Assessment of Heavy Metal and Oil-Contaminated Silty Sand Treatment by Electrical Resistance Heating Method

Abstract

:Featured Application

Abstract

1. Introduction

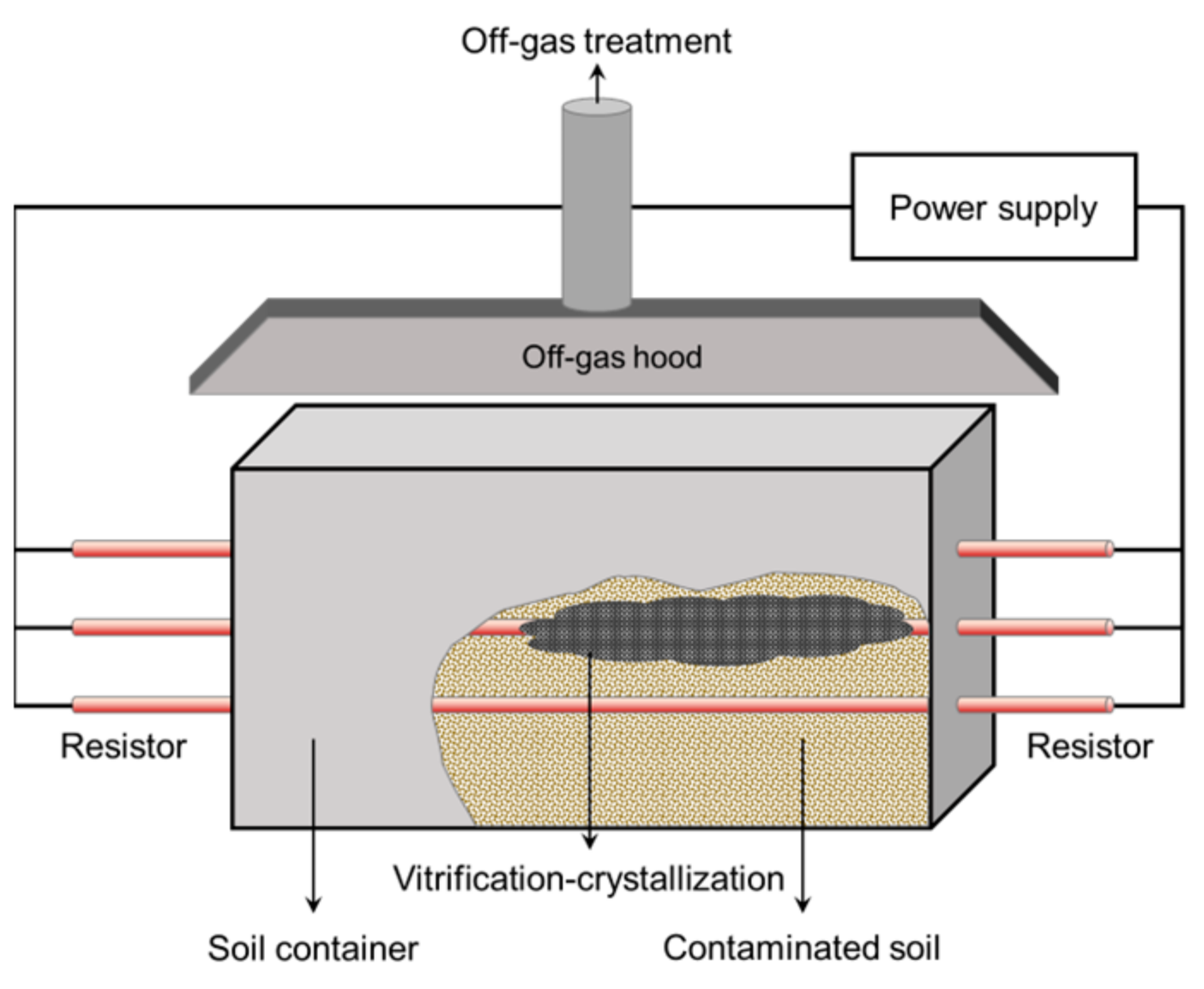

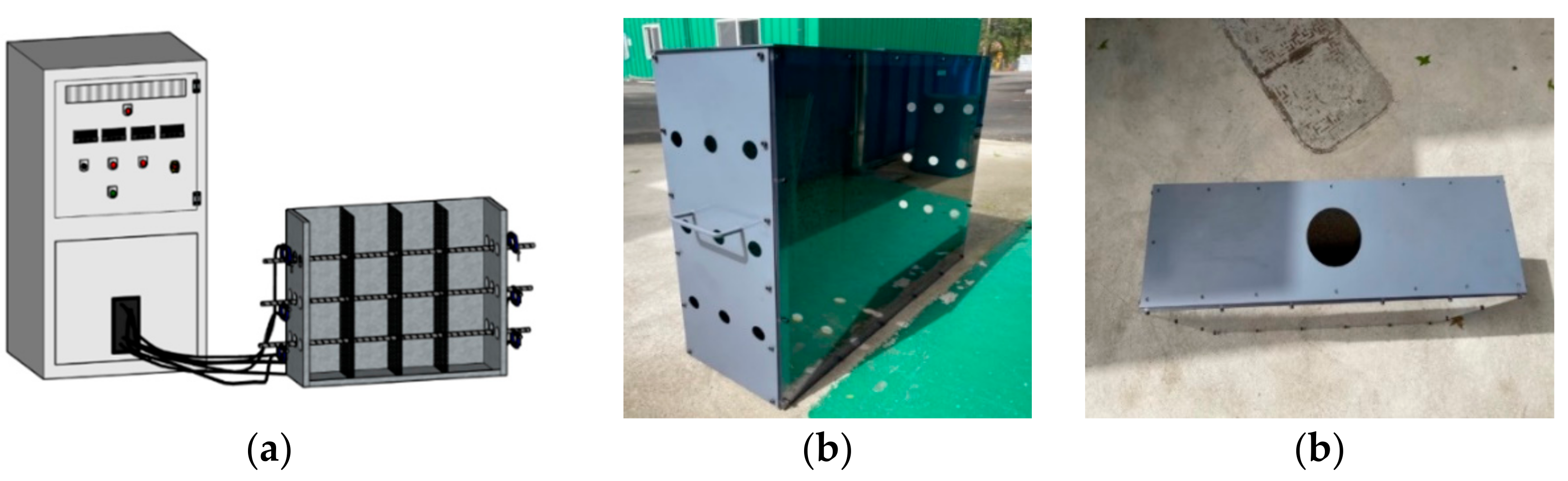

2. Experimental Program

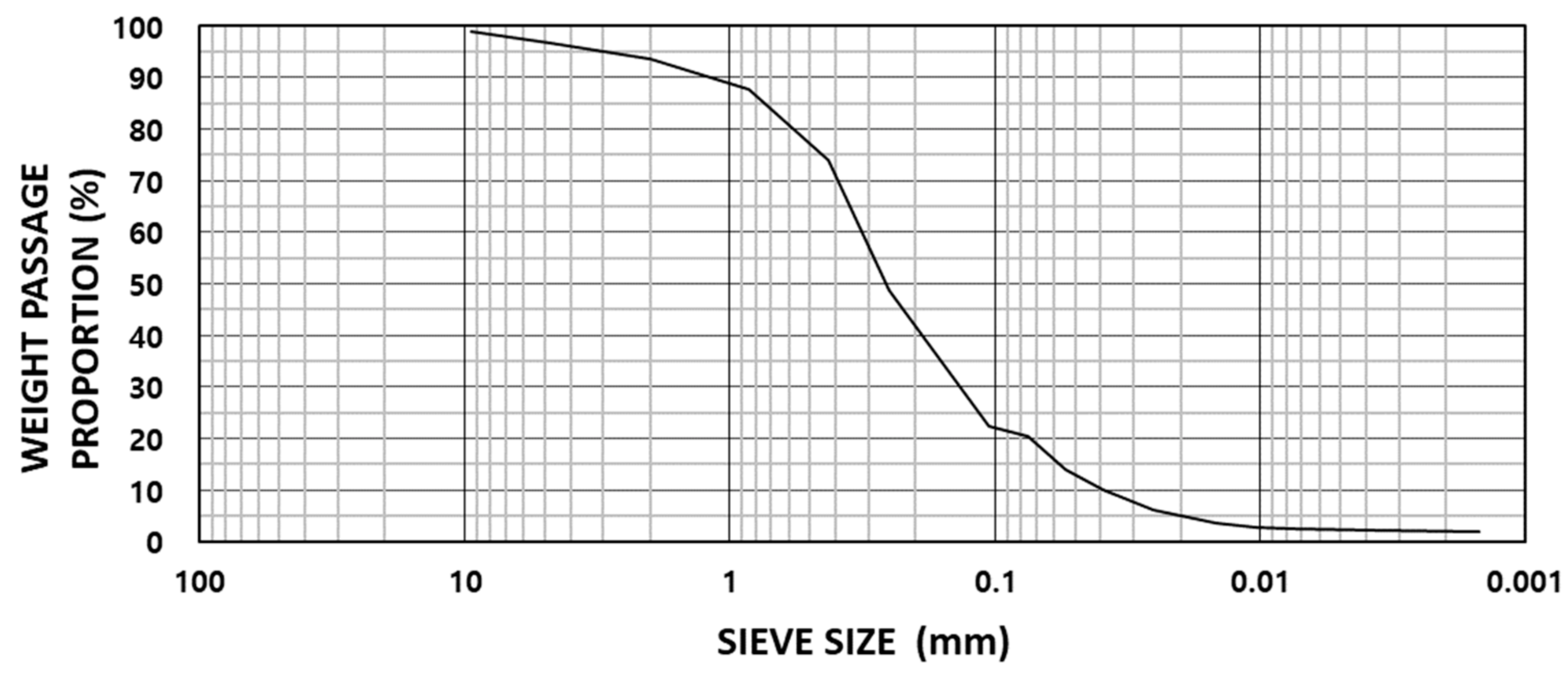

2.1. Experimental Materials

2.2. Analysis of Contaminants

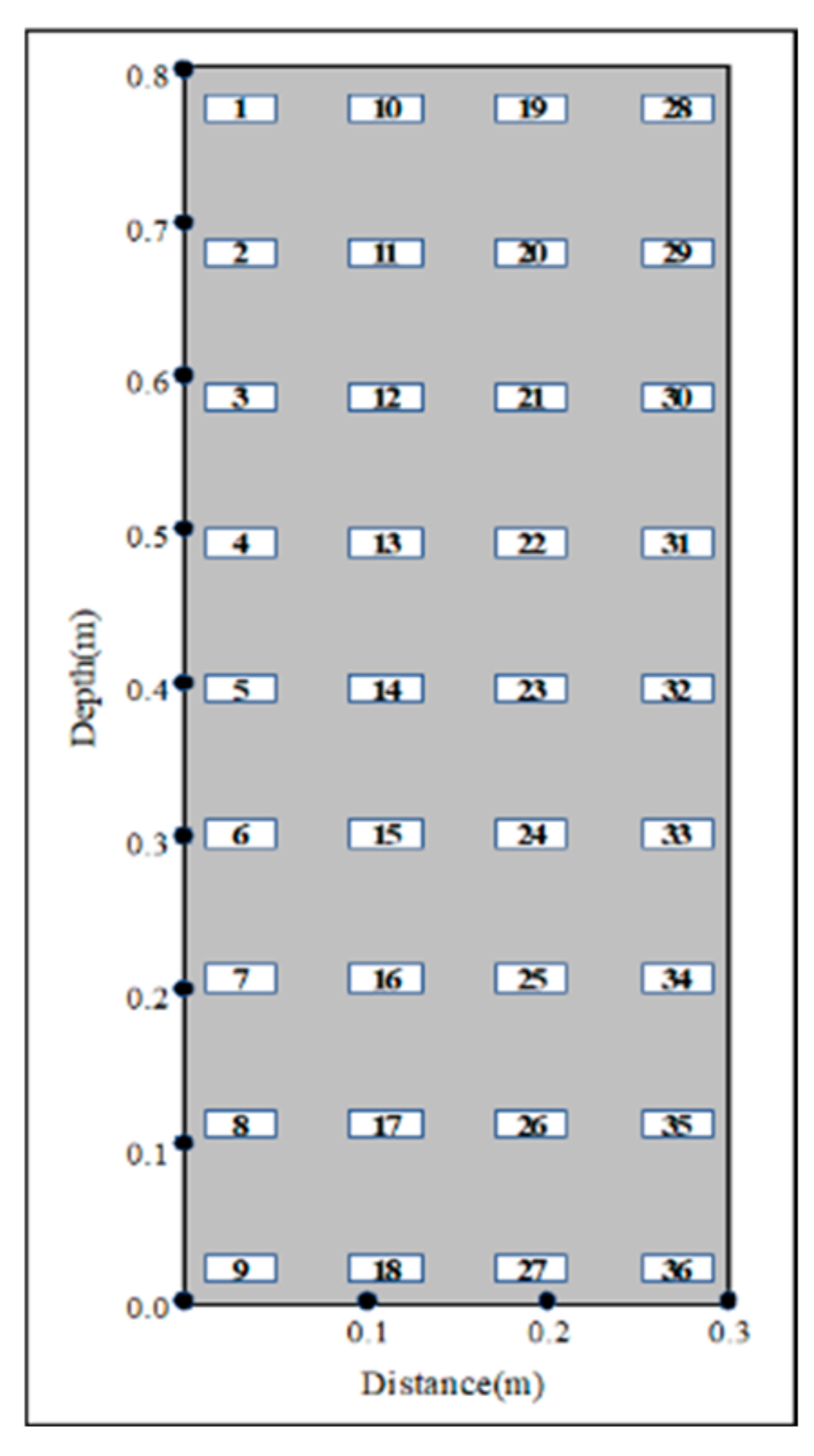

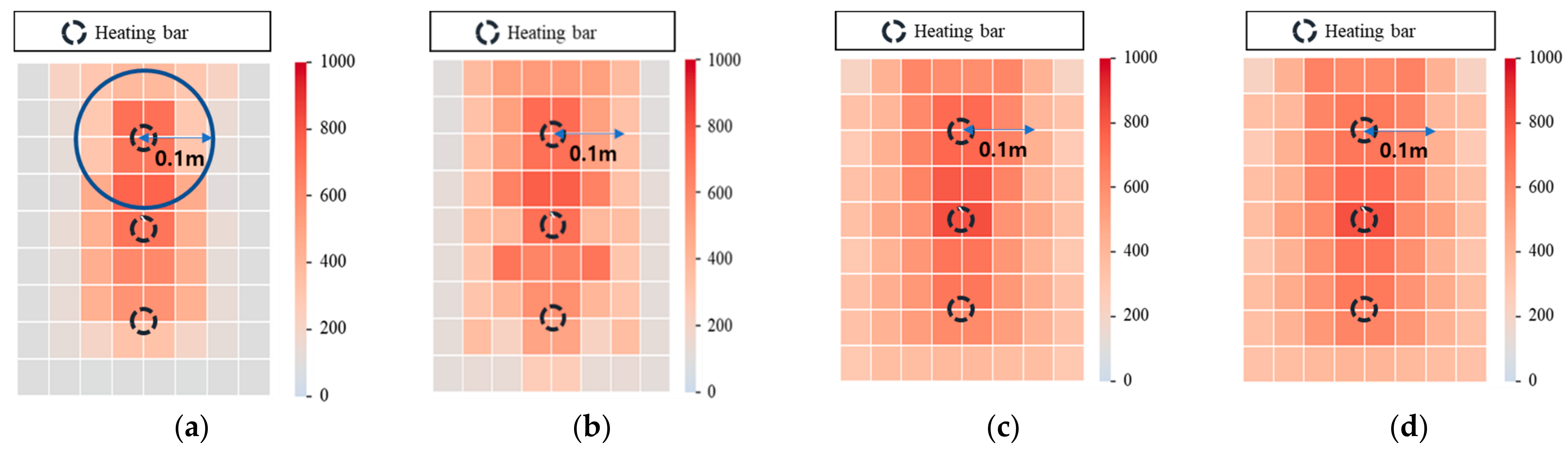

2.3. Experimental Design

3. Experimental Results

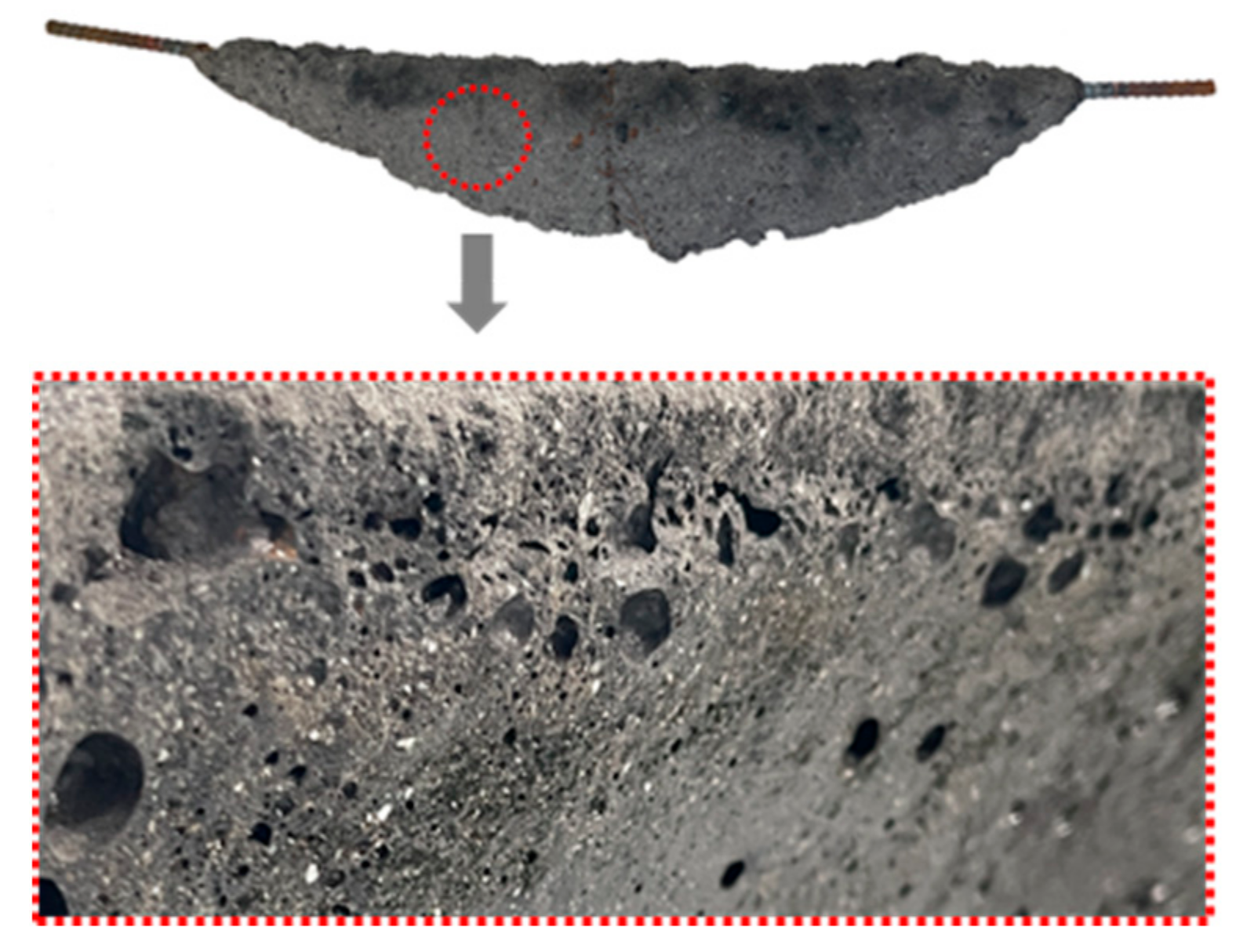

3.1. Soil Remediation Results

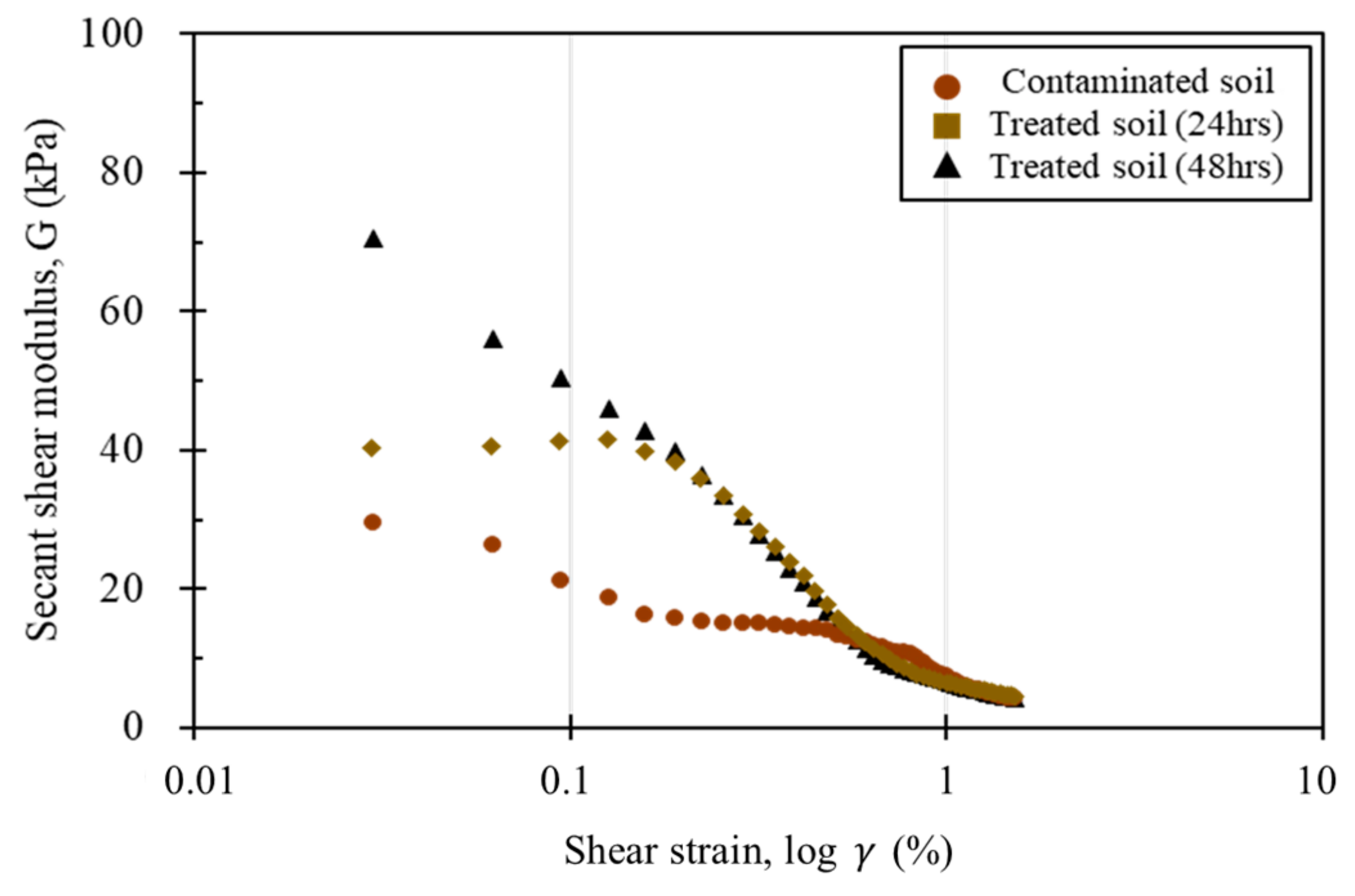

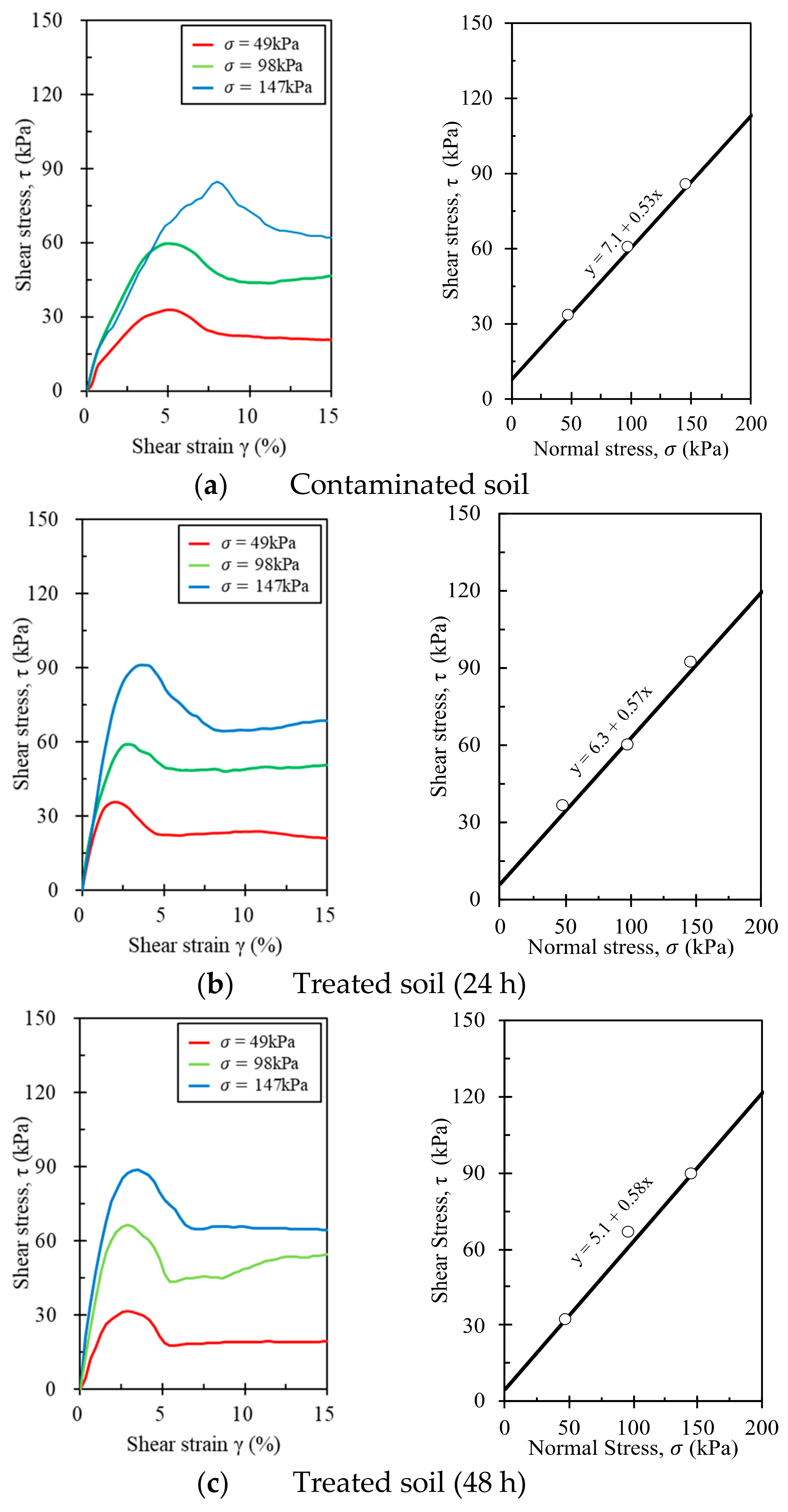

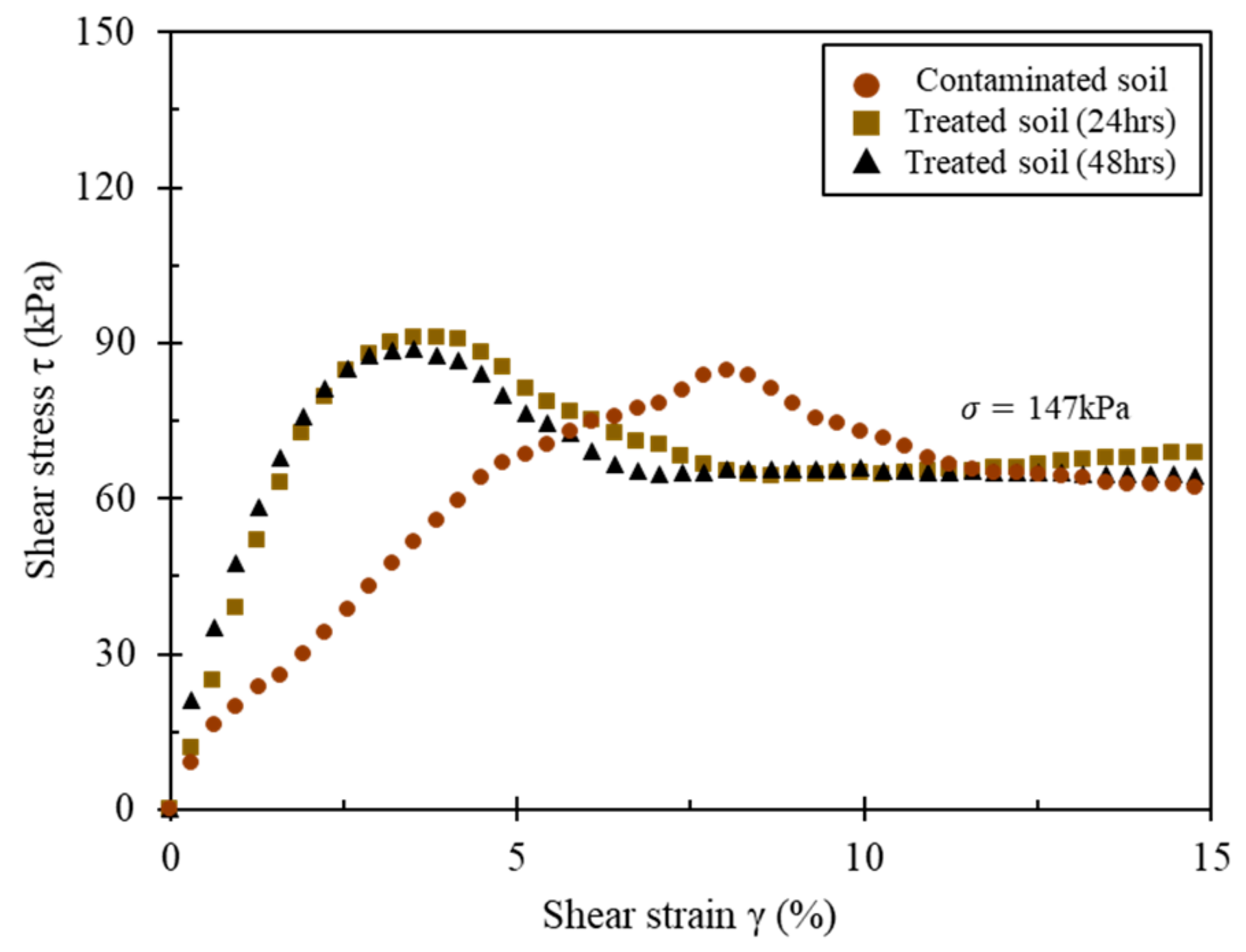

3.2. Direct Shear Test

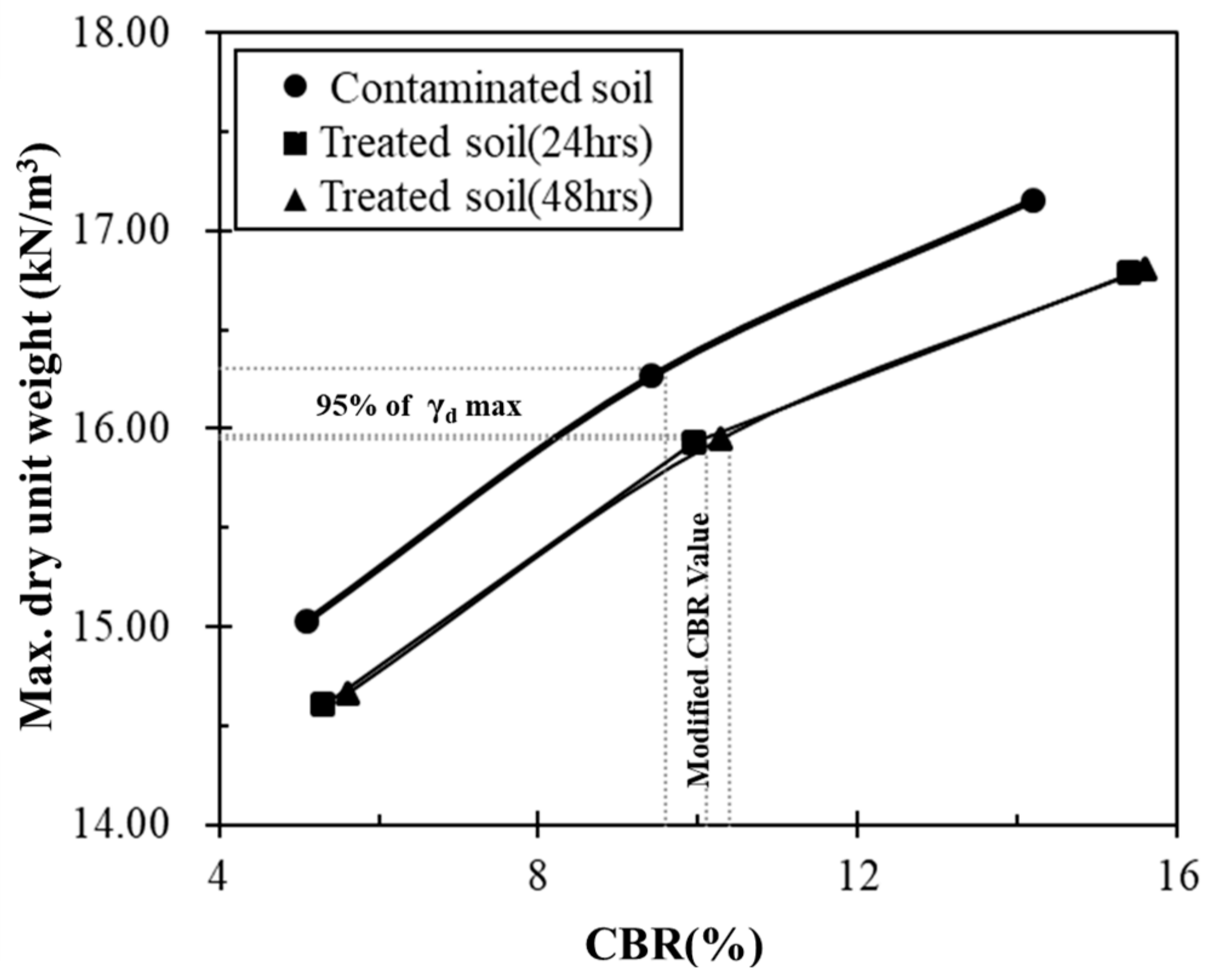

3.3. Modified California Bearing Ratio Test

3.4. Recyclability Assessment of Remediated Soil

4. Conclusions

- (1)

- Based on the Korean Ministry of Environment standards [5], contaminants, such as heavy oil, organic matter and heavy metal, were not detected; the removal efficiency of TPH was estimated as 99.99% and heavy metals, as some of the contaminants, were isolated as a crystal in a treated soil without any harmful leakage.

- (2)

- It was also geotechnically found that decontamination processes, such as the thermal treatment of heavy metals and heavy oils, had an effect on the increase in the internal friction angle, shear modulus and modified CBR of treated silty sand. The obtained results are attributed to the reduction in the lubrication effect of oil occupied between soil particles.

- (3)

- The physical properties (particle size and Atterberg limits) and improved mechanical properties (internal friction angle, shear modulus and modified CBR) of remediated silty sand satisfied the criteria for construction fill materials.

- (4)

- In conclusion, it was shown that the electrical resistance heating method developed in this study is an environmentally and geotechnically effective technology for the recovery of clean construction fill material from hazardous-waste-contaminated silty sand.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shin, E.C.; Lee, J.B.; Das, B.M. Bearing capacity of a model scale footing on crude oil-contaminated sand. Geotech. Geol. Eng. 1999, 17, 123–132. [Google Scholar] [CrossRef]

- Al-Sanad, H.A.; Eid, W.K.; Ismael, N.F. Geotechnical properties of oil-contaminated Kuwaiti sand. J. Geotech. Eng. 1995, 125, 407–412. [Google Scholar] [CrossRef]

- Shin, E.C.; Das, B.M. Bearing capacity of unsaturated oil-contaminated sand. Int. J. Offshore Polar Eng. 2000, 11, 220–227. [Google Scholar]

- McBride, M.B. Environmental Chemistry of Soils; Oxford University Press Inc.: New York, NY, USA, 1994. [Google Scholar]

- Ministry of Korean Environment. Soil and Groundwater Remediation Technology; Jinhan M&B: Seoul, Korea, 2014; pp. 135–157.

- ASTM D-2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System)1. ASTM International: West Conshohocken, PA, USA, 2011; No. 19428-2959.

- ASTM D-698; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort. ASTM International: West Conshohocken, PA, USA, 2007; No. 19428-2959.

- ASTM D-4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017; No. 19428-2959.

- ASTM D-792; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 2020; No. 19428-2959.

- ASTM D-6913; Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis. ASTM International: West Conshohocken, PA, USA, 2009; No. 19428-2959.

- KS M ISO 16703; Korea Industrial Standards Commission, Soil Quality—Determination of Content of Hydrocarbon in the Range C10 to C40 by Gas Chromatography. ISO: Geneva, Switzerland, 2005.

- ASTM D-3080; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. ASTM International: West Conshohocken, PA, USA, 2012; No. 19428-2959.

- ASTM D-1883; Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. ASTM International: West Conshohocken, PA, USA, 2021; No. 19428-2959.

- KS F 2320:2020; Standard Test Method for the California Bearing Ratio Soils. Korea Industrial Standard: Seoul, Korea, 2020.

- Abdulhamid, S.N.; Hasan, A.M.; Aziz, S.Q. Solidification/Stabilization of Contaminated Soil in a South Station of the Khurmala Oil Field in Kurdistan Region, Iraq. Appl. Sci. 2021, 11, 7474. [Google Scholar] [CrossRef]

- Elsaigh, W.A.H.; Oluremi, J.R. Assessment of Geotechnical Properties of Oil Contaminated Subgrade Soil: Review. Soil Sediment Contam. Int. J. 2021, 1–25. [Google Scholar] [CrossRef]

- Ministry of Land, Infrastructure and Transport. Road Construction Specification; Korea Road Associates: Seoul, Korea, 2015.

- Vidonish, J.E.; Zygourakis, K.; Masiello, C.A.; Sabadell, G.; Alvarez, P.J. Thermal Treatment of Hydrocarbon-Impacted Soils: A Review of Technology Innovation for Sustainable Remediation. Engineering 2016, 2, 426–437. [Google Scholar] [CrossRef]

| Item | Unit | Value | References |

|---|---|---|---|

| USCS classification | - | SM | ASTM D-2487 [6] |

| Optimum moisture contents | % | 13.9 | ASTM D-698 [7] |

| Max. dry unit weight | kN/m3 | 17.16 | ASTM D-698 [7] |

| Liquid limit † | - | * N.P. | ASTM D-4318 [8] |

| Plastic limit † | - | N.P. | ASTM D-4318 [8] |

| Plasticity index † | - | N.P. | ASTM D-4318 [8] |

| Specific gravity | g/cm3 | 2.56 | ASTM D-792 [9] |

| Coefficient of uniformity | - | 10.7 | ASTM D-6913 [10] |

| Coefficient of curvature | - | 2.3 | ASTM D-6913 [10] |

| Type | Unit | Criteria | Results | Remarks |

|---|---|---|---|---|

| Copper (Cu) | mg/kg | 2000 | 27.1 | |

| Lead (Pb) | mg/kg | 700 | 39.8 | |

| Zinc (Zn) | mg/kg | 2000 | 243.8 | |

| Nickel (Ni) | mg/kg | 500 | 15.7 | |

| Hexavalent chrome (Cr6+) | mg/kg | 40 | 0.8 | |

| Cyanide (CN) | mg/kg | 120 | 55.6 | |

| Mercury (Hg) | mg/kg | 20 | 21.63 | Exceeded |

| Arsenic (As) | mg/kg | 200 | 5.42 | |

| Benzene | mg/kg | 3 | 0.7 | |

| TPH | mg/kg | 2000 | 21,081 | Exceeded |

| Benzo(a)Pyrene | mg/kg | 7 | 0.901 |

| Type | Unit | Remediation Time (h) | ||

|---|---|---|---|---|

| 0 | 24 | 48 | ||

| Copper (Cu) | mg/kg | 27.1 | 16.8 | * N.D. |

| Lead (Pb) | mg/kg | 39.8 | 27.3 | 0.01 |

| Zinc (Zn) | mg/kg | 243.8 | 204.4 | N.D. |

| Nickel (Ni) | mg/kg | 15.7 | 15.0 | N.D. |

| Hexavalent chrome (Cr6+) | mg/kg | 0.8 | N.D. | N.D. |

| Cyanide (CN) | mg/kg | 55.6 | 0.2 | N.D. |

| Mercury (Hg) | mg/kg | 21.63 | 0.78 | N.D. |

| Arsenic (As) | mg/kg | 5.42 | 5.2 | N.D. |

| Benzene | mg/kg | 0.7 | N.D. | N.D. |

| TPH | mg/kg | 21,081 | N.D. | N.D. |

| Benzo(a)Pyrene | mg/kg | 0.901 | N.D. | N.D. |

| Sample | Cohesion (C) | |

|---|---|---|

| Contaminated soil Treated soil (24 h) | 7.1 6.3 | 27.9 29.6 |

| Treated soil (48 h) | 5.1 | 30.2 |

| Type | Criteria (%) | Contaminated Soil | Treated Soil (24 h) | Treated Soil (48 h) |

|---|---|---|---|---|

| Subsoil | more than 2.5 | satisfied | satisfied | satisfied |

| Subgrade | more than 10 | not satisfied | satisfied | satisfied |

| Subbase | more than 10 | not satisfied | satisfied | satisfied |

| Anti-frost layer | more than 10 | not satisfied | satisfied | satisfied |

| Type | Category | Unit | Criteria | Test Result | Remarks |

|---|---|---|---|---|---|

| Fill material | Maximum aggregate size | mm | less than 100 | 4.75 | satisfied |

| 5 mm Sieve pass rate | % | 25~100 | 99.1 | satisfied | |

| 0.08 mm Sieve pass rate | % | 0~25 | 21.7 | satisfied | |

| Liquid limit † | % | less than 50 | N.P. | satisfied | |

| Plastic limit † | % | less than 25 | N.P. | satisfied | |

| Plasticity index † | less than 10 | N.P. | satisfied | ||

| Modified CBR | more than 10 | 10.4 | satisfied |

| Technology | Removal Mechanisms | Treatment Conditions | Contaminants Targeted | Cost (USD per Metric Ton) |

|---|---|---|---|---|

| Developed electrical resistance heating | Entrapment in molten glass, desorption, pyrolysis, oxidation | 500–1300 °C | Full range of hydrocarbons | USD 35–USD 70 (2021) |

| Ex situ thermal desorption | Desorption (pyrolysis and oxidation often occur) | Low temp.: 100–300 °C High temp.: 300–550 °C | Volatile and semi-volatile hydrocarbons, creosote, and TPH | USD 46–USD 99 (2016) |

| Incineration | Oxidation | 600–1600 °C | Full range of hydrocarbons | USD 150–USD 2900 (2016) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, C.; Koh, T.; Lee, D.; Park, D. Assessment of Heavy Metal and Oil-Contaminated Silty Sand Treatment by Electrical Resistance Heating Method. Appl. Sci. 2022, 12, 4630. https://doi.org/10.3390/app12094630

Kim C, Koh T, Lee D, Park D. Assessment of Heavy Metal and Oil-Contaminated Silty Sand Treatment by Electrical Resistance Heating Method. Applied Sciences. 2022; 12(9):4630. https://doi.org/10.3390/app12094630

Chicago/Turabian StyleKim, Changju, Taehoon Koh, Donggeun Lee, and Duhee Park. 2022. "Assessment of Heavy Metal and Oil-Contaminated Silty Sand Treatment by Electrical Resistance Heating Method" Applied Sciences 12, no. 9: 4630. https://doi.org/10.3390/app12094630

APA StyleKim, C., Koh, T., Lee, D., & Park, D. (2022). Assessment of Heavy Metal and Oil-Contaminated Silty Sand Treatment by Electrical Resistance Heating Method. Applied Sciences, 12(9), 4630. https://doi.org/10.3390/app12094630