Springback Prediction of Free Bending Based on Experimental Method

Abstract

1. Introduction

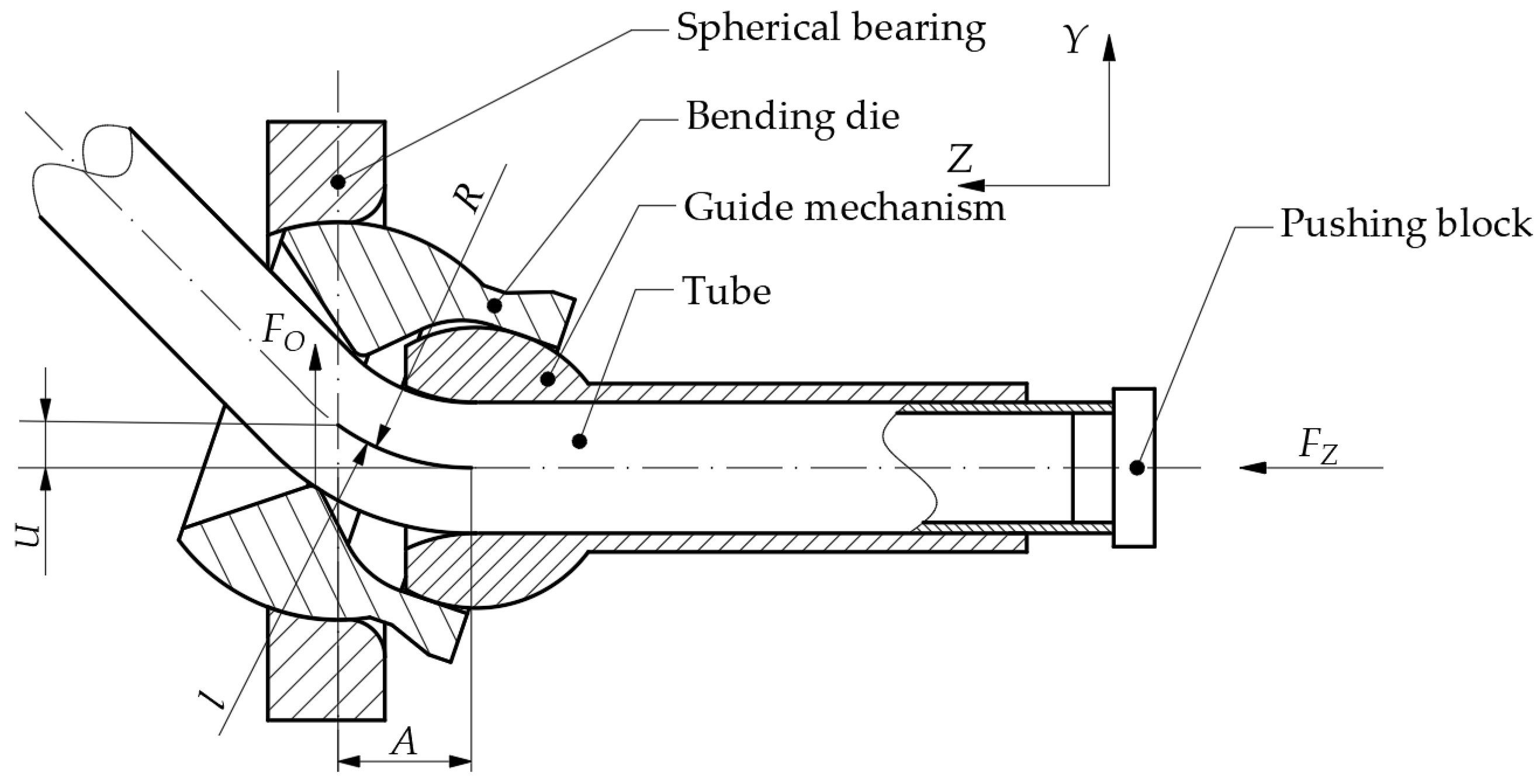

2. Free-Bending Technology

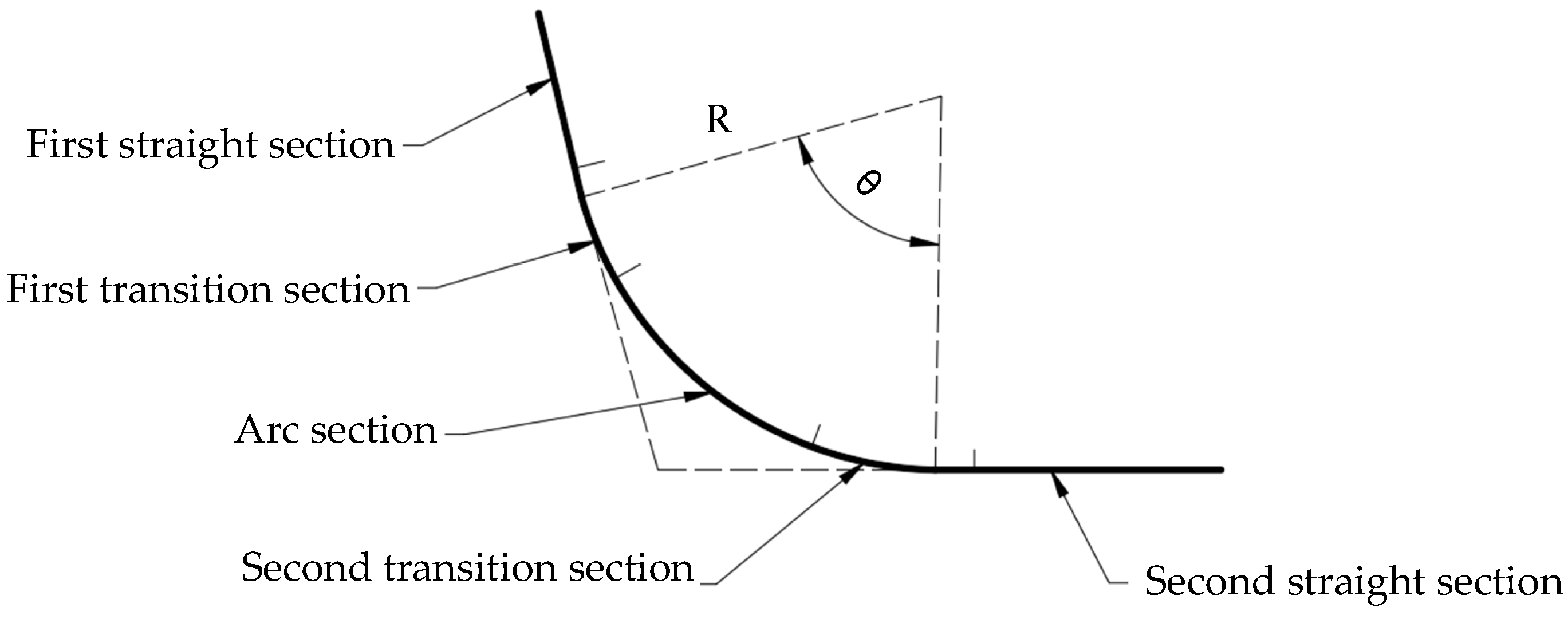

- (1)

- First transition section

- (2)

- Arc section

- (3)

- Second transition section

3. Experimental Verification

3.1. U-R Experiment

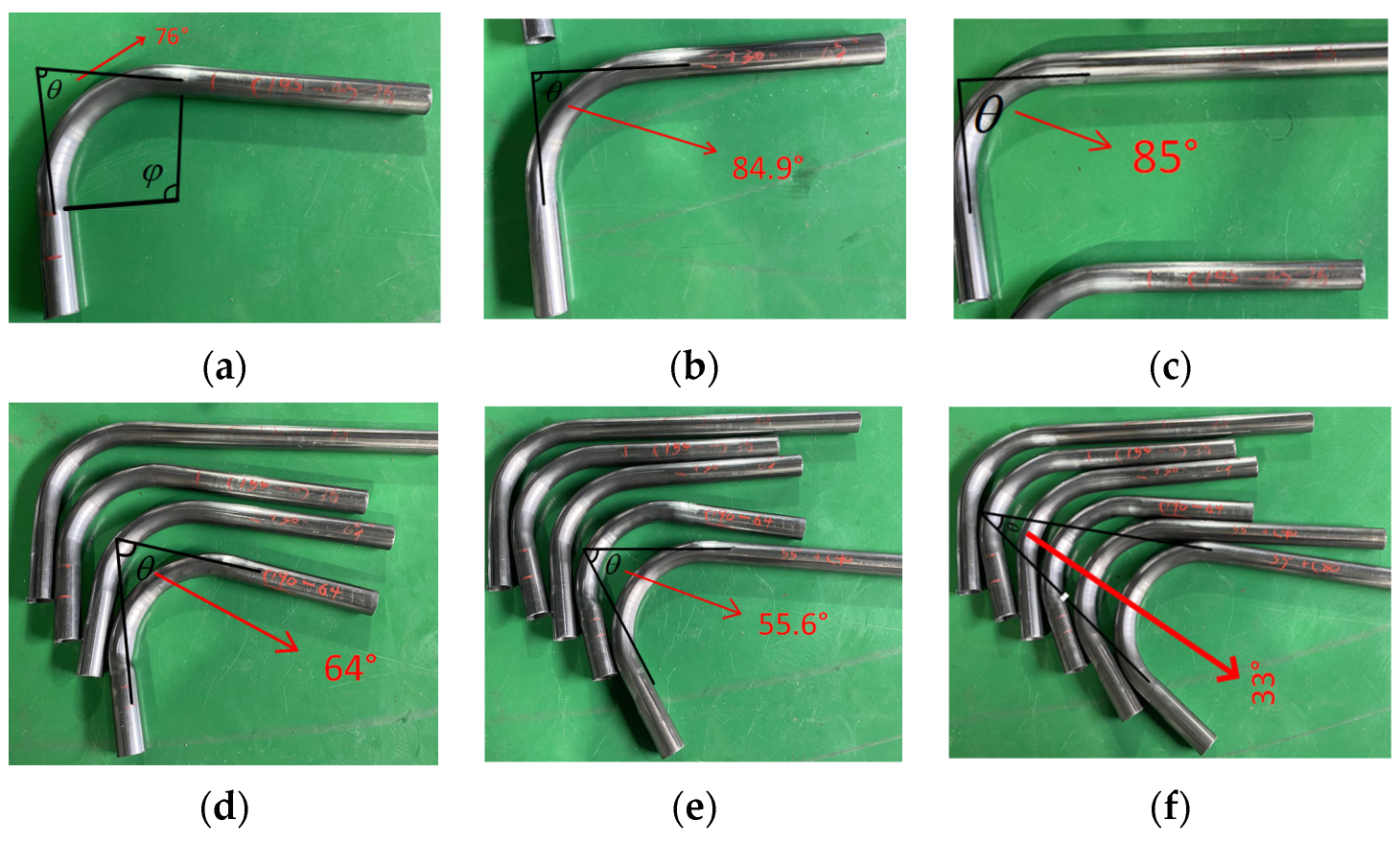

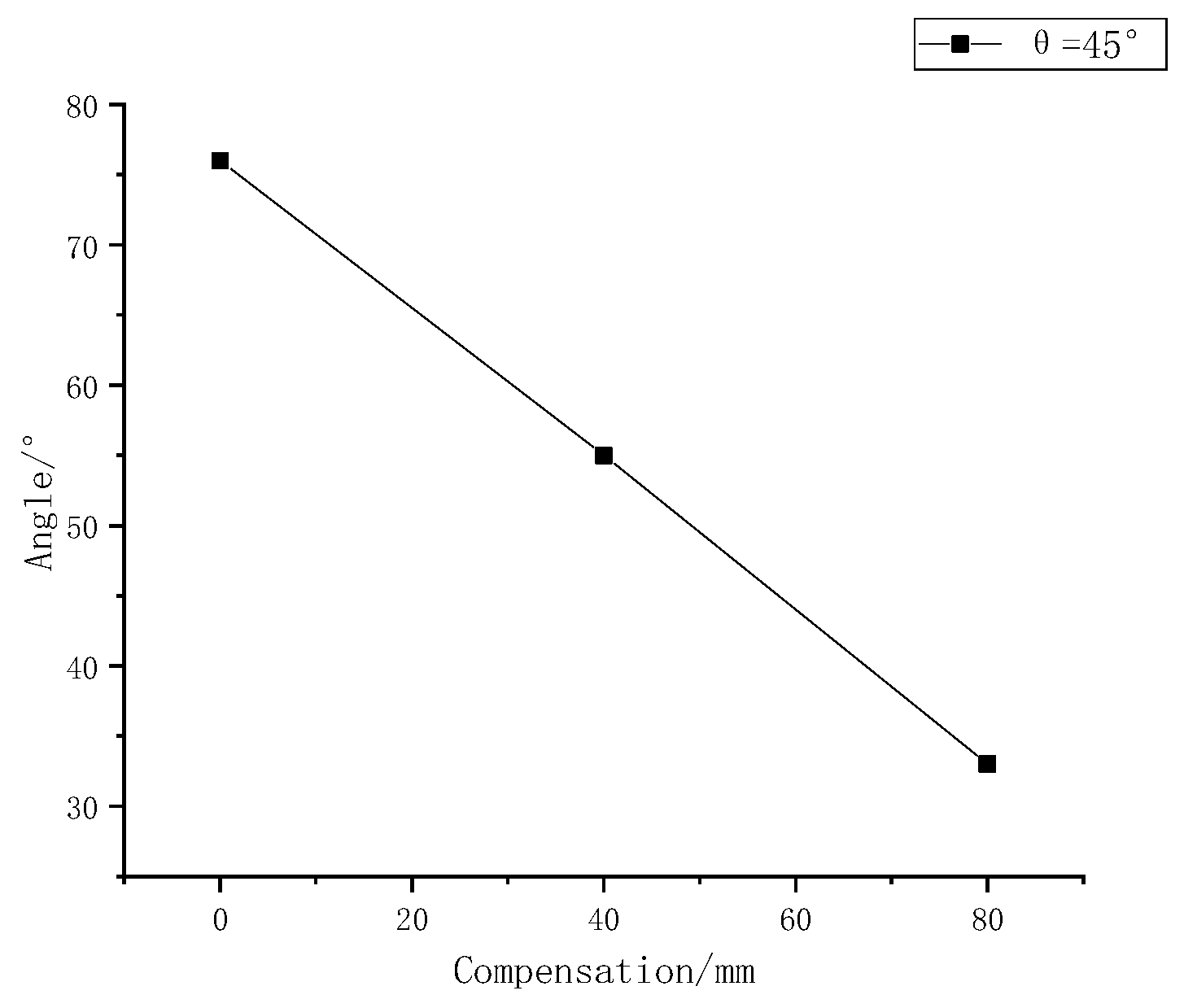

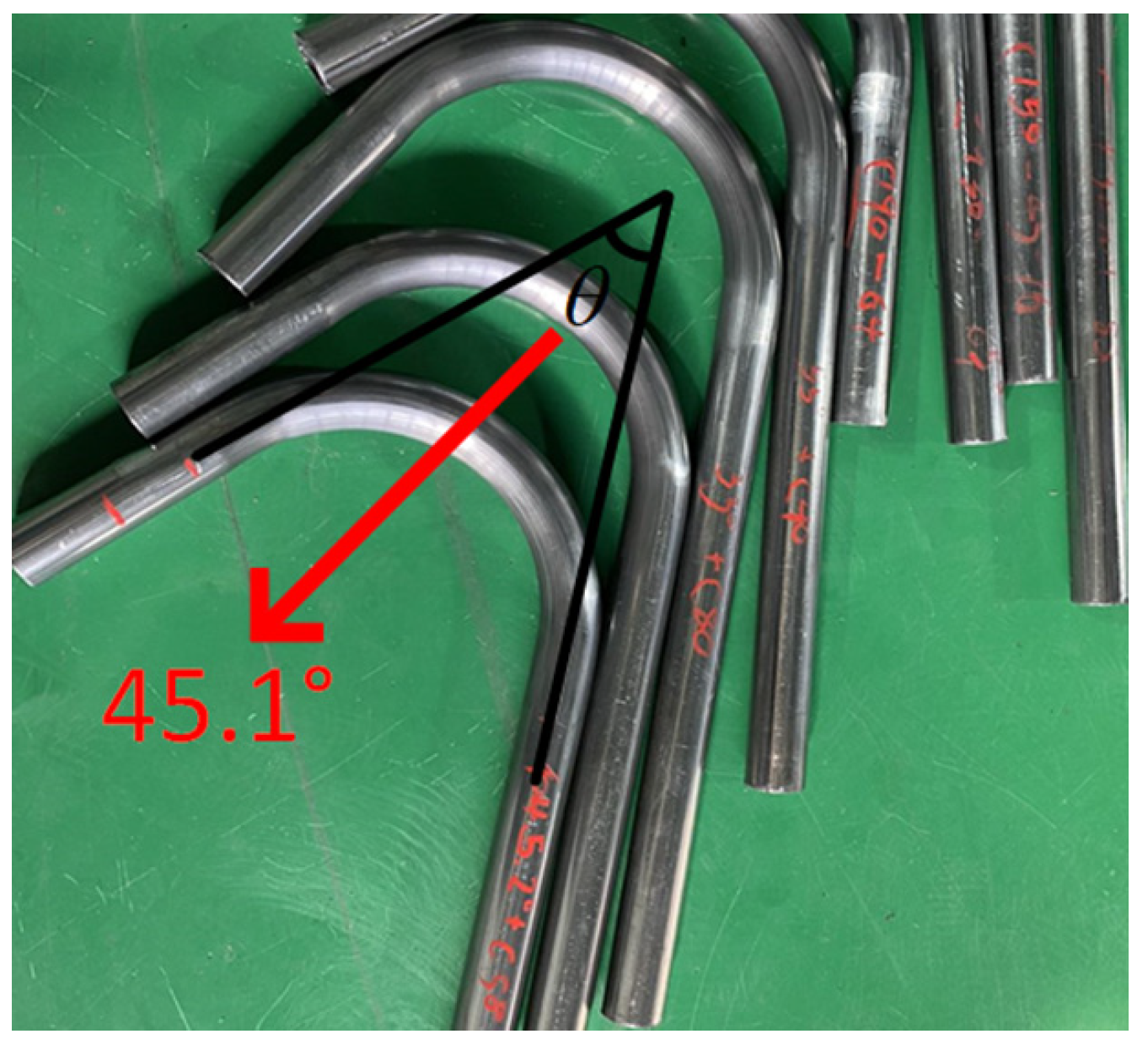

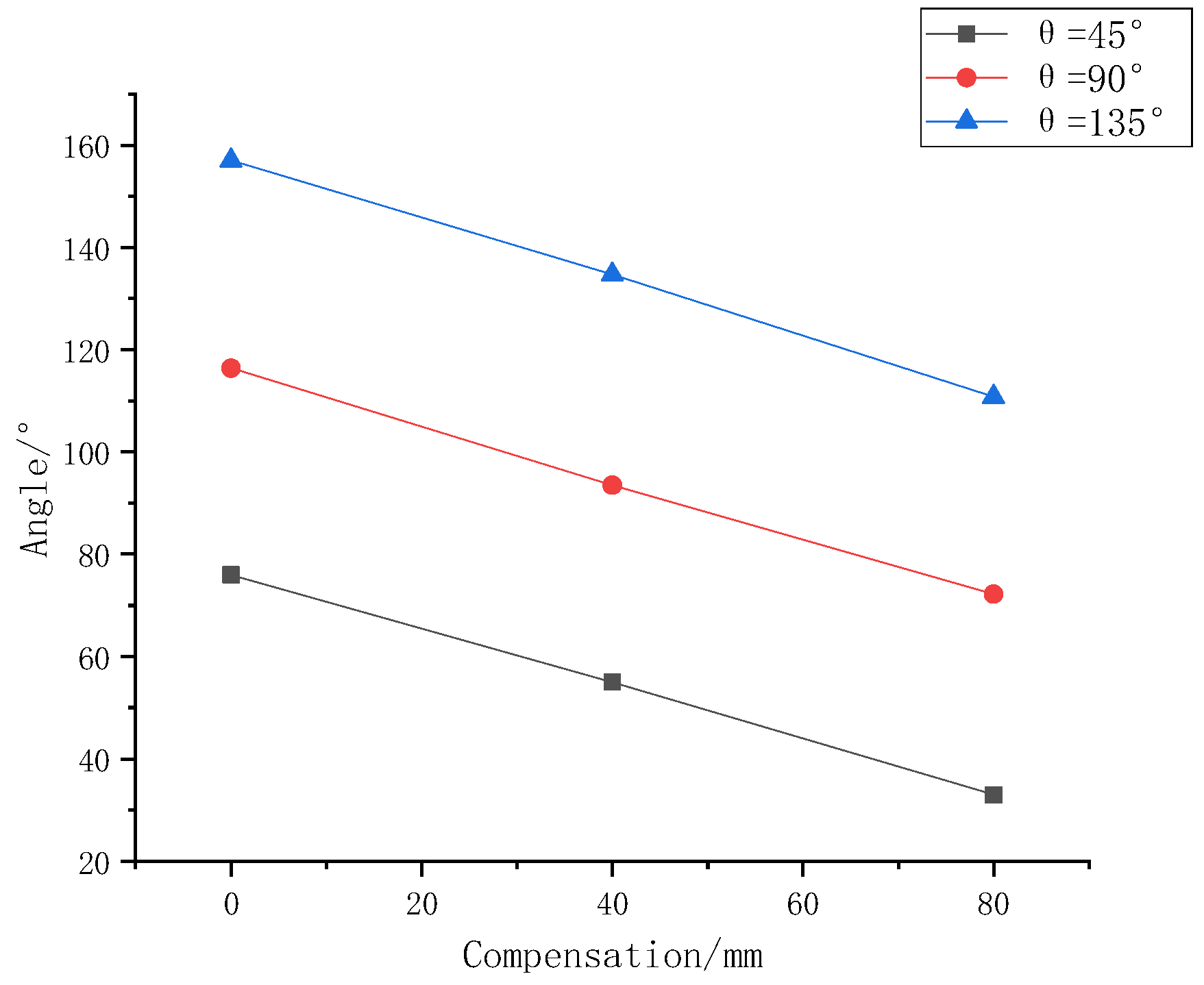

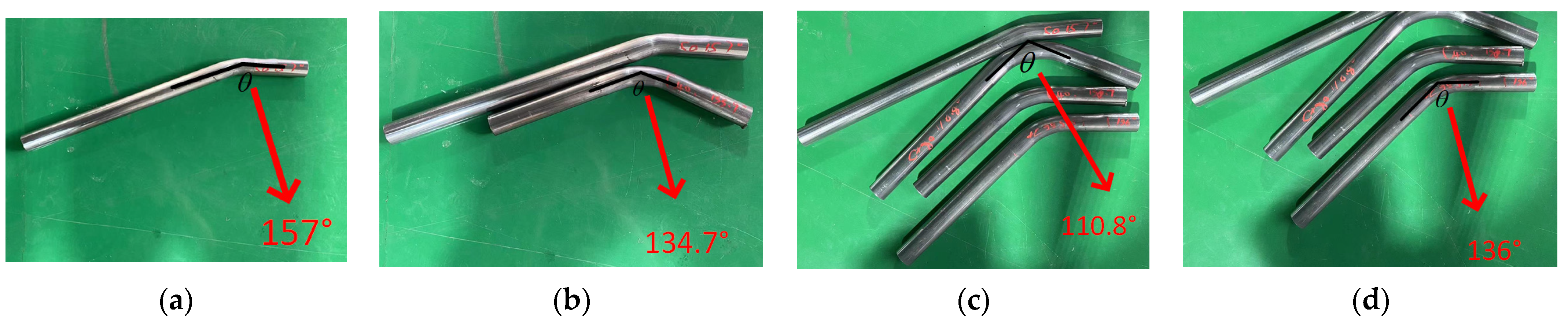

3.2. Springback Experiment

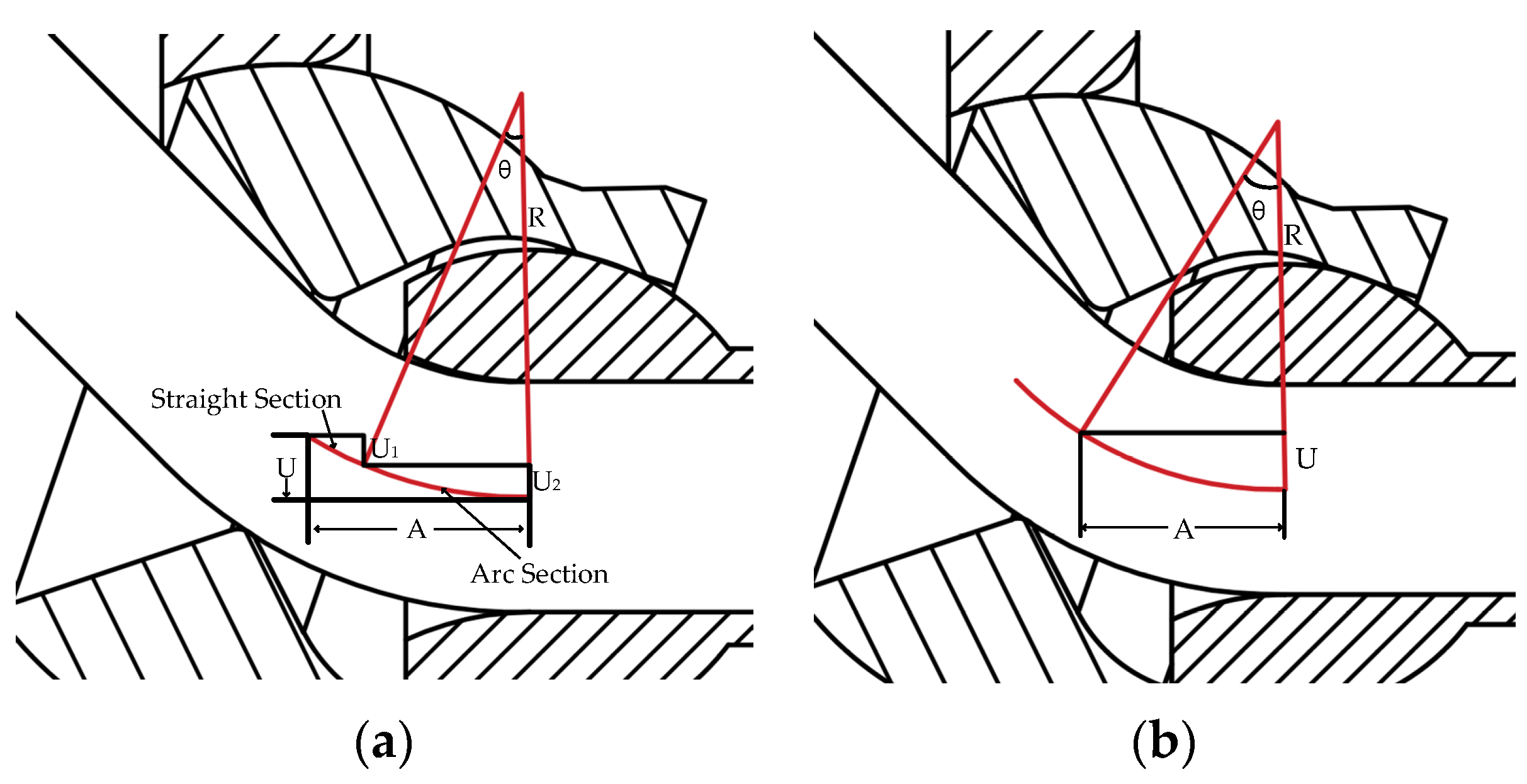

- (1)

- Compensate the first transition section

- (2)

- Compensate the second transition section

- (3)

- Compensate the arc segment

4. Conclusions

- (1)

- The theoretical U-R relationship cannot meet the actual processing requirements, and the actual processing is affected by many factors. The experimental U-R data show that the larger the bending die offset U is, the smaller the bending radius R is. Different materials have different U-R relationships;

- (2)

- From the cross-section, it can be seen that in the process of free bending, the material outside the arc is thinner, and the material inside the arc is thicker. This will cause the tube to be squeezed and stretched unnecessarily during the actual process. However, the length of the arc section of the actual bent pipe is shorter than the length of the theoretical arc section, which also verifies this point;

- (3)

- Compensating the transition section cannot solve the springback problem, while compensating the arc section can solve the springback problem well. The springback angle, with a small error, can be obtained using the experimental method. The general rule of the springback of the tube can be obtained by the springback compensation experiment: with the increase of the compensation value, the included angle is smaller. An ideal tube can be obtained according to that rule.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Wu, J.; Liang, B.; Wang, M.; Yang, J.; Muzamil, M. A new strategy for acquiring the forming parameters of a complex spatial tube product in free bending technology. J. Mater. Process Technol. 2020, 282, 116662. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, J.; Shang, Q.; Jiang, Q.; Yang, J.; Guo, R. A new strategy for describing the characteristics of bending line in flexible push bending. Eng. Comput. 2019, 36, 1597–1607. [Google Scholar] [CrossRef]

- Al-Qureshi, H. Elastic-plastic analysis of tube bending. Int. J. Mach. Tool. Manuf. 1999, 39, 87–104. [Google Scholar] [CrossRef]

- Yang, H.; Li, H.; Zhang, Z.; Zhan, M.; Liu, J.; Li, G. Advances and Trends on Pipe Bending Forming Technologies. Chin. J. Aeronaut. 2012, 25, 1–12. [Google Scholar] [CrossRef]

- Fang, J.; Liang, C.; Lu, S.; Wang, K. Effect of geometrical parameters on forming quality of high-strength TA18 titanium alloy pipe in numerical control bending. Trans. Nonferrous Met. Soc. China 2017, 28, 309–318. [Google Scholar] [CrossRef]

- Murata, M.; Kuboki, T. CNC Pipe Forming Method for Manufacturing Flexibly and 3-Dimensionally Bent Pipes. In 60 Excellent Inventions in Metal Forming; Springer: Berlin/Heidelberg, Germany, 2015; Volume 820, pp. 363–368. [Google Scholar]

- Murata, M.; Ohashi, N.; Suzuki, H. New flexible penetration bending of a pipe:1st report, a study of MOS bending method. Trans. Jpn. Soc. Mech. Eng. 1989, 55, 2488–2492. [Google Scholar] [CrossRef]

- Gantner, P.; Bauer, H.; Harrison, D.K.; De Silva, A.K. Free-bending—A new bending technique in the hydroforming process chain. J. Mater. Process. Technol. 2005, 167, 302–308. [Google Scholar] [CrossRef]

- Kawasumi, S.; Takeda, Y.; Matsuura, D. Precise pipe-bending by 3-RPSR parallel mechanism considering springback and clearances at dies. Trans. JSME 2014, 80, 820. [Google Scholar]

- Guo, X.; Wei, W.; Yong, X.; Ali, A.E.-A.; Hai, L.; Hui, W.; Xinyi, L.; Jie, T. Wall thickness distribution of Cu–Al bimetallic pipe based on free bending process. Int. J. Mech. Sci. 2019, 150, 12–19. [Google Scholar] [CrossRef]

- Guo, X.; Xiong, H.; Xu, Y.; Ma, Y.; El-Aty, A.A.; Tao, J.; Jin, K. Free-bending process characteristics and forming process design of copper tubular components. Int. J. Adv. Manuf. Tech. 2018, 96, 3585–3601. [Google Scholar] [CrossRef]

- Guo, X.; Ma, Y.; Chen, W.; Xiong, H.; Xu, Y.; El-Aty, A.A.; Jin, K. Simulation and experimental research of the free bending process of a spatial pipe. J. Mater. Process Tech. 2018, 255, 137–149. [Google Scholar] [CrossRef]

- Guo, X.; Xiong, H.; Li, H.; Xu, Y.; Ma, Z.; El-Aty, A.A.; Ma, Y.; Jin, K. Forming characteristics of pipe free-bending with small bending radii based on a new spherical connection. Int. J. Mach. Tool. Manuf. 2018, 133, 72–84. [Google Scholar] [CrossRef]

- El-Aty, A.A.; Guo, X.; Lee, M.-G.; Tao, J.; Hou, Y.; Hu, S.; Li, T.; Wu, C.; Yang, Q. A review on flexibility of free bending forming technology for manufacturing thin-walled complex-shaped metallic pipes. Int. J. Light. Mater. Manuf. 2023, 6, 165–188. [Google Scholar]

- Cheng, C.; Chen, H.; Guo, J.; Guo, X.; Shi, Y. Investigation on the influence of mandrel on the forming quality of thin-walled pipe during free bending process. J. Manuf. Process. 2021, 72, 215–226. [Google Scholar] [CrossRef]

- Guo, X.; Xiong, H.; Xu, Y.; El-Aty, A.A.; Ma, Y.; Zhao, Y.; Zhang, S. U-R relationship prediction method for aluminum alloy circular pipe free-bending process based on sensitivity analysis of material parameters. Int. J. Adv. Manuf. Technol. 2018, 99, 1967–1977. [Google Scholar] [CrossRef]

- Cheng, X.; Guo, X.; Tao, J.; Xu, Y.; El-Aty, A.A.; Liu, H. Investigation of the effect of relative thickness (t/d) on the formability of the AA6061 pipes during free bending process. Int. J. Mech. Sci. 2019, 160, 103–113. [Google Scholar] [CrossRef]

- Wang, W.; Hu, S.; El-Aty, A.A.; Wu, C.; Yang, Q.; Chen, H.; Shen, Y.; Tao, J. Springback analysis of different A-values of Cu and Al pipes in free bending forming technology: Experimentation and finite element modeling. Int. J. Adv. Manuf. Tech. 2021, 113, 705–719. [Google Scholar] [CrossRef]

- Li, Y.; Li, A.; Yue, Z.; Qiu, L.; Badreddine, H.; Gao, J.; Wang, Y. Springback prediction of AL6061 pipe in free bending process based on finite element and analytic methods. Int. J. Adv. Manuf. Tech. 2020, 109, 1789–1799. [Google Scholar] [CrossRef]

- El Megharbel, A.; El Nasser, G.A.; El Domiaty, A. Bending of pipe and section made of strain-hardening materials. J. Mater. Process Tech. 2008, 203, 372–380. [Google Scholar] [CrossRef]

- Zhang, S.; Fu, M.; Wang, Z.; Fang, D.; Lin, W. Springback prediction model and its compensation method for the variable curvature metal pipe bending forming. Int. J. Adv. Manuf. Tech. 2021, 112, 3151–3165. [Google Scholar] [CrossRef]

- Shi, C.; Fu, W.; Li, M.; Yi, Z. Springback Analysis in Flexible-bending Process of Pipes. Mater. Sci. Eng. 2019, 540, 012012. [Google Scholar]

- Razali, N.A.; Chung, S.H.; Chung, W.J.; Joun, M.S. Implicit elastoplastic finite element analysis of pipe-bending with an emphasis on springback prediction. Int. J. Adv. Manuf. Tech. 2022, 120, 6377–6391. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, Y.; Qiu, L.; Zhang, S.; Fang, D.; He, C.; Wang, L. Spatial variable curvature metallic pipe bending springback numerical approximation prediction and compensation method considering cross-section distortion defect. Int. J. Adv. Manuf. Technol. 2022, 118, 1811–1827. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, S.; Qiu, L.; Wang, Z. Springback angle prediction of circular metal pipe considering the interference of cross-sectional distortion in mandrel-less rotary draw bending. Sci. Progress. 2021, 104, 1–30. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Wang, H.; El-Aty, A.A.; Qin, Y.; Li, J.; Zhang, Y.; Li, T.; Guo, X. Impact of bending dies with different friction forms on forming force and quality of pipes manufactured by free bending technology. Chin. J. Aeronaut. 2021, 34, 253–264. [Google Scholar] [CrossRef]

| U (mm) | 2 | 2.5 | 3 | 4 | 6 | 10 | 15 | |

|---|---|---|---|---|---|---|---|---|

| 1 | 4998.16 | 1823.5 | 1167.2 | 619.85 | 312.8 | 155.11 | 97.32 | |

| 2 | 5137.7 | 1892.7 | 1172.7 | 624.5 | 317.22 | 155.11 | 94.42 | |

| 3 | 6096.1 | 1982.9 | 1255.2 | 619.85 | 315 | 154.03 | 94.83 | |

| 4 | 4806.3 | 2047.9 | 1212.6 | 621.39 | 313.9 | 161.88 | 95.64 | |

| 5 | 4097.2 | 1810.4 | 1172.7 | 626.06 | 321.77 | 157.3 | 64.42 | |

| 6 | 5317.7 | 1892.7 | 1161.8 | 613.76 | 319.48 | 159.56 | 96.23 | |

| 7 | 5433.3 | 1982.9 | 1151.1 | 613.76 | 322.93 | 158.42 | 95.23 | |

| 8 | 4715.6 | 1878.5 | 1178.2 | 612.26 | 319.48 | 151.92 | 94.83 | |

| 9 | 5206.9 | 1892.7 | 1195.1 | 612.26 | 319.9 | 156.19 | 93.63 | |

| 10 | 5680.4 | 1759.4 | 1200.9 | 615.27 | 319.48 | 147.88 | 93.23 | |

| Average | 5148.936 | 1896.36 | 1186.75 | 617.896 | 318.196 | 155.74 | 91.978 | |

| U (mm) | 2.2 | 2.35 | 2.5 | 2.55 | 2.7 | 3.25 | 3.5 | 5 | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 1771.2 | 1427.5 | 1207.6 | 1115.11 | 1015.3 | 762.93 | 635.61 | 373.3 | |

| 2 | 1734.9 | 1427.5 | 1207.6 | 1090.7 | 1012.9 | 770.56 | 627.63 | 373.54 | |

| 3 | 1747.1 | 1419.3 | 1210.3 | 1120.1 | 989.7 | 773.13 | 629.21 | 373.3 | |

| 4 | 1878.5 | 1403.4 | 1199.6 | 1172.1 | 1005.5 | 768 | 627.63 | 376.66 | |

| 5 | 1797.4 | 1419.3 | 1200.3 | 1188.2 | 1000.3 | 765.46 | 626.06 | 373.86 | |

| 6 | 1734.9 | 1435.7 | 1203 | 1140.5 | 1021.3 | 760.42 | 637.23 | 373.3 | |

| 7 | 1734.9 | 1357.6 | 1198.5 | 1139.3 | 997.3 | 765.46 | 627.23 | 371.65 | |

| 8 | 1771.9 | 1460.9 | 1196.7 | 1141.1 | 1110.1 | 760.42 | 630.8 | 375.54 | |

| 9 | 1771.9 | 1411.3 | 1201.7 | 1137.3 | 1005.4 | 762.93 | 632.39 | 372.75 | |

| 10 | 1759.4 | 1411.3 | 1201.7 | 1155.1 | 1002.3 | 760.42 | 622.94 | 373.86 | |

| Average | 1770.21 | 1417.38 | 1202.7 | 1139.55 | 1015.81 | 764.973 | 629.673 | 373.776 | |

| Compensation (mm) | = 90° | = 135° |

|---|---|---|

| The Angle of the Actual Springback (°) | ||

| 0 | 116.4 | 157 |

| 40 | 93.5 | 134.7 |

| 80 | 72.2 | 110.8 |

| Functional relation | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, M.; Zhang, W. Springback Prediction of Free Bending Based on Experimental Method. Appl. Sci. 2023, 13, 8288. https://doi.org/10.3390/app13148288

Hong M, Zhang W. Springback Prediction of Free Bending Based on Experimental Method. Applied Sciences. 2023; 13(14):8288. https://doi.org/10.3390/app13148288

Chicago/Turabian StyleHong, Ming, and Weiwei Zhang. 2023. "Springback Prediction of Free Bending Based on Experimental Method" Applied Sciences 13, no. 14: 8288. https://doi.org/10.3390/app13148288

APA StyleHong, M., & Zhang, W. (2023). Springback Prediction of Free Bending Based on Experimental Method. Applied Sciences, 13(14), 8288. https://doi.org/10.3390/app13148288