Nonlinear-Observer-Based Neural Fault-Tolerant Control for a Rehabilitation Exoskeleton Joint with Electro-Hydraulic Actuator and Error Constraint

Abstract

1. Introduction

2. Preliminaries

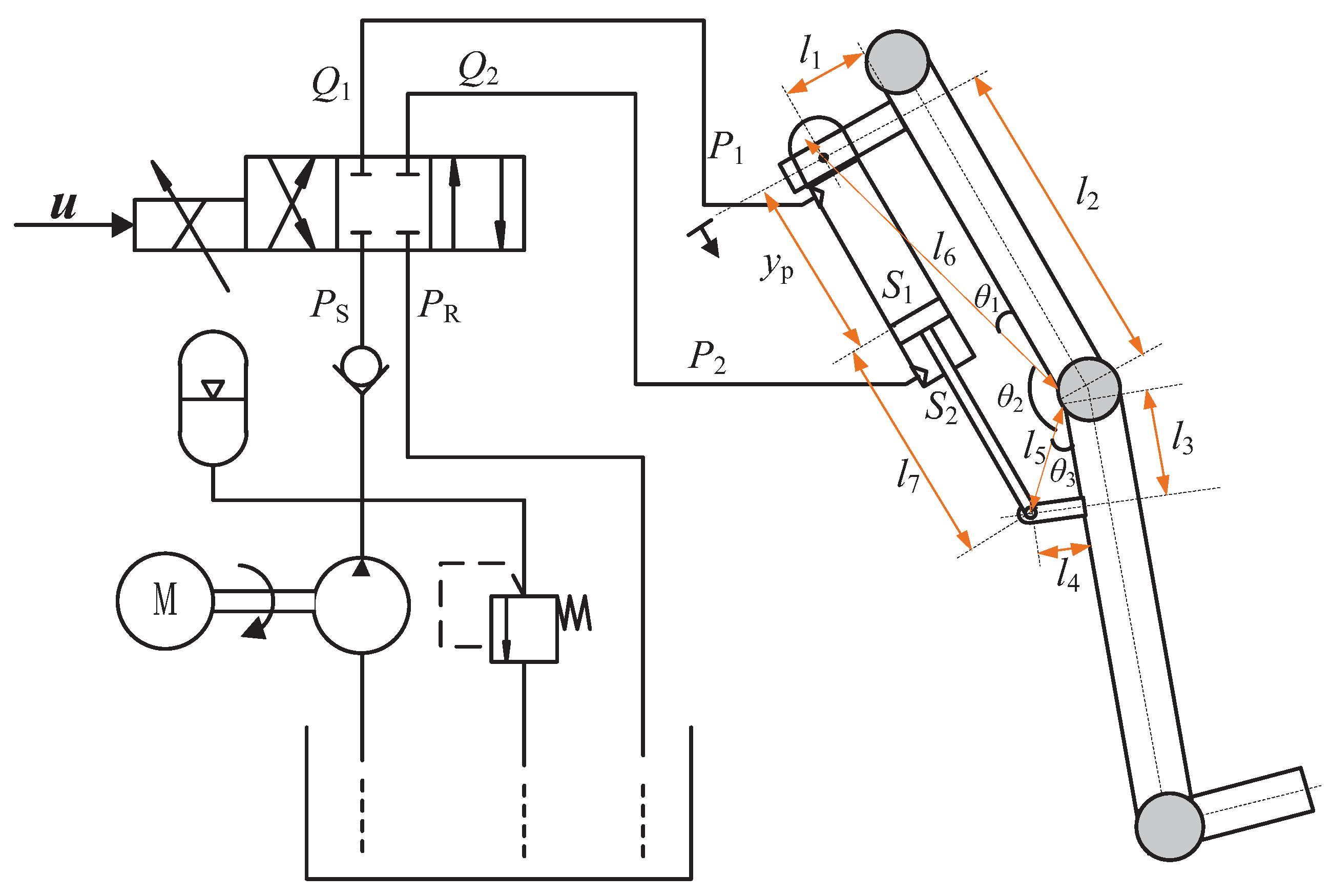

2.1. The EHA Exoskeleton

2.2. Problem Formulation

3. Control Design and Main Results

Controller Development

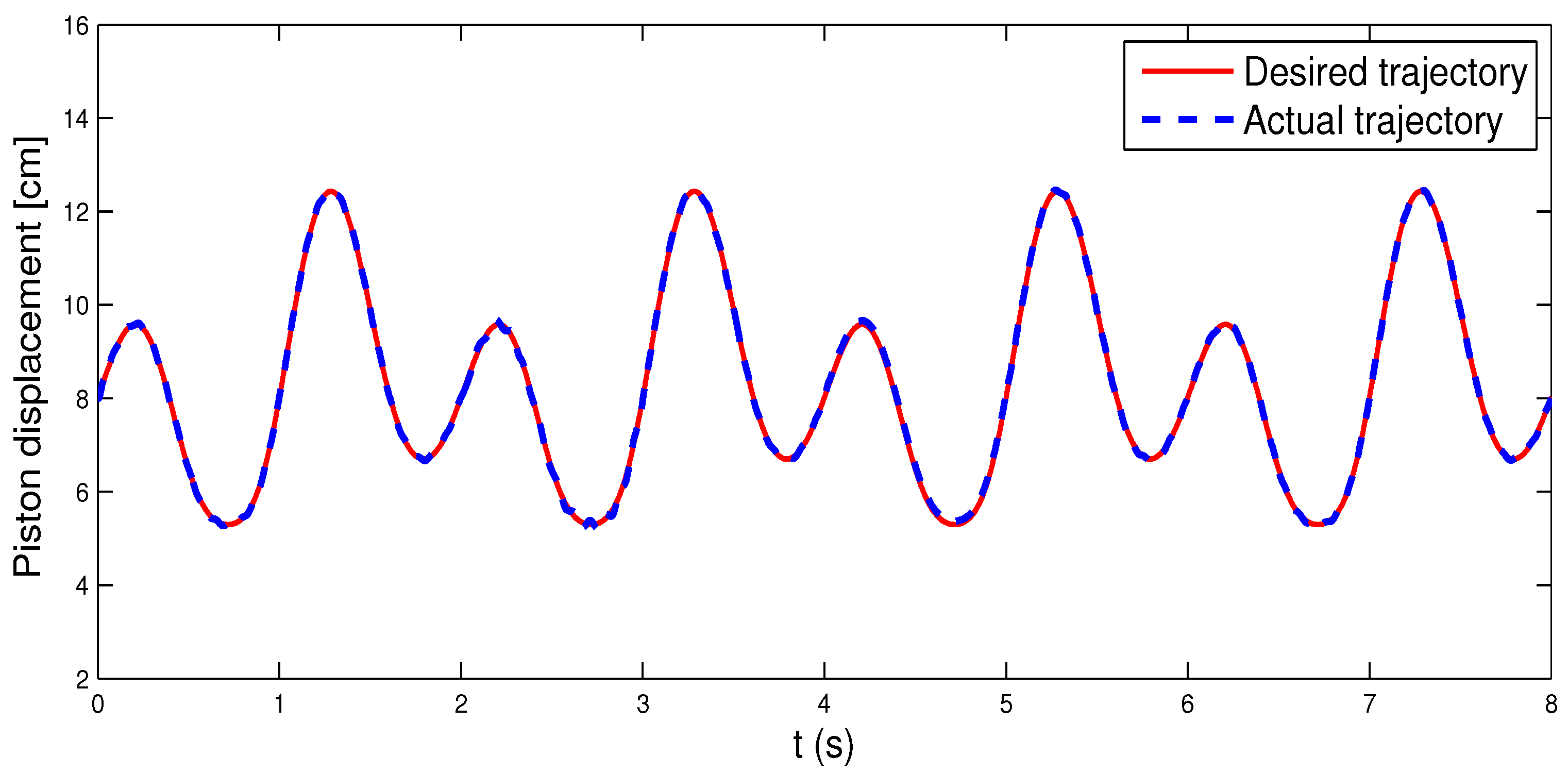

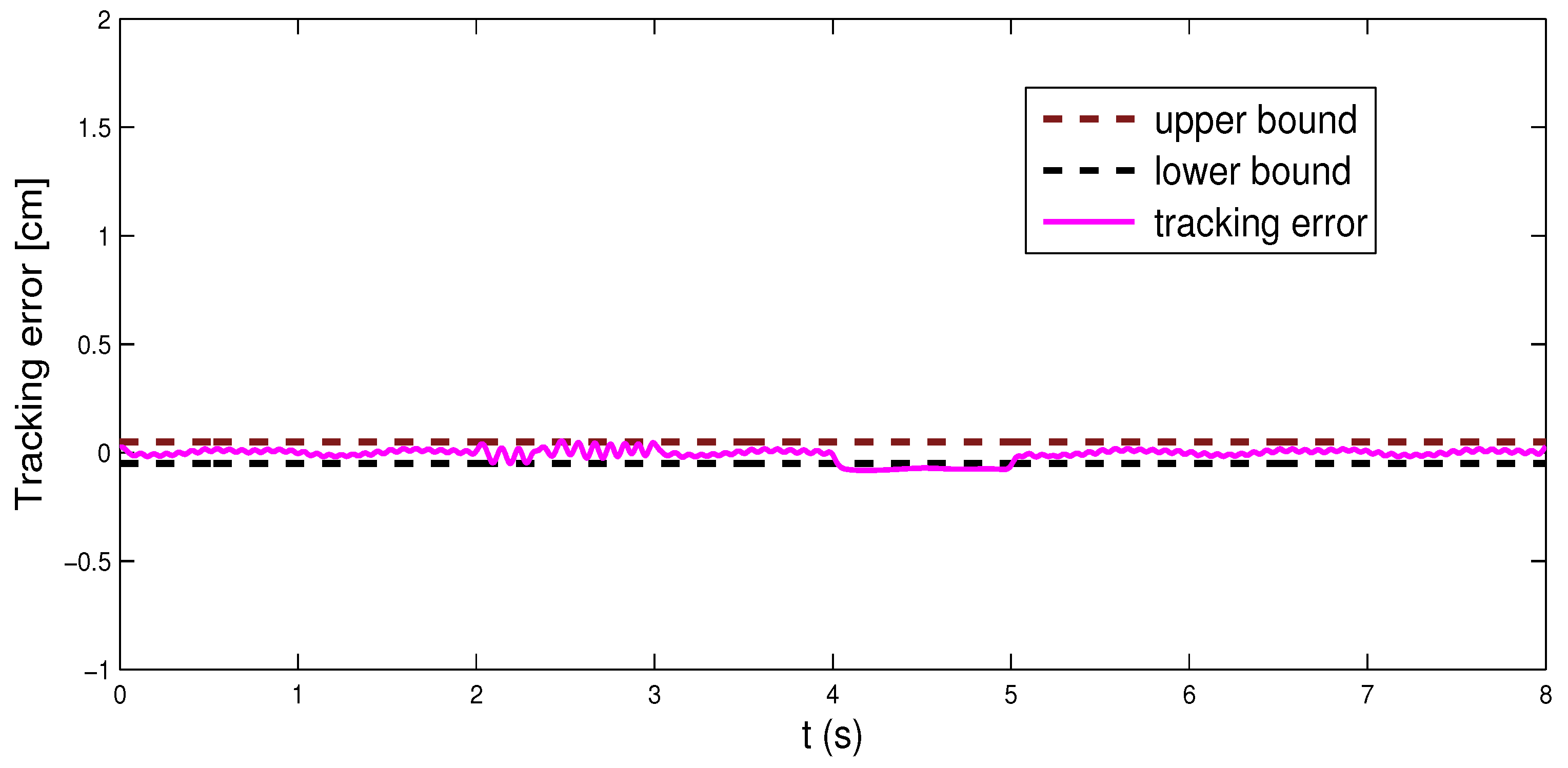

4. Simulation Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Masengo, G.; Zhang, X.; Dong, R.; Alhassan, A.; Hamza, K.; Mudaheranwa, E. Lower limb exoskeleton robot and its cooperative control: A review, trends, and challenges for future research. Front. Neurorobot. 2023, 16, 913748. [Google Scholar] [CrossRef]

- Yang, J.; He, Y.; Shi, P.; Yu, H. A review on human intent understanding and compliance control strategies for lower limb exoskeletons. Proc. Inst. Mech. Eng. Part I—J. Syst. Control Eng. 2022, 236, 1067–1086. [Google Scholar] [CrossRef]

- Zhang, X.; Li, J.; Ovur, S.; Chen, Z.; Li, X.; Hu, Z.; Hu, Y. Novel design and adaptive fuzzy control of a lower-limb elderly rehabilitation. Electronics 2020, 9, 343. [Google Scholar] [CrossRef]

- Chen, C.; Lien, W.; Chen, C.; Twu, M.; Wu, Y. Dynamic modeling and motion control of a cable-driven robotic exoskeleton with pneumatic artificial muscle actuators. IEEE Access 2020, 8, 149796–149807. [Google Scholar] [CrossRef]

- Pehlivan, A.; Losey, D.; O’Malley, M. Minimal assist-as-needed controller for upper limb robotic rehabilitation. IEEE Trans. Robot. 2015, 32, 113–124. [Google Scholar] [CrossRef]

- Martinez-Peon, D.; Olguín-Díaz, E.; Munoz-Vázquez, A.; Francisco, P.; Méndez, D. Modeling and control of exoskeleton for wrist and forearm rehabilitation. Biomed. Signal Process. Control 2021, 70, 103022. [Google Scholar] [CrossRef]

- Wu, Q.; Chen, B.; Wu, H. Neural-network-enhanced torque estimation control of a soft wearable exoskeleton for elbow assistance. Mechatronics 2019, 63, 102279. [Google Scholar] [CrossRef]

- Milecki, A.; Nowak, P. Review of Fault-Tolerant Control Systems Used in Robotic Manipulators. Appl. Sci. 2023, 13, 2675. [Google Scholar] [CrossRef]

- Shi, P.; Wang, X.; Meng, X.; He, M.; Mao, Y.; Wang, Z. Adaptive fault-tolerant control for open-circuit faults in dual three-phase pmsm drives. IEEE Trans. Power Electron. 2022, 38, 3676–3688. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, Z. Integrated fault estimation and fault tolerant attitude control for rigid spacecraft with multiple actuator faults and saturation. IET Contr. Theory Appl. 2019, 13, 2365–2375. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, G. Temperature fault-tolerant control system of CSTR with coil and jacket heat exchanger based on dual control and fault diagnosis. J. Cent. South Univ. 2017, 24, 655–664. [Google Scholar] [CrossRef]

- Liu, C.; Jiang, B.; Zhang, K.; Ding, S. Hierarchical structure-based fault-tolerant tracking control of multiple 3-DOF laboratory helicopters. IEEE Trans. Syst. Man Cybern. Syst. 2021, 52, 4247–4258. [Google Scholar] [CrossRef]

- Ren, Y.; Fang, Y.; Wang, A.; Zhang, H.; Wang, H. Collaborative operational fault tolerant control for stochastic distribution control system. Automatica 2018, 98, 141–149. [Google Scholar] [CrossRef]

- Amin, A.; Hasan, K. A review of fault tolerant control systems: Advancements and applications. Measurement 2019, 143, 58–68. [Google Scholar] [CrossRef]

- Tee, K.; Ge, S.; Tay, E. Barrier Lyapunov functions for the control of output-constrained nonlinear systems. Automatica 2009, 45, 918–927. [Google Scholar]

- Ding, S.; Zhang, B.; Mei, K.; Park, J. Adaptive fuzzy sosm controller design with output constraints. IEEE Trans. Fuzzy Syst. 2021, 30, 2300–2311. [Google Scholar] [CrossRef]

- Sun, W.; Lan, J.; Yeow, J. Constraint adaptive output regulation of output feedback systems with application to electrostatic torsional micromirror. Int. J. Robust Nonlinear Control 2015, 25, 504–520. [Google Scholar] [CrossRef]

- Zhao, Z.; He, W.; Ge, S. Adaptive neural network control of a fully actuated marine surface vessel with multiple output constraints. IEEE Trans. Control Syst. Technol. 2013, 22, 1536–1543. [Google Scholar]

- Hu, H.; Cao, J. Practical tracking control for dual-arm robot with output constraints. Int. J. Control Autom. Syst. 2022, 20, 3264–3273. [Google Scholar]

- Liu, Y.; Lu, S.; Tong, S. Neural network controller design for an uncertain robot with time-varying output constraint. IEEE Trans. Syst. Man Cybern. Syst. 2017, 47, 2060–2068. [Google Scholar] [CrossRef]

- Jin, L.; Li, S.; Hu, B.; Liu, M. A survey on projection neural networks and their applications. Appl. Soft. Comput. 2019, 76, 533–544. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Xu, X.; Chin, C. Adaptive fixed-time neural network tracking control of nonlinear interconnected systems. Entropy 2021, 23, 1152. [Google Scholar] [CrossRef] [PubMed]

- Fei, J.; Chen, Y.; Liu, L.; Fang, Y. Fuzzy multiple hidden layer recurrent neural control of nonlinear system using terminal sliding-mode controller. IEEE Trans. Cybern. 2021, 52, 9519–9534. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Li, S.; Zhang, J.; Wu, F.; Zhang, T. Neural adaptive funnel dynamic surface control with disturbance-observer for the pmsm with time delays. Entropy 2022, 24, 1028. [Google Scholar] [CrossRef]

- Sun, X. Kinematics model identification and motion control of robot based on fast learning neural network. J. Ambient Intell. Humaniz. Comput. 2021, 11, 6145–6154. [Google Scholar] [CrossRef]

- Chen, J.; Huang, J. Application of adaptive observer to sensorless induction motor via parameter-dependent transformation. IEEE Trans. Control Syst. Technol. 2018, 27, 2630–2637. [Google Scholar] [CrossRef]

- Cai, H.; Huang, J. Output based adaptive distributed output observer for leader–follower multiagent systems. Automatica 2021, 125, 109413. [Google Scholar] [CrossRef]

- Wei, X.; Chen, N.; Li, W. Composite adaptive disturbance observer-based control for a class of nonlinear systems with multisource disturbance. Int. J. Adapt. Control Signal Process. 2013, 27, 199–208. [Google Scholar] [CrossRef]

- Li, X.; Wei, X.; Zhang, H.; Han, J.; Hu, X.; Liu, X. Adaptive nonlinear disturbance observer-based control for stochastic systems with multiple heterogeneous disturbances. Trans. Inst. Meas. Control 2020, 42, 2020–2030. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Y.; Liu, X.; Huang, D. Adaptive neural network control for a hydraulic knee exoskeleton with valve deadband and output constraint based on nonlinear disturbance observer. Neurocomputing 2022, 473, 14–23. [Google Scholar] [CrossRef]

- Jiang, C.; Sui, S.; Tong, S. Finite-time fuzzy adaptive output feedback control of electro-hydraulic system with actuator faults. Inf. Sci. 2023, 623, 577–591. [Google Scholar] [CrossRef]

| Description | Symbol | Value |

|---|---|---|

| Mechanical length 1 | ||

| Mechanical length 2 | ||

| Mechanical length 3 | ||

| Mechanical length 4 | ||

| Mechanical length 7 | ||

| m | Equivalent load acted on the piston rod | |

| c | Combined friction coefficient | 950 |

| The piston area of the non-rod chamber | ||

| The piston area of the rod chamber | ||

| Effective bulk modulus | ||

| The areas ratio | ||

| The valve flow/signal gain | ||

| Initial volume of the non-rod chamber | ||

| Initial volume of the rod chamber |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, C.; Yang, Y. Nonlinear-Observer-Based Neural Fault-Tolerant Control for a Rehabilitation Exoskeleton Joint with Electro-Hydraulic Actuator and Error Constraint. Appl. Sci. 2023, 13, 8294. https://doi.org/10.3390/app13148294

Song C, Yang Y. Nonlinear-Observer-Based Neural Fault-Tolerant Control for a Rehabilitation Exoskeleton Joint with Electro-Hydraulic Actuator and Error Constraint. Applied Sciences. 2023; 13(14):8294. https://doi.org/10.3390/app13148294

Chicago/Turabian StyleSong, Changlin, and Yong Yang. 2023. "Nonlinear-Observer-Based Neural Fault-Tolerant Control for a Rehabilitation Exoskeleton Joint with Electro-Hydraulic Actuator and Error Constraint" Applied Sciences 13, no. 14: 8294. https://doi.org/10.3390/app13148294

APA StyleSong, C., & Yang, Y. (2023). Nonlinear-Observer-Based Neural Fault-Tolerant Control for a Rehabilitation Exoskeleton Joint with Electro-Hydraulic Actuator and Error Constraint. Applied Sciences, 13(14), 8294. https://doi.org/10.3390/app13148294