Grasp Analysis for the Robot-Based Manipulation of Pre-Assembled Cables with Electrical Connectors

Abstract

1. Introduction

2. State of the Art

2.1. Contact Modeling for Two-Jaw Grippers and Rigid Objects

2.2. Grasping and Mating of ECs

2.3. Assembly and Manipulation Planning of DLOs

2.4. Evaluation of the State of the Art

2.5. Contribution

- combining a novel contact model for NSCs with a physics simulation for DLOs,

- presenting a methodology to estimate the required grasp force for ECs, including the dynamic cable behavior,

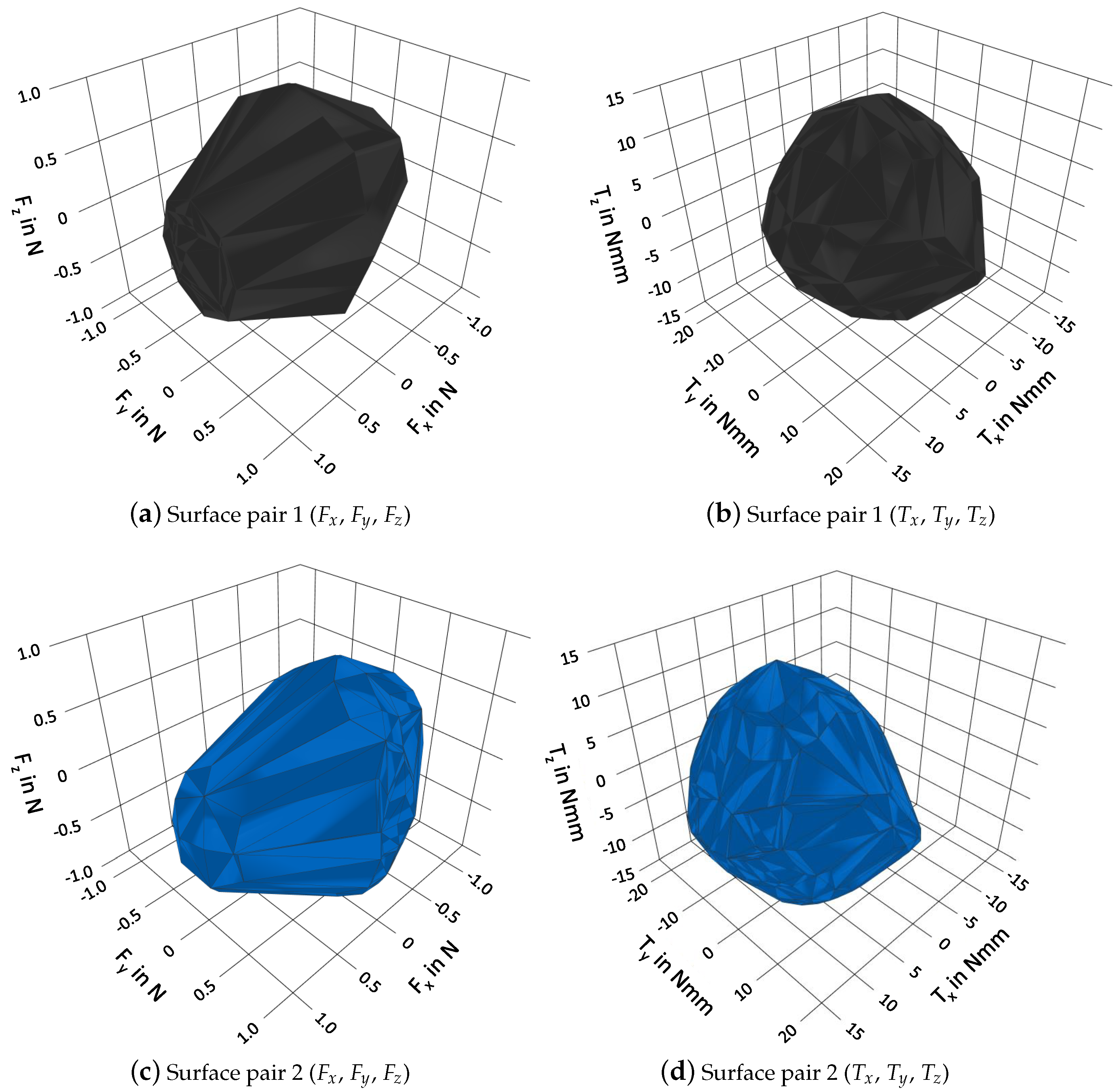

- showing the effect of dynamic cable deformations on different surface pairs of a plug,

- demonstrating a procedure to automatically generate a physics simulation scenario to sample the dynamic cable wrenches.

3. Methodology

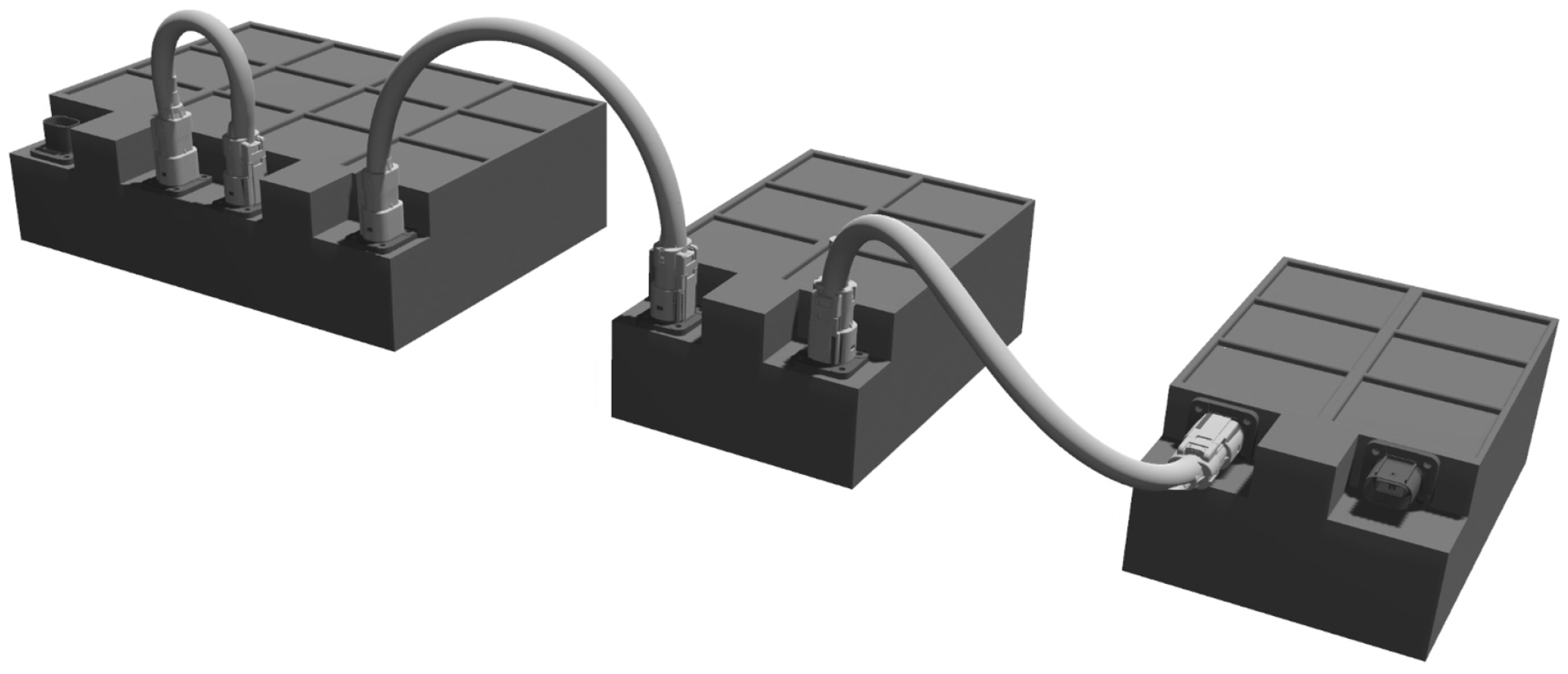

3.1. Broader Context

3.2. Methodology Overview

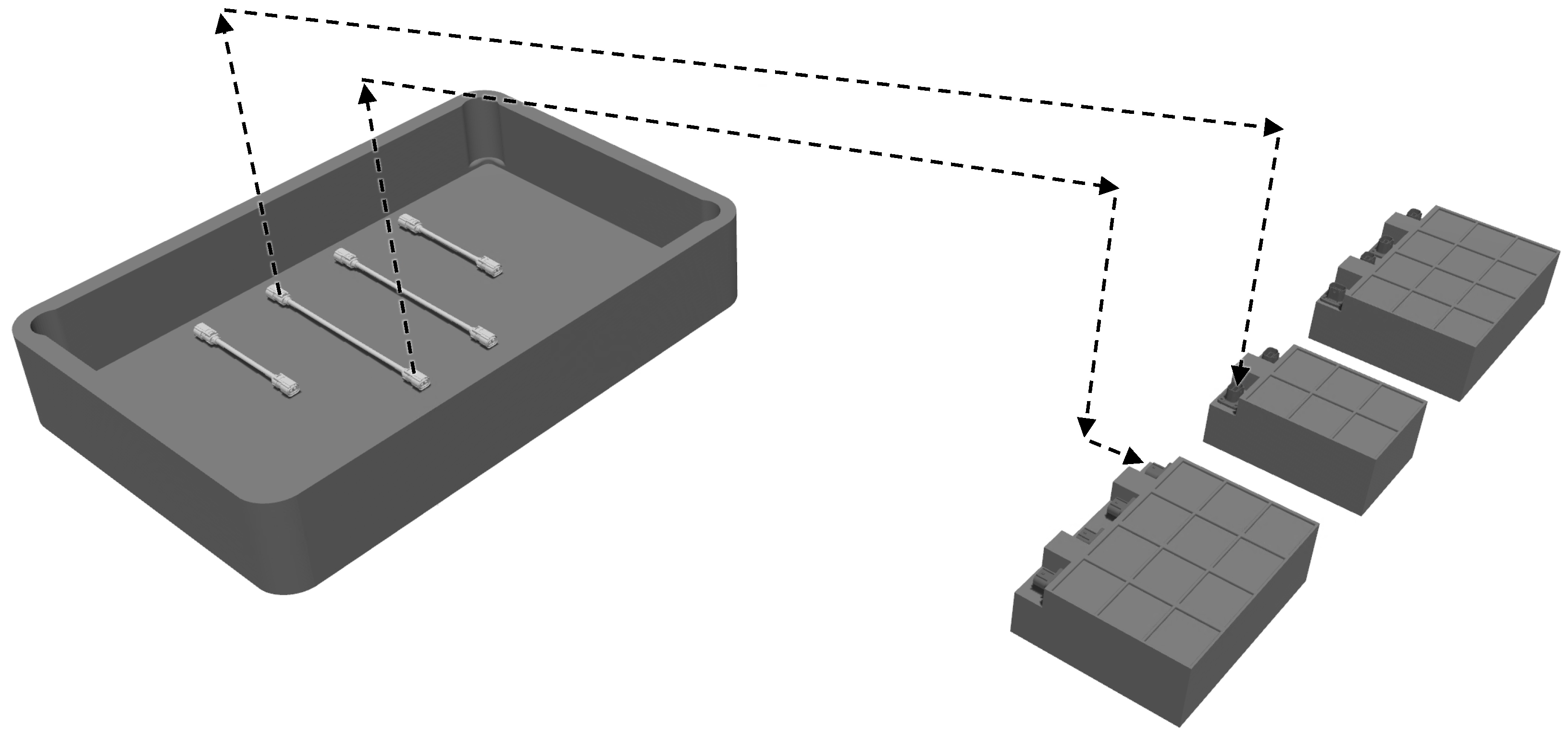

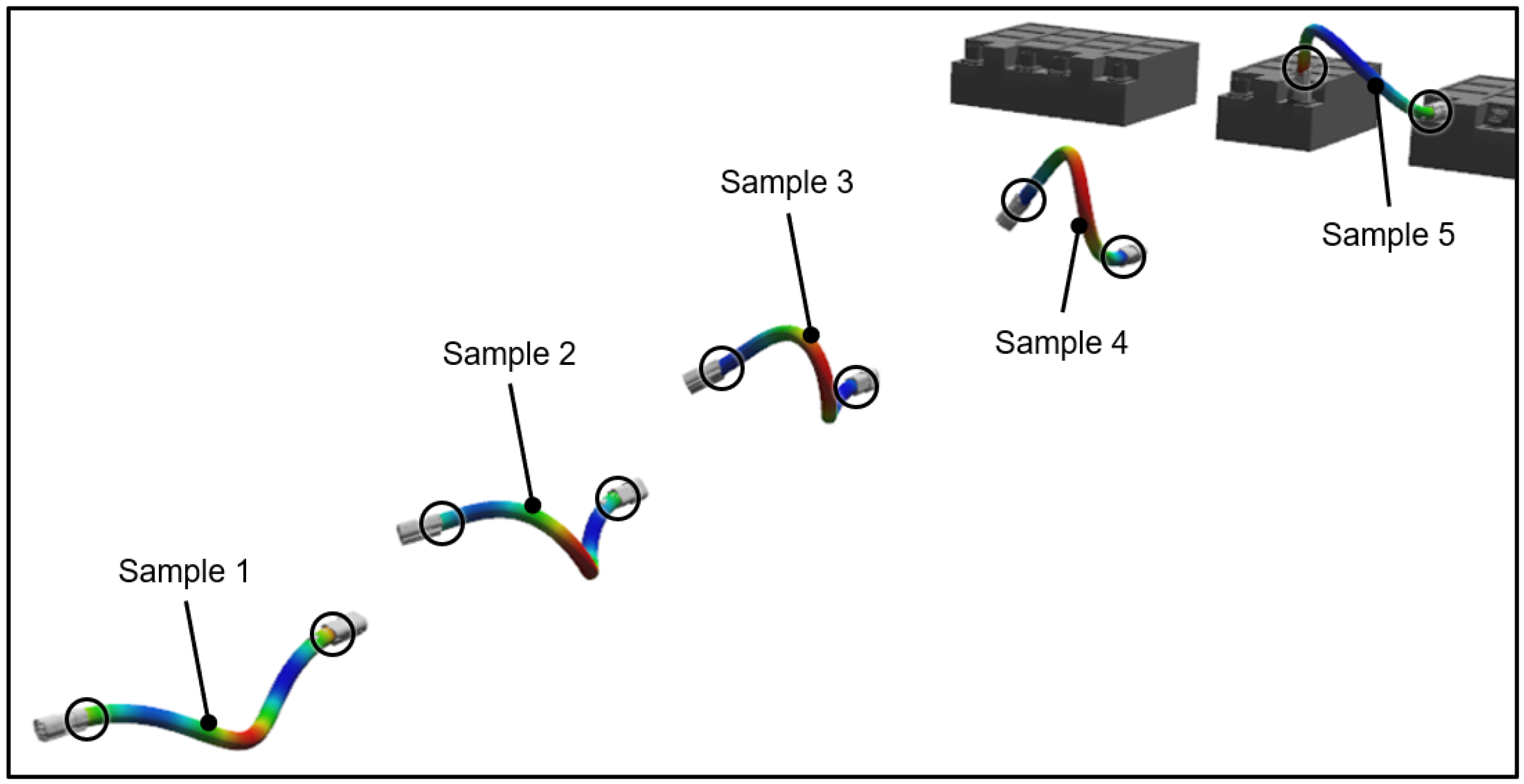

3.3. Scenario Generation and Cable Load Quantification

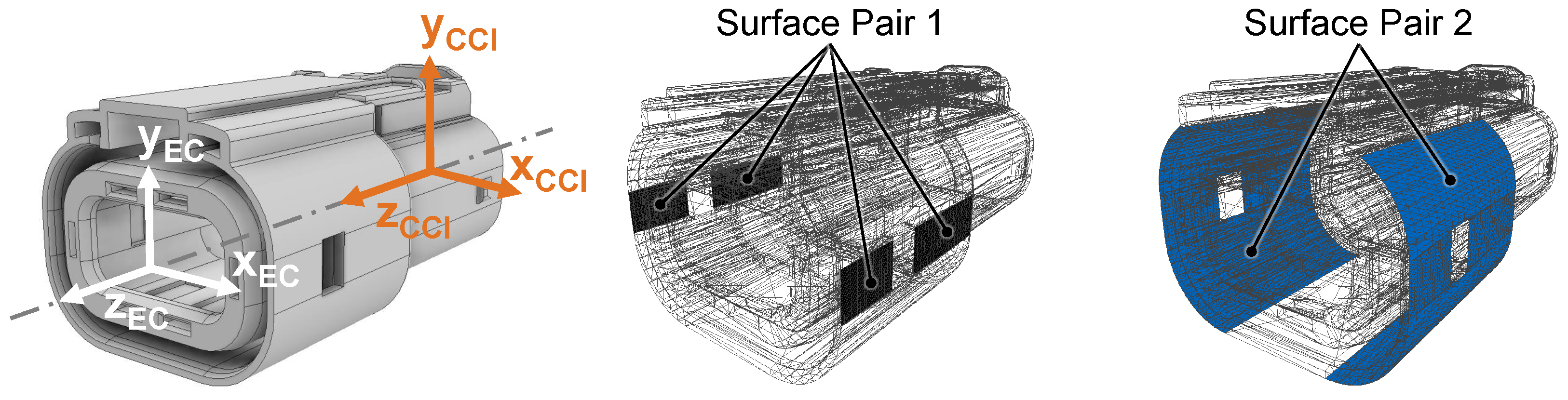

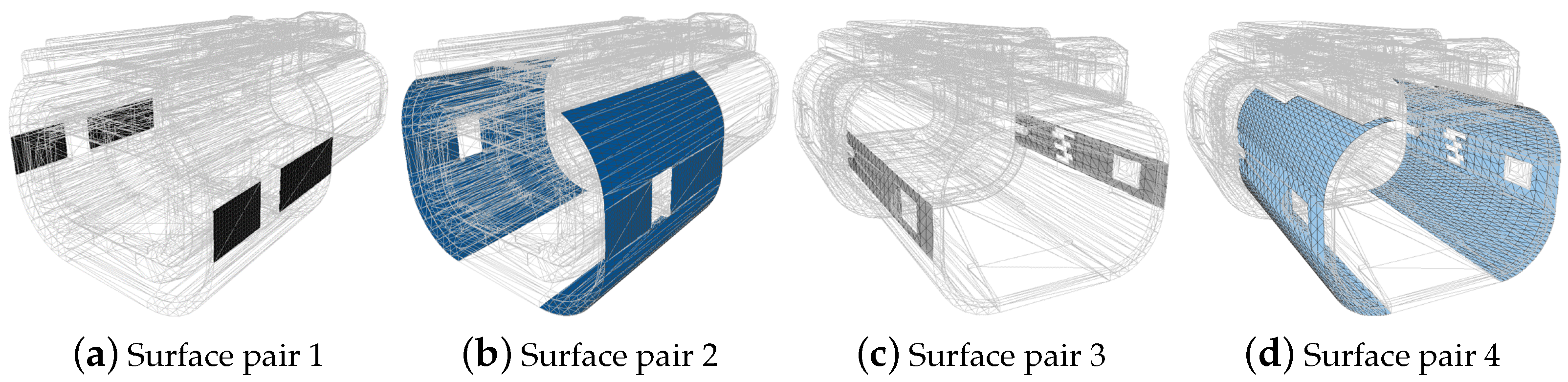

3.4. Contact Modeling and Grasp Force Estimation

3.5. Implementation

4. Results

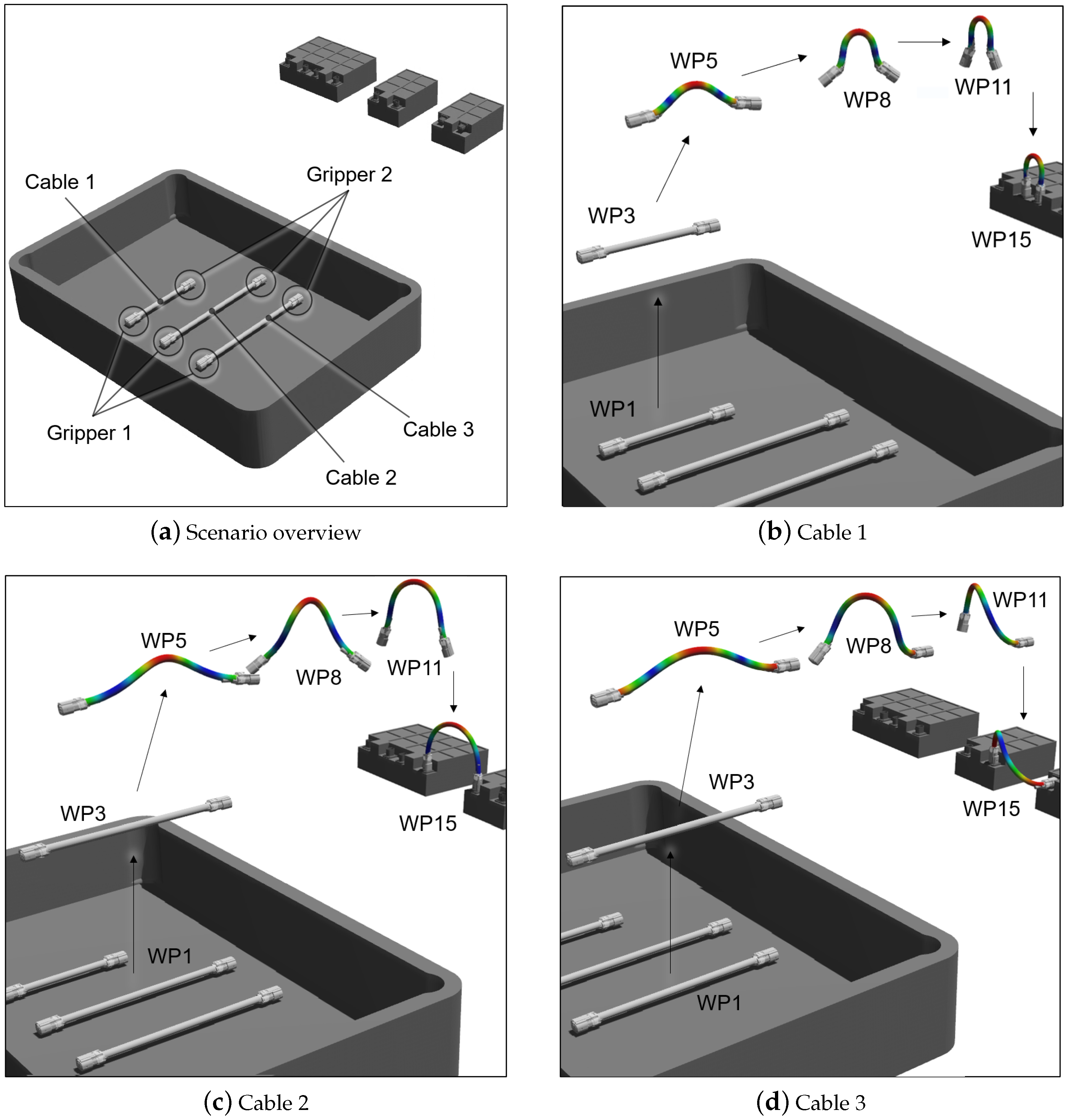

4.1. Reference Scenario

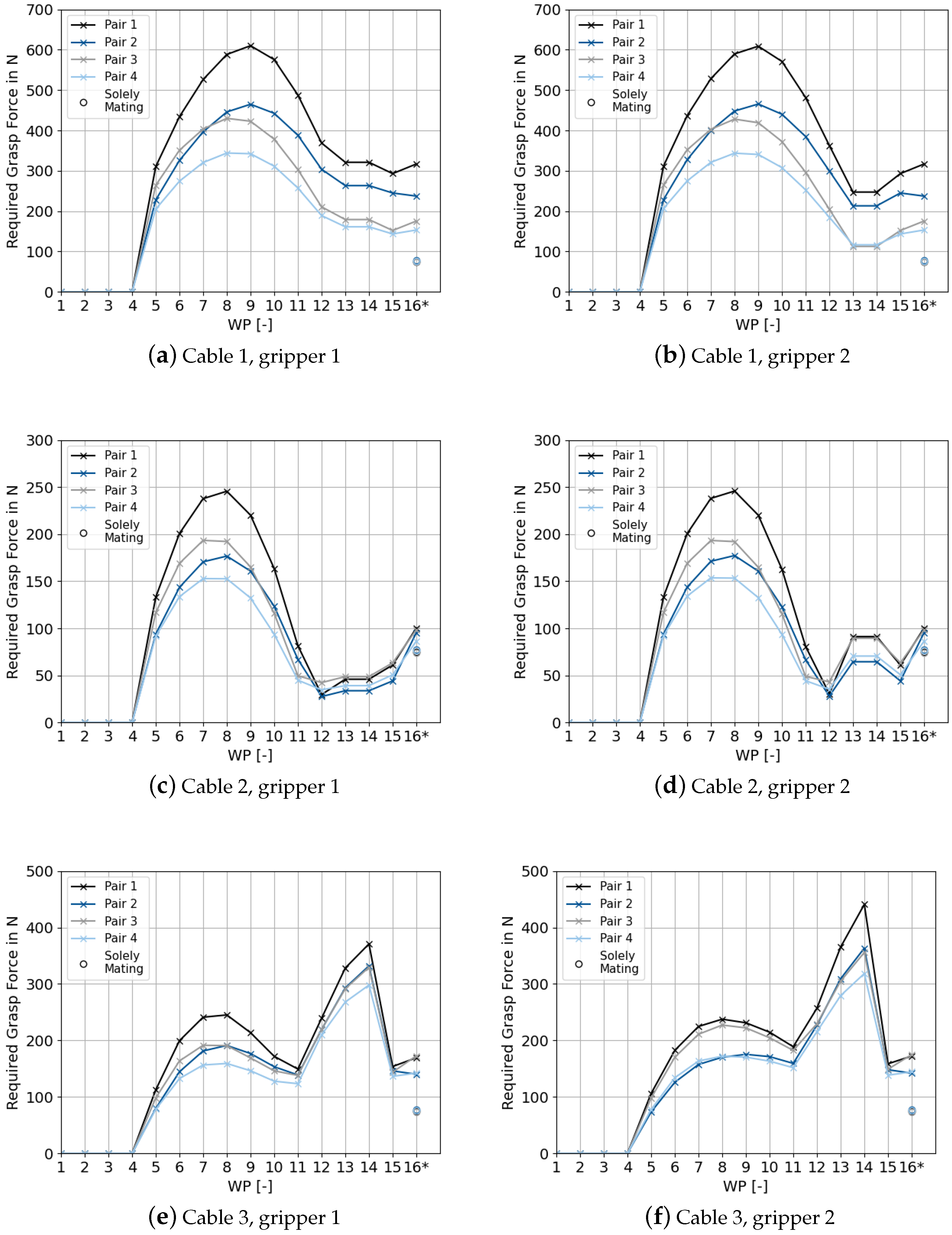

4.2. Grasp Analysis for High-Voltage Cables

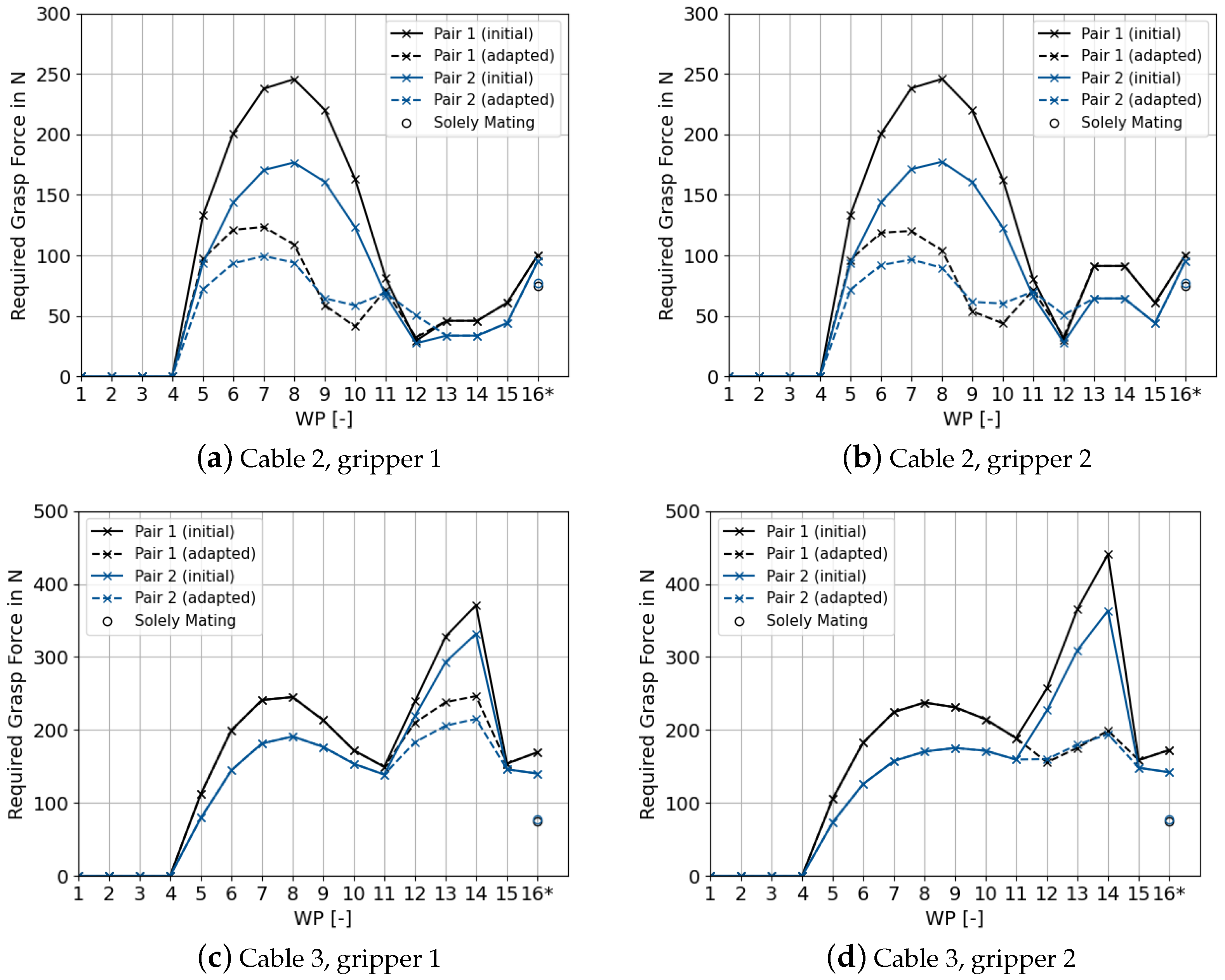

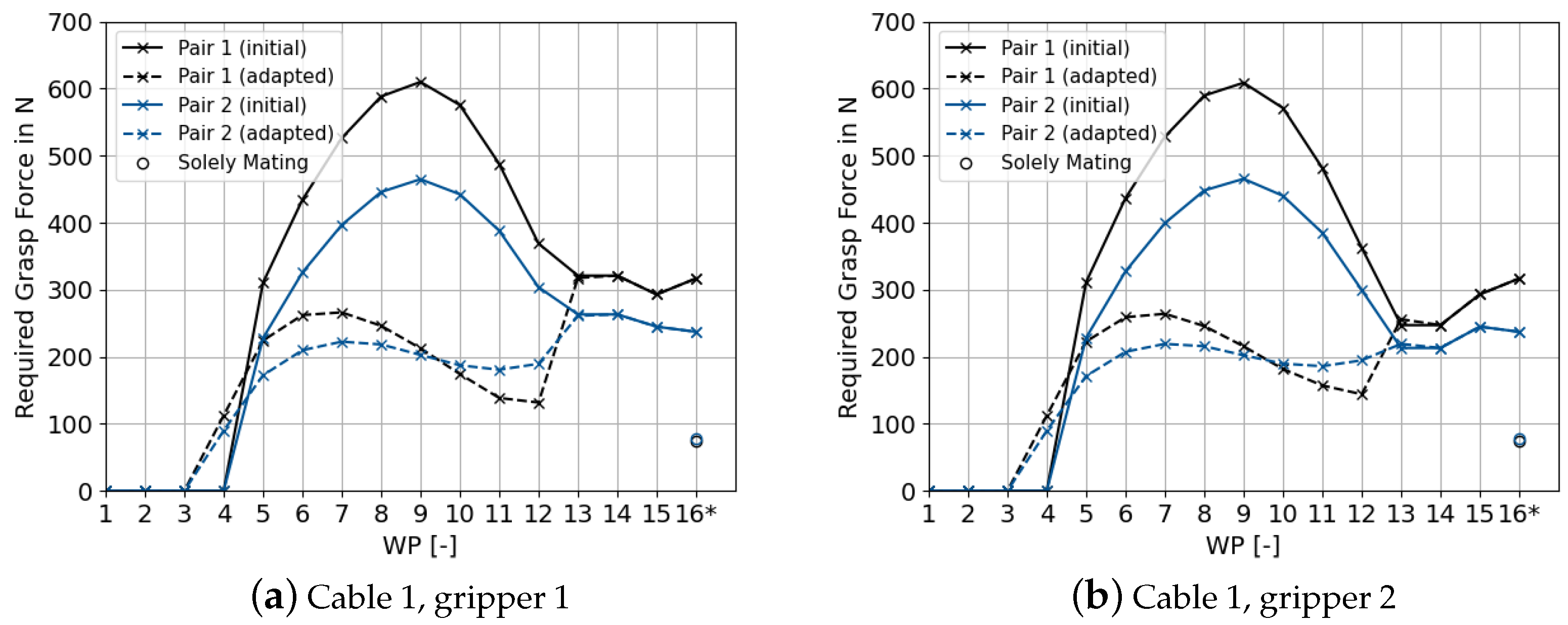

4.3. Manual Adaptation of the Automatically Generated Trajectories

4.4. Comparison of Different High-Voltage Cables

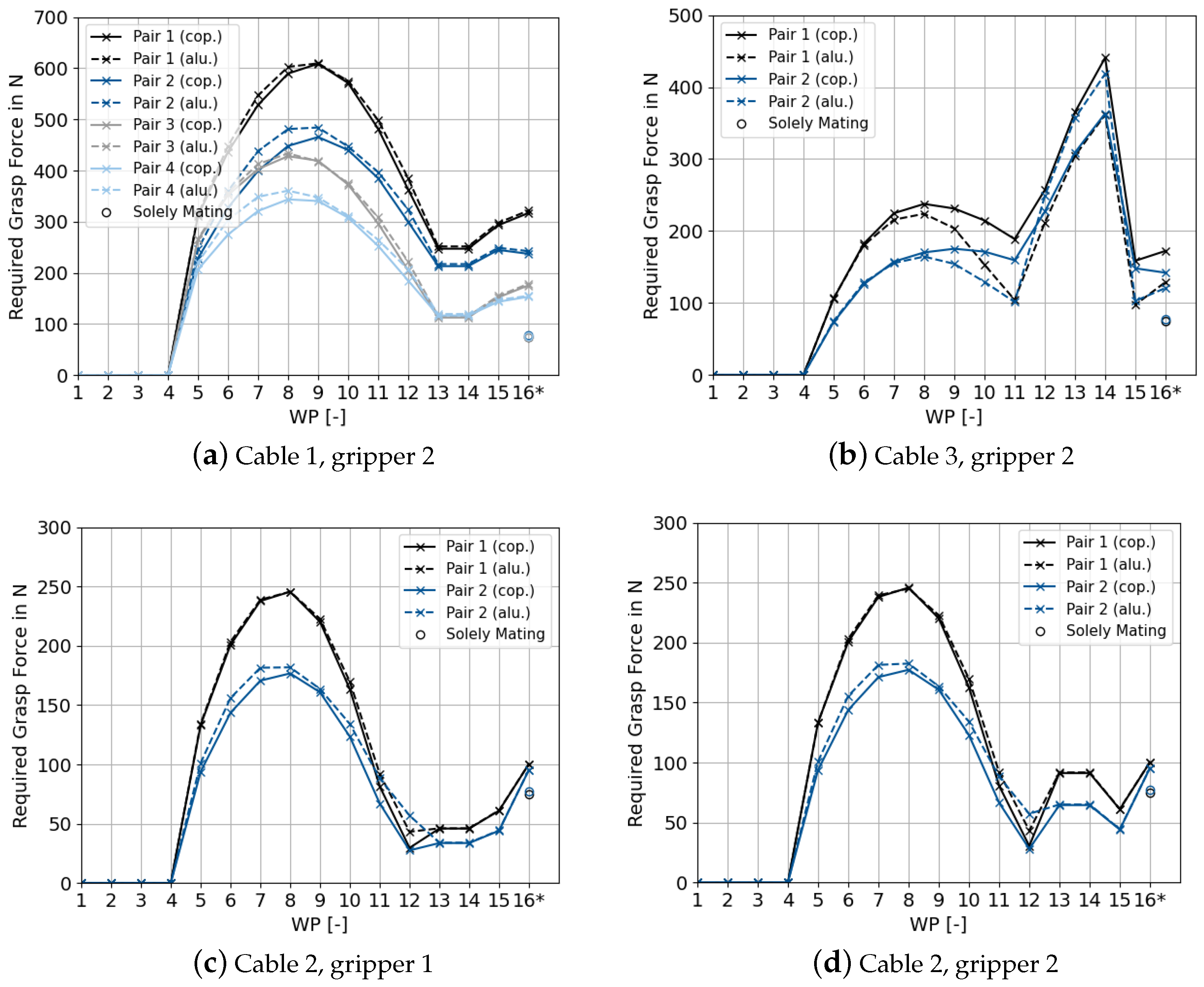

5. Discussion

5.1. Key Findings

5.2. Limitations and Potential Solution Approaches

6. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Results of the Grasp Force Estimation

References

- Honarpardaz, M.; Tarkian, M.; Ölvander, J.; Feng, X. Finger design automation for industrial robot grippers: A review. Robot. Auton. Syst. 2017, 87, 104–119. [Google Scholar] [CrossRef]

- Gebauer, D.; Dirr, J.; Daub, R. Automated Design of Gripper Systems for Electrical Connectors (submitted). In Proceedings of the CIRP ICME, Naples, Italy, 13–15 July 2022. [Google Scholar]

- Hesse, S. Greifertechnik: Effektoren für Roboter und Automaten; Carl Hanser: Munich, Germany, 2011. [Google Scholar]

- Schmalz, J. Rechnergestützte Auslegung und Auswahl von Greifersystemen; Utzverlag: Munich, Germany, 2018. [Google Scholar]

- Böger, T. Beitrag zur Projektierung von Greifelementen für die Handhabung flächiger, biegeweicher Materialien; Praxiswissen Service: Dortmund, Germany, 1998. [Google Scholar]

- Kao, I.; Lynch, K.M.; Burdick, J.W. Contact modeling and manipulation. In Springer Handbook of Robotics; Siciliano, B., Khatib, O., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 931–954. [Google Scholar]

- Prattichizzo, D.; Trinkle, J.C. Grasping. In Springer Handbook of Robotics; Siciliano, B., Khatib, O., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 955–988. [Google Scholar]

- Miller, A.T.; Allen, P.K. GraspIt! A Versatile Simulator for Robotic Grasping. IEEE Robot. Autom. Mag. 2004, 11, 110–122. [Google Scholar] [CrossRef]

- Ferrari, C.; Canny, J. Planning Optimal Grasps. In Proceedings of the IEEE International Conference on Robotics and Automation, Nice, France, 12–14 May 1992; pp. 2290–2295. [Google Scholar]

- Lin, Y.; Sun, Y. Task-Based Grasp Quality Measures for Grasp Synthesis. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 485–490. [Google Scholar]

- Xu, J.; Aykut, T.; Ma, D.; Steinbach, E. 6DLS: Modeling Nonplanar Frictional Surface Contacts for Grasping Using 6-D Limit Surfaces. IEEE Trans. Robot. 2021, 37, 2099–2116. [Google Scholar] [CrossRef]

- Ji, W.; Tang, C.; Xu, B.; He, G. Contact force modeling and variable damping impedance control of apple harvesting robot. Comput. Electron. Agric. 2022, 198, 107026. [Google Scholar] [CrossRef]

- Ji, W.; Zhang, J.; Xu, B.; Tang, C.; Zhao, D. Grasping mode analysis and adaptive impedance control for apple harvesting robotic grippers. Comput. Electron. Agric. 2021, 186, 106210. [Google Scholar] [CrossRef]

- Xu, J.; Hou, Z.; Liu, Z.; Qiao, H. Compare Contact Model-based Control and Contact Model-free Learning: A Survey of Robotic Peg-in-hole Assembly Strategies. arXiv 2019, arXiv:1904.05240. [Google Scholar] [CrossRef]

- Song, H.C.; Kim, Y.L.; Lee, D.H.; Song, J.B. Electric connector assembly based on vision and impedance control using cable connector-feeding system. J. Mech. Sci. Technol. 2017, 31, 5997–6003. [Google Scholar] [CrossRef]

- Ortner, M.; Gadringer, S.; Gattringer, H.; Mueller, A.; Naderer, R. Automatized Insertion of Multipolar Electric Plugs by Means of Force Controlled Industrial Robots. In Proceedings of the 25th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020; pp. 1465–1472. [Google Scholar] [CrossRef]

- Yumbla, F.; Yi, J.S.; Abayebas, M.; Shafiyev, M.; Moon, H. Tolerance dataset: Mating process of plug-in cable connectors for wire harness assembly tasks. Intell. Serv. Robot. 2020, 13, 159–168. [Google Scholar] [CrossRef]

- Sanchez, J.; Corrales, J.A.; Bouzgarrou, B.C.; Mezouar, Y. Robotic manipulation and sensing of deformable objects in domestic and industrial applications: A survey. Int. J. Robot. Res. 2018, 37, 688–716. [Google Scholar] [CrossRef]

- Nadon, F.; Valencia, A.J.; Payeur, P. Multi-Modal Sensing and Robotic Manipulation of Non-Rigid Objects: A Survey. Robotics 2018, 7, 74. [Google Scholar] [CrossRef]

- Herguedas, R.; López-Nicolás, G.; Aragüés, R.; Sagüés, C. Survey on multi-robot manipulation of deformable objects. In Proceedings of the 24th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2019; pp. 977–984. [Google Scholar] [CrossRef]

- Hermansson, T.; Bohlin, R.; Carlson, J.S.; Söderberg, R. Automatic assembly path planning for wiring harness installations. J. Manuf. Syst. 2013, 32, 417–422. [Google Scholar] [CrossRef]

- Hermansson, T.; Bohlin, R.; Carlson, J.S.; Söderberg, R. Automatic routing of flexible 1D components with functional and manufacturing constraints. Comput.-Aided Des. 2016, 79, 27–35. [Google Scholar] [CrossRef]

- Du, H.; Jiang, Q.; Xiong, W. Computer-assisted assembly process planning for the installation of flexible cables modeled according to a viscoelastic Cosserat rod model. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022. [Google Scholar] [CrossRef]

- Roussel, O.; Taïx, M. Deformable Linear Object manipulation planning with contacts. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS)—Robot Manipulation: What Has Been Achieved and What Remains to Be Done? Chicago, IL, USA, 14–18 September 2014. [Google Scholar]

- Zhou, H.; Lu, Q.; Qian, J. Representation of Cable Harness for Assembly Sequence Planning. In Proceedings of the IEEE International Conference on Advanced Robotics and Mechatronics, Guilin, China, 09–11 July 2022; pp. 886–891. [Google Scholar] [CrossRef]

- Leão, G.; Sousa, A.; Dinis, D.; Veiga, G. Simulated Mounting of a Flexible Wire for Automated Assembly of Vehicle Cabling Systems. In Proceedings of the ROBOT2022: Fifth Iberian Robotics Conference, Zaragoza, Spain, 23–25 November 2022; pp. 385–397. [Google Scholar] [CrossRef]

- Yang, Y.; Stork, J.A.; Stoyanov, T. Learning differentiable dynamics models for shape control of deformable linear objects. Robot. Auton. Syst. 2022, 158, 104258. [Google Scholar] [CrossRef]

- Zhang, X.; Li, C.; Xi, N. Cable Assembly Based on Robot Manipulation and Control. Proceedings of 12th IEEE International Conference on CYBER Technology in Automation, Control, and Intelligent Systems, Baishan, China, 27–31 July 2022; pp. 597–602. [Google Scholar] [CrossRef]

- Lin, X.; Wang, Y.; Olkin, J.; Held, D. SoftGym: Benchmarking Deep Reinforcement Learning for Deformable Object Manipulation. Proceedings of 4th Conference on Robot Learning, Cambridge, MA, USA, 16–18 November 2020; pp. 432–448. [Google Scholar] [CrossRef]

- Du, H.; Xiong, W.; Wang, H.; Wang, Z. A review: Virtual assembly of flexible cables based on physical modeling. Assem. Autom. 2020, 40, 293–304. [Google Scholar] [CrossRef]

- Industrial Path Solutions. User Manual Version 2022-R1 n.p; Industrial Path Solutions: Gothenburg, Sweden, 2021. [Google Scholar]

- Hertz, H. Über die Berührung fester elastischer Körper und über die Härte. Verhandlungen des Vereins zur Beförderung des Gewerbfleißes; Verein zur Beförderung des Gewerbefleisses: Berlin, Germany, 1882; pp. 449–463. [Google Scholar]

- Xu, J. Modeling Nonplanar Frictional Surface Contacts for Robust Robot Grasping (submitted). Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2023. [Google Scholar]

- Lin, Y.; Sun, Y. Grasp planning to maximize task coverage. Int. J. Robot. Res. 2015, 34, 1195–1210. [Google Scholar] [CrossRef]

- Fraunhofer-Chalmers Centre. IPS Cable Simulation: API for Lua Scripting in IPS 2022-R1; Fraunhofer-Chalmers Centre: Gothenburg, Sweden, 2021. [Google Scholar]

- Dirr, J.; Gebauer, D.; Daub, R. Localization and Grasp Planning for Bin Picking of Deformable Linear Objects (submitted). In Proceedings of the CIRP ICME, Naples, Italy, 13–15 July 2022. [Google Scholar]

- Dirr, J.; Gebauer, D.; Yao, J.; Daub, R. Automatic Image Generation Pipeline for Instance Segmentation of Deformable Linear Objects. Sensors 2023, 23, 3013. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Abbreviation | Unit |

|---|---|---|

| Tensile stiffness | N | |

| Bending stiffness 1 | Nm | |

| Bending stiffness 2 | Nm | |

| Torsional stiffness | Nm | |

| Length density |

| Conductor | |||

|---|---|---|---|

| Copper | 13,406,400 N | 0.095109 Nm | 0.0922964 Nm |

| Aluminum | 4,483,500 N | 0.0955892 Nm | 0.580454 Nm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gebauer, D.; Dirr, J.; Martin, L.; Daub, R. Grasp Analysis for the Robot-Based Manipulation of Pre-Assembled Cables with Electrical Connectors. Appl. Sci. 2023, 13, 6462. https://doi.org/10.3390/app13116462

Gebauer D, Dirr J, Martin L, Daub R. Grasp Analysis for the Robot-Based Manipulation of Pre-Assembled Cables with Electrical Connectors. Applied Sciences. 2023; 13(11):6462. https://doi.org/10.3390/app13116462

Chicago/Turabian StyleGebauer, Daniel, Jonas Dirr, Luca Martin, and Rüdiger Daub. 2023. "Grasp Analysis for the Robot-Based Manipulation of Pre-Assembled Cables with Electrical Connectors" Applied Sciences 13, no. 11: 6462. https://doi.org/10.3390/app13116462

APA StyleGebauer, D., Dirr, J., Martin, L., & Daub, R. (2023). Grasp Analysis for the Robot-Based Manipulation of Pre-Assembled Cables with Electrical Connectors. Applied Sciences, 13(11), 6462. https://doi.org/10.3390/app13116462