Investigation of a Precise Control Scheme for Rice Quality

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Drying Equipment and Procedure

2.3. Moisture Content

2.4. Drying Time

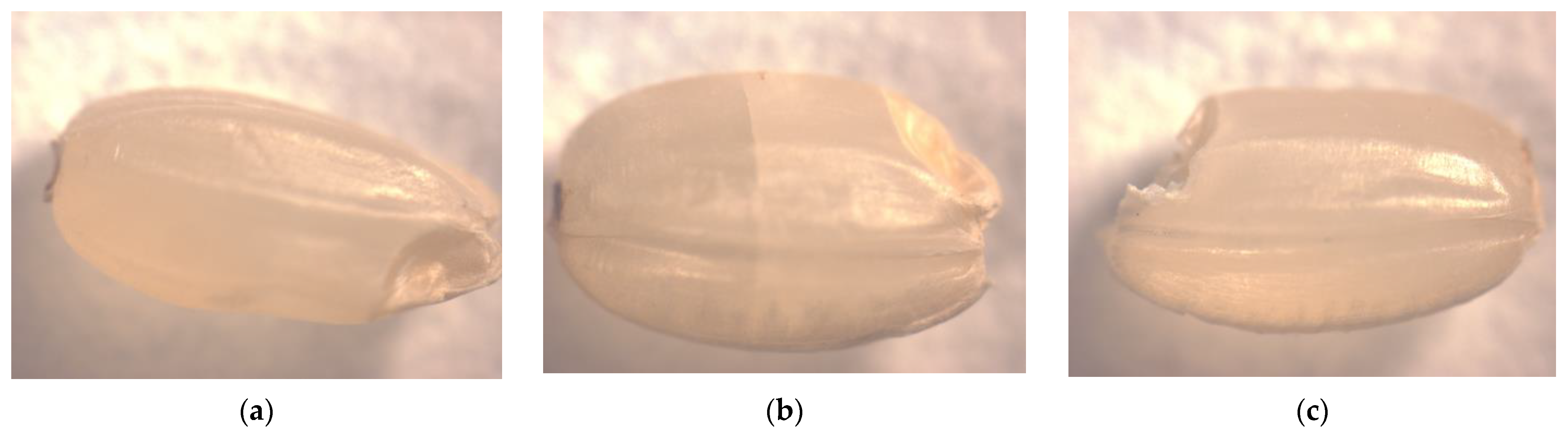

2.5. Additional Crack Percentage

2.6. Head Rice Yield

2.7. Experimental Design

2.8. Process Reference Charts

2.9. Statistical Analysis

3. Results and Discussion

3.1. Drying Time

3.2. Milling Quality

3.2.1. Additional Crack Percentage

3.2.2. Head Rice Yield

3.3. Model Validation

3.4. Process Reference Chart for Quality

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tohidi, M.; Sadeghi, M.; Torki-Harchegani, M. Energy and quality aspects for fixed deep bed drying of paddy. Renew. Sustain. Energy Rev. 2017, 70, 519–528. [Google Scholar] [CrossRef]

- Tong, C.; Chen, Y.; Tang, F.; Xu, F.; Huang, Y.; Chen, H.; Bao, J. Genetic diversity of amylose content and RVA pasting parameters in 20 rice accessions grown in Hainan, China. Food Chem. 2014, 161, 239–245. [Google Scholar] [CrossRef] [PubMed]

- Reddy, K.R.N.; Reddy, C.S.; Abbas, H.K.; Abel, C.A.; Muralidharan, K. Mycotoxigenic fungi, mycotoxins, and management of rice grains. Toxin Rev. 2008, 27, 287–317. [Google Scholar] [CrossRef]

- Oktay, H.; Ahmet, C.; Kamil, K. A liquid diffusion model for thin-layer drying of rough rice. Eur. Food Res. Technol. 2008, 226, 787–793. [Google Scholar] [CrossRef]

- Ling, F.; Sun, T. Study on the drying characteristics of rice by microwave and hot air drying. J. Eng. 2021, 4, 201–208. [Google Scholar] [CrossRef]

- Luthra, K.; Sadaka, S.S. Challenges and opportunities associated with drying rough rice in fluidized bed dryers: A review. Trans. ASABE 2020, 63, 583–595. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, W.; Sun, Z. Mechanical properties of sound and fissured rice kernels and their implications for rice breakage. J. Food Eng. 2005, 68, 65–72. [Google Scholar] [CrossRef]

- Iguaz, A.; Rodríguez, M.; Vírseda, P. Influence of handling and processing of rough rice on fissures and head rice yields. J. Food Eng. 2006, 77, 803–809. [Google Scholar] [CrossRef]

- Hwang, S.S.; Cheng, Y.C.; Chang, C.; Lur, H.S.; Lin, T.T. Magnetic resonance imaging and analyses of tempering processes in rice kernels. J. Cereal Sci. 2009, 50, 36–42. [Google Scholar] [CrossRef]

- Aquerreta, J.; Iguaz, A.; Arroqui, C.; Vírseda, P. Effect of high temperature intermittent drying and tempering on rough rice quality. J. Food Eng. 2007, 80, 611–618. [Google Scholar] [CrossRef]

- Dong, R.; Lu, Z.; Liu, Z.; Koide, S.; Cao, W. Effect of drying and tempering on rice fissuring analysed by integrating intra-kernel moisture distribution. J. Food Eng. 2010, 97, 161–167. [Google Scholar] [CrossRef]

- Shei, H.J.; Chen, Y.L. Computer simulation on intermittent drying of rough rice. Dry. Technol. 2007, 20, 615–636. [Google Scholar] [CrossRef]

- Golmohammadi, M.; Rajabi-Hamane, M.; Hashemi, S.J. Optimization of Drying–Tempering Periods in a Paddy Rice Dryer. Dry. Technol. 2012, 30, 106–113. [Google Scholar] [CrossRef]

- Zecchi, B.; Gerla, P. Breakage and mass transfer models during drying of rough rice. Dry. Technol. 2007, 25, 1405–1410. [Google Scholar] [CrossRef]

- Nanvakenari, S.; Movagharnejad, K.; Latifi, A. Evaluating the fluidized-bed drying of rice using response surface methodology and artificial neural network. LWT 2021, 147, 111589. [Google Scholar] [CrossRef]

- Huang, X.; Li, W.; Wang, Y.; Wan, F. Drying characteristics and quality of Stevia rebaudiana leaves by far-infrared radiation. LWT 2021, 140, 110638. [Google Scholar] [CrossRef]

- Jin, Y.; Wong, K.W.; Wu, Z.; Qi, D.; Wang, R.; Han, F.; Wu, W. Relationship between accumulated temperature and quality of paddy. Int. J. Food Prop. 2019, 22, 19–33. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.B.; Cao, C.W.; Yu, Q.L.; Zhong, Q.X. Study on rough rice fissuring during intermittent drying. Dry. Technol. 1998, 17, 1779–1793. [Google Scholar] [CrossRef]

- Sharma, A.D.; Kunze, O.R. Post-Drying Fissure Developments in Rough Rice. Trans. ASAE 1982, 25, 465–468. [Google Scholar] [CrossRef]

- Dibagar, N.; Amiri Chayjan, R. Rough rice convective drying enhancement by intervention of airborne ultrasound—A response surface strategy for experimental design and optimization. Dry. Technol. 2019, 37, 1097–1112. [Google Scholar] [CrossRef]

- Soltani, A.; Azzouz, S.; Romdhana, H.; Goujot, D.; El Cafsi, M.A. Multi-response optimization of drying process parameters for Laurus Nobilis. J. Appl. Res. Med. Aromat. Plants 2021, 22, 100302. [Google Scholar] [CrossRef]

- Kumar, D.; Prasad, S.; Murthy, G.S. Optimization of microwave-assisted hot air drying conditions of okra using response surface methodology. J. Food Sci. Technol. 2014, 51, 221–232. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Liu, Z.; Zhao, H.; Xu, Y.; Cui, F. Statistical optimization of xylanase production from new isolated Penicillium oxalicum ZH-30 in submerged fermentation. Biochem. Eng. J. 2007, 34, 82–86. [Google Scholar] [CrossRef]

- Šumić, Z.; Vakula, A.; Tepić, A.; Čakarević, J.; Vitas, J.; Pavlić, B. Modeling and optimization of red currants vacuum drying process by response surface methodology (RSM). Food Chem. 2016, 203, 465–475. [Google Scholar] [CrossRef]

- Onwude, D.I.; Hashim, N.; Chen, G. Recent advances of novel thermal combined hot air drying of agricultural crops. Trends Food Sci. Technol. 2016, 57, 132–145. [Google Scholar] [CrossRef] [Green Version]

- Sagar, V.R.; Suresh Kumar, P. Recent advances in drying and dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vimercati, W.C.; da Silva Araújo, C.; Macedo, L.L.; Maradini Filho, A.M.; Saraiva, S.H.; Teixeira, L.J.Q. Influence of drying temperature on drying kinetics, energy consumption, bioactive compounds and cooking quality of pasta enriched with spinach. J. Food Process Eng. 2020, 43, e13571. [Google Scholar] [CrossRef]

- Bertotto, M.M.; Gastón, A.; Sánchez Sarmiento, G.; Gove, B. Effect of drying conditions on the quality of IRGA 424 rice. J. Sci. Food Agric. 2019, 99, 1651–1659. [Google Scholar] [CrossRef]

- Candioti, L.V.; De Zan, M.M.; Cámara, M.S.; Goicoechea, H.C. Experimental design and multiple response optimization. Using the desirability function in analytical methods development. Talanta 2014, 124, 123–138. [Google Scholar] [CrossRef]

- Müller, A.; Nunes, M.T.; Maldaner, V.; Coradi, P.C.; Moraes, R.S.d.; Martens, S.; Leal, A.F.; Pereira, V.F.; Marin, C.K. Rice Drying, Storage and Processing: Effects of Post-Harvest Operations on Grain Quality. Rice Sci. 2022, 29, 16–30. [Google Scholar] [CrossRef]

| Coded and Uncoded Values | |||||

|---|---|---|---|---|---|

| Factor | −α = 2.378 | −1 | 0 | 1 | α = 2.378 |

| Drying temperature (T/°C) | 35 | 40.8 | 45 | 49.2 | 55 |

| Moisture content (MC/%) | 20 | 22.3 | 24 | 25.7 | 28 |

| Relative humidity (RH/%) | 30 | 35.8 | 40 | 44.2 | 50 |

| Air velocity (V/m/s) | 0.36 | 0.5 | 0.6 | 0.7 | 0.84 |

| Tempering ratio (TR) | 1 | 1.9 | 2.5 | 3.1 | 4 |

| Runs | T (°C) | RH (%) | MC (%) | V (m/s) | TR | Dtn (min) | Dtt (min) | ACP (%) | HRY (%) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 40.8 | 35.8 | 22.3 | 0.5 | 1.9 | 157.9 | 442.9 | 2.87 | 70.2 |

| 2 | 49.2 | 35.8 | 22.3 | 0.5 | 1.9 | 117.4 | 316.9 | 4.62 | 68.9 |

| 3 | 40.8 | 44.2 | 22.3 | 0.5 | 1.9 | 201.7 | 572.2 | 1.53 | 71.4 |

| 4 | 49.2 | 44.2 | 22.3 | 0.5 | 1.9 | 179.6 | 493.1 | 3.43 | 68.8 |

| 5 | 40.8 | 35.8 | 25.7 | 0.5 | 1.9 | 200.4 | 570.9 | 2.93 | 70.3 |

| 6 | 49.2 | 35.8 | 25.7 | 0.5 | 1.9 | 140 | 396.5 | 5.02 | 68.5 |

| 7 | 40.8 | 44.2 | 25.7 | 0.5 | 1.9 | 258.8 | 743.3 | 2.22 | 70.6 |

| 8 | 49.2 | 44.2 | 25.7 | 0.5 | 1.9 | 208.6 | 579.1 | 4.63 | 68.8 |

| 9 | 40.8 | 35.8 | 22.3 | 0.7 | 1.9 | 129.6 | 357.6 | 3.48 | 70.4 |

| 10 | 49.2 | 35.8 | 22.3 | 0.7 | 1.9 | 98.5 | 269.5 | 5.79 | 68.5 |

| 11 | 40.8 | 44.2 | 22.3 | 0.7 | 1.9 | 160.4 | 445.4 | 2.28 | 71.2 |

| 12 | 49.2 | 44.2 | 22.3 | 0.7 | 1.9 | 152.4 | 437.4 | 4.01 | 69.1 |

| 13 | 40.8 | 35.8 | 25.7 | 0.7 | 1.9 | 200.3 | 570.8 | 3.35 | 70.2 |

| 14 | 49.2 | 35.8 | 25.7 | 0.7 | 1.9 | 127.1 | 355.1 | 5.39 | 68.3 |

| 15 | 40.8 | 44.2 | 25.7 | 0.7 | 1.9 | 258.1 | 742.6 | 3.21 | 70.1 |

| 16 | 49.2 | 44.2 | 25.7 | 0.7 | 1.9 | 178.1 | 491.6 | 5.02 | 68.5 |

| 17 | 40.8 | 35.8 | 22.3 | 0.5 | 3.1 | 141.4 | 559.9 | 1.26 | 71.5 |

| 18 | 49.2 | 35.8 | 22.3 | 0.5 | 3.1 | 92.2 | 371.2 | 2.99 | 70.1 |

| 19 | 40.8 | 44.2 | 22.3 | 0.5 | 3.1 | 183.7 | 741.7 | 0.31 | 72.3 |

| 20 | 49.2 | 44.2 | 22.3 | 0.5 | 3.1 | 116.4 | 441.9 | 2.13 | 69.7 |

| 21 | 40.8 | 35.8 | 25.7 | 0.5 | 3.1 | 188.4 | 746.4 | 1.21 | 71.7 |

| 22 | 49.2 | 35.8 | 25.7 | 0.5 | 3.1 | 130 | 502 | 3.17 | 70.1 |

| 23 | 40.8 | 44.2 | 25.7 | 0.5 | 3.1 | 226.5 | 924 | 1 | 71.1 |

| 24 | 49.2 | 44.2 | 25.7 | 0.5 | 3.1 | 163 | 628 | 3.22 | 69.8 |

| 25 | 40.8 | 35.8 | 22.3 | 0.7 | 3.1 | 123.6 | 495.6 | 1.79 | 71.7 |

| 26 | 49.2 | 35.8 | 22.3 | 0.7 | 3.1 | 77.3 | 309.8 | 3.41 | 70.1 |

| 27 | 40.8 | 44.2 | 22.3 | 0.7 | 3.1 | 140 | 558.5 | 0.87 | 72 |

| 28 | 49.2 | 44.2 | 22.3 | 0.7 | 3.1 | 108.1 | 433.6 | 2.46 | 70.4 |

| 29 | 40.8 | 35.8 | 25.7 | 0.7 | 3.1 | 166.9 | 678.4 | 1.5 | 71.2 |

| 30 | 49.2 | 35.8 | 25.7 | 0.7 | 3.1 | 106.9 | 432.4 | 3.69 | 68.8 |

| 31 | 40.8 | 44.2 | 25.7 | 0.7 | 3.1 | 180 | 738 | 1.64 | 71.3 |

| 32 | 49.2 | 44.2 | 25.7 | 0.7 | 3.1 | 133.6 | 505.6 | 3.58 | 69.5 |

| 33 | 35 | 40 | 24 | 0.6 | 2.5 | 229.6 | 792.1 | 0.79 | 72.1 |

| 34 | 55 | 40 | 24 | 0.6 | 2.5 | 101.3 | 326.3 | 5.04 | 68.3 |

| 35 | 45 | 30 | 24 | 0.6 | 2.5 | 104.1 | 329.1 | 3.1 | 70.5 |

| 36 | 45 | 50 | 24 | 0.6 | 2.5 | 227 | 789.5 | 1.62 | 70.7 |

| 37 | 45 | 40 | 20 | 0.6 | 2.5 | 94 | 319 | 2.23 | 70.3 |

| 38 | 45 | 40 | 28 | 0.6 | 2.5 | 179.9 | 592.4 | 3.38 | 69 |

| 39 | 45 | 40 | 24 | 0.36 | 2.5 | 169.6 | 582.1 | 2.44 | 70.4 |

| 40 | 45 | 40 | 24 | 0.84 | 2.5 | 131.5 | 431.5 | 3.91 | 70.2 |

| 41 | 45 | 40 | 24 | 0.6 | 1 | 201.8 | 396.8 | 4.52 | 68.6 |

| 42 | 45 | 40 | 24 | 0.6 | 4 | 120 | 540 | 0.89 | 71.8 |

| 43 | 45 | 40 | 24 | 0.6 | 2.5 | 150 | 487.5 | 2.32 | 69.2 |

| 44 | 45 | 40 | 24 | 0.6 | 2.5 | 144.4 | 481.9 | 2.21 | 69.4 |

| 45 | 45 | 40 | 24 | 0.6 | 2.5 | 145.3 | 482.8 | 2.11 | 69.4 |

| 46 | 45 | 40 | 24 | 0.6 | 2.5 | 147.3 | 484.8 | 2.33 | 70 |

| 47 | 45 | 40 | 24 | 0.6 | 2.5 | 157.7 | 532.7 | 2.21 | 69.6 |

| 48 | 45 | 40 | 24 | 0.6 | 2.5 | 137.4 | 474.9 | 2.11 | 70.1 |

| 49 | 45 | 40 | 24 | 0.6 | 2.5 | 151.7 | 489.2 | 2.33 | 70.1 |

| 50 | 45 | 40 | 24 | 0.6 | 2.5 | 141.7 | 479.2 | 2.11 | 69.8 |

| 51 | 45 | 40 | 24 | 0.6 | 2.5 | 134.4 | 434.4 | 2.55 | 69.9 |

| 52 | 45 | 40 | 24 | 0.6 | 2.5 | 147.3 | 484.8 | 2.55 | 69.5 |

| 53 | 45 | 40 | 24 | 0.6 | 2.5 | 157.6 | 532.6 | 2.22 | 70.2 |

| 54 | 45 | 40 | 24 | 0.6 | 2.5 | 152.8 | 490.3 | 2.67 | 70 |

| 55 | 45 | 40 | 24 | 0.6 | 2.5 | 134.4 | 434.4 | 2.21 | 69.6 |

| 56 | 45 | 40 | 24 | 0.6 | 2.5 | 145 | 482.5 | 2.11 | 70.3 |

| 57 | 45 | 40 | 24 | 0.6 | 2.5 | 154.7 | 529.7 | 2.33 | 69.9 |

| 58 | 45 | 40 | 24 | 0.6 | 2.5 | 147.2 | 484.7 | 2.11 | 69.5 |

| 59 | 45 | 40 | 24 | 0.6 | 2.5 | 140.4 | 477.9 | 2.38 | 68.9 |

| Source | df | Drying Time (Net) | Drying Time (Total) | ||

|---|---|---|---|---|---|

| Sum of Squares | F-Value | Sum of Squares | F-Value | ||

| Model | 20 | 87,941.38 | 51.87 ** | 1.02 × 106 | 40.17 ** |

| T: Temperature | 1 | 27,649.52 | 326.17 ** | 3.75 × 105 | 296.74 ** |

| RH: Relative air humidity | 1 | 20,578.66 | 242.76 ** | 2.36 × 105 | 186.31 ** |

| MC: Moisture content | 1 | 18,349.45 | 216.46 ** | 2.09 × 105 | 165.1 ** |

| V: Air speed | 1 | 4780.03 | 56.39 ** | 56,639.38 | 44.77 ** |

| TR: Tempering ratio | 1 | 10,810.37 | 127.52 ** | 60,791.82 | 48.05 ** |

| T*RH | 1 | 75.03 | 0.89 | 5.87 | 4.64 × 10−3 |

| T*MC | 1 | 1205.41 | 14.22 ** | 16,366.93 | 12.94 ** |

| T*V | 1 | 36.13 | 0.43 | 1522.14 | 1.2 |

| T*TR | 1 | 105.85 | 1.25 | 15,819.76 | 12.51 ** |

| RH*MC | 1 | 57.78 | 0.68 | 308.14 | 0.24 |

| RH*V | 1 | 249.76 | 2.95 | 3467.36 | 2.74 |

| RH*TR | 1 | 1265.05 | 14.92 ** | 3804.1 | 3.01 |

| MC*V | 1 | 41.41 | 0.49 | 100.47 | 0.079 |

| MC*TR | 1 | 114.76 | 1.35 | 509.6 | 0.4 |

| V*TR | 1 | 62.16 | 0.73 | 3166.09 | 2.5 |

| T2 | 1 | 896.38 | 10.57 ** | 15,360.22 | 12.14 ** |

| RH2 | 1 | 904.88 | 10.67 ** | 15,395.35 | 12.17 ** |

| MC2 | 1 | 108.75 | 1.28 | 513.6 | 0.41 |

| V2 | 1 | 78.06 | 0.92 | 2471.69 | 1.95 |

| TR2 | 1 | 558.68 | 6.59 ** | 21.85 | 0.017 |

| Residual | 38 | 3221.3 | 48,072.37 | ||

| Lack of Fit | 22 | 2373.58 | 2.04 | 36,175.52 | 2.21 |

| Pure Error | 16 | 847.72 | 11,896.86 | ||

| Cor Total | 58 | 91,162.68 | 1.06 × 106 | ||

| Source | df | Drying Time (Net) | Drying Time (Total) | ||

|---|---|---|---|---|---|

| Sum of Squares | F-Value | Sum of Squares | F-Value | ||

| Model | 20 | 84.52 | 123.79 ** | 56.09 | 25.05 ** |

| T: Temperature | 1 | 39.22 | 1148.95 ** | 33.93 | 303.1 ** |

| RH: Relative air humidity | 1 | 4.82 | 141.21 ** | 0.48 | 4.32 * |

| MC: Moisture content | 1 | 2.44 | 71.54 ** | 2.59 | 23.14 ** |

| V: Air speed | 1 | 3.56 | 104.42 ** | 0.2 | 1.83 |

| TR: Tempering ratio | 1 | 26.98 | 790.24 ** | 14.56 | 130.03 ** |

| T*RH | 1 | 2.28 × 10−3 | 0.067 | 0.07 | 0.63 |

| T*MC | 1 | 0.15 | 4.47 * | 0.025 | 0.23 |

| T*V | 1 | 0.013 | 0.39 | 7.81 × 10−3 | 0.07 |

| T*TR | 1 | 0.029 | 0.86 | 0.015 | 0.14 |

| RH*MC | 1 | 1.73 | 50.81 ** | 0.26 | 2.35 |

| RH*V | 1 | 2.28 × 10−3 | 0.067 | 0.09 | 0.81 |

| RH*TR | 1 | 0.34 | 10.03 ** | 0.17 | 1.48 |

| MC*V | 1 | 0.029 | 0.86 | 0.38 | 3.42 |

| MC*TR | 1 | 2.81 × 10−5 | 8.24 × 10−4 | 0.038 | 0.34 |

| V*TR | 1 | 0.083 | 2.43 | 3.13 × 10−4 | 2.79 × 10−3 |

| T2 | 1 | 1.22 | 35.81 ** | 0.48 | 4.26 |

| RH2 | 1 | 0.1 | 2.99 | 1.58 | 14.11 |

| MC2 | 1 | 0.9 | 26.43 ** | 7.84 × 10−3 | 0.07 |

| V2 | 1 | 2.17 | 63.63 ** | 0.69 | 6.19 |

| TR2 | 1 | 0.65 | 19.13 ** | 0.48 | 4.26 |

| Residual | 38 | 1.3 | 4.25 | ||

| Lack of Fit | 22 | 0.82 | 1.24 | 1.9 | 0.59 |

| Pure Error | 16 | 0.48 | 2.36 | ||

| Cor Total | 58 | 85.82 | 60.34 | ||

| Response | Second-Order Polynomial Model Equation | R2 | CV (%) |

|---|---|---|---|

| Dtn | Y = −319.54457 − 4.19846 × T − 5.87506 × RH + 51.29726 × MC − 104.10679 × V + 32.72127 × TR − 0.86797 × T*MC − 2.37116 × RH*TR + 0.21134 × T2 + 0.21234 × RH2 + 7.41511 × TR2 | 0.9545 | 6.03 |

| Dtt | Y = −1362.71399 − 3.21407 × T − 52.57475 × RH + 185.21498 × MC − 358.36273 × V + 436.73255 × TR− 3.19833 × T*MC − 8.38511 × T*TR + 0.87549 × T2 + 0.87649 × RH2 | 0.9399 | 7.05 |

| ACP | Y = 87.48851 − 0.71122 × T − 0.96706 × RH − 3.62912 × MC − 18.85010 × V − 4.08123 × TR + 9.76691 × 10−3 × T*MC + 0.032925 × RH*MC + 0.039009 × RH*TR + 7.81273 × 10−3 × T2 + 0.041955 × RH2 + 18.07766 × V2 + 0.25390 × TR2 | 0.9818 | 6.76 |

| HRY | Y = 108.88074 − 0.64910 × T − 0.68473 × RH − 0.14540 × MC − 12.91655 × V − 0.16367 × TR + 4.87314 × 10−3 × T2 + 8.87314 × 10−3 × RH2 + 10.19643 × V2 + 0.21658 × TR2 | 0.9118 | 0.47 |

| Run | Parametric Setting | Net Drying Time (min) | Total Drying Time (min) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| T (°C) | RH (%) | MC (%) | V (m/s) | TR | Predicted | Measured | Discrepancy | Predicted | Measured | Discrepancy | |

| 1 | 37 | 45 | 27 | 0.7 | 2.4 | 283.7 | 301.4 | 6.23% | 965.3 | 938.4 | 2.87% |

| 2 | 52 | 45 | 23 | 0.8 | 1.5 | 172.5 | 168.5 | −2.30% | 465.8 | 480.1 | 2.98% |

| 3 | 42 | 35 | 27 | 0.75 | 2 | 190.2 | 210.3 | 10.57% | 562.2 | 545.3 | 3.1% |

| 4 | 44 | 48 | 22 | 0.6 | 1.3 | 234.6 | 220.9 | −5.84% | 571.6 | 560.8 | 1.92% |

| Run | Parametric Setting | Net Drying Time (min) | Total Drying Time (min) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| T (°C) | RH (%) | MC (%) | V (m/s) | TR | Predicted | Measured | Discrepancy | Predicted | Measured | Discrepancy | |

| 1 | 37 | 45 | 27 | 0.7 | 2.4 | 2.29 | 2.67 | 16.50% | 71.57 | 71.2 | −0.52% |

| 2 | 52 | 45 | 23 | 0.8 | 1.5 | 6.4 | 6 | −6.25% | 68.54 | 68.1 | −0.64% |

| 3 | 42 | 35 | 27 | 0.75 | 2 | 3.94 | 4.33 | 9.90% | 69.78 | 71.2 | 2.03% |

| 4 | 44 | 48 | 22 | 0.6 | 1.3 | 2.45 | 2.5 | 2.04% | 70.21 | 69.1 | −1.58% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Y.; Yin, J.; Xie, H.; Zhang, Z. Investigation of a Precise Control Scheme for Rice Quality. Appl. Sci. 2023, 13, 7532. https://doi.org/10.3390/app13137532

Jin Y, Yin J, Xie H, Zhang Z. Investigation of a Precise Control Scheme for Rice Quality. Applied Sciences. 2023; 13(13):7532. https://doi.org/10.3390/app13137532

Chicago/Turabian StyleJin, Yi, Jun Yin, Huihuang Xie, and Zhongjie Zhang. 2023. "Investigation of a Precise Control Scheme for Rice Quality" Applied Sciences 13, no. 13: 7532. https://doi.org/10.3390/app13137532

APA StyleJin, Y., Yin, J., Xie, H., & Zhang, Z. (2023). Investigation of a Precise Control Scheme for Rice Quality. Applied Sciences, 13(13), 7532. https://doi.org/10.3390/app13137532