Abstract

The study aims to evaluate the change in the behavior of sub-base materials being used in road pavements through blending fines of different types in different amounts. Fines are added in aggregate samples as part of gradations proposed by the American Association for State and Highway Transportation Official (AASHTO). Composite samples conforming to AASHTO gradations B and C were prepared by mixing coarse aggregates in varying proportions, ranging from 0 to 15%. Laboratory tests—including aggregate quality tests (abrasion test, flakiness index and elongation Index), physical tests (particle size analysis and specific gravity), and strength test (modified Proctor, California bearing ratio, and permeability test)—were performed on the control as well as the modified samples. It was observed that the material with 0% fines yielded the highest CBR values (greater than 98%) and coefficient of permeability of 4.4 × 10−4 cm/s. However, with the increasing of the fines up to 15%, a substantial reduction in CBR value up to 10% and coefficient of permeability to 1.62 × 10−7 cm/s was noticed. Based on these results, the modulus of rigidity (MR) and the corresponding structural numbers were determined for each layer. Conclusively, the required thickness of the base course was increased from 11 cm for the samples with 0% fines to 24 cm (118%) for the samples with the addition of 15% fines according to the AASHTO Design method.

1. Introduction

Sub-base is an important part of the flexible pavement structure and road serviceability that largely depends upon the quality of sub-base and base materials. The functions of the sub-base layer in flexible pavement are to: reduce subgrade stresses; encase subgrade against the punching of the base material; provide a working platform for construction machinery; preventing the intrusion of fines from the subgrade to the wearing course; and serve as a free draining material in the absence of a drainage layer below it. This study is focused on evaluating the impact of increasing the percentage of fines on the strength behavior of the sub-base layer. Previously, various researchers [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16] studied the effect of extra fine material on the behavior of aggregates and, some of them, concluded that the behavior of aggregate fine mixtures mainly depends on the type, shape, and gradation of the aggregates in addition to the quantity of fines, moisture content, and testing procedure. Additionally, some researchers [3,17,18,19] also noticed that the presence of extra fines did not have an impact upon the subgrade performance if proper drainage was provided through the aggregate mixture. Studies carried out by different researchers in this context are summarized below.

The prime function of the granular sub-base is to provide uniform support to the base course and compensating the inadequate subgrade strength rather than increasing the stability of the pavement [1]. Uthus et al. [2] studied the impact of fines upon the deformation characteristics and frost heave of unbound aggregates used in road construction, and concluded that the frost susceptibility of aggregates depends on their mineralogical composition, quantity of fine particles, and hydraulic conductivity. Lekarp et al. [3] reported that the deformation behavior of unbound aggregates under repeated traffic loading can be interpreted through their resilient response and availability of fines up to specific limit. However, these fines will have little effect on performance if the drainage conditions are excellent. Tian et al. [4] determined the resilient modulus (MR) for base materials by selecting finer, medium, and coarser gradation limits as specified by the Oklahoma Department of Transportation. In their study, three varying moisture contents, namely, optimum moisture content (OMC, 2% below and 2% above the OMC), were considered. The reported variability in MR values ranged between 10 and 50% for three different gradations, and between 10 and 20% for three different moisture contents. Additionally, they proposed a predictive model for MR values based upon multiple linear regression. Kamal et al. [5] conducted research on an unbound granular base using eight different grain size distributions to identify a free draining material to dissipate excess pore water pressure quickly and reduce pumping, and that had a high in situ stiffness and adequate resistance to permanent deformation. Raad et al. [6] compared the effect of fines on the dynamic response for open and dense graded base courses and observed that, under saturated conditions, the damage probability for the pavement with open graded aggregates is lesser. This is owing to fact that they offer more resistance to pore pressure build-up than dense-graded aggregates.

Thom and Brown [7] conducted a series of repeated load triaxial tests on aggregates by varying the gradation, degree of compaction, and moisture contents and concluded that, with the increase in moisture content, the elastic stiffness decreases slightly in the case of broadly graded materials. They also observed a reduction in stiffness with the increase in the fine proportion. Hicks and Monismith [8] studied the influence of density, gradation, and degree of saturation on the modulus of resilience and concluded that the value of the resilient modulus was directly proportional to the confining pressure, whereas a variation in resilience modulus was insignificant with an increase in axial stress. Moreover, the effect of density, fines, and the degree of saturation on the resilient modulus and Poisson’s ratio was marginal. Yoder and Witczak [11] mentioned that, for a specific particle size distribution of coarser materials, the proportion of fines affect the performance of the base course. Rigid pavements experiencing pumping have 3–4 percent or more fines than pavements that do not experience this phenomenon, which revealed the significance of fines on the performance of base or sub-base materials. Siswosoebrotho et al. [12] observed that the maximum dry density and California bearing ratio (CBR) increases with the increase in the fine content and the maximum value is attained at unique fine and moisture contents. The peak values reported were different for the varying type of fines. Cheung [13] stated that the CBR test can be used as a performance indicator for materials under traffic load. Additionally, limiting the value of the plasticity index for fines present in aggregates does not ensure the suitable performance of road materials under traffic load. Haung [14] stated that the sub-base layer contributes almost 45% of the total pavement structure for stability against failure. Furthermore, the engineering characterization of road material is necessary prior to use in any rehabilitation or reconstruction of road works. Cedergen [15] proposed that the useful life of a pavement can be increased three times by using a free draining base/sub-base layer. Gandara et al. [16] conducted a study to evaluate the engineering properties of granular materials with an emphasis on the particle size and fine content. From their study, it was revealed that fines have a large impact on the engineering performance of base materials and the fine content be limited to 10% in the base course. If the fines remain within the range of 5% to 10% in the base course, it possesses a high compressive strength and modulus of resilience. The Federal Highway Administration [20] stated that the granular unbound layers provided in the pavement have a significant contribution in the overall structural capacity of the pavement. The thickness of the pavement layer above the subgrade decreases significantly as the CBR value of the subgrade increases.

2. Materials and Methods

The samples used in this study comprised coarse aggregates and fines. Coarse aggregates were collected from Sargodha quarry, whereas non-plastic fines were prepared from the locally available silty soil (Ghassu). Fines with medium and high plasticity were obtained from the locally available and Nandipur clay, respectively. These fines were blended with coarse aggregates in different proportions, i.e., 5%, 10%, and 15%, to prepare composite samples as per AASHTO gradations ‘B’ and ‘C’, as shown in Table 1.

Table 1.

Grading requirement for samples as per the AASHTO standard.

Composite samples with non-plastic fines were designated with letters from A1 to A4, while those with medium- and high-plasticity fines were denoted by letters from B1 to B4 and from C1 to C4, respectively. The details of sample designation and classification are summarized in Table 2.

Table 2.

Laboratory test results for the composite samples.

All the samples were subjected to a series of laboratory tests, including grain size distribution, Los Angeles abrasion test, shape test, specific gravity, and consistency limit tests, to determine the physical properties of the samples. Modified Proctor compaction tests were performed in accordance with the ASTM standard D 1557 to ascertain the maximum dry density (MDD) and optimum moisture content (OMC) for each sample. These samples were compacted in CBR molds using modified Proctor hammer at OMC in five layers by applying 10, 30, and 65 blows per layer. The molds were soaked in water for 96 h. The CBR test was conducted as per ASTM-D 1883 and CBR values at 0.1″ and 0.2″ penetration were determined.

3. Test Results and Discussion

Grain size analysis, specific gravity, and shape tests, including flakiness and elongation indices, Los Angeles abrasion test, modified Proctor compaction test and California bearing ratios, were performed on all the samples. The results of the various laboratory tests are discussed in the following sub-sections.

3.1. Engineering Characteristics of Soil Aggregate Mixtures

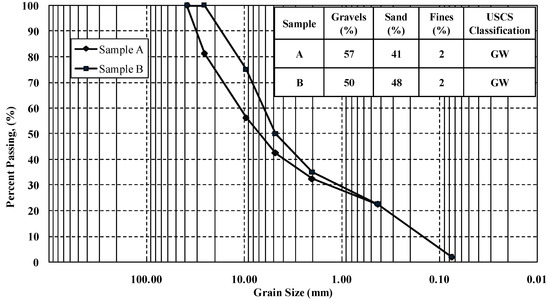

The gradation curves of the coarse aggregate samples are shown in Figure 1. The effective grain size (D10) of these samples is 0.17 mm, while the median grain size (D50) is in the range of 5.0~7.0 mm. The gravel content (fraction coarser than US #4) ranges between 50 and 57%, whereas the sand content varies from 41 to 48%. The percentage of fines (size lesser than Sieve No. 200) present in the samples is only 2%. Grain sizes with a reference to 60%, 30%, and 10% fines (D60, D30 and D10, respectively) were calculated from the GSD curves. The coefficients of uniformity and curvature vary from 33 to 55 and from 1.0 to 1.12, respectively. Both samples were classified as well-graded gravels (GW), according to the Unified Soil Classification System (USCS), ASTM D-2487 whereas the inherent fines present in the samples were non-plastic. These samples were mixed with non-medium and high-plasticity fines to prepare the composites. The gradation curves of the aggregate samples used in the study are shown in Figure 1.

Figure 1.

Gradations for the sub-base samples.

Laboratory tests were performed on these composite samples and the results are summarized in Table 2. All the samples belong to gradings B or C as per the AASHTO gradation. The blended samples were classified as per the Unified Soil Classification System (USCS). With the addition of medium-plasticity fines up to 15% and high-plasticity fines up to 5%, the sample’s classification changes from GW–GM to GW–GC (well-graded gravel with clay). Details of the classification tests for all composite samples prepared as per AASHTO gradings B or C are summarized in Table 2.

Composite samples prepared as per the AASHTO gradation ‘B’ have an average specific gravity of 2.65, a flakiness index (FI) of 34, an elongation index (EI) value of 42, and a Los Angeles abrasion (LAAV) value of 19, whereas for composite samples prepared as per the AASHTO gradation ‘C’, these values were 2.66, 16, 39, and 42, respectively.

3.2. Effect of Fines on the Compaction Characteristics of Soil Aggregate Mixtures

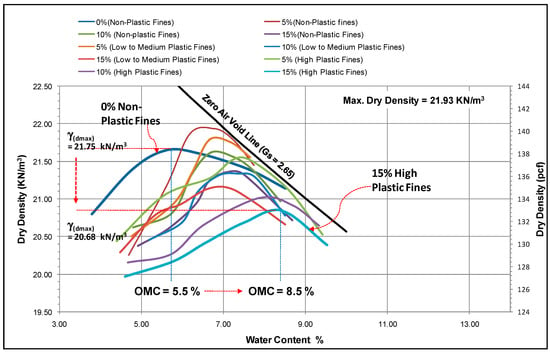

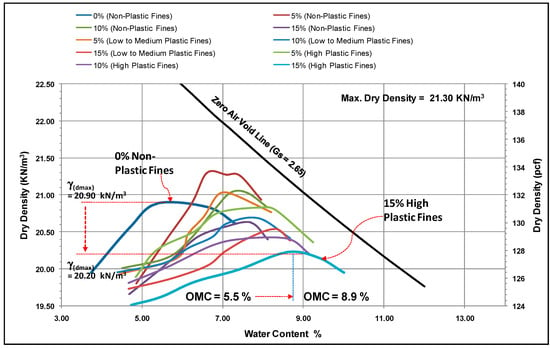

The compaction curves of the samples belonging to gradation ‘B’ are shown in Figure 2. The figure depicts that, with the increase in fines from 0 to 15%, the OMC increases from 5.5 to 8.8%, whereas MDD decreases from 21.75 to 20.68 kN/m3. Likewise, for the samples with the AASHTO gradation ‘C’ that showed similar trends, i.e., with an increase in fines up to 15%, OMC increases in the range of 5.8~9% with a reduction in MDD value from 20.90 to 20.20 kN/m3, as presented in Figure 3.

Figure 2.

Compaction curves of the composite samples (gradation B).

Figure 3.

Compaction curves of the composite samples (gradation C).

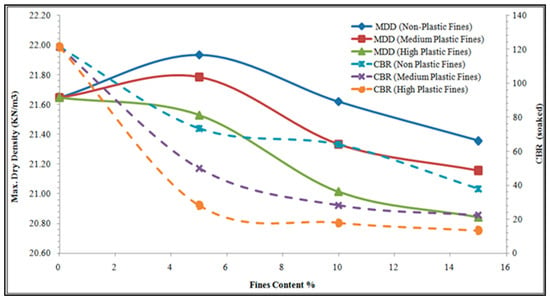

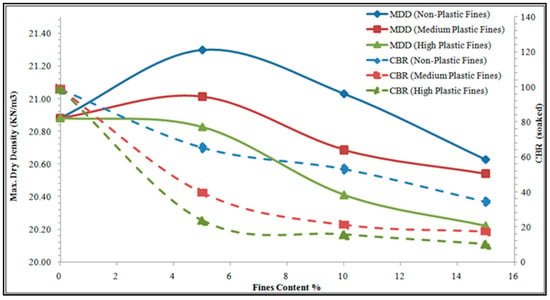

Specifically for gradation ‘B’, with the addition of 5% of non-plastic and medium-plasticity fines, MDD first increased from 21.64 KN/m3 to 21.92 kN/m3 and 21.74 kN/m3, respectively; however, with the inclusion of 5% of high-plasticity fines, the value of MDD reduced to 21.53 kN/m3. Moreover, the addition of 10 and 15% of non-plastic fines reduced the MDD value to 21.62 kN/m3 and 21.35 kN/m3, respectively. Similarly, MDD values for medium-plasticity fines were 21.33 kN/m3 and 21.15 kN/m3 and, for high-plasticity fines, they were 21.01 kN/m3 and 20.84 kN/m3. The variation in MDD with the change in fine content for gradations B and C is shown in Figure 4 and Figure 5, respectively.

Figure 4.

Effect of fines on the MDD and CBR values for the composite samples (gradation B).

Figure 5.

Effect of fines on the MDD and CBR values for the composite samples (gradation C).

It can be inferred from Figure 4 and Figure 5 that the addition of 5% of non-plastic and medium-plasticity fines caused an almost 10% increase in the value of MDD for both gradations. However, beyond this, the maximum dry density decreased with the further addition of fines. The increase in the value of MDD may be attributed to the filling of void spaces, thus causing the denser packing of the samples, which resulted into a higher unit weight. However, after 5% fines, the aggregates are being replaced by fines that have a lesser specific gravity, resulting in a lower maximum dry density of the matrix.

3.3. Effect of Fines on the California Bearing Ratio (CBR) of Soil Aggregate Mixture

With increase in the percentage of fines (0–15%) for the composite samples with gradation ‘B’, the CBR values decreased from 122 to 39 for non-plastic fines, to 22 for medium-plasticity fines, and to 14 for high-plasticity fines.

For the composite samples that have the AASHTO gradation ‘C’, the addition of non-plastic and medium- and high-plasticity fines up to 15% caused a reduction in the soaked CBR from 99 to 65, 35 and 10, respectively. The variation in CBR values with the addition of fines is shown in Figure 4 and Figure 5. Thus, the composite samples that have a CBR value of more than 30% are regarded as suitable samples that can be used for construction as per the National Highway Authority of Pakistan specifications [21].

3.4. Effect of Fines on the Permeability of Soil Aggregate Mixtures

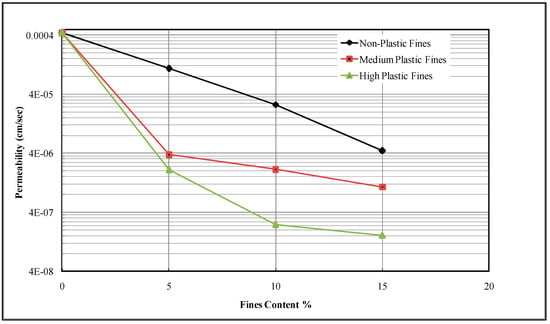

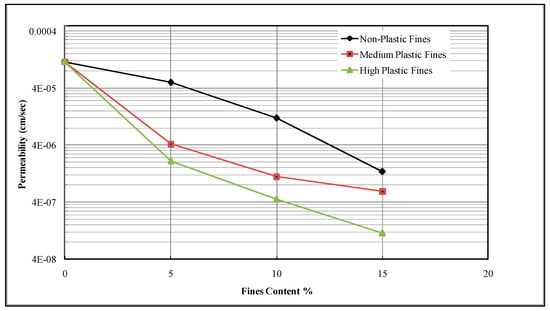

Falling head permeability tests were carried out on each composite sample. The results of the permeability tests are presented in Figure 6 and Figure 7 for gradation B and gradation C, respectively. The coefficients of permeability (k) for non-plastic and medium-plasticity and high-plasticity fines reduced from 4.4 × 10−4 cm/s to 4.4 × 10−6 cm/s, 1.1 × 10−6 cm/s, and 1.6 × 10−7 cm/s, respectively, for gradation ‘B’, while for gradation ‘C’, the k value reduced from 1.2 × 10−4 cm/s to 1.4 × 10−6 cm/s, 6.2 × 10−7 cm/s, and 1.1 × 10−7 cm/s with the addition of non-plastic and medium-plasticity and high-plasticity fines. The k values were used for specific road geometry that has a length of 24 ft and slope of 0.02 ft/ft to determine the drainage time for pavement design.

Figure 6.

Effect of fines on permeability for the composite samples (gradation B).

Figure 7.

Effect of fines on permeability for the composite samples (gradation C).

For sub-base materials with 0~6% of non-plastic fines, the material depicted fair drainage characteristics. However, as the fine content increased from 6~11%, drainage is poor and, with the addition of non-plastic fines in excess of 11%, drainage characteristics are very poor and the material is characterized as nearly impermeable. Similarly, for medium-plasticity fines up to 2%, the sub-base material showed fair drainage characteristics, while drainage characteristics are poor for a fine content in the range of 2~5% and are the worst for medium-plasticity fines with a content of more than 5%. Sub-base materials with high-plasticity fines exhibit fair drainage characteristics with fines in the range of 0~1% and drainage characteristics are poor for a fine content in the range of 1~3%, while for contents of more than 3% of fines, very poor drainage characteristics are observed.

4. Field Implications

The laboratory test results were utilized to design the pavement in accordance with the AASHTO 1993 guidelines. The pavement design parameters are shown in Table 3.

Table 3.

Road design parameters for AASHTO gradations B and C.

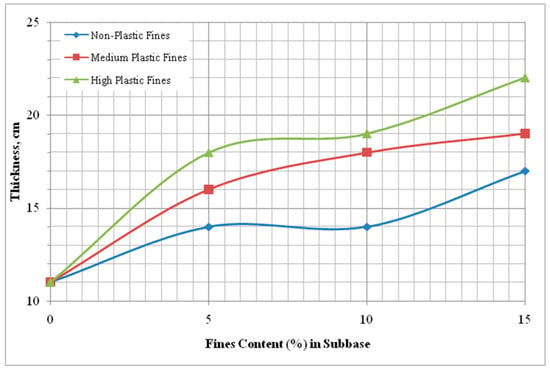

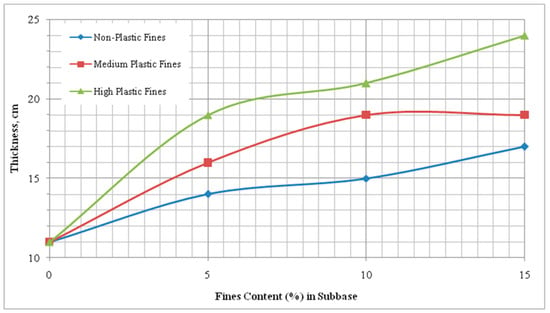

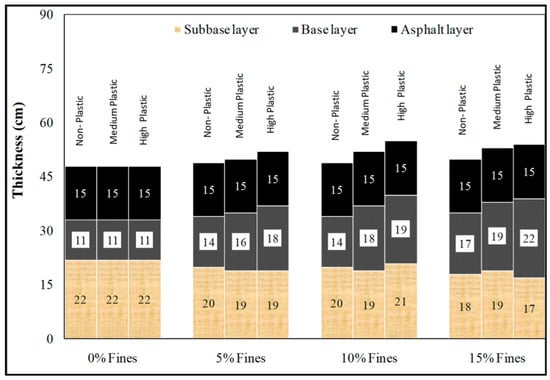

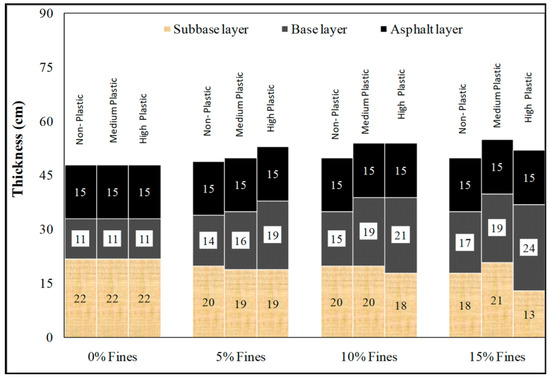

The required base course thicknesses using layered equations were obtained for each type of sub-base for fines of varying types in different proportions. The required base course thicknesses for the AASHTO gradings B and C are shown in Figure 8 and Figure 9, respectively. The figures depict that, with a maximum fine proportion of up to 15%, the thickness of the base course layer varies between 11 and 22 cm for grading B and between 11 and 24 cm for grading C. The effect of adding fines to the sub-base material on the overall flexible pavement thickness is presented in Figure 10 and Figure 11 for the AASHTO gradings B and C, respectively.

Figure 8.

Base thickness with the use of composite samples (gradation B).

Figure 9.

Base thickness with the use of composite samples (gradation C).

Figure 10.

Thickness of the various pavement layers for gradation B.

Figure 11.

Thickness of the various pavement layers for gradation C.

5. Conclusions

The current study was carried out to study the effect of fines on the performance of sub-base materials. Classification and quality assessment tests were performed on composite sub-base samples. The laboratory test results were utilized to design a pavement following AASHTO 1993 guidelines. On the basis of the study, the following conclusions were drawn:

- The impact of blending fines with sub-base materials on the compaction characteristics is subtle as the maximum dry unit weight decreased only by about 4%, whereas the optimum moisture content increased by about 3% with the addition of fines up to 15%.

- The permeability characteristics of sub-base materials showed a drastic change with the increase in fines and the drainage characteristics of the blended samples changed from fair to very poor. The plasticity of the fines present in the sub-base materials has a significant impact on the prediction of the drainage characteristics of the sub-base materials.

- The California bearing ratio (CBR) of the sub-base materials decreased with the increase in fine content. The sub-base materials exhibited a maximum strength and fair drainage characteristics at a 0% fine content. With the addition of non-plastic fines up to 10%, the sub-base material exhibited a good strength (CBR > 30); however, the drainage characteristics were poor. With the addition of 15% of non-plastic fines and more than 5% of medium-plasticity fines, the strength was substantially reduced (CBR < 30) with very poor drainage characteristics, thus making the material unsuitable for road construction. The addition of only 5% of high-plasticity fines or more than 10% of medium-plasticity fines resulted in very poor strength/stiffness and drainage characteristics of the sub-base material.

- The results of the pavement design using AASHTO 1993 guidelines using the composite samples of the sub-base materials depict that the required thickness of the base course layer increases by 72~118% with the respective addition of 5~15% of plastic fines as compared to the case of not adding fines. However, the same amount of non-plastic fines results in a 27~55% increase in the base course thickness.

- Based on the overall evaluation, we conclude that the mixing of non-plastic fines with a sub-base material up to 5~6% results in improved compaction, good strength, fair drainage, and a minimum requirement of increased base course thickness. Furthermore, the composite samples prepared as per the AASHTO gradation “B” exhibited a better strength and drainage characteristics compared to the composite samples prepared as per the AASHTO gradation “C”.

Author Contributions

K.F.: conceptualization, formulation of the methodology and top supervision of the entire study. H.M.: formal analysis and writing—original draft preparation. S.M. provided his input for the investigation and data curation. S.Z.A. contributed to the writing—review and editing. S.M.S.K. carried out the final review and visualization. M.J.M. performed the visualization and writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors highly acknowledge the support of the Department of Civil Engineering, University of Engineering and Technology, Lahore, Pakistan, for providing laboratory facilities, library access, and a research environment to accomplish the study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- O’Flaherty, C.A. Materials used in road pavements. In Highways, 4th ed.; CRC Press: Boca Raton, FL, USA, 2001; pp. 150–203. [Google Scholar]

- Uthus, L.; Hermansson, Å.; Horvli, I.; Hoff, I. A study on the influence of water and fines on the deformation properties and frost heave of unbound aggregates. In Proceedings of the 13th International Conference on Cold Regions Engineering, Orono, ME, USA, 23–26 July 2006; pp. 1–13. [Google Scholar]

- Lekarp, F.; Isacsson, U.; Dawson, A. State of the Art I: Resilient Response of Unbound Aggregates. J. Transp. Eng. 2000, 126, 66–75. [Google Scholar] [CrossRef] [Green Version]

- Tian, P.; Zaman, M.; Laguros, J. Variation of resilient modulus of aggregate base and its influence on pavement performance. J. Test. Eval. 1998, 26, 329–335. [Google Scholar]

- Kamal, M.A.; Dawson, A.R.; Farouki, O.T.; Hughes, D.A.B.; Sha’at, A.A. Field and Laboratory Evaluation Behaviour of Unbound Granular Material in Pavements; Transportation Research Board: Washington, DC, USA, 1993; Volume 1406, pp. 88–97. [Google Scholar]

- Raad, L.; Minassian, G.H.; Gartin, S. Characterization of Saturated Granular Bases under Repeated Loads; Transportation Research Board: Washington, DC, USA, 1997; Volume 1369, pp. 73–82. [Google Scholar]

- Thom, N.H.; Brown, S. Effect of Moisture on the Structural Performance of a Crushed-Limestone Road Base; Transportation Research Board: Washington, DC, USA, 1987; Volume 1121, pp. 50–56. [Google Scholar]

- Hicks, R.G.; Monismith, C.L. Factors Influencing the Resilient Response of Granular Materials; Transportation Research Board: Washington, DC, USA, 1971; Volume 345, pp. 15–31. [Google Scholar]

- Barksdale, R.D.; Itani, S.Y. Influence of Aggregate Shape on Base Behavior; Transportation Research Board: Washington, DC, USA, 1989; Volume 1227, pp. 173–182. [Google Scholar]

- Nataatmadja, A.; Parkin, A.K. Characterization of granular materials for pavements. Can. Geotech. J. 1989, 26, 725–730. [Google Scholar] [CrossRef]

- Yoder, E.J.; Witczak, M.W. Principals of Pavement Design, 2nd ed.; John Wiley and Sons Inc.: New York, NY, USA, 1991; pp. 223–289. [Google Scholar]

- Siswosoebrotho, B.I.; Widodo, P.; Augusta, E.; Ganesha, J. The influence of fines content and plasticity on strength and permeability of aggregate base course material. In Proceedings of the Eastern Asia Society for Transportation Studies; 2015; Corpus ID: 98754532; Available online: https://www.semanticscholar.org/paper/THE-INFLUENCE-OF-FINES-CONTENT-AND-PLASTICITY-ON-OF-Siswosoebrotho-Widodo/b9e38d7174f3d702f66c84f91f23a6105717f4c0 (accessed on 21 March 2022).

- Cheung, L.W. Laboratory Assessment of Pavement Foundation Materials. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 1994. Available online: http://etheses.nottingham.ac.uk/944/ (accessed on 29 October 2021).

- Haung, Y.H. Pavement Analysis and Design, 2nd ed.; Pearson: Chennai, India, 2009; pp. 297–366. [Google Scholar]

- Cedergen, H.R. Why all important Pavements should be well drained. Transp. Res. Rec. 1971, 1188, 56–62. [Google Scholar]

- Gandara, J.A.; Kancherla, A.; Alvarado, G.; Nazarian, S.; Scullion, T. Impact of Aggregate Gradation on Base Material Performance; Research Report 2005, 4358–2; Texas Department of Transportation: Austin, TX, USA, 2005.

- Pereira, P.A.A.; Oliveria, J.R.M.; Picado-Santos, L.G. Mechanical characterization of hot mix recycled material. Int. J. Pavement Eng. 2004, 5, 211–220. [Google Scholar] [CrossRef]

- Babić, B.; Prager, A.; Rukavina, T. Effect of fine particles on some characteristics of granular base courses. Mater. Struct. 2000, 33, 419–424. [Google Scholar] [CrossRef]

- Bilodeau, J.P.; Plamondon, C.P.; Dore, G. Estimation of resilient modulus of unbound granular materials used as pavement base: Combined effect of grain-size distribution and aggregate source frictional properties. Mater. Struct. 2016, 49, 4363–4373. [Google Scholar] [CrossRef]

- Geotechnical Aspects of Pavements; National Highway Institute (NHI): Arlington, VA, USA; Federal Highway Administration Publication (FHWA): McLean, VA, USA, 2006.

- General Specification; National Highway Authority (NHA): Islamabad, Pakistan; Government of Pakistan: Islamabad, Pakistan, 1998.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).