Numerical Investigation on the Flow-Induced Vibration Characteristics of Fire Turbopump with the Turbine-Pump Structure

Abstract

:1. Introduction

2. Materials and Methods

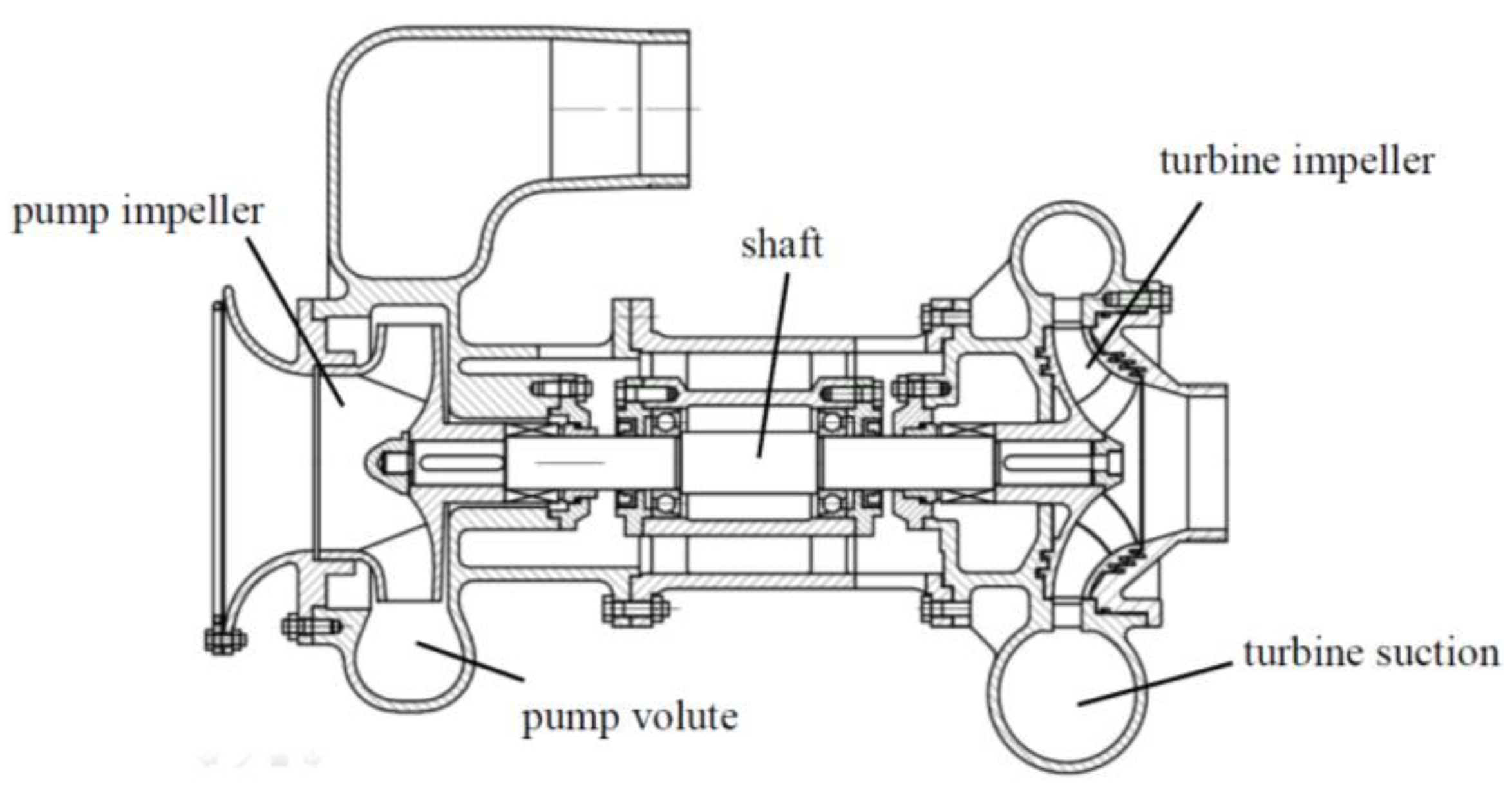

2.1. Fire Turbopump Specifications

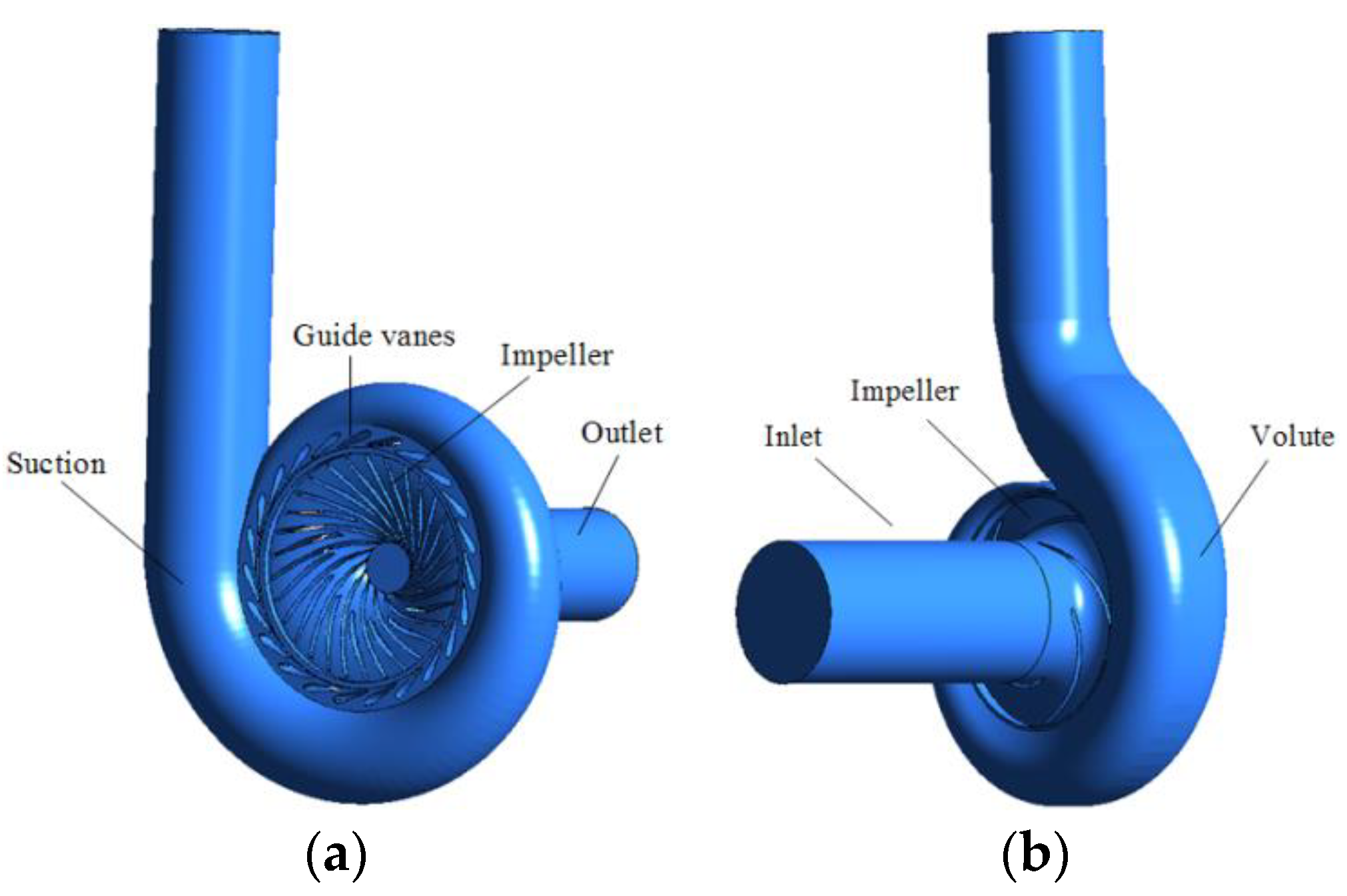

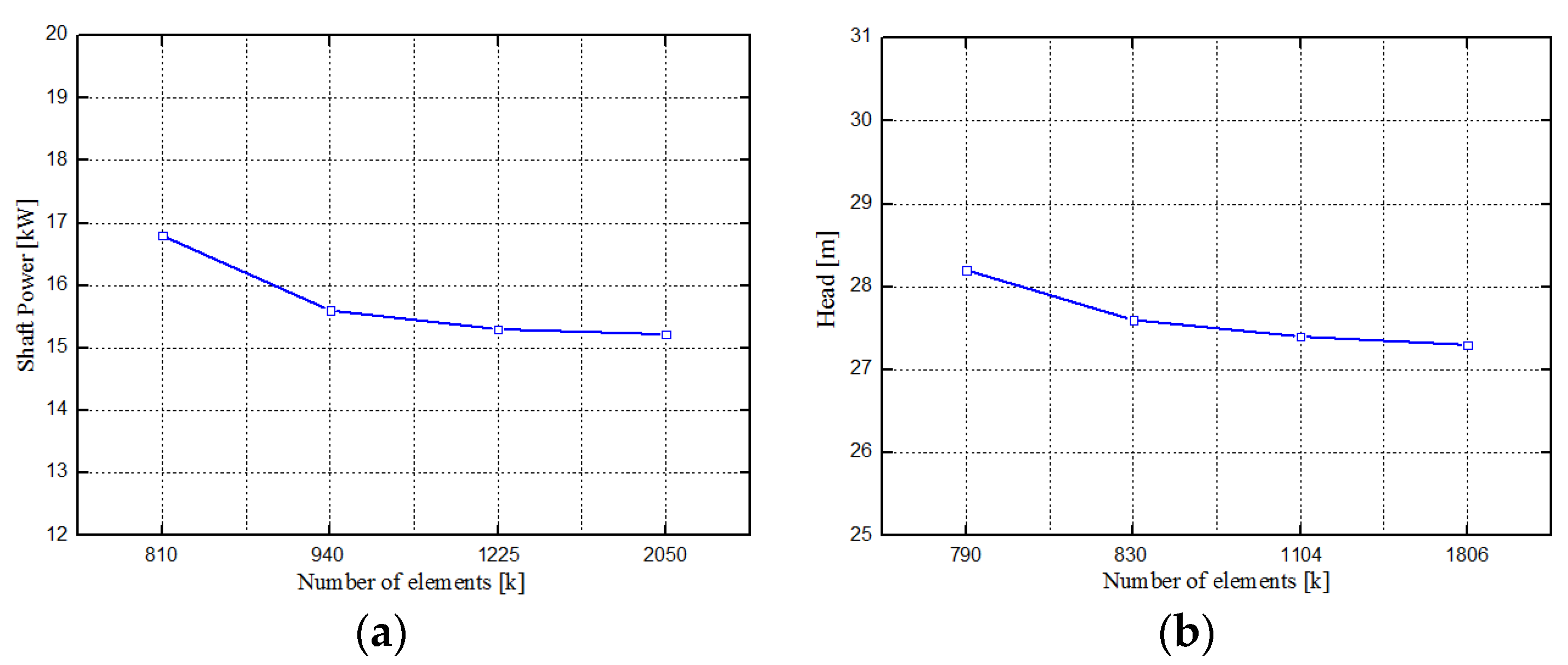

2.2. CFD Methodology

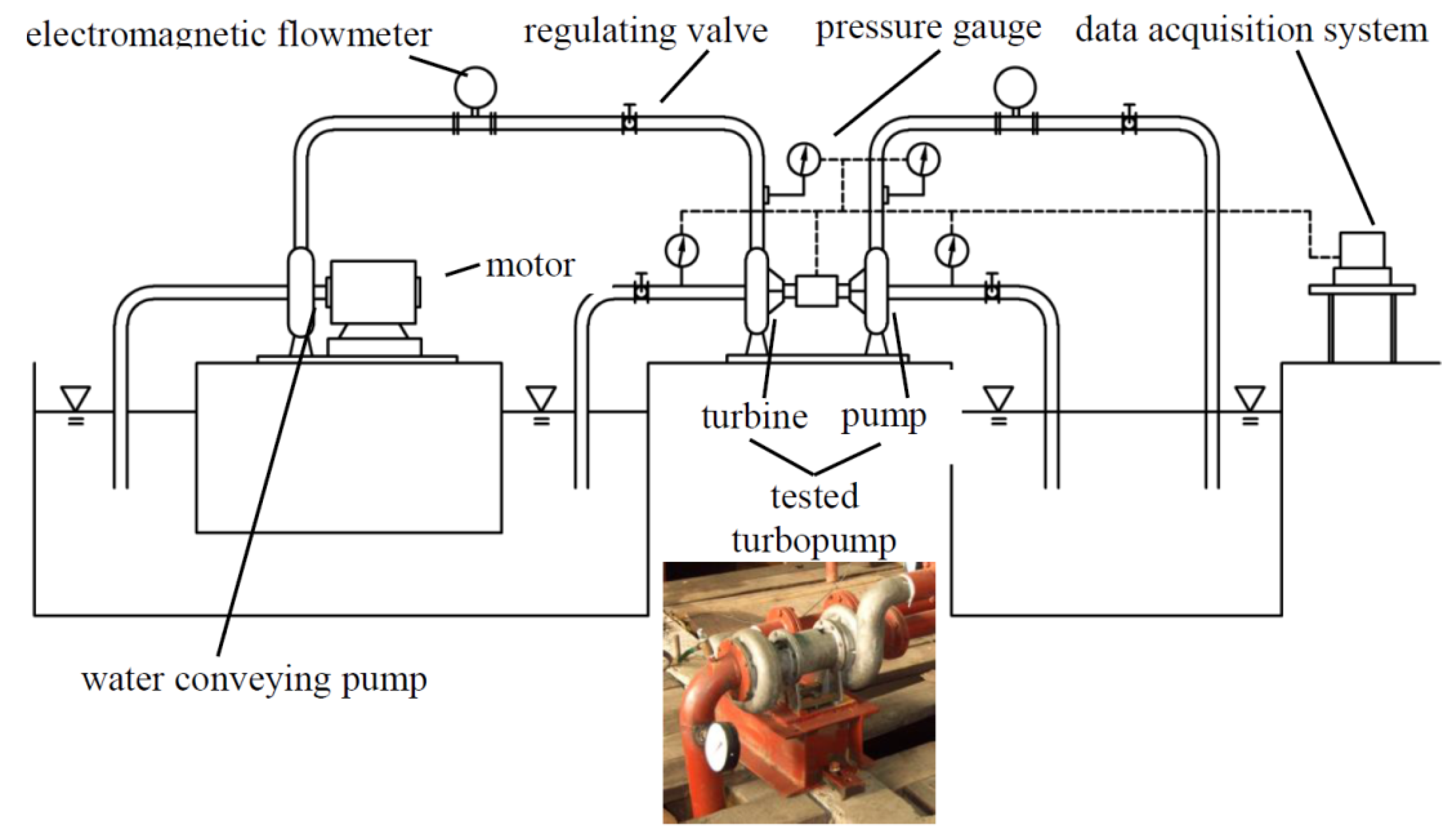

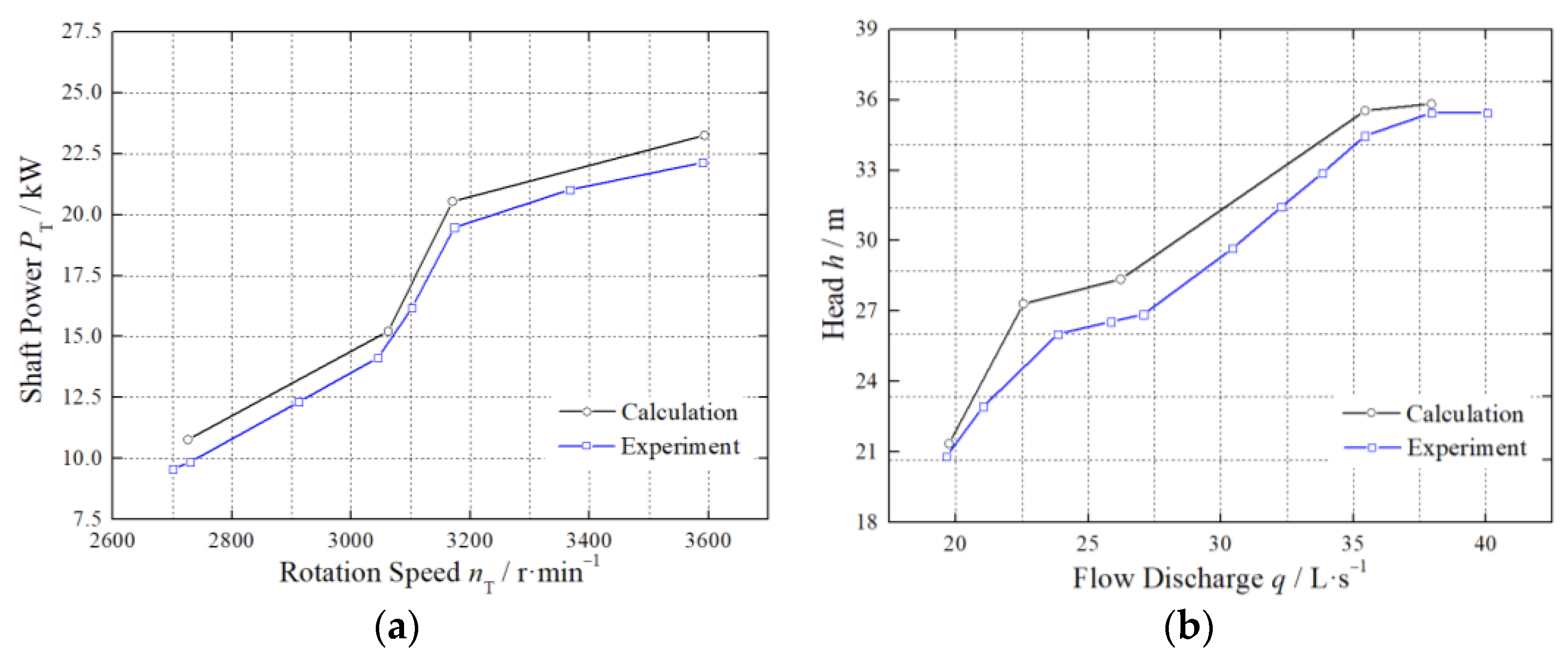

2.3. Experimental Measurements

3. Results and Discussions

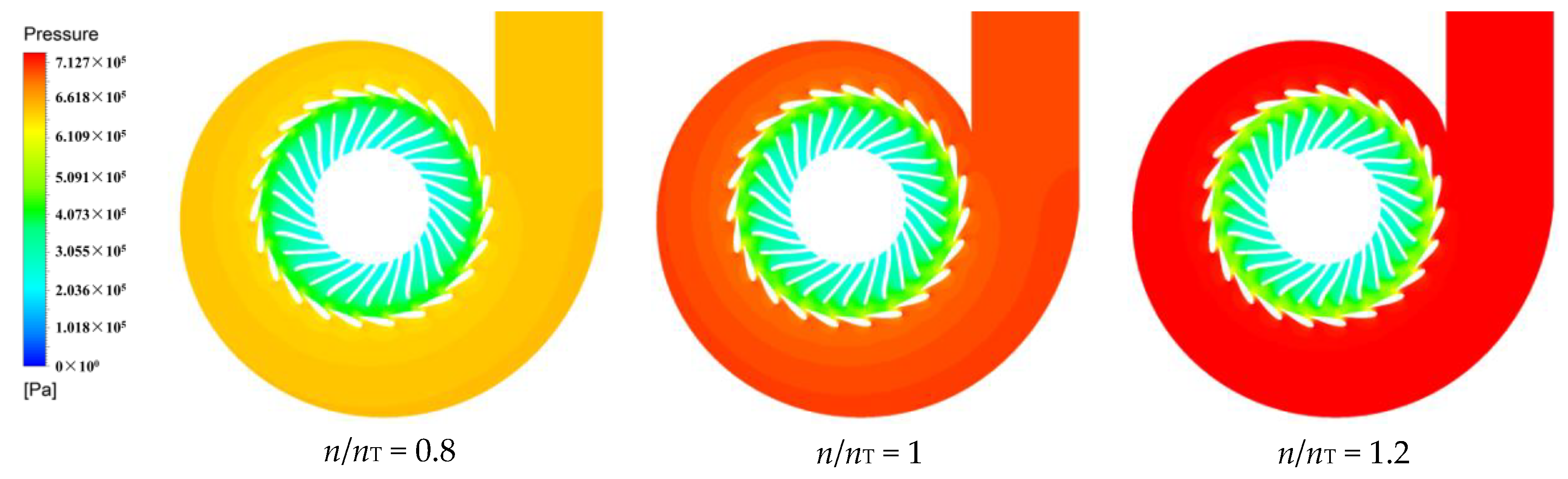

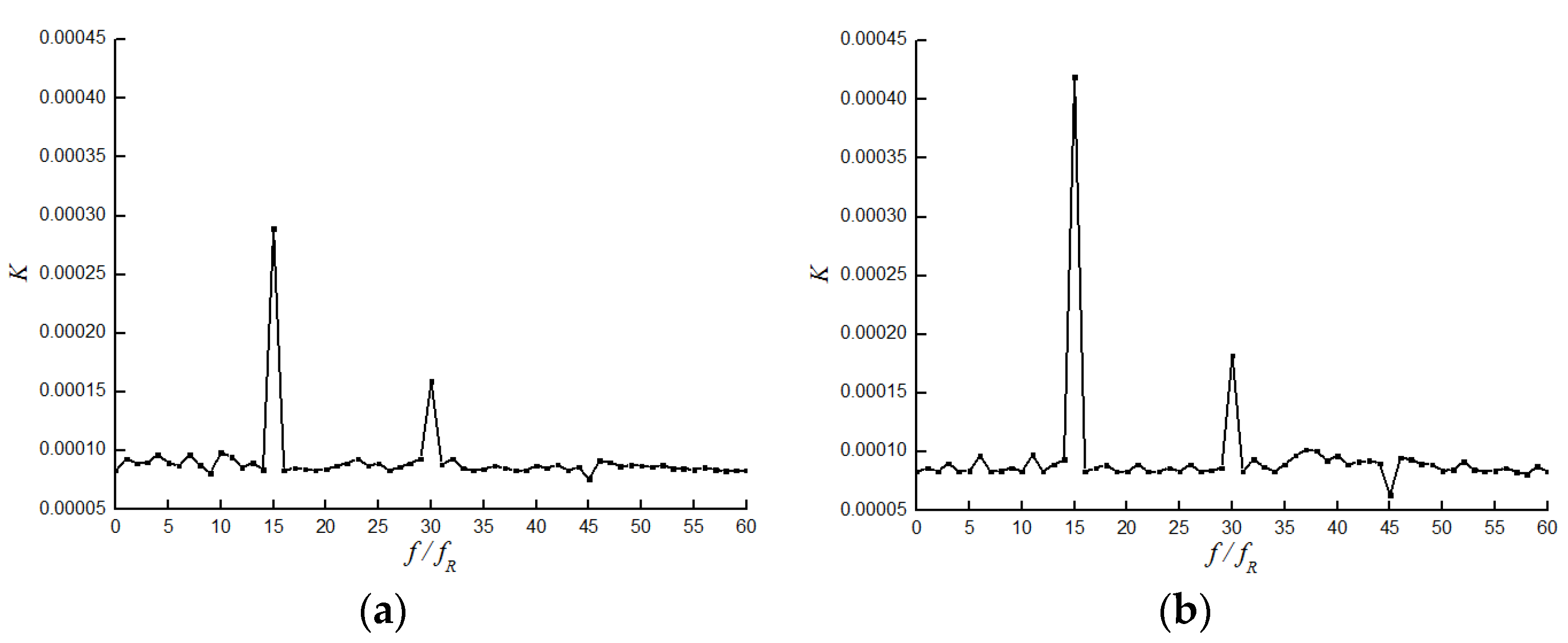

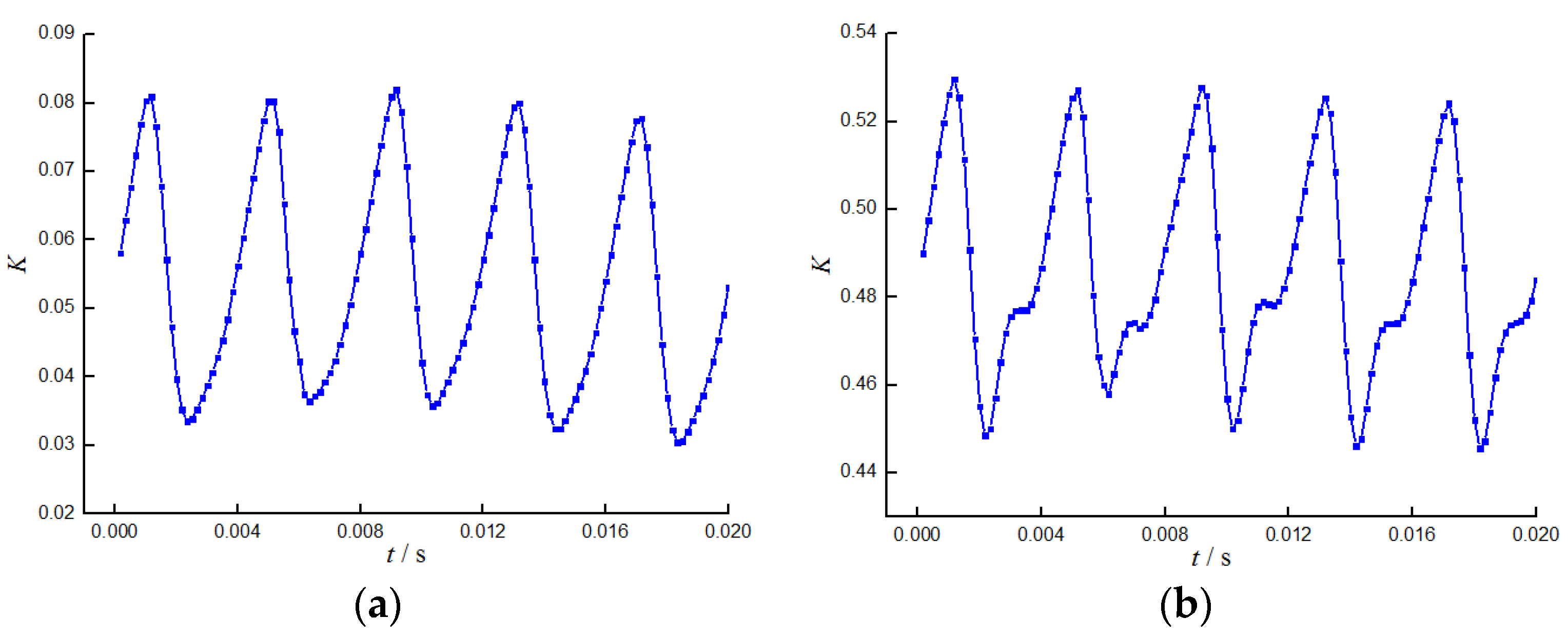

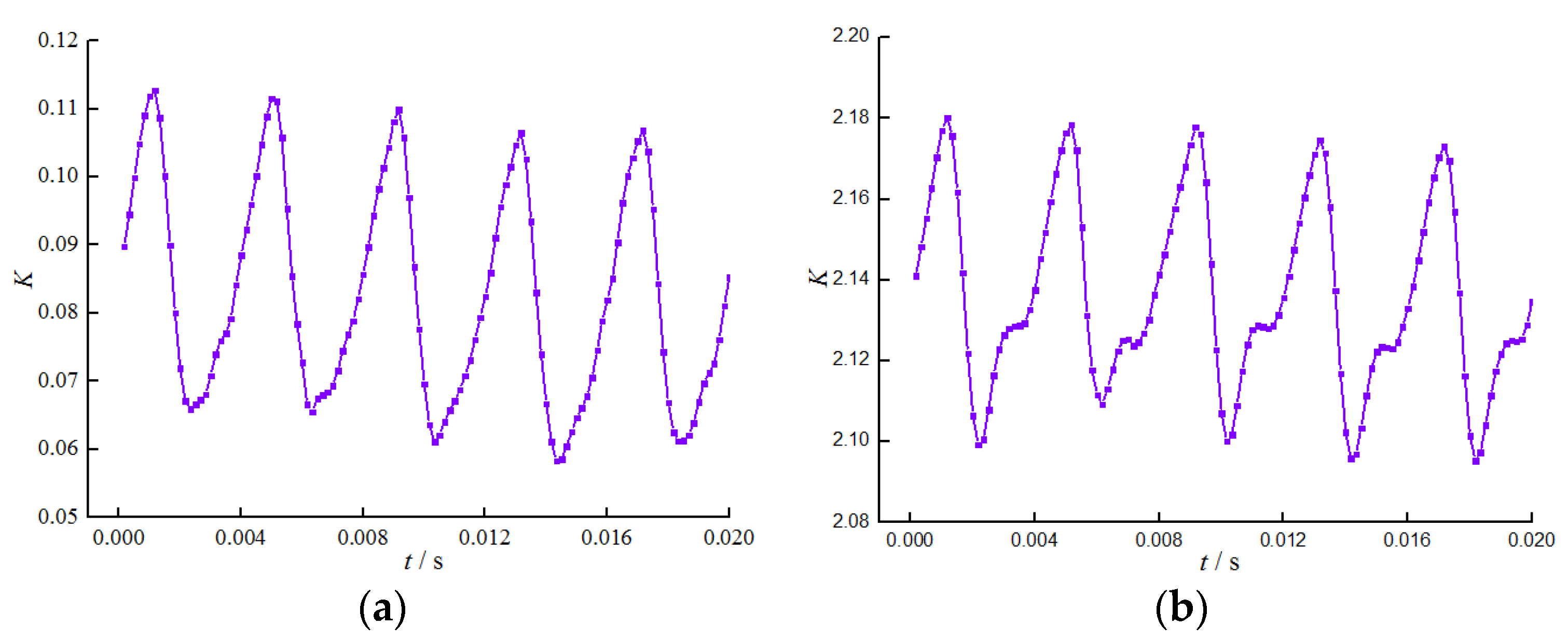

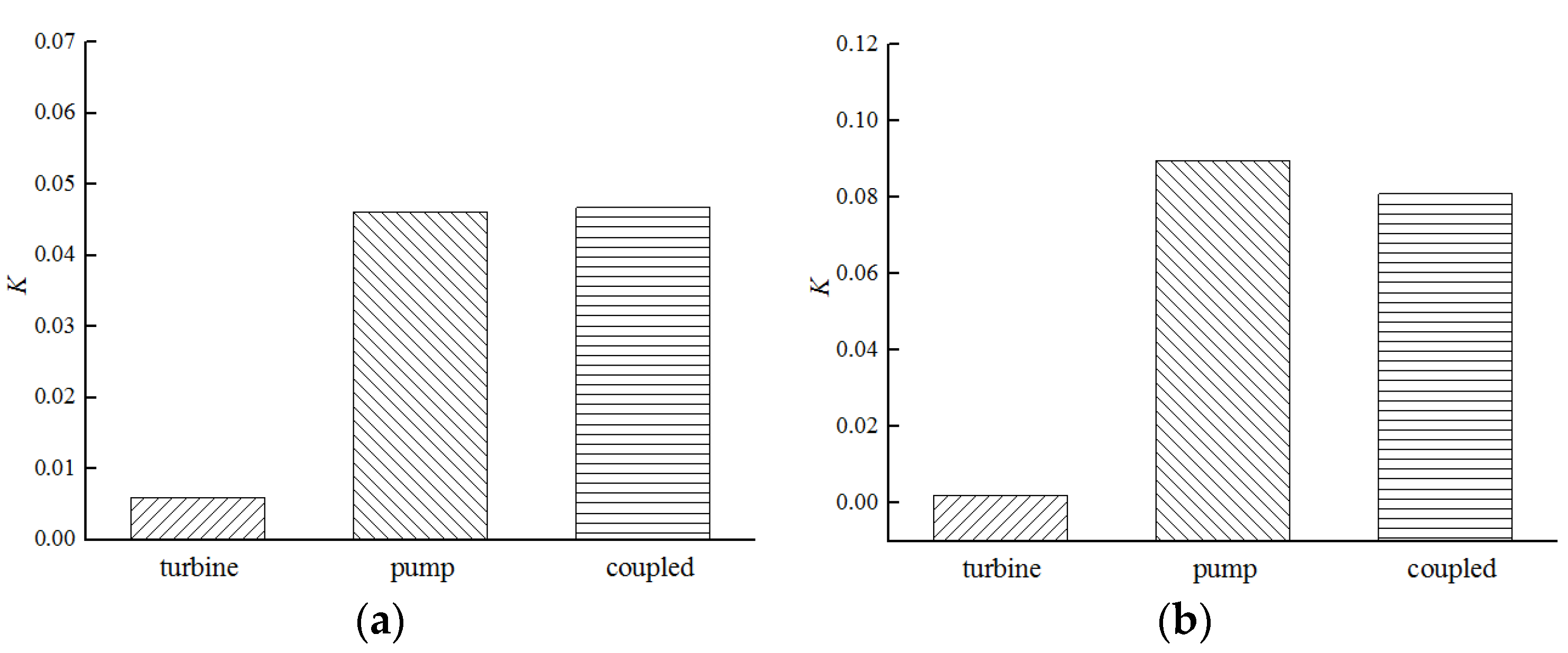

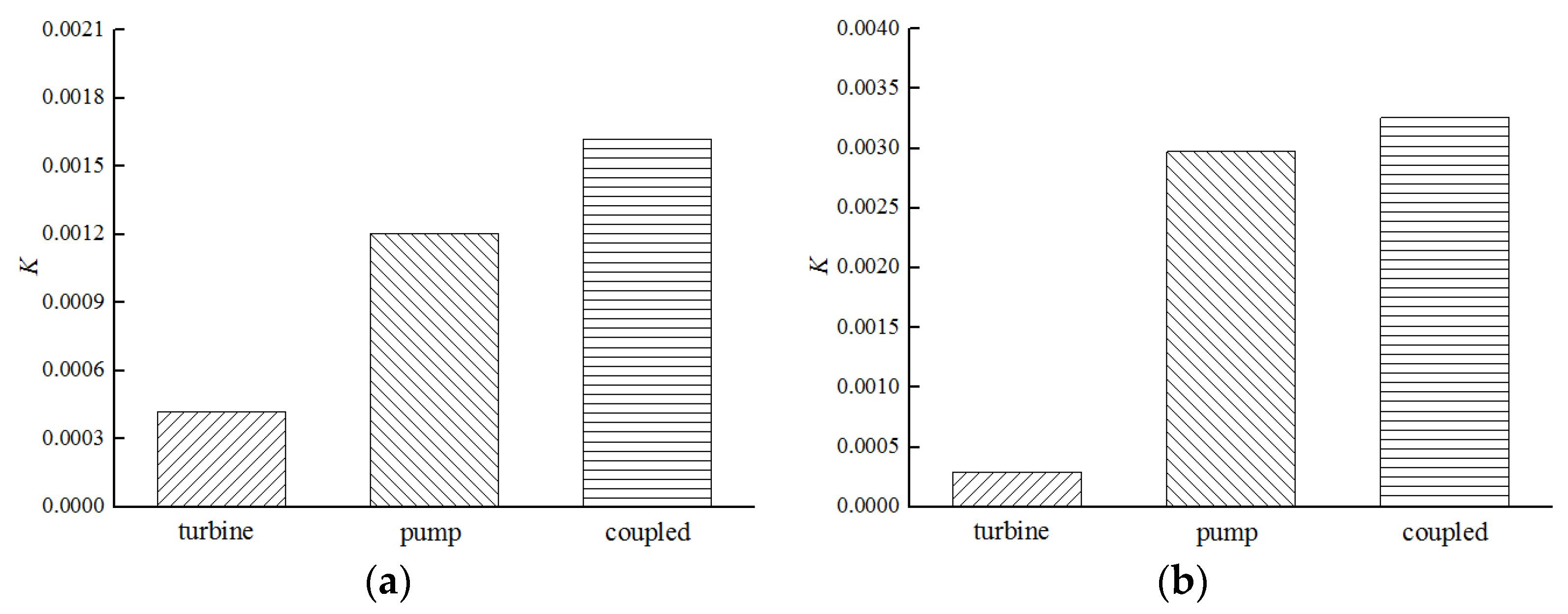

3.1. Radial Hydraulic Force on the Separate Turbine

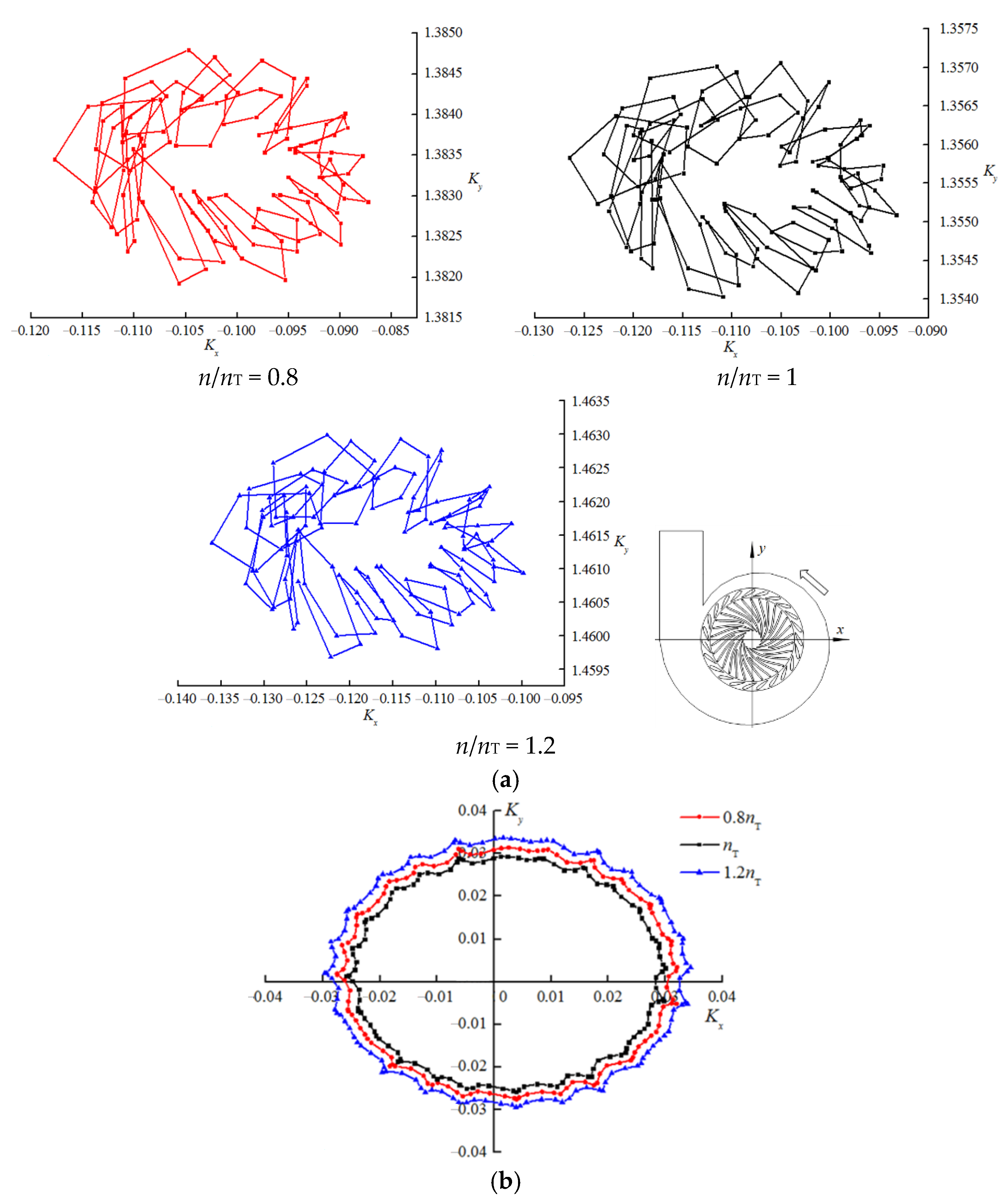

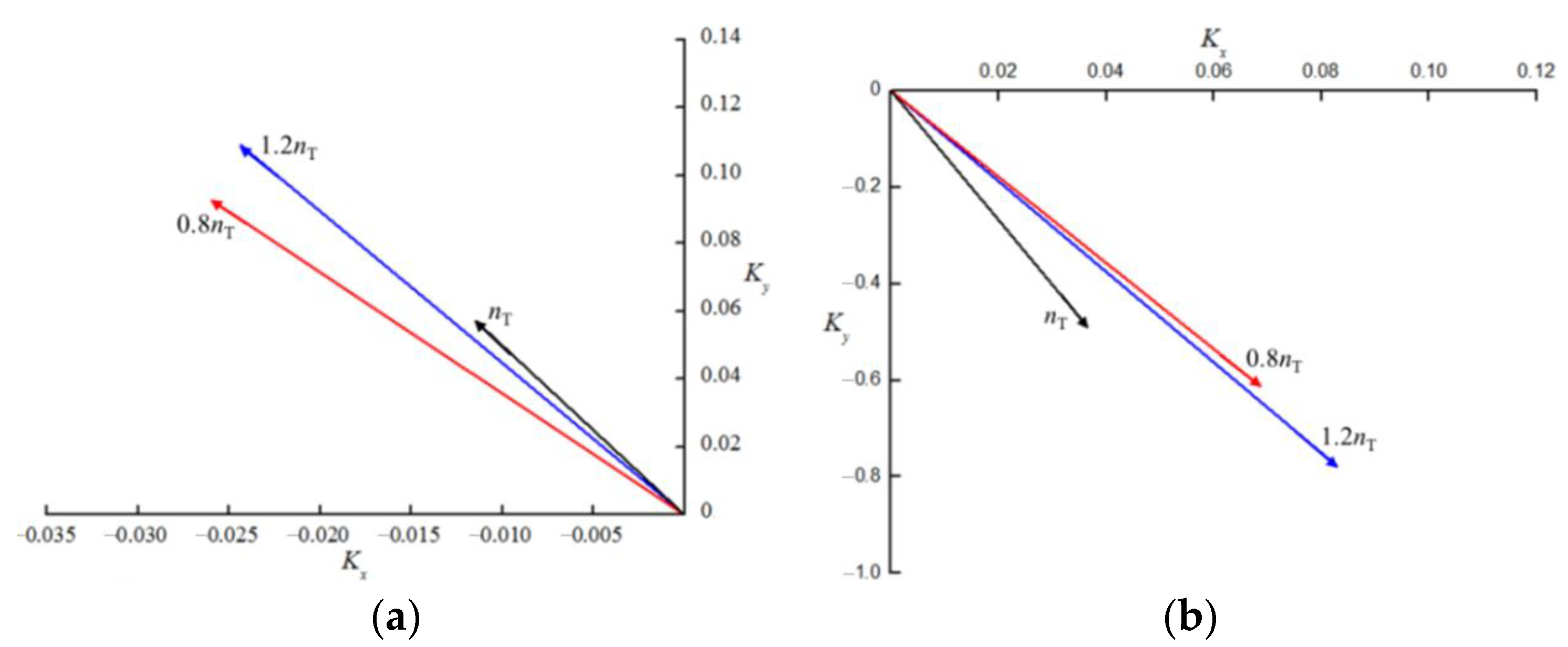

3.2. Radial Hydraulic Force on the Separate Pump

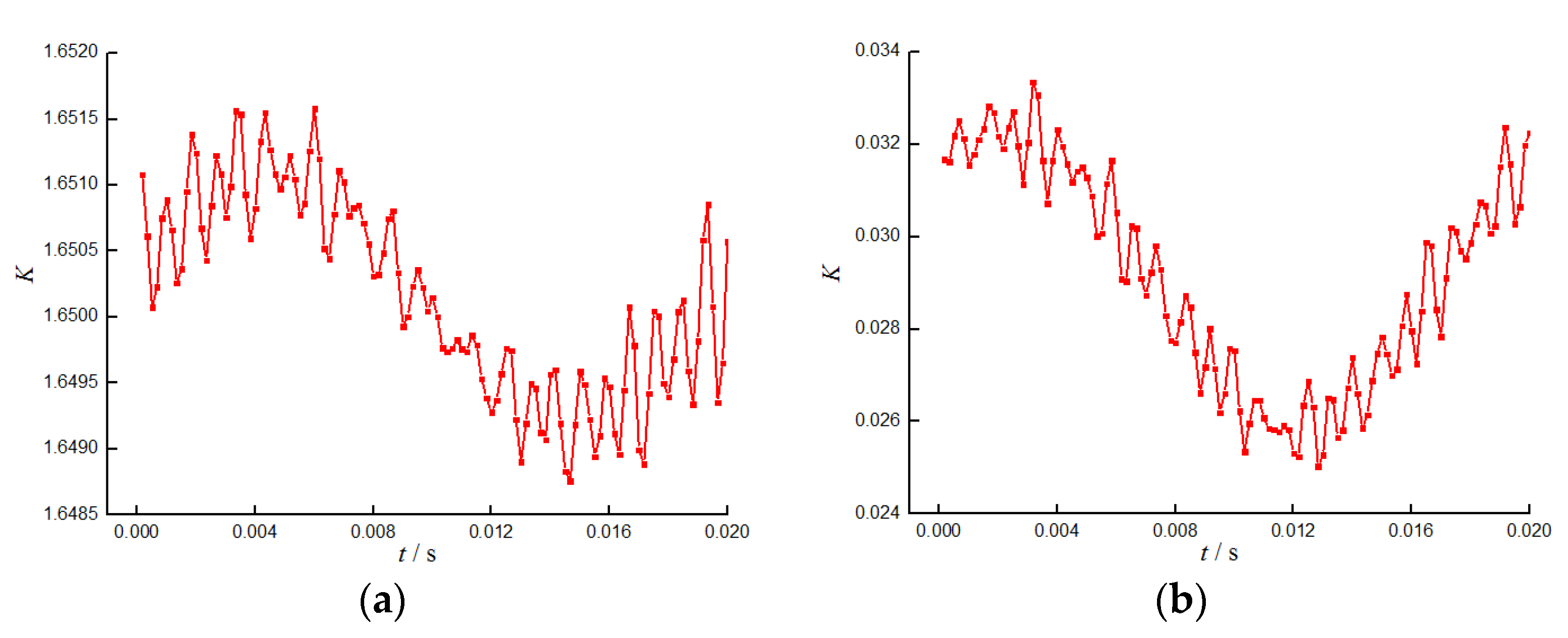

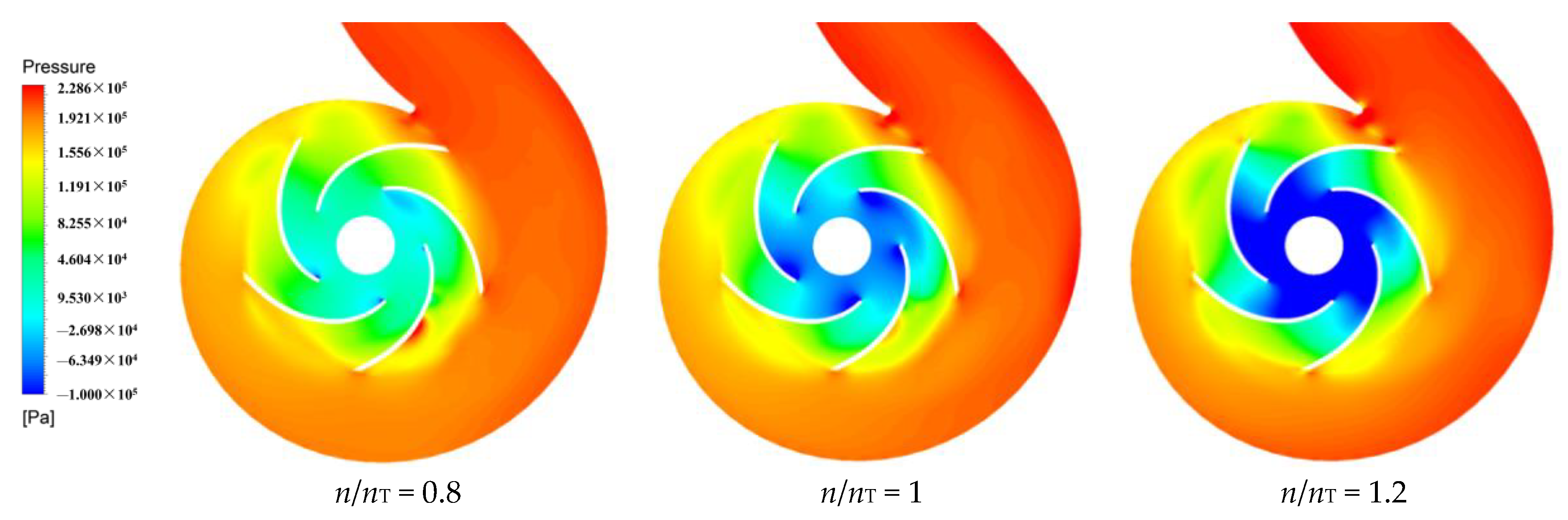

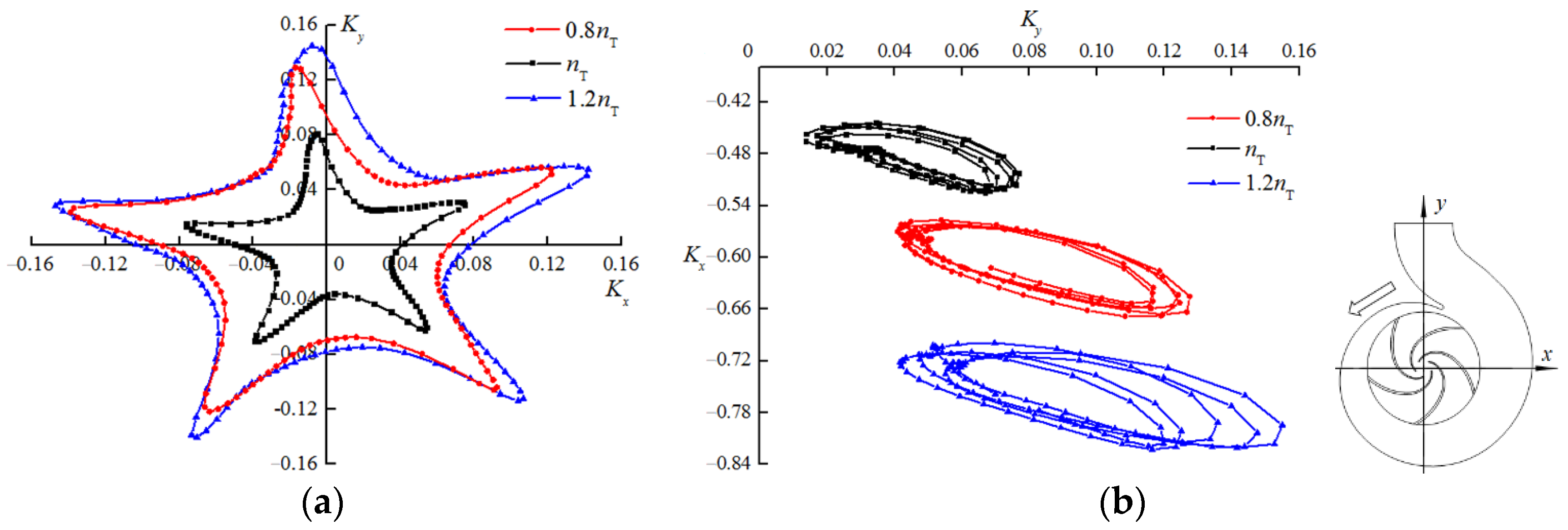

3.3. Coupled Characteristics of Radial Hydraulic Force on the Turbopump

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Weng, A.H. Research state of water turbine pump. Water Turbine Pump. 1994, 1, 1–7. [Google Scholar]

- Fujian RI, M. Turbopump; China Machine Press: Beijing, China, 1978. [Google Scholar]

- Liang, J.W.; Cai, L.Q. Overview for Water turbine pump industry. Water Turbine Pump. 2000, 2, 4–8. [Google Scholar]

- Wang, L.J.; Yuan, Y.; Xue, L. Research on design of high-efficiency fire turbopump supplying water from low-level water resources. Adv. Mater. Res. 2013, 694, 652–658. [Google Scholar] [CrossRef]

- Wang, L.J.; Yuan, Y.; Xue, L. Research on unsteady pressure fluctuation within the whole flow passage of a fire turbopump. Adv. Mater. Res. 2014, 945, 956–963. [Google Scholar] [CrossRef]

- Tan, L.W.; Yang, Y.F.; Shi, W.D.; Chen, C.; Xie, Z.S. Influence of blade wrap angle on the hydrodynamic radial force of single blade centrifugal pump. Appl. Sci. 2021, 11, 9052. [Google Scholar] [CrossRef]

- Huang, S.; Wu, Y.L. Analysis of flow field asymmetry and force on a centrifugal pump by 3-D numerical simulation. Fluid Mach. 2006, 34, 30–33. [Google Scholar]

- Hideo, O. Vibration and Oscillation of Hydraulic Machinery; Avebury Technical Gower House: Farnham, UK, 1991. [Google Scholar]

- Guelich, J.; Jud, W.; Hughes, S.F. Review of parameters influencing hydraulic forces on centrifugal impellers. Proc. IMechE Part A J. Power Energy. 1987, 201, 163–174. [Google Scholar] [CrossRef]

- Yuan, Y.; Yuan, S.Q.; Tang, L.D. Numerical investigation on the mechanism of double-volute balancing radial hydraulic force on the centrifugal pump. Processes. 2019, 7, 689. [Google Scholar] [CrossRef] [Green Version]

- Christian, L. The determination of dynamic radial forces in hydraulic machines. Voith Res. Constr. 1992, 28, 27–30. [Google Scholar]

- Miyabe, M.; Furukawa, A.; Maeda, H.; Umeki, I. Rotating stall behavior in a diffuser of mixed flow pump and its suppression. In Proceedings of the ASME Fluids Engineering Division Summer Conference (FEDSM ’08), Jacksonville, FL, USA, 10–14 August 2008; pp. 1147–1152. [Google Scholar]

- Gayo, J.L.; Gonzalez, J.; Fernandez-francos, J. The effect of the operating point on the pressure fluctuations at the blade passage frequency in the volute of a centrifugal pump. Trans. ASME J. Fluids Eng. 2002, 124, 784–790. [Google Scholar] [CrossRef]

- Guo, S.; Maruta, Y. Experimental investigations on pressure fluctuations and vibration of the impeller in a centrifugal pump with vaned diffusers. JSME Int. J. Ser. B. 2005, 48, 136–143. [Google Scholar] [CrossRef] [Green Version]

- Arndt, N.; Acosta, A.J.; Brennen, C.E.; Caughey, T.K. Experimental investigation of rotor–stator interaction in a centrifugal pump with several vaned diffusers. ASME J. Turbomach. 1990, 112, 98–108. [Google Scholar] [CrossRef]

- Zhang, L.; Li, H.; Xu, H.; Shi, W.D.; Yang, Y.; Wang, W.H.; Zhou, L. Experimental and numerical investigation of pressure fluctuation in a low-specific-speed centrifugal pump with a gap drainage impeller. Shock Vib. 2021, 2021, 5571178. [Google Scholar] [CrossRef]

- Yang, F.; Li, Z.B.; Yuan, Y.; Liu, C.; Zhang, Y.Q.; Jin, Y. Numerical and experimental investigation of internal flow characteristics and pressure fluctuation in inlet passage of axial flow pump under deflection flow conditions. Energies 2021, 14, 5245. [Google Scholar] [CrossRef]

- Gonzalez, J.; Fernandez, J.; Blanco, E.; Santolaria, C. Numerical simulation of the dynamic effects due to impeller-volute interaction in a centrifugal pump. Trans. ASME J. Fluid Eng. 2002, 124, 348–355. [Google Scholar] [CrossRef]

- Zhang, M.; Tsukamoto, H. Unsteady hydrodynamic forces due to rotor-stator interaction on a diffuser pump with identical number of vanes on the impeller and diffuser. ASME Fluids Eng. 2005, 127, 743–751. [Google Scholar] [CrossRef]

- Tang, L.D.; Yuan, S.Q.; Tang, Y.; Gao, Z.J. Performance characteristics in runner of an impulse water turbine with splitter blade. Processes. 2021, 9, 303. [Google Scholar] [CrossRef]

- Muggli, F.A.; Eisele, K.; Zhang, Z.; Casey, M.V. Numerical investigations of the flow in a pump turbine in pump mode. In Proceedings of the 3rd European Conference on Turbomachinery, London, UK, 2–5 March 1999; pp. 997–1002. [Google Scholar]

- Yuan, Y.; Yuan, S.Q.; Tang, L.D. Investigation on the effect of complex impeller on vibration characteristics for a high-speed centrifugal pump. Proc. Inst. Mech. Eng. Part A J. Power Energy. 2020, 234, 611–624. [Google Scholar] [CrossRef]

| Turbine Head P/MPa | Turbine Flow Discharge Q/L·s−1 | Pump Flow Discharge q/L·s−1 | Pump Head h/m | Rotate Speed n/r·min−1 |

|---|---|---|---|---|

| 0.7 | 35 | 37 | 26 | 3000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Y.; Jin, R.; Tang, L. Numerical Investigation on the Flow-Induced Vibration Characteristics of Fire Turbopump with the Turbine-Pump Structure. Appl. Sci. 2022, 12, 4650. https://doi.org/10.3390/app12094650

Yuan Y, Jin R, Tang L. Numerical Investigation on the Flow-Induced Vibration Characteristics of Fire Turbopump with the Turbine-Pump Structure. Applied Sciences. 2022; 12(9):4650. https://doi.org/10.3390/app12094650

Chicago/Turabian StyleYuan, Ye, Rong Jin, and Lingdi Tang. 2022. "Numerical Investigation on the Flow-Induced Vibration Characteristics of Fire Turbopump with the Turbine-Pump Structure" Applied Sciences 12, no. 9: 4650. https://doi.org/10.3390/app12094650

APA StyleYuan, Y., Jin, R., & Tang, L. (2022). Numerical Investigation on the Flow-Induced Vibration Characteristics of Fire Turbopump with the Turbine-Pump Structure. Applied Sciences, 12(9), 4650. https://doi.org/10.3390/app12094650