Experimental Study on the Influence of Delay Time on Rock Fragmentation in Bench Blasting

Abstract

1. Introduction

2. Experiments

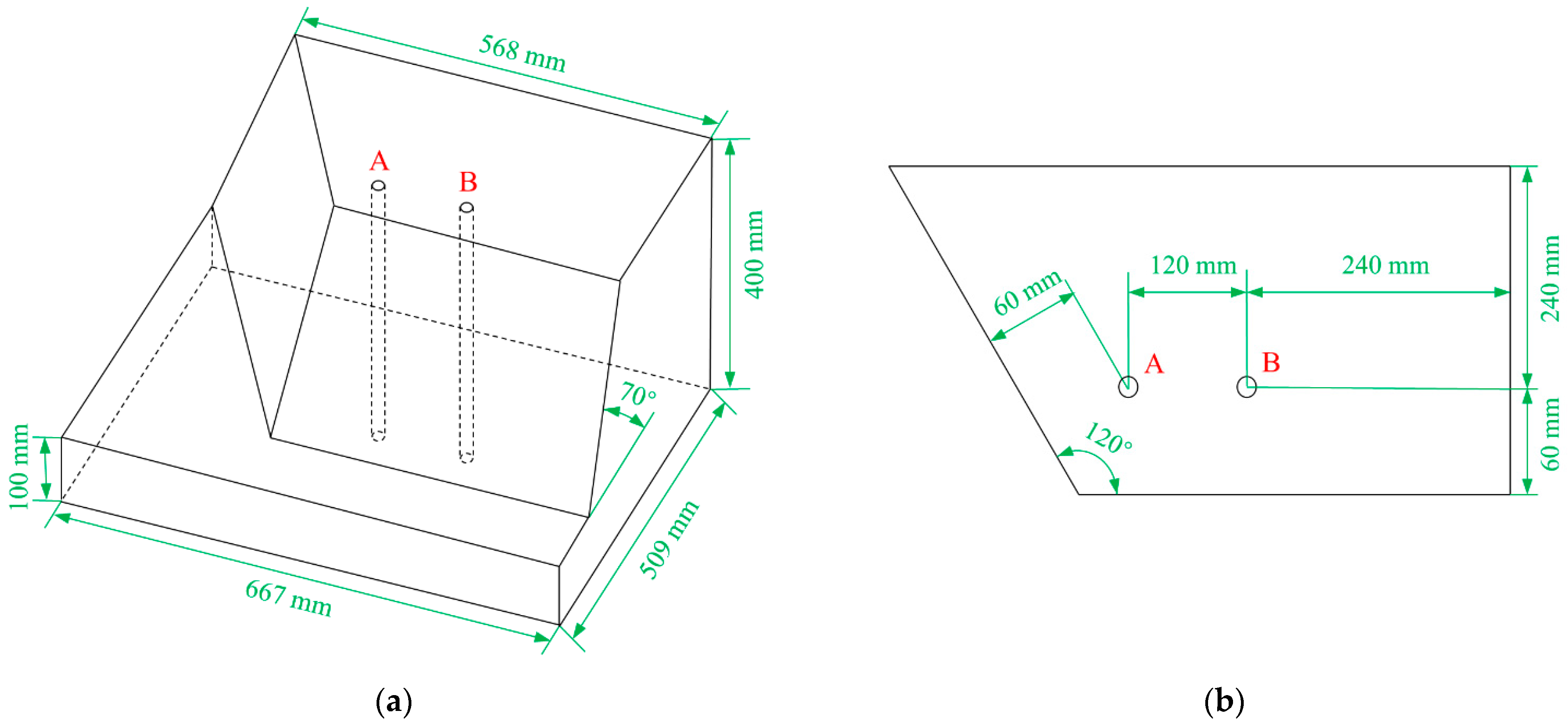

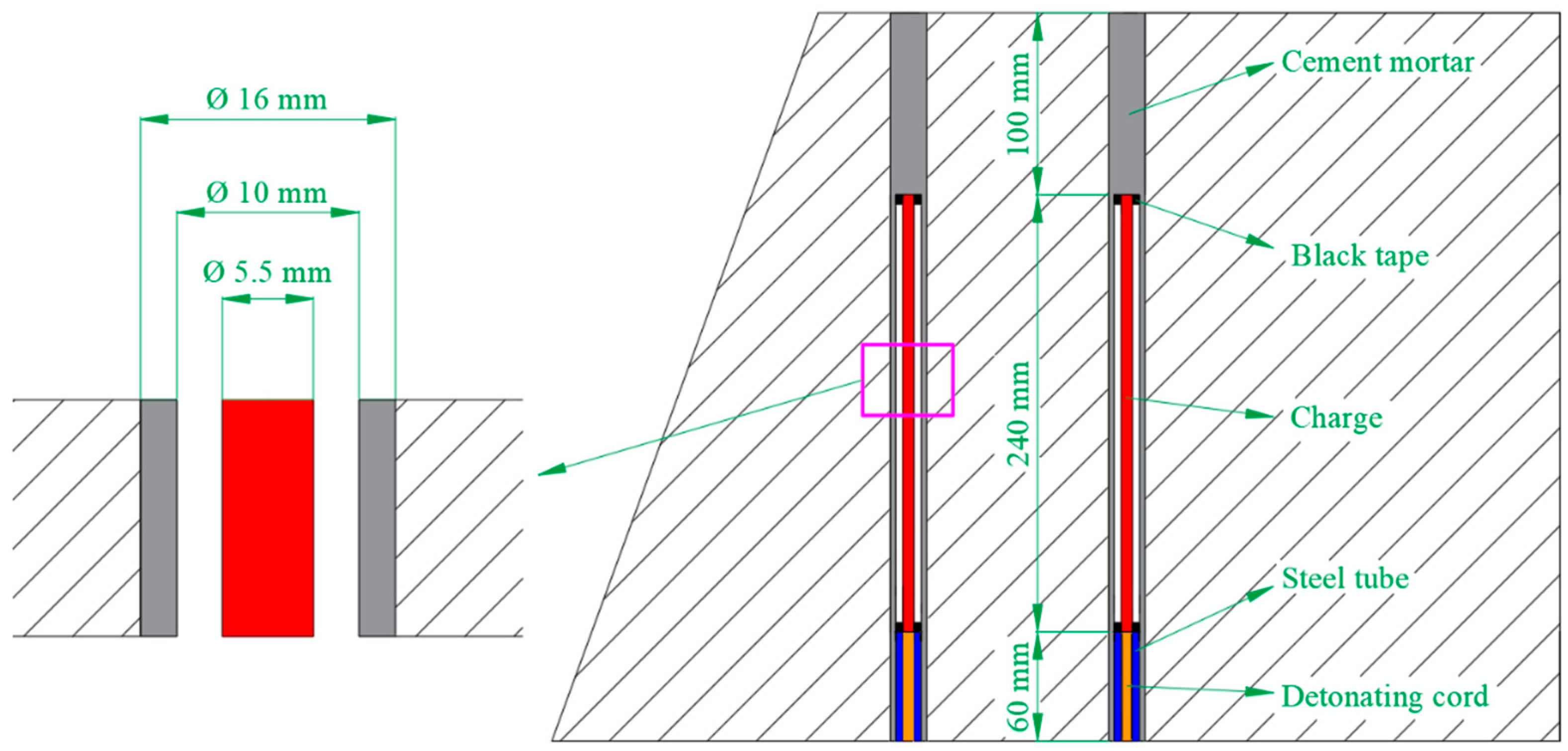

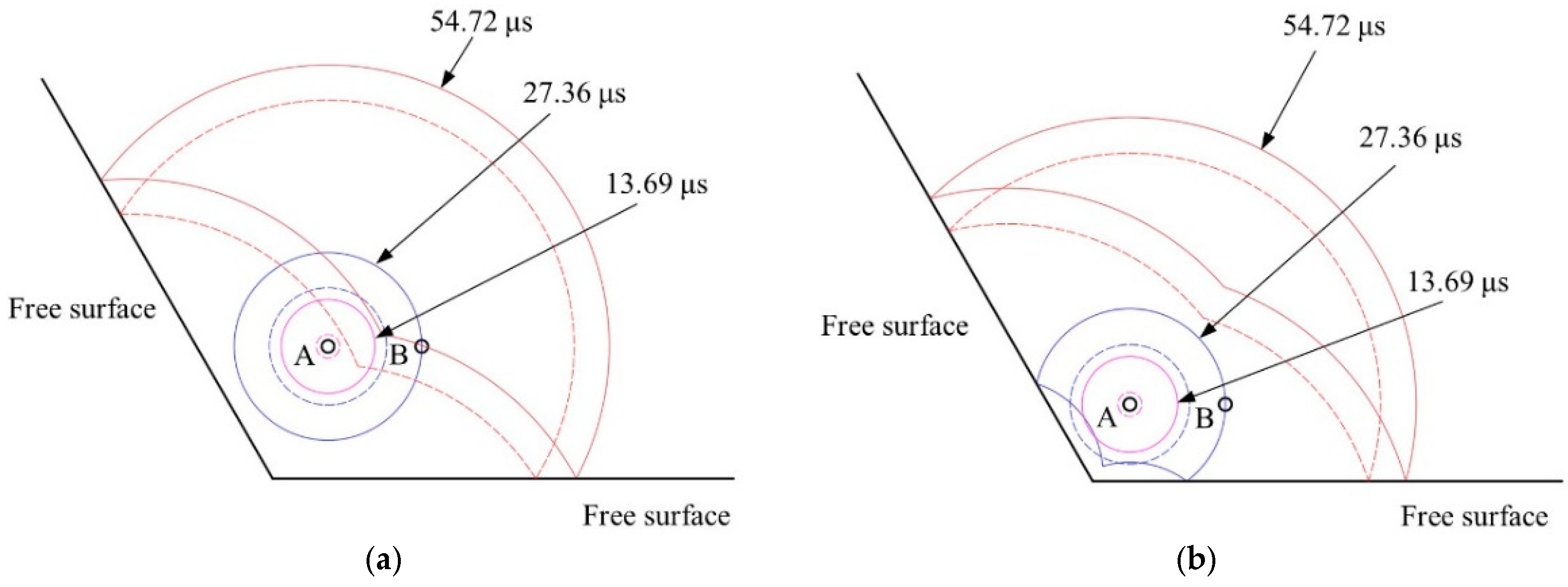

2.1. Specimen Design and Explosive

2.2. Experiment Setup

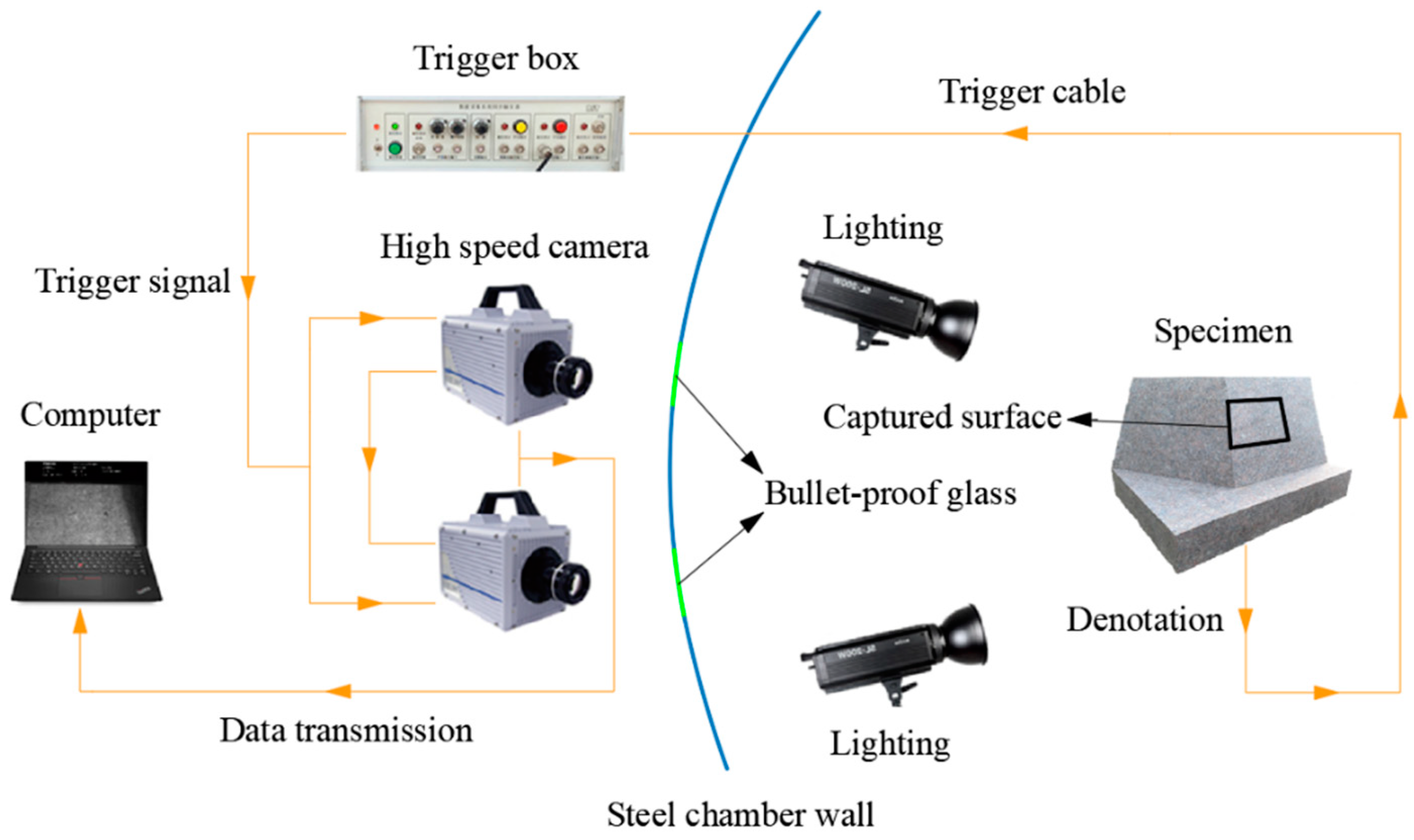

2.3. High-Speed Camera and DIC

3. Experimental Results

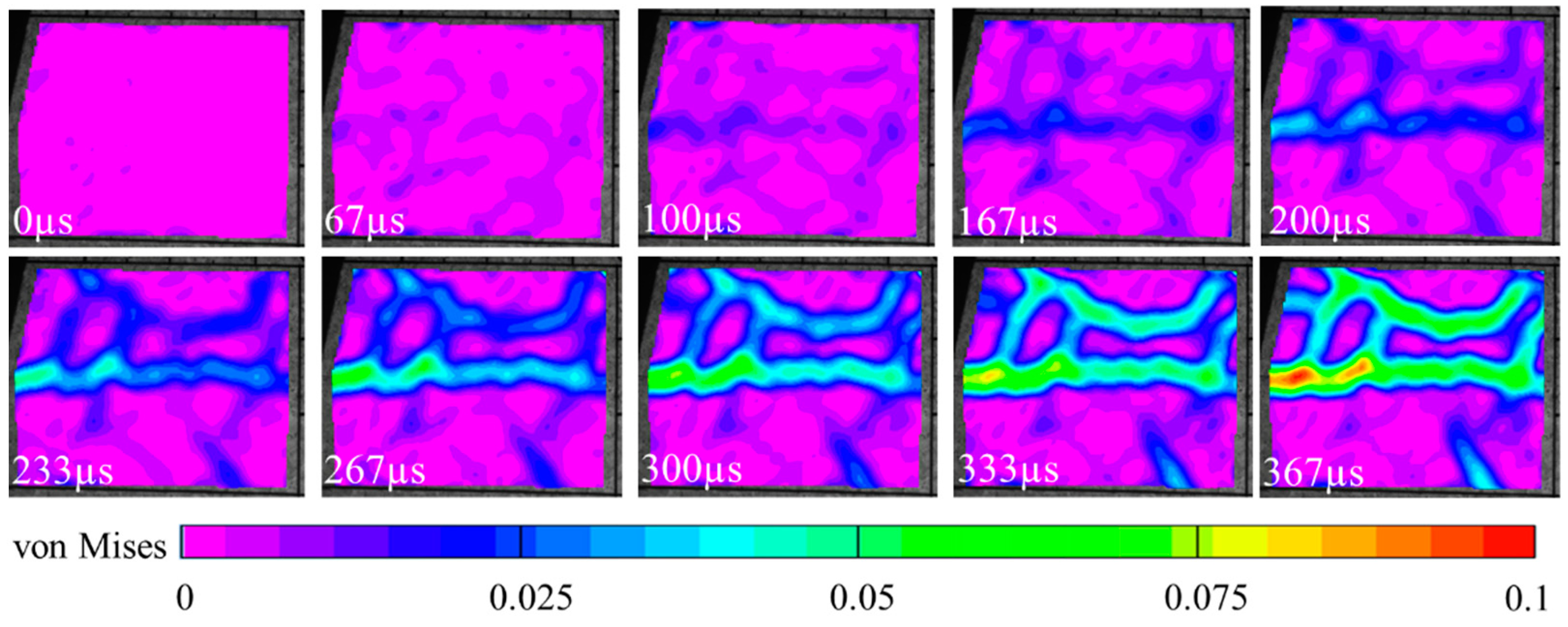

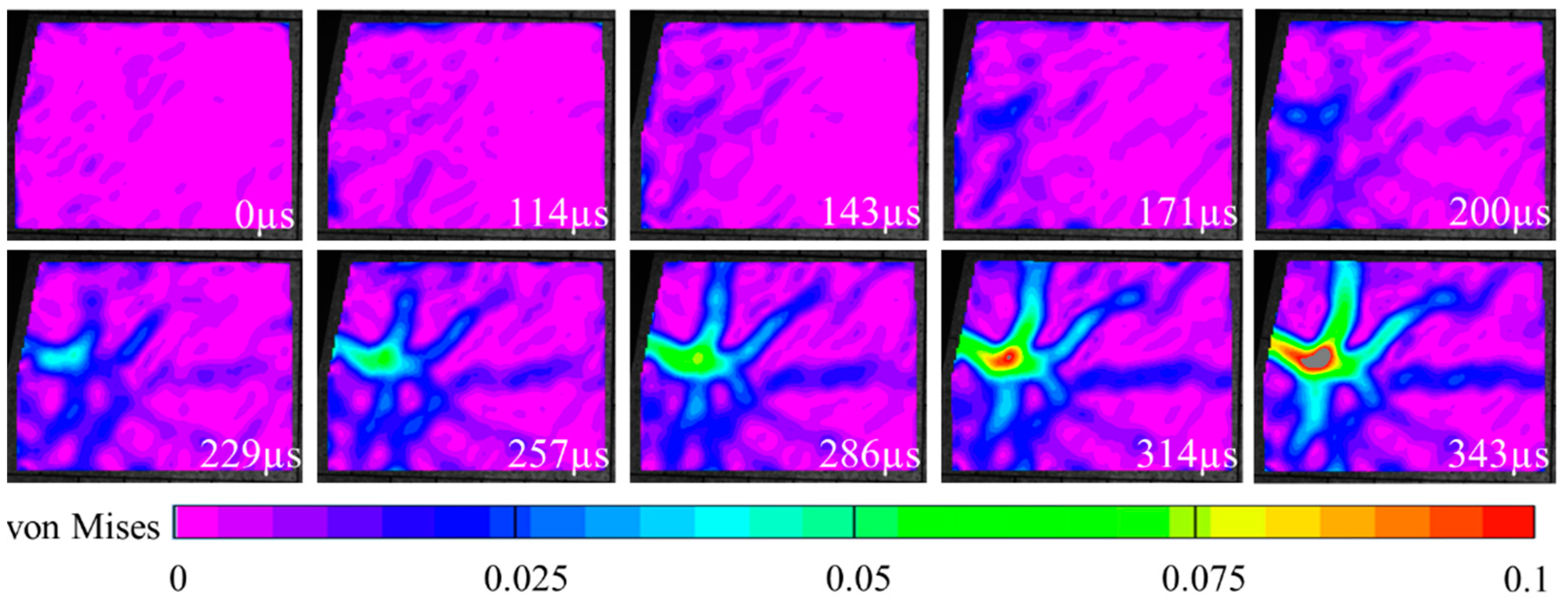

3.1. Full-Field Strain of Typical Specimens

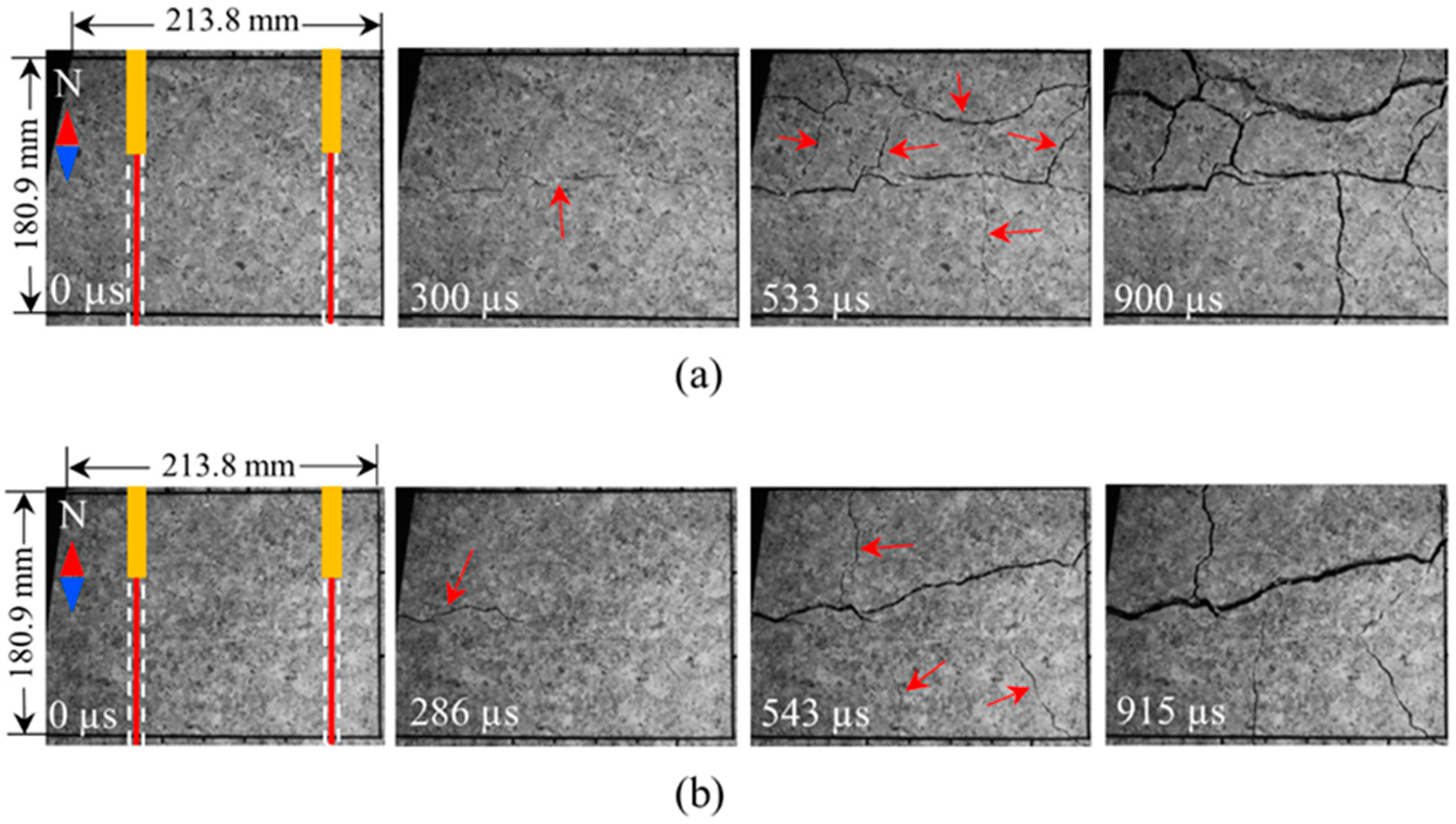

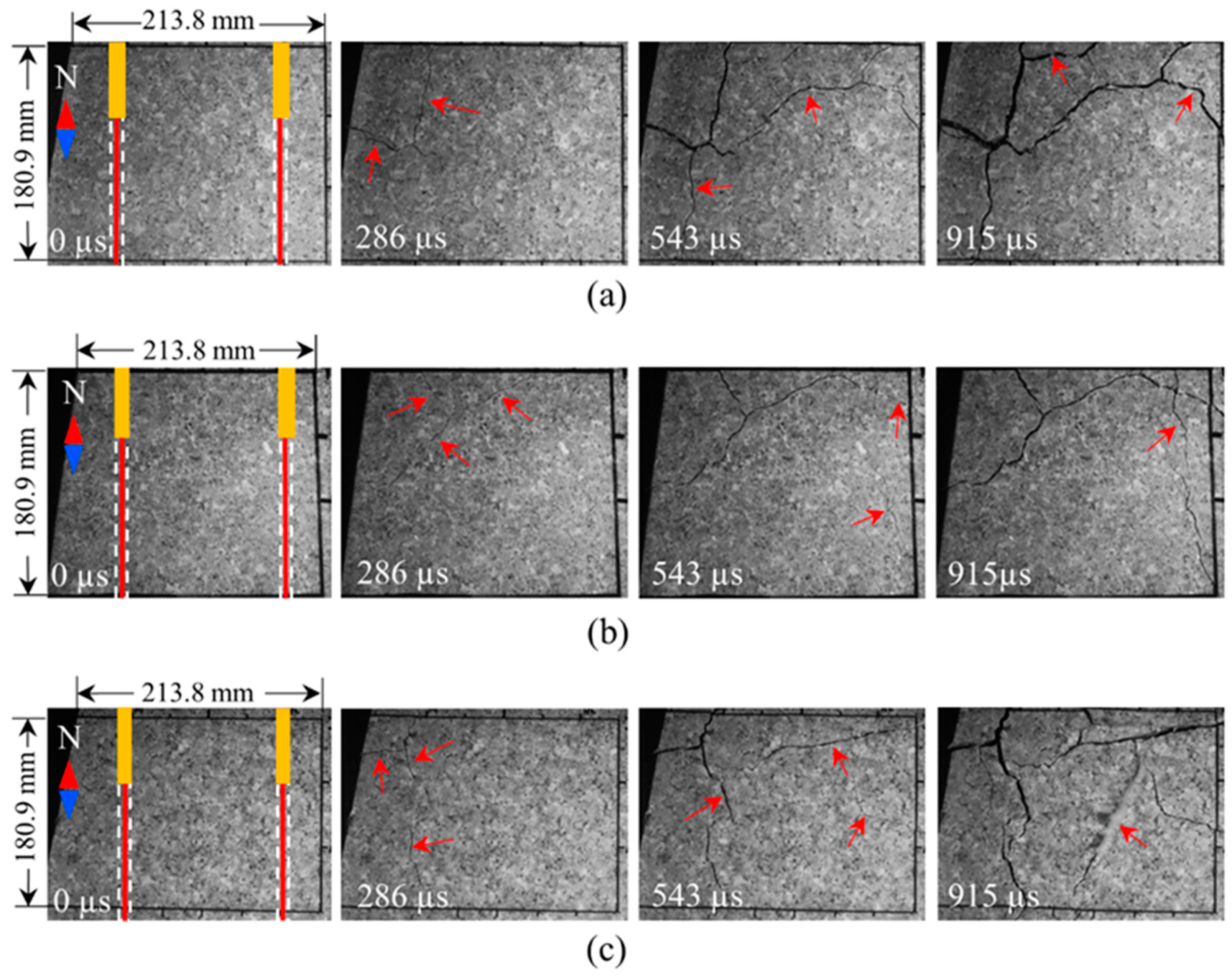

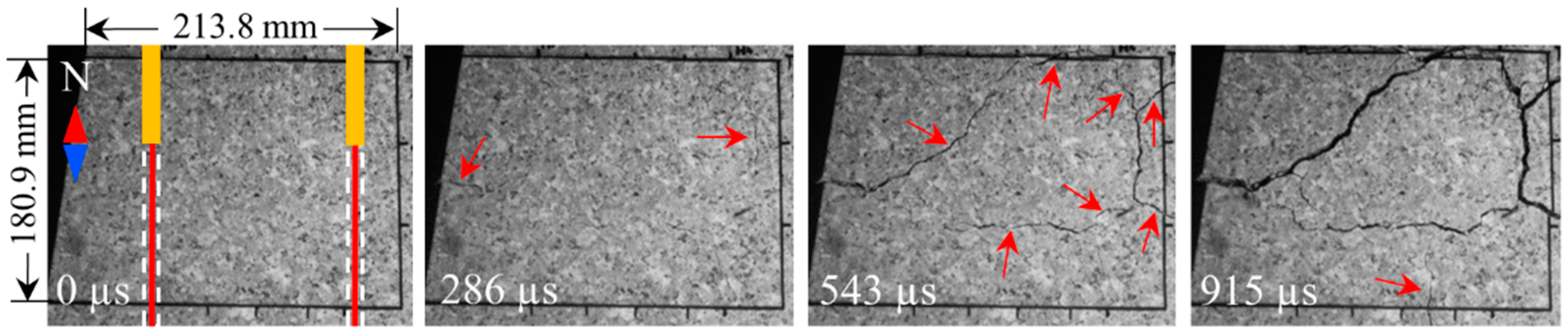

3.2. Progressive Breakage Process

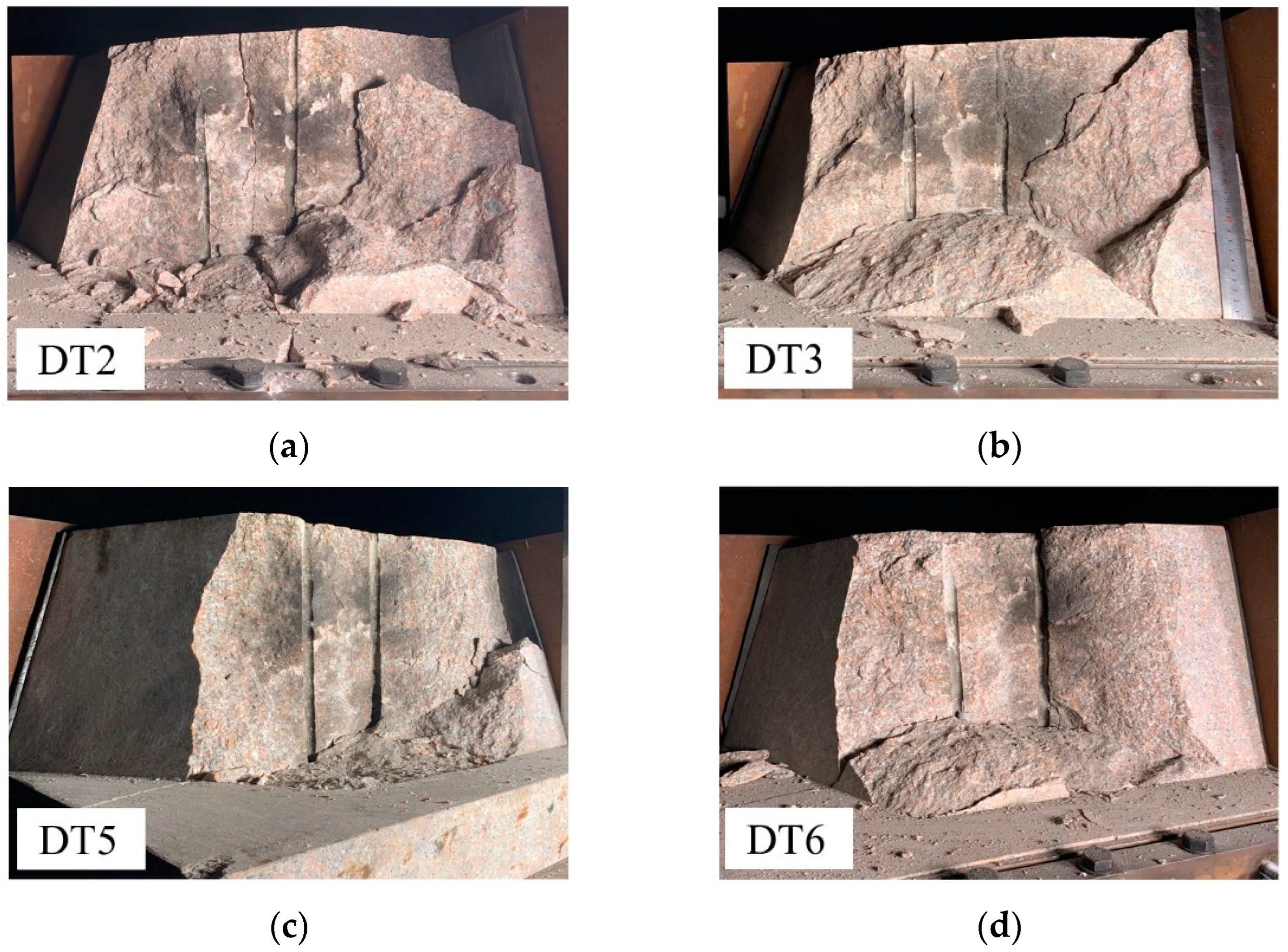

3.3. Post-Blast Pattern with Fragments Backfilled

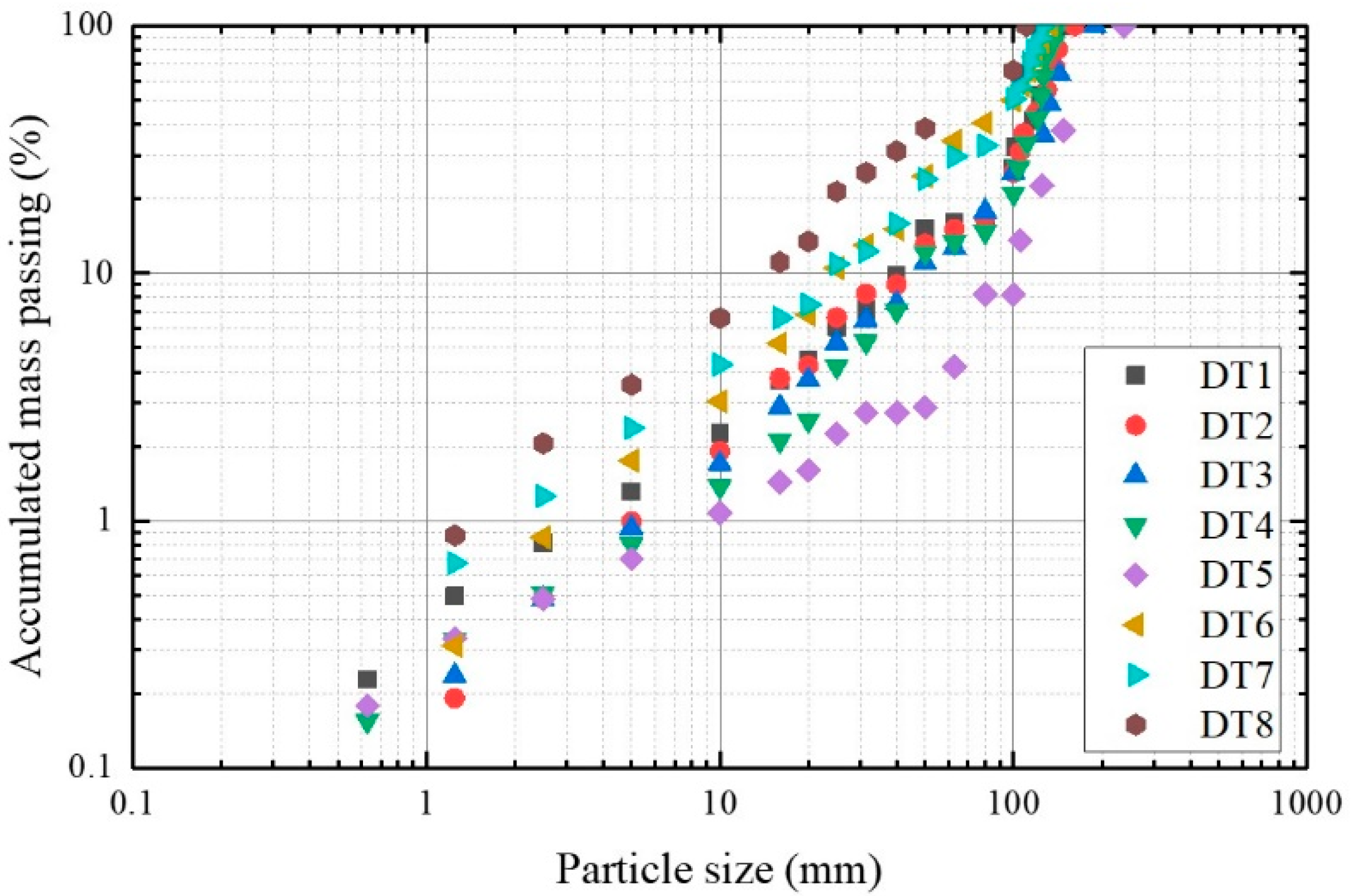

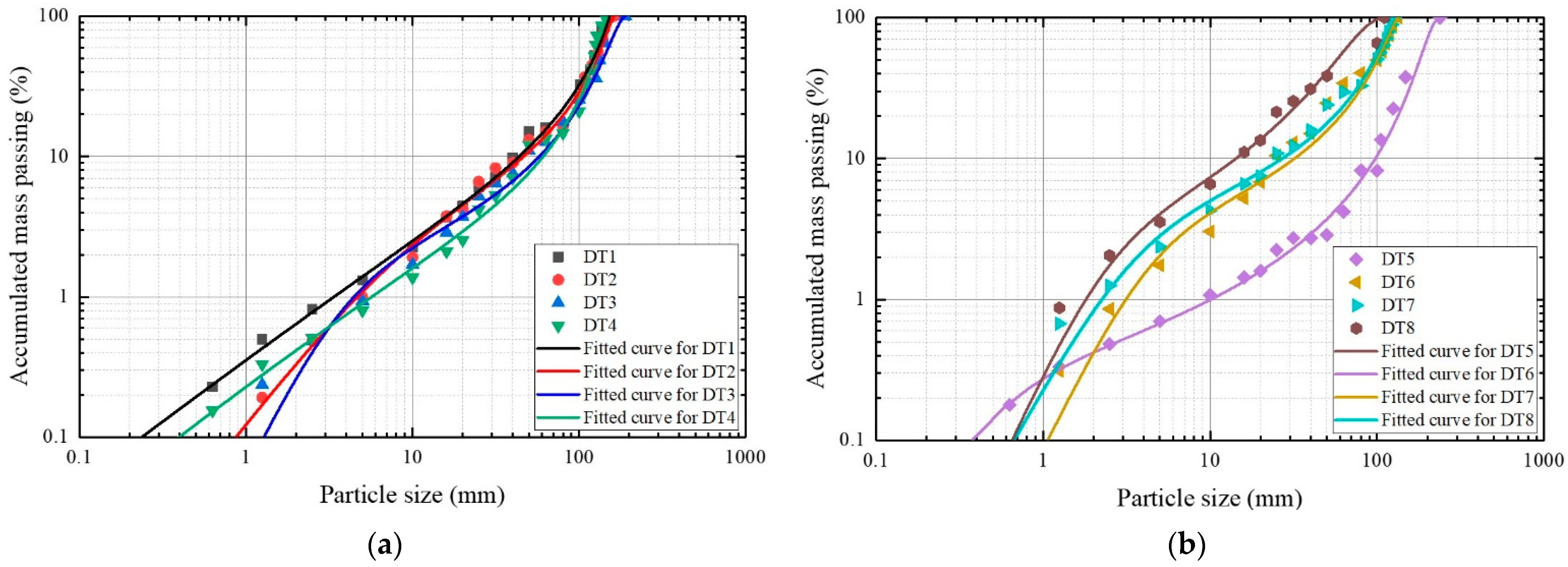

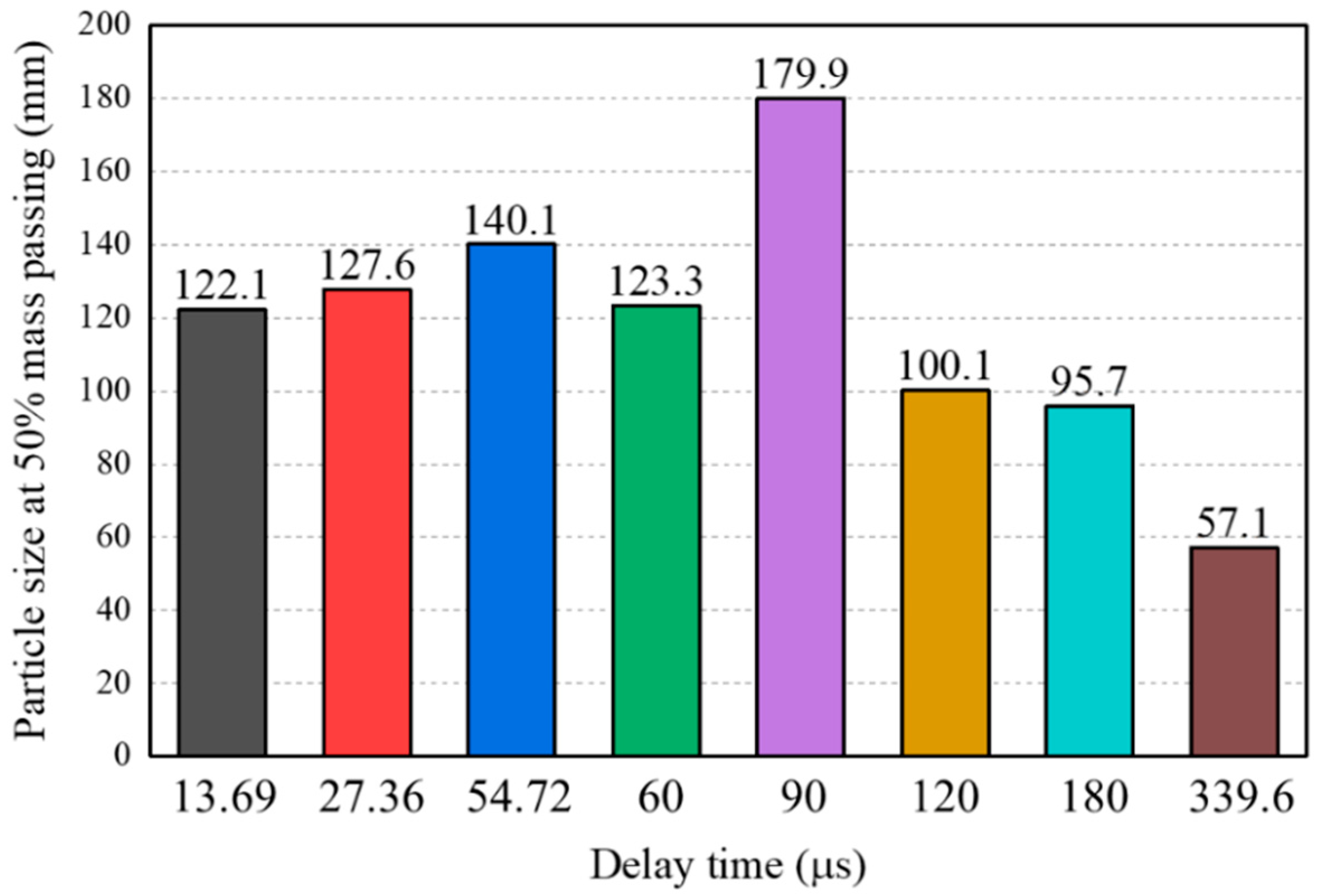

3.4. Fragment Size Distribution

4. Discussion

5. Conclusions

- The 3D-DIC technique is successfully applied to analyze the strain field before visible cracks appear on the bench slope. The results indicate that the development direction of the strain concentration zone changes from horizontal to vertical as the delay time increases.

- The fracture pattern on the bench slope shows that with the delay time increased, the breakage pattern of the bench slope transforms from horizontal cracks dominated to vertical cracks dominated.

- The extended Swebrec function is used to fit the curve of fragment size distribution. As the delay time increases, the difference in fragment size at the same percentage of mass passing becomes progressively significant. While maintaining the excavated rock mass, DT7 can be considered to have the optimal delay time of 180 µs by the average fragment size, ×50, as an evaluation parameter.

- Delay time affects the fragmentation of rock. Fragmentation improves when the delay time is long without the stress wave interaction, especially in the coarse zone.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Size (mm) | DT1 | DT2 | DT3 | DT4 | DT5 | DT6 | DT7 | DT8 |

|---|---|---|---|---|---|---|---|---|

| 0.08 | 3.5 | 0 | 0 | 1.1 | 3.1 | 0 | 1.0 | 0 |

| 0.15 | 11.4 | 0 | 1.3 | 6.9 | 17.4 | 0 | 4.0 | 1.3 |

| 0.315 | 40.0 | 3.5 | 2.5 | 33.6 | 31.6 | 5.6 | 13.8 | 2.3 |

| 0.63 | 64.9 | 52.6 | 56.6 | 47.2 | 45.1 | 67.3 | 152.2 | 43.5 |

| 1.25 | 76.1 | 85.6 | 62.7 | 47.7 | 43.5 | 127.1 | 148.0 | 63.9 |

| 2.5 | 118.6 | 148.1 | 116.2 | 78.5 | 63.1 | 208.4 | 281.6 | 80.6 |

| 5 | 227.3 | 268.7 | 196.1 | 153.4 | 108.6 | 300.6 | 483.8 | 164.3 |

| 10 | 345.6 | 540.0 | 300.8 | 197.7 | 104.7 | 505.5 | 592.5 | 243 |

| 16 | 184.9 | 137.7 | 212.1 | 118.1 | 47.8 | 377.4 | 218.5 | 127.5 |

| 20 | 333.8 | 699.9 | 390.8 | 443.9 | 187.9 | 852.4 | 868.0 | 428.4 |

| 25 | 306.2 | 481.3 | 315.1 | 288.3 | 141.7 | 578.9 | 355.8 | 225.3 |

| 31.5 | 650.5 | 212.9 | 279.1 | 476.1 | 0 | 488.9 | 907.6 | 303.9 |

| 40 | 1274.5 | 1202.2 | 875.5 | 1360.5 | 41.0 | 2244.2 | 2066.0 | 397.0 |

| 50 | 223.7 | 567.5 | 430.5 | 329.3 | 384.3 | 2227.7 | 1431.0 | 152.3 |

| 63 | 0 | 462.6 | 1300.1 | 369.8 | 1169.0 | 1467.0 | 800.1 | 0 |

| 80 | 2530.9 | 2600.1 | 1985.0 | 1681.5 | 0 | 2194.0 | 4503.2 | 1321.3 |

| >100 | 1421.7 | 1577.9 | 2715.0 | 1524.5 | 1572.4 | 1682.3 | 1512.6 | 1847.1 |

| >100 | 2172.1 | 1711.1 | 3134.4 | 1831.0 | 2631.6 | 1930.7 | 1730.1 | |

| >100 | 2563.3 | 2333.6 | 3968.3 | 2385.1 | 4375.9 | 2256.1 | 1957.0 | |

| >100 | 3233.6 | 2975.4 | 9162.2 | 2578.4 | 18,122.7 | 2596.2 | 2146.6 | |

| >100 | 3501.8 | 3625.3 | 2731.8 | 3214.1 | 2474.9 | |||

| >100 | 4761.4 | 3831.7 | 2814.2 | 2710.4 | ||||

| >100 | 5681.1 | 3454.6 | ||||||

| >100 | 3884.3 |

References

- Zhang, Z.-X. Rock Fracture and Blasting: Theory and Applications; Butterworth-Heinemann: Oxford, UK, 2016; ISBN 0128027045. [Google Scholar]

- Fernández, P.R.; Rodríguez, R.; Bascompta, M. Holistic Approach to Define the Blast Design in Quarrying. Minerals 2022, 12, 191. [Google Scholar] [CrossRef]

- Ylitalo, R.M.; Zhang, Z.X.; Bergström, P. Effect of detonator position on rock fragmentation: Full-scale field tests at Kevitsa open pit mine. Int. J. Rock Mech. Min. Sci. 2021, 147, 104918. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Ouchterlony, F. Energy Requirement for Rock Breakage in Laboratory Experiments and Engineering Operations: A Review. Rock Mech. Rock Eng. 2022, 55, 629–667. [Google Scholar] [CrossRef]

- Nikkhah, A.; Vakylabad, A.B.; Hassanzadeh, A.; Niedoba, T.; Surowiak, A. An Evaluation on the Impact of Ore Fragmented by Blasting on Mining Performance. Minerals 2022, 12, 258. [Google Scholar] [CrossRef]

- Wilson, W.H.; Holloway, D.C. Fragmentation studies in instrumented concrete models. In Proceedings of the 6th ISRM Congress, Montreal, Canada, 30 August–3 September 1987; OnePetro: Richardson, TX, USA, 1987. [Google Scholar]

- Johansson, D.; Ouchterlony, F. Shock Wave Interactions in Rock Blasting: The Use of Short Delays to Improve Fragmentation in Model-Scale. Rock Mech. Rock Eng. 2013, 46, 18. [Google Scholar] [CrossRef]

- Hashemi, A.S.; Katsabanis, P. The Effect of Stress Wave Interaction and Delay Timing on Blast-Induced Rock Damage and Fragmentation. Rock Mech. Rock Eng. 2020, 53, 2327–2346. [Google Scholar] [CrossRef]

- Yin, Z.; Wang, D.; Wang, X.; Dang, Z.; Li, W. Optimization and application of spacing parameter for loosening blasting with 24-m-high bench in barun open-pit mine. Shock Vib. 2021, 2021, 6670276. [Google Scholar] [CrossRef]

- Sanchidrián, J.A.; Segarra, P.; Ouchterlony, F.; Gómez, S. The Influential Role of Powder Factor vs. Delay in Full-Scale Blasting: A Perspective Through the Fragment Size-Energy Fan. Rock Mech. Rock Eng. 2022, 55, 4209–4236. [Google Scholar] [CrossRef]

- Rossmanith, H.P.; Kouzniak, N. Supersonic Detonation in Rock Mass—Part 2: Particle Displacements and Velocity Fields for Single and Multiple Non-Delayed and Delayed Detonating Blastholes. Fragblast 2004, 8, 95–117. [Google Scholar] [CrossRef]

- Rossmanith, H.P. The Use of Lagrange Diagrams in Precise Initiation Blasting. Part I: Two Interacting Blastholes. Fragblast 2002, 6, 104–136. [Google Scholar] [CrossRef]

- Vanbrabant, F.; Espinosa, A. Impact of short delays sequence on fragmentation by means of electronic detonators: Theoretical concepts and field validation. Fragblast 2006, 8, 326–331. [Google Scholar]

- Chiappetta, F. Combining electronic detonators with stem charges and air decks. In Proceedings of the Drill and Blast 2010 Conference, Brisbane, QLD, Australia, 12–14 October 2010. [Google Scholar]

- Mckinstry, R. Implementation of Electronic Detonators at Barrick Goldstrike Mines, Inc. In Proceedings of the Annual Conference on Explosives and Blasting Technique, New Orleans, LA, USA, 1–4 February 2004; Volume 1, pp. 349–360. [Google Scholar]

- Blair, D. Blast vibration control in the presence of delay scatter and random fluctuations between blastholes. Int. J. Numer. Anal. Methods Geomech. 1993, 17, 95–118. [Google Scholar] [CrossRef]

- Blair, D. A comparison of Heelan and exact solutions for seismic radiation from a short cylindrical charge. Geophysics 2007, 72, E33–E41. [Google Scholar] [CrossRef]

- Katsabanis, P.D.; Tawadrous, A.; Braun, C.; Kennedy, C. Timing effects on the fragmentation of small scale blocks of granodiorite. Fragblast 2006, 10, 83–93. [Google Scholar] [CrossRef]

- Schimek, P. Improvement of Fragmentation by Blasting-Investigation of the Influence of Delay-Times on the Crack Development in the Surrounding Rock, the Characteristics of the Blasted Bench Face and the Fragmentation of the Further Rows. Ph.D. Thesis, University of Leoben, Leoben, Austria, 2015. [Google Scholar]

- Omidi, O. Timing Effects on Fragmentation by Blasting. Ph.D. Thesis, Queen’s University, Kingston, ON, Canada, 2015. [Google Scholar]

- Schill, M.; Sjöberg, J. Finite Element simulations of blasting and fragmentation with precise initiation. In Proceedings of the 12th International LS-DYNA Users Conference, Detroit, MI, USA, 3–5 June 2012; pp. 1–10. [Google Scholar]

- Rathore, S.S.; Bhandari, S. Controlled fracture growth by blasting while protecting damages to remaining rock. Rock Mech. Rock Eng. 2007, 40, 317–326. [Google Scholar] [CrossRef]

- Wu, B.; Xia, K.; Guo, Y. Influence of hydrostatic confining pressure on the dynamic tensile failure of rock material. In Proceedings of the 50th US Rock Mechanics/Geomechanics Symposium, Houston, TX, USA, 26–29 June 2016; OnePetro: Richardson, TX, USA, 2016. [Google Scholar]

- Zhao, J.; Zhou, Y.X.; Hefny, A.M.; Cai, J.G.; Chen, S.G.; Li, H.B.; Liu, J.F.; Jain, M.; Foo, S.T.; Seah, C.C. Rock dynamics research related to cavern development for ammunition storage. Tunn. Undergr. Space Technol. 1999, 14, 513–526. [Google Scholar] [CrossRef]

- Zhang, Q.B.; Zhao, J. A review of dynamic experimental techniques and mechanical behaviour of rock materials. Rock Mech. Rock Eng. 2014, 47, 1411–1478. [Google Scholar] [CrossRef]

- Zhang, Q.B.; Zhao, J. Determination of mechanical properties and full-field strain measurements of rock material under dynamic loads. Int. J. Rock Mech. Min. Sci. 2013, 60, 423–439. [Google Scholar] [CrossRef]

- Lenoir, N.; Bornert, M.; Desrues, J.; Bésuelle, P.; Viggiani, G. Volumetric digital image correlation applied to X-ray microtomography images from triaxial compression tests on argillaceous rock. Strain 2007, 43, 193–205. [Google Scholar] [CrossRef]

- Bornert, M.; Vales, F.; Gharbi, H.; Nguyen Minh, D. Multiscale full-field strain measurements for micromechanical investigations of the hydromechanical behaviour of clayey rocks. Strain 2010, 46, 33–46. [Google Scholar] [CrossRef]

- Hedan, S.; Cosenza, P.; Valle, V.; Dudoignon, P.; Fauchille, A.-L.; Cabrera, J. Investigation of the damage induced by desiccation and heating of Tournemire argillite using digital image correlation. Int. J. Rock Mech. Min. Sci. 2012, 51, 64–75. [Google Scholar] [CrossRef]

- Cheng, J.-L.; Yang, S.-Q.; Chen, K.; Ma, D.; Li, F.-Y.; Wang, L.-M. Uniaxial experimental study of the acoustic emission and deformation behavior of composite rock based on 3D digital image correlation (DIC). Acta Mech. Sin. 2017, 33, 999–1021. [Google Scholar] [CrossRef]

- Munoz, H.; Taheri, A. Local damage and progressive localisation in porous sandstone during cyclic loading. Rock Mech. Rock Eng. 2017, 50, 3253–3259. [Google Scholar] [CrossRef]

- Xing, H.Z.; Zhang, Q.B.; Ruan, D.; Dehkhoda, S.; Lu, G.X.; Zhao, J. Full-field measurement and fracture characterisations of rocks under dynamic loads using high-speed three-dimensional digital image correlation. Int. J. Impact Eng. 2018, 113, 61–72. [Google Scholar] [CrossRef]

- Zhou, Z.; Yuan, Z.; Jiang, Y.; Yang, Z.O.U.; Xin, C.A.I.; Li, D. Dynamic behavior of rock during its post failure stage in SHPB tests. Trans. Nonferrous Met. Soc. China 2017, 27, 184–196. [Google Scholar] [CrossRef]

- Xu, X.; Chi, L.-Y.; Yang, J.; Yu, Q. Experimental Study on the Temporal and Morphological Characteristics of Dynamic Tensile Fractures in Igneous Rocks. Appl. Sci. 2021, 11, 11230. [Google Scholar] [CrossRef]

- Xu, X.; Chi, L.-Y.; Yang, J.; Lv, N. Investigation on the Deformation and Failure Characteristics of Concrete in Dynamic Splitting Tests. Materials 2022, 15, 1681. [Google Scholar] [CrossRef]

- Yang, L.; Ding, C.; Yang, R.; Lei, Z.; Wang, J. Full field strain analysis of blasting under high stress condition based on digital image correlation method. Shock Vib. 2018, 2018, 4894078. [Google Scholar] [CrossRef]

- Chi, L.Y.; Zhang, Z.X.; Aalberg, A.; Yang, J.; Li, C.C. Fracture Processes in Granite Blocks Under Blast Loading. Rock Mech. Rock Eng. 2019, 52, 853–868. [Google Scholar] [CrossRef]

- Yang, J.; Liu, X.; Xu, Z.; Tang, H.; Yu, Q. Full-Field Strain Characterizations and Fracture Process of Rock Blasting Using a Small-Scale Double-Hole Bench Model. Adv. Civ. Eng. 2020, 2020, 8649258. [Google Scholar] [CrossRef]

- He, C.; Yang, J. Experimental and numerical investigations of dynamic failure process in rock under blast loading. Tunn. Undergr. Space Technol. 2019, 83, 552–564. [Google Scholar] [CrossRef]

- Yang, J.; Liu, X.; Xu, Z.; Tang, H.; Yu, Q. Study of Rock Blasting Failure Pattern with One Free Boundary. Adv. Civ. Eng. 2020, 2020, 1926824. [Google Scholar] [CrossRef]

- Zhang, Z.-X.; Hou, D.-F.; Guo, Z.; He, Z.; Zhang, Q. Experimental study of surface constraint effect on rock fragmentation by blasting. Int. J. Rock Mech. Min. Sci. 2020, 128, 104278. [Google Scholar] [CrossRef]

- Zhang, Z.-X.; Hou, D.-F.; Guo, Z.; He, Z. Laboratory experiment of stemming impact on rock fragmentation by a high explosive. Tunn. Undergr. Space Technol. 2020, 97, 103257. [Google Scholar] [CrossRef]

- Liu, M.; Liu, J.; Zhen, M.; Zhao, F.; Xiao, Z.; Shan, P.; Wang, Y.; Ou, C.; Zheng, H.; Liu, Z. A comprehensive evaluation method of bench blast performance in open-pit mine. Appl. Sci. 2020, 10, 5398. [Google Scholar] [CrossRef]

- Ouchterlony, F. The Swebrec function: Linking fragmentation by blasting and crushing. Min. Technol. 2005, 114, 29–44. [Google Scholar] [CrossRef]

- Sanchidrián, J.A.; Ouchterlony, F.; Moser, P.; Segarra, P.; López, L.M. Performance of some distributions to describe rock fragmentation data. Int. J. Rock Mech. Min. Sci. 2012, 53, 18–31. [Google Scholar] [CrossRef]

- Yi, C.; Sjöberg, J.; Johansson, D.; Petropoulos, N. A numerical study of the impact of short delays on rock fragmentation. Int. J. Rock Mech. Min. Sci. 2017, 100, 250–254. [Google Scholar] [CrossRef]

- Yi, C.; Sjöberg, J.; Johansson, D. Numerical modelling for blast-induced fragmentation in sublevel caving mines. Tunn. Undergr. Space Technol. 2017, 68, 167–173. [Google Scholar] [CrossRef]

- Chi, L.Y.; Zhang, Z.-X.; Aalberg, A.; Li, C.C. Experimental Investigation of Blast-Induced Fractures in Rock Cylinders. Rock Mech. Rock Eng. 2019, 52, 2569–2584. [Google Scholar] [CrossRef]

- Sanchidrián, J.A.; Segarra, P.; López, L.M.; Ouchterlony, F.; Moser, P. Evaluation of some distribution functions for describing rock fragmentation data. In Proceedings of the 9th International Symposium on Rock Fragmentation by Blasting, FRAGBLAST 9, Granada, Spain, 13–17 August 2009; pp. 239–248. [Google Scholar]

- Sanchidrián, J.A.; Ouchterlony, F.; Segarra, P.; Moser, P. Size distribution functions for rock fragments. Int. J. Rock Mech. Min. Sci. 2014, 71, 381–394. [Google Scholar] [CrossRef]

- Ouchterlony, F. Reply to Discussion of “The Case for the Median Fragment Size as a Better Fragment Size Descriptor than the Mean” by Finn Ouchterlony, Rock Mech. Rock Eng., published online 15 March 2015. Rock Mech. Rock Eng. 2016, 49, 339–342. [Google Scholar] [CrossRef]

- Bergmann, O.R.; Riggle, J.W.; Wu, F.C. Model rock blasting—Effect of explosives properties and other variables on blasting results. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1973, 10, 585–612. [Google Scholar] [CrossRef]

| Specimen No. | Delay Time (µs) | Charge Weight of A (g) | Charge Weight of B (g) |

|---|---|---|---|

| DT1 | 13.69 | 4.6 | 4.63 |

| DT2 | 27.36 | 4.58 | 4.57 |

| DT3 | 54.72 | 4.59 | 4.61 |

| DT4 | 60 | 4.58 | 4.59 |

| DT5 | 90 | 4.63 | 4.58 |

| DT6 | 120 | 4.61 | 4.57 |

| DT7 | 180 | 4.56 | 4.62 |

| DT8 | 339.6 | 4.57 | 4.59 |

| Specimen No. | Delay Time (μs) | xmax (mm) | x50 (mm) | a | b | c | R2 |

|---|---|---|---|---|---|---|---|

| DT1 | 13.69 | 152.3 | 122.1 | 0.2227 | 1.438 | 0.907 | 0.9784 |

| DT2 | 27.36 | 161.5 | 127.6 | 0.9568 | 1.249 | 1.528 | 0.9629 |

| DT3 | 54.72 | 189.4 | 140.1 | 0.9996 | 1.599 | 2.425 | 0.9514 |

| DT4 | 60 | 142.3 | 123.3 | 0.3709 | 1.357 | 0.9428 | 0.9631 |

| DT5 | 90 | 237.7 | 179.9 | 0.9998 | 1.889 | 1.968 | 0.9637 |

| DT6 | 120 | 133.6 | 100.1 | 0.9995 | 1.365 | 2.443 | 0.9654 |

| DT7 | 180 | 126.2 | 95.7 | 0.9989 | 1.266 | 2.145 | 0.9728 |

| DT8 | 339.6 | 111.0 | 57.1 | 0.9987 | 1.929 | 2.601 | 0.9441 |

| Specimen No. | Delay Time (μs) | x0.1 (mm) | x1 (mm) | x50 (mm) | x100 (mm) |

|---|---|---|---|---|---|

| DT1 | 13.69 | 0.24 | 3.37 | 122.1 | 152.3 |

| DT2 | 27.36 | 0.87 | 4.65 | 127.6 | 161.5 |

| DT3 | 54.72 | 1.27 | 4.44 | 140.1 | 189.4 |

| DT4 | 60 | 0.39 | 5.67 | 123.3 | 142.3 |

| DT5 | 90 | 0.37 | 10.10 | 179.9 | 237.7 |

| DT6 | 120 | 1.06 | 3.13 | 100.1 | 133.6 |

| DT7 | 180 | 0.67 | 2.25 | 95.7 | 126.2 |

| DT8 | 339.6 | 0.65 | 1.80 | 57.1 | 111.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, H.-L.; Liu, X.; Yang, J.; Yu, Q. Experimental Study on the Influence of Delay Time on Rock Fragmentation in Bench Blasting. Appl. Sci. 2023, 13, 85. https://doi.org/10.3390/app13010085

Tang H-L, Liu X, Yang J, Yu Q. Experimental Study on the Influence of Delay Time on Rock Fragmentation in Bench Blasting. Applied Sciences. 2023; 13(1):85. https://doi.org/10.3390/app13010085

Chicago/Turabian StyleTang, Hong-Liang, Xin Liu, Jun Yang, and Qi Yu. 2023. "Experimental Study on the Influence of Delay Time on Rock Fragmentation in Bench Blasting" Applied Sciences 13, no. 1: 85. https://doi.org/10.3390/app13010085

APA StyleTang, H.-L., Liu, X., Yang, J., & Yu, Q. (2023). Experimental Study on the Influence of Delay Time on Rock Fragmentation in Bench Blasting. Applied Sciences, 13(1), 85. https://doi.org/10.3390/app13010085