Abstract

Applications of a quadrotor with payload, particularly for chemical spraying, have increased in recent times. The variation in payload mass over time causes a change in the moments of inertia (MOI). Moreover, large tilt angles are required for fast reference tracking and external disturbance rejection. These variations in plant parameters (i.e., mass and inertia) and large tilt angles can degrade the control scheme’s performance and stability. This article proposes a linear matrix inequalities (LMIs)-based linear parameter varying (LPV) control scheme for a quadrotor subject to time-varying mass, time-varying inertia, mass flow rate, and large tilt angles. The control strategy is designed by solving LMIs derived from quadratic performance and D-stability. The robust stability and quadratic performance are assessed by LMIs. The efficacy of the proposed methodology is established using numerical simulations, and its performance is compared to the linear time-invariant (LTI) design with pole placement constraints. The results obtained show that the LPV control scheme gives better tracking performance in the presence of time-varying parameters, noise, and external disturbances without actuator saturation. In comparison to the LTI design technique, the proposed LPV scheme improves the rise time (), settling time (), and mean squared error (MSE) by up to , , and , respectively. Moreover, smooth transitions are observed in the tilt angles and control signals with the LPV scheme, contrary to the LTI controller, which exhibits significant oscillations.

1. Introduction

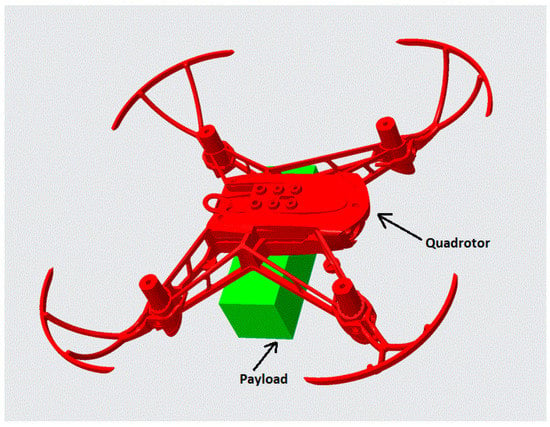

Quadrotors are used nowadays for a wide range of applications [1,2]. Among these, crop spraying is a significant one that has resulted in enhanced productivity [3,4]. In such applications, the quadrotor mass and MOI change over time. Such large parameter variations, in addition to the standard features of system dynamics, such as nonlinearities, under-actuation, noise, external disturbances, actuator constraint, etc., make the control system design a challenging problem. The quadrotor with payload (liquid tank) is depicted in Figure 1.

Figure 1.

The 3D CAD model of quadrotor with Payload.

Various control strategies have been developed for standard quadrotors to achieve stability and effective tracking. To tackle the quadrotor’s tracking control issue, linear control approaches such as proportional–integral–derivative, linear-quadratic-regulator, and have been proposed [5,6,7,8,9]. The above-mentioned control algorithms are based on local linearization, and the performance of an LTI control scheme deteriorates with deviation from the operating point and can even lead to instability. To overcome the impediments caused by local linearization, LPV approaches have been proposed for the quadrotor. In [10], LPV control scheme was suggested for a quadrotor to handle the large perturbation from the nominal condition. Tilt angles were limited to rad. In [11], the LPV controller was proposed for high-speed maneuvering of a quadrotor that requires large tilt angles. Tilt angles were accounted up to rad. In [12], a switched LPV control approach was recommended in order to handle huge attitude angles and external disturbances. The region for roll angle was considered to rad and for pitch angle , the region was limited to rad. Time-varying mass and time-varying inertia were not taken into consideration in the control strategies outlined above.

The design of the control system for a quadrotor with variable payload has also been investigated in the literature. In [13], LMI-based static output feedback LPV controller was suggested for Attitude/Altitude control of a quadrotor to handle the rotors’ velocity variation and step change in mass. The rotors’ velocity and mass were assumed to be measurable. Longitudinal and latitudinal translational motions were ignored, and the small angle assumption (i.e., ) was employed to design the control scheme. Moreover, the mass flow rate was ignored, and the control scheme was conservative due to coupling in the scheduling parameters. In [14], Hybrid LPV control scheme was suggested for the reference tracking of a quadrotor with variable mass and variable inertia. A combination of integral backstepping control and proportional-derivative controls were designed to control the quadrotor’s position and altitude. PD controllers were designed using the small angle assumption (i.e., , , and ). Variation in mass was not considered during the control algorithm design. LPV controller was recommended to control the quadrotor rotational dynamics subject to time-varying inertia and variation in the rotors’ speed. Mass and rotor speed were considered measurable. The variations in MOI were recalculated in real-time from the changes in the mass. The mass flow rate was not taken into account and the scheduling parameters selected in the proposed scheme did not vary independently, which led to conservative control. A robust LPV controller was proposed for Altitude/Attitude stabilization of a quadrotor to handle mass, inertia, and rotors velocity variations [15]. The proposed controller was designed using the LMI framework. The small angle approximation was considered to design the LPV scheme for the 4 DOF model of the quadrotor. Moreover, position control and the mass flow rate were not taken into consideration, and the coupling in the scheduling parameters led to conservative control. A switched LPV control technique was suggested for the 3 DOF model of a quadrotor subject to large attitude angles, variable inertia, and outside disturbances [16]. Position control dynamics are not considered. In [17], the author recommended a self-tuning PID control scheme for the reference tracking of a quadrotor. Mass and wind disturbance estimators based on a neural network with online learning were suggested to cope with the system’s mass variation and wind disturbances. Variations in MOI due to variable mass and mass flow rate were not taken into consideration. Adaptive sliding mode control (SMC) based on backstepping was advised to reduce the effect of variable load and wind disturbances [18]. Only the changing mass is estimated using the adaptive estimation controller. A fractional SMC was designed to cope with external disturbances and variations in inertia. Actuator limitations and mass flow rate were not considered, and chattering issues existed due to the use of the signum function in the control law. Adaptive non-singular fast terminal SMC was proposed in [19]. External disturbances and mass are estimated online. To address the chattering issue, the saturation function was used in place of the signum function in the control law. Changes in MOI, mass flow rate, and actuator limitation were not taken into consideration. In [20], an adaptive SMC control algorithm was suggested for the quadcopter’s altitude tracking in the presence of time-varying payload and ground effect. Position control, MOI variations with mass, and mass flow rate were ignored.

In the LPV control algorithms described in the literature, time-varying mass and large tilt angles have not been considered simultaneously, whereas, in the nonlinear adaptive control schemes suggested for a quadrotor to handle time-varying mass, the controller gains will take time to adapt to the new values. In addition, the computation and execution of gains are online, which will increase the computational burden compared to the LPV approaches, where the gains are computed offline but executed online. The motivation of this paper is to suggest an LMIs-based LPV control scheme for the quadrotor’s position control in the presence of time-varying mass, time-varying inertia, mass flow rate, large tilt angles, noise, and external disturbances without actuator saturation.

Contributions

Compared to the prior work, the key contributions of this paper are as follows.

- (i)

- A novel 6 DOF LPV model considering variable mass, variable inertia, mass flow rate, large tilt angles, and wind disturbance is established for the quadrotor.

- (ii)

- The model equations for the variable mass and variable MOI are developed using a curve fitting tool, and a triangle polytope is chosen rather than a rectangular polytope to reduce the number of vertices in the LPV control system. This will reduce the computational load and conservatism of the LPV control strategy.

- (iii)

- LPV control scheme based on LMIs is designed for the LPV model. The robust stability and quadratic performance are assessed by LMIs. The efficacy of the suggested scheme is validated through numerical simulations, and the results are compared with the LTI control scheme.

The rest of the paper is organized as follows. The system dynamic model is presented in Section 2. The steps in the LPV control algorithms are described in Section 3. Section 4 presents the simulation results and their brief descriptions. The paper is concluded in Section 5, followed by the references.

2. System Dynamic Model

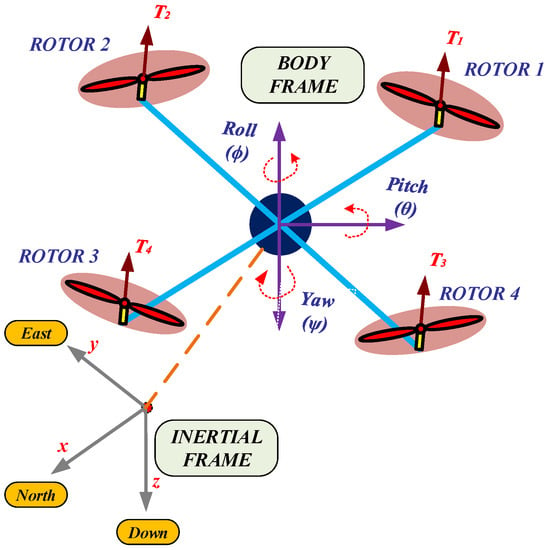

A quadrotor is a four-rotor, under-actuated system as depicted in Figure 2. The quadrotor’s linear and angular positions are represented by and , respectively. The thrust forces produced by the rotors are represented by . The adjacent rotors spin in opposite directions. Two rotors (1 & 3) rotate clockwise, whereas rotors (3 & 4) spin anticlockwise.

Figure 2.

The X-configuration of quadrotor.

A quadrotor with variable payload can be mathematically modeled using the Newton and Euler equations. The quadrotor’s translational dynamics with time-varying mass is given by [21,22]

where stands for the resultant force, P represents the linear momentum, m denotes the quadrotor’s mass with variable payload, and v indicates the quadrotor’s translational velocity.

Equation (1) can be written as

where

T represents the thrust force exerted by the rotors, whereas , , and represent the wind forces in x, y, and z directions, respectively.

The wind force can be expressed as [23]

and show the translational and wind velocity, and the parameters and indicate the drag factors on the lower-upper faces and sides of the quadrotor, respectively.

Furthermore, referring to [21,22], the quadrotor’s rotational dynamics with time-varying inertia is given by

where indicates the net moment, J denotes the inertia tensor, and shows the angular speed.

Equation (5) can be written as

where , , and represent the rolling, pitching, and yawning moments, respectively. represents the rotor inertia, , while indicates the speed of rotors.

Control signals are defined for moments and thrust force, which are as follows:

The relationship between control signals and motor commands is as follows [24,25]:

where represent the squared speed references of the motor (i.e., ).

Table 1 shows the quadrotor’s parameters with full payload.

Table 1.

Quadrotor parameters with full payload.

Variation in the System’s Mass and Moments of Inertia Parameters

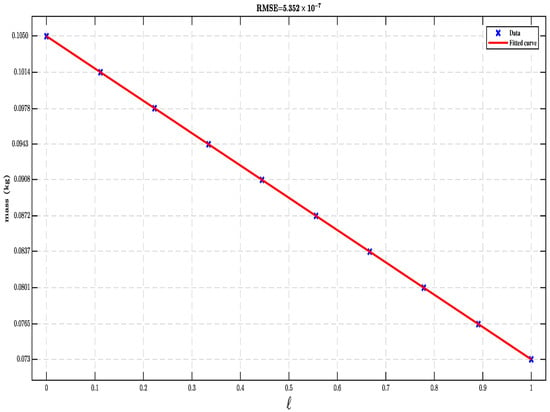

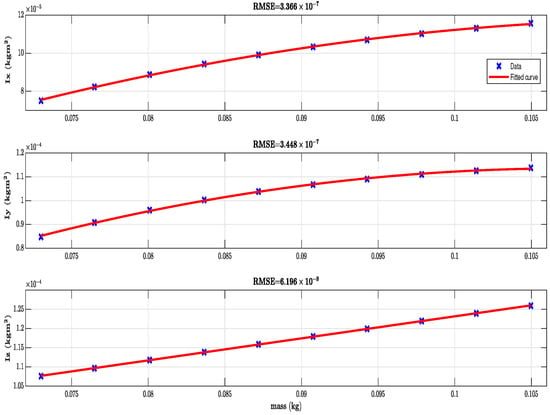

To develop the model equations for time-varying mass and time-varying inertia, we have used SOLIDWORKS. The 3D CAD (three-dimensional computer-aided design) model of the quadrotor with payload developed in SOLIDWORKS is shown in Figure 1. The mass and MOI values are noted at different levels of the water in the liquid tank. The values recorded are listed in Table 2. The curve fitting toolbox available in MATLAB was used to find the model equations for mass and MOI. The root mean squared error () was used to assess the goodness of fit. The variation in the values of the system’s mass and MOI are shown in Figure 3 and Figure 4.

Table 2.

Mass and inertia values at different water levels.

Figure 3.

Variation in mass with parameter ℓ.

Figure 4.

Variation in MOI with mass.

A parameter ℓ has been introduced which is given as:

where h represents the level of the water in the tank and indicates the water level when the payload is filled to capacity.

The equations of the mass and MOI obtained using curve fitting are:

The derivatives are:

Table 3.

Parameter values.

The LPV model for a dynamic system is not unique. Multiple LPV models can exist for a dynamic system. The time-varying parameters chosen in the LPV model determine the complexity and effectiveness of the control system. The following assumptions are taken into account in order to establish an affine LPV model of quadrotor with time-varying payload [11,16].

- The sine and cosine of tilt angles are approximated by the second-order Taylor’s expansion.

- The input , , and are considered to make the dependency between system states explicitly.

Using the above assumptions, and considering the small gyro effect, the simplified nonlinear model is obtained, which is as follows:

By using Equations (11)–(13), the LPV model of the quadrotor is obtained, which is given as

where is a time-varying parameters vector. The terms and are neglected because of their high power and relatively modest contribution. denote the bounded disturbances and are given as

The scheduling parameters of the LPV model are

where the units of mass and angles are kg and rad, respectively.

3. LPV Control Design

In this section, we present an LMIs-based LPV control design for position tracking of the quadrotor. The goal is that the state variables follow the desired reference trajectories , while the yaw angle is required to remain at . All the state variables and the water level in the liquid tank are considered as measurable. Based on the system dynamics, the control system is split into subsystems.

- (1)

- The fully actuated subsystem dynamics that consist of and .

- (2)

- The under-actuated subsystem dynamics made up of , , , and .

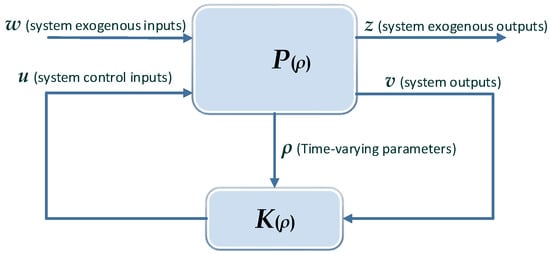

The LPV control system configuration is depicted in Figure 5. shows the generalized LPV plant and depicts the LPV controller gains.

Figure 5.

The structure of closed-loop LPV system.

The generalized LPV plant’s state-space realization is as follows [26,27]:

where

- (1)

- , , , and are the system states, exogenous inputs (i.e., reference signals and disturbances), control signals, exogenous outputs, and sensed outputs, respectively.

- (2)

- and are parameter dependent state-space matrices of appropriate dimensions.

- (3)

- is a time-varying parameters vector that varies in a convex polytope of vertices . N represents the number of vertices.

The LPV control law is given as:

In the LPV polytopic form, the matrices of can be written as

In the polytopic form, LPV controller gains can be expressed as

represent the barycentric weights (for details, see [28,29]). The time-varying parameter vector can be expressed as

To design an LPV controller, a mixed sensitivity control approach is adopted [30,31]. The weighted closed-loop system for mixed sensitivity control design is shown in Figure 6.

Figure 6.

The mixed sensitivity control problem.

shows the LPV model of the dynamic system to the control signal u and the disturbance signal , is the weighting filter that is chosen to impose meaningful requirements on the closed-loop system, such as trajectory tracking and disturbance rejection, and are the static weights that represent the maximum values of control signal and disturbance signal, respectively.

The state-space realization of and is given by

The state-space realization for LPV controller synthesis is given as:

The scaled control input is given by

The LPV controller is designed using the following well-known lemmas, which describe the -norm and regional pole placement in the LMI region [32,33].

Lemma 1.

-norm

The -norm of closed-loop LPV system from exogenous inputs w to exogenous outputs z will be lower than a positive scalar γ, if and only if there exists a positive-definite symmetric matrix , and a matrix for all the admissible values of time-varying parameter vector ρ satisfying

Lemma 2.

Regional pole constraints

The closed-loop LPV system’s eigenvalues will be located in the desirable LMI region , if and only if there exist , and , such that

and

where the LMI region . The system will be D-stable if both conditions (25) and (26) are satisfied. The sub-LMI regions and are shown in Figure 7 and Figure 8.

Figure 7.

Strip region .

Figure 8.

Conic sector .

The LPV controller gains can be determined as follows:

Equations (24)–(26) impose an unlimited number of LMIs that are difficult to solve. The total number of LMIs can be squeezed to a finite set using a polytopic LPV system. Using convexity, (24)–(26) will hold if it holds at the vertices of the polytope.

3.1. LPV Control for Fully Actuated Subsystem

LPV controller is devised for the fully actuated subsystem dynamics by solving the LMIs given in (24)–(26) at each vertex of the rectangular polytope using the LMI control toolbox [34].

The descriptor LPV form of altitude dynamics is

where

The descriptor LPV form of yaw dynamics is

where

The weighting filters and are selected as follows,

The static weights and are expected to be 0.5 and 1, respectively. The static weight is taken into consideration. The bounded disturbance is assumed as kg/s. The parameters associated with the desired LMI regions are:

The LPV controller gains are:

where and represent the state feedback gains, and represent the barycentric weights, and = and = are the time-varying parameters.

The robust closed-loop system stability and quadratic performance of the LPV system are tested by using the functions and from the MATLAB LMI Toolbox’s. The LPV system will be stable, if the quantity returned by the function is negative (i.e., ). The values achieved using the functions are given in Table 4.

Table 4.

and values of fully actuated subsytem.

The quantity , which ensures the closed-loop system’s robust stability.

3.2. LPV Control for Under-Actuated Subsystem

To address the under-actuation, a multi-loop control strategy is adopted. An inner-loop LPV scheme is suggested for roll and pitch dynamics, while an outer-loop LPV strategy is proposed for the y-position and x-position dynamics to generate the roll and pitch commands. The inner-loop receives the roll and pitch commands from the outer-loop to track the desired reference positions . The scheduling parameters and are not independent, which leads to conservatism. To reduce conservatism, we use a triangle polytope, BED, rather than a rectangular polytope, ABCD, as shown in Figure 9 (for details, see [35,36]).

Figure 9.

The structure of the Polytopes.

The roll dynamics in descriptor LPV form is

where

The descriptor LPV form of pitch dynamics is

where

The LPV form of x-position dynamics is

where

The descriptor LPV form of y-position dynamics is

where

The weight functions are chosen as:

Weighting filters , , , and are chosen as follows:

The values of weights , , , and are considered. The values of static weights and are assumed. The values of the parameters associated with the LMI regions are:

The following are the gains of the LPV controllers designed using conditions (24)–(26):

where , , , and represent the state feedback gains, , , , and represent the barycentric weights, and = , = , = , and = are the scheduling parameters.

The values of and achieved using the MATLAB functions for the under-actuated subsytem are given in Table 5.

Table 5.

and values of under-actuated subsytem.

The quantity , which ensures the closed-loop system’s robust stability.

4. Simulation Results and Discussion

This section presents the simulations to validate the proposed approach. The numerical simulations were carried out using the quadrotor nonlinear model represented in the Equation (9). Multiple scenarios were considered during simulations. In the first scenario, the proposed LPV algorithm was tested for reference tracking in the presence of full payload, time-varying payload, and an empty payload. Wind disturbance was applied in the second scenario, while noise was introduced to the system states in the third. Moreover, controller with regional pole constraints was designed for the quadrotor’s linear model that was obtained using small angle assumption and the average values of the mass and inertia parameters [7]. The results of the LPV scheme were compared with those attained with the LTI control design.

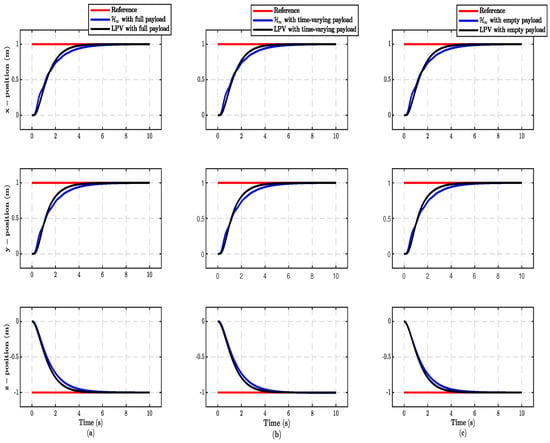

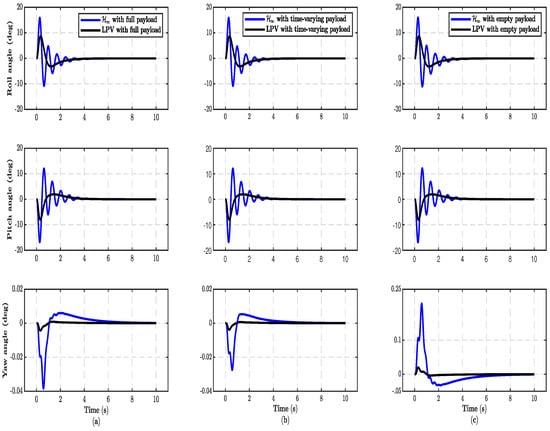

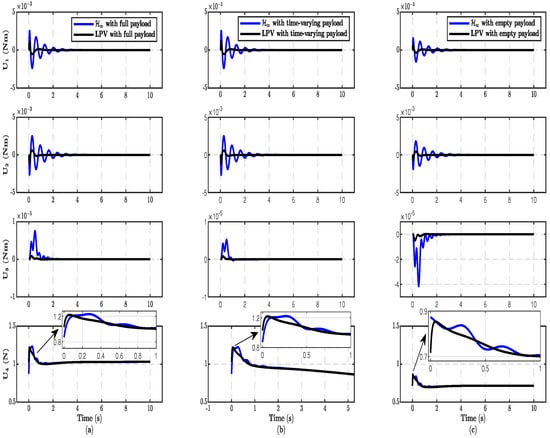

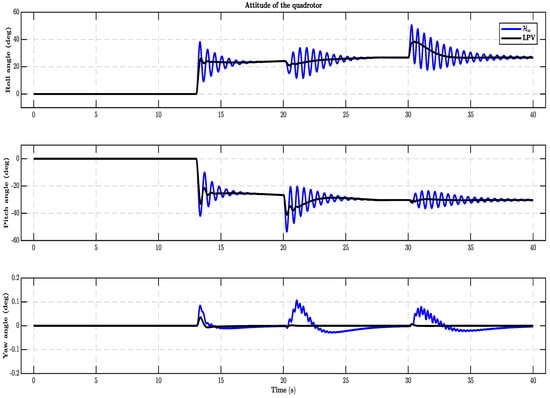

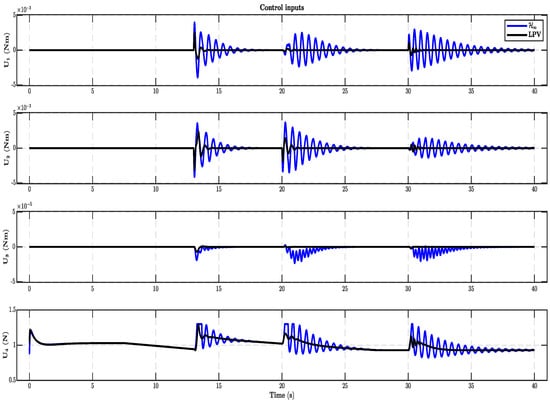

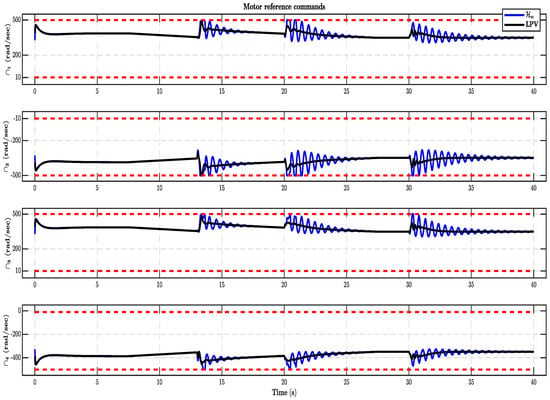

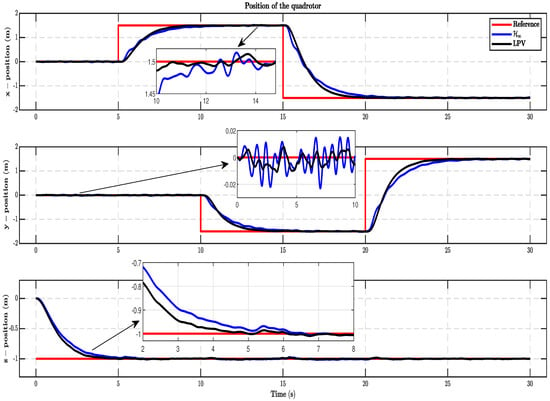

Case 1: The quadrotor’s position is required to track a unit step signal, while the yaw angle needs to be maintained at . The reference signals and the quadrotor’s position for full payload, time-varying payload, and an empty payload are depicted in Figure 10. Figure 11 depicts the corresponding attitude angles. The control inputs and motor commands are shown in Figure 12 and Figure 13, respectively. The tracking performance was examined in terms of system rise time (), system settling time (), system overshoot (OS), and system MSE. The values of the performance parameters and percentage improvements are listed in Table 6, Table 7 and Table 8, respectively. The actuator will become saturated if the motor command value is higher than 500 rad/s. Control inputs were used to calculate motor commands using (8). Effective position tracking and yaw angle stabilization were accomplished in the presence of variable mass and variable MOI using the LPV scheme as compared to the LTI controller.

Figure 10.

(a) The positions [] with full payload; (b) The positions [] with time-varying payload; (c) The positions [] with empty payload.

Figure 11.

(a) The attitude angles [] with full payload; (b) The attitude angles [] with time-varying payload; (c) The attitude angles [] with empty payload.

Figure 12.

(a) The control inputs [] with full payload; (b) The control inputs [] with time-varying payload; (c) The control inputs [] with empty payload.

Figure 13.

(a) The motor commands [] with full payload; (b) The motor commands [] with time-varying payload; (c) The motor commands [] with empty payload.

Table 6.

The closed-loop performance parameters with full payload.

Table 7.

The closed-loop performance parameters with time-varying payload.

Table 8.

The closed-loop performance parameters with empty payload.

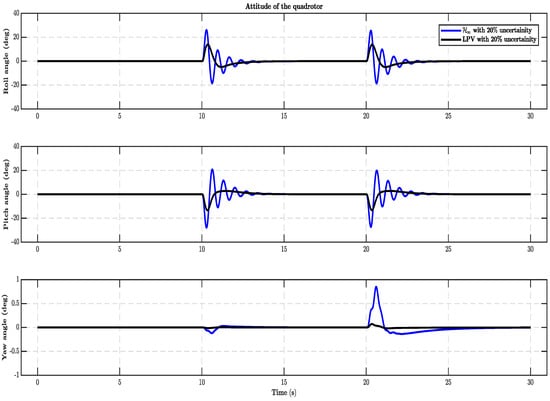

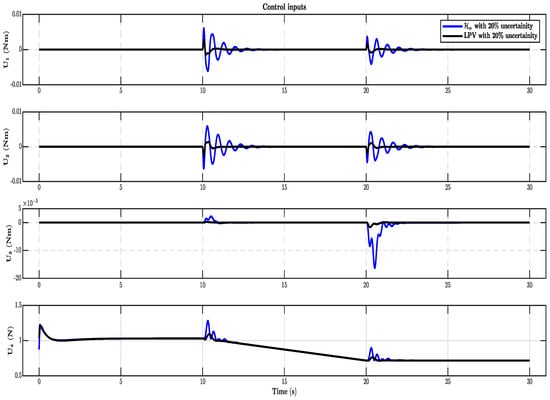

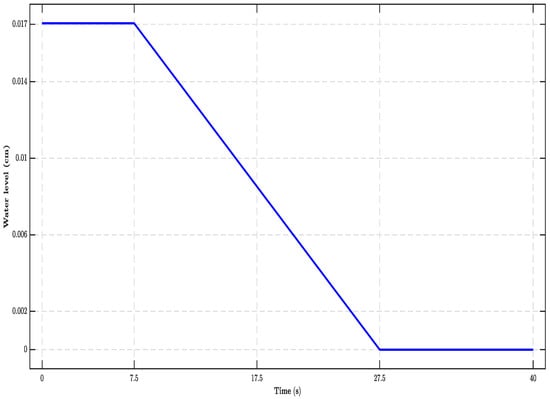

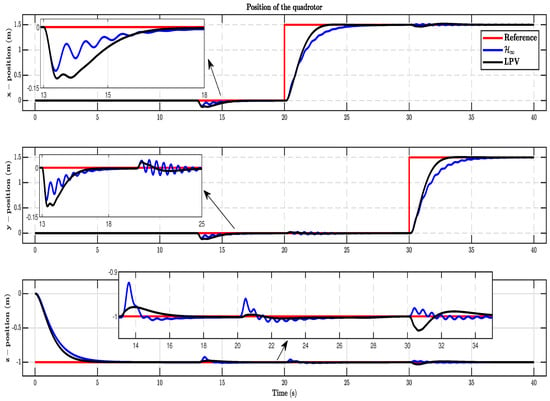

Case 2: The inertia parameters may vary due to the tilting of the quadrotor. To check the performance of the proposed control scheme in the presence of inertia parameter variation, we have considered a variation in the inertia. Figure 14 depicts the variation in the water level considered over time. Figure 15 depicts the variation in the inertia with the mass. The reference signals and the quadrotor’s position are depicted in Figure 16. Figure 17 depicts the corresponding attitude angles. The control inputs and motor commands are shown, respectively, in Figure 18 and Figure 19. The simulation results indicate that the LPV scheme gives good position tracking and yaw angle stabilization in the presence of variation in the inertia parameters as compared to the LTI controller.

Figure 14.

Variation in the water level with time.

Figure 15.

Variation in the inertia parameters with mass.

Figure 16.

The positions [] with variation in the inertia.

Figure 17.

The attitude angles [] with variation in the inertia.

Figure 18.

The control inputs [] with variation in the inertia.

Figure 19.

The motor commands [] with variation in the inertia.

Case 3: To test the position tracking performance of the LPV scheme subject to dynamic payload and wind disturbance at the same time that required large tilting angle, variation in the payload was introduced at s, and wind disturbance was applied at s. A horizontal wind model in SIMULINK was used for wind generation. A constant north-east wind speed of 5.3 m/s was assumed. The water level variation over time is shown in Figure 20. Figure 21 presents the reference signals and the position of the quadrotor. The corresponding attitude angles are shown in Figure 22. Figure 23 and Figure 24 depict the control signals and motor commands. As can be seen, the quadrotor tracks the reference signal more effectively in the presence of time-varying payload and wind disturbance as compared to the LTI controller, which introduces significant oscillations and also results in actuator saturation as the demand for tilt angles gets higher.

Figure 20.

Variation in the water level with time.

Figure 21.

The positions [] with payload variation and wind disturbance.

Figure 22.

The attitude angles [] with payload variation and wind disturbance.

Figure 23.

The control inputs [] with payload variation and wind disturbance.

Figure 24.

The motor commands [] with payload variation and wind disturbance.

Case 3: Gaussian noise was introduced into the quadrotor outputs in this case [37]. Noise cm) was added to the x, y, and z positions, and Noise was introduced to the yaw, pitch, and roll angles. The water level variation over time is shown in Figure 14. Figure 25 shows the reference signals, the position of the quadrotor, and the error plots. The attitude signals are depicted in Figure 26. Figure 27 and Figure 28 illustrate the control signals and motor commands. The simulation results indicate that, in contrast to the LTI control scheme, the LPV design has improved tracking performance subject to dynamic mass, changing MOI, and gaussian noise.

Figure 25.

The positions [] with payload variation and noise.

Figure 26.

The attitude angles [] with payload variation and noise.

Figure 27.

The control inputs [] with payload variation and noise.

Figure 28.

The motor commands [] with payload variation and noise.

5. Conclusions

This paper proposes an LMIs-based LPV algorithm for full motion control of a 6 DOF quadrotor model. First, an LPV model was developed for the nonlinear quadrotor model with variable payload, and then LMIs of quadratic performance and D-stability were used to design the LPV control strategy. The proposed scheme was successfully evaluated in a nonlinear simulation environment. Several scenarios were simulated and studied. The outcomes of the LPV algorithm were compared with the control design with pole placement constraints. The results indicate that the recommended LPV approach can achieve better position tracking in the presence of variable mass, variable inertia, mass flow rate, wind disturbance, and noise in contrast to the LTI controller. In the future, we intend to broaden our research to the hardware implementation of the suggested control scheme in order to assess its stability, robustness, and effectiveness.

Author Contributions

Conceptualization, A.S., A.I.B. and F.M.M.; Methodology, A.S., A.I.B. and F.M.M.; Software, A.S.; Validation, A.S.; Formal analysis, A.S.; Investigation, A.S.; data curation, A.S.; writing—original draft preparation, A.S.; writing—review and editing, A.S., A.I.B. and F.M.M.; Visualization, A.S.; Supervision, A.I.B. and F.M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Li, Y.; Song, S. A survey of control algorithms for quadrotor unmanned helicopter. In Proceedings of the IEEE 5th International Conference on Advanced Computational Intelligence (ICACI), Nanjing, China, 18–20 October 2012; pp. 365–369. [Google Scholar]

- Maaruf, M.; Mahmoud, M.S.; Ma’arif, A. A survey of control methods for quadrotor uav. Int. J. Robot. Control Syst. 2022, 2, 652–665. [Google Scholar] [CrossRef]

- Shaw, K.K.; Vimalkumar, R. Design and development of a drone for spraying pesticides, fertilizers and disinfectants. Eng. Res. Technol. (IJERT) 2020, 9, 1181–1185. [Google Scholar]

- Hanif, A.S.; Han, X.; Yu, S.H. Independent Control Spraying System for UAV-Based Precise Variable Sprayer: A Review. Drones 2022, 6, 383. [Google Scholar] [CrossRef]

- Li, J.; Li, Y. Dynamic analysis and PID control for a quadrotor. In Proceedings of the 2011 IEEE International Conference on Mechatronics and Automation, Beijing, China, 7–10 August 2011; pp. 573–578. [Google Scholar]

- Dong, W.; Gu, G.Y.; Zhu, X.; Ding, H. Modeling and control of a quadrotor UAV with aerodynamic concepts. World Acad. Sci. Eng. Technol. 2013, 7, 901–906. [Google Scholar]

- Martins, L.; Cardeira, C.; Oliveira, P. Linear quadratic regulator for trajectory tracking of a quadrotor. IFAC-PapersOnLine 2019, 52, 176–181. [Google Scholar] [CrossRef]

- Mokhtari, A.; Benallegue, A.; Daachi, B. Robust feedback linearization and GH/sub/spl infin//controller for a quadrotor unmanned aerial vehicle. In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems, Edmonton, AB, Canada, 2–6 August 2005; pp. 1198–1203. [Google Scholar]

- Araar, O.; Aouf, N. Full linear control of a quadrotor UAV, LQ vs. H∞. In Proceedings of the 2014 UKACC International Conference on Control (CONTROL), Loughborough, UK, 9–11 July 2014; pp. 133–138. [Google Scholar]

- Rangajeeva, S.L.; Whidborne, J.F. Linear parameter varying control of a quadrotor. In Proceedings of the 2011 6th International Conference on Industrial and Information Systems, Kandy, Sri Lanka, 16–19 August 2011; pp. 483–488. [Google Scholar]

- Cisneros, P.S.; Hoffmann, C.; Bartels, M.; Werner, H. Linear parameter-varying controller design for a nonlinear quad-rotor helicopter model for high speed trajectory tracking. In Proceedings of the 2016 American Control Conference (ACC), Boston, MA, USA, 6–8 July 2016; pp. 486–491. [Google Scholar]

- Nie, L.; Cai, B.; Lu, S.; Qin, H.; Zhang, L. Finite-time switched LPV control of quadrotors with guaranteed performance. J. Frankl. Inst. 2021, 358, 7032–7054. [Google Scholar] [CrossRef]

- Pham, T.H.; Mammar, S. Quadrotor lpv control using static output feedback. In Proceedings of the 2019 IEEE 16th International Conference on Networking, Sensing and Control (ICNSC), Banff, AB, Canada, 9–11 May 2019; pp. 74–79. [Google Scholar]

- Pham, T.H.; Ichalal, D.; Mammar, S. LPV and Nonlinear-based control of an Autonomous Quadrotor under variations of mass and moments of inertia. IFAC-PapersOnLine 2019, 52, 176–183. [Google Scholar] [CrossRef]

- Pham, T.H.; Ichalal, D.; Mammar, S. Lpv state-feedback controller for attitude/altitude stabilization of a mass-varying Quadrotor. In Proceedings of the 2020 20th International Conference on Control, Automation and Systems (ICCAS), Busan, Republic of Korea, 13–16 October 2020; pp. 212–218. [Google Scholar]

- Nie, L.; Cai, B.; Zhu, Y.; Yang, J.; Zhang, L. Switched linear parameter-varying tracking control for quadrotors with large attitude angles and time-varying inertia. Optim. Control Appl. Methods 2021, 42, 1320–1336. [Google Scholar] [CrossRef]

- Sierra, J.E.; Santos, M. Wind and payload disturbance rejection control based on adaptive neural estimators: Application on quadrotors. Complexity 2019, 2019, 6460156. [Google Scholar] [CrossRef]

- Vahdanipour, M.; Khodabandeh, M. Adaptive fractional order sliding mode control for a quadrotor with a varying load. Aerosp. Sci. Technol. 2019, 86, 737–747. [Google Scholar] [CrossRef]

- Zhao, J.; Ding, X.; Jiang, B.; Jiang, G.; Xie, F. A novel control strategy for quadrotors with variable mass and external disturbance. Int. J. Robust Nonlinear Control 2021, 31, 8605–8631. [Google Scholar] [CrossRef]

- Lee, J.W.; Xuan-Mung, N.; Nguyen, N.P.; Hong, S.K. Adaptive altitude flight control of quadcopter under ground effect and time-varying load: Theory and experiments. J. Vib. Control 2023, 29, 571–581. [Google Scholar] [CrossRef]

- Wu, X.; Xiao, B.; Qu, Y. Modeling and sliding mode-based attitude tracking control of a quadrotor UAV with time-varying mass. ISA Trans. 2019, 124, 436–443. [Google Scholar] [CrossRef]

- Yang, P.; Wang, Z.; Zhang, Z.; Hu, X. Sliding Mode Fault Tolerant Control for a Quadrotor with Varying Load and Actuator Fault. Actuators 2021, 10, 323. [Google Scholar] [CrossRef]

- Kun, D.W.; Hwang, I. Linear matrix inequality-based nonlinear adaptive robust control of quadrotor. J. Guid. Control Dyn. 2016, 39, 996–1008. [Google Scholar] [CrossRef]

- Okasha, M.; Kralev, J.; Islam, M. Design and Experimental Comparison of PID, LQR and MPC Stabilizing Controllers for Parrot Mambo Mini-Drone. Aerospace 2022, 9, 298. [Google Scholar] [CrossRef]

- Noordin, A.; Basri, M.A.M.; Mohamed, Z. Simulation and experimental study on PID control of a quadrotor MAV with perturbation. Bull. Electr. Eng. Inform. 2020, 9, 1811–1818. [Google Scholar] [CrossRef]

- Apkarian, P. Lmi techniqes in control engineering from theory to practice. In Proceedings of the IEEE Conference on Decision and Control (IEEE CDC’96 Workshop), Kobe, Japan, 11–13 December 1996. [Google Scholar]

- Han, J.; Liu, X.; Wei, X.; Sun, S. A dynamic proportional-integral observer-based nonlinear fault-tolerant controller design for nonlinear system with partially unknown dynamic. IEEE Trans. Syst. Man Cybern. Syst. 2021, 52, 5092–5104. [Google Scholar] [CrossRef]

- Apkarian, P.; Gahinet, P.; Becker, G. Self-scheduled H∞ control of linear parameter-varying systems: A design example. Automatica 1995, 31, 1251–1261. [Google Scholar] [CrossRef]

- Zollars, M.D.; Cobb, R.G.; Grymin, D.J. Optimal path planning for suas waypoint following in urban environments. In Proceedings of the 2018 IEEE Aerospace Conference, Big Sky, MT, USA, 3–10 March 2018; pp. 1–8. [Google Scholar]

- Theis, J.; Pfifer, H. Observer-based synthesis of linear parameter-varying mixed sensitivity controllers. Int. J. Robust Nonlinear Control 2020, 30, 5021–5039. [Google Scholar] [CrossRef]

- Liu, Y.; Jiang, C. Mixed-Sensitivity Control for Drag-Free Spacecraft Based on state space. Aerospace 2022, 9, 708. [Google Scholar] [CrossRef]

- Chilali, M.; Gahinet, P. H/sub/spl infin//design with pole placement constraints: An lmi approach. IEEE Trans. Autom. Control 1996, 41, 358–367. [Google Scholar] [CrossRef]

- Chilali, M.; Gahinet, P.; Apkarian, P. Robust pole placement in LMI regions. IEEE Trans. Autom. Control 1999, 44, 2257–2270. [Google Scholar] [CrossRef]

- Gahinet, P.; Nemirovskii, A.; Laub, A.J.; Chilali, M. The lmi control toolbox. In Proceedings of the 1994 33rd IEEE Conference on Decision and Control, Lake Buena Vista, FL, USA, 14–16 December 1994; Volume 3, pp. 2038–2041. [Google Scholar]

- Wada, N.; Takahashi, A.; Saeki, M.; Nishimura, M. Vehicle yaw control using an active front steering system with measurements of lateral tire forces. In The Abstracts of the International Conference on Advanced Mechatronics: Toward Evolutionary Fusion of IT and Mechatronics (ICAM 2010.5); The Japan Society of Mechanical Engineers: Tokyo, Japan, 2010; pp. 319–324. [Google Scholar]

- Li, P.; Nguyen, A.T.; Du, H.; Wang, Y.; Zhang, H. Polytopic LPV approaches for intelligent automotive systems: State of the art and future challenges. Mech. Syst. Signal Process. 2021, 161, 107931. [Google Scholar] [CrossRef]

- Trapiello, C.; Puig, V.; Morcego, B. Position-heading quadrotor control using LPV techniques. IET Control Theory Appl. 2019, 13, 783–794. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).