Prediction of Chatter Stability in Bull-Nose End Milling of Thin-Walled Cylindrical Parts Using Layered Cutting Force Coefficients

Abstract

1. Introduction

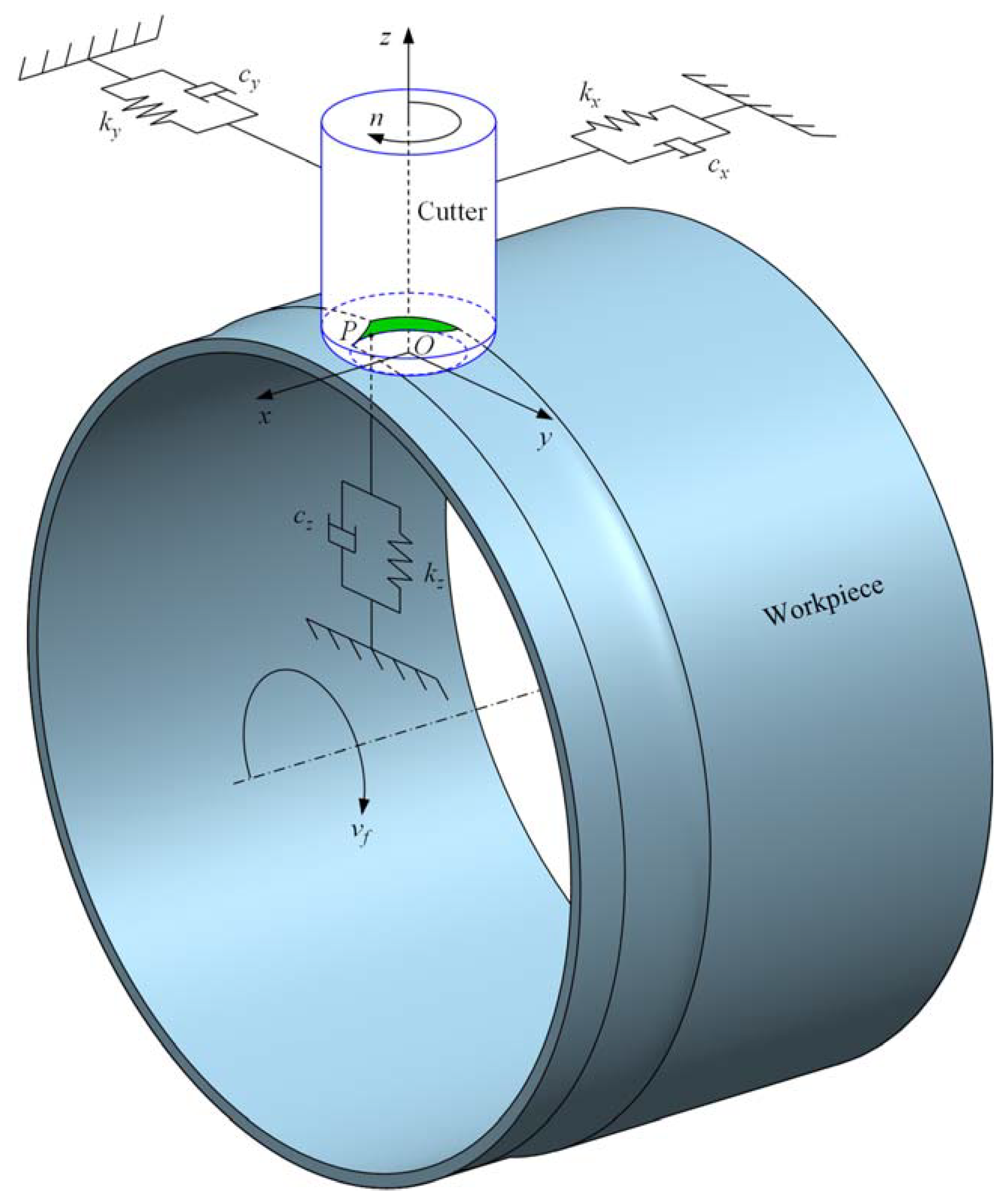

2. 3-DOF Chatter Stability Model

2.1. Milling System for a Thin-Walled Cylinder

2.2. Dynamic Cutting Force Modeling for Bull-Nose End Milling

2.3. Calculation of CWE

- Input the machined surface of the workpiece Sm and the toroidal surface of the tool Sc, and determine the cutting contact point Pc according to the cutter axis orientation and the milling line position. The machined surface of the workpiece Sm and the toroidal surface of the tool Sc are tangent to each other at the cutting contact point Pc;

- Input the total number of slices Ns and the machining allowance h, and set the initial value of an index variable i to 1;

- Offset the workpiece’s machined surface Sm towards the outside by the distance Δh = i∙h/Ns to obtain a slice Si;

- Calculate the intersection curve Ci between the slice Si and the toroidal surface of the tool Sc. The intersection curve Ci is essentially boundary 2 with the corresponding machining allowance;

- Calculate the minimum distance points Pi and Qi from the intersection curve Ci to the reference planes Pr1 and Pr2, and store the minimum distance points into the set of boundary points {P};

- Go to Step (3) and repeat the process until the index variable i is greater than the total number of slices Ns;

- Fit the set of boundary points {P} of the CWE as a spline curve B;

- Trim the cutter’s toroidal surface Sc using the spline curve B and the intersection curve Ca to extract the CWE in bull-nose end slotting of the thin-walled cylindrical workpiece. The CWEs under the following cut conditions can be obtained by trimming operations.

2.4. Identification of Layered Cutting Force Coefficients

2.5. Calculation of SLD with SDM

3. Predicted Results and Experimental Validation

3.1. CWE

3.2. Layered Cutting Force Coefficients

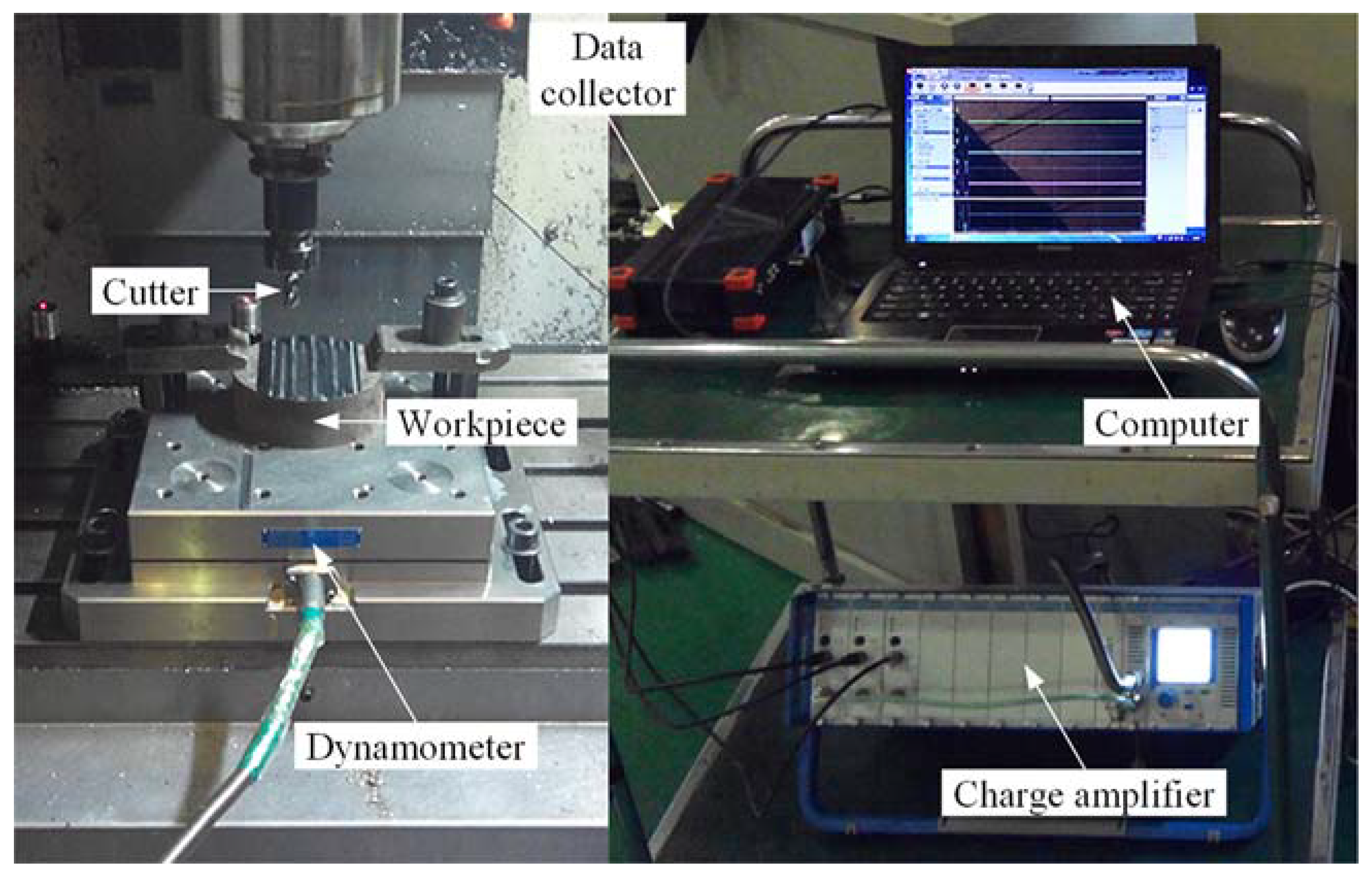

3.3. Dynamic Parameters

3.4. Chatter Stability Analysis and Experimental Validation

4. Conclusions

- (1)

- A 3-DOF chatter stability model is developed, which is applicable to forecast the regenerative chatter in the bull-nose end finish milling of thin-walled cylindrical parts. It reflects the dynamics of the cutter subsystem in the x-axis and y-axis directions and the dynamic of the workpiece subsystem in the surface normal (namely, z-axis) direction. The SDM is employed to solve the dynamic equation describing the 3-DOF milling system;

- (2)

- A slice-intersection-based method for calculating the engagement boundary curve is established. The method is applicable to determining the CWE geometries with different milling conditions, such as slotting and following cuts. Furthermore, a lead angle of 0 degrees is recommended to maximize the machined strip width;

- (3)

- The approach to layered cutting force coefficient identification is presented considering the effect of varying cutter diameter. The specific coefficients for each cutting disk element can be determined by substituting the corresponding height into the cubic fitting polynomial;

- (4)

- The validation tests of the proposed model are performed on a four-axis CNC machine tool. The predicted SLD agrees well with the experimental data. The spindle speed and the axial depth of the cut can be optimally chosen using the SLD to effectively avoid regenerative chatter and achieve smooth surfaces.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dong, J.; Chang, Z.; Chen, P.; He, J.; Wan, N. Two-Dimensional Profile Simulation Model for Five-Axis CNC Machining with Bull-Nose Cutter. Appl. Sci. 2022, 12, 8230. [Google Scholar] [CrossRef]

- Fan, H.Z.; Xi, G.; Wang, W.; Cao, Y.L. An efficient five-axis machining method of centrifugal impeller based on regional milling. Int. J. Adv. Manuf. Technol. 2016, 87, 789–799. [Google Scholar] [CrossRef]

- Tang, X.; Zhu, Z.; Yan, R.; Chen, C.; Peng, F.; Zhang, M.; Li, Y. Stability Prediction Based Effect Analysis of Tool Orientation on Machining Efficiency for Five-Axis Bull-Nose End Milling. J. Manuf. Sci. Eng. 2018, 140, 121015. [Google Scholar] [CrossRef]

- Yue, C.; Gao, H.; Liu, X.; Liang, S.Y.; Wang, L. A review of chatter vibration research in milling. Chin. J. Aeronaut. 2019, 32, 215–242. [Google Scholar] [CrossRef]

- Du, X.; Ren, P.; Zheng, J. Predicting Milling Stability Based on Composite Cotes-Based and Simpson’s 3/8-Based Methods. Micromachines 2022, 13, 810. [Google Scholar] [CrossRef] [PubMed]

- Wan, M.; Zhang, W.H.; Dang, J.W.; Yang, Y. A unified stability prediction method for milling process with multiple delays. Int. J. Mach. Tools Manuf. 2010, 50, 29–41. [Google Scholar] [CrossRef]

- Altintas, Y.; Budak, E. Analytical Prediction of Stability Lobes in Milling. CIRP Ann. Manuf. Technol. 1995, 44, 357–362. [Google Scholar] [CrossRef]

- Budak, E.; Altintas, Y. Analytical Prediction of Chatter Stability in Milling—Part I: General Formulation. J. Dyn. Sys. Meas. Control. 1998, 120, 22–30. [Google Scholar] [CrossRef]

- Budak, E.; Altintas, Y. Analytical Prediction of Chatter Stability in Milling—Part II: Application of the General Formulation to Common Milling Systems. J. Dyn. Sys. Meas. Control. 1998, 120, 31–36. [Google Scholar] [CrossRef]

- Merdol, S.D.; Altintas, Y. Multi Frequency Solution of Chatter Stability for Low Immersion Milling. J. Manuf. Sci. Eng. 2004, 126, 459–466. [Google Scholar] [CrossRef]

- Zhu, L.; Liu, C. Recent progress of chatter prediction, detection and suppression in milling. Mech. Syst. Signal Process. 2020, 143, 106840. [Google Scholar] [CrossRef]

- Insperger, T.; Stépán, G. Updated semi-discretization method for periodic delay-differential equations with discrete delay. Int. J. Numer. Methods Eng. 2004, 61, 117–141. [Google Scholar] [CrossRef]

- Insperger, T.; Stépán, G.; Turi, J. On the higher-order semi-discretizations for periodic delayed systems. J. Sound Vib. 2008, 313, 334–341. [Google Scholar] [CrossRef]

- Jiang, S.; Sun, Y.; Yuan, X.; Liu, W. A second-order semi-discretization method for the efficient and accurate stability prediction of milling process. Int. J. Adv. Manuf. Technol. 2017, 92, 583–595. [Google Scholar] [CrossRef]

- Yan, Z.; Zhang, C.; Jia, J.; Ma, B.; Jiang, X.; Wang, D.; Zhu, T. High-order semi-discretization methods for stability analysis in milling based on precise integration. Precis. Eng. 2022, 73, 71–92. [Google Scholar] [CrossRef]

- Ding, Y.; Zhu, L.M.; Zhang, X.J.; Ding, H. A full-discretization method for prediction of milling stability. Int. J. Mach. Tools Manuf. 2010, 50, 502–509. [Google Scholar] [CrossRef]

- Ding, Y.; Zhu, L.M.; Zhang, X.J.; Ding, H. Second-order full-discretization method for milling stability prediction. Int. J. Mach. Tools Manuf. 2010, 50, 926–932. [Google Scholar] [CrossRef]

- Quo, Q.; Sun, Y.; Jiang, Y. On the accurate calculation of milling stability limits using third-order full-discretization method. Int. J. Mach. Tools Manuf. 2012, 62, 61–66. [Google Scholar] [CrossRef]

- Ma, J.; Li, Y.; Zhang, D.; Zhao, B.; Wang, G.; Pang, X. A Novel Updated Full-Discretization Method for Prediction of Milling Stability. Micromachines 2022, 13, 160. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Peng, F.; Yan, R.; Gong, Y.; Li, Y.; Jiang, L. Accurate and efficient prediction of milling stability with updated full discretization method. Int. J. Adv. Manuf. Technol. 2017, 88, 2357–2368. [Google Scholar] [CrossRef]

- Yan, Z.; Wang, X.; Liu, Z.; Wang, D.; Jiao, L.; Ji, Y. Third order updated full-discretization method for milling stability prediction. Int. J. Adv. Manuf. Technol. 2017, 92, 2299–2309. [Google Scholar] [CrossRef]

- Herranz, S.; Campa, F.J.; López de Lacalle, L.N.; Rivero, A.; Lamikiz, A.; Ukar, E.; Sánchez, J.A.; Bravo, U. The milling of airframe components with low rigidity: A general approach to avoid static and dynamic problems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2005, 219, 789–801. [Google Scholar] [CrossRef]

- Fei, J.; Xu, F.; Lin, B.; Huang, T. State of the art in milling process of the flexible workpiece. Int. J. Adv. Manuf. Technol. 2020, 109, 1695–1725. [Google Scholar] [CrossRef]

- Dong, H.; Ji, Y.; Wang, X.; Bi, Q. Stability analysis of thin-walled parts end milling considering cutting depth regeneration effect. Int. J. Adv. Manuf. Technol. 2021, 113, 3319–3328. [Google Scholar] [CrossRef]

- Campa, F.J.; López de Lacalle, L.N.; Lamikiz, A.; Sánchez, J.A. Selection of cutting conditions for a stable milling of flexible parts with bull-nose end mills. J. Mater. Process. Technol. 2007, 191, 279–282. [Google Scholar] [CrossRef]

- Campa, F.J.; López de Lacalle, L.N.; Celaya, A. Chatter avoidance in the milling of thin floors with bull-nose end mills: Model and stability diagrams. Int. J. Mach. Tools Manuf. 2011, 51, 43–53. [Google Scholar] [CrossRef]

- Seguy, S.; Campa, F.J.; López de Lacalle, L.N.; Arnaud, L.; Dessein, G.; Aramendi, G. Toolpath dependent stability lobes for the milling of thin-walled parts. Int. J. Mach. Mach. Mater. 2008, 4, 377–392. [Google Scholar] [CrossRef]

- Puma-Araujo, S.D.; Olvera-Trejo, D.; Martinez-Romero, O.; Urbikain, G.; Elías-Zúñiga, A.; López de Lacalle, L.N. Semi-Active Magnetorheological Damper Device for Chatter Mitigation during Milling of Thin-Floor Components. Appl. Sci. 2020, 10, 5313. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, D.; Luo, M.; Wu, B. Chatter stability prediction in four-axis milling of aero-engine casings with bull-nose end mill. Chin. J. Aeronaut. 2015, 28, 1766–1773. [Google Scholar] [CrossRef]

- Adetoro, O.B.; Sim, W.M.; Wen, P.H. An improved prediction of stability lobes using nonlinear thin wall dynamics. J. Mater. Process. Tech. 2010, 210, 969–979. [Google Scholar] [CrossRef]

- Fei, J.; Lin, B.; Yan, S.; Zhang, X.; Lan, J.; Dai, S. Chatter prediction for milling of flexible pocket-structure. Int. J. Adv. Manuf. Technol. 2017, 89, 2721–2730. [Google Scholar] [CrossRef]

- Gu, D.; Wei, Y.; Xiong, B.; Liu, S.; Zhao, D.; Wang, B. Three degrees of freedom chatter stability prediction in the milling process. J. Mech. Sci. Technol. 2020, 34, 3489–3496. [Google Scholar] [CrossRef]

- Yan, R.; Gong, Y.; Peng, F.; Tang, X.; Li, H.; Li, B. Three degrees of freedom stability analysis in the milling with bull-nosed end mills. Int. J. Adv. Manuf. Technol. 2016, 86, 71–85. [Google Scholar] [CrossRef]

- Dang, X.B.; Wan, M.; Zhang, W.H.; Yang, Y. Stability analysis of the milling process of the thin floor structures. Mech. Syst. Signal Process. 2022, 165, 108311. [Google Scholar] [CrossRef]

- Yu, G.; Wang, L.; Wu, J. Prediction of chatter considering the effect of axial cutting depth on cutting force coefficients in end milling. Int. J. Adv. Manuf. Technol. 2018, 96, 3345–3354. [Google Scholar] [CrossRef]

- Adetoro, O.B.; Sim, W.M.; Wen, P.H. Stability Lobes Prediction for Corner Radius End Mill Using Nonlinear Cutting Force Coefficients. Mach. Sci. Technol. 2012, 16, 111–130. [Google Scholar] [CrossRef]

- Altintas, Y. Manufacturing Automation: Metal Cutting Mechanics, Machine Tool Vibrations, and CNC Design, 2nd ed.; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Yang, Y.; Liu, Q.; Zhang, B. Three-dimensional chatter stability prediction of milling based on the linear and exponential cutting force model. Int. J. Adv. Manuf. Technol. 2014, 72, 1175–1185. [Google Scholar] [CrossRef]

- Bedi, S.; Ismail, F.; Mahjoob, M.J.; Chen, Y. Toroidal versus ball nose and flat bottom end mills. Int. J. Adv. Manuf. Technol. 1997, 13, 326–332. [Google Scholar] [CrossRef]

- Fan, W.; Ye, P.; Zhang, H.; Fang, C.; Wang, R. Using rotary contact method for 5-axis convex sculptured surfaces machining. Int. J. Adv. Manuf. Technol. 2013, 67, 2875–2884. [Google Scholar] [CrossRef]

- Gradišek, J.; Kalveram, M.; Weinert, K. Mechanistic identification of specific force coefficients for a general end mill. Int. J. Mach. Tools Manuf. 2004, 44, 401–414. [Google Scholar] [CrossRef]

- Gao, G.; Wu, B.; Zhang, D.; Luo, M. Mechanistic identification of cutting force coefficients in bull-nose milling process. Chin. J. Aeronaut. 2013, 26, 823–830. [Google Scholar] [CrossRef]

| Cutter Type | Cutter Material | Number of Flutes | Diameter (mm) | Fillet Radius (mm) | Helix Angle (°) | Overhang (mm) |

|---|---|---|---|---|---|---|

| Bull-nose end mill | 3 μm TiAlN-coated carbide | 4 | 12 | 2 | 38 | 75 |

| Workpiece Material | Geometries (mm) | Density (kg/m3) | Young’s Modulus (GPa) | Poisson’s Ratio | ||

|---|---|---|---|---|---|---|

| Inner Diameter | Outer Diameter | Height | ||||

| 06Cr19Ni10 | 211 | 217 | 90 | 7930 | 194 | 0.3 |

| Spindle Speed (r/min) | Feed Rate per Tooth (mm/tooth) | Axial Depth of Cut (mm) |

|---|---|---|

| 5000 | 0.008, 0.016, 0.024, 0.032 | 0.2, 0.4, 0.6, 0.8, 1.0, 1.2, 1.4, 1.6, 1.8, 2.0 |

| Cases | Frequency (Hz) | Damping (%) | Stiffness (N/m) |

|---|---|---|---|

| Cutter (x-axis) | 1768 | 2.6 | 1.85 × 108 |

| Cutter (y-axis) | 1753 | 2.3 | 1.79 × 108 |

| Workpiece (z-axis) | 794 | 3.6 | 4.25 × 107 |

| No. | Spindle Speed (r/min) | Feed Rate (mm/min) | Axial Depth of Cut (mm) | Stability State |

|---|---|---|---|---|

| 1 | 3000 | 192 | 0.5 | Critical |

| 2 | 3000 | 192 | 1.0 | Unstable |

| 3 | 3500 | 224 | 0.5 | Stable |

| 4 | 3500 | 224 | 1.0 | Critical |

| 5 | 4000 | 256 | 0.5 | Stable |

| 6 | 4000 | 256 | 1.0 | Stable |

| 7 | 4500 | 288 | 0.5 | Stable |

| 8 | 4500 | 288 | 1.0 | Unstable |

| 9 | 5000 | 320 | 0.5 | Unstable |

| 10 | 5000 | 320 | 1.0 | Unstable |

| 11 | 5500 | 352 | 0.5 | Unstable |

| 12 | 5500 | 352 | 1.0 | Unstable |

| 13 | 6000 | 384 | 0.5 | Critical |

| 14 | 6000 | 384 | 1.0 | Unstable |

| 15 | 6500 | 416 | 0.5 | Stable |

| 16 | 6500 | 416 | 1.0 | Stable |

| 17 | 7000 | 448 | 0.5 | Stable |

| 18 | 7000 | 448 | 1.0 | Stable |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Zhang, C.; Xu, M.; Wu, B.; Zhang, D. Prediction of Chatter Stability in Bull-Nose End Milling of Thin-Walled Cylindrical Parts Using Layered Cutting Force Coefficients. Appl. Sci. 2023, 13, 6737. https://doi.org/10.3390/app13116737

Zhou X, Zhang C, Xu M, Wu B, Zhang D. Prediction of Chatter Stability in Bull-Nose End Milling of Thin-Walled Cylindrical Parts Using Layered Cutting Force Coefficients. Applied Sciences. 2023; 13(11):6737. https://doi.org/10.3390/app13116737

Chicago/Turabian StyleZhou, Xu, Congpeng Zhang, Minggang Xu, Baohai Wu, and Dinghua Zhang. 2023. "Prediction of Chatter Stability in Bull-Nose End Milling of Thin-Walled Cylindrical Parts Using Layered Cutting Force Coefficients" Applied Sciences 13, no. 11: 6737. https://doi.org/10.3390/app13116737

APA StyleZhou, X., Zhang, C., Xu, M., Wu, B., & Zhang, D. (2023). Prediction of Chatter Stability in Bull-Nose End Milling of Thin-Walled Cylindrical Parts Using Layered Cutting Force Coefficients. Applied Sciences, 13(11), 6737. https://doi.org/10.3390/app13116737