Preparation and Properties of SBS/REOB-Modified Rejuvenated Asphalt

Abstract

:1. Introduction

2. Test Materials

2.1. Base Asphalt

2.2. Recycled Engine Oil Bottom (REOB)

2.3. SBS Modifier

2.4. Stabilizer

3. Test Method

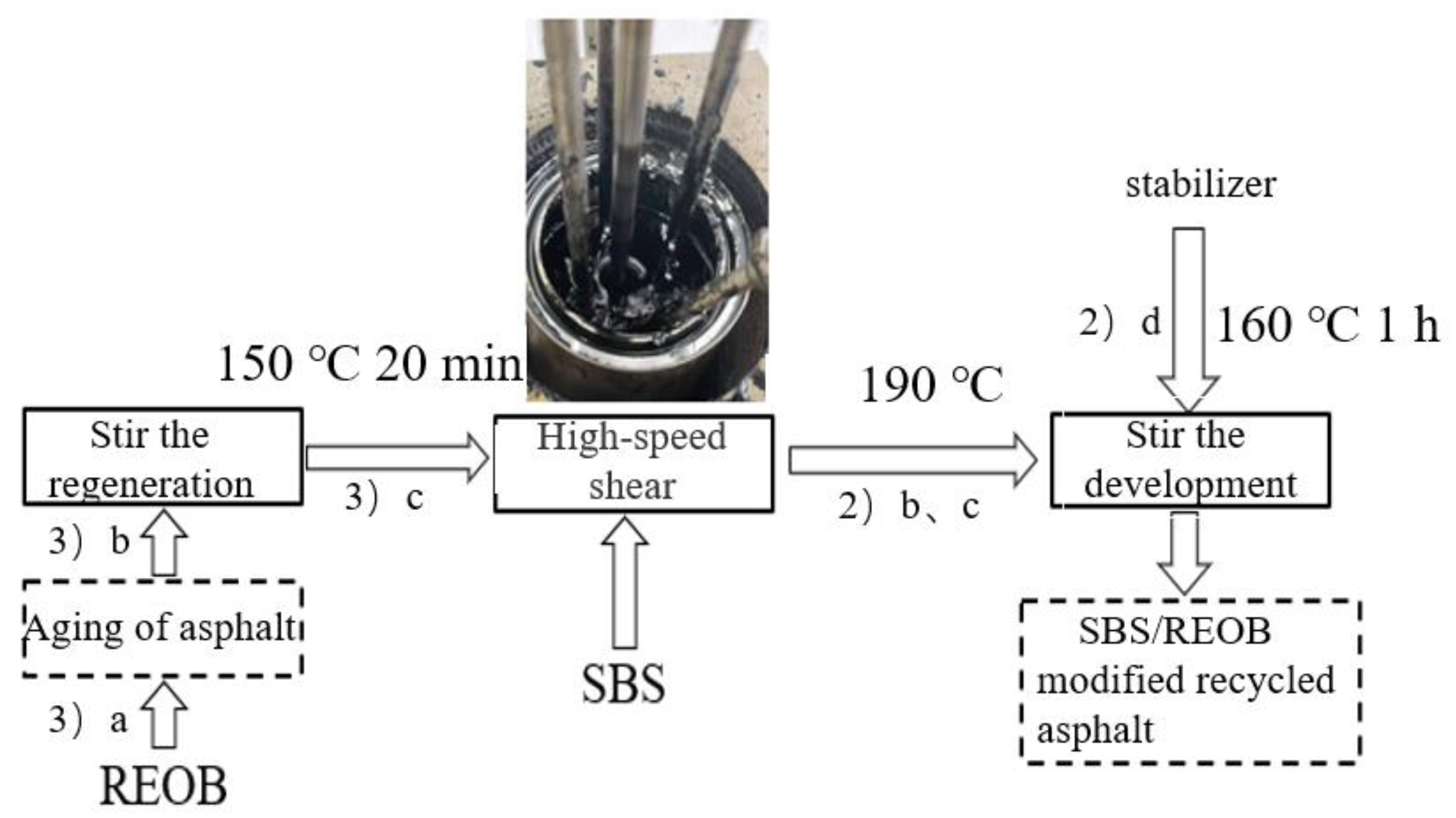

3.1. SBS/REOB-Modified Rejuvenated Asphalt Sample Preparation

Simulated Aging Test of Base Asphalt

Preparation of SBS/REOB-Modified Rejuvenated Asphalt

- (1)

- REOB rejuvenated asphalt.

- (a)

- We heated and melted the aging matrix asphalt in an oven at 150 °C ± 2 °C until it was in a flowing state. The REOB was placed in the oven at 60 °C for 20 min (to avoid the influence of the instantaneous large temperature difference when pouring asphalt).

- (b)

- According to the test plan, the REOB of the corresponding proportion in the test design was added to the hot aging asphalt, and the glass rod was continuously stirred for 5 min during the process to ensure the material was fully mixed with the asphalt.

- (c)

- We stirred at a temperature of 150 °C and a speed of 2500 r/min for 15 min.

- (d)

- Then, we stirred at 4000 r/min for 40 min and at 1000 r/min for 10 min at low speed to remove bubbles.

- (2)

- SBS-modified asphalt.

- (a)

- The aging matrix asphalt was heated in an oven at 150 °C ± 2 °C until flowing.

- (b)

- We adjusted the speed of the shear machine to 3000 r/min and added SBS or SBS and the stabilizer, successively, within 5 min. Due to the heat release in the process of adding SBS and since the temperature in the process of adding modifier is not easy to control, the next step was to control the shear temperature at 190 °C.

- (c)

- We sheared at a speed of 4500 r/min for 50 min and stirred at a speed of 1000 r/min for 10 min to remove bubbles. (d) Then, we left it to swell and develop at 160 °C for 1 h.

- (d)

- Then, we left it to swell and develop at 160 °C for 1 h.

- (3)

- SBS/REOB-modified rejuvenated asphalt.

- (a)

- EOB was placed in an oven at 60 °C for 20 min.

- (b)

- REOB was first added into the hot aging asphalt, and the glass rod was continuously stirred for 5 min during the process to ensure the material was fully mixed with the asphalt.

- (c)

- REOB was initially dispersed into the asphalt at a temperature of 150 °C and a stirring speed of 2500 r/min for 20 min.

3.2. SBS/REOB-Modified Rejuvenated Asphalt Orthogonal Test Design

3.3. Rheological and Microscopic Tests of SBS/REOB-Modified Rejuvenated Asphalt

3.3.1. Rheological Test

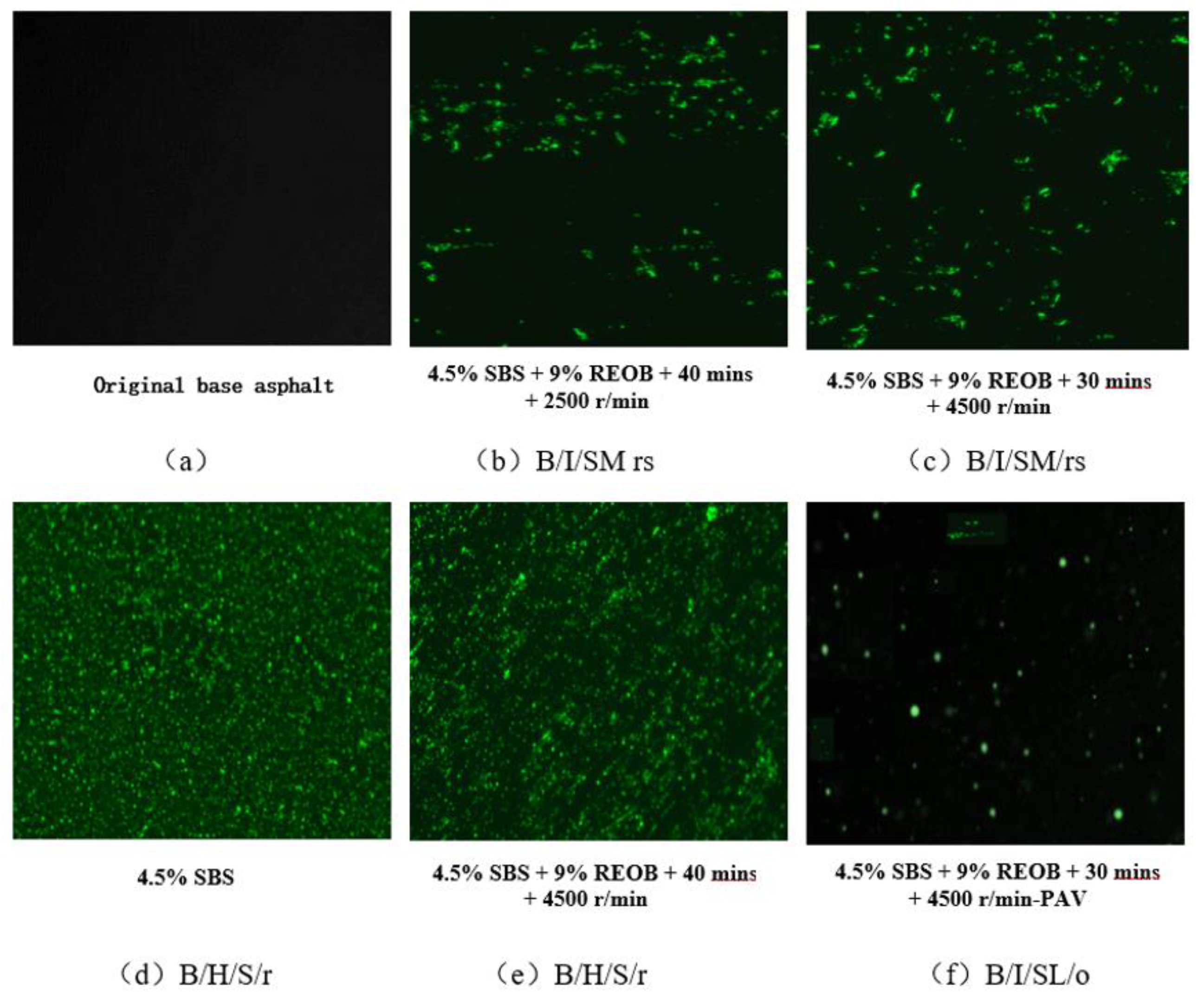

3.3.2. Fluorescence Microscopic Test

4. Results and Analysis

4.1. Orthogonal Test

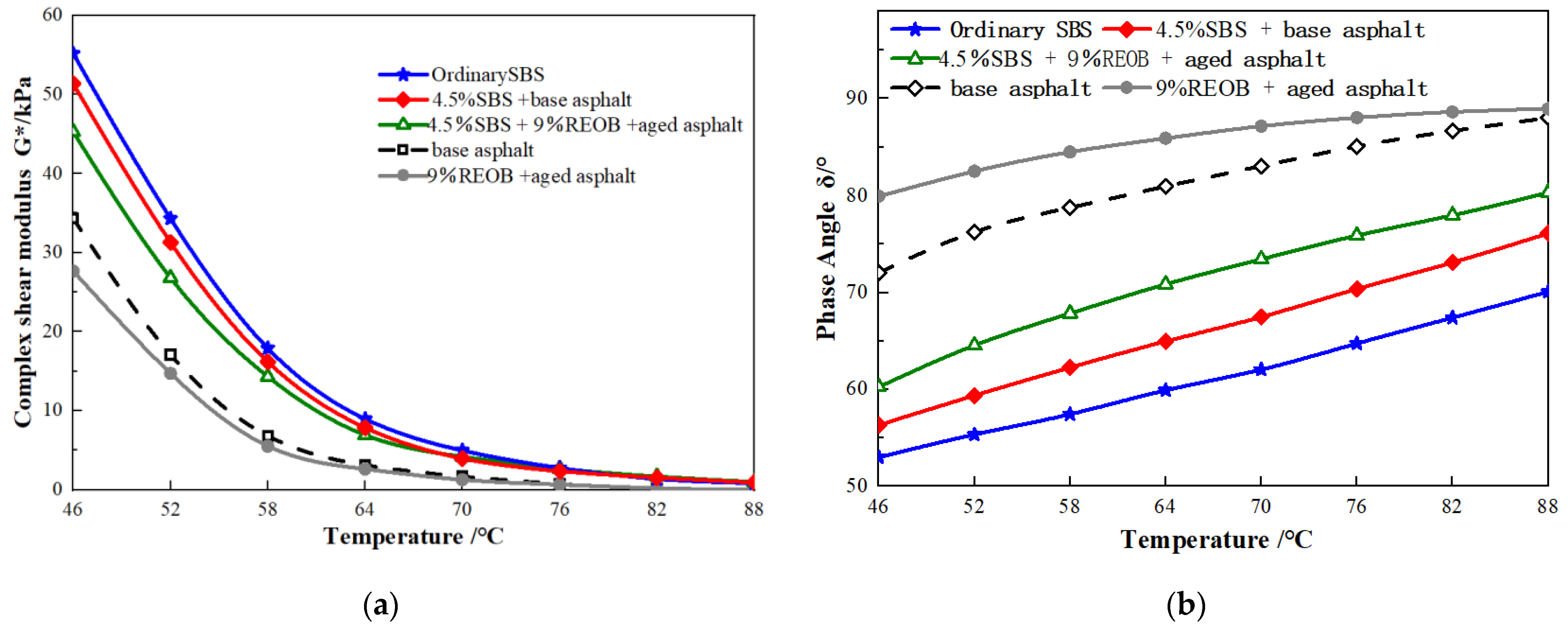

4.2. Dynamic Shear Rheological Test

4.2.1. Temperature Characteristics

Complex Modulus and Phase Angle

Rutting Factor and Critical Temperature

4.2.2. Frequency Characteristic

4.3. Rheological Test of Low-Temperature Bending Beam

4.4. Microscopic Test

5. Conclusions

- (1)

- Based on the orthogonal test, SBS/REOB-modified rejuvenated asphalt was prepared, and it was determined that the performance indicators of the SBS/REOB-modified rejuvenated asphalt reached the optimal combination of 9% REOB + 4.5% SBS. The process conditions were a shear time of 40 min and a shear rate of 5000 r/min.

- (2)

- Through a DSR test, SBS modification of REOB rejuvenated asphalt obtained the same excellent high-temperature performance as ordinary SBS-modified asphalt. The rutting resistance of the modified rejuvenated asphalt was further improved. The rutting resistance of 4.5% SBS + 9% REOB at 46 °C was more than 65% higher than that of rejuvenated asphalt; compared with the base asphalt, it also improved about 42%. Frequency scanning shows that the modified rejuvenated asphalt presented a low G* value at high temperature and low frequency, and a high G* value at low temperature and high frequency, indicating that it had a certain dependence on temperature and loading frequency.

- (3)

- The BBR test showed that the REOB content remained unchanged at 9%. Within the range of SBS content 3.5–4.5%, the higher the content, the better the low-temperature performance of the modified rejuvenated asphalt. When the SBS content was kept unchanged at 4.5%, it was found that in the range of 7–9% REOB content, the low-temperature performance of asphalt increased with the increase in REOB, while the low-temperature cracking resistance decreased when the content was increased to 11%, indicating that the saturated REOB regenerated agent had the opposite effect on the low-temperature performance of asphalt.

- (4)

- The fluorescence microscopic test showed that an insufficient shear rate and shear time led to uneven dispersion of the SBS modifier and a poor modification effect. The SBS-modified new asphalt and the modified rejuvenated asphalt prepared in the laboratory had continuous asphalt phases, and the microstructure of the two was similar. SBS was uniformly suspended in the asphalt phase, forming a network structure with the asphalt, and the SBS phase in the modified rejuvenated asphalt basically reached the level of the finished modified asphalt.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, Y.; Liu, D.; Xu, W.; Shen, L. The Actuality and Key Technologies Study of Waste Lubricating Oil Recycling in Transportation Industry. China Resour. Compr. Util. 2010, 28, 25–29. [Google Scholar]

- Xie, H.; Ma, Z.; Han, Y.; Dai, M. Test of regeneration processes of waste gasoline engine oil. Pet. Process. Petrochem. 2017, 48, 85–88. [Google Scholar]

- Feng, Z.; Zhao, P.; Yao, D. Research progress on application of re-refined engine oil bottom in asphalt mixture. China Sci. 2021, 16, 121–127. [Google Scholar]

- Ackbarali, D.S.; Maharaj, R. The Viscoelastic Properties of Trinidad Lake Asphalt-Used Engine Oil Blends. Int. J. Appl. Chem. 2011, 7, 1–8. [Google Scholar]

- Li, J.; Yu, M.; Cui, X.; Li, Y.; Cheng, Y. Anti-aging Performance of Recycled Engine Oil Bottom Rejuvenated Asphalt. J. Build. Mater. 2021, 24, 224–230. [Google Scholar]

- Yan, X.; Zheng, X. Study on Properties of Stabilized Rubber Powder and SBS Composite Modified Asphalt and Asphalt Mixture. Highway Eng. 2021, 46, 195–200. [Google Scholar]

- Xiang, L. Mechanism and Performance Investigation of Crumb Rubber/Sbs Composite Modified Asphalt Binder; China University of Petroleum: Beijing, China, 2011. [Google Scholar]

- JTG E20-2019; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Beijing Highway Research Institute, Ministry of Transport: Beijing, China, 2019.

- Wang, W. Influence of Recycled Engine Oil Bottom on Physical and Rheological Properties of Aging Asphalt; Shandong Jiaotong University: Jinan, China, 2018. [Google Scholar]

- Fu, Z.; Chang, X.; Dai, S.; Dong, W.; Zhou, Y. Performance Analysis of Compound Modified Asphalt with SEBS and Crumb Rubber Based on Orthogonal Test. Sci. Technol. Eng. 2021, 21, 2445–2451. [Google Scholar]

- Xiao, F.; Amirkhanian, S.; Wang, H.; Hao, P. Rheological property investigations for polymer and polyphosphoric acid modified asphalt binders at high temperatures. Constr. Build. Mater. 2014, 64, 316–323. [Google Scholar] [CrossRef]

- Quan, Y. Study on Rheologieal Performance of Coupling SBS for Modified Asphalt; Chang’an University: Xi’an, China, 2014. [Google Scholar]

- Zhu, L.; Gao, E.; Zhang, Y.; Li, J.; Yu, M.; Wang, X. Dynamic modulus analysis of SBS modified asphalt mixture in Hailar cold area. J. Shandong Jiaotong Univ. 2021, 29, 85–91. [Google Scholar]

- Wang, W.; Chen, J.; Sun, Y.; Xu, B.; Li, J.; Liu, J. Laboratory performance analysis of high percentage artificial RAP binder with WMA additives. Constr. Build. Mater. 2017, 147, 58–65. [Google Scholar] [CrossRef]

- Xia, P.; Hu, L.; Yan, J.; Wang, S.; Yang, Z. Low-temperature performance evaluation indices of high-rviscosity modified asphalt. China Sci. 2020, 15, 1417–1421. [Google Scholar]

- Kou, C.; Wu, X.; Kang, A.; Liu, Y. Quantitative analysis of fluorescence micrograph of SBS modified asphalt. China Sci. 2020, 15, 1110–1117. [Google Scholar]

| Test Project | Test Results | Standard Indicators | |

|---|---|---|---|

| Needle penetration 100 g, 5 s, 25 °C/0.1 mm | 73.2 | 60–80 | |

| Insertion index PI | −1.1 | −1.5~1.0 | |

| Softening point/°C | 47.9 | ≥46 | |

| 60 °C dynamic viscosity/Pa·s | 271 | ≥180 | |

| 10 °C degrees/cm | 73 | ≥25 | |

| 15 °C degrees/cm | >100 | ≥100 | |

| Flash point (COC)/°C | 280 | ≥260 | |

| Wax content (distillation)/% | 0.8 | ≤2.2 | |

| Density (15 °C)/(g/cm3) | 1.054 | The measured | |

| TFOT (Thin Film Oven Test) after 163 °C, 5 h | Quality change/% | ±0.8 | −0.255 |

| Residual penetration ratio (25 °C) | ≥61 | 61.3 | |

| Residual ductility (10 °C)/cm | ≥6 | 10.6 | |

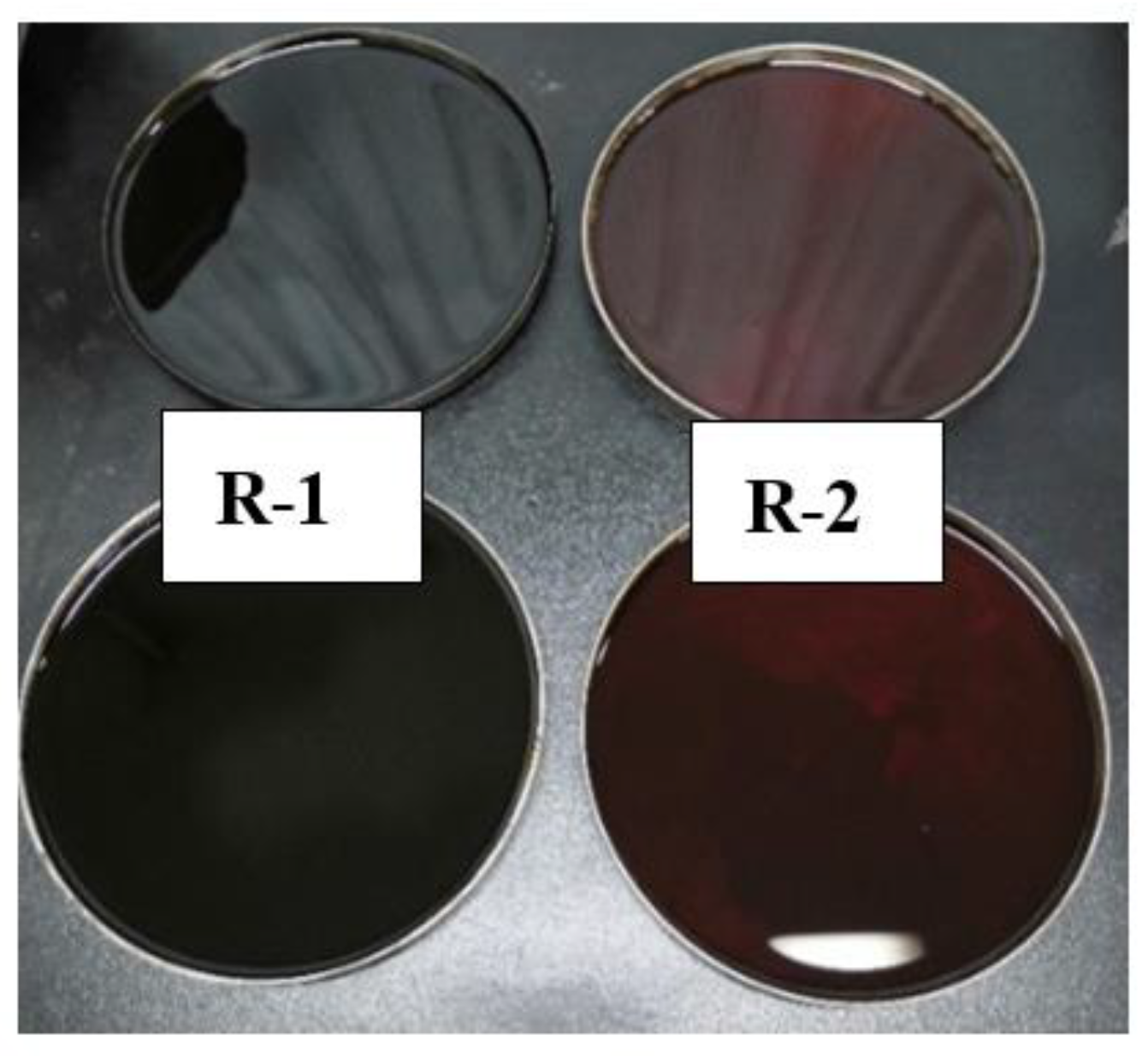

| Inspection Items | R-1 | R-2 | RA-1 Regenerant | |

|---|---|---|---|---|

| Aromatic content/% | 77.6 | 82.1 | The measured | |

| Saturation fraction content/% | 11.4 | 7.6 | ≤30 | |

| Asphaltene content | 0.8 | 0.6 | / | |

| Pectin content | 10.2 | 9.7 | / | |

| color | Dark brown | Red brown | / | |

| Relative density | 0.941 | 0.822 | The measured | |

| 60 °C viscosity/cSt | 57.6 | 57.0 | 50–175 | |

| Flash point/°C | 227 | 247 | ≥220 | |

| TFOT post | Viscosity ratio | 1.88 | 1.69 | ≤3 |

| Quality change/% | −2.14 | −1.99 | −4–4 | |

| Brand | S/B Ratio | Structure | Molecular Weight (m) | Oil Charge Rate (%) | Volatile (≤%) | Ash (≤%) | 300% Constant Tensile Stress (≥MPa) | Tensile Strength (≥MPa) | Elongation at Break (≥%) | Permanent Deformation at Break (≤%) | Shore Hardness (A) | Melt Flow Rate (g/min) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SBS792 | 40/60 | linear | 9.5 ± 1 | 0 | 0.70 | 0.20 | 3.5 | 15.0 | 730 | 0.10–5.00 | ≥85 | 0.10–5.00 |

| Project | Test Results | Normative |

|---|---|---|

| Sulfur content (%) | 99.98 | ≥99.5 |

| Ash (%) | 0.0086 | ≤0.03 |

| Acidity (H2SO4) (%) | 0.0024 | ≤0.003 |

| Organic matter (%) | 0.0068 | ≤0.03 |

| Arsenic (AS) content (%) | 0.0001 | ≤0.0001 |

| Moisture (%) | 0.02 | ≤0.1 |

| Sieve residue (particle size 75 μm~150 μm) (%) | 0.01 | ≤0.5 |

| Level | A: REOB Dosage/% | B: SBS Dosage/% | C: Shear Time/Min | D: Shear Rate/(r/min) |

|---|---|---|---|---|

| 1 | A1 | B1 | C1 | D1 |

| 2 | A2 | B2 | C2 | D2 |

| 3 | A3 | B3 | C3 | D3 |

| Experimental Group | Level Combination | Experimental Factor | |||

|---|---|---|---|---|---|

| A | B | C | D | ||

| REOB Dosage/% | SBS Dosage/% | Shear Time/min | Shear Rate/(r/min) | ||

| 1 | A1B1C1D1 | 1 (11%) | 1 (3.5%) | 1 (40) | 1 (4000) |

| 2 | A1B2C2D2 | 1 (11%) | 2 (4.0%) | 2 (50) | 2 (4500) |

| 3 | A1B3C3D3 | 1 (11%) | 3 (4.5%) | 3 (60) | 3 (5000) |

| 4 | A2B1C3D2 | 2 (9%) | 1 (3.5%) | 2 (50) | 3 (5000) |

| 5 | A2B2C3D1 | 2 (9%) | 2 (4.0%) | 3 (60) | 1 (4000) |

| 6 | A2B3C1D2 | 2 (9%) | 3 (4.5%) | 1 (40) | 2 (4500) |

| 7 | A3B1C3D2 | 3 (7%) | 1 (3.5%) | 3 (60) | 2 (4500) |

| 8 | A3B2C1D3 | 3 (7%) | 2 (4.0%) | 1 (40) | 3 (5000) |

| 9 | A3B3C2D1 | 3 (7%) | 3 (4.5%) | 2 (50) | 1 (4000) |

| Name of Test | The Asphalt | Test Indicators |

|---|---|---|

| DSR temperature scan | Original asphalt | Phase Angle δ, complex shear modulus G*, rut factor G*/sinδ |

| DSR frequency scanning | Original asphalt | Phase Angle δ, complex shear modulus G* |

| Bending creep stiffness test (BBR) | PAV(Pressure Aging Vessel) aged asphalt | Modulus of creep stiffness S, slope of creep curve M |

| Test Group | REOB Dosage | SBS Dosage | Shear Time/Min | Shear Rate /(r/min) | Needle Penetration/mm | Softening Point/°C | Extension/cm | Elastic Recovery/% |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 (11%) | 1 (3.5%) | 1 (40) | 1 (4000) | 84 | 56.5 | 23.9 | 79 |

| 2 | 1 (11%) | 2 (4.0%) | 2 (50) | 2(4500) | 80.2 | 61.2 | 25.2 | 85 |

| 3 | 1 (11%) | 3 (4.5%) | 3 (60) | 3 (5000) | 63.8 | 61.9 | 29.3 | 82 |

| 4 | 2 (9%) | 1 (3.5%) | 2 (50) | 3 (5000) | 78.3 | 57.7 | 26.5 | 81 |

| 5 | 2 (9%) | 2 (4.0%) | 3 (60) | 1 (4000) | 79.1 | 62.3 | 27.2 | 86 |

| 6 | 2 (9%) | 3 (4.5%) | 1 (40) | 2 (4500) | 64.5 | 63.7 | 33.4 | 89 |

| 7 | 3 (7%) | 1 (3.5%) | 3 (60) | 2 (4500) | 76.9 | 58.3 | 24.8 | 79 |

| 8 | 3 (7%) | 2 (4.0%) | 1 (40) | 3 (5000) | 76 | 62.1 | 29.8 | 88 |

| 9 | 3 (7%) | 3 (4.5%) | 2 (50) | 1 (4000) | 62.7 | 63.2 | 30.5 | 81 |

| Range Calculated Value | Experimental Factor | Impact Priority | ||||

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| REOB Dosage | SBS Dosage | Shear Time | Shear Rate | |||

| Needle penetration/mm | 76.00 | 79.73 | 74.83 | 75.27 | B > A > D > C | |

| 72.93 | 78.43 | 73.73 | 73.87 | |||

| 72.90 | 63.67 | 73.27 | 72.70 | |||

| 4.10 | 16.06 | 1.56 | 2.57 | |||

| The optimal level | A3 | B3 | C3 | D3 | ||

| Softening point/°C | 59.87 | 57.50 | 60.83 | 61.07 | B > A > D > C | |

| 61.17 | 61.87 | 60.70 | 60.67 | |||

| 61.27 | 62.93 | 60.77 | 60.57 | |||

| 1.40 | 5.43 | 0.13 | 0.50 | |||

| The optimal level | A3 | B3 | C1 | D1 | ||

| 5 °C extension/cm | 26.13 | 25.07 | 27.97 | 27.80 | B > A > C > D | |

| 29.03 | 27.40 | 27.40 | 28.07 | |||

| 28.37 | 31.07 | 28.17 | 27.67 | |||

| 2.90 | 6.00 | 0.77 | 0.40 | |||

| The optimal level | A2 | B3 | C1 | D2 | ||

| Extension/% | 81.67 | 79.00 | 84.67 | 82.67 | B > A > C > D | |

| 85.33 | 87.00 | 82.00 | 82.33 | |||

| 82.00 | 83.00 | 82.33 | 84.00 | |||

| 3.67 | 8.00 | 2.67 | 1.67 | |||

| The optimal level | A2 | B2 | C1 | D3 | ||

| Range mean | 3.02 | 8.87 | 1.29 | 1.41 | B > A > D > C | |

| Test Temperature | −12 °C | −18 °C | −24 °C | ||||

|---|---|---|---|---|---|---|---|

| Indicators | Stiffness Modulus S/MPa | Creep Rate/m | S/ MPa | m | S/ MPa | m | |

| ① | 70# base asphalt | 186.5 | 0.359 | 467.4 | 0.264 | 679.7 | 0.201 |

| ② | 9% REOB+ aged asphalt | 323.8 | 0.314 | 506.3 | 0.253 | 748.6 | 0.190 |

| ③ | 4.5% SBS + 7% REOB + aged asphalt | 40.5 | 0.447 | 139.6 | 0.361 | 299.5 | 0.289 |

| ④ | 4.5% SBS + 9% REOB + aged asphalt | 39.9 | 0.447 | 121.0 | 0.348 | 288.6 | 0.304 |

| ⑤ | 4.5%SBS + 11% REOB+ aged asphalt | 67.1 | 0.436 | 184.2 | 0.336 | 373.6 | 0.277 |

| ⑥ | 3.5% SBS + 9% REOB + aged asphalt | 115.6 | 0.399 | 326.5 | 0.320 | 489.0 | 0.253 |

| ⑦ | 4% SBS + 9% REOB + aged asphalt | 77.3 | 0.386 | 215.6 | 0.328 | 397.8 | 0.264 |

| Describe | The Letter | Meaning |

|---|---|---|

| Continuous phase | P | Continuous polymer phase |

| B | Continuous bituminous phase | |

| X | Both phases are continuous | |

| Phase | H | Uniform |

| I | Uneven | |

| Size | S | Small |

| M | Medium | |

| L | Large | |

| Shape | r | Circular |

| s | Stripe | |

| o | Other |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Y.; Li, J.; Zhu, L.; Zuo, S.; Yu, M.; Liu, P.; Cui, X. Preparation and Properties of SBS/REOB-Modified Rejuvenated Asphalt. Appl. Sci. 2022, 12, 4063. https://doi.org/10.3390/app12084063

Cui Y, Li J, Zhu L, Zuo S, Yu M, Liu P, Cui X. Preparation and Properties of SBS/REOB-Modified Rejuvenated Asphalt. Applied Sciences. 2022; 12(8):4063. https://doi.org/10.3390/app12084063

Chicago/Turabian StyleCui, Yanchen, Jin Li, Li Zhu, Shen Zuo, Miaozhang Yu, Peng Liu, and Xinzhuang Cui. 2022. "Preparation and Properties of SBS/REOB-Modified Rejuvenated Asphalt" Applied Sciences 12, no. 8: 4063. https://doi.org/10.3390/app12084063

APA StyleCui, Y., Li, J., Zhu, L., Zuo, S., Yu, M., Liu, P., & Cui, X. (2022). Preparation and Properties of SBS/REOB-Modified Rejuvenated Asphalt. Applied Sciences, 12(8), 4063. https://doi.org/10.3390/app12084063