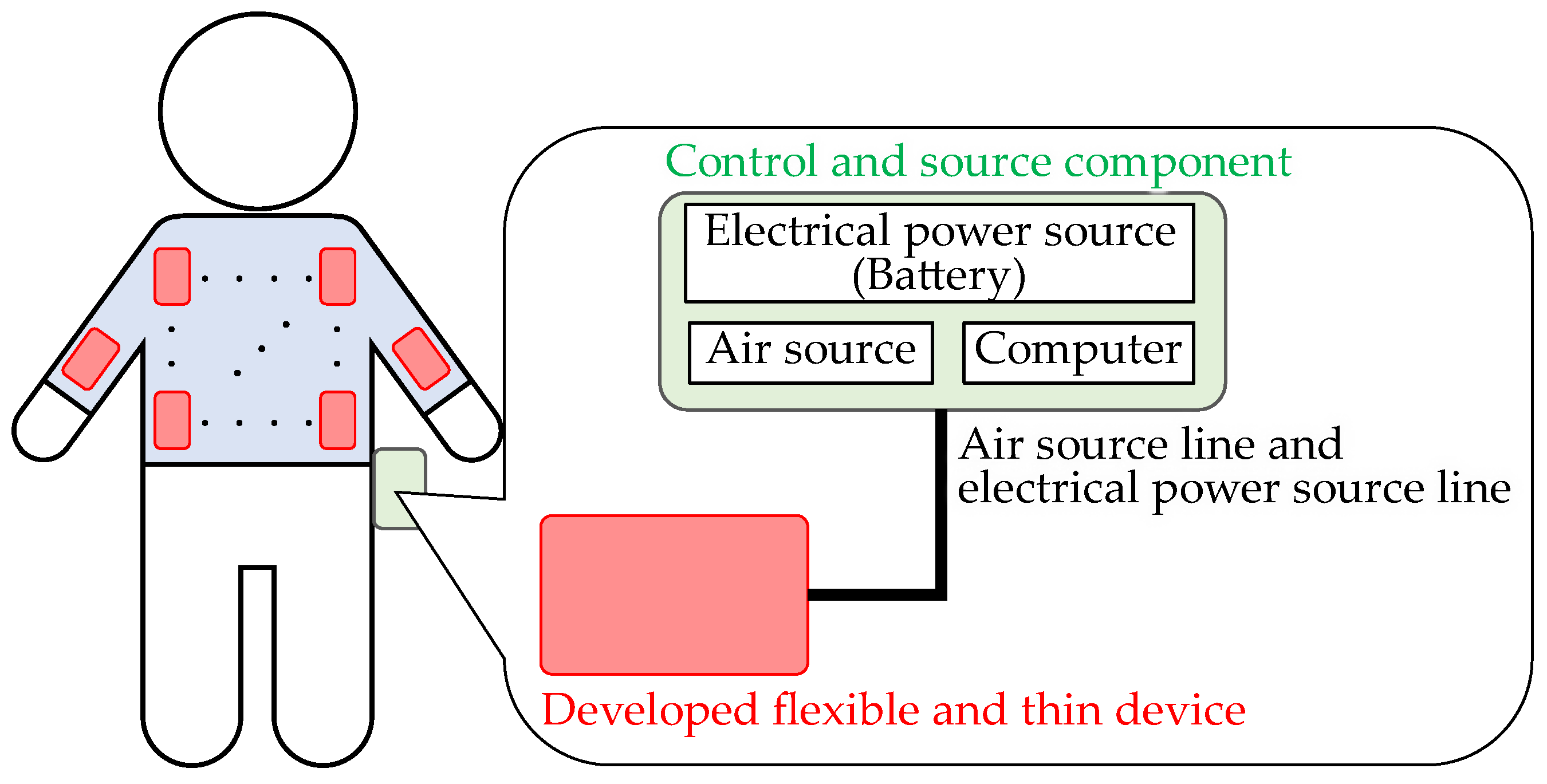

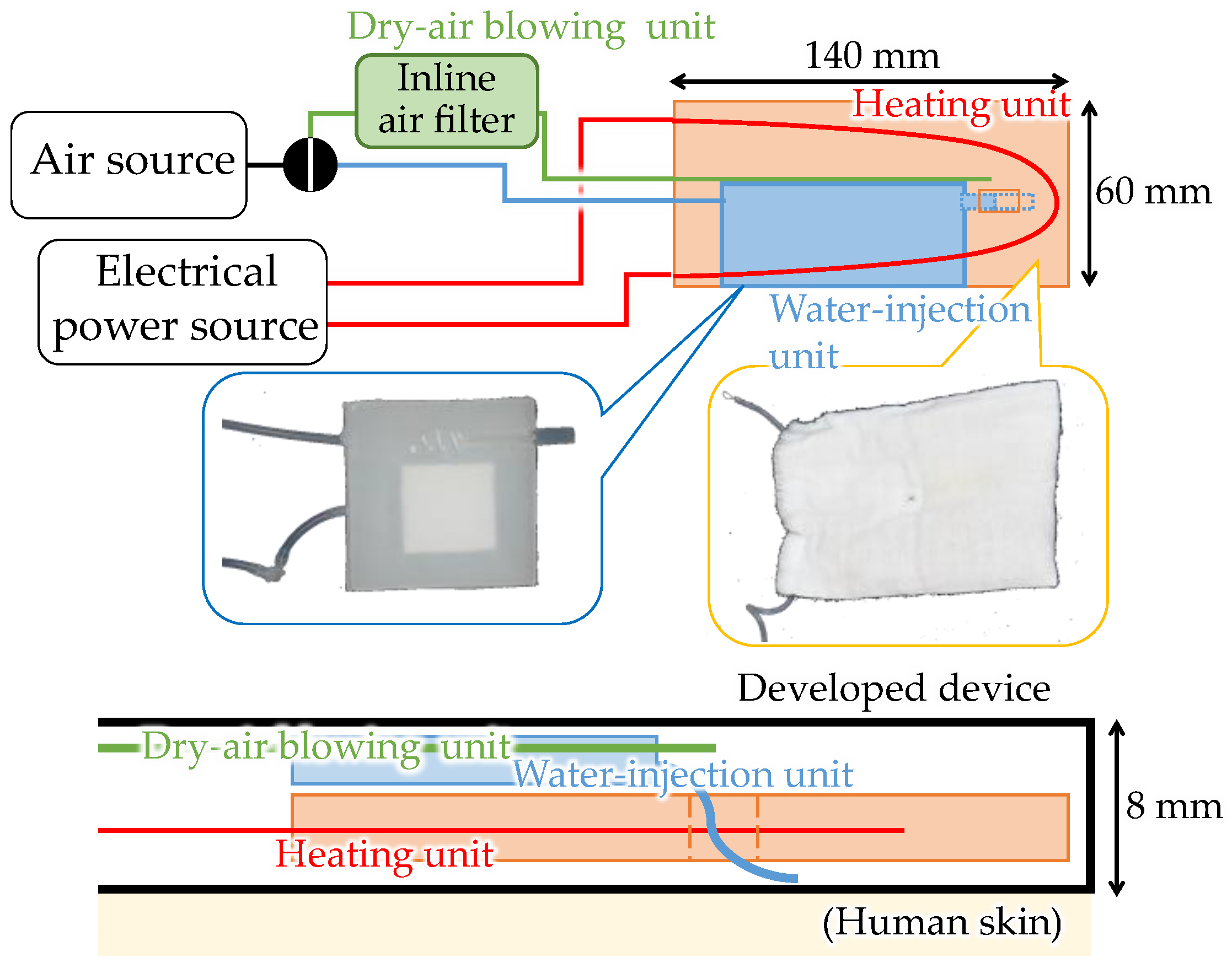

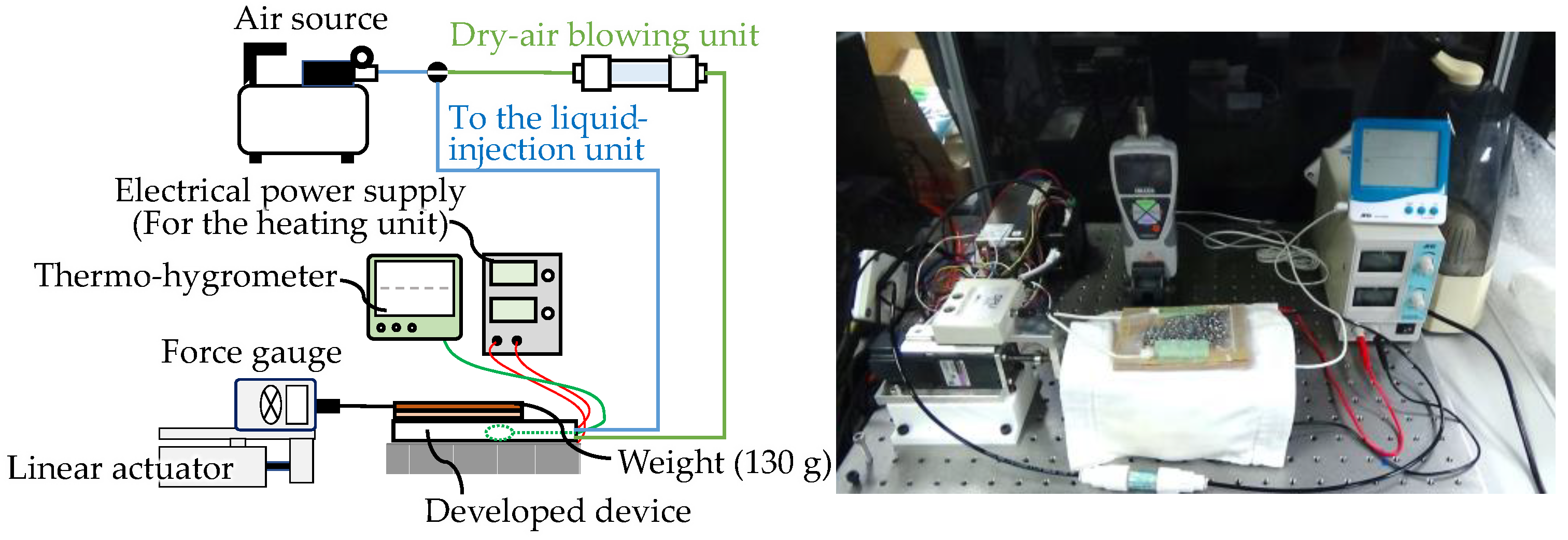

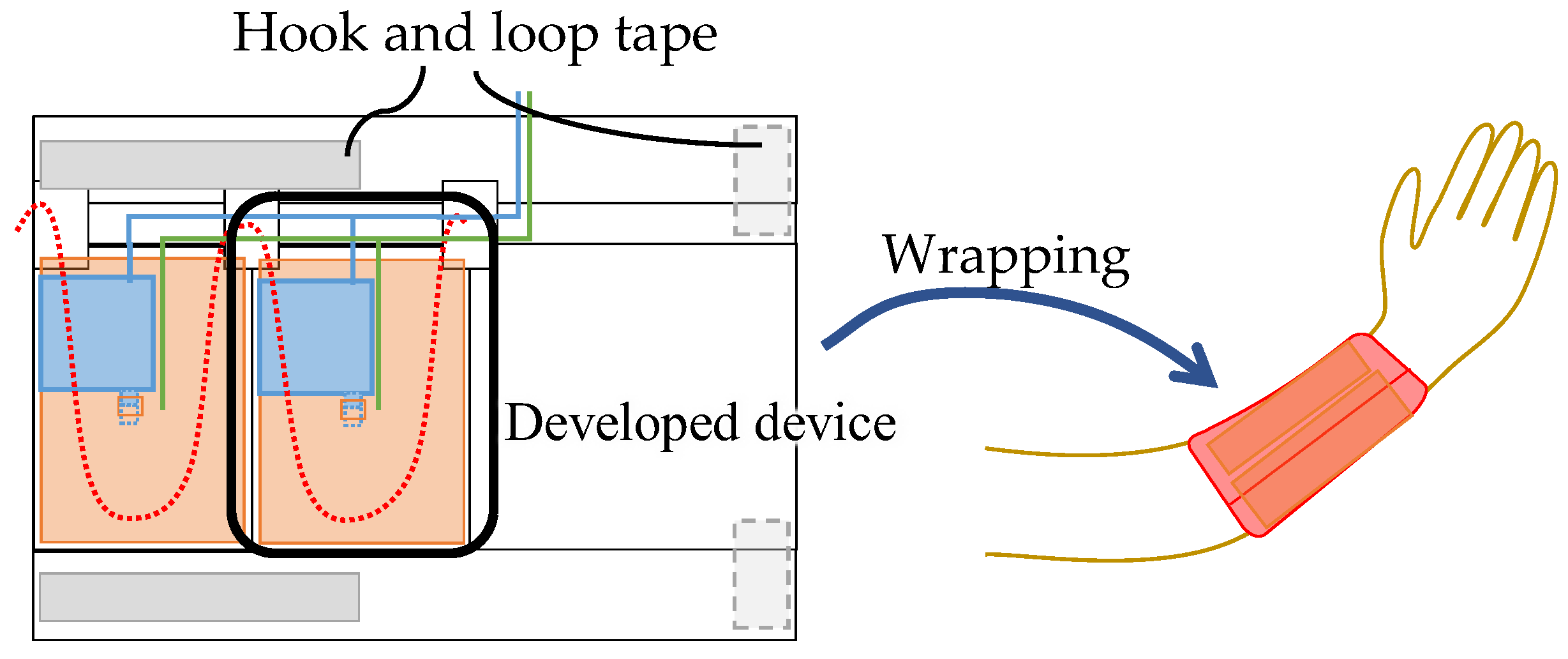

2.2. Overview of the Developed Device

3. Principles of the Tuning the Temperature, Humidity, and Friction

3.1. Structure of the Developed Units

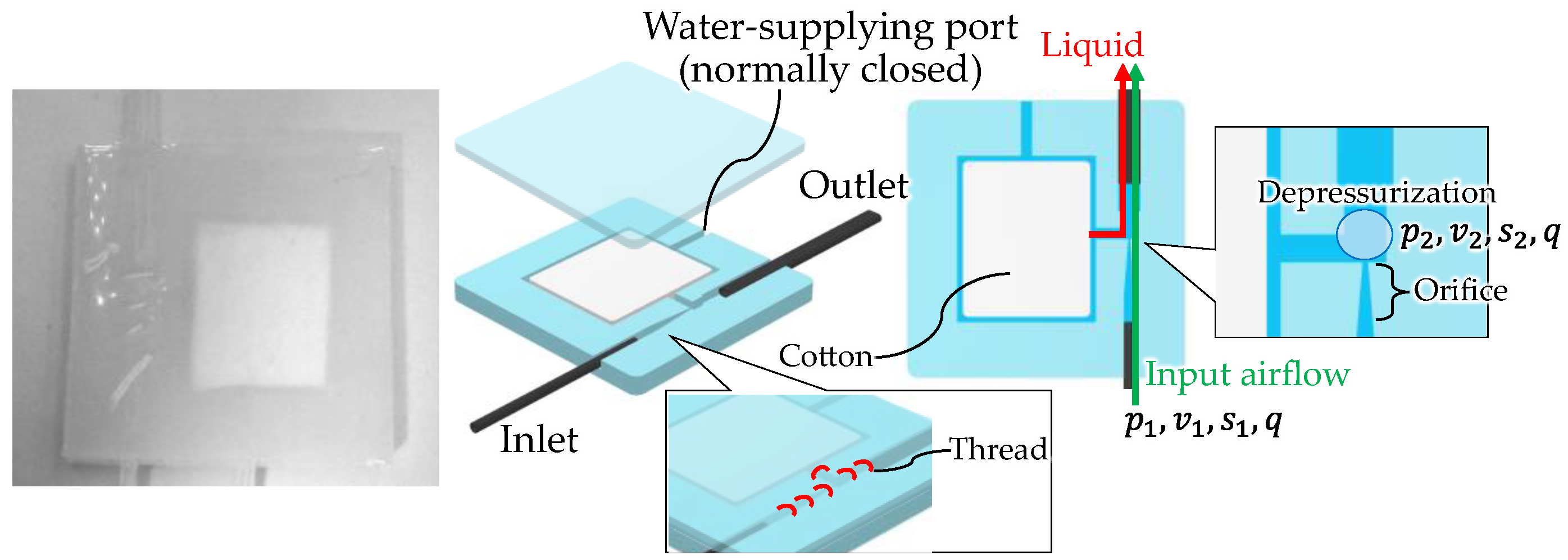

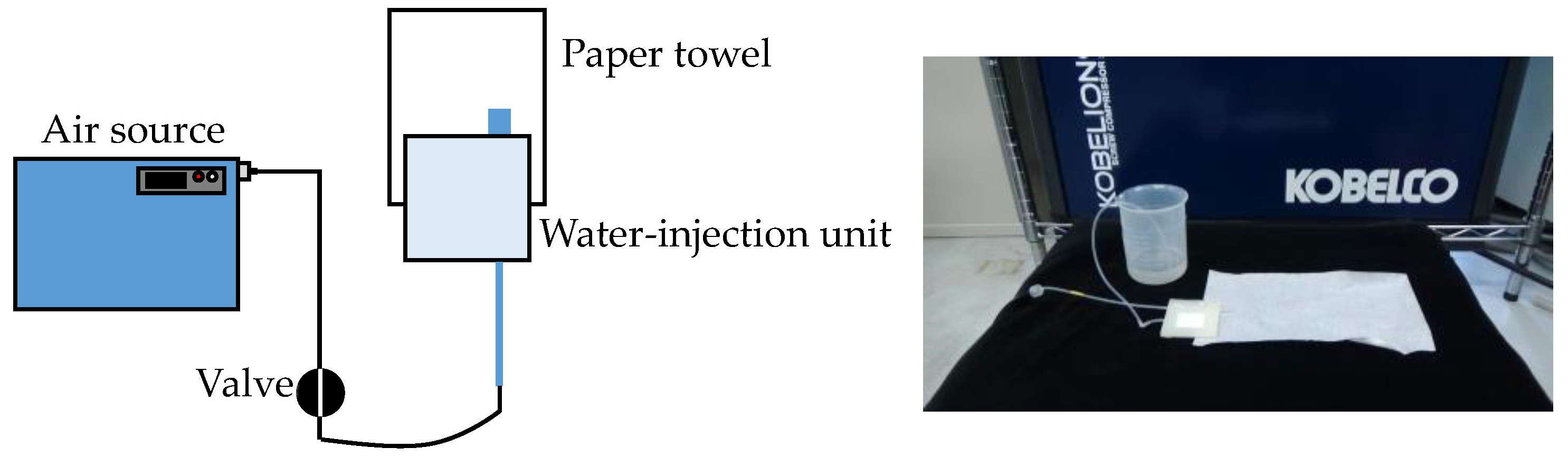

3.1.1. Liquid-Injection Unit

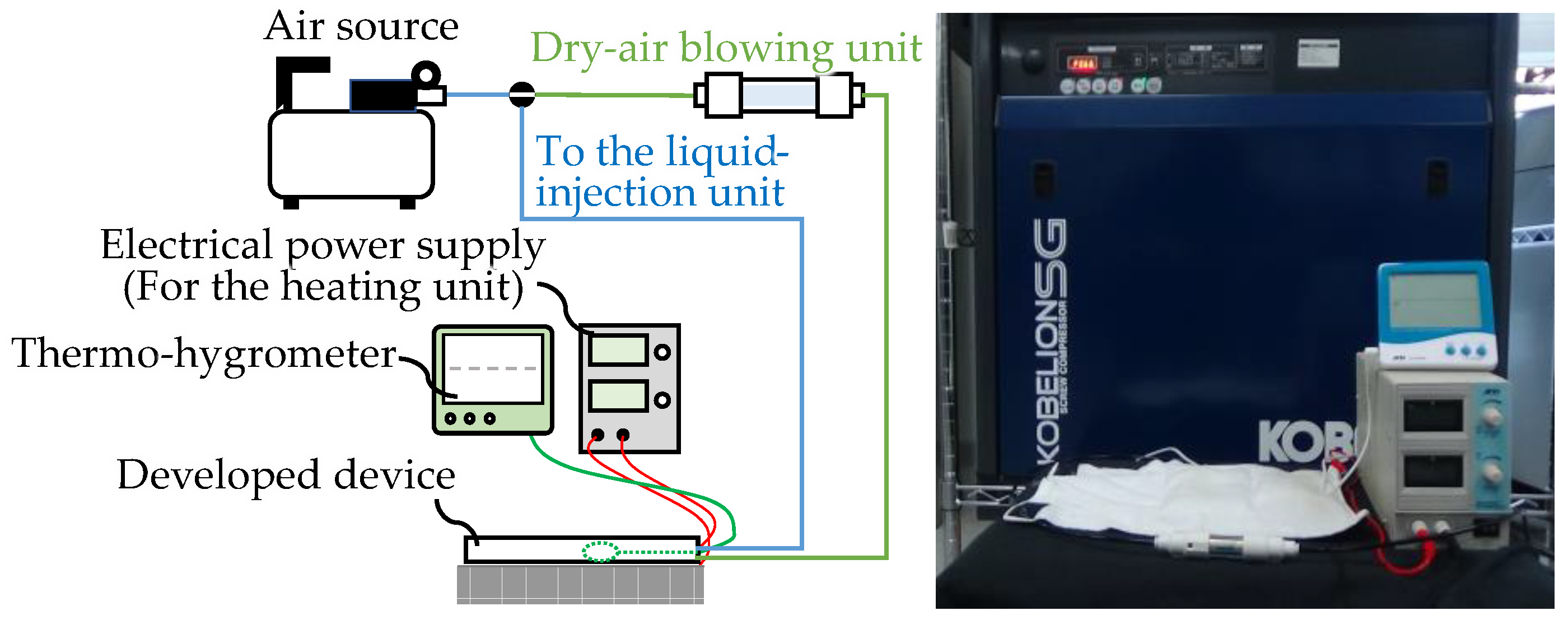

3.1.2. Dry-Air Blowing Unit

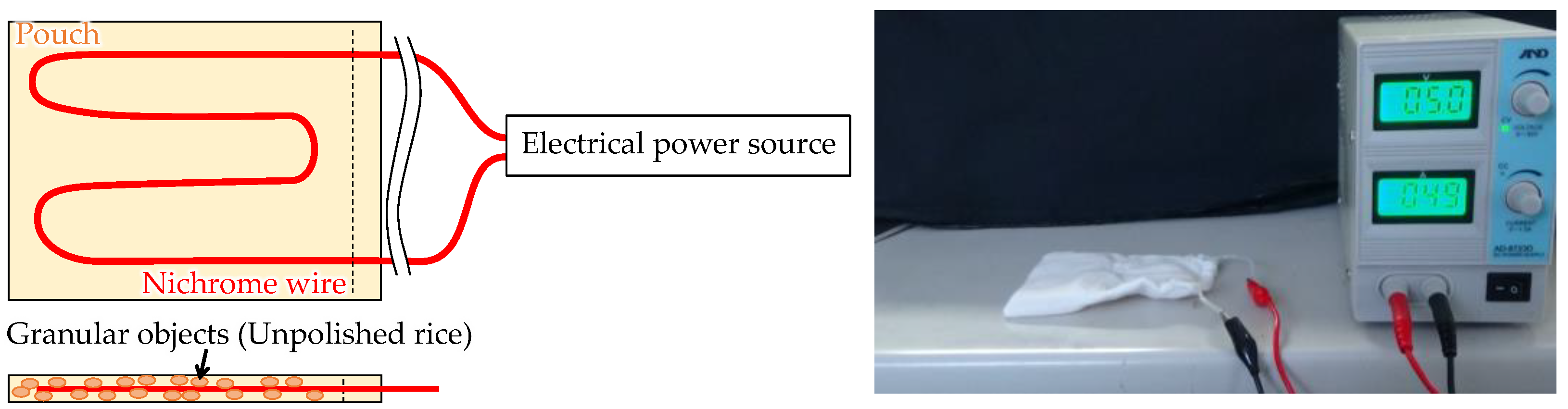

3.1.3. Heating Unit

3.2. Principles of Modifying the Conditions

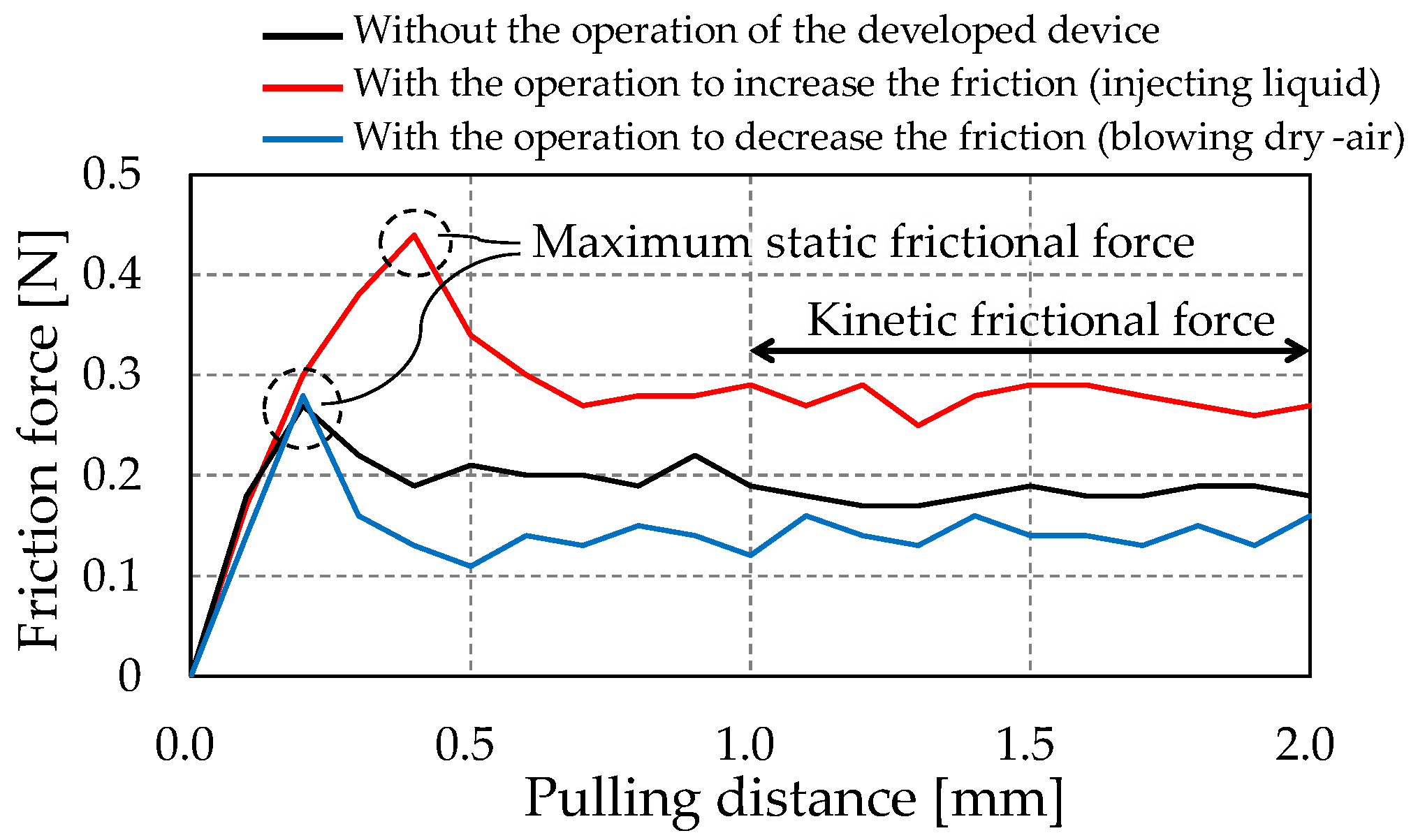

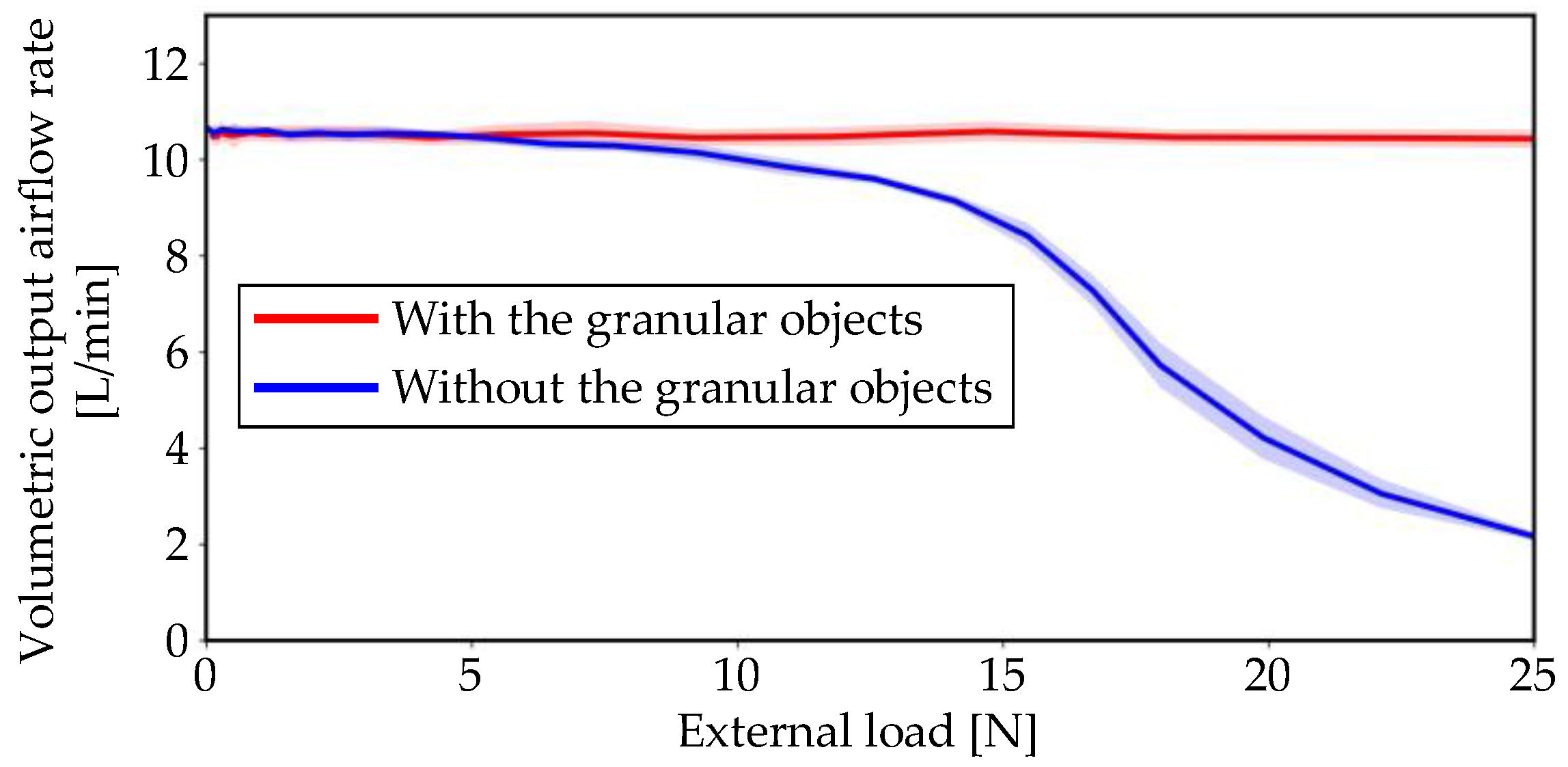

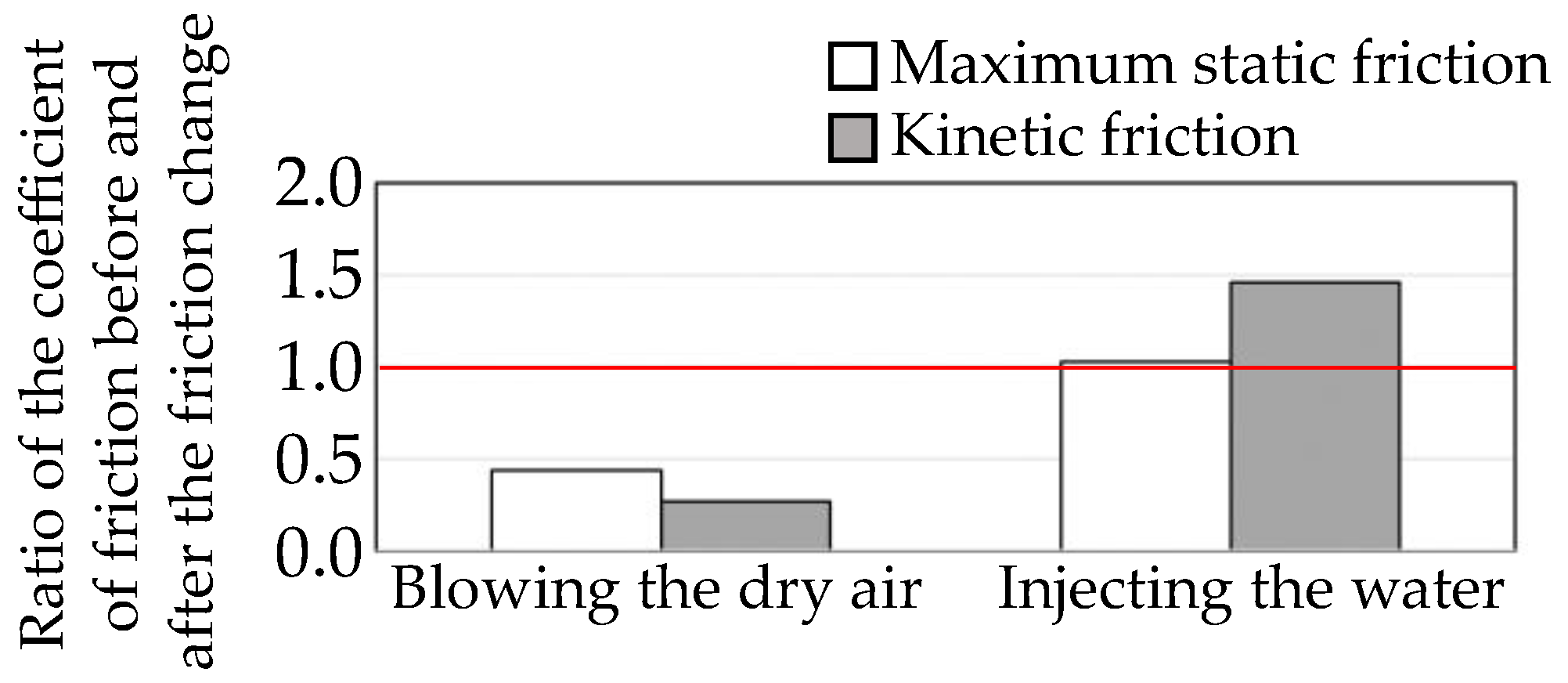

- The injection of a liquid with a large surface tension onto the contact area increases the adhesion force [32], which increases friction; when dry air is blown into a cotton bag containing granulated materials, an air pocket or an air-lubricated layer is formed near the contact area, thereby reducing the actual contact area and friction [33].

- The temperature is increased by the heating unit and decreased via the evaporation-cooling method [8]. A liquid is injected by the liquid-injection unit and vaporized by the dry-air blowing unit.

- Humidity is increased through spraying a liquid onto the contact area and reduced through blowing dry air into the contact area.

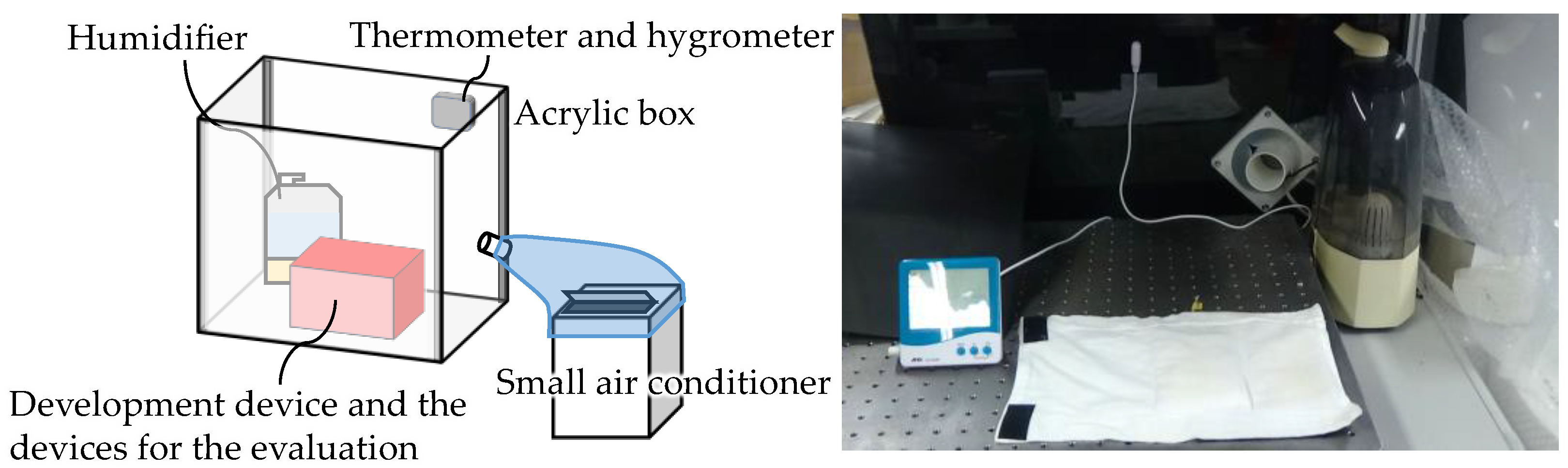

4. Evaluation of the Developed Unit

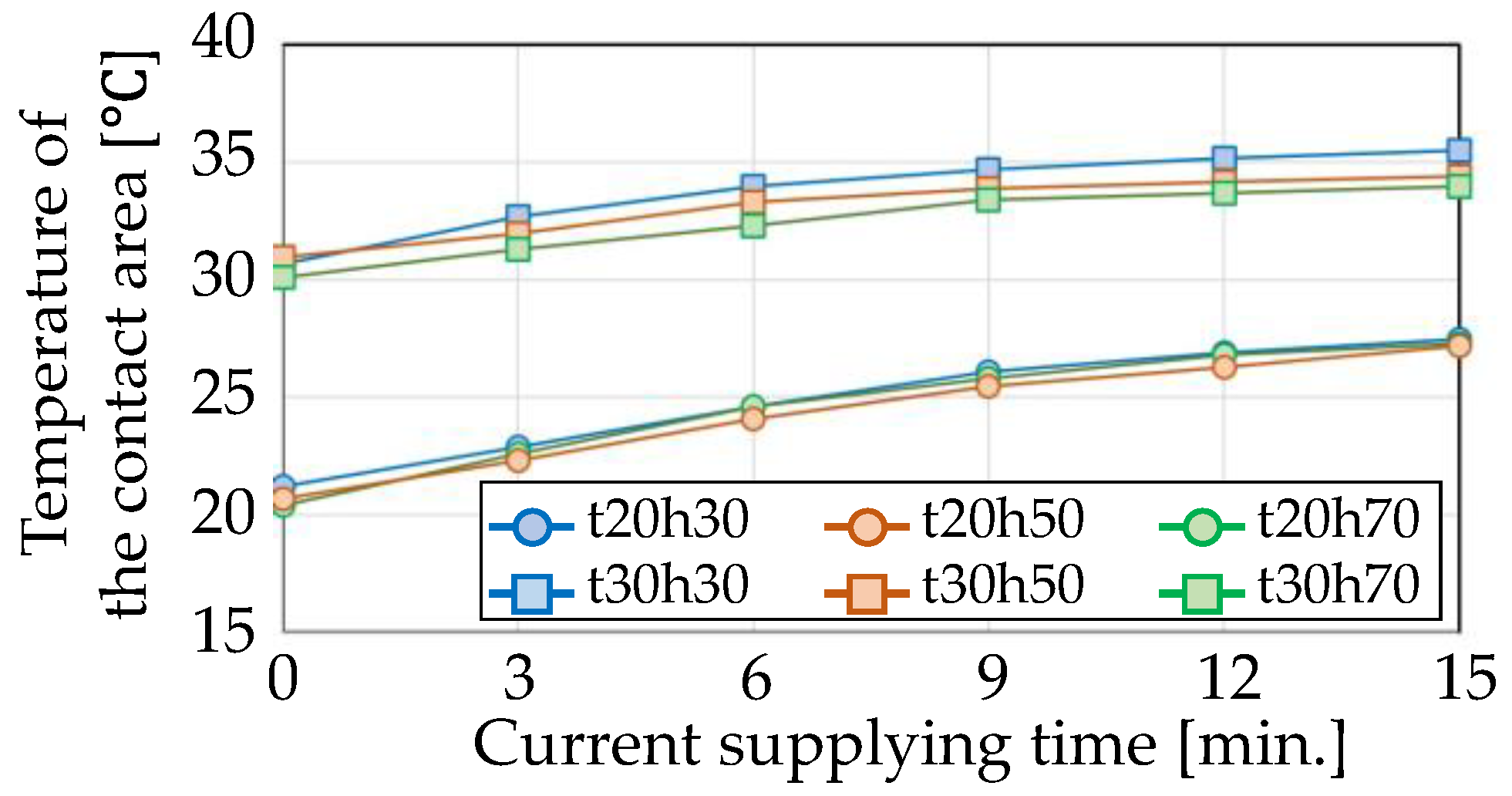

4.1. Tuning the Temperature

4.2. Tuning the Humidity

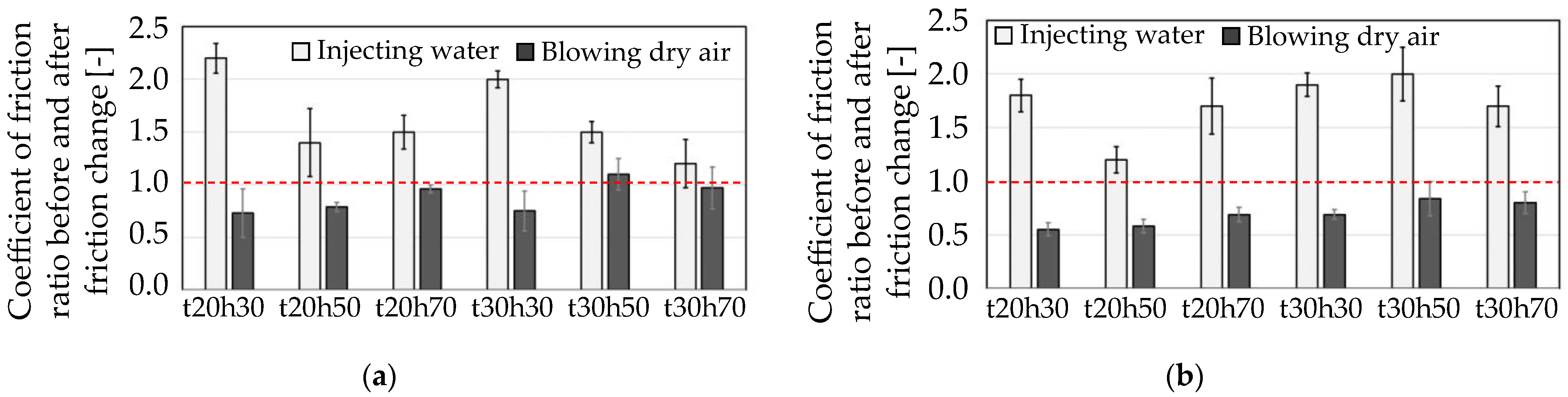

4.3. Tuning the Friction

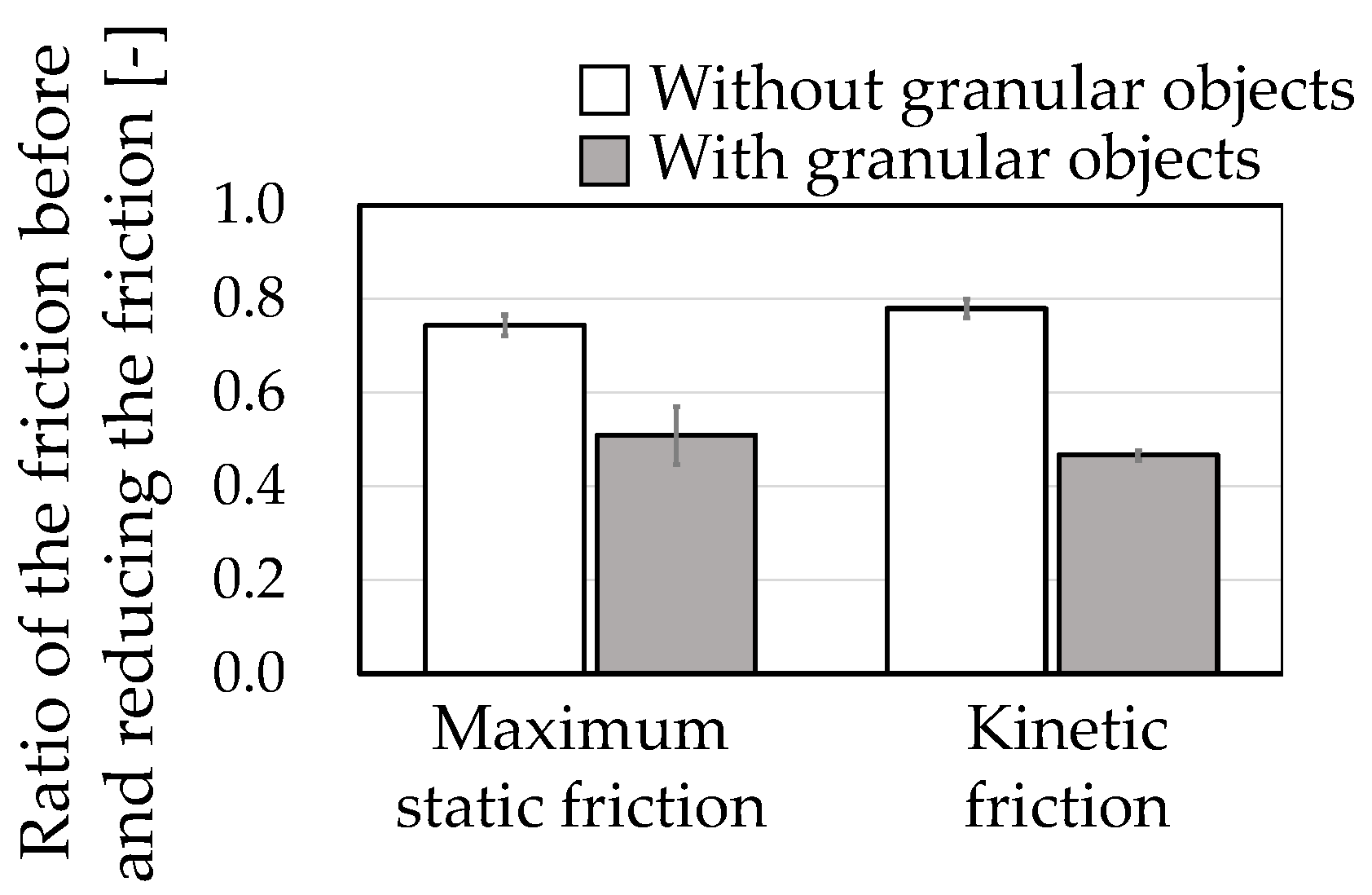

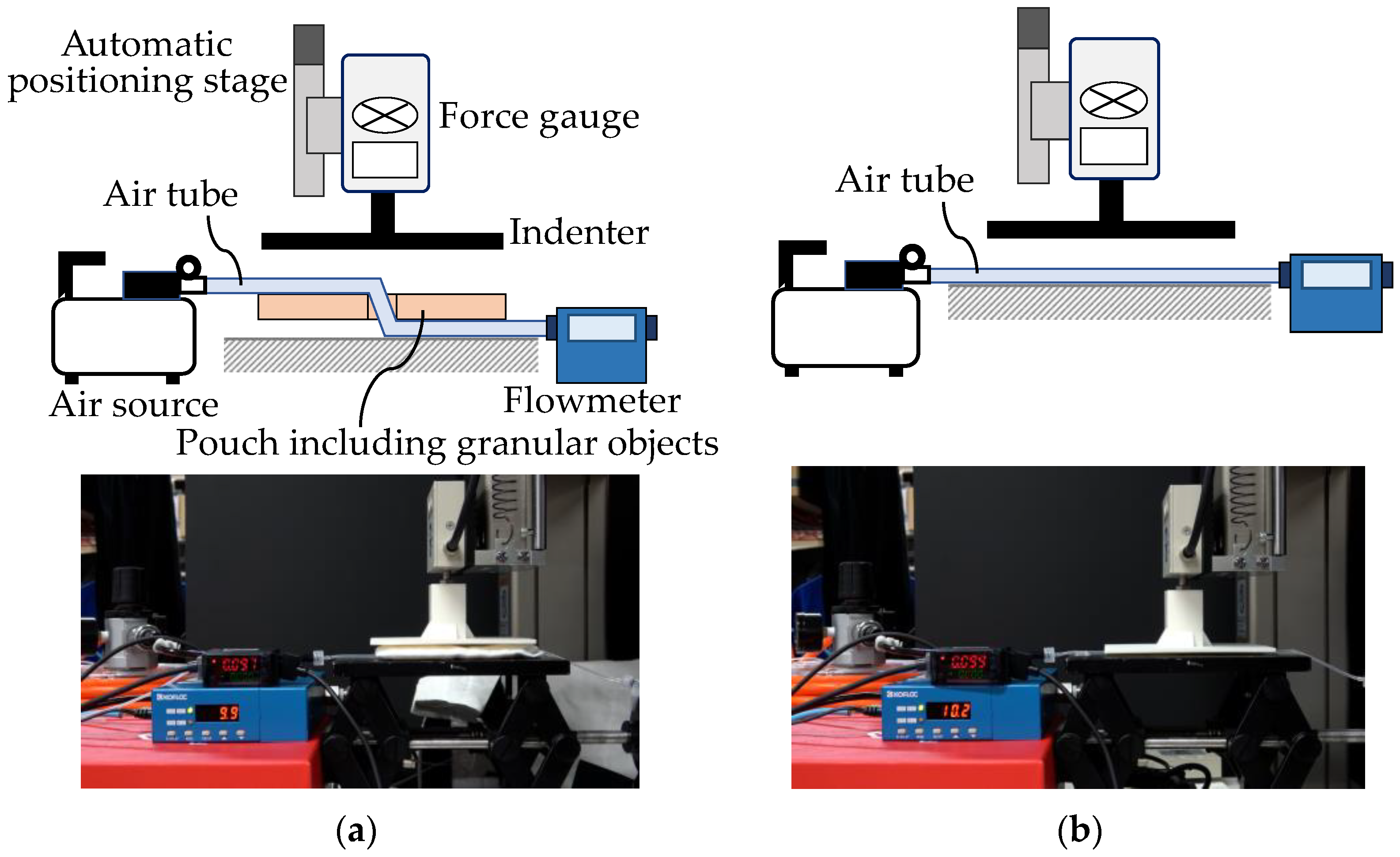

4.4. Effect of the Granular Objects

4.5. Discussion

5. Installation into Clothes

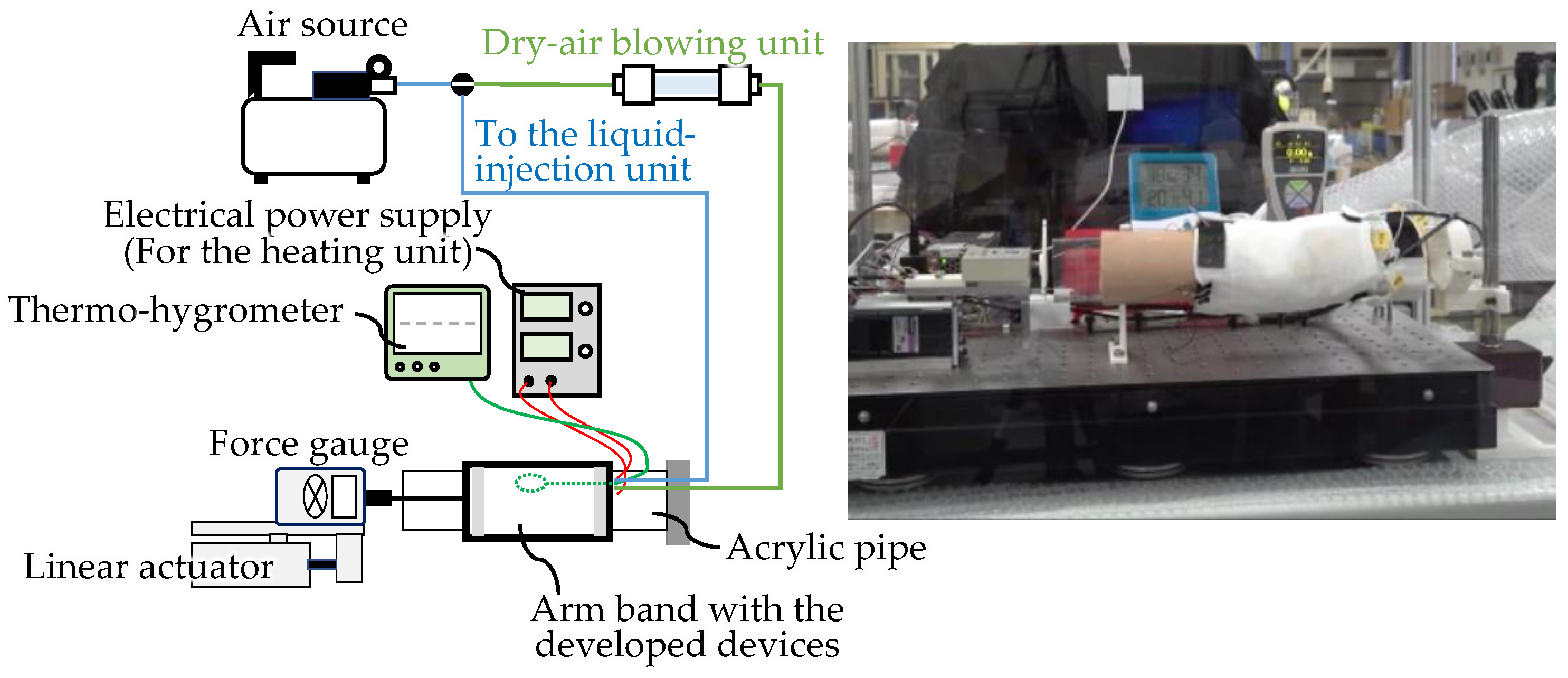

5.1. Tuning the Temperature

5.2. Tuning the Humidity

5.3. Tuning the Friction

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Stevens, K.; Fuller, M. Textile-Led Design for the Active Ageing Population; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 9780857095381. [Google Scholar]

- Havenith, G. Interaction of Clothing and Thermoregulation. Exog. Dermatol. 2002, 1, 221–230. [Google Scholar] [CrossRef]

- Sanchez, V.; Walsh, C.J.; Wood, R.J. Textile Technology for Soft Robotic and Autonomous Garments. Adv. Funct. Mater. 2021, 31, 2008278. [Google Scholar] [CrossRef]

- Okui, M.; Nagura, Y.; Iikawa, S.; Yamada, Y.; Nakamura, T. A Pneumatic Power Source Using a Sodium Bicarbonate and Citric Acid Reaction with Pressure Booster for Use in Mobile Devices. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; IEEE: New York, NY, USA; pp. 1040–1045. [Google Scholar]

- Hu, R.; Liu, Y.; Shin, S.; Huang, S.; Ren, X.; Shu, W.; Cheng, J.; Tao, G.; Xu, W.; Chen, R.; et al. Emerging Materials and Strategies for Personal Thermal Management. Adv. Energy Mater. 2020, 10, 1903921. [Google Scholar] [CrossRef]

- Kotagama, P.; Phadnis, A.; Manning, K.C.; Rykaczewski, K. Rational Design of Soft, Thermally Conductive Composite Liquid-Cooled Tubes for Enhanced Personal, Robotics, and Wearable Electronics Cooling. Adv. Mater. Technol. 2019, 4, 1800690. [Google Scholar] [CrossRef]

- Guo, T.; Shang, B.; Duan, B.; Luo, X. Design and Testing of a Liquid Cooled Garment for Hot Environments. J. Therm. Biol. 2015, 49, 47–54. [Google Scholar] [CrossRef]

- Mondal, S. Phase Change Materials for Smart Textiles—An Overview. Appl. Therm. Eng. 2008, 28, 1536–1550. [Google Scholar] [CrossRef]

- Bühler, M.; Popa, A.M.; Scherer, L.J.; Lehmeier, F.K.S.; Rossi, R.M. Heat Protection by Different Phase Change Materials. Appl. Therm. Eng. 2013, 54, 359–364. [Google Scholar] [CrossRef]

- Wang, R.; Xu, Z.; Zhuang, J.; Liu, Z.; Peng, L.; Li, Z.; Liu, Y.; Gao, W.; Gao, C. Highly Stretchable Graphene Fibers with Ultrafast Electrothermal Response for Low-Voltage Wearable Heaters. Adv. Electron. Mater. 2017, 3, 1600425. [Google Scholar] [CrossRef]

- Guo, Y.; Dun, C.; Xu, J.; Mu, J.; Li, P.; Gu, L.; Hou, C.; Hewitt, C.A.; Zhang, Q.; Li, Y.; et al. Ultrathin, Washable, and Large-Area Graphene Papers for Personal Thermal Management. Small 2017, 13, 1702645. [Google Scholar] [CrossRef]

- Zhang, L.; Baima, M.; Andrew, T.L. Transforming Commercial Textiles and Threads into Sewable and Weavable Electric Heaters. ACS Appl. Mater. Interfaces 2017, 9, 32299–32307. [Google Scholar] [CrossRef]

- Choi, J.; Dun, C.; Forsythe, C.; Gordon, M.P.; Urban, J.J. Lightweight Wearable Thermoelectric Cooler with Rationally Designed Flexible Heatsink Consisting of Phase-Change Material/Graphite/Silicone Elastomer. J. Mater. Chem. A 2021, 9, 15696–15703. [Google Scholar] [CrossRef]

- Kishore, R.A.; Nozariasbmarz, A.; Poudel, B.; Sanghadasa, M.; Priya, S. Ultra-High Performance Wearable Thermoelectric Coolers with Less Materials. Nat. Commun. 2019, 10, 1765. [Google Scholar] [CrossRef]

- Zaia, E.W.; Gordon, M.P.; Yuan, P.; Urban, J.J. Progress and Perspective: Soft Thermoelectric Materials for Wearable and Internet-of-Things Applications. Adv. Electron. Mater. 2019, 5, 1800823. [Google Scholar] [CrossRef]

- Panasonic Corporation. Available online: https://www.na.panasonic.com/ (accessed on 6 June 2023).

- Sharp Electronics Corporation. Available online: https://www.sharpusa.com/ (accessed on 6 June 2023).

- Suzuki, K.; Ohzono, T. Wrinkles on a Textile-Embedded Elastomer Surface with Highly Variable Friction. Soft Matter 2016, 12, 6176–6183. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Broer, D.J. Self-Assembled Dynamic 3D Fingerprints in Liquid-Crystal Coatings Towards Controllable Friction and Adhesion. Angew. Chemie 2014, 126, 4630–4634. [Google Scholar] [CrossRef]

- Glick, P.; Suresh, S.A.; Ruffatto, D.; Cutkosky, M.; Tolley, M.T.; Parness, A. A Soft Robotic Gripper with Gecko-Inspired Adhesive. IEEE Robot. Autom. Lett. 2018, 3, 903–910. [Google Scholar] [CrossRef]

- Golan, Y.; Shapiro, A.; Rimon, E. Jamming-Free Immobilizing Grasps Using Dual-Friction Robotic Fingertips. IEEE Robot. Autom. Lett. 2020, 5, 2889–2896. [Google Scholar] [CrossRef]

- Abdi, H.; Asgari, M.; Nahavandi, S. Active Surface Shaping for Artificial Skins. In Proceedings of the 2011 IEEE International Conference on Systems, Man, and Cybernetics, Anchorage, AK, USA, 9–12 October 2011; IEEE: New York, NY, USA; pp. 2910–2915. [Google Scholar]

- Nojiri, S.; Mizushima, K.; Suzuki, Y.; Tsuji, T.; Watanabe, T. Development of Contact Area Variable Surface for Manipulation Requiring Sliding. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Republic of Korea, 14–18 April 2019; IEEE: New York, NY, USA; pp. 131–136. [Google Scholar]

- Becker, K.P.; Bartlett, N.W.; Malley, M.J.D.; Kjeer, P.M.; Wood, R.J. Tunable Friction through Constrained Inflation of an Elastomeric Membrane. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; IEEE: New York, NY, USA; pp. 4352–4357. [Google Scholar]

- Spiers, A.J.; Calli, B.; Dollar, A.M. Variable-Friction Finger Surfaces to Enable Within-Hand Manipulation via Gripping and Sliding. IEEE Robot. Autom. Lett. 2018, 3, 4116–4123. [Google Scholar] [CrossRef]

- Lu, Q.; Clark, A.B.; Shen, M.; Rojas, N. An Origami-Inspired Variable Friction Surface for Increasing the Dexterity of Robotic Grippers. IEEE Robot. Autom. Lett. 2020, 5, 2538–2545. [Google Scholar] [CrossRef]

- Kim, S.; Sitti, M.; Xie, T.; Xiao, X. Reversible Dry Micro-Fibrillar Adhesives with Thermally Controllable Adhesion. Soft Matter 2009, 5, 3689. [Google Scholar] [CrossRef]

- Shintake, J.; Rosset, S.; Schubert, B.; Floreano, D.; Shea, H. Versatile Soft Grippers with Intrinsic Electroadhesion Based on Multifunctional Polymer Actuators. Adv. Mater. 2016, 28, 231–238. [Google Scholar] [CrossRef] [PubMed]

- Hawkes, E.W.; Christensen, D.L.; Han, A.K.; Jiang, H.; Cutkosky, M.R. Grasping without Squeezing: Shear Adhesion Gripper with Fibrillar Thin Film. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; IEEE: New York, NY, USA, 2015; pp. 2305–2312. [Google Scholar]

- Mizushima, K.; Suzuki, Y.; Tsuji, T.; Watanabe, T. Deformable Fingertip with a Friction Reduction System Based on Lubricating Effect for Smooth Operation under Both Dry and Wet Conditions. Adv. Robot. 2019, 33, 508–519. [Google Scholar] [CrossRef]

- Nishimura, T.; Shimizu, K.; Nojiri, S.; Tadakuma, K.; Suzuki, Y.; Tsuji, T.; Watanabe, T. Soft Robotic Hand with Finger-Bending/Friction-Reduction Switching Mechanism Through 1-Degree-of-Freedom Flow Control. IEEE Robot. Autom. Lett. 2022, 7, 5695–5702. [Google Scholar] [CrossRef]

- Nishi, T.; Moriyasu, K.; Harano, K.; Nishiwaki, T. Influence of Dewettability on Rubber Friction Properties with Different Surface Roughness under Water/Ethanol/Glycerol Lubricated Conditions. Tribol. Online 2016, 11, 601–607. [Google Scholar] [CrossRef]

- Nojiri, S.; Nishimura, T.; Tadakuma, K.; Watanabe, T. Flexible and Slim Device Switching Air Blowing and Suction by a Single Airflow Control. IEEE Robot. Autom. Lett. 2023, 8, 2637–2644. [Google Scholar] [CrossRef]

- Kwon, J.; Choi, J. Clothing Insulation and Temperature, Layer and Mass of Clothing under Comfortable Environmental Conditions. J. Physiol. Anthropol. 2013, 32, 11. [Google Scholar] [CrossRef]

- Dermidia, DSI Sense. Available online: https://dermidia.com/what-indoor-humidity-is-the-optimum-level-for-healthy-skin/ (accessed on 6 June 2023).

- Chen, X.-Q.; Fan, S.-J.; Han, C.; Wu, T.; Wang, L.-J.; Jiang, W.; Dai, W.; Yang, J.-P. Multiscale Architectures Boosting Thermoelectric Performance of Copper Sulfide Compound. Rare Met. 2021, 40, 2017–2025. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, H.; Zhao, Y.; Liu, W.-D.; Dai, W.; Wu, T.; Lu, X.; Wu, C.; Luo, W.; Fan, Y.; et al. Carbon-Encapsulated Copper Sulfide Leading to Enhanced Thermoelectric Properties. ACS Appl. Mater. Interfaces 2019, 11, 22457–22463. [Google Scholar] [CrossRef]

| Tuning the Temperature | Tuning the Humidity | Tuning the Friction | |||

|---|---|---|---|---|---|

| Increasing | Decreasing | Increasing | Decreasing | Increasing or Decreasing | |

| This work | Yes | Yes | Yes | Yes | Yes |

| [6] | - | Yes | - | - | - |

| [7] | - | Yes | - | - | - |

| [10] | Yes | - | - | - | - |

| [11] | Yes | Yes (passive) | - | - | - |

| [12] | Yes | - | - | - | - |

| [13] | - | Yes | - | - | - |

| [14] | - | Yes | - | - | - |

| [16] | - | - | Yes | Yes | - |

| [17] | - | - | Yes | Yes | - |

| [18] | - | - | - | - | Yes |

| [19] | - | - | - | - | Yes |

| [20] | - | - | - | - | Yes |

| [21] | - | - | - | - | Yes |

| [22] | - | - | - | - | Yes |

| [23] | - | - | - | - | Yes |

| [24] | - | - | - | - | Yes |

| [25] | - | - | - | - | Yes |

| [26] | - | - | - | - | Yes |

| [27] | - | - | - | - | Yes |

| [28] | - | - | - | - | Yes |

| [29] | - | - | - | - | Yes |

| [30] | - | - | - | - | Yes |

| [31] | - | - | - | - | Yes |

| Component | Material/Property | Flexibility | Specifications (Model Name, Manufacturer) | |

|---|---|---|---|---|

| Heating unit | Electrical heating wire | Nichrome | Flexible | Wire diameter: 0.26 mm (HK-NK05H, Asahi electric Co., Ltd., Osaka, Japan) |

| Wire cover | Silicone | Flexible (Shore A50) | Outer diameter: 2 mm (MGJG-1 × 2, Monotaro, Hyogo, Japan) | |

| Electrical cable | - | Flexible | Diameter of the electrical wire: 0.1 sq (U-0817, Suzuden Corporation, Tokyo, Japan) | |

| Liquid-injection unit | Main body | Silicone (Dragon skin 10) | Flexible (Shore A10) | (Dragon skin 10, Smooth-On, Macungie, PA, USA) |

| Liquid-storing object | Cotton | Flexible | Size: 100 mm × 100 mm (31,413, Worldjb Co., Ltd., Tokyo, Japan) | |

| Air tube | Silicone | Flexible (Shore A50) | Outer diameter: 2 mm (MGJG-1 × 2, Monotaro) | |

| Dry-air blowing unit | Air tube | Silicone | Flexible (Shore A50) | Outer diameter: 2 mm (MGJG-1 × 2, Monotaro) |

| Cotton bag | Cotton | Flexible | - | |

| Granular objects | Unpolished rice | Flowable | - | |

| Inline air filter | - | (Rigid) * | Diameter: 22 mm, length: 115 mm (IAD3-N20-T4, kitz micro filter corporation, Nagano, Japan) |

| Condition | Change | Heating Mechanism | Liquid-Injection Mechanism | Dry-Air Blowing Mechanism |

|---|---|---|---|---|

| Temperature | Increase | Yes | - | - |

| Decrease | - | Yes | Yes | |

| Humidity | Increase | - | Yes | - |

| Decrease | - | - | Yes | |

| Friction | Increase | - | Yes | - |

| Decrease | - | - | Yes |

| Relative Humidity [%] | ||||

|---|---|---|---|---|

| 30 | 50 | 70 | ||

| Temperature [°C] | 20 | t20h30 | t20h50 | t20h70 |

| 30 | t30h30 | t30h50 | t30h70 | |

| t20h30 | t20h50 | t20h70 | t30h30 | t30h50 | t30h70 | |

|---|---|---|---|---|---|---|

| Change of the contact-area-temperature [°C] (Standard deviation) | −4.7 (1.0) | −3.6 (2.1) | −1.5 (0.9) | −12.0 (3.4) | −8.0 (1.6) | −10.8 (2.3) |

| t20h30 | t20h50 | t20h70 | t30h30 | t30h50 | t30h70 | |

|---|---|---|---|---|---|---|

| After injecting the liquid [%] (Standard deviation) | +47 (2.1) | +25 (9.5) | +6.3 (2.9) | +41 (10) | +23 (3.8) | +8 (2.0) |

| After blowing dry air [%] (Standard deviation) | −2 (1.0) | −24 (1.0) | −40 (2.3) | −10 (2.5) | −31 (2.0) | −48 (1.5) |

| Environmental Temperature | Environmental Humidity | |

|---|---|---|

| Increase in the temperature | −0.98 | −0.24 |

| Decrease in the temperature | −0.92 | 0.24 |

| Increase in the humidity | −0.069 | −0.99 |

| Decrease in the humidity | −0.24 | −0.97 |

| Increase in the maximum static friction | 0.59 | −0.24 |

| Decrease in the maximum static friction | 0.81 | 0.49 |

| Increase in the kinetic friction | −0.19 | −0.88 |

| Decrease in the kinetic friction | 0.42 | 0.68 |

| Initial Condition | Blowing Dry Air | Injecting Water | |

|---|---|---|---|

| Relative humidity [%] (Change after installing the device into clothes) | 52 | 33 (−19) | 45 (+12) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nishimura, T.; Kuramata, N.; Nojiri, S.; Horiuchi, Y.; Tadakuma, K.; Watanabe, T. Development of a Flexible Thin Wearable Device for Tuning Temperature, Humidity, and Surface Friction on Its Surface. Appl. Sci. 2023, 13, 8352. https://doi.org/10.3390/app13148352

Nishimura T, Kuramata N, Nojiri S, Horiuchi Y, Tadakuma K, Watanabe T. Development of a Flexible Thin Wearable Device for Tuning Temperature, Humidity, and Surface Friction on Its Surface. Applied Sciences. 2023; 13(14):8352. https://doi.org/10.3390/app13148352

Chicago/Turabian StyleNishimura, Toshihiro, Natsuko Kuramata, Seita Nojiri, Yuki Horiuchi, Kenjiro Tadakuma, and Tetsuyou Watanabe. 2023. "Development of a Flexible Thin Wearable Device for Tuning Temperature, Humidity, and Surface Friction on Its Surface" Applied Sciences 13, no. 14: 8352. https://doi.org/10.3390/app13148352

APA StyleNishimura, T., Kuramata, N., Nojiri, S., Horiuchi, Y., Tadakuma, K., & Watanabe, T. (2023). Development of a Flexible Thin Wearable Device for Tuning Temperature, Humidity, and Surface Friction on Its Surface. Applied Sciences, 13(14), 8352. https://doi.org/10.3390/app13148352