K-Means Module Division Method of FDM3D Printer-Based Function–Behavior–Structure Mapping

Abstract

1. Introduction

2. FDM3D Printer Module Division Principles and Indicators

2.1. Principle of Module Division

- (1)

- The principle of similarity

- (2)

- Hierarchical compression principle

- (3)

- The principle of module clustering

2.2. Divide Indicators Based on Environmentally Sustainable Modules

- (1)

- Maintainability

- (2)

- Reusability

- (3)

- Recyclability

- (4)

- Interchangeability

3. Module Partition Method

3.1. Customer Demand Survey and Analysis and Product Modularization Possibility Evaluation

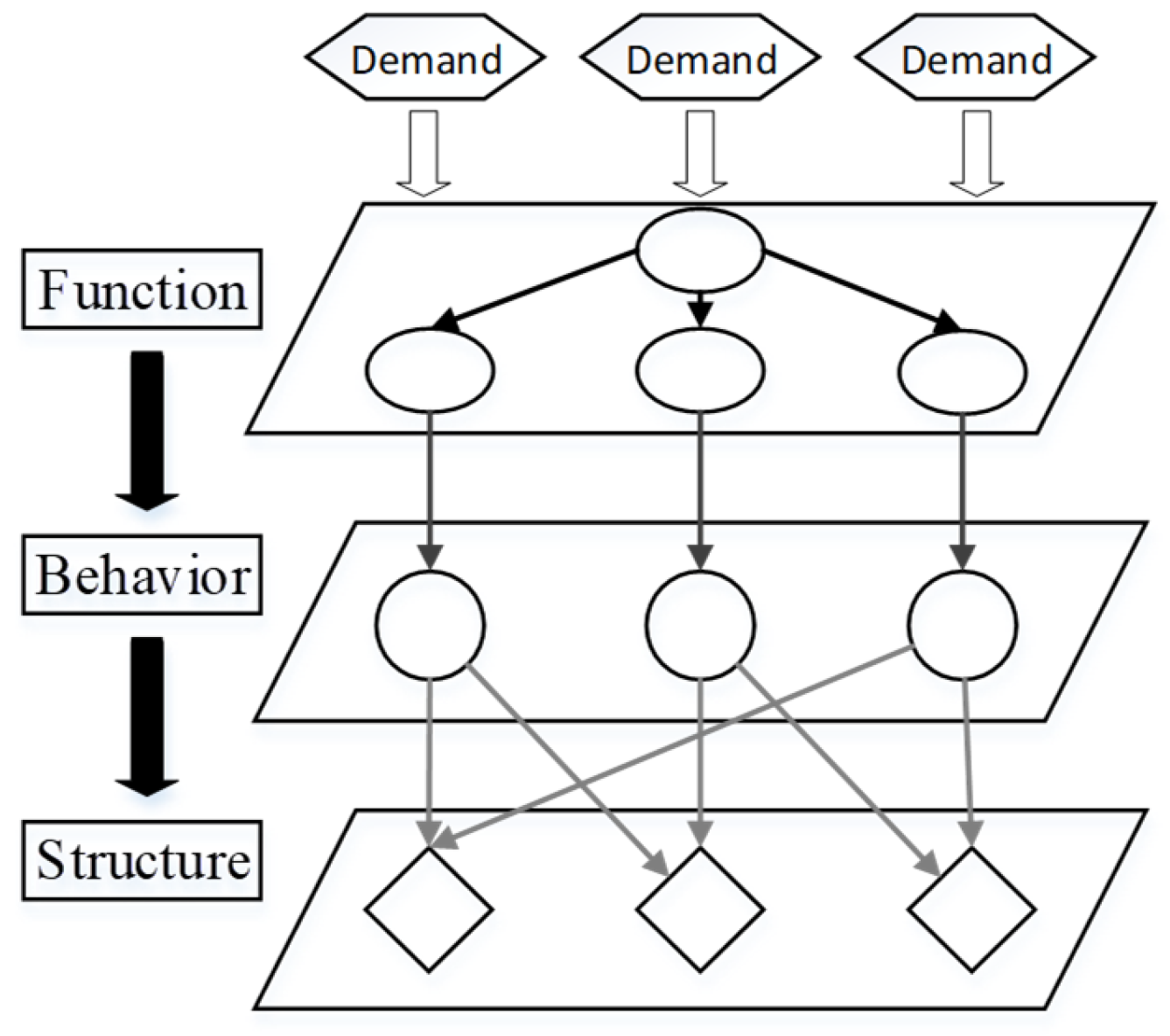

3.2. FBS-Based Product Overview Design

- (1)

- Function, an attribute that meets customer needs, that is, functions necessary for modular products in order to meet the performance, parameters, service life, etc., required by customer needs;

- (2)

- Behavior, in accordance with functional requirements, through a certain technical solution or principle to achieve the corresponding function;

- (3)

- Structure, the structural modules required to realize various technical solutions or principles while showing the relationship between entities.

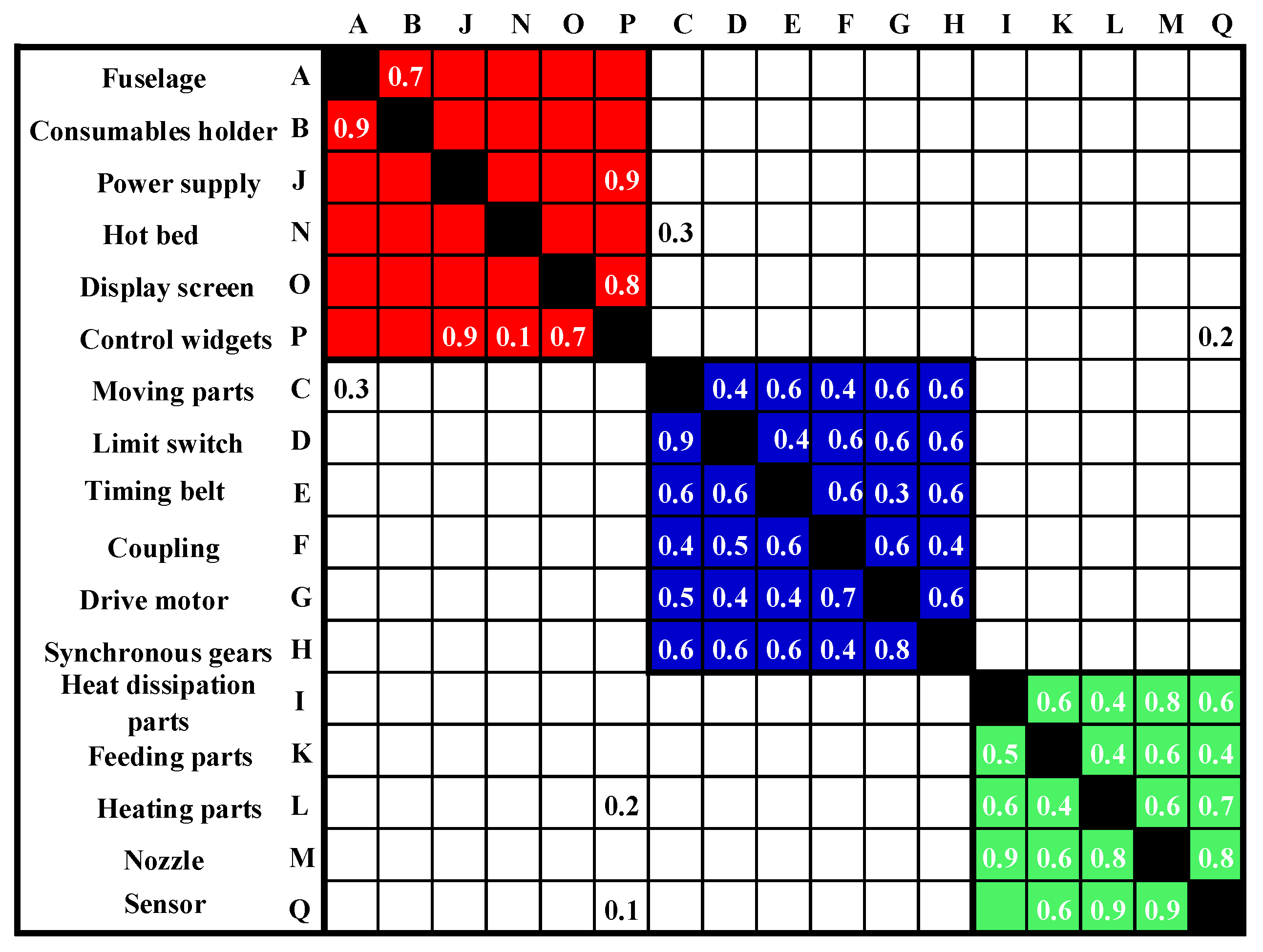

3.3. DSM Construction Based on FBS

- (1)

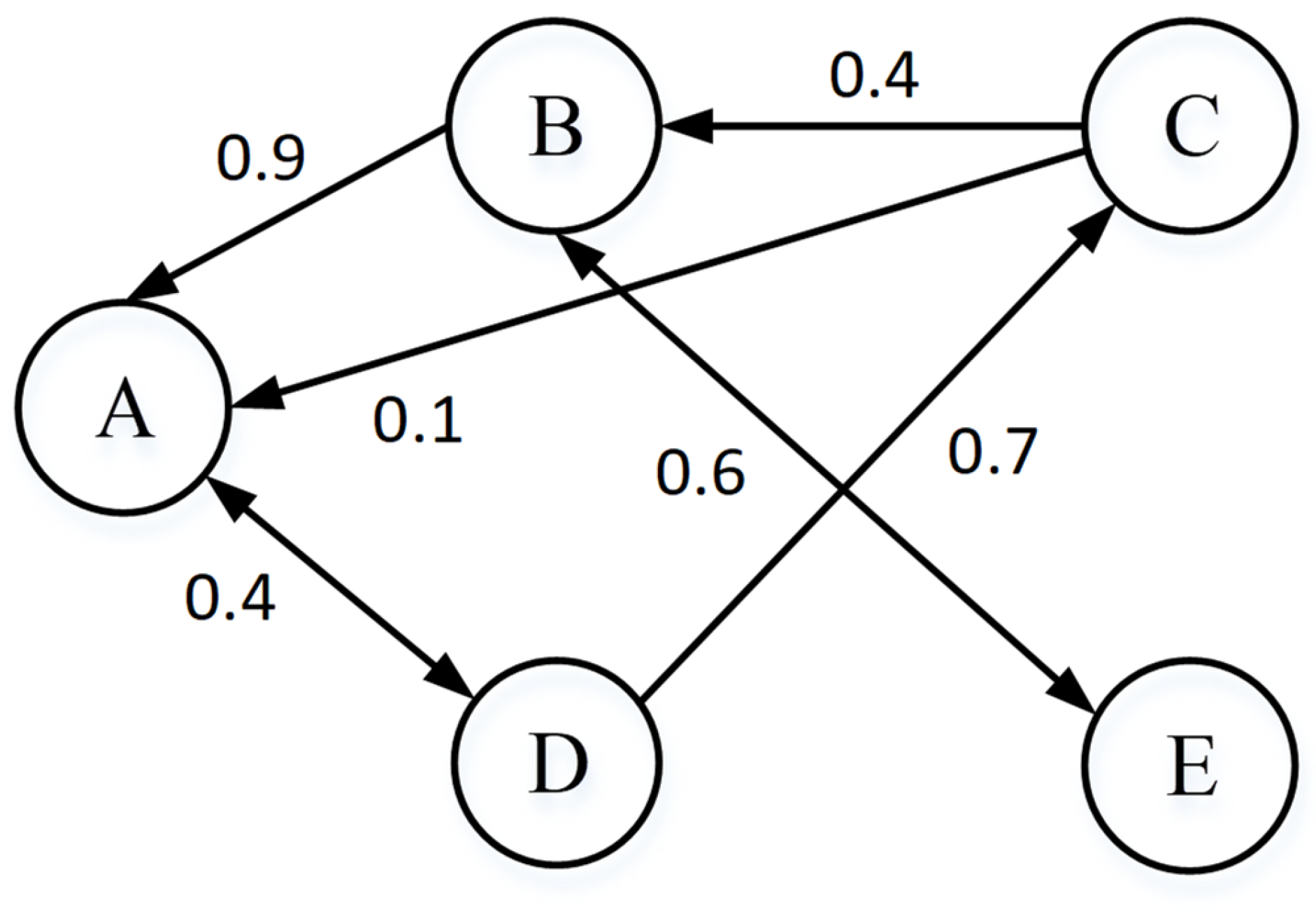

- The FBS model creates the weighted directed graph between components, as shown in Figure 4. A directed graph G = (V,E) representing the product’s weights has node sets V = [v1, v2,..., vn] and edge sets E = [e1, e2,..., em]. A matrix R is created by the weighted directed graph, which also describes the degree of reliance between product components.

- (2)

- Build DSM C for the product.

3.4. DSM Module Division Based on K-Means Algorithm

- (1)

- First, determine a K value; that is, the data pair is clustered and analyzed to obtain K clusters;

- (2)

- K initial clustering centers are randomly selected from the data objects;

- (3)

- Calculate the distance between each data object and each cluster center, and assign the object to the nearest cluster center according to the minimum distance criterion;

- (4)

- Calculate the centroid of the new cluster center, and then reassign it to the nearest cluster center according to the minimum distance criterion;

- (5)

- Compare the distance between the new cluster center and the cluster center of the previous iteration, and end the cluster if the distance is less than the set threshold; Otherwise, go back to step 3 and continue iterating until the clustering end condition is met.

3.5. FDM3D Printer Module Division Process

4. FDM3D Printer Module Division

4.1. FDM 3D Printer Product Requirements

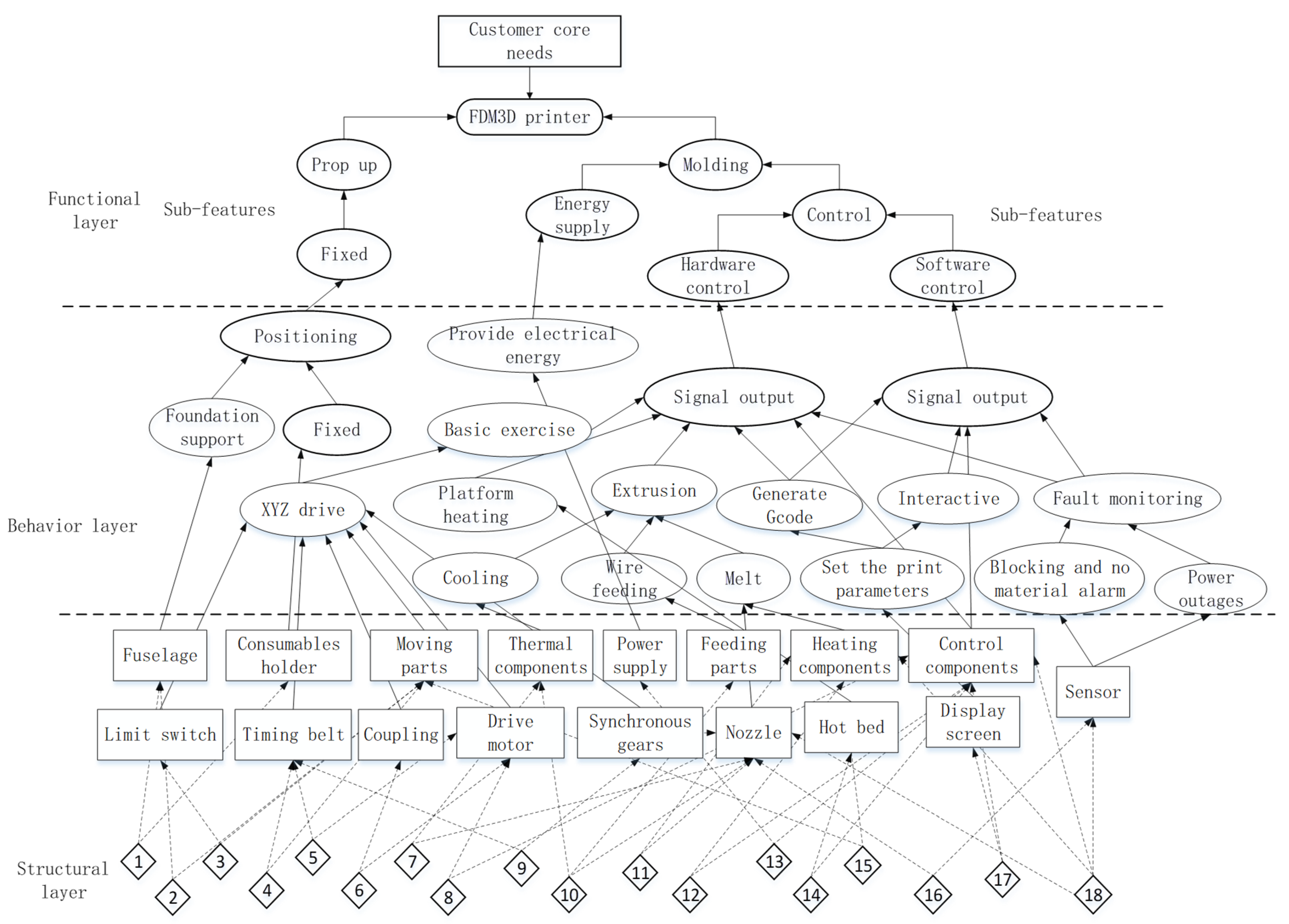

4.2. Establishment of FDM Printer FBS Model

4.3. Establishment and Clustering of DSM Model of FDM Printer

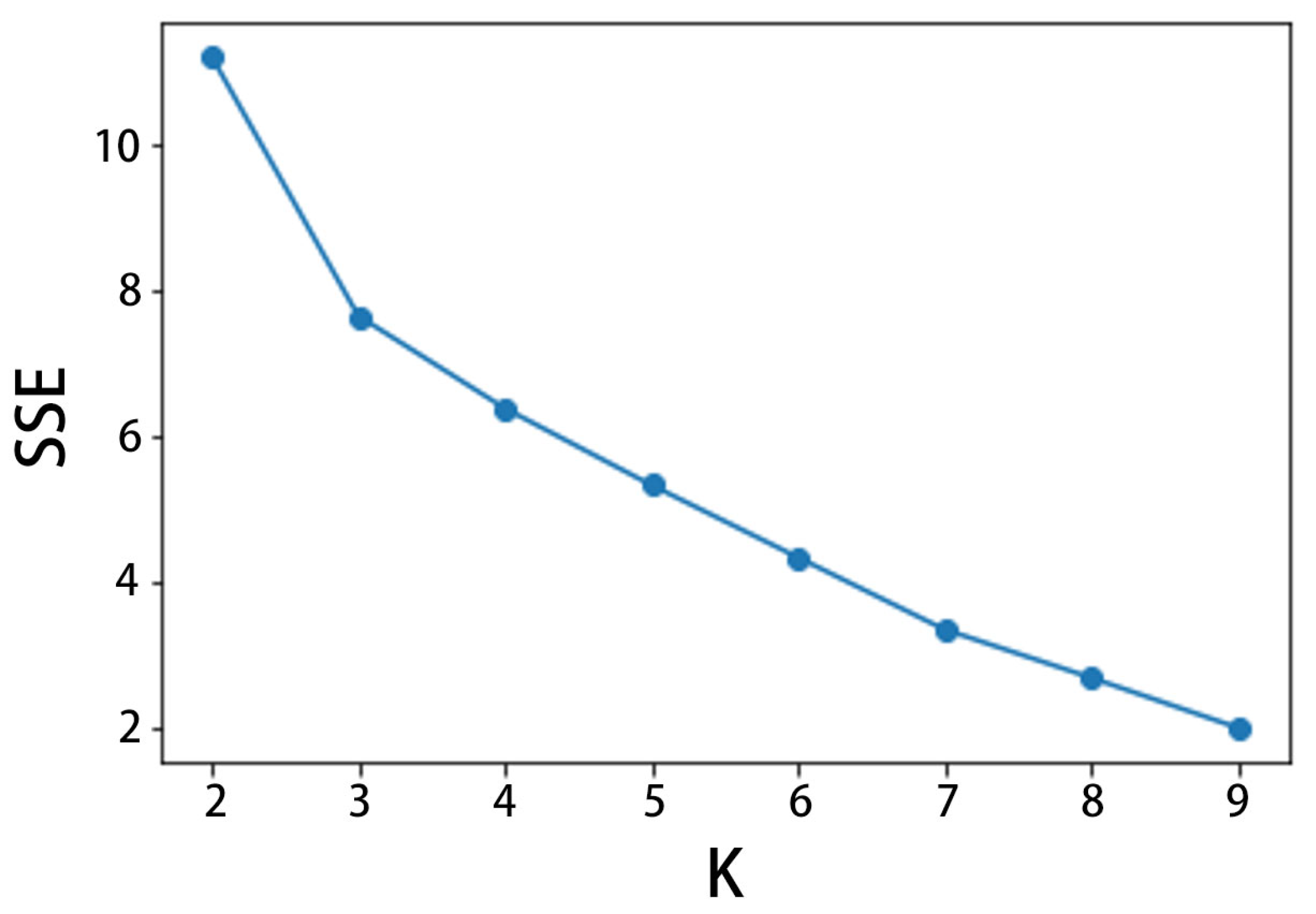

4.4. Evaluation of FDM3D Printer Module Division Results

- (1)

- The sum of squares due to error (SSE)

- (2)

- Silhouette Coefficient (SC)

5. Conclusions

- (1)

- By analyzing and comparing the three mainstream module classification principles in the market, the module clustering principle was determined as the module classification principle for FDM3D printers, and the environmental sustainability indicators for module classification were proposed, taking into account the possible impact of modular products on society, environment, and economy;

- (2)

- The FDM 3D printer DSM model was established through the analysis of customer needs and market research, and on the basis of the module clustering principle. The K-Means algorithm was then used to examine the product DSM clustering, in which K = 3, 4, 5, and 6 were chosen for cluster analysis, and four distinct division results were obtained;

- (3)

- The elbow method–intracluster error variance (SEE) and average profile coefficient (SC) were used as evaluation indicators to evaluate the division results in order to obtain the best module division results and confirm the practicability of the module division method. The results revealed that when K = 3, the image of intra-cluster error variance (SEE) obviously showed the inflection point, and the FDM3D printer was best divided into three modules, which verified the practicability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Uludag, M.; Ulkir, O.; Ertugrul, I.; Kaplanoglu, E. Design, Fabrication, and Experiments of a Soft Pneumatic Gripper with Closed-Loop Position Control. J. Test. Eval. 2022, 51, 378. [Google Scholar] [CrossRef]

- Zhang, L.; Dong, H.; Yu, Y.; Liu, L.; Zang, P. Application and challenges of 3D food printing technology in manned spaceflight: A review. Int. J. Food Sci. Technol. 2022, 57, 4906–4917. [Google Scholar] [CrossRef]

- Gao, G.; Xu, F.; Xu, J.; Tang, G.; Liu, Z. A Survey of the Influence of Process Parameters on Mechanical Properties of Fused Deposition Modeling Parts. Micromachines 2022, 13, 553. [Google Scholar] [CrossRef] [PubMed]

- Lupone, F.; Padovano, E.; Casamento, F.; Badini, C. Process Phenomena and Material Properties in Selective Laser Sintering of Polymers: A Review. Materials 2022, 15, 183. [Google Scholar] [CrossRef]

- Wang, H.; Ba, S.; Zhang, B.; Li, L. DLP Light-Curing 3D Printing Combustible Lighting Shell and Performance Study. Appl. Sci. 2022, 12, 10401. [Google Scholar] [CrossRef]

- Garg, H.K.; Singh, R. Modelling the Peak Elongation of Nylon6 and Fe Powder Based Composite Wire for FDM Feedstock Filament. J. Inst. Eng. India Ser. C 2017, 98, 567–573. [Google Scholar] [CrossRef]

- Recchioni, M.; Mandorli, F.; Germani, M.; Faraldi, P.; Polverini, D. Life-Cycle Assessment simplification for modular products. In Advances in Life Cycle Engineering for Sustainable Manufacturing Businesses; Takata, S., Umeda, Y., Eds.; Springer: London, UK, 2007. [Google Scholar] [CrossRef]

- Umeda, Y.; Fukushige, S.; Tonoike, K.; Kondoh, S. Product modularity for life cycle design. CIRP Ann. 2008, 57, 13–16. [Google Scholar] [CrossRef]

- Mesa, J.; Maury, H.; Arrieta, R.; Bula, A.; Riba, C. Characterization of modular architecture principles towards reconfiguration: A first approach in its selection process. Int. J. Adv. Manuf. Technol. 2015, 80, 221–232. [Google Scholar] [CrossRef]

- Mesa, J.A.; Esparragoza, I.; Maury, H. Trends and Perspectives of Sustainable Product Design for Open Architecture Products: Facing the Circular Economy Model. Int. J. Precis. Eng. Manuf. Technol. 2019, 6, 377–391. [Google Scholar] [CrossRef]

- Sonego, M.; Echeveste, M.E.S.; Debarba, H.G. The role of modularity in sustainable design: A systematic review. J. Clean. Prod. 2018, 176, 196–209. [Google Scholar] [CrossRef]

- Ma, J.; Kremer, G.E.O. A sustainable modular product design approach with key components and uncertain end-of-life strategy consideration. Int. J. Adv. Manuf. Technol. 2016, 85, 741–763. [Google Scholar] [CrossRef]

- Ginani, L.S.; Motta, J.M.S.T. Theoretical and practical aspects of robot calibration with experimental verification. J. Braz. Soc. Mech. Sci. Eng. 2011, 33, 15–21. [Google Scholar] [CrossRef]

- Roman, R.-C.; Precup, R.-E.; Petriu, E.M. Hybrid data-driven fuzzy active disturbance rejection control for tower crane systems. Eur. J. Control. 2021, 58, 373–387. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, Y.; Su, J.; Zheng, Y. Modelling and analysis of complex products design based on supernetwork. Kybernetes 2019, 48, 861–887. [Google Scholar] [CrossRef]

- Li, Z.-K.; Wang, S.; Yin, W.-W. Determining optimal granularity level of modular product with hierarchical clustering and modularity assessment. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 342. [Google Scholar] [CrossRef]

- Li, Y.; Chu, X.; Chen, D.; Liu, Q.; Shen, J. An integrated module portfolio planning approach for complex products and systems. Int. J. Comput. Integr. Manuf. 2014, 28, 988–998. [Google Scholar] [CrossRef]

- Gu, P.; Sosale, S. Product modularization for life cycle engineering. Robot. Comput. Integr. Manuf. 1999, 15, 387–401. [Google Scholar] [CrossRef]

- Ji, Y.; Jiao, R.J.; Chen, L.; Wu, C. Green modular design for material efficiency: A leader–follower joint optimization model. J. Clean. Prod. 2013, 41, 187–201. [Google Scholar] [CrossRef]

- Yu, S.; Yang, Q.; Tao, J.; Tian, X.; Yin, F. Product modular design incorporating life cycle issues—Group Genetic Algorithm (GGA) based method. J. Clean. Prod. 2011, 19, 1016–1032. [Google Scholar] [CrossRef]

- Zheng, H.; Feng, Y.; Tan, J.; Zhang, Z. An integrated modular design methodology based on maintenance performance consideration. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 313–328. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, W.; Ding, X. Modular design method for filament winding process equipment based on GGA and NSGA-II. Int. J. Adv. Manuf. Technol. 2018, 94, 2057–2076. [Google Scholar] [CrossRef]

- Arasteh, B.; Abdi, M.; Bouyer, A. Program source code comprehension by module clustering using combination of discretized gray wolf and genetic algorithms. Adv. Eng. Softw. 2022, 173, 103252. [Google Scholar] [CrossRef]

- Yan, J.; Feng, C.; Cheng, K. Sustainability-oriented product modular design using kernel-based fuzzy c-means clustering and genetic algorithm. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 1635–1647. [Google Scholar] [CrossRef]

- Kongsin, T.; Klongboonjit, S. Machine Component Clustering with Mixing Technique of DSM, Jaccard Distance Coefficient and k-Means Algorithm. In Proceedings of the 2020 IEEE 7th International Conference on Industrial Engineering and Applications (ICIEA), Bangkok, Thailand, 16–18 April 2020; pp. 251–255. [Google Scholar] [CrossRef]

- Li, B.; Xie, S. Module partition for 3D CAD assembly models: A hierarchical clustering method based on component dependencies. Int. J. Prod. Res. 2015, 53, 5224–5240. [Google Scholar] [CrossRef]

- Li, S.; Mirhosseini, M. A matrix-based modularization approach for supporting secure collaboration in parametric design. Comput. Ind. 2012, 63, 619–631. [Google Scholar] [CrossRef]

- Li, Z.; Cheng, Z.; Feng, Y.; Yang, J. An integrated method for flexible platform modular architecture design. J. Eng. Des. 2013, 24, 25–44. [Google Scholar] [CrossRef]

- Smith, S.; Yen, C.-C. Green product design through product modularization using atomic theory. Robot. Comput. Integr. Manuf. 2010, 26, 790–798. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Zhong, X.; Zou, F. Identification of influential function modules within complex products and systems based on weighted and directed complex networks. J. Intell. Manuf. 2019, 30, 2375–2390. [Google Scholar] [CrossRef]

- Ren, B.; Liu, J. Design of a Plantar Pressure Insole Meas-uring System Based on Modular Photoelectric Pressure Sensor Unit. Sensors 2021, 21, 3780. [Google Scholar] [CrossRef]

- Cammarata, A.; Sinatra, R.; Maddìo, P.D. Interface reduction in flexible multibody systems using the Floating Frame of Reference Formulation. J. Sound Vib. 2022, 523, 116720. [Google Scholar] [CrossRef]

- Natividad, R.F.; Miller-Jackson, T.; Chen-Hua, R.Y. A 2-DOF Shoulder Exosuit Driven by Modular, Pneumatic, Fabric Actuators. IEEE Trans. Med. Robot. Bionics 2021, 3, 166–178. [Google Scholar] [CrossRef]

- van Beek, T.J.; Erden, M.S.; Tomiyama, T. Modular design of mechatronic systems with function modeling. Mechatronics 2010, 20, 850–863. [Google Scholar] [CrossRef]

- Eppinger, S.D.; Browning, T.R. Design Structure Matrix Methods and Applications; MIT Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Sinaga, K.P.; Yang, M. -S. Unsupervised K-Means Clustering Algorithm. IEEE Access 2020, 8, 80716–80727. [Google Scholar] [CrossRef]

| First-Order Principle | Secondary Principle | Content |

|---|---|---|

| Module clustering principle | Structural interaction principle | The greater the interaction between two modules, the more they should be separated into the same module |

| Principle of energy interaction | ||

| Principle of material interaction | ||

| Signal interaction principle | ||

| Interaction principle of forces |

| Customer Characteristics | Description | |

|---|---|---|

| Customer demand | Performance | Identify and complement customer needs |

| Economy | ||

| Reliability | ||

| Convenience | ||

| Function | ||

| Appearance | ||

| Customer demand weight Customer evaluation of product requirements of the same type | Priority of requirements | |

| Satisfaction degree | ||

| Current needs are similar to customers | ||

| Problem | Yes | No |

|---|---|---|

| Are the components connected closely? | √ | |

| Are the majority of the parts reversible? | √ | |

| Can a system or subsystem be modified without affecting the product’s overall functionality? | √ | |

| Are certain components reusable? | √ | |

| Can the modules be isolated from one another? | √ | |

| Can I modify the functionality of some products without disassembling them entirely? | √ |

| Scale | Weight | Meaning |

|---|---|---|

| Higher | 0.9, 0.8 | Higher dependency intensity |

| High | 0.7, 0.6 | High dependency intensity |

| Medium | 0.5, 0.4 | Medium strength of dependence |

| Low | 0.3, 0.2 | Low dependency intensity |

| Lower | 0.1 | Lower dependency intensity |

| Requirement Type | Demand Classification | Core Requirement |

|---|---|---|

| Performance | Accuracy | XY axis positioning accuracy is high; high printing precision |

| Noise | ≤50 dB | |

| Speed | Faster printing speed | |

| Economy | Three types | Within 1000 RMB; 1000~2000 RMB; 2000~4000 RMB |

| Reliability | Security | High structural strength, printing stability |

| Intelligent control | Automatic leveling; power off continued to play; blocked material and no material alarm | |

| Convenience | Operating interface | Chinese/English; full-color HD touchscreen |

| Function | Printing mode | TF card; USB connection |

| Support format | STL; OBJ; Gcode | |

| Print size | Print in a variety of sizes to suit different environments | |

| Support consumables | PLA; ABS | |

| Slicing software | Cura; Simplify3D; Repetier-Host | |

| Appearance | Style | The appearance is diverse, beautiful, and simple |

| K = 3 | K = 4 | K = 5 | K = 6 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Component | Number | Distance | Module | Component | Number | Distance | Module | Component | Number | Distance | Module | Component | Number | Distance |

| 1 | fuselage | A | 0.695 | 1 | fuselage | A | 0.695 | 1 | fuselage | A | 0.682 | 1 | fuselage | A | 0.564 |

| Consumables holder | B | 0.834 | Consumables holder | B | 0.834 | Consumables holder | B | 0.811 | Consumables holder | B | 0.651 | ||||

| Power supply | J | 0.613 | Power supply | J | 0.613 | Power supply | J | 0.613 | Hotbed | N | 0.429 | ||||

| Hotbed | N | 0.626 | Hotbed | N | 0.626 | Hotbed | N | 0.626 | 2 | Power supply | J | 0.050 | |||

| Display screen | O | 0.556 | Display screen | O | 0.556 | Display screen | O | 0.556 | Display screen | O | 0.050 | ||||

| Control components | P | 0.519 | Control components | P | 0.519 | 2 | Control components | P | 0.000 | 3 | Control components | P | 0.000 | ||

| 2 | Moving parts | C | 0.588 | 2 | Moving parts | C | 0.588 | 3 | Moving parts | C | 0.588 | 4 | Moving parts | C | 0.613 |

| Limit switch | D | 0.629 | Limit switch | D | 0.629 | Limit switch | D | 0.629 | Limit switch | D | 0.626 | ||||

| Timing belt | E | 0.504 | Timing belt | E | 0.411 | Timing belt | E | 0.411 | Timing belt | E | 0.556 | ||||

| Coupling | F | 0.676 | Coupling | F | 0.676 | Coupling | F | 0.608 | Coupling | F | 0.519 | ||||

| Drive motor | G | 0.474 | Drive motor | G | 0.576 | Drive motor | G | 0.588 | Drive motor | G | 0.588 | ||||

| Synchronous gears | H | 0.577 | Synchronous gears | H | 0.629 | Synchronous gears | H | 0.629 | Synchronous gears | H | 0.629 | ||||

| 3 | Fan | I | 0.890 | 3 | Fan | I | 0.411 | 4 | Fan | I | 0.411 | 5 | Fan | I | 0.411 |

| Feeding assembly | K | 0.465 | Feeding assembly | K | 0.576 | Feeding assembly | K | 0.576 | Feeding assembly | K | 0.576 | ||||

| Heating devices | L | 0.586 | Sensor | L | 0.559 | Sensor | Q | 0.559 | Sensor | Q | 0.559 | ||||

| Nozzle | M | 1.028 | 4 | Heating devices | M | 0.534 | 5 | Heating devices | L | 0.534 | 6 | Heating devices | L | 0.534 | |

| Sensor | Q | 0.836 | Nozzle | Q | 0.534 | Nozzle | M | 0.475 | Nozzle | M | 0.534 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, Y.; Liu, Z.; Liu, Y.; Peng, N.; Wang, J.; Huang, Y.; Huang, Q. K-Means Module Division Method of FDM3D Printer-Based Function–Behavior–Structure Mapping. Appl. Sci. 2023, 13, 7453. https://doi.org/10.3390/app13137453

You Y, Liu Z, Liu Y, Peng N, Wang J, Huang Y, Huang Q. K-Means Module Division Method of FDM3D Printer-Based Function–Behavior–Structure Mapping. Applied Sciences. 2023; 13(13):7453. https://doi.org/10.3390/app13137453

Chicago/Turabian StyleYou, Ying, Zhiqiang Liu, Youqian Liu, Ning Peng, Jian Wang, Yizhe Huang, and Qibai Huang. 2023. "K-Means Module Division Method of FDM3D Printer-Based Function–Behavior–Structure Mapping" Applied Sciences 13, no. 13: 7453. https://doi.org/10.3390/app13137453

APA StyleYou, Y., Liu, Z., Liu, Y., Peng, N., Wang, J., Huang, Y., & Huang, Q. (2023). K-Means Module Division Method of FDM3D Printer-Based Function–Behavior–Structure Mapping. Applied Sciences, 13(13), 7453. https://doi.org/10.3390/app13137453