Design and Test of a Single-Row Harvesting and Cutting Integrated Handheld Garlic Harvester

Abstract

1. Introduction

2. Materials and Methods

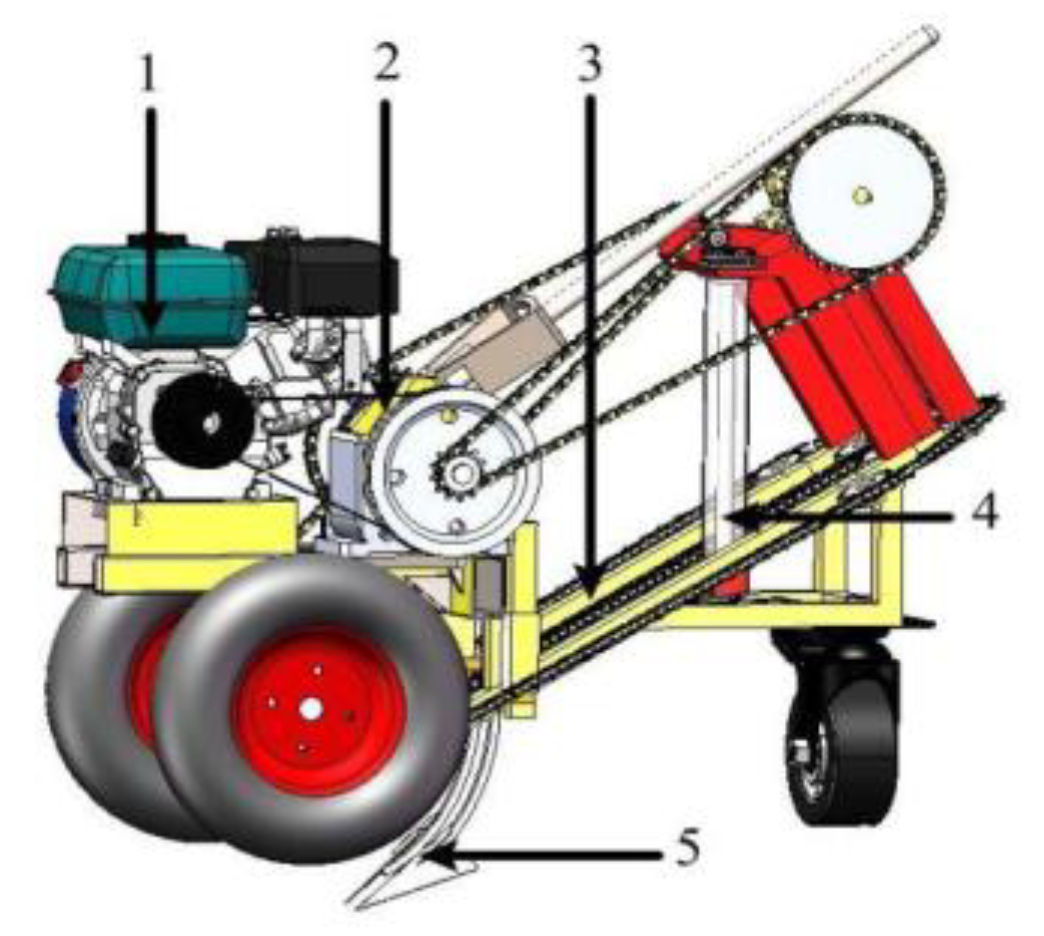

2.1. Overall Structure and Working Principle of the Machine

2.1.1. Overall Structure of the Machine

2.1.2. Working Principle and Main Technical Parameters

2.2. Key Component Design

2.2.1. Height-Adjustable Groundbreaking Device

2.2.2. Clamping Transport Device

2.2.3. Gearing

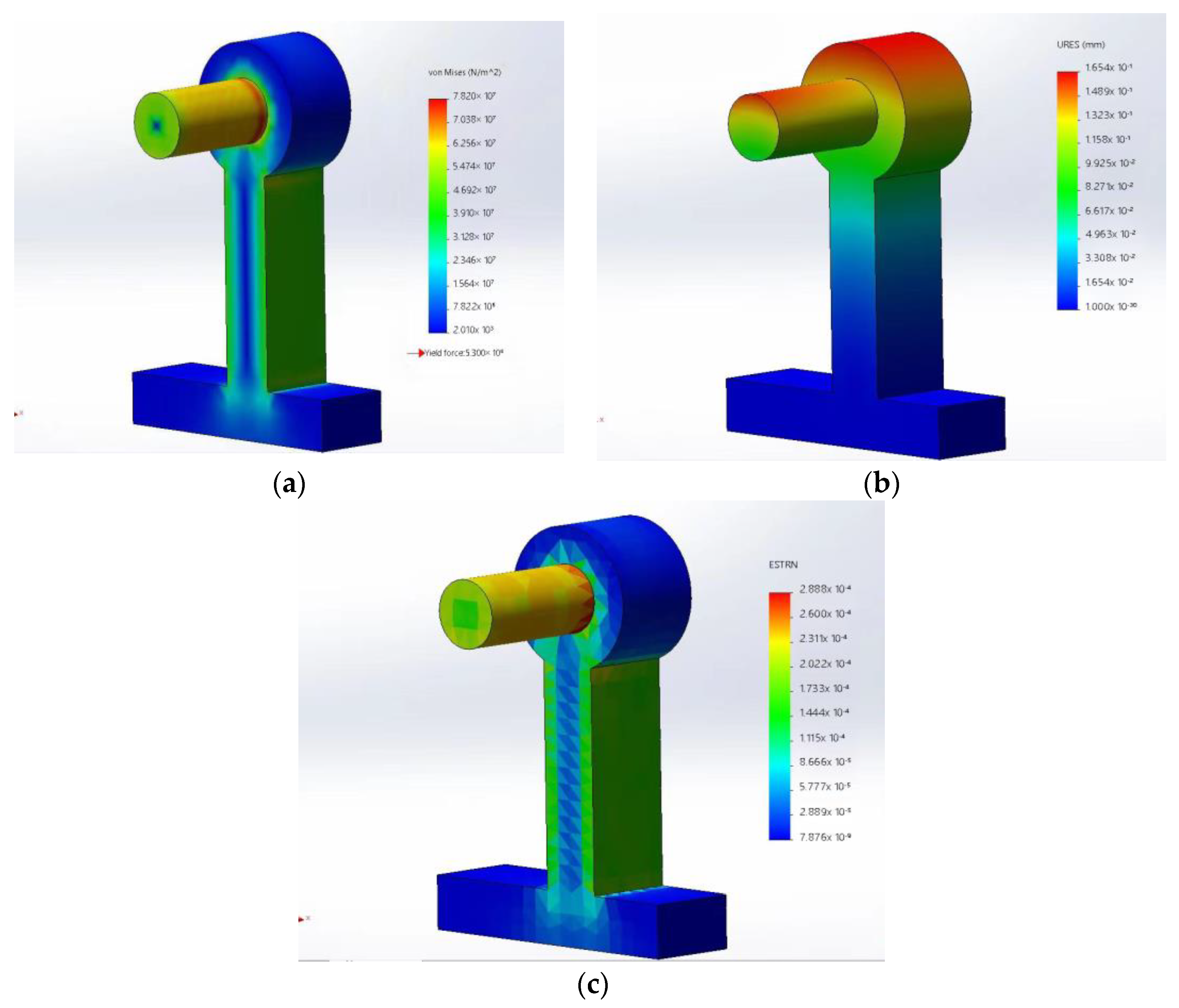

2.2.4. Material Selection of Commutation Seat in Power Unit

2.3. Analysis of Garlic Harvester Dynamics

2.3.1. Analysis of Groundbreaking Device Dynamics

2.3.2. Clamping Mechanism Dynamics Analysis

2.4. Orthogonal Analysis Method

2.4.1. Test Conditions and Methods

2.4.2. Experimental Factors and Index Selection

2.4.3. Orthogonal Experimental Design

2.4.4. Orthogonal Test Results

2.4.5. Regression Modeling and Significance Testing

3. Results

3.1. Sideswipe Threshold Analysis Results

3.2. Orthogonal Test Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bisen, P.S.; Emerald, M. Nutritional and Therapeutic Potential of Garlic and Onion (Allium sp.). Curr. Nutr. Food Sci. 2016, 12, 190–199. [Google Scholar] [CrossRef]

- de Queiroz, Y.S.; Antunes, P.B.; Vicente, S.J.V.; Sampaio, G.R.; Shibao, J.; Bastos, D.H.M.; Torres, E.A.F.d.S. Bioactive compounds, in vitroantioxidant capacity and Maillard reaction products of raw, boiled and fried garlic (Allium sativum L.). Int. J. Food Sci. Technol. 2014, 49, 1308–1314. [Google Scholar] [CrossRef]

- Lawson, L.D.; Hunsaker, S.M. Allicin Bioavailability and Bioequivalence from Garlic Supplements and Garlic Foods. Nutrients 2018, 10, 812. [Google Scholar] [CrossRef] [PubMed]

- Shang, A.; Cao, S.-Y.; Xu, X.-Y.; Gan, R.-Y.; Tang, G.-Y.; Corke, H.; Mavumengwana, V.; Li, H.-B. Bioactive Compounds and Biological Functions of Garlic (Allium sativum L.). Foods 2019, 8, 246. [Google Scholar] [CrossRef] [PubMed]

- Zhichang, Q.; Yiteng, Q.; Bin, Z.; Dongxiao, S.; Zhenjia, Z. Bioactive polysaccharides and oligosaccharides from garlic (Allium sativum L.): Production, physicochemical and biological properties, and structure-function relationships. Compr. Rev. Food Sci. Food Saf. 2022, 21, 3033–3095. [Google Scholar]

- Sepehripour, S.; Filobbos, G. Mechanism of Action of Topical Garlic on Wound Healing. Dermatol. Surg. 2020, 46, 845. [Google Scholar] [CrossRef]

- Borlinghaus, J.; Albrecht, F.; Gruhlke, M.C.H.; Nwachukwu, I.D.; Slusarenko, A.J. Allicin: Chemistry and Biological Properties. Molecules 2014, 19, 12591–12618. [Google Scholar] [CrossRef]

- Marchese, A.; Barbieri, R.; Sanches-Silva, A.; Daglia, M.; Nabavi, S.F.; Jafari, N.J.; Izadi, M.; Ajami, M.; Nabavi, S.M. Antifungal and antibacterial activities of allicin: A review. Trends Food Sci. Technol. 2016, 52, 49–56. [Google Scholar] [CrossRef]

- Koca, I.; Tasci, B. Garlic as a functional food. Acta Hortic. 2016, 1143, 139–146. [Google Scholar] [CrossRef]

- Varshney, R.; Budoff, M.J. Garlic and Heart Disease. J. Nutr. 2016, 146, 416S–421S. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Z.; Chen, Q.; Dai, J.; Li, X.; Sha, R.; Wang, H.; Mao, J.; Huang, J. Machine learning-based metabolomics for resolving metabolite differences during storage of Lablab garlic. Food Ind. Sci. Technol. 2023, 44, 26–34. [Google Scholar] [CrossRef]

- Rana, M.J.; Islam, S.; Kamruzzaman, M. Growth and instability in area, production and productivity of major spices in Bangladesh. J. Agric. Food Res. 2021, 6, 100216. [Google Scholar] [CrossRef]

- Srivastava, S.C.; Sharma, U.C.; Singh, B.K.; Yadava, H.S. A profile of Garlic production in India: Facts, trends and opportunities. Int. J. Agric. Environ. Biotechnol. 2013, 5, 477–482. [Google Scholar]

- Liu, S.-F.; Jia, H.-X.; Wang, J.-Y. Popularization and application of mechanization technology for garlic production. Agric. Mach. Sci. Technol. Ext. 2022, 238, 17–19+22. [Google Scholar]

- Qiao, L.; Guo, J.; Zhao, B.; Hou, J. Evaluation of full mechanization production efficiency and promotion strategy of garlic in Shandong Province. Chin. Melons 2022, 35, 110–115. [Google Scholar] [CrossRef]

- Tian, Z.; Zhao, Y.; Sui, Y.; Hou, J.; Sun, Q.; Wang, C.; Wang, Z.; Zhao, L. Design and Experiment of a Replant Crops Separating Garlic Harvester. Open Mech. Eng. J. 2018, 12, 67–80. [Google Scholar] [CrossRef]

- Yang, K.; Hu, Z.; Peng, B.; Yu, Z.; Wang, S.; You, Z.; Xu, H. Research and experiment on mechanical garlic beard cutting technology. Chin. J. Agric. Chem. 2015, 36, 153–159. [Google Scholar] [CrossRef]

- Yang, H.; Hu, Z.; Peng, B.; Wang, B.; Zhang, Y.; Yu, Z. Design and test of a multi-row combined harvester seedling and fruit collection and delivery device for garlic. Chin. J. Agric. Mach. Chem. 2021, 42, 8–12. [Google Scholar] [CrossRef]

- Wang, H.; Li, T.; Wu, Y.; Geng, A.; Li, Y.; Hou, J. Current status and outlook of garlic harvesting machinery research. Chin. J. Agric. Mach. Chem. 2018, 39, 102–107. [Google Scholar] [CrossRef]

- Borkar, N.T.; Sahoo, P.K.; Barik, P.M. Design and Development of Tractor Operated Garlic Harvester with Oscillating Soil Separator. J. Agric. Eng. 2018, 55, 13–20. [Google Scholar]

- Qin, L.; Yang, L. Research Status of Garlic Harvester. In 2016 International Conference on Economy, Management and Education Technology; Atlantis Press: Chongqing, China, 2016; pp. 724–725. [Google Scholar]

- Hou, J.; Li, C.; Lou, W.; Li, T.; Li, Y.; Zhou, K. Design and test of a pressurized root cutting device for garlic combine harvester. J. Agric. Mach. 2022, 53, 167–174. [Google Scholar]

- Yang, K.; Hu, Z.; Yu, Z.; Peng, B.; Zhang, Y.; Gu, F. Design and experiment of garlic harvesting and root cutting device based on deep learning target determination. J. Agric. Mach. 2022, 53, 123–132. [Google Scholar]

- Zhu, Z.; Cheng, J.; Wu, F.; Hu, Z.; Yu, Z. Optimization of Operation Parameters of the Garlic Plant Divider and Lifter Mechanisms. Agriculture 2023, 13, 189. [Google Scholar] [CrossRef]

- Yu, Z.; Yang, K.; Hu, Z.; Peng, B.; Gu, F.; Yang, L.; Yang, M. Parameter optimization and simulation analysis of floating root cutting mechanism for garlic harvester. Comput. Electron. Agric. 2023, 204, 107521. [Google Scholar] [CrossRef]

- Gao, X.; Zhao, D.; Xu, S.; Liu, C.; Huang, W. Application and research of modular design for general chassis of garlic machinery. J. Phys. Conf. Ser. 2019, 1237, 052037. [Google Scholar] [CrossRef]

- Li, J. Experiment on the Introduction of Garlic Planting and Harvesting Equipment; Tianjin Agricultural Machinery Testing and Certification Station: Tianjin, China, 2019. [Google Scholar]

- Xing, B. High-yielding cultivation technology of garlic stubble corn. Seed Ind. Guide 2018, 13, 10–11. [Google Scholar]

- Cao, Y. Planting pattern and high-yielding cultivation technology of garlic corn. Fujian Agric. Sci. Technol. 2016, 3, 34–36. [Google Scholar] [CrossRef]

- Li, J.; Cao, T.; Wang, W. Experimental analysis of 4S-85 garlic harvester. Jiangsu Agric. Mech. 2007, 4, 27–28. [Google Scholar] [CrossRef]

- Li, X.; Cui, J.; Yuan, H.; Lu, H.L.; Wang, C.W. Development and test demonstration of 4DS-40 garlic harvester. Jiangsu Agric. Mech. 2021, 203, 11–14. [Google Scholar] [CrossRef]

- Ding, A.; Peng, B.; Yang, K.; Zhang, Y.; Yang, X.; Zou, X.; Zhu, Z. Design of a Machine Vision-Based Automatic Digging Depth Control System for Garlic Combine Harvester. Agriculture 2022, 12, 2119. [Google Scholar] [CrossRef]

- Cui, J.; Zhong, Z.; Wang, C.; Wu, X.; Li, X.; Jiang, T. Design of a six-row crawler garlic combine harvester. Agric. Dev. Equip. 2021, 229, 138–139. [Google Scholar]

- Hou, J.; Li, C.; Zhang, Z.; Li, T.; Li, Y.; Wu, Y. Design and test of a two-row hand-held garlic combine harvester. J. Agric. Eng. 2021, 37, 1–11. (In English) [Google Scholar]

- Sun, Q.; Sui, Y.; Zhao, L.; Hou, J.; Wang, C.; Ying, C.; Shangguan, J. Design and Development of Self-Propelled Garlic Harvester. Agric. Res. 2018, 7, 495–505. [Google Scholar] [CrossRef]

| Parameter | Number |

|---|---|

| Dimensions (L × W × H)/(mm × mm × mm) | 1100 × 550 × 970 |

| Overall machine mass/kg | 90 |

| Mating engine power/kw | 90 |

| Calibrated engine speed/(r/min) | 1440 |

| Number of rows/row harvested | 1 |

| Working width/mm | 500 |

| Digging depth/mm | 110 |

| Breaking angle/° | 0~60 |

| Parameter | Number |

|---|---|

| Elastic modulus/(N/m2) | 2.1 × 1011 |

| Poisson’s ratio | 0.269 |

| Mass density/(kg/m3) | 7.85 × 103 |

| Tensile strength/(N/m2) | 6.25 × 108 |

| Yield strength/(N/m2) | 5.3 × 108 |

| Thermal conductivity/(W/(m·k)) | 49.8 |

| Specific heat/(J/(m·k)) | 486 |

| Normalizing/(°C) | 850 |

| Quench/(°C) | 840 |

| Tempering/(°C) | 600 |

| Physical Parameters | Numerical Value |

|---|---|

| Garlic plant height/mm | 200–300 |

| Bulb depth/mm | 50–80 |

| Spacing/mm | 150 |

| Soil water content/% | 450 |

| Soil firmness/(kN/mm) | 7.8 × 10−2 |

| Row spacing/mm | 220 |

| Code Value | Influencing Factors | |||

|---|---|---|---|---|

| Conveying Speed x1/(m/s) | Tool Speed x2/(r/min) | Groundbreaking Angle x3/(°) | Forward Speed x4/(m/s) | |

| −1 | 0.50 | 120 | 15 | 0.4 |

| 0 | 0.75 | 130 | 20 | 0.8 |

| 1 | 1.00 | 140 | 25 | 1.2 |

| Serial Number | Influencing Factors | Performance Indicators | |||||

|---|---|---|---|---|---|---|---|

| x1/(m/s) | x2/(r/min) | x3/(°) | x4/(m/s) | y1/% | y2/% | y3/% | |

| 1 | 0.5 | 130 | 20 | 0.4 | 0.468 | 1.118 | 93.447 |

| 2 | 0.5 | 140 | 20 | 0.8 | 0.489 | 1.155 | 93.781 |

| 3 | 0.5 | 120 | 20 | 0.8 | 0.486 | 1.08 | 94.2 |

| 4 | 0.5 | 130 | 15 | 0.8 | 0.524 | 1.087 | 92.526 |

| 5 | 0.5 | 130 | 20 | 1.2 | 0.52 | 1.116 | 94.534 |

| 6 | 0.5 | 130 | 25 | 0.8 | 0.514 | 1.147 | 95.455 |

| 7 | 0.75 | 130 | 20 | 0.8 | 0.501 | 1.166 | 94.437 |

| 8 | 0.75 | 130 | 20 | 0.8 | 0.502 | 1.166 | 94.437 |

| 9 | 0.75 | 130 | 20 | 0.8 | 0.502 | 1.166 | 94.437 |

| 10 | 0.75 | 130 | 15 | 0.4 | 0.542 | 1.136 | 92.43 |

| 11 | 0.75 | 120 | 20 | 0.4 | 0.493 | 1.129 | 94.103 |

| 12 | 0.75 | 130 | 20 | 0.8 | 0.5 | 1.166 | 94.437 |

| 13 | 0.75 | 130 | 15 | 1.2 | 0.576 | 1.135 | 93.516 |

| 14 | 0.75 | 120 | 15 | 0.8 | 0.549 | 1.098 | 93.182 |

| 15 | 0.75 | 130 | 25 | 0.4 | 0.493 | 1.196 | 95.358 |

| 16 | 0.75 | 140 | 25 | 0.8 | 0.563 | 1.16 | 96.524 |

| 17 | 0.75 | 140 | 20 | 1.2 | 0.556 | 1.202 | 94.771 |

| 18 | 0.75 | 130 | 25 | 1.2 | 0.58 | 1.195 | 96.445 |

| 19 | 0.75 | 120 | 25 | 0.8 | 0.561 | 1.158 | 96.111 |

| 20 | 0.75 | 140 | 15 | 0.8 | 0.548 | 1.173 | 92.764 |

| 21 | 0.75 | 130 | 20 | 0.8 | 0.502 | 1.166 | 94.437 |

| 22 | 0.75 | 120 | 20 | 1.2 | 0.548 | 1.127 | 95.19 |

| 23 | 0.75 | 140 | 20 | 0.4 | 0.491 | 1.204 | 93.685 |

| 24 | 1 | 130 | 25 | 0.8 | 0.598 | 1.244 | 96.348 |

| 25 | 1 | 120 | 20 | 0.8 | 0.558 | 1.176 | 95.093 |

| Source | Sum of Square | Df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 0.0382 | 14 | 0.0027 | 34.04 | <0.0001 | significant |

| A: Conveying speed | 0.0173 | 1 | 0.0173 | 215.97 | <0.0001 | |

| B: Tool speed | 0.0000 | 1 | 0.0000 | 0.1755 | 0.6816 | |

| C: Groundbreaking angle | 0.0001 | 1 | 0.0001 | 0.6491 | 0.4339 | |

| D: Forward | 0.0092 | 1 | 0.0092 | 114.48 | <0.0001 | |

| AB | 0.0000 | 1 | 0.0000 | 0.0000 | 1.0000 | |

| AC | 0.0000 | 1 | 0.0000 | 0.0000 | 0.4800 | |

| AD | 0.0000 | 1 | 0.0000 | 0.0000 | 0.4800 | |

| BC | 2.25 × 10−6 | 1 | 2.25 × 10−6 | 8.39 | 0.8694 | |

| BD | 0.0000 | 1 | 0.0000 | 0.0000 | 0.5855 | |

| CD | 0.0007 | 1 | 0.0007 | 0.0000 | 0.0104 | |

| A2 | 0.0018 | 1 | 0.0018 | 0.3185 | 0.0003 | |

| B2 | 0.0006 | 1 | 0.0006 | 1.64 | 0.0149 | |

| C2 | 0.0103 | 1 | 0.0103 | 1.64 | <0.0001 | |

| D2 | 0.0008 | 1 | 0.0008 | 0.3185 | 0.0079 |

| Source | Sum of Square | Df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 0.0488 | 14 | 0.0488 | 21.96 | <0.0001 | significant |

| A: Conveying speed | 0.0280 | 1 | 0.0280 | 176.65 | <0.0001 | |

| B: Tool speed | 0.0118 | 1 | 0.0118 | 74.63 | <0.0001 | |

| C: Groundbreaking angle | 0.0069 | 1 | 0.0069 | 43.25 | <0.0001 | |

| D: Forward | 8.333 × 10−6 | 1 | 8.3 × 10−6 | 0.0525 | 0.8221 | |

| AB | 0.0000 | 1 | 0.0000 | 0.0000 | 1.0000 | |

| AC | 0.0000 | 1 | 0.0000 | 0.0000 | 1.0000 | |

| AD | 0.0000 | 1 | 0.0000 | 0.0000 | 1.0000 | |

| BC | 0.0013 | 1 | 0.0000 | 8.39 | 0.0117 | |

| BD | 0.0000 | 1 | 0.0000 | 0.0000 | 1.0000 | |

| CD | 0.0000 | 1 | 0.0000 | 0.0000 | 1.0000 | |

| A2 | 0.0001 | 1 | 0.0001 | 0.3185 | 0.5814 | |

| B2 | 0.0003 | 1 | 0.0003 | 1.64 | 0.2212 | |

| C2 | 0.0003 | 1 | 0.0003 | 1.64 | 0.2212 | |

| D2 | 0.0001 | 1 | 0.0001 | 0.3185 | 0.5814 |

| Source | Sum of Square | Df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 34.66 | 14 | 2.48 | 120.16 | <0.0001 | significant |

| A: Conveying speed | 2.40 | 1 | 2.40 | 116.25 | <0.0001 | |

| B: Tool speed | 0.2349 | 1 | 0.2349 | 11.40 | 0.0045 | |

| C: Groundbreaking angle | 28.22 | 1 | 28.22 | 1369.90 | <0.0001 | |

| D: Forward | 3.54 | 1 | 3.54 | 171.90 | <0.0001 | |

| AB | 2.500 × 10−7 | 1 | 2.500 × 10−7 | 0.0000 | 0.9973 | |

| AC | 2.500 × 10−7 | 1 | 2.500 × 10−7 | 0.0000 | 0.9973 | |

| AD | 2.500 × 10−7 | 1 | 2.500 × 10−7 | 0.0000 | 0.9973 | |

| BC | 0.1726 | 1 | 0.1726 | 8.38 | 0.011 | |

| BD | 2.500 × 10−7 | 1 | 2.500 × 10−7 | 0.0000 | 0.9973 | |

| CD | 2.500 × 10−7 | 1 | 2.500 × 10−7 | 0.0000 | 0.9973 | |

| A2 | 0.0077 | 1 | 0.0077 | 0.3185 | 0.549 | |

| B2 | 0.0313 | 1 | 0.0313 | 1.52 | 0.2381 | |

| C2 | 0.0313 | 1 | 0.0313 | 1.52 | 0.2381 | |

| D2 | 0.0077 | 1 | 0.0077 | 0.3757 | 0.5498 |

| Serial Number | Single-Row Harvesting and Cutting Integrated Handheld Garlic Harvester | ||

|---|---|---|---|

| Garlic Injury Rate/% | Leakage Rate/% | Net Garlic Collection Rate/% | |

| 1 | 0.497 | 1.116 | 94.066 |

| 2 | 0.479 | 1.124 | 93.893 |

| 3 | 0.492 | 1.098 | 94.281 |

| 4 | 0.526 | 1.077 | 93.894 |

| 5 | 0.481 | 1.195 | 94.681 |

| Average value | 0.495 | 1.122 | 94.163 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Qiu, L.; Sun, Q.; Jing, Y.; Zhao, Y.; Yao, P. Design and Test of a Single-Row Harvesting and Cutting Integrated Handheld Garlic Harvester. Appl. Sci. 2023, 13, 7077. https://doi.org/10.3390/app13127077

Zhang X, Qiu L, Sun Q, Jing Y, Zhao Y, Yao P. Design and Test of a Single-Row Harvesting and Cutting Integrated Handheld Garlic Harvester. Applied Sciences. 2023; 13(12):7077. https://doi.org/10.3390/app13127077

Chicago/Turabian StyleZhang, Xieliang, Liqi Qiu, Qun Sun, Yigang Jing, Ying Zhao, and Penghui Yao. 2023. "Design and Test of a Single-Row Harvesting and Cutting Integrated Handheld Garlic Harvester" Applied Sciences 13, no. 12: 7077. https://doi.org/10.3390/app13127077

APA StyleZhang, X., Qiu, L., Sun, Q., Jing, Y., Zhao, Y., & Yao, P. (2023). Design and Test of a Single-Row Harvesting and Cutting Integrated Handheld Garlic Harvester. Applied Sciences, 13(12), 7077. https://doi.org/10.3390/app13127077