Heat Transfer Enhancement of Nanofluids with Non-Spherical Nanoparticles: A Review

Abstract

:1. Introduction

2. Thermal Conductivity of NSN Nanofluids

2.1. Experimental Data Evaluation

2.1.1. CNTs/Nanofibers/Nanowires

2.1.2. Nanorods/Ellipsoids

2.1.3. Platelets/Blades/Bricks/Diamonds/Polygons

| Authors | Nanofluid Type | Particle Shape and Size (nm as Default) | Volume Fraction ϕ (Vol. as Default) | Temperature | Maximum TCE |

|---|---|---|---|---|---|

| Xie et al. [30] | SiC–water/EG | Cylindrical 600 (d) | <4.2% | 4 °C | 22.9% |

| Xie et al. [22] | CNTs–DE/EG/DW | Nanotube 15 (d) × 30 mm (l) | 1% | - | 19.6% in DE, 12.7% in EG, 7.0% in DW |

| Assael et al. [45] | CNTs–water | Nanotube, 30 to 250 (d), l > 70,000 | 0.6% | Room | 38% |

| Murshed et al. [2] | TiO2–water | Nanorod 10 (d) × 40 (l) | <5% | Room | 33% |

| Yang and Han [31] | Bi2Te3–perfluoro–n–hexane | Nanorod 20 (d) × 170 (l) | 0.8% | 3–50 °C | 7.7% at 3 °C, 6.3% at 50 °C |

| Yang and Han [31] | Bi2Te3–hexadecane oil | Nanorod 20 (d) × 170 (l) | 0.8% | 20–50 °C | 6.1% at 20 °C, 3.9% at 50 °C |

| Zhang et al. [15] | CNTs–water | Nanofiber 150 (d) × 10,000 (l) | 0.1–0.89% | 23 °C | 40% |

| Zhu et al. [33] | CuO–water | Nanorod 30–50 (d) × 200–300 (l) | 0.1–10% | Room | 18% at ϕ = 1%, 28% at ϕ = 3%, 31% at ϕ = 5% |

| Chen et al. [3] | TiO2–water | Nanorod 10 (d) × 100 (l) | 0.12, 0.24, and 0.60% | 20–40 °C | 5.38% |

| Singh et al. [38] | SiC–water | Platelet 170 (d) | <4% | Room | ~29.51% |

| Timofeeva et al. [34] | Al2O3–EG and water (50/50) | Platelet 16 (d) × 3 (l) | <7% | 21 °C | 18% at ϕ = 7% |

| Timofeeva et al. [34] | Al2O3–EG and water (50/50) | Blade36 (d) × 6 (l) | <7% | 21 °C | 18% at ϕ = 7% |

| Timofeeva et al. [34] | Al2O3–EG and water (50/50) | Cylinder 8 (d) × 64 (l) | <8.5% | 21 °C | 35% at ϕ = 8.5% |

| Timofeeva et al. [34] | Al2O3–EG and water (50/50) | Brick 54 (l) | <7% | 21 °C | 25% at ϕ = 7% |

| Torii and Yang [40] | nanodiamonds–water | Diamond 10 (d) | <5% | - | 16% |

| Xie et al. [41] | nanodiamonds–water/EG | Diamond 30–50 (d) | <2% | 10–60 °C | 18% |

| Yu et al. [10] | Al2O3–PAO | Nanorod 7 (d) ×85 (l) | <1.3% | 25 °C | 12% at ϕ = 1.3% |

| Nasiri et al. [46] | SWNT/SWNT/ FWNT/MWNT–water | - | 0.25 wt.% | 15–40 °C | 13%, 16%, 21% |

| Gu et al. [24] | CNTs–water | Nanofiber 10–15 (d) × 10–20 µm (l) | 0.2% | 25 °C | 3.7% |

| Gu et al. [24] | Ag–water | Nanowire 60 (d) × 20,000–30,000 (l) | 0.2% | 25 °C | 12.1% |

| Gu et al. [24] | Cu–water | Nanowire 100–200 (d) × 800–6000 (l) | 0.2% | 25 °C | 2.8% |

| Ferrouillat et al. [42] | SiO2–water | Banana-like | 0.82% | 20–70 °C | 2% at 70 °C |

| Ferrouillat et al. [42] | ZnO–water | Nanorod | 0.93% | 20–70 °C | 1% at 70 °C |

| Fang et al. [47] | Ag–EG | Nanowire 100 (d) × 50,000 (l) | 0.1% | 10–30 °C | 15.6% |

| Platelet, 300–400 (d) × 30–40 (l) | 5.3% | ||||

| Jeong et al. [48] | ZnO–water | Nanorod, 150–370 (d) | 0.5–5% | Room | 19.8% |

| Kim et al. [39] | Al2O3–water | Platelets,15 (d) × 5 (l) | 0.3–7% | 20–80 °C | 23% |

| Blades, 15 (l) × 8 (w) × 5 (h) | 16% | ||||

| Bricks, 40 (d) × 40 (l) × 20 (l) | 28% | ||||

| Farbod et al. [49] | CuO–engine oil | Nanorod | <6 wt.% | 25 °C | 8.3% |

| 8.3% | TiO2–water | Cubic, 87.21 (d) Nanorod, 8.27 (d) × 92.47 (l) | <2.5 wt.% | 27–87 °C | 169% |

| 96% | |||||

| Zhang et al. [28] | Ag–EG | Nanowire 40 (d) × 1000 (l) | 0.46% | 25 °C | 13.42% |

| Zhu et al. [27] | CuO–dimethicone | Nanowire 30–80 (d) × 3500–5500 (l) | 0.15% | 25 °C | 13.42% |

| 0.3% | 23.15% | ||||

| 0.45% | 36.98% | ||||

| 0.6% | 47.67% | ||||

| 0.75% | 60.78% | ||||

| Shah et al. [50] | CuO–EG and DW (70/30) | Cube, 68.4 (l) | 0.3% | 30–80 °C | 16.98% |

| Brick, AR = 1.07 | 22.30% | ||||

| Polygonal, AR = 1.57 | 29.50% | ||||

| Nanorod, AR = 5.84 | 33.17% | ||||

| Carbajal et al. [29] | Ag–water | Nanowire 96 (d) × 40,000 (l) | 0.0174% | Room | 20.8% |

| Maheshwary et al. [25] | CuO–water | Cubic, | 2.5 wt.% | 30 °C | 72.49% |

| Nanorod | 48.81% | ||||

| Maheshwary et al. [25] | MgO–water | Cubic, | 2.5 wt.% | 30 °C | 110.96% |

| Nanorod | 72.57% | ||||

| Maheshwary et al. [25] | TiO2–water | Cubic | 2.5 wt.% | 30 °C | 148.46% |

| Nanorod | 115.55% | ||||

| Maheshwary et al. [25] | ZrO2–water | Cubic, | 2.5 wt.% | 30 °C | 164.01% |

| Nanorod | 135.36% | ||||

| Maheshwary et al. [25] | Al2O3–water | Cubic, | 2.5 wt.% | 30 °C | 209.70% |

| Nanorod | 173.31% | ||||

| Nithiyanantham et al. [36] | Al2O3–molten salt | Nanorod, 3–7 (d) × 30–70 (l) | 1 wt.% | 50–200 °C | 10.08% |

| Cui et al. [35] | TiO2–water | Ellipsoidal, 20 (d) × 30 (l) | 0.5–4% | 20–60 °C | 20.58% |

| Nanorod, 15 (d) × 35 (l) | 20.63% | ||||

| Sheet, 5 (w) × 70 (l) × 70 (h) | 23.43% | ||||

| Ni et al. [51] | Cu2O–water | Nanowire, 2–3 (d) | - | 30–80 °C | 66.8% |

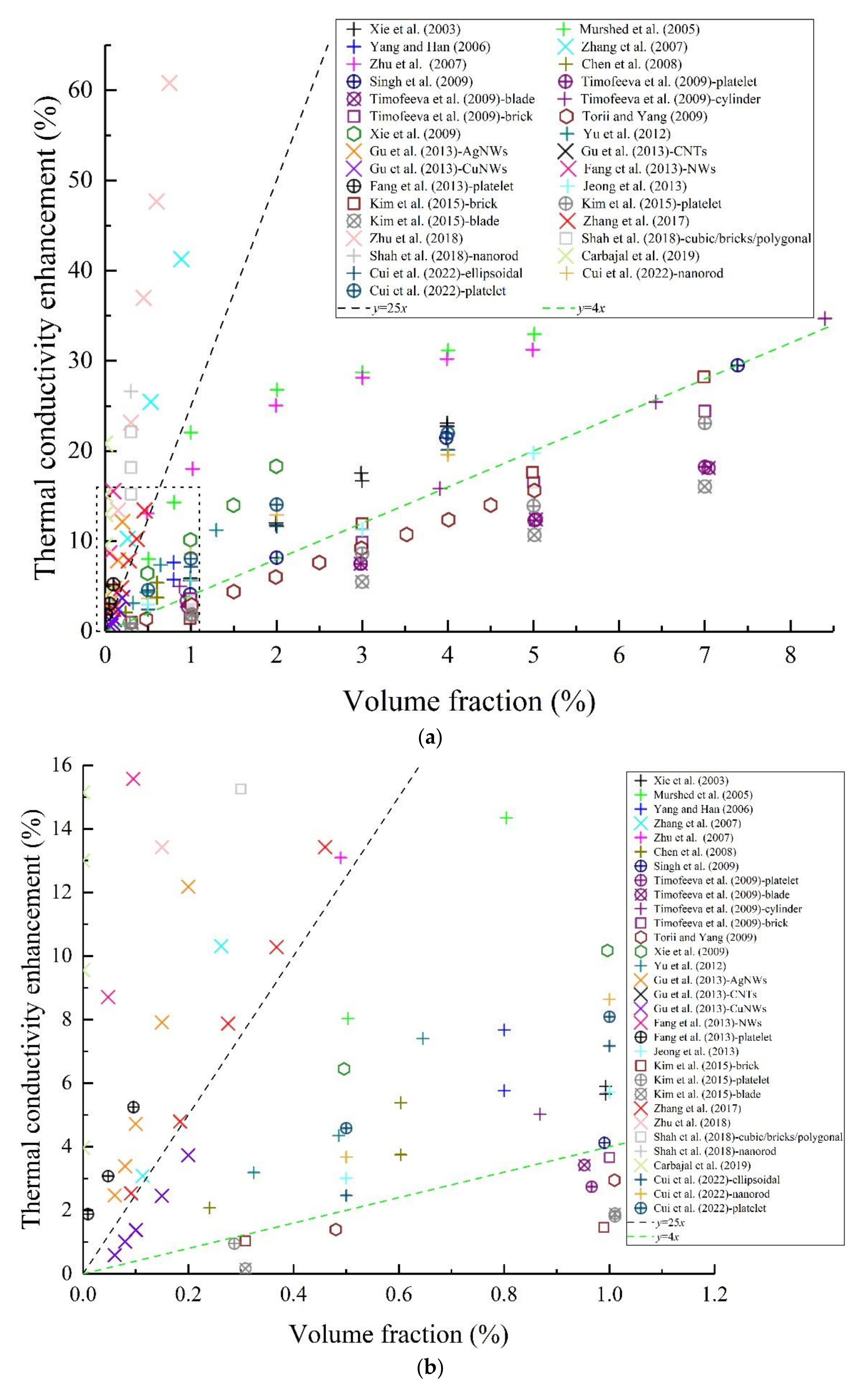

: platelets;

: platelets;  : blades; □: bricks;

: blades; □: bricks;  : diamonds). (a) Full range. (b) Enlarged low-volume-fraction region (volume fraction < 1.2%, TCE < 16%) [2,3,10,15,22,24,27,28,29,31,33,34,35,38,39,40,41,47,48,50].

: diamonds). (a) Full range. (b) Enlarged low-volume-fraction region (volume fraction < 1.2%, TCE < 16%) [2,3,10,15,22,24,27,28,29,31,33,34,35,38,39,40,41,47,48,50].

: platelets;

: platelets;  : blades; □: bricks;

: blades; □: bricks;  : diamonds). (a) Full range. (b) Enlarged low-volume-fraction region (volume fraction < 1.2%, TCE < 16%) [2,3,10,15,22,24,27,28,29,31,33,34,35,38,39,40,41,47,48,50].

: diamonds). (a) Full range. (b) Enlarged low-volume-fraction region (volume fraction < 1.2%, TCE < 16%) [2,3,10,15,22,24,27,28,29,31,33,34,35,38,39,40,41,47,48,50].

2.2. Numerical Predictions and Mechanism Discussion

2.2.1. Interfacial Layer Theory

2.2.2. Nanoparticle Aggregation

2.2.3. Network Effect

2.2.4. Rotational Diffusion and Micro Convection

| Authors | Particle Shape | Models (knf/kf as Default) | Remarks |

|---|---|---|---|

| Hamilton and Crosser [53] | Arbitrary | Reduce to Maxwell model when n = 3 | |

| Yamada and Ota [79] | Cylinder | Unit-cell model Consider the shape factor K = 2ϕ0.2 (2 l/d) for cylindrical particles | |

| Wang et al. [54] | Aggregates | Combine the effective medium approximation and the fractal theory | |

| Nan et al. [57] | CNTs | Incorporating the interface thermal resistance | |

| Xue [73] | CNTs | Based on Maxwell theory and considering the random CNT orientation distribution | |

| Zhou and Gao [58] | Ellipsoid | Complicated | Differential effective medium theory |

| Ebrahimi et al. [74,75] | Cylinders/CNTs | Interfacial layer theory Brownian motion is neglected | |

| Sastry et al. [71] | CNTs | Assuming CNT contacts only two neighboring CNTs | |

| Koo et al. [72] | CNTs/CNFs | Based on model proposed by [71] | Excluded volume concept Monte Carlo simulation |

| Murshed et al. [59] | Cylinder | Deduced in cylindrical coordinates | |

| Timofeeva et al. [34] | Rods/bricks/ platelets/blades | Consider particle shape and interfacial contributions | |

| Chandrasekar et al. [61] | Arbitrary | Consider interfacial layer, particle shape, and Brownian motion | |

| Cui et al. [78] | Cylinder | 14.8% enhancement MD simulation based on the Green–Kubo formula | |

| Jiang et al. [60] | CNTs | Interfacial layer theory | |

| Yang et al. [64] | Cylinder | Interfacial layer theory Consider end effect of cylinder | |

| Yang et al. [62] | Cylinder | Interfacial layer theory Anisotropy analysis | |

| Yang and Xu [63] | Cylinder | Based on Hamilton–Crosser model Interfacial layer theory Anisotropy analysis | |

| Wang et al. [67] | Aggregates (2–6 spheres) | Increases linearly with decrease in fractal dimension of aggregations | MD simulation Interfacial layer effect |

| Du et al. [69] | Aggregates (6–32 spheres) | Increases linearly with decrease in fractal dimension of aggregations | MPCD-MD simulation Interfacial layer effect |

| Tahmooressi et al. [44] | Cylinder | Lattice Boltzmann method | |

| Cui et al. [35] | Arbitrary | - | CFFNN model Artificial intelligence estimation |

3. Convective Heat Transfer of NSN Nanofluids

3.1. Experimental Data Evaluation

3.1.1. Different Analysis Parameters and Values

3.1.2. Thermohydraulic Performance Evaluation

- The ratio of CHT coefficient, ;

- The ratio of the maximum overall temperature difference, ;

- Cooling with minimum pumping power, ;

- The relative ratio of heat transfer rate and pumping power, .

| Authors | Nanofluid | Particle Shape and Size (nm) | Particle Loading | Flow State | CHT Enhancement |

|---|---|---|---|---|---|

| Yang et al. [23] | Graphite–ATF graphite–oils | Plate-like, 1–2 µm (d) × 20–40 (l) | 2, 2.5 wt.% | Laminar, 5 < Re < 110 | Re↑, h↑ ϕ↑, h↑ T↑, h↓ |

| Ding et al. [105] | CNTs–water | - | <1 wt.% | Laminar, 800 < Re < 1200 | ϕ↑, h↑ (significantly) x/D↑, h↓, Δh/h  pH↑, h↓ |

| Chen et al. [3] | Titanate NTs–water | Nanotube 10 (d) × 100 (l) | 0.5, 1.0 and 2.5 wt.% | Laminar, 1100 < Re < 2300 | ϕ↑, h↑ x/D↑, h↓ Re↑, h↑ |

| Nelson et al. [97] | Graphite–PAO | Plate-like, 20 µm (d) × 100 (l) | 0.3 and 0.6 wt.% | Laminar, 72 < Re < 365 | ϕ↑, h↑ |

| Ji et al. [96] | Al2O3–EG and water (50/50) | Platelet, 9 (l) Blade, 60 (l) Cylinder, 80 (l)Brick, 40 (l) | 0.3, 1, 3, and 5 vol.% | Oscillating heat pipe with input power 25–250 W | Heat transfer was enhanced significantly, nanofluids with cylindrical nanoparticles achieve the best performance |

| Yu et al. [10] | Al2O3–PAO | Nanorod 7 (d) × 85 (l) | 0.65, 1.3 vol.% | Laminar, 150 < Re < 450 | Re↑, h↑ ϕ↑, h↑ x/D↑, h↓ |

| Ferrouillat et al. [42] | SiO2–water | Banana-like (nanorod) | 2.28 vol.% | 200 < Re < 15,000 | Larger Nu for particles in banana shape than sphere in turbulent regime |

| Ferrouillat et al. [42] | ZnO–water | Polygonal/nanorod | 0.82, 0.9 vol.% | 200 < Re < 15,000 | 8% and 3% increase in Nu, respectively |

| Paul et al. [95] | Al2O3–NEILs | Whisker | 0.18, 0.36, 0.9 vol.% | - | Degradation of natural convection |

| Wu et al. [102] | CNTs–water | Nanotube 9.5 (d) × 1500 (l) | <1 wt.% | - | Has no CHT enhancement |

| Arshad and Ali [100] | Graphene–water | Platelet, 5000–10,000 (d) | 10 vol.% | 300 < Re < 1000 | Re↑, h↑ Pumping power increases as well |

| Mikkola et al. [101] | Al2O3–water | Ellipsoid, 10 (d) | 0.5, 1 vol.% | 1000 < Re < 11,000 | Re↑, h↑, Nu↑ Φ/k↑, h = enhancement < 5% |

| Contreras et al. [103] | Graphene–EG and water (50/50) | Platelet | 0.01, 0.05, 1 vol.% | Thermohydraulic performance coefficient ≈ 1 | |

| Bai et al. [104] | Graphene oxide–DI | Platelet, 0.8–1.2 (h) × 500–5000 (d) | 0.02, 0.05, 0.075, 0.1 vol.% | 150–800 | ϕ↑, Nu ratio↑ Re↑, Nu ratio↑ |

3.2. Numerical Predictions and Mechanism Discussion

3.2.1. Particle Concentration Distribution and Interaction

3.2.2. Particle Rotational Diffusion and Orientation Distribution

| Authors | Nanofluid | Particle Shape and Size (nm) | Particle Loading | Flow State | CHT Enhancement |

|---|---|---|---|---|---|

| Elias et al. [112,113] | γ-AlOOH–EG and water (50/50) | Cylinder, AR = 1:8 Brick, AR = 1:1:1 Blade, AR = 1:6:1/12 Platelet, AR = 1:1/8 | <1 vol.% | In shell and tube heat exchanger | Cylinder >brick > blade > platelet > sphere, for h, entropy generation, and heat transfer rate of nanofluid |

| Amin et al. [114] | Al2O3–water/Ethylene glycol | Platelets, AR = 0.125 Blades, 1:6:1.12 Cylinders, AR = 8 Bricks, 1:1:1 | 1 vol.% | Flat-plate solar collector tube 12,000 < Re < 25,000 | Brick-shape particles have the highest Nusselt number |

| Ooi and Popov [115] | Cu–water | Oblate spheroid, Prolate spheroid | <20 vol.% | Natural convection in a square cavity | Increases the CHT as well as flow resistance |

| Lin et al. [116] | Cu–water | Cube, rod, lamina, tetrahedron | <6 vol.% | Marangoni boundary layer flow | Sphere nanoparticles have the best CHT enhancement |

| Lin et al. [107] | Al2O3–PAO | Cylinder AR = 6, 12, 18 | 0.65, 1.3, 2.5 vol.% | Laminar, 100 < Re < 2000 | Nusselt number increases with ϕ, derived Nu formula based on the numerical data |

| Yuan et al. [117] | ZnO–water | Cylinder AR = 8, 12, 16 | 0.4, 0.93, 1.3 vol.% | Turbulent, 2500 < Re < 15,000 | Nunf/Nuf increases when Reynolds number, AR and ϕ grow |

| Trodi and Benhamza [118] | Al2O3–water | Oblate spheroid, dp = 1 Prolate spheroid, dp = 2, 5, 7.5 and 10 | 5, 10 vol.% | Flow in differentially heated square enclosures, 103 < Ra < 106 | Heat transfer increases with Ra and ϕ, oblate spheroid has the best performance |

| Liu et al. [119] | Al2O3–water | Platelet, 78.6 (d) × 9.8 (l) Blade, 85 (l) × 14.15 (w) ×1.18 (h) Cylinder, 19.6 (d) × 157 (l) Brick, 36.6 (l) | 0.5, 1, 1.5, 2 vol.% | Curved square duct laminar flow | Eulerian–Lagrangian two-phase approach |

| Sheikhzadeh and Aghaei [120] | Al2O3/SiO2–water | Platelets, AR = 0.125 Blades, 1:6:1.12 Cylinders, AR = 8 Bricks, 1:1:1 | 2–4 vol.% | Square cavity flow, 105 < Ra < 107 | Platelets and cylindrical nanoparticles are more effective |

| Lin et al. [121] | ZnO–water | Cylinder AR = 2, 6, 10, 14 | <5 vol.% | Curved pipe flow, 5000 ≤ Re ≤ 30,000 | Nanofluid PEC is higher than base fluid PEC |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| NSN nanofluid | Nanofluid containing non-spherical nanoparticles |

| TCE | Thermal conductivity enhancement |

| CHT | Convective heat transfer |

| DW | Distilled water |

| CNTs | Carbon nanotubes |

| GNPs | Graphene nanoplatelets |

| AR | Aspect ratio |

| EG | Ethylene glycol |

| EHC | Effective heat conductivity |

| MD | Molecular dynamics |

| FOM | Figure of merit |

| PEC | Performance evaluation criteria |

| PAO | Polyalphaolefin |

| DFT | Density functional theory |

| Nomenclature | |

| k | Thermal conductivity (W/(m·K)) |

| Re | Reynolds number |

| Nu | Nusselt number |

| h | Convective heat transfer coefficient (W/(m2·K)) |

| ϕ | Particle volume fraction |

| d | Particle diameter (nm) |

| l | Particle length (nm) |

| h | Particle length (nm) |

| P | Pumping power |

| Q | Flow rate |

| q | Heat flux (kW/m2) |

| cp | Specific heat capacity |

| ρ | Density (kg/m3) |

| Tsi | Temperature (K) sphericity |

| Subscripts | |

| f | Base fluid |

| nf b | Nanofluid Bulk |

References

- Choi, S.; Eastman, J. Enhancing thermal conductivity of fluids with nanoparticles. In Proceedings of the ASME International Mechanical Engineering Congress & Exposition, San Franscisco, CA, USA, 12–17 November 1995; pp. 99–106. [Google Scholar]

- Murshed, S.M.S.; Leong, K.C.; Yang, C. Enhanced thermal conductivity of TiO2—water based nanofluids. Int. J. Therm. Sci. 2005, 44, 367–373. [Google Scholar] [CrossRef]

- Chen, H.; Yang, W.; He, Y.; Ding, Y.; Zhang, L.; Tan, C.; Lapkin, A.A.; Bavykin, D.V. Heat transfer and flow behaviour of aqueous suspensions of titanate nanotubes (nanofluids). Powder Technol. 2008, 183, 63–72. [Google Scholar] [CrossRef]

- Chen, H.; Ding, Y.; Lapkin, A. Rheological behaviour of nanofluids containing tube/rod-like nanoparticles. Powder Technol. 2009, 194, 132–141. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Estellé, P. A state of the art review on viscosity of nanofluids. Renew. Sustain. Energy Rev. 2017, 76, 1134–1152. [Google Scholar] [CrossRef]

- Yu, W.; France, D.M.; Routbort, J.L.; Choi, S.U.S. Review and Comparison of Nanofluid Thermal Conductivity and Heat Transfer Enhancements. Heat Transf. Eng. 2008, 29, 432–460. [Google Scholar] [CrossRef]

- Aybar, H.; Sharifpur, M.; Azizian, M.R.; Mehrabi, M.; Meyer, J.P. A Review of Thermal Conductivity Models for Nanofluids. Heat Transf. Eng. 2015, 36, 1085–1110. [Google Scholar] [CrossRef] [Green Version]

- Murshed, S.S.; de Castro, C.N.; Lourenço, M.; Lopes, M.; Santos, F. A review of boiling and convective heat transfer with nanofluids. Renew. Sustain. Energy Rev. 2011, 15, 2342–2354. [Google Scholar] [CrossRef]

- Hussein, A.M.; Sharma, K.; Bakar, R.; Kadirgama, K. A review of forced convection heat transfer enhancement and hydrodynamic characteristics of a nanofluid. Renew. Sustain. Energy Rev. 2014, 29, 734–743. [Google Scholar] [CrossRef]

- Yu, L.; Liu, D.; Botz, F. Laminar Convective Heat Transfer of Alumina-Polyalphaolefin Nanofluids Containing Spherical and Non-Spherical Nanoparticles. In Proceedings of the International Electronic Packaging Technical Conference and Exhibition, Portland, OR, USA, 6–8 July 2011; Volume 44625, pp. 343–355. [Google Scholar] [CrossRef]

- Yang, L.; Chen, X.; Xu, M.; Du, K. Roles of surfactants and particle shape in the enhanced thermal conductivity of TiO2 nanofluids. AIP Adv. 2016, 6, 95104. [Google Scholar] [CrossRef] [Green Version]

- Zahmatkesh, I.; Sheremet, M.; Yang, L.; Heris, S.Z.; Sharifpur, M.; Meyer, J.P.; Ghalambaz, M.; Wongwises, S.; Jing, D.; Mahian, O. Effect of nanoparticle shape on the performance of thermal systems utilizing nanofluids: A critical review. J. Mol. Liq. 2020, 321, 114430. [Google Scholar] [CrossRef]

- Qiu, L.; Zhu, N.; Feng, Y.; Michaelides, E.E.; Żyła, G.; Jing, D.; Zhang, X.; Norris, P.M.; Markides, C.N.; Mahian, O. A review of recent advances in thermophysical properties at the nanoscale: From solid state to colloids. Phys. Rep. 2019, 843, 1–81. [Google Scholar] [CrossRef]

- Bird, R.B.; Stewart, W.E.; Lightfoot, E.N. Transport Phenomena; JohnWiley & Sons: New York, NY, USA, 2002. [Google Scholar]

- Zhang, X.; Gu, H.; Fujii, M. Effective thermal conductivity and thermal diffusivity of nanofluids containing spherical and cylindrical nanoparticles. Exp. Therm. Fluid Sci. 2007, 31, 593–599. [Google Scholar] [CrossRef]

- Cao, G.; Wang, Y. Nanostructures and Nanomaterials: Synthesis, Properties and Applications; World Scientific: London, UK, 2011. [Google Scholar]

- Buschmann, M.; Azizian, R.; Kempe, T.; Juliá, J.E.; Martínez-Cuenca, R.; Sundén, B.; Wu, Z.; Seppälä, A.; Ala-Nissila, T. Correct interpretation of nanofluid convective heat transfer. Int. J. Therm. Sci. 2018, 129, 504–531. [Google Scholar] [CrossRef]

- Mahian, O.; Kolsi, L.; Amani, M.; Estellé, P.; Ahmadi, G.; Kleinstreuer, C.; Marshall, J.S.; Siavashi, M.; Taylor, R.A.; Niazmand, H.; et al. Recent advances in modeling and simulation of nanofluid flows-Part I: Fundamentals and theory. Phys. Rep. 2018, 790, 1–48. [Google Scholar] [CrossRef]

- Murshed, S.S.; de Castro, C.A.N. Superior thermal features of carbon nanotubes-based nanofluids—A review. Renew. Sustain. Energy Rev. 2014, 37, 155–167. [Google Scholar] [CrossRef]

- Yazid, M.N.A.W.M.; Sidik, N.A.C.; Yahya, W.J. Heat and mass transfer characteristics of carbon nanotube nanofluids: A review. Renew. Sustain. Energy Rev. 2017, 80, 914–941. [Google Scholar] [CrossRef]

- Ali, N.; Bahman, A.; Aljuwayhel, N.; Ebrahim, S.; Mukherjee, S.; Alsayegh, A. Carbon-Based Nanofluids and Their Advances towards Heat Transfer Applications—A Review. Nanomaterials 2021, 11, 1628. [Google Scholar] [CrossRef]

- Xie, H.; Lee, H.; Youn, W.; Choi, M. Nanofluids containing multiwalled carbon nanotubes and their enhanced thermal conductivities. J. Appl. Phys. 2003, 94, 4967. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Z.G.; Grulke, E.A.; Anderson, W.B.; Wu, G. Heat transfer properties of nanoparticle-in-fluid dispersions (nanofluids) in laminar flow. Int. J. Heat Mass Transf. 2005, 48, 1107–1116. [Google Scholar] [CrossRef]

- Gu, B.; Hou, B.; Lu, Z.; Wang, Z.; Chen, S. Thermal conductivity of nanofluids containing high aspect ratio fillers. Int. J. Heat Mass Transf. 2013, 64, 108–114. [Google Scholar] [CrossRef]

- Maheshwary, P.; Handa, C.; Nemade, K.; Chaudhary, S. Role of nanoparticle shape in enhancing the thermal conductivity of nanofluids. Mater. Today Proc. 2020, 28, 873–878. [Google Scholar] [CrossRef]

- Maheshwary, P.; Handa, C.; Nemade, K. A comprehensive study of effect of concentration, particle size and particle shape on thermal conductivity of titania/water based nanofluid. Appl. Therm. Eng. 2017, 119, 79–88. [Google Scholar] [CrossRef]

- Zhu, D.; Wang, L.; Yu, W.; Xie, H. Intriguingly high thermal conductivity increment for CuO nanowires contained nanofluids with low viscosity. Sci. Rep. 2018, 8, 5282. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Yu, W.; Zhu, D.; Xie, H.; Huang, G. Enhanced Thermal Conductivity for Nanofluids Containing Silver Nanowires with Different Shapes. J. Nanomater. 2017, 2017, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Carbajal-Valdez, R.; Rodríguez-Juárez, A.; Jiménez-Pérez, J.; Sánchez-Ramírez, J.; Cruz-Orea, A.; Correa-Pacheco, Z.; Macias, M.; Luna-Sánchez, J. Experimental investigation on thermal properties of Ag nanowire nanofluids at low concentrations. Thermochim. Acta 2018, 671, 83–88. [Google Scholar] [CrossRef]

- Xie, H.; Wang, J.; Xi, T.; Liu, Y. Thermal Conductivity of Suspensions Containing Nanosized SiC Particles. Int. J. Thermophys. 2002, 23, 571–580. [Google Scholar] [CrossRef]

- Yang, B.; Han, Z.H. Temperature-dependent thermal conductivity of nanorod-based nanofluids. Appl. Phys. Lett. 2006, 89, 83111. [Google Scholar] [CrossRef]

- Becker, J.; Trügler, A.; Jakab, A.; Hohenester, U.; Sönnichsen, C. The Optimal Aspect Ratio of Gold Nanorods for Plasmonic Bio-sensing. Plasmonics 2010, 5, 161–167. [Google Scholar] [CrossRef]

- Zhu, H.T.; Zhang, C.Y.; Tang, A.Y.M.; Wang, J.X. Novel Synthesis and Thermal Conductivity of CuO Nanofluid. J. Phys. Chem. C 2007, 111, 1646–1650. [Google Scholar] [CrossRef]

- Timofeeva, E.V.; Routbort, J.L.; Singh, D. Particle shape effects on thermophysical properties of alumina nanofluids. J. Appl. Phys. 2009, 106, 14304. [Google Scholar] [CrossRef]

- Cui, W.; Cao, Z.; Li, X.; Lu, L.; Ma, T.; Wang, Q. Experimental investigation and artificial intelligent estimation of thermal conductivity of nanofluids with different nanoparticles shapes. Powder Technol. 2021, 398, 117078. [Google Scholar] [CrossRef]

- Nithiyanantham, U.; González-Fernández, L.; Grosu, Y.; Zaki, A.; Igartua, J.M.; Faik, A. Shape effect of Al2O3 nanoparticles on the thermophysical properties and viscosity of molten salt nanofluids for TES application at CSP plants. Appl. Therm. Eng. 2020, 169, 114942. [Google Scholar] [CrossRef]

- Jiang, W.; Ding, G.; Peng, H. Measurement and model on thermal conductivities of carbon nanotube nanorefrigerants. Int. J. Therm. Sci. 2009, 48, 1108–1115. [Google Scholar] [CrossRef]

- Singh, D.J.; Timofeeva, E.V.; Yu, W.; Routbort, J.L.; France, D.M.; Smith, D.Y.; Lopez-Cepero, J.M. An investigation of silicon carbide-water nanofluid for heat transfer applications. J. Appl. Phys. 2009, 105, 64306. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, S.-H.; Lee, J.-H.; Jang, S.P. Effect of particle shape on suspension stability and thermal conductivities of water-based bohemite alumina nanofluids. Energy 2015, 90, 1290–1297. [Google Scholar] [CrossRef]

- Torii, S.; Yang, W.-J. Heat Transfer Augmentation of Aqueous Suspensions of Nanodiamonds in Turbulent Pipe Flow. J. Heat Transf. 2009, 131, 43203. [Google Scholar] [CrossRef]

- Xie, H.; Yu, W.; Li, Y. Thermal performance enhancement in nanofluids containing diamond nanoparticles. J. Phys. D: Appl. Phys. 2009, 42, 95413. [Google Scholar] [CrossRef]

- Ferrouillat, S.; Bontemps, A.; Poncelet, O.; Soriano, O.; Gruss, J.-A. Influence of nanoparticle shape factor on convective heat transfer and energetic performance of water-based SiO2 and ZnO nanofluids. Appl. Therm. Eng. 2013, 51, 839–851. [Google Scholar] [CrossRef]

- Yang, L.; Ji, W.; Huang, J.-N.; Xu, G. An updated review on the influential parameters on thermal conductivity of nano-fluids. J. Mol. Liq. 2019, 296, 111780. [Google Scholar] [CrossRef]

- Tahmooressi, H.; Kasaeian, A.; Yavarinasab, A.; Tarokh, A.; Ghazi, M.; Hoorfar, M. Numerical simulation of nanoparticles size/aspect ratio effect on thermal conductivity of nanofluids using lattice Boltzmann method. Int. Commun. Heat Mass Transf. 2020, 120, 105033. [Google Scholar] [CrossRef]

- Assael, M.J.; Chen, C.-F.; Metaxa, I.; Wakeham, W.A. Thermal Conductivity of Suspensions of Carbon Nanotubes in Water. Int. J. Thermophys. 2004, 25, 971–985. [Google Scholar] [CrossRef]

- Nasiri, A.; Shariaty-Niasar, M.; Rashidi, A.; Khodafarin, R. Effect of CNT structures on thermal conductivity and stability of nanofluid. Int. J. Heat Mass Transf. 2012, 55, 1529–1535. [Google Scholar] [CrossRef]

- Fang, X.; Ding, Q.; Fan, L.-W.; Yu, Z.-T.; Xu, X.; Cheng, G.-H.; Hu, Y.-C.; Cen, K.-F. Thermal Conductivity Enhancement of Ethylene Glycol-Based Suspensions in the Presence of Silver Nanoparticles of Various Shapes. J. Heat Transf. 2013, 136, 34501. [Google Scholar] [CrossRef]

- Jeong, J.; Li, C.; Kwon, Y.; Lee, J.; Kim, S.H.; Yun, R. Particle shape effect on the viscosity and thermal conductivity of ZnO nanofluids. Int. J. Refrig. 2013, 36, 2233–2241. [Google Scholar] [CrossRef]

- Farbod, M.; Asl, R.K.; Abadi, A.R.N. Morphology dependence of thermal and rheological properties of oil-based nanofluids of CuO nanostructures. Colloids Surfaces A Physicochem. Eng. Asp. 2015, 474, 71–75. [Google Scholar] [CrossRef]

- Shah, J.; Kumar, S.; Ranjan, M.; Sonvane, Y.; Thareja, P.; Gupta, S.K. The effect of filler geometry on thermo-optical and rheological properties of CuO nanofluid. J. Mol. Liq. 2018, 272, 668–675. [Google Scholar] [CrossRef]

- Ni, Z.; Cao, X.; Wang, X.; Zhou, S.; Zhang, C.; Xu, B.; Ni, Y. Facile Synthesis of Copper(I) Oxide Nanochains and the Photo-Thermal Conversion Performance of Its Nanofluids. Coatings 2021, 11, 749. [Google Scholar] [CrossRef]

- Maxwell, J.C. A Treatise on Electricity and Magnetism; Clarendon Press: London, UK, 1881; Volume 1. [Google Scholar]

- Hamilton, R.L.; Crosser, O.K. Thermal Conductivity of Heterogeneous Two-Component Systems. Ind. Eng. Chem. Fundam. 1962, 1, 187–191. [Google Scholar] [CrossRef]

- Wang, B.-X.; Zhou, L.-P.; Peng, X.-F. A fractal model for predicting the effective thermal conductivity of liquid with suspension of nanoparticles. Int. J. Heat Mass Transf. 2003, 46, 2665–2672. [Google Scholar] [CrossRef]

- Hasselman, D.; Johnson, L.F. Effective Thermal Conductivity of Composites with Interfacial Thermal Barrier Resistance. J. Compos. Mater. 1987, 21, 508–515. [Google Scholar] [CrossRef]

- Xue, L.; Keblinski, P.; Phillpot, S.; Choi, S.-S.; Eastman, J. Effect of liquid layering at the liquid–solid interface on thermal transport. Int. J. Heat Mass Transf. 2004, 47, 4277–4284. [Google Scholar] [CrossRef]

- Nan, C.-W.; Liu, G.; Lin, Y.; Li, M. Interface effect on thermal conductivity of carbon nanotube composites. Appl. Phys. Lett. 2004, 85, 3549–3551. [Google Scholar] [CrossRef]

- Zhou, X.F.; Gao, L. Effective thermal conductivity in nanofluids of nonspherical particles with interfacial thermal resistance: Differential effective medium theory. J. Appl. Phys. 2006, 100, 24913. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Leong, K.; Yang, C. Investigations of thermal conductivity and viscosity of nanofluids. Int. J. Therm. Sci. 2008, 47, 560–568. [Google Scholar] [CrossRef]

- Jiang, H.; Xu, Q.; Huang, C.; Shi, L. The role of interfacial nanolayer in the enhanced thermal conductivity of carbon nanotube-based nanofluids. Appl. Phys. A 2014, 118, 197–205. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Suresh, S.; Srinivasan, R.; Bose, A.C. New Analytical Models to Investigate Thermal Conductivity of Nanofluids. J. Nanosci. Nanotechnol. 2009, 9, 533–538. [Google Scholar] [CrossRef]

- Yang, L.; Xu, X.; Jiang, W.; Du, K. A new thermal conductivity model for nanorod-based nanofluids. Appl. Therm. Eng. 2017, 114, 287–299. [Google Scholar] [CrossRef]

- Yang, L.; Xu, X. A renovated Hamilton–Crosser model for the effective thermal conductivity of CNTs nanofluids. Int. Commun. Heat Mass Transf. 2016, 81, 42–50. [Google Scholar] [CrossRef]

- Yang, L.; Du, K.; Zhang, X. A theoretical investigation of thermal conductivity of nanofluids with particles in cylindrical shape by anisotropy analysis. Powder Technol. 2016, 314, 328–338. [Google Scholar] [CrossRef]

- Khalifeh, A.; Vaferi, B. Intelligent assessment of effect of aggregation on thermal conductivity of nanofluids—Comparison by experimental data and empirical correlations. Thermochim. Acta 2019, 681, 178377. [Google Scholar] [CrossRef]

- Alawi, O.A.; Sidik, N.A.C.; Xian, H.W.; Kean, T.H.; Kazi, S. Thermal conductivity and viscosity models of metallic oxides nanofluids. Int. J. Heat Mass Transf. 2018, 116, 1314–1325. [Google Scholar] [CrossRef]

- Wang, R.; Qian, S.; Zhang, Z. Investigation of the aggregation morphology of nanoparticle on the thermal conductivity of nanofluid by molecular dynamics simulations. Int. J. Heat Mass Transf. 2018, 127, 1138–1146. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, T.; Guo, Y.; Wang, J.; Wei, J.; Yu, Q. Recent advances in simultaneous removal of SO2 and NOx from exhaust gases: Removal process, mechanism and kinetics. Chem. Eng. J. 2020, 420, 127588. [Google Scholar] [CrossRef]

- Du, J.; Su, Q.; Li, L.; Wang, R.; Zhu, Z. Evaluation of the influence of aggregation morphology on thermal conductivity of nanofluid by a new MPCD-MD hybrid method. Int. Commun. Heat Mass Transf. 2021, 127, 105501. [Google Scholar] [CrossRef]

- Lee, J.W.; Nilson, R.H.; Templeton, J.A.; Griffiths, S.K.; Kung, A.; Wong, B.M. Comparison of Molecular Dynamics with Classical Density Functional and Poisson–Boltzmann Theories of the Electric Double Layer in Nanochannels. J. Chem. Theory Comput. 2012, 8, 2012–2022. [Google Scholar] [CrossRef]

- Sastry, N.N.V.; Bhunia, A.; Sundararajan, T.; Das, S.K. Predicting the effective thermal conductivity of carbon nanotube based nanofluids. Nanotechnology 2008, 19, 55704. [Google Scholar] [CrossRef]

- Koo, J.; Kang, Y.; Kleinstreuer, C. A nonlinear effective thermal conductivity model for carbon nanotube and nanofiber suspensions. Nanotechnology 2008, 19, 375705. [Google Scholar] [CrossRef]

- Xue, Q.Z. Model for thermal conductivity of carbon nanotube-based composites. Phys. B Condens. Matter 2005, 368, 302–307. [Google Scholar] [CrossRef]

- Sabbaghzadeh, J.; Ebrahimi, S. Effective Thermal Conductivity of Nanofluids Containing Cylindrical Nanoparticles. Int. J. Nanosci. 2007, 6, 45–49. [Google Scholar] [CrossRef]

- Ebrahimi, S.; Sabbaghzadeh, J.; Lajevardi, M.; Hadi, I. Cooling performance of a microchannel heat sink with nanofluids containing cylindrical nanoparticles (carbon nanotubes). Heat Mass Transf. 2010, 46, 549–553. [Google Scholar] [CrossRef]

- Yang, B. Thermal Conductivity Equations Based on Brownian Motion in Suspensions of Nanoparticles (Nanofluids). J. Heat Transf. 2008, 130, 42408. [Google Scholar] [CrossRef]

- Koo, J.; Kleinstreuer, C. Impact analysis of nanoparticle motion mechanisms on the thermal conductivity of nanofluids. Int. Commun. Heat Mass Transf. 2005, 32, 1111–1118. [Google Scholar] [CrossRef]

- Cui, W.; Bai, M.; Lv, J.; Li, G.; Li, X. On the Influencing Factors and Strengthening Mechanism for Thermal Conductivity of Nanofluids by Molecular Dynamics Simulation. Ind. Eng. Chem. Res. 2011, 50, 13568–13575. [Google Scholar] [CrossRef]

- Yamada, E.; Ota, T. Effective thermal conductivity of dispersed materials. Wärme-Und Stoffübertragung 1980, 13, 27–37. [Google Scholar] [CrossRef]

- Liang, G.; Mudawar, I. Review of pool boiling enhancement with additives and nanofluids. Int. J. Heat Mass Transf. 2018, 124, 423–453. [Google Scholar] [CrossRef]

- Kamel, M.S.; Lezsovits, F. Boiling heat transfer of nanofluids: A review of recent studies. Therm. Sci. 2019, 23, 109–124. [Google Scholar] [CrossRef] [Green Version]

- Barber, J.; Brutin, D.; Tadrist, L. A review on boiling heat transfer enhancement with nanofluids. Nanoscale Res. Lett. 2011, 6, 280. [Google Scholar] [CrossRef] [Green Version]

- Vallejo, J.P.; Prado, J.I.; Lugo, L. Hybrid or mono nanofluids for convective heat transfer applications. A critical review of experimental research. Appl. Therm. Eng. 2021, 203, 117926. [Google Scholar] [CrossRef]

- Al-Hossainy, A.; Eid, M.R. Structure, DFT calculations and heat transfer enhancement in [ZnO/PG + H2O]C hybrid nanofluid flow as a potential solar cell coolant application in a double-tube. J. Mater. Sci. Mater. Electron. 2020, 31, 15243–15257. [Google Scholar] [CrossRef]

- Alam, M.; Hussain, S.; Souayeh, B.; Khan, M.; Farhan, M. Numerical Simulation of Homogeneous–Heterogeneous Reactions through a Hybrid Nanofluid Flowing over a Rotating Disc for Solar Heating Applications. Sustainability 2021, 13, 8289. [Google Scholar] [CrossRef]

- Hussain, S.; Pour, M.; Jamal, M.; Armaghani, T. MHD Mixed Convection and Entropy Analysis of Non-Newtonian Hybrid Nanofluid in a Novel Wavy Elbow-Shaped Cavity with a Quarter Circle Hot Block and a Rotating Cylinder. Exp. Technol. 2022, 46, 1–20. [Google Scholar] [CrossRef]

- Khodabandeh, E.; Akbari, O.A.; Toghraie, D.; Pour, M.S.; Jönsson, P.G.; Ersson, M. Numerical investigation of thermal performance augmentation of nanofluid flow in microchannel heat sinks by using of novel nozzle structure: Sinusoidal cavities and rectangular ribs. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 443. [Google Scholar] [CrossRef]

- Souayeh, B.; Bhattacharyya, S.; Hdhiri, N.; Alam, M.W.; Yasin, E.; Aamir, M. Investigation on inlet obstruction in transitional flow regime: Heat transfer augmentation and pressure drop analysis. Case Stud. Therm. Eng. 2022, 34, 102016. [Google Scholar] [CrossRef]

- Ghasemiasl, R.; Hashemi, S.; Armaghani, T.; Tayebi, T.; Pour, M.S. Recent Studies on the Forced Convection of Nano-Fluids in Channels and Tubes: A Comprehensive Review. Exp. Technol. 2022, 46, 1–35. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, L.; Sundén, B. Pressure drop and convective heat transfer of water and nanofluids in a double-pipe helical heat exchanger. Appl. Therm. Eng. 2013, 60, 266–274. [Google Scholar] [CrossRef]

- Buongiorno, J. Convective Transport in Nanofluids. J. Heat Transfer. 2006, 128, 240–250. [Google Scholar] [CrossRef]

- Myers, T.G.; Ribera, H.; Cregan, V. Does mathematics contribute to the nanofluid debate? Int. J. Heat Mass Transf. 2017, 111, 279–288. [Google Scholar] [CrossRef] [Green Version]

- Yu, L.; Liu, N. Study of the Thermal Effectiveness of Laminar Forced Convection of Nanofluids for Liquid Cooling Applications. IEEE Trans. Compon. Packag. Manuf. Technol. 2013, 3, 1693–1704. [Google Scholar] [CrossRef]

- Alkasmoul, F.S.; Al-Asadi, M.; Myers, T.; Thompson, H.; Wilson, M. A practical evaluation of the performance of Al2O3-water, TiO2-water and CuO-water nanofluids for convective cooling. Int. J. Heat Mass Transf. 2018, 126, 639–651. [Google Scholar] [CrossRef] [Green Version]

- Paul, T.C.; Morshed, A.; Fox, E.; Khan, J.A. Experimental investigation of natural convection heat transfer of Al2O3 Nanoparticle Enhanced Ionic Liquids (NEILs). Int. J. Heat Mass Transf. 2015, 83, 753–761. [Google Scholar] [CrossRef] [Green Version]

- Ji, Y.; Wilson, C.; Chen, H.-H.; Ma, H. Particle shape effect on heat transfer performance in an oscillating heat pipe. Nanoscale Res. Lett. 2011, 6, 296. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nelson, I.C.; Banerjee, D.; Ponnappan, R. Flow Loop Experiments Using Polyalphaolefin Nanofluids. J. Thermophys. Heat Transf. 2009, 23, 752–761. [Google Scholar] [CrossRef]

- Ben Mansour, R.; Galanis, N.; Nguyen, C.T. Effect of uncertainties in physical properties on forced convection heat transfer with nanofluids. Appl. Therm. Eng. 2007, 27, 240–249. [Google Scholar] [CrossRef]

- Ali, H.M.; Arshad, W. Effect of channel angle of pin-fin heat sink on heat transfer performance using water based graphene nanoplatelets nanofluids. Int. J. Heat Mass Transf. 2017, 106, 465–472. [Google Scholar] [CrossRef]

- Arshad, W.; Ali, H.M. Graphene nanoplatelets nanofluids thermal and hydrodynamic performance on integral fin heat sink. Int. J. Heat Mass Transf. 2017, 107, 995–1001. [Google Scholar] [CrossRef]

- Mikkola, V.; Puupponen, S.; Granbohm, H.; Saari, K.; Ala-Nissila, T.; Seppälä, A. Influence of particle properties on convective heat transfer of nanofluids. Int. J. Therm. Sci. 2018, 124, 187–195. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.; Wang, L.; Sundén, B.; Wadsö, L. Aqueous carbon nanotube nanofluids and their thermal performance in a helical heat exchanger. Appl. Therm. Eng. 2016, 96, 364–371. [Google Scholar] [CrossRef]

- Contreras, E.M.C.; Oliveira, G.A.; Filho, E.B. Experimental analysis of the thermohydraulic performance of graphene and silver nanofluids in automotive cooling systems. Int. J. Heat Mass Transf. 2019, 132, 375–387. [Google Scholar] [CrossRef]

- Bai, M.-J.; Liu, J.-L.; He, J.; Li, W.-J.; Wei, J.-J.; Chen, L.-X.; Miao, J.-Y.; Li, C.-M. Heat transfer and mechanical friction reduction properties of graphene oxide nanofluids. Diam. Relat. Mater. 2020, 108, 107982. [Google Scholar] [CrossRef]

- Ding, Y.; Alias, H.; Wen, D.; Williams, R.A. Heat transfer of aqueous suspensions of carbon nanotubes (CNT nanofluids). Int. J. Heat Mass Transf. 2006, 49, 240–250. [Google Scholar] [CrossRef]

- Minea, A.A.; Buonomo, B.; Burggraf, J.; Ercole, D.; Karpaiya, K.R.; Di Pasqua, A.; Sekrani, G.; Steffens, J.; Tibaut, J.; Wichmann, N.; et al. NanoRound: A benchmark study on the numerical approach in nanofluids’ simulation. Int. Commun. Heat Mass Transf. 2019, 108, 104292. [Google Scholar] [CrossRef]

- Lin, J.; Xia, Y.; Ku, X. Friction factor and heat transfer of nanofluids containing cylindrical nanoparticles in laminar pipe flow. J. Appl. Phys. 2014, 116, 133513. [Google Scholar] [CrossRef]

- Yuan, F.; Yu, W.; Lin, J. Numerical study of the effects of nanorod aspect ratio on Poiseuille flow and convective heat transfer in a circular minichannel. Microfluid. Nanofluidics 2020, 24, 1–15. [Google Scholar] [CrossRef]

- Lin, J.; Shi, R.; Yuan, F.; Yu, M. Distribution and penetration efficiency of cylindrical nanoparticles in turbulent flows through a curved tube. Aerosol Sci. Technol. 2020, 54, 1255–1269. [Google Scholar] [CrossRef]

- Lin, W.; Shi, R.; Lin, J. Distribution and Deposition of Cylindrical Nanoparticles in a Turbulent Pipe Flow. Appl. Sci. 2021, 11, 962. [Google Scholar] [CrossRef]

- Lin, J.-Z.; Xia, Y.; Ku, X.-K. Flow and heat transfer characteristics of nanofluids containing rod-like particles in a turbulent pipe flow. Int. J. Heat Mass Transf. 2016, 93, 57–66. [Google Scholar] [CrossRef]

- Elias, M.; Miqdad, M.; Mahbubul, I.; Saidur, R.; Kamalisarvestani, M.; Sohel, M.; Hepbasli, A.; Rahim, N.; Amalina, M. Effect of nanoparticle shape on the heat transfer and thermodynamic performance of a shell and tube heat exchanger. Int. Commun. Heat Mass Transf. 2013, 44, 93–99. [Google Scholar] [CrossRef]

- Elias, M.; Shahrul, I.; Mahbubul, I.; Saidur, R.; Rahim, N. Effect of different nanoparticle shapes on shell and tube heat exchanger using different baffle angles and operated with nanofluid. Int. J. Heat Mass Transf. 2014, 70, 289–297. [Google Scholar] [CrossRef]

- Amin, T.E.; Roghayeh, G.; Fatemeh, R.; Fatollah, P. Evaluation of Nanoparticle Shape Effect on a Nanofluid Based Flat-Plate Solar Collector Efficiency. Energy Explor. Exploit. 2015, 33, 659–676. [Google Scholar] [CrossRef] [Green Version]

- Ooi, E.H.; Popov, V. Numerical study of influence of nanoparticle shape on the natural convection in Cu-water nanofluid. Int. J. Therm. Sci. 2013, 65, 178–188. [Google Scholar] [CrossRef]

- Lin, Y.; Li, B.; Zheng, L.; Chen, G. Particle shape and radiation effects on Marangoni boundary layer flow and heat transfer of copper-water nanofluid driven by an exponential temperature. Powder Technol. 2016, 301, 379–386. [Google Scholar] [CrossRef]

- Yuan, F.; Lin, J.; Ku, X. Convective Heat Transfer and Resistance Characteristics of Nanofluids with Cylindrical Particles. Heat Transf. Eng. 2017, 39, 526–535. [Google Scholar] [CrossRef]

- Trodi, A.; Benhamza, M.E.H. Particle Shape and Aspect Ratio Effect of Al2O3–Water Nanofluid on Natural Convective Heat Transfer Enhancement in Differentially Heated Square Enclosures. Chem. Eng. Commun. 2016, 204, 158–167. [Google Scholar] [CrossRef]

- Liu, F.; Cai, Y.; Wang, L.; Zhao, J. Effects of nanoparticle shapes on laminar forced convective heat transfer in curved ducts using two-phase model. Int. J. Heat Mass Transf. 2017, 116, 292–305. [Google Scholar] [CrossRef]

- Sheikhzadeh, G.A.; Aghaei, A.; Soleimani, S. Effect of nanoparticle shape on natural convection heat transfer in a square cavity with partitions using water-SiO2 nanofluid. Chall. Nano Micro Scale Sci. Technol. 2018, 6, 27–38. [Google Scholar] [CrossRef]

- Lin, W.; Shi, R.; Lin, J. Heat Transfer and Pressure Drop of Nanofluid with Rod-like Particles in Turbulent Flows through a Curved Pipe. Entropy 2022, 24, 416. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Yuan, F.; Tian, W.; Dai, C.; Yang, X.; Wang, D.; Du, J.; Yu, W.; Yuan, H. Heat Transfer Enhancement of Nanofluids with Non-Spherical Nanoparticles: A Review. Appl. Sci. 2022, 12, 4767. https://doi.org/10.3390/app12094767

Li X, Yuan F, Tian W, Dai C, Yang X, Wang D, Du J, Yu W, Yuan H. Heat Transfer Enhancement of Nanofluids with Non-Spherical Nanoparticles: A Review. Applied Sciences. 2022; 12(9):4767. https://doi.org/10.3390/app12094767

Chicago/Turabian StyleLi, Xiaoyin, Fangyang Yuan, Wenma Tian, Chenlong Dai, Xinjun Yang, Dongxiang Wang, Jiyun Du, Wei Yu, and Huixin Yuan. 2022. "Heat Transfer Enhancement of Nanofluids with Non-Spherical Nanoparticles: A Review" Applied Sciences 12, no. 9: 4767. https://doi.org/10.3390/app12094767

APA StyleLi, X., Yuan, F., Tian, W., Dai, C., Yang, X., Wang, D., Du, J., Yu, W., & Yuan, H. (2022). Heat Transfer Enhancement of Nanofluids with Non-Spherical Nanoparticles: A Review. Applied Sciences, 12(9), 4767. https://doi.org/10.3390/app12094767