A Lifetime Prediction Method of Pressured Gas Polyethylene Pipes by Strain-Hardening Modulus and Tensile Test

Abstract

:1. Introduction

2. Materials and Methods

2.1. Polyethylene Material

2.2. Experimental Principle

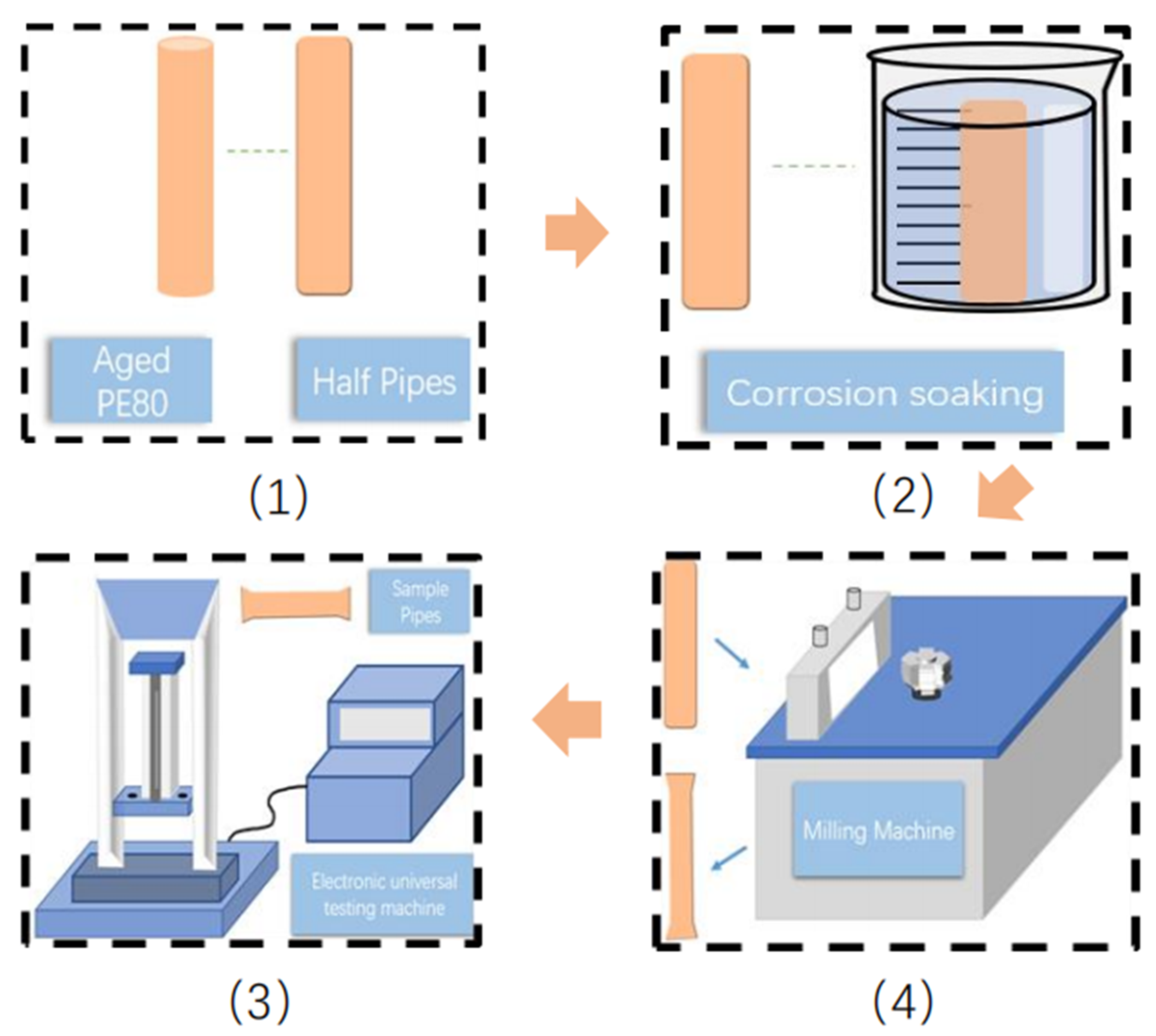

2.3. The Research Methodology

2.4. Experimental Setup

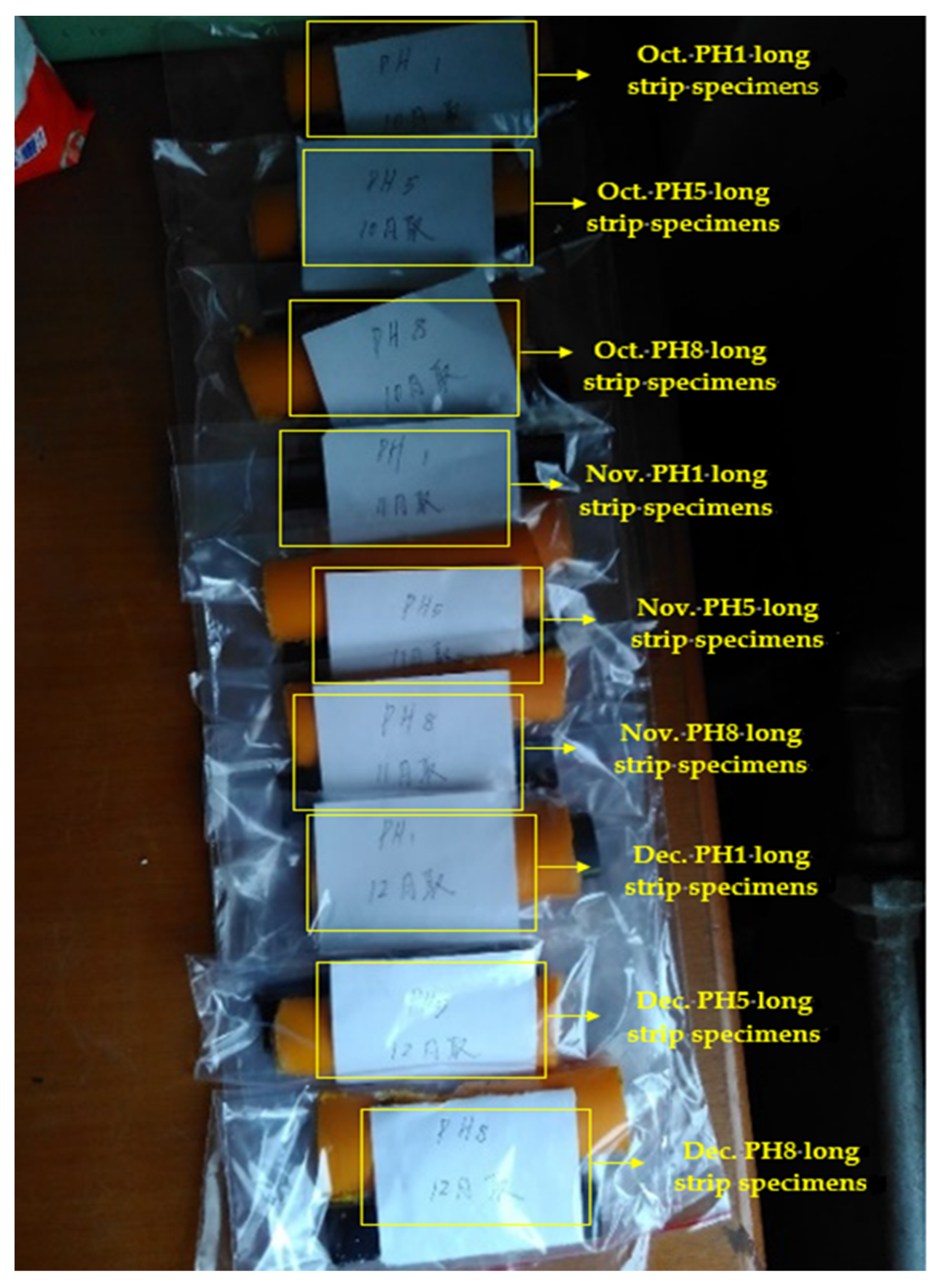

2.5. Specimen Preparation

2.6. Experimental Conditions

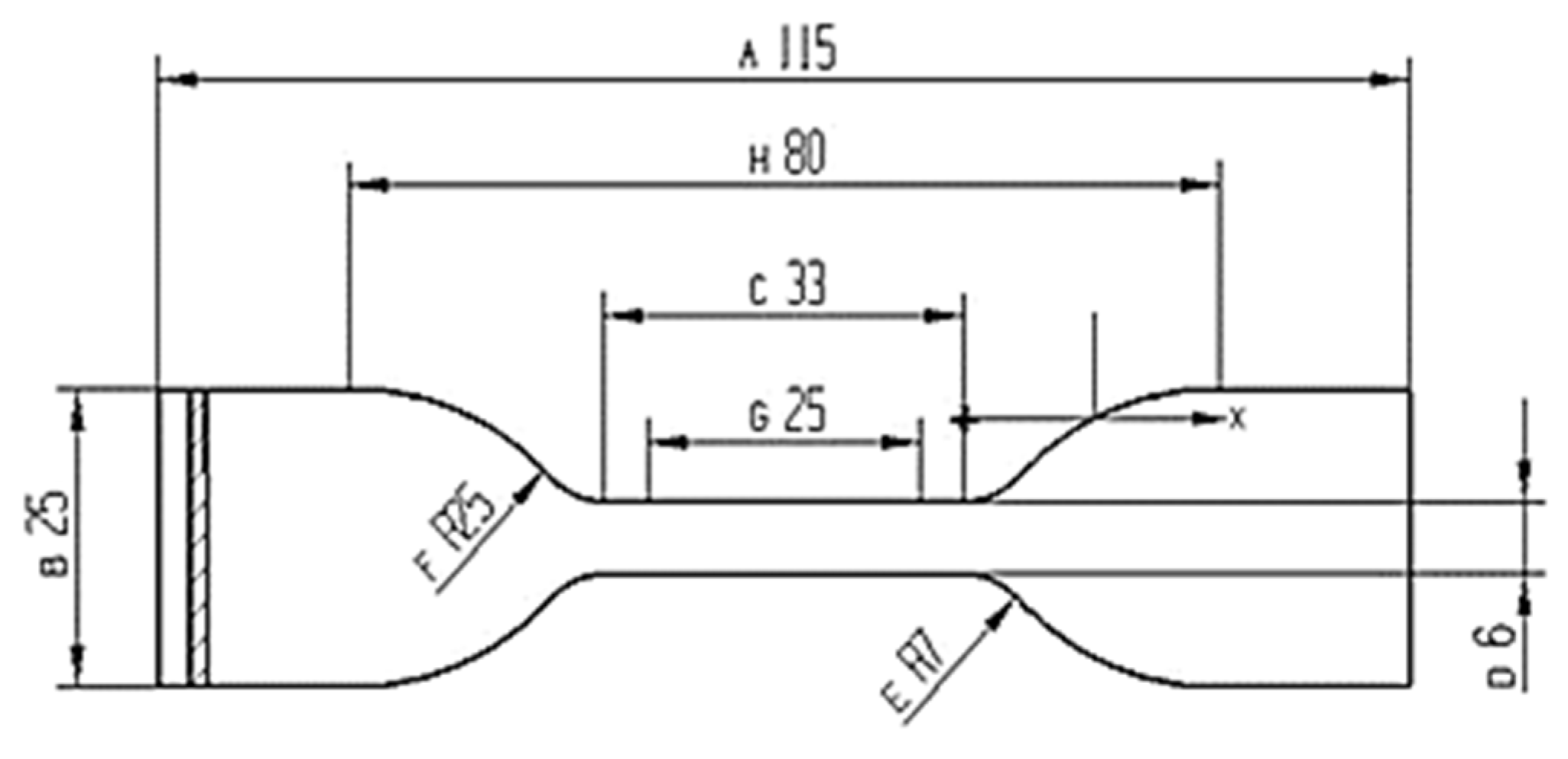

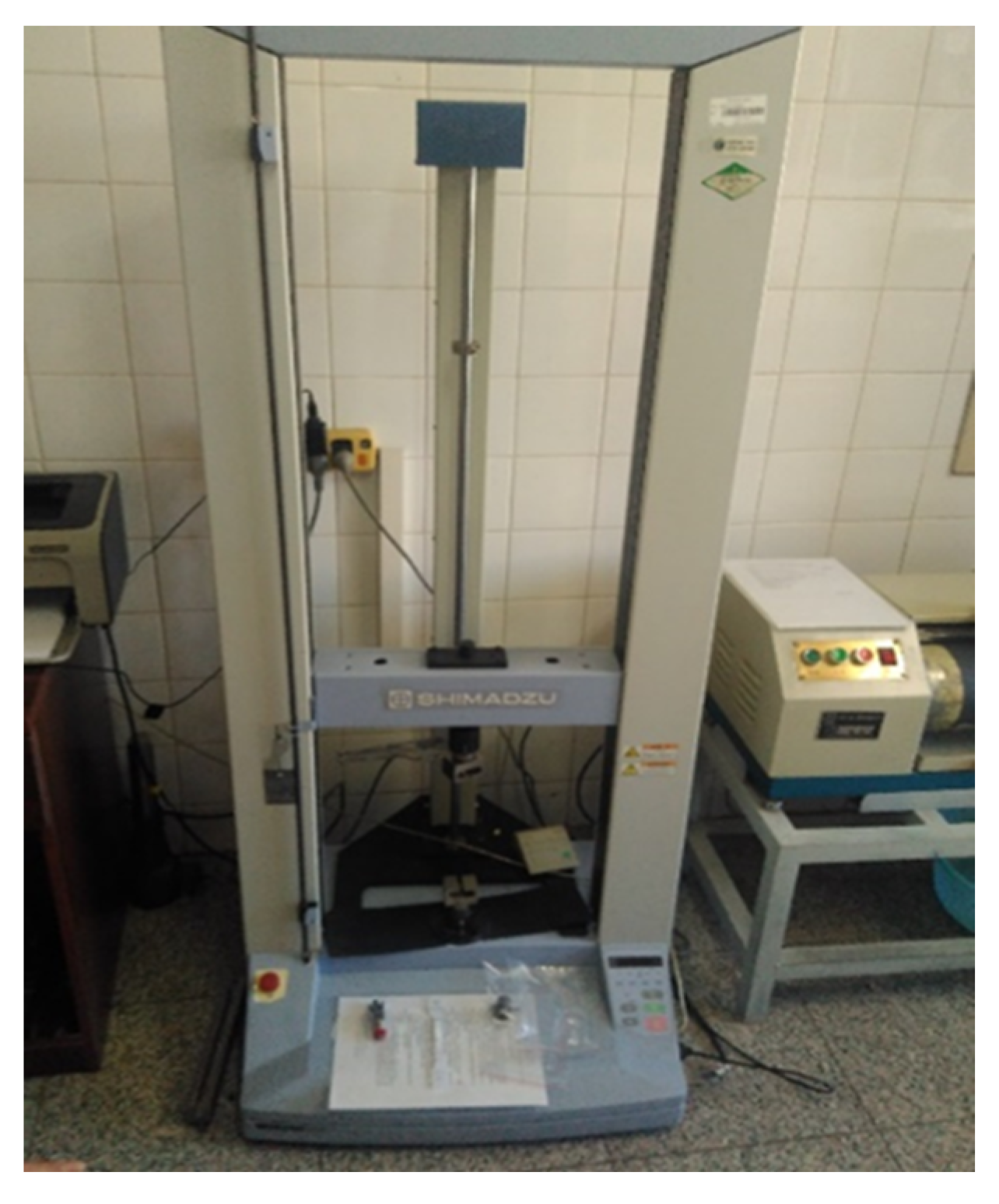

2.7. Mechanical Performance Testing

3. Results and Discussion

3.1. Lifetime Prediction Methods

3.2. Data Analysis

3.3. Predicting Lifetime

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Lan, H.Q.; Meng, T.; Chen, S.; Zuo, J.D.; Lin, N. A Lifetime Prediction Method of Pressured Gas Polyethylene Pipes by Thermal-Oxidative Aging Test and Tensile Test. J. Press. Vessel. Technol. 2017, 140, 011404. [Google Scholar] [CrossRef]

- Robledo, N.; Domínguez, C.; García-Muñoz, R.A. Alternative accelerated and short-term methods for evaluating slow crack growth in polyethylene resins with high crack resistance. Polym. Test. 2017, 62, 366–372. [Google Scholar] [CrossRef]

- Zha, S.; Lan, H.Q.; Lin, N.; Meng, T. Degradation and characterization methods for polyethylene gas pipes after natural and accelerated aging. Polym. Degrad. Stab. 2023, 208, 110247. [Google Scholar] [CrossRef]

- Wang, Y.; Lan, H.Q.; Meng, T.; Wang, B.; Guo, D.D.; Zhuang, L.J. Pressure Effects on the Lifetime of Gas High Density Polyethylene Pipes. J. Press. Vessel. Technol. 2022, 144, 154–163. [Google Scholar] [CrossRef]

- Zhang, Y.; Weng, W.G. Bayesian network model for buried gas pipeline failure analysis caused by corrosion and external interference. Reliab. Eng. Syst. Saf. 2020, 203, 107089. [Google Scholar] [CrossRef]

- Anna, P.; Bertalan, G.; Marosi, G.; Ravadits, I.; Maatoug, M.A. Effect of interface modification on the photo-stability of pigmented polyethylene films. Polym. Degrad. Stab. 2001, 73, 463–466. [Google Scholar] [CrossRef]

- Adams, T.M.; Hall, S.; Scavuzzo, R.J.; Munson, D.; Andrasik, J.W.; Findlan, S. Tensile testing and material property development of high density polyethylene pipe materials. In Proceedings of the ASME Pressure Vessels and Piping Conference, Chicago, IL, USA, 27–31 July 2008; Volume 48241, pp. 267–274. [Google Scholar]

- Lan, H.; Sha, D.; Meng, T.; Fang, X.; Zuo, J.; Li, X. Thermal Oxidative Aging Laws of PE Gas Pressure Pipes. Nat. Gas Ind. 2016, 36, 78–83. [Google Scholar] [CrossRef]

- Li, P.; Wang, F.; Gao, J.; Lin, D.; Gao, J.; Lu, J.; Qiu, E.; Liu, C. Failure Mode and the Prevention and Control Technology of Buried PE Pipeline in Service: State of the Art and Perspectives. Adv. Civ. Eng. 2022, 2022, 2228690. [Google Scholar] [CrossRef]

- Zha, S.; Lan, H.-Q.; Huang, H. Review on lifetime predictions of polyethylene pipes: Limitations and trends. Int. J. Press. Vessel. Pip. 2022, 198, 104663. [Google Scholar] [CrossRef]

- Haward, R. The derivation of a strain hardening modulus from true stress-strain curves for thermoplastics. Polymer 1994, 35, 3858–3862. [Google Scholar] [CrossRef]

- Nezbedová, E.; Pinter, G.; Frank, A.; Hutař, P.; Poduška, J.; Hodan, J. Accelerated Tests for Lifetime Prediction of PE-HD Pipe Grades. Macromol. Symp. 2017, 373, 1600096. [Google Scholar] [CrossRef]

- Gerets, B.; Wenzel, M.; Engelsing, K.; Bastian, M. Slow crack growth of polyethylene—Accelerated and alternative test methods. In Deformation and Fracture Behaviour of Polymer Materials; Grellmann, W., Langer, B., Eds.; Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 2017; Volume 247, pp. 177–187. [Google Scholar] [CrossRef]

- Huang, Y.-Q.; Zhang, Q.-L.; Lu, X.-Y.; Gong, Y.-B.; Zhou, H.; Feng, J.-C. Comparative Investigation on Step-cycle Tensile Behaviors of Two Bimodal Pipe-grade Polyethylene with Different Slow Crack Growth Resistance. Chin. J. Polym. Sci. 2019, 38, 611–619. [Google Scholar] [CrossRef]

- Amjadi, M.; Fatemi, A. Creep and fatigue behaviors of High-Density Polyethylene (HDPE): Effects of temperature, mean stress, frequency, and processing technique. Int. J. Fatigue 2020, 141, 105871. [Google Scholar] [CrossRef]

- Mao, Q.; Su, B.; Ma, R.; Li, Z. Investigation of Tensile Creep Behavior for High-Density Polyethylene (HDPE) via Experiments and Mathematical Model. Materials 2021, 14, 6188. [Google Scholar] [CrossRef]

- Van Dinh, C.; Kubouchi, M.; Sakai, T.; Tsuda, K.; Kobayashi, R. Degradation of Different Types of Polyethylene Using for Lining System Exposed to Hydrochloric Acid Solution. J. Jpn. Soc. Colour Mater. 2009, 82, 105–111. [Google Scholar] [CrossRef] [Green Version]

- ISO 1872-2:2007; Plastics—Polyethylene (PE) Moulding and Extrusion Materials—Part 2: Preparation of Test Specimens and Determination of Properties. ISO: Geneva, Switzerland, 2007.

- ISO 1167-1:2006; Thermoplastics Pipes, Fittings and Assemblies for the Conveyance of Fluids—Determination of the Resistance to Internal Pressure—Part 1: General Method. ISO: Geneva, Switzerland, 2006.

- Choi, B.H.; Chudnovsky, A.; Paradkar, R.; Michie, W.; Zhou, Z.; Cham, P.M. Experimental and theoretical investigation of stress corrosion crack (SCC) growth of polyethylene pipes. Polym. Degrad. Stab. 2009, 94, 859–867. [Google Scholar] [CrossRef]

- ISO/TR 9272:2005; Rubber and Rubber Products—Determination of Precision for Test Method Standards. ISO: Geneva, Switzerland, 2005.

- Kurelec, L.; Teeuwen, M.; Schoffeleers, H.; Deblieck, R. Strain hardening modulus as a measure of environmental stress crack resistance of high density polyethylene. Polymer 2005, 46, 6369–6379. [Google Scholar] [CrossRef]

- Deblieck, R.; Gerets, B.; Boerakker, M.; Caelers, H.; Wilbers, A.; Boonen, T. Relation between life time, failure stress and craze microstructure in polyethylene as evidenced by fracture surface texture analysis after an accelerated Full-Notch Creep Test. Polymer 2019, 176, 264–273. [Google Scholar] [CrossRef]

- Pinter, G.; Haager, M.; Lang, R.W. Influence of nonylphenol–polyglycol–ether environments on the results of the full notch creep test. Polym. Test. 2007, 26, 700–710. [Google Scholar] [CrossRef]

- ISO 16241:2005; Notch Tensile Test to Measure the Resistance to Slow Crack Growth of Polyethylene Materials for Pipe and Fitting Products (PENT). ISO: Geneva, Switzerland, 2005.

- ISO 16770:2004; Plastics—Determination of Environmental Stress Cracking (ESC) of Polyethylene—Full-Notch Creep Test (FNCT). ISO: Geneva, Switzerland, 2004.

- Nezbedová, E.; Hodan, J.; Kotek, J.; Krulis, Z.; Hutař, P.; Lach, R. Lifetime of Polyethylene (PE) Pipe Material—Prediction Using Strain Hardening Test. Deform. Fract. Behav. Polym. Mater. 2017, 247, 203–210. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiang, A.; Lu, X.; Zhou, H.; Yin, D.; Tian, H. Research on slow crack growth resistance of polyethylene pipe based on strain hardening modulus. J. Vinyl Addit. Technol. 2022, 28, 226–234. [Google Scholar] [CrossRef]

- Fawaz, J.; Deveci, S.; Mittal, V. Molecular and morphological studies to understand slow crack growth (SCG) of polyethylene. Colloid Polym. Sci. 2016, 294, 1269–1280. [Google Scholar] [CrossRef]

- Kovar, M.; Nezbedova, E.; Hodan, J.; Stary, Z. Strain Hardening Test: Short Term Test for Estimating Service Life of High-Density Polyethylene. Macromol. Symp. 2022, 403, 2200056. [Google Scholar] [CrossRef]

- Gorghiu, L.M.; Jipa, S.; Zaharescu, T.; Setnescu, R.; Mihalcea, I. The effect of metals on thermal degradation of polyethylenes. Polym. Degrad. Stab. 2004, 84, 7–11. [Google Scholar] [CrossRef]

- Haward, R.N. Strain hardening of high density polyethylene. J. Polym. Sci. Part B Polym. Phys. 2010, 45, 1090–1099. [Google Scholar] [CrossRef]

| Symbols | Description | Size |

|---|---|---|

| A | Minimum total length | 115 mm |

| B | End width | 25 mm |

| C | Parallel section length | 33 mm |

| D | Parallel section width | 6 mm |

| E | Small radius | 14 mm |

| F | Large radius | 25 mm |

| G | Distance between markers | 25 mm |

| H | Distance between wall thickness clamps | 80 mm |

| Serial Number | Length at Fracture l/mm | Tensile Ratio λ | True Stress σture/MPa | Strain-Hardening Modulus Gp | |

|---|---|---|---|---|---|

| PH1 | 1 | 49.0631 | 1.9625 | 34.2 | −39.75 |

| 2 | 180.2725 | 7.2109 | 152.3092 | ||

| 3 | 48.9328 | 1.9573 | 35.0546 |

| Serial Number | Length at Fracture l/mm | Tensile Ratio λ | True Stress σture/MPa | Strain-Hardening Modulus Gp | |

|---|---|---|---|---|---|

| PH5 | 1 | 60.4675 | 2.4187 | 52.4370 | 9.905 |

| 2 | 80.8125 | 3.2325 | 53.5489 | ||

| 3 | 201.4075 | 8.0563 | 169.0365 |

| Serial Number | Length at Fracture l/mm | Tensile Ratio λ | True Stress σture/MPa | Strain-Hardening Modulus Gp | |

|---|---|---|---|---|---|

| PH8 | 1 | 176.805 | 7.0722 | 150.3760 | 5.6469 |

| 2 | 183.66 | 7.3464 | 156.9173 | ||

| 3 | 199.7375 | 7.9895 | 165.9158 |

| Number | PE-S-PH1 | PE-S-PH5 | PE-S-PH8 |

|---|---|---|---|

| Expiration time (Days) | 1.872 | 1060.507 | 1128.58 |

| Serial Number | Algorithms | Formulas | Parameters a/b/c | R-Squared |

|---|---|---|---|---|

| 1 | Exp2PMod2 | y = e(a + b × x) | a = −2.45627, b = 0.61248 | 0.631 |

| 2 | Allometric1 | y = a × xb | a = 0.8158, b = 1.3052 | 0.672 |

| 3 | Asymptotic1 | y = a − b × cx | a = −16.426, b = 11.03702, c = 0.3153 | 0.728 |

| 4 | Log2P1 | y = b × ln(x − a) | a = 2.93547, b = 3.12234 | 0.898 |

| 5 | Secondary regression curve | y = a + b × x + c × x2 | a = −1.19352, b = 1.29333, c = −0.0947 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ran, W.-S.; Niu, L.; Wang, Y.; Lin, N.; Feng, G.-W.; Lan, H.-Q. A Lifetime Prediction Method of Pressured Gas Polyethylene Pipes by Strain-Hardening Modulus and Tensile Test. Appl. Sci. 2023, 13, 7965. https://doi.org/10.3390/app13137965

Ran W-S, Niu L, Wang Y, Lin N, Feng G-W, Lan H-Q. A Lifetime Prediction Method of Pressured Gas Polyethylene Pipes by Strain-Hardening Modulus and Tensile Test. Applied Sciences. 2023; 13(13):7965. https://doi.org/10.3390/app13137965

Chicago/Turabian StyleRan, Wen-Shen, Li Niu, Yang Wang, Nan Lin, Guo-Wei Feng, and Hui-Qing Lan. 2023. "A Lifetime Prediction Method of Pressured Gas Polyethylene Pipes by Strain-Hardening Modulus and Tensile Test" Applied Sciences 13, no. 13: 7965. https://doi.org/10.3390/app13137965

APA StyleRan, W.-S., Niu, L., Wang, Y., Lin, N., Feng, G.-W., & Lan, H.-Q. (2023). A Lifetime Prediction Method of Pressured Gas Polyethylene Pipes by Strain-Hardening Modulus and Tensile Test. Applied Sciences, 13(13), 7965. https://doi.org/10.3390/app13137965