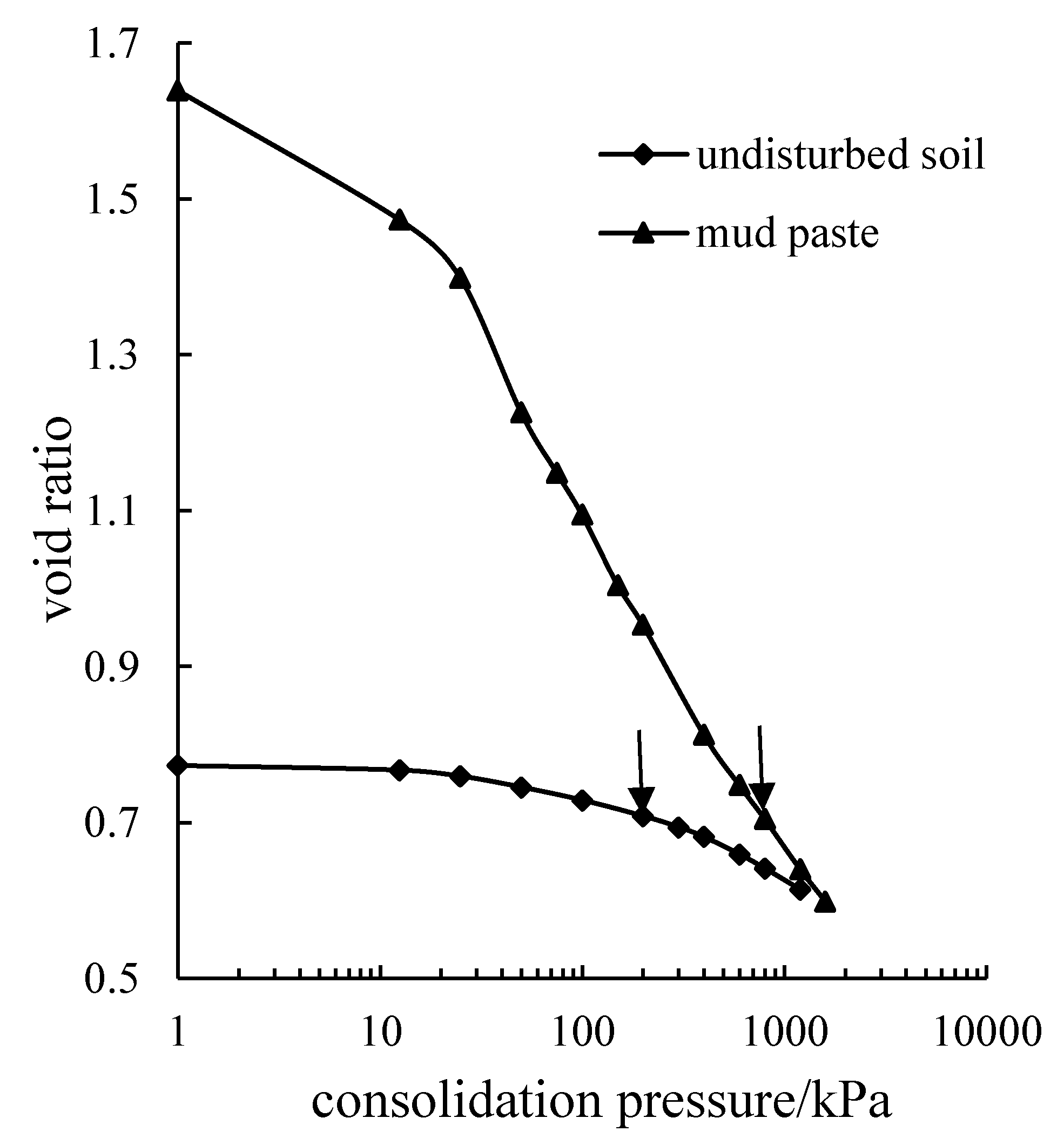

3.1. Compression Curves of Mud Paste

Mud paste with a moisture content of approximately 57% was prepared on the consolidation instrument using a Φ61.8 × 20 mm cutting-ring sample, after which a uniaxial consolidation compression experiment [

25] was conducted by applying a load step-by-step as follows: 12.5→25→50→100→200→300→400→600→800→1200 kPa, and an appropriate compression curve was obtained. Based on the Casagrande method, the

Pc was determined to be approximately 10 kPa, which is consistent with the state of mud paste without structure or stress history. Comparing the compression curves of the mud paste and undisturbed soil (

Figure 4), it is evident that although the

Pc of the undisturbed soil is approximately 200 kPa, the initial void ratio is very low. The expansive clay in the Nanyang area is mainly lacustrine sedimentary and alluvial expansive clay. The void ratio of the mud-remolded expansive clay after consolidation under a consolidation pressure of 200 kPa is much higher than that of the undisturbed soil. When the pressure gradually increases, the compression curves of the mud-remolded and undisturbed soils gradually converge. Comparing the compression curves of the mud-remolded soil and undisturbed soil, it is evident that to compress the void ratio of the soil to 0.71, the axial pressure of the undisturbed soil is 200 kPa, whereas that of the mud-remolded soil is as high as 800 kPa.

Consequently, it can be inferred that the initial high density and low void ratio of the undisturbed soil are not caused by large loads alone but are also influenced by external environmental factors such as temperature and climate, which have a great influence on the formation of its special structure.

3.2. Drying–Wetting Cycle Test of Mud-Remolded Soil

Mud with a moisture content higher than the liquid limit was prepared and consolidated at 200 kPa using a sample preparation device. The first drying–wetting cycle was conducted after unloading and expansion in a constant-temperature and -humidity chamber. The soil sample was dehydrated to a moisture content of approximately 10%, after which the moisture absorption of the soil sample was made uniform through continuous spraying with water, before being soaked in water for a day and night to complete the drying–wetting cycle. As shown in

Figure 5, after the drying–wetting cycle, a large quantity of soil on the side wall of the sample disintegrates, filling the gap between the soil sample and the sample cylinder, with the overall soil sample bulging upward.

An in situ drying–wetting cycle is often performed under a certain stress state. Consequently, after the first drying–wetting cycle (the red arrow), the sample was consolidated under a pressure of 200 kPa (the blue arrow), and the second drying–wetting cycle was performed after unloading and expansion, with the above process being repeated. After five drying–wetting cycles, the soil samples were produced as drying–wetting cycle samples. The changing heights of the samples during the preparation process are shown in

Figure 6.

It is evident that the consolidation settlement deformation of soil under a consolidation pressure of 200 kPa after the drying–wetting cycle decreases with an increase in the number of cycles. The expansion of the soil after the drying–wetting cycle also decreases with increasing cycles. After three drying–wetting cycles, the final height of the sample after consolidation gradually stabilizes.

3.3. Influence of Drying–Wetting Cycles on Compression Characteristics

Uniaxial consolidation compression experiments were conducted on mud-remolded soils with consolidation pressures of 200, 400, and 600 kPa, a drying–wetting cycle sample, and undisturbed soil to analyze the influence of drying–wetting cycles on the soils’ compression characteristics (

Figure 7). Additionally, a secondary consolidation sample was prepared after the primary consolidation was completed under a consolidation pressure of 200 kPa (the secondary consolidation time was 14 d) to compare and study the differences in the effects of secondary consolidation and drying–wetting cycles on the compression characteristics of expansive clay.

Compression tests of different soils can be used to determine the differences between their compression characteristics using Φ61.8 × 20 mm cutting-ring samples. The results show that for the mud-remolded soils consolidated under consolidation pressures of 200, 400, and 600 kPa, the Pc is approximately 200, 400, and 600 kPa, respectively, determined based on the Casagrande method, which is consistent with the consolidation pressure in the actual sample preparation process.

The initial void ratio of the secondary consolidation sample is smaller than that of the remolded soil without secondary consolidation under the same consolidation pressure of 200 kPa, but the straight-line segments in the latter part of the compression curve are still parallel to one another, indicating that secondary consolidation can continue to compact the soil after the completion of the primary consolidation process. The creep effect of the soil skeleton further reduces the void ratio of the soil; however, when the consolidation pressure reaches its Pc, the compression characteristics of the secondary consolidation soil—namely, the compression index—are similar to those of the normal consolidation mud-remolded soils.

Comparing the compression curves of the undisturbed soil and mud-remolded soil with different consolidation pressures, it is evident that although the Pc of the undisturbed soil is smaller than that of the mud-remolded soil, the initial void ratio is considerably smaller than that of the mud-remolded soil with a 600 kPa consolidation pressure. Moreover, the compression modulus of the undisturbed soil is much larger than that of the mud-remolded soil, which is related to the long geological history and climate changes experienced during the formation of the undisturbed soil. Comparing the compression curves of the drying–wetting cycle sample and the mud-remolded soil with different consolidation pressures, it is evident that the drying–wetting cycle sample can achieve a lower void ratio under the same consolidation pressure of 200 kPa, with its initial void ratio being even lower than that of the mud-remolded soil with 600 kPa consolidation pressure, gradually approaching the initial void ratio of the undisturbed soil. The slope of the straight line segments in the latter part of the compression curve of the drying–wetting cycle sample is clearly smaller than that of the mud-remolded soil without a drying–wetting cycle, but closer to the compression characteristics of the undisturbed soil.

The undisturbed soil is affected by various factors in its long-term formation history, finally forming its unique structural characteristics. The mud-remolded soil completely breaks the natural structure of the undisturbed soil, whereas the drying–wetting cycle sample restores its structure to a certain extent, not only reducing the void ratio of the sample but also changing its compressibility. It can be inferred that the drying–wetting cycle caused by climate change is the main reason for the overconsolidation of undisturbed expansive clay. The low void ratio and high strength of undisturbed expansive clay are caused primarily by the fabric changes in clay particles after drying–wetting cycles, and not by the compaction effect owing to the large stress history or secondary consolidation effect owing to the earlier formation period.

3.4. Effect of Drying–Wetting Cycles on the Lateral Stress of Expansive Clay

It is well known that the coefficient of the lateral earth pressure of overconsolidated soil (K0) is larger than that of normal consolidated soil. The K0 also increases with increasing overconsolidation; consequently, high lateral earth pressure makes overconsolidated expansive clay more prone to instantaneous damage than normal consolidated soil after lateral unloading during slope excavation.

To understand the effect of the drying–wetting cycle on the lateral stress of expansive clay, a

K0 consolidation instrument [

25] was used to test the lateral stress of the drying–wetting cycle sample, after which we compared it with the mud-remolded soil under 200 kPa consolidation pressure and the undisturbed soil using Φ61.8 × 40 mm cutting-ring samples. The axial stress–lateral stress relationship curves of the different soils are shown in

Figure 8.

Based on the axial stress–lateral stress relationship curve, in the initial stage of loading, the K0 (the ratio of lateral stress to axial stress) of the three soils is maintained at a low level. With an increase in axial load, K0 also increases and gradually stabilizes. Under the same axial stress, the K0 value of the mud-remolded soil is the largest, followed by that of the drying–wetting cycle sample, with that of the undisturbed soil being the lowest. Under axial unloading conditions, the soils are in an overconsolidated state. Under the same axial stress, the lateral stress during unloading is considerably higher than that during loading. With an increase in unloading—that is, the overconsolidation ratio—K0 gradually increases. The K0 values of the three soils during unloading maintain their size relationship during loading. Moreover, when the axial stress is unloaded to a lower level, the K0 values of the three soils are very close.

The in situ monitoring of over-consolidated expansive clay slopes conducted by Zhan et al. [

9] showed that unsaturated expansive clays tended to expand after absorbing water; however, under lateral constraints, this expansion potential was expressed in the form of an expansive force, and the horizontal lateral stress increased considerably, but decreased with the local softening of the soil. It is evident that the lateral stress of the expansive clay increases during the drying–wetting cycle, but the

K0 of the soil decreases after the drying–wetting cycle as the fabric of the remolded soil changes owing to the drying–wetting cycle itself. Subsequently, the void ratio decreases and the density increases. Moreover, the drying–wetting cycles without loading result in the soil loosening as the number of drying–wetting cycles increases. However, for the soil undergoing drying–wetting cycles and reconsolidation, combined with the results of the uniaxial and

K0 consolidation experiments, the soil is compacted and its

K0 decreases.

The change in the remolded soil fabric caused by the drying–wetting cycle does not increase the lateral stress of the soil, which decreases after the drying–wetting cycle owing to an increase in the soil density. Moreover, the K0 of the undisturbed soil is always the smallest during the loading and unloading stages.

3.5. Influence of Drying–Wetting Cycles on Water Retention Characteristics of Expansive Clay

To study the influence of different overconsolidation stress histories on the water retention characteristics of expansive clay, a pressure plate instrument produced by the Soil Moisture Company was used to test the soil–water characteristic curves (SWCCs) of expansive clay samples with different stress histories. Six groups of Φ61.8 × 20 mm cutting-ring samples fully absorbed water, including mud-remolded soil with preconsolidation pressures of 200, 400, and 600 kPa, remolded soil with five drying–wetting cycles, remolded soil with the same void ratio as the undisturbed soil, and undisturbed soil. After the expansion had stabilized, the soil samples were placed into a pressure plate instrument for the SWCC test by applying pressure in a stepwise manner. After the suction balance of 600 kPa was reached, the soil samples were removed and placed in the oven, dried at 106 ℃ to a constant weight, and the dry soil mass was weighed. After measuring the gravity water content of the remolded soil and undisturbed soil under different suction levels with different historical stresses, the SWCC represented by the gravity water content could be plotted in a semi-logarithmic coordinate system, as shown in

Figure 9.

Owing to the difference in stress histories, the initial water content of the remolded soil also differs. The larger the stress history, the smaller the initial water content. Consequently, the entire SWCC of the sample with a high-stress history is below that of the sample with a low-stress history, with the effects of different stress histories on the water retention characteristics of the remolded soil being reflected mainly in their air-entry values. The air-entry value of the remolded soil increases considerably with increasing stress history, with the decrease in the initial void ratio making it more difficult for air to enter the soil. Additionally, with an increase in suction, the influence of stress history gradually weakens, the gravity moisture content of samples with different stress histories gradually approach one another, and the SWCCs converge. Comparing the slope of the SWCC of the remolded soil after obtaining the air-entry value (water storage coefficient), it is evident that the water storage coefficient of the remolded soil with a Pc of 600 kPa is smaller than that of the remolded soil with Pc values of 200 and 400 kPa, indicating that when the matric suction exceeds the air-entry value, the dehumidification rate of the samples subjected to a low-stress history is much faster than that of the samples subjected to a high-stress history, even though the samples subjected to a low-stress history have a high water retention capacity under a specific matric suction.

For undisturbed soil, the air-entry value and water storage coefficient are low. The consolidation pressure of the remolded soil can be calculated using the compression and expansion coefficients to eliminate the influence of the void ratio, which is similar to that of the undisturbed soil, after which the influence of the soil structure on the water retention characteristics of the expansive clay can be analyzed. Comparing the SWCCs of the undisturbed soil and the remolded soil with similar void ratios (

Figure 8), it is evident that the SWCC of the remolded soil with a similar void ratio has an obvious turning point, which can be regarded as comprising two straight-line segments. The former section is essentially horizontal, suggesting that it could be difficult to dehumidify the soil sample. The latter section is an oblique line corresponding to the internal connection state of the unsaturated soil.

The air-entry value of the undisturbed soil is small, and the moisture content decreases rapidly with increasing suction. The soil particles of the undisturbed soil constantly adjust their positions during the long-term drying–wetting cycles, such that the pore structure has a specific direction, and a specific “breathing” channel is formed. The existence of microcracks in the soil also provides a good channel for the migration of water and air. During the dehumidification of the undisturbed soil, air first enters the large crack channels and removes the pore water in them. The water in the cracked channels gradually decreases with increasing suction, whereas the water in the non-cracked channels is removed slowly, exhibiting a high water retention capacity. Consequently, the undisturbed sample exhibits characteristics of low air entry and high water retention capacity. For the remolded soil, the pores in the soil are evenly distributed with poor internal connectivity and a lack of good migration channels, making it difficult for air to enter the soil, presenting a high air-entry value on the SWCC, an indication that the influence of the soil structure on the SWCC is substantial.

The SWCC of the drying–wetting cycle sample can be compared with that of the remolded soil with a Pc of 200 kPa and that of the undisturbed soil. It is evident that the initial moisture content and air-entry value of the drying–wetting cycle sample is smaller than that of the remolded soil, indicating that the changes in soil structure after the drying–wetting cycles improve the connectivity of pores in the samples, facilitating the entry of air. Consequently, the drying–wetting cycle samples also exhibit the characteristics of low air entry and high water retention capacity, which means that the water retention characteristics of the drying–wetting cycle samples are more similar to those of the undisturbed soil than those of the remolded soil.

3.6. Microstructure Analysis

The influence of the drying–wetting cycles on the compressive characteristics and lateral stress of the expansive clay mentioned above is the macroscopic expression of the effects of the drying–wetting cycle on the soil properties. A Quanta scanning electron microscope (SEM) and Poremaster high-pressure pore structure instrument were used to analyze the microstructure of the mud-remolded soil with a

Pc of 200 kPa, the drying–wetting cycle sample, and the undisturbed soil, and the microscopic mechanism of the effect of the drying–wetting cycle on the soil was analyzed. The specimen for the SEM tests was a cube of 10 mm × 10 mm × 10 mm. Before SEM was performed, a fresh section of the sample was sprayed with gold to increase its electrical conductivity. Images with a representative field-of-view with magnifications of 100, 800 and 2000× were selected for each sample, as shown in

Figure 10,

Figure 11 and

Figure 12, respectively.

The stacking structure of particles in the mud-remolded soil can be clearly identified in

Figure 10a,

Figure 11a and

Figure 12a because the mud-remolded sample is slowly consolidated by mud under a certain consolidation pressure; its particles have good orientation and tend to be arranged horizontally, and there are almost no penetrating microfissures. However, the drying–wetting cycle sample shown in

Figure 10b,

Figure 11b and

Figure 12b is segmented by numerous fissures with a high degree of penetration. In

Figure 10c,

Figure 11c and

Figure 12c, the undisturbed soil has a small quantity of curved and crimped flaky particles with skirted edges, with the microstructure unit containing more agglomeration of particles. There are a large number of microcracks in the undisturbed soil, which are convenient for the infiltration of precipitation and can lead to the gradual failure of soil strength attenuation.

Drying shrinkage causes the agglomeration and rearrangement of clay particles, which changes the microstructure of the soil. The irreversible van der Waals force between clay particles causes the clay particles to agglomerate into large aggregates, resulting in a decrease in the content of dispersed fine particles in the soil, a decrease in the specific surface area, and deterioration of the orientation of the particles. The effect of dry shrinkage is often irreversible, and is shown as capillary hysteresis in the SWCC. Moreover, the effect of wet expansion does not restore the soil to its state before dry shrinkage but changes the structure and compressibility of the remolded soil. Consequently, the drying–wetting cycled sample achieves a lower void ratio under the same consolidation pressure, which is consistent with the effect of the drying–wetting cycles on the compression characteristics.

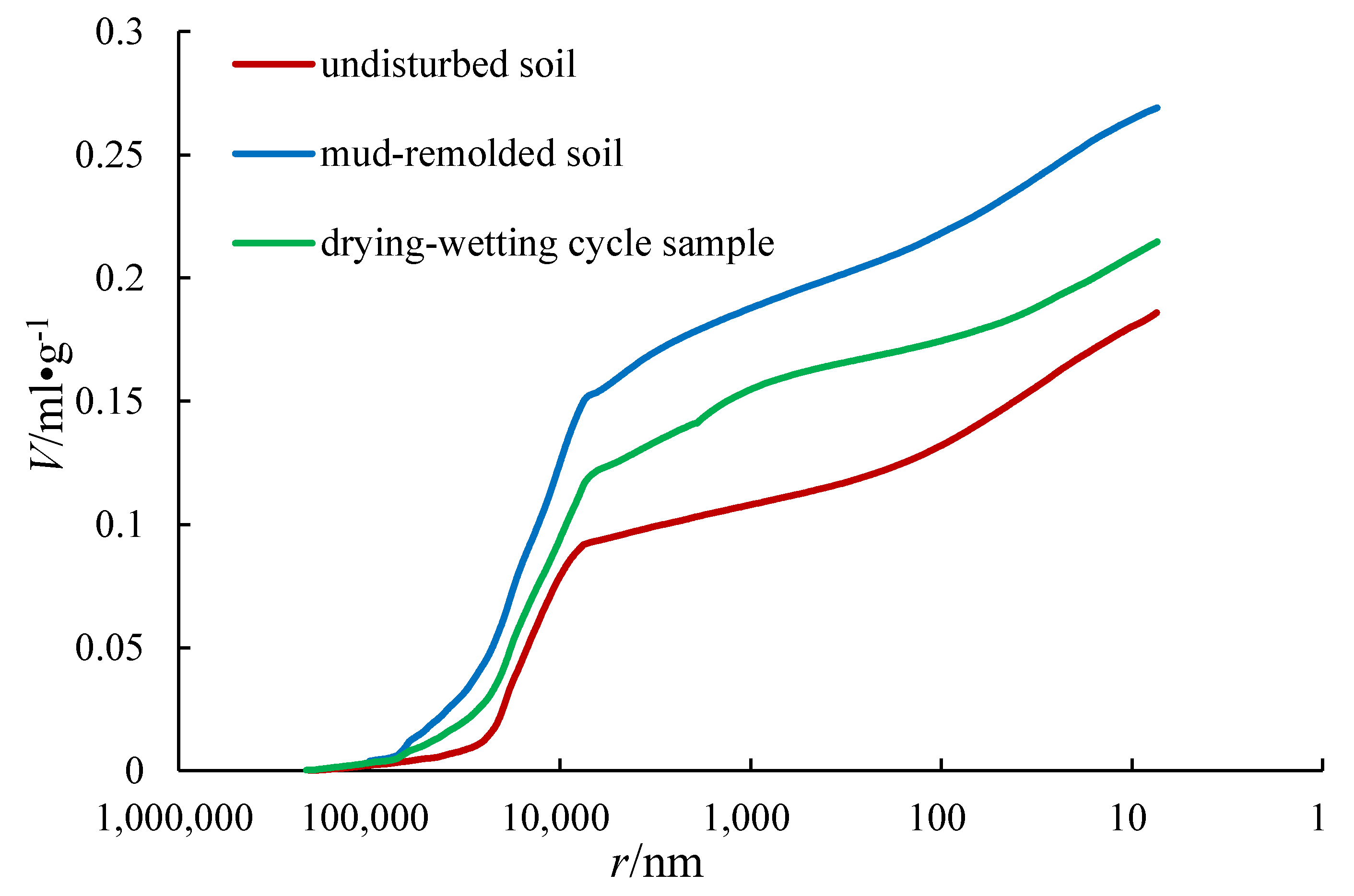

The pore size distribution characteristics—that is, the curve of mercury intrusion porosimetry—of the mud-remolded soil, the drying–wetting cycle sample, and the undisturbed soil are shown in

Figure 13. It is evident that the total pore volume of the remolded soil is the largest (0.269 mL⋅g

−1), the total pore volume of the undisturbed soil is the smallest (0.186 mL⋅g

−1), and the total pore volume of the drying–wetting cycle sample occupies the middle region (0.215 mL⋅g

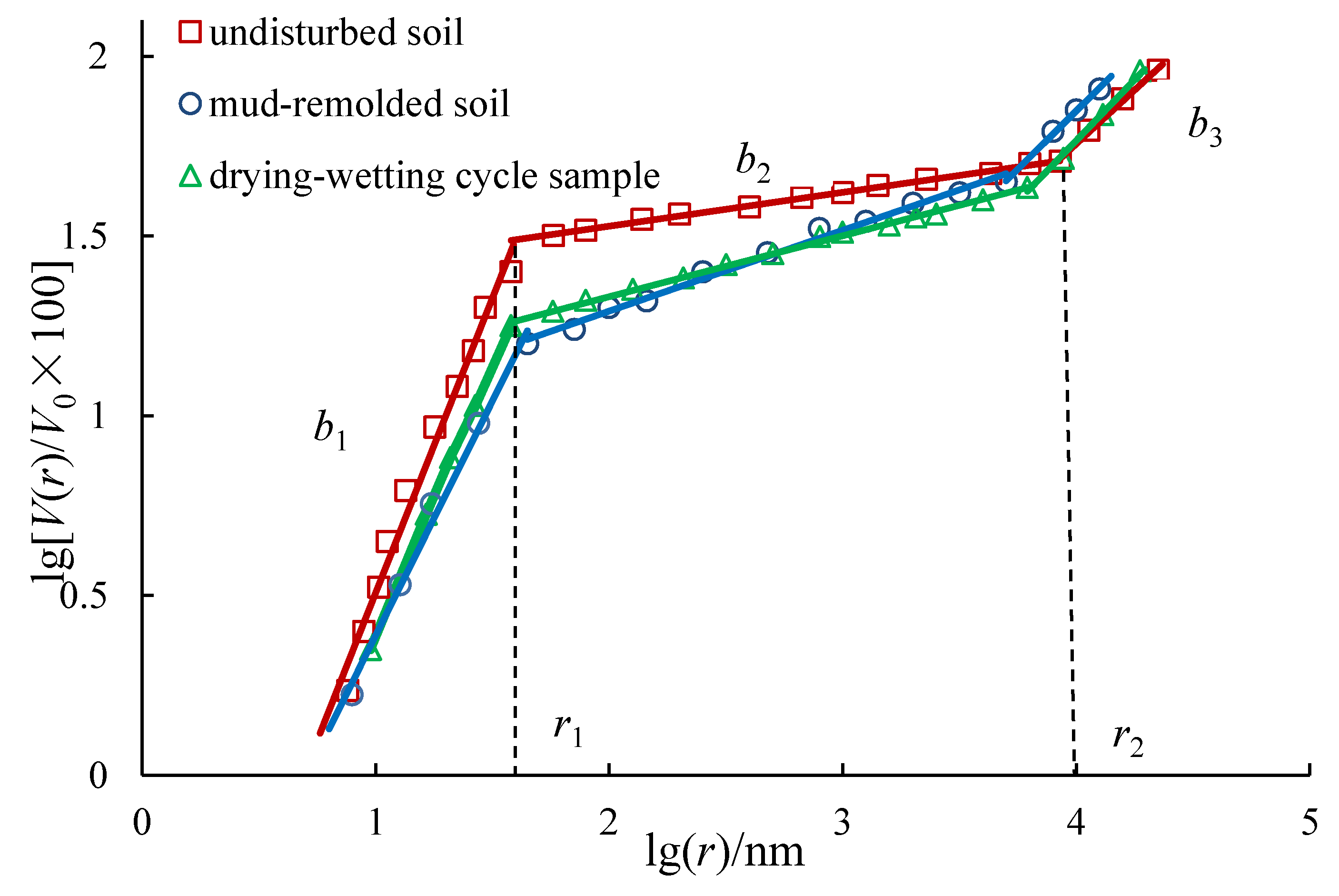

−1), which is consistent with the initial void ratio obtained from the consolidation compression curve. The mercury intrusion porosimetry curve moves upward with an increase in void ratio. The pore size distribution curve of the soil can be reorganized into a curve of lg (

) − lg(

r) according to fractal theory, where

V0 denotes the total pore volume of the test sample, and (

) denotes the percentage of the pore volume with a pore radius less than

r in the total pore volume. The curve in

Figure 14 shows that the curve of lg

) − lg(

r) can be divided into three straight-line segments based on fractal theory, with the pores within each line having self-similar characteristics. In other words, the pore sizes within the range of this segment have the same morphological characteristics and properties.

Consequently, the pore structure of expansive clay can be divided into three types—that is,

r, which corresponds to the inflection point as the critical value;

r1, which denotes the maximum critical equivalent radius of the pores between flaky particles in particle units; and

r2, which denotes the maximum equivalent radius of the pores when the particle units are in close contact. Pores with pore sizes larger than

r2 are those with aerial characteristics between particle aggregates. Subsequently, the fractal dimension value (

D) of the straight-line segments can be obtained from the slopes of the three straight-line segments (

b1,

b2, and

b3) in

Figure 14 as

D = 3 −

b. The fractal dimension can reasonably describe the heterogeneity of microscopic pore distribution: the larger the difference in the fractal dimension

D, the stronger the heterogeneity.

b reveals the degree of pore development. The larger

b is, the more pores develop.

The distribution of the three types of pore in the remolded soil is relatively uniform, with the D3 value of the remolded soil being close to that of D2. Meanwhile, the D2 value of the drying–wetting cycle sample increases gradually (b2 decreases), indicating that the drying–wetting cycle increases the content of aerial pores between particle aggregates and decreases the content of pores between particle units. Moreover, the number of micropores in the particle unit does not change much. For the undisturbed soil, it is evident that the content of pores between particle units in the middle segment is very small (b2 is close to 0), the value of D2 is the largest, and the difference between the fractal dimension of D2 and D3 is large, indicating that the pores between the particle units transition to the aerial pores between particle aggregates. The extent of aerial pores in the undisturbed soil is relatively high, with the number of large pores being relatively large. The large aerial pores between the particle aggregates play a decisive role in soil permeability.

In general, the microstructure of the mud-remolded soil undergoing drying–wetting cycles changes drastically, making the microstructure of the drying–wetting cycle sample more similar to that of the undisturbed soil. The microcosmic results are verified by the test results of the mechanical properties, indicating that the drying–wetting cycle plays an important role in the natural formation of undisturbed soil.