Featured Application

Based on data from multinational domain experts in the field of Industrial Maintenance, this study demonstrated the application cases and advantages of asymmetric VR set-up to address needs present in the industry.

Abstract

Virtual Reality (VR) is a critical emerging technology in industrial contexts, as it facilitates collaboration and supports the product development lifecycle. However, its broad adoption is constrained by complex and high-cost integration. The use of VR among devices with various immersion and control levels may solve this obstacle, and increase the scalability of VR technologies. This article presents a case study on applying asymmetry between the COVE-VR platform and Microsoft Teams to enable distributed collaboration of multinational departments and enhance the maintenance method and documentation creation processes. Overall, five remote collaborative sessions were held with 20 experts from four countries. Our findings suggest that asymmetry between head-mounted display and Teams users enhances the quality of communication among geographically dispersed teams and their spatial understanding, which positively influences knowledge transfer and efficiency of industrial processes. Based on qualitative evaluation of the asymmetric VR setup, we further suggest a list of guidelines on how to enhance the collaboration efficiency for low-cost distributed asymmetric VR from three perspectives: organization, collaboration and technology.

1. Introduction

In light of the recent shift towards remote working and social distancing, due to the COVID-19 pandemic, collaboration in VR (Virtual Reality) has become a viral topic of discussion in the fields of HCI (Human-Computer Interaction) and CSCW (Computer Supported Cooperative Work). In over three decades of academic and industrial research [1,2,3,4], VR has shown its potential to diminish the barrier between the real and the virtual. It can safely simulate diverse industrial contexts [3] and provide support in a variety of industrial use cases: from training [5,6,7] to virtual prototyping [8,9] and collaborative design reviews [8,9,10]. VR has been evaluated as one of the most important emerging technologies for Industry 4.0 interventions [11,12] due to flexibility of operations within virtual environments (VEs), and the richness of communication and multimodal interactions with virtual objects [13] coupled with enthusiasm toward utilizing novel technologies among industrial employees [14].

When it comes to the manufacturing and maintenance of heavy machinery, such as in the operations of KONE, VR technology provides solutions to overcome the limitations of the real world and, hence, addresses the challenges present in the industry [3,8]. Integrating VR technology into the whole product development lifecycle [15,16] demonstrates positive effects on overall optimization even at the early stages, by supporting design efforts and decision making [17]. Multi-user VR further advances quality and efficiency of collaboration among geographically dispersed teams in multinational companies [16,18] and integrates industrial practices in depth, such as Lean and Agile [15,19]. Moreover, the same industrial Collaborative VEs (CVEs) can be re-utilized to support other industrial activities, such as maintenance method development and associated technical documentation creation for heavy machinery. Industrial Maintenance and Assembly is the second largest application case for VR [20], as efficient maintenance plays a critical role in companies’ competitiveness, in addition to being an important source of revenue. VR allows experts from different multinational departments to collaboratively access simulated environments in cases where it would be difficult, unsafe, or impossible with real equipment. Further, they can interact on a 1:1 scale with virtual tools and virtual prototypes, thus advancing their spatial understanding and enriching communication. That potentially contributes to overall optimization and maintainability [2,21] via decreasing the number of design errors and associated high costs. In addition, industrial VR systems can be utilized for other critical tasks, such as prototyping of AR-based (Augmented Reality) in-field guidance for maintenance technicians [14], which in turn is another desired technology of Industry 4.0 to enhance maintenance services [22,23,24].

Despite all the benefits, industrial use of VR technology is still associated with a high cost-to-benefit ratio. Implementation is slowed down due to significant implementation costs [25], since every employee should have Head-Mounted Displays (HMDs) and/or powerful personal computers to utilize VR in their work. Additionally, the pandemic caused significant disruptions for supply chains for HMDs and PCs, further hindering the adoption rate of VR technologies in industries. This obstacle might be partly addressed with asymmetric VR usage, a relatively fresh research direction, studying the use of VR among devices with different levels of immersion and control, focusing on non-HMD user groups. The current body of research on asymmetry is mostly focused on co-located settings [26,27,28,29], where the physical presence of collaborators is an important design factor.

With forced social isolation, due to the worldwide pandemic, remote collaboration and, particularly, distributed asymmetric VR, becomes a more prominent research direction, the nature of which is still not fully explored [13,30]. By distributed asymmetric VR we refer to the technically supported remote collaboration of global teams, who use VR as an enhancement technology and have different access to it. In our case, we investigated the asymmetry when merging the collaboration over two digital worlds: the COVE-VR platform (see Figure 1) and Microsoft Teams (the company’s existing communication and teamwork tool). One distributed user group (referred to as VR-users) is present in the immersive multi-user collaborative environment, wearing HMDs and can interact with 3D CAD models and virtual tools. The second user group (referred to as Teams-users or non-interactive desktop users) can see the virtual environment through the eyes of VR-users and communicate with them via voice connection. Despite Teams users having no interaction with the virtual environment itself, they still have an active participatory role in the collaboration process by taking notes and snapshots with their laptop tools, thus contributing to the shared tasks.

Figure 1.

Multi-user interaction in COVE-VR platform.

This practical approach originated as a response to a preceding study [31,32], which suggested that the increased visualization capabilities of VR may be achieved even with a single user being present in VR and their interactions recorded or streamed to other industrial groups. Furthermore, the COVID-19 pandemic severely limited the availability of VR equipment on the global market and set some limitations to the study setup. The goal of the study was to explore how distributed asymmetric VR usage between VR and Teams users may shift traditional industrial practices in the pipeline of maintenance method development and technical documentation creation. The study addressed the following research questions:

RQ1: What are the relevant and beneficial use cases of applying asymmetric VR to aid industrial collaboration activities of geographically distributed teams?

RQ2: How to efficiently adopt distributed asymmetry between VR platforms and traditional conferencing tools in the industrial context?

To address the research questions and explore the asymmetry between a traditional conferencing tool and a VR platform in the industrial context, we conducted a remote user study with 20 experts from 4 countries: Finland, China, India and the USA. The study procedure was built to replicate the actual industrial tasks between geographically isolated teams.

2. Related Work

Virtual Reality (VR) is a promising technology to address the challenges of industries and shift traditional ways of working into virtual spaces [20,33]. Considering the rapid digitalization and increasing quality of digital content in line with industry 4.0 [11], VR can safely simulate a variety of industrial contexts and enable natural interactions with virtual objects, for instance, with 3D CAD models [4,9,34]. This is especially beneficial for many industries, such as elevator manufacturing and maintenance, since access to real objects may be time consuming, difficult, not possible, or even dangerous in real-life scenarios. In this section, we firstly describe the application of VR for industrial needs and further provide background on collaborative VR solutions and VR asymmetry.

2.1. Industrial VR

Following the Industry 4.0 intervention, industries strive to innovate and increase the productivity and efficiency of their operations by transforming traditional practices with the use of emerging and convergent technologies [11]. The major goal of Industry 4.0 [12] is to intertwine and centralize tasks in product development through automation and digitalization. The possibilities of VR technology, blended with other immersive technologies and supported via integrated data chains [3,35], offer ways not only to advance the Industry 4.0 production model, but also to affect management philosophies positively, such as Lean and Agile [19,36,37]. Virtual reality and other immersive technologies have the potential to enhance the Lean principles of waste reduction to optimize value creation [19,38]. For instance, an example from the construction field [37] demonstrated how a combination of innovative technologies, such as AR, VR and BIM (Building Information Modelling) positively influence key performance metrics and sustainability, thus enhancing Lean Construction. Similarly, as technology evolves, Agile practices procure and enhance team collaboration, and performance can benefit from adopting virtual reality, especially for distributed teams [36,39].

The usefulness of VR technology to support the design process in complex product development and related services is definite. For over three decades, multiple sectors have adopted VR solutions to explore its potential in different stages of the product development process [17,20,35,40,41,42]. These studies demonstrated that VR is a powerful production tool [20], which delivers benefits throughout the following activities of the whole production cycle [8]: early design phases, 3D modelling and virtual prototyping, co-design and design review sessions, product evaluations, virtual assembly, and education and training. In early design phases, VR enables the sense of scale which allows design and testing of virtual prototypes and identification of critical design flaws that are often overlooked with traditional computer tools [17,20]. This, in turn, supports design for maintainability [2,21] and helps to guide existing and future design directions [17], thus positively affecting overall product optimization [43]. Further, VR enables the creation of full-scale and immersive virtual environments that simulate the industrial context, where users can naturally, and safely, interact with virtual prototypes in different scenarios [20,25]. Evidence has shown that users experience a strong physical presence and provide both real-life physical and psychological responses in a VR environment [44,45,46]. Moreover, the same VE can be utilized to facilitate design reviews and enable employees to examine digital prototypes [15,47,48,49] to support maintenance method development and documentation creation [21,31], to perform product evaluations and testing with end-users [48,50] and training activities [6,7,51] in a safe and controlled environment.

2.2. Collaborative VR

As remote work has become more common, collaborative multi-user VR applications have gained popularity, offering a wide range of commercial-based and research software for use [42,52]. Collaborative VE (CVE), or “distributed virtual environments” [1], is known as a better alternative to traditional video-conferencing tools for many tasks related to product development. CVEs are capable of immersing employees from various teams and distributed geographical locations into a shared virtual workspace, where they can interact with each other and have access to virtual objects (e.g., 3D CAD models). Furthermore, multi-user VR ensures discussion quality [44,53] by providing a shared context, awareness of others, clarity, richness and openness of distributed communication, which are the critical elements of effective remote collaboration [46]. Due to the potential of blurring geographical barriers and delivering realistic experiences within completely virtual environments, collaborative VR systems may not only enhance the quality of communication, knowledge transfer, and interactions among multidisciplinary teams [17,33,52] but also potentially support business goals, while decreasing project duration, resource span, and overall costs [52].

The industry is the driver in adopting and developing collaborative VR, which is used mostly for the “Meetings” and “Design” use cases [52]. Collaborative VR has proven its potential to facilitate the collaboration of multidisciplinary industrial experts throughout the product development process [16,25,40]. In the early design phases, the use of VR leads to significant benefits for the team’s design efforts when applied to support design reviews in the field of manufacturing [17]. Further, in the design chain, VR is proven to be useful to facilitate communication between engineers and assembly operators, which enables the validation of installation processes, testing of services and maintenance tasks [49]. Another case study on VR-integrated collaboration workflow in the design chain, despite demonstrating the usefulness of VR simulations to address industrial challenges, highlighted that software and hardware expenses are the major obstacles to the wide adoption of VR technologies [25]. One of the ways to overcome the scarcity of equipment and reduce hardware expenses is to facilitate a hybrid collaboration between users who are present in fully immersive virtual environments (VR-users) and users who access VR via other devices (non-HMD-users), thus enabling the asymmetric use of VR.

2.3. Asymmetric VR

Asymmetric VR is a relatively new definition that originated from studies on virtual telepresence [54]. It describes a variety of interactions of co-located users in multi-user VE [55,56,57]. Lately, the traditional focus on single-user experiences with VR has shifted towards exploring multi-user VR interaction [58], which may occur on different levels of immersion and control among user groups. Despite asymmetry in cooperation being initially reviewed as a challenge to overcome, it delivers benefits in terms of flexibility and freedom in degree of participation [29]. Presence and experience in asymmetric VR were found to be significantly influenced by roles and tasks that were assigned to user groups [58]; therefore, when designing asymmetric VR collaboration, the asymmetry should be leveraged by defining roles in a way to embrace the differences of user groups [27] and extract their advantages [26].

A variety of research studies demonstrated how to increase immersion and presence of non-HMD users and facilitate the co-located asymmetric collaboration between a variety of devices. Gugenheimer et.al. [26] presented the ShareVR proof-of-concept (co-located multi-user VR system), which increases the non-HMD users’ enjoyment, presence, and social interaction by immersing them into VE via floor projection and mobile displays in combination with positional tracking. Another article [28] identified the challenges and goals of asymmetric VR based on expert interviews and conducted a co-located user study on collaboration between VR-users and external users who observed VR-users via external tablet and interacted with the virtual environment by directly drawing over it. The presented TransceiVR system was proved to increase the quality of communication and positively affected task completion time, error rate, and task load index. A recent study [59] demonstrated an asymmetric collaboration setup between technicians in VR and experts in a meeting room based on a video stream from VR. Their findings showed the potential of the approach for other use cases and suggested a base virtual collaboration on several spaces, rather than focusing on a single space with rich interactions. Despite the presented positive effects on collaboration, the proposed systems still rely on costly additional technologies and were explored in a co-located setup, where the attributes of the physical world play a significant role [59]. According to the Composite framework for Asymmetric VR (CAVR) [56] in co-located settings, the simultaneous engagement of physical and virtual worlds is the base for facilitating collaboration over a mixed-reality space. The framework further introduced the dimensions of asymmetry: spatial copresence, transportation, informational richness, team interdependence, and balance of power.

Nevertheless, there is no clear understanding of how asymmetry might occur in distributed settings, when all users are located in different physical spaces and have different levels of interactivity with the virtual space and each other. Furthermore, there is a lack of generalizable knowledge on how VR and other novel technologies affect remote collaboration [30]. To address this gap and further explore the effects of asymmetry in distributed settings, our article explores how VR can be used as an enhancement technology to facilitate collaboration among geographically dispersed departments in an industrial context. Since in some countries access to technology was limited, due to the pandemic situation, we investigated how communication and shared tasks would be performed by VR-users and remote users who observe video feed from VR streamed over Teams. By merging two virtual spaces, an immersive virtual world and a digital space in Teams, we generated a mixed-reality space for asymmetric VR collaboration.

3. Materials and Methods

This study is action-based research, conducted in collaboration with industry and academia. In this section, we firstly describe the industrial corporation, its processes and associated challenges. Further, we detail the requirements for VR system design, linking these to the industrial scenario and required tasks. Finally, we briefly describe the components of the COVE-VR platform that are relevant for the user study conducted.

3.1. Industrial Context: Maintenance Method and Technical Documentation Creation

KONE is a large manufacturing company, producing elevators, escalators, and automatic building doors. In addition, KONE provides maintenance services, which is an essential part of the revenue. Design for maintainability is an important area of product innovation, and maintenance methods are developed, and corresponding documentation created, as a part of the product development process. The maintenance instructions on how to perform maintenance tasks are used both in field work and in training [60].

Maintenance methods and the related technical documentation are developed iteratively in close cooperation with the maintenance development department (MDD) and the technical documentation department (TDD). The departments consist of multinational multidisciplinary teams, located in different locations and time zones. The major challenges of such collaboration include the lack of access to real equipment and the limitations of traditional channels (e.g., Teams, emails) to communicate complex product information, such as geometry and assembly/disassembly procedures.

Figure 2 shows the current pipeline of maintenance method development and technical documentation creation. Method developers create and design maintenance methods, which are further written and illustrated by technical writers and illustrators from TDD. Due to the frequent unavailability of physical equipment or prototypes, the method developers might never interact with real equipment and perform their tasks based on 2D images or 3D models on a computer screen. Such an approach is error-prone due to the limited spatial and contextual understanding and might lead to a situation where the method cannot be performed in reality, or requires unexpected additional work. Maintenance method developers use markups in existing pdf files or paper copies to create an outline: a draft version of the maintenance method. Once the outline is ready, technical writers and illustrators develop it further into technical instructions. If the writers and illustrators have no access to the equipment, they rely solely on the outline and notes given by the maintenance method developer. In many cases, this results in misinterpretations and mistakes. When a draft is available, it is reviewed and commented on by the method developer, and the comments are then implemented into the draft by the technical writer and illustrator. The commenting might take several rounds until both parties are happy with the draft. The number of rounds is increased by any misunderstandings or communication problems, especially if the parties involved are not physically in the same location.

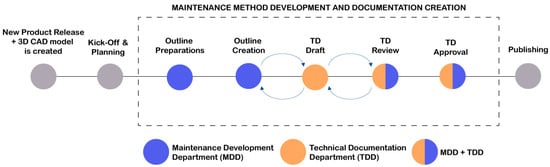

Figure 2.

The process of maintenance method development and documentation creation at KONE.

VR technology can optimize these processes by facilitating both asynchronous and synchronous collaboration activities within a simulated virtual environment and provide access to virtual prototypes throughout the method development process. Whereas the preceding study [31,32] investigated and demonstrated the usefulness of VR for asynchronous collaboration scenarios (where the departments were accessing VR in a sequence), this study is focused on synchronous collaboration practices. In particular, it explores the role of the synchronous collaboration scenario 1 at the phase “outline preparations” (see Figure 3), which may potentially minimize the misinterpretations and communication problems in the later phases of the maintenance method and technical documentation creation. In this scenario, both departments can jointly access virtual prototypes for the first time, exchange knowledge and generate digital content together, e.g., text and pictures, that can be re-utilized for technical documentation creation.

Figure 3.

Maintenance Method Development and Technical Documentation creation.

3.2. COVE-VR: VR System for Industrial Collaboration

The platform was designed as a co-creation project between academic and industrial researchers from KONE, imitating the industrial process of product development [31]. The major purposes of this VR system are the following: (a) facilitate easy access to, and natural interactions with, virtual prototypes (3D CAD models), (b) aid the synchronous and asynchronous collaboration of multinational remote teams and (c) enable digital content creation directly in VE. By digital content we refer to materials, such as textual notes, photos, and videos that may be further used for communication and documentation purposes. The COVE-VR platform consists of two virtual environments and seven virtual tools.

3.2.1. Virtual Environments

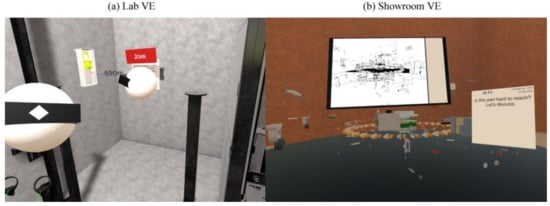

Two virtual environments were created to cover multiple scenarios of synchronous and asynchronous collaboration (shown in Figure 4). The Lab VE (1) is a small-sized working space for individual or pair-work that replicates a real elevator shaft based on existing 3D CAD models. This space allows quick and safe access to the virtual *space*, which is a time consuming and hazardous process in real life. The Showroom VE (2), on the contrary, was designed to allow assembly/disassembly of virtual prototypes and facilitate collaborative work between larger groups of people, including client presentations.

Figure 4.

Working virtual environments: (a) the Lab VE, which replicates a real elevator shaft and (b) the Showroom VE with a disassembled 3D CAD model.

3.2.2. Virtual Tools

We define virtual tools as virtually tangible elements of VE, which have a function to perform over VE (whether it be the creation of new digital content or manipulation of VEs to facilitate the execution of industrial tasks). Eight virtual tools were created to aid the process of maintenance method development and technical documentation creation.

The Showroom is equipped with a 3D model pedestal, the so-called (1) Disassembler, which allows in-depth investigation of 3D models (assembly/disassembly), including changing their size, rotation, and vertical position via the wall menu. The models can be disassembled into parts, which in turn can also be highlighted or removed.

All other tools are accessible in both virtual spaces; they are opened via the wrist menu on the left controller. The Model Placement tool (2) allows importing any 3D CAD model in the STEP format to the virtual environment. The models are converted asynchronously in the background by a separate application, which we developed to continuously check for new models placed in the application’s directory. The import process in the VR application itself was also made to be as asynchronous as possible, although it still resulted in slowdown and a loading screen was therefore added. Several levels of detail are created, of which the highest is only used for visuals and the lower levels can be used for collision. However, in our case, a simple box collider was enough and significantly faster for interactions in the VE. Colors are preserved, but metadata is not converted, which is a shortcoming of our approach.

The TextBox tool (3) was designed to create textual notes in VR, which can be used to support asynchronous communication or directly as textual elements for technical documentation. Text can be inputted via speech recognition or virtual keyboard in two languages (in our case study): English and Finnish. Support for other languages could be added as needed. The note can be left as a text box or as a smaller message bubble icon in virtual space. All text notes created in VR are further able to be exported to a file with the author’s name, the message number and a timestamp.

The Camera tool (4) is a multipurpose tool made to allow taking pictures and videos from a virtual environment. All created media files can be accessed from the desktop. In addition to regular photo and video modes in front- or back-facing mode, with or without a timer, the tool also supports outline rendering, which captures only the line art in black and white.

The Measure tool (5) was added to allow taking measurements of the dimensions and distances required for maintenance method creation. To lock the movements of 3D models and measures over grid points, the Grid Snipping tool (6) was created. The grid size can be adjusted. With the Delete tool (7), 3D objects and other tools can be removed from a virtual environment. Finally, the Save World State tool (8) is used to save all created content in the VE, or to load an existing state, for example, one left by the previous worker.

In summary, our virtual tools were designed to fulfil industrial needs: to advance department-to-department communication and to enable digital content creation for maintenance documentation. At the same time, the tools are generic enough to support many other industrial use cases that were not considered here.

3.3. Hybrid User Study with Domain Experts

This article presents the action-research case study with domain experts on how the COVE-VR platform, designed to advance industrial practices in the pipeline of maintenance method development and technical documentation creation, can be integrated into the company’s working processes to support collaboration among geographically distributed departments. The goal of the study was to investigate the role of asymmetry between the VR platform and the currently used teamwork tool, the Teams, and how to expand the VR system design to advance collaboration practices. The study aimed to measure the experts’ perception of VR technology and remote collaboration, as well as find the differences in workload, and other elements of user experience, between two distributed participant groups. To address the study goal, a remote user study that replicates the actual industrial collaboration tasks was conducted with expert participants.

3.3.1. Participants

In total, 20 experts (16 male and 4 female) aged from 27 to 60 (with an average of 40), participated in an asymmetric VR collaboration process between the COVE-VR and Teams. All the participants belong to KONE company with, on average, 5.5 years of experience in their areas (Min = 1, Max = 22); ten of them represented the technical documentation department (TDD), eight represented the maintenance development department (MDD) and two were from mechanical design. Regarding education level, 17 participants hold a bachelor’s degree or similar, two hold a master’s degree or similar and one graduated from a vocational school. Bin terms of country of residence, 11 participants were from Finland, six from India, two from China and one from the USA. Five experts had previous single-user experience with the COVE-VR system.

3.3.2. Participant Groups and Roles

The participants were divided into two groups: (1) VR-participants, who were present in the virtual environment and were able to interact with it, and (2) Teams-participants who watched a streamed video from the perspective of one of the VR-participants via Teams desktop application. Teams-participants were able to communicate verbally with VR-participants and performed tasks outside of the VE using their laptop tools. In total, 5 remote sessions with 20 participants were organized: ten VR-participants, wearing HMD, and ten Teams-participants (referred to as VR and T). Each session was planned to have four participants: two VR and two Teams participants. However, due to a scheduling conflict, one Teams participant skipped their session and joined a later one, causing one session to have 3 participants, and another session 5 participants.

The battery replacement procedure was performed collaboratively during the test; every participant had their own role and related set of tasks, represented in Table 1, thus mimicking their real work tasks and role. The battery replacement task was chosen because it is a fairly complex procedure consisting of identifying the components and parts, opening and closing lids, releasing fixings, and disconnecting and reconnecting cables. As the task is performed in a high-risk environment, the replacement also involves several safety measures both before and after the replacement. The tasks were further split into two scenarios: (1) 3D CAD model exploration in the Showroom space and (2) Assembly/Disassembly of a 3D CAD model in a simulated context (Lab VE). The VR-participant 1 acted as the eyes for the Teams participants while performing assigned tasks and followed the instructions from Teams participants to find the best view. VR-participant 2 was mostly responsible for interacting with 3D models and virtual tools. Teams-participant 1 took notes during the whole process as well as asked for more details, e.g., additional measures of the 3D components. Teams-participant 2 instructed VR-participant 2 to find the best possible position and took screenshots from their view. Overall, the tasks were designed to perform the collaboration between VR-participants as well as collaboration between VR and Teams participants.

Table 1.

Tasks for the user study.

3.3.3. Remote User Study Set-Up

The user study was held remotely, meaning that all the participants were present from different locations. In each session, VR-participants performed testing at KONE facilities from two different rooms, whereas Teams-participants connected from other countries.

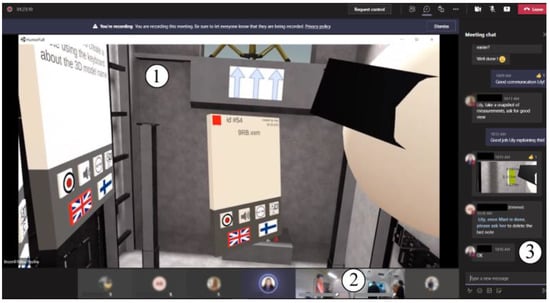

All communication was conducted via Teams, as shown in Figure 5. The main facilitator moderated the user test from the same room with VR-participant 1, whose point-of-view was streamed over Teams. The support facilitator was present in another room with VR-participant 2 to provide guidance and technical assistance. The chat facilitator was present in Teams meetings to manage Teams-participants and track the completion of their tasks. All sessions were observed by at least one industrial researcher.

Figure 5.

Screenshots from the test procedure: (1) streamed VR image from the VR-participant’s point-of-view, (2) streamed video of the VR-participants, (3) Teams chat activity.

VR-participants and facilitators could listen and talk to others on the call using external speakers with built-in microphones, while the meeting audio was transferred to the VR headsets utilizing their built-in microphones for communication by adjusting Teams audio settings. In other words, the headsets acted as the aforementioned external speakers. Additionally, the rooms with VR-participants were equipped with standalone cameras to stream the physical view of the rooms via Teams. A more detailed description of the setup and procedure is presented in [61].

The user study procedure started with signing the consent forms, followed by a brief introduction to Teams and a training video about the COVE-VR. after which participants filled in a pre-survey on expectations. VR-participants proceeded with a hands-on training session in VE (both used Vive Pro Headset), while Team-participants observed the training and could ask questions in the Teams chat. To avoid the risk of motion sickness in VR, VR-participants were instructed to immediately take off their headset and inform the moderator in the event of feeling any sickness.

Next, the collaboration process between the COVE-VR participants and Teams-participants was performed, based on a set of tasks designed to replicate a real industrial context (Table 1). All the participants were encouraged to follow the think-aloud protocol for the duration of the procedure and freely express any emotions and opinions aloud. After all the tasks were completed, the participants discussed their experience in a group interview and filled in a post-survey.

3.3.4. Collected Data and Analysis

Both qualitative and quantitative data was collected during the study. The qualitative data was collected through a semi-structured interview and observations, while the quantitative data was collected via online pre- and post-questionnaires, created with the LimeSurvey tool.

In the pre-questionnaire, participants shared their expectations on the COVE-VR system based on the video they watched. This was the first part of the SUXES questionnaire, which was used to access the differences in expectations and experiences with VR technology [62]. The post-questionnaire consisted of six parts: (1) experiences with the system (as the 2nd part of the SUXES), (2) self-designed statements on collaboration, (3) workload via raw SIM-TLX [63], (4) self-designed statements on the perception of VR technology, (5) statements on immersion for VR-participants, adopted from Presence Questionnaire [64], and (6) background information. In this paper, we present the data from the 1st, 2nd, 4th and 6th sections.

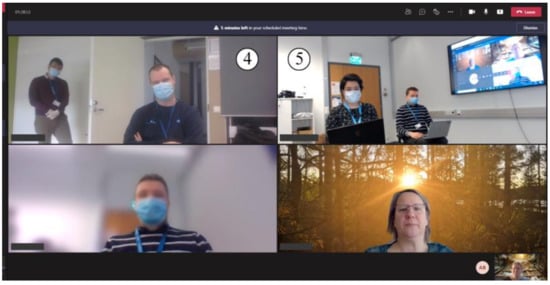

The semi-structured group interview was conducted at the end of the study by the main facilitator to raise discussion on the usability of the system, the asymmetry between VR and Teams and related collaboration practices; the participants were asked to turn on their cameras during the interview (Figure 6). The interview script consisted of five sections, covering (1) general UX, (2) VR system’s usefulness and efficiency for industrial tasks, (3) experiences of asymmetric use between VR and Teams, (4) roles and tasks in asymmetric collaboration, and (5) improvements for the COVE-VR platform and asymmetric collaboration practices. Additionally, observation forms with pre-defined questions were used to collect observation-based data systematically.

Figure 6.

Group interview via Teams: (4) VR-participant 2 and support facilitator, (5) VR-participant 1 and main facilitator.

The collected data was analyzed in collaboration with academic and industrial researchers. A descriptive statistical analysis was performed over quantitative data because of the relatively small sample size. The observations and interviews were analyzed using thematic qualitative data analysis [65]; the gathered data was categorized by themes with affinity diagrams. The most popular themes were multi-user and teamwork interaction, roles in asymmetric interaction, remote participant UX, VR tools, and complimenting teamwork with voice commands.

4. Results

This section presents the combined results of qualitative and quantitative results, starting from overall reaction to the industrial VR platform, its usefulness for the company’s processes, and usability of the asymmetric use, followed by evaluation of the digitally-hybrid collaboration process and reflection on how to advance it. The results of the questionnaires, as well as experts’ quotations, are presented by the participant groups, since VR-participants’ (VR#) and Teams-participants’ (T#) experiences with the system were different in terms of interactivity with VE and immersion.

In summary, both participant groups actively participated in the collaboration process, seriously accepted their roles and were able to finish their tasks successfully, helping each other, sharing knowledge, and generating useful digital materials. Based on the observations, the shared tasks and communication between VR- and Teams-participants not only positively influenced the efficiency of the industrial work process, but also increased the spatial understanding of both participant groups. Teams-participants supported this observation during the interview:

T2: “With the current tools [it] is really hard to see the views from the product, with this kind of view it would be easier and easily understandable to begin the illustrations at the beginning [of the documentation process]”

T3: “Measurements were excellent, for example, you get the scale of things”.

4.1. Overall Reaction and Usability of the COVE-VR Platform

The concept of a VR system to facilitate the collaboration of multinational departments in various phases of product, and related services, development was found to be extremely advantageous by industrial experts. They further reviewed it as “a low-cost option” (VR1) to address existing industrial challenges, to “save a lot of time”, and “reduce the number of iterations” (T4). One of the VR-participants further suggested:

T6: “I think VR has to be done in every milestone so we can really integrate VR to the KONE process. The milestones in the process should be aligned with the product workflow so then it aligns with the schedule of the product”.

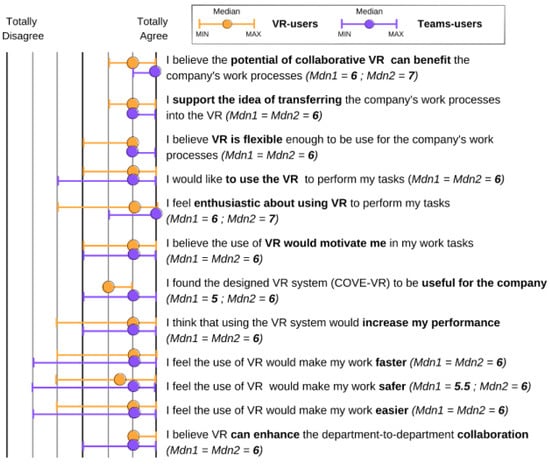

The digitally hybrid collaboration approach with the COVE-VR was found to be beneficial by both participant groups, whereas virtual working spaces and interaction with virtual prototypes were seen as a way “to improve the communication and have high-efficient meetings” (T1). The results of the survey on the subjective perception of VR technology are shown in Figure 7, that visualizes the minimum, maximum and median of survey answers in two groups: orange for VR-participants and violet for Teams-participants. The figure demonstrates the main trends of perception and minor differences between the two groups, by showing the division of answers over a 7-point scale, together with the middle value of answers. The results revealed that all industrial experts agreed or strongly agreed that the potential of collaborative VR can benefit the company’s working processes and supported the idea of transferring their working processes into VR. In general, the figure shows that VR was evaluated as a technology to advance industrial working processes by a majority: only one VR-participant and two Teams-participants left negative responses to several statements. On the opposite side, all experts believed that VR can enhance department-to-department collaboration. Further, 95% of the experts found VR to be flexible for the company’s work processes, felt enthusiastic to use VR to perform their work tasks and believed that the use of VR would increase their motivation. 90% would like to use VR at work and agreed that VR would increase their performance. Finally, when counting the percentage of agreements for the statements, the use of VR was found to make their work easier by 85%, safer by 75%, and faster by 70%.

Figure 7.

Employees’ perceptions of VR technology for the industrial context.

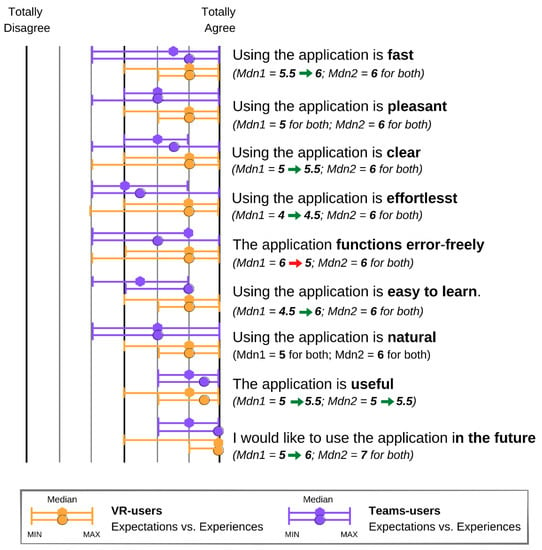

The usability of the COVE-VR was measured by the SUXES questionnaire, which compares expectations towards the system and the actual experiences with it (Figure 8). Overall, expectations and experiences for both participant groups were mostly positive and neutral; none of the participants selected negative extremes. Furthermore, VR-participants and Teams-participants found the COVE-VR system to be useful and would like to use it in the future. In addition, the general trend observed was that the expectations were lower than the actual experiences with the COVE-VR system; only two VR-participants and two Teams-participants somewhat disagreed with several statements after using the system.

Figure 8.

Expectations and experiences with the VR platform.

Additionally, the figure shows the increase in the VR-participants’ perception after using the application: the VR-participants perceived the system to be faster, clearer, and easier to learn after completing the user study tasks. Decrease was only observed for the statement that the application functions error-freely; several interactions and UX errors were identified during the user study.

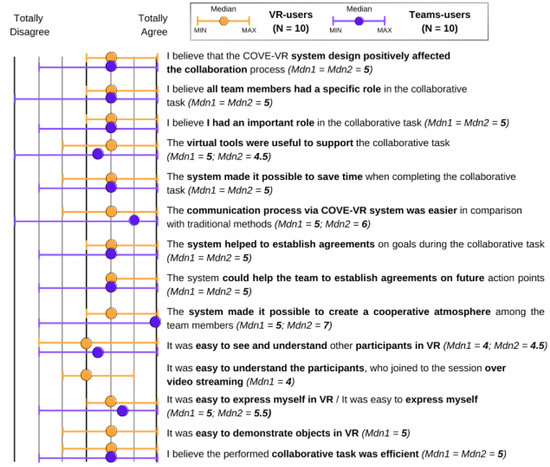

4.2. Digitally-Hybrid Collaboration

The asymmetric COVE-VR use between VR-participants and Teams-participants was reviewed as a more promising alternative to traditional communication channels (such as emails and video calls, or chatting over Teams) for industrial collaboration needs. The results of the survey showed (Figure 9) that although the asymmetric collaboration was perceived less positively than the COVE-VR system itself, the medians are still on the positive or neutral side. Only one Teams-participant, who is highly experienced with VR technologies, left negative or extremely negative responses to all the statements on collaboration.

Figure 9.

The results of the collaboration-related questionnaire.

Otherwise, 95% of experts agreed that the system could help the team to establish agreements on future action points and 80% agreed that the system made it possible to create a cooperative atmosphere among the team members. The experts, who participated through Teams, highlighted the usefulness of a multi-user VR environment, where “one can do things in the same location even if not in the same place” (T5). Moreover, such hybrid collaboration was found to save time during the collaborative task by 60% of the experts and may further save time by advancing the Lean and Agile philosophy, since “the iterations can be reduced because some clarifications can be done there with other team members.” (T7). Another expert commented that with collaborative VR. “we can avoid ping-pong email-you can directly ask and discuss” (VR2).

Further, some VR- and Teams-participants alike reported positive effects of the VR system on co-presence, commenting: “Even though *name* was there virtually, it felt like he was really there” (VR3) and “it looked like that we were in the same environment. I thought people were standing besides me” (VR4) and “I was asking the VR participants to change views or do things and I was seeing directly their view, so I felt we were in the same place” (T2).

However, the quality of communication between experts and the efficiency of asymmetric collaboration could be significantly increased; even though 75% of experts agreed that the COVE-VR system design positively affected the collaboration process, only 55% found that the virtual tools were useful for collaboration and would like “to have better tools for interaction” (VR6). In general, hybrid collaboration would benefit from having more visual elements to support the communication, which were lacking in the current system design. Additionally, it was not easy to see and understand participants in VR, and also 40% of the VR-participants found it somewhat difficult to understand the participants who joined via Teams. Experts commented that they wish to have “more transparency on what the other participants are doing” (VR5) and “would like to have pointers from the other participants” (VR1 and VR7, or the “possibility to highlight objects” (VR8), which would support the collaboration process visually.

During the interview, experts further discussed the issues of asymmetric settings and provided suggestions to enhance it. One of them commented that “the communication with all the participants was quite natural, the only issue was that I didn’t know who was talking” (VR1). Another participant commented: “I don’t think there was many differences between the communication among participants. Ultimately, we all were in different places” (VR9). Interestingly, the experts’ communication greatly benefited from the “think-aloud” approach, used for research purposes. Although the lack of visual elements hindered the overall experience, some experts commented that “the voice helped us communicate with others” (VR9). The verbal communication happened mostly between Team- and VR-participants; by the end of the sessions, Team-participants gained more confidence to guide the VR-participants to overcome the lack of visual cues. However, for some participants, the non-interactive role within VR was not sufficient, one of them said “[I was] lacking the immersion, lack of being able to control things was difficult.” (T8); they suggested adding access to the COVE-VR via the desktop user interface; “even partial control for remote [desktop] users for the viewpoint [would be good]. I was trying to scroll to get my own view-would be good to have a possibility to get your own view as remote user” (T9).

5. Discussion

This article presented the results of the expert case study on integrating COVE-VR platform using asymmetric setup with Teams to facilitate the collaboration of geographically distributed departments involved in the pipeline of maintenance method development and technical documentation creation. The study addressed the actual challenge present in the industry, whereas the study design on asymmetric VR was dictated by real-life limitations, such as travel restrictions during the COVID-19 pandemic and the unavailability of HMDs for purchase in global markets.

Previous studies on asymmetric VR have mostly focused on co-located settings and explored how to increase the immersion and feeling of control for non-HMD users relying on additional costly technologies [26,28,55]. However, there is still no clear knowledge on how asymmetry might occur in distributed settings. To address this shortcoming, this study explored a scalable approach to distributed asymmetric VR, based on adding desktop users via Microsoft Teams, who get a visual representation of VE over streamed video and can interact with the VR-users over voice to complete shared tasks. This setup can still be referred to as collaboration over a mixed-reality continuum, since the collaboration happened via merging two virtual worlds with different immersion levels. The strongest contribution of this industry-focused study lies in eliciting the data involving multinational domain experts based on actual industrial scenarios, roles, and tasks.

Overall, our study indicates the potential of a practical asymmetric VR setup to fulfil industrial needs. By merging the use of VR with traditional conferencing tools, it is possible to extract the value of VR technology without the need to provide expensive equipment to every employee. In contrast, distributed asymmetric use of VR is sufficient to improve the communication of departments in several industrial scenarios, which, in turn, leads to increased scalability, accessibility, and cost reduction. Therefore, with this article, we suggest that the adoption of VR technology for industrial needs can reach a wider range of interactive and non-interactive users when it can be performed without extensive hardware costs, which was noted as one of the main obstacles towards wide VR adoption [25].

5.1. Industrial Use Cases for Asymmetric VR

Supporting the previous studies [2,8,16,17], we argue that VR technology is a game-changer for industrial processes and one of the most important production tools to supplement and optimize product and related services design and development processes in line with Industry 4.0.

Particularly answering RQ1, our case study demonstrated the value of asymmetric VR settings to support the collaboration of multinational departments in two key ways: (1) to design maintenance methods and (2) to draft technical documentation. Design for maintainability requires an understanding of how maintenance can be done efficiently (e.g., Can the technician reach something? or Is there enough space for performing maintenance tasks?). Hence, it is critical to correctly perceive the scale of the space. One shortcoming of exploring 3D CAD models on a 2D computer screen is lack of understanding of the real spatial dimensions. Therefore, one of the major tasks for these use cases is to accommodate 3D model exploration tasks in VE on a 1:1 scale among geographically distributed experts. In addition to improving the spatial understanding of the VR-users [57,66], our expert study showed that the spatial understanding of the Teams-users was also improved with the asymmetric settings. The possibility to communicate verbally while observing and guiding VR-users (and their avatars) to interact with the 3D model in virtual space improved their understanding of the scale. Furthermore, the use of virtual tools for content creation (e.g., Textbox or Camera tools) enables easy capture of digital materials that can be utilized for compiling draft versions of documents and further supporting the communication process.

Interaction with 3D CAD models is an important task in many industrial contexts [4,34,49] which may be performed throughout the product development lifecycle in other use cases. The asymmetry for this task can be applied to boost scalability and include users with no access to HMDs in the collaboration process, thus addressing existing challenges of industrial maintenance, such as the lack of understanding of the real scale when developing maintenance methods. The asymmetry in both use cases can be dynamically arranged to enable appropriate knowledge transfer, depending on team composition, and requires only one VR-user to manipulate a 3D model and demonstrate it to remote users.

Expert insight also showed the value of the asymmetry between VR-users and non-interactive desktop users for other industrial use cases, such as (3) global training and (4) virtual maintenance assessment. Asymmetry in the training process is based on knowledge transfer from experts to novice learners in a simulated safe environment [7]. In this scenario, an expert (knowledge owner) would participate as the VR-user, whose point-of-view would be streamed to learners via traditional conferencing tools. This way, learners may follow the educational materials from any physical location and any platform. Similarly, as described by Clergeaud et.al., [59], another use case for asymmetric VR settings in industry is in virtual maintenance assessments. In this case, the asymmetry is reversed. The maintenance expert (knowledge owner) would be a desktop user, who would follow a technician’s actions in VR and evaluate the efficiency of the maintenance method. Performing both use cases mentioned in a real industrial context might be dangerous or even impossible. Hence, applying asymmetric VR to enable global training and virtual maintenance assessment could improve the company’s overall accessibility and sustainability by granting access to flexible simulated environments and, consequentially, reducing travel costs. Therefore, distributed asymmetric VR in the industry can prompt agility in the processes by reducing travelling times to training or testing sites [67] while increasing access for users that do not have HMD hardware available [35].

5.2. Advantages of Asymmetry

Our study highlights that the distributed asymmetric VR between VR-users and non-interactive desktop users is a valid low-cost solution to advance the communication and knowledge transfer between multinational and geographically dispersed departments in a variety of industrial use cases. The majority of experts were intrinsically motivated toward utilizing VR in any available form despite several usability issues. The experts’ desire to adopt VR for their work tasks and synchronize it with product development milestones highlights the value of the designed COVE-VR system for industrial contexts.

Expanding on the previous findings [17], our article suggests that asymmetric VR positively affects decision making and increases the number of employees who may participate and contribute to the collaboration process, because it enables accessibility for employees that do not have access to HMDs or other advanced technologies. Such asymmetry may further advance flexibility in terms of engagement levels and degree of participation in work activities [3], which potentially increases workplace satisfaction levels. Further, due to the ability to support industrial collaboration [4,42,48,49] by providing rapid access to virtual prototypes and tools for content creation, asymmetric VR is a promising approach to advancing and integrating Lean and Agile industrial practices [19,39]. Our study showed that distributed asymmetric collaboration in VR may reduce the number of iterations in product development and, thus, minimize lean waste and support cost reduction. It also allows faster and less expensive execution of industrial tasks, resulting in faster time-to-market and overall optimization.

Our findings further indicate that such an asymmetric approach, apart from enhancing teamwork and communication between industrial departments from different countries, may also raise awareness and knowledge of VR among industrial employees with no previous experience and access to VR devices, which potentially delivers several benefits. One of the remote participants (a first-time user of VR, located in India) commented: “It was an amazing, very thrilling experience. Once when we get the real VR experience it would be great” (T2). First, this allows extending the pool of test users, who might be included for further VR software development, which is critical for adopting and localizing the software for different cultural user groups in multinational companies. Additionally, such an approach would enable a smooth introduction to VR technologies and steadily prepare employees for Industry 4.0 interventions. Therefore, our study suggests that asymmetric collaboration between VR platforms and traditional conferencing software, such as Teams, is a worthy strategy to facilitate knowledge transfer between industrial experts, and is generalizable to other industrial contexts and collaboration scenarios.

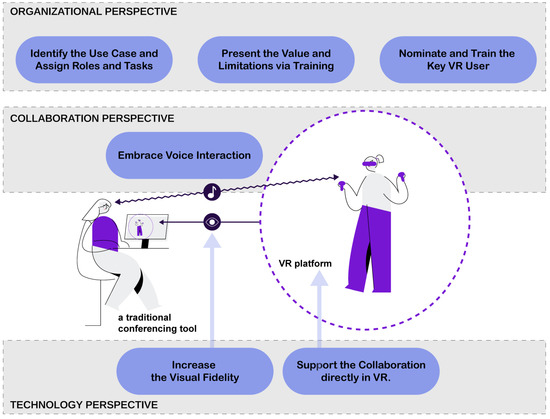

5.3. Asymmetric VR: Guidelines

In this section, we answer RQ2 by summarizing our findings in a form of six guidelines on how to support remote industrial collaboration and efficiently adopt distributed asymmetry between VR platforms and traditional conferencing tools for this purpose.

The guidelines are supported by Figure 10, which visualizes the nature of asymmetry between VR platform and traditional conferencing tools and further determines the perspective from which the guidelines should be approached: organization, collaboration and technology perspectives.

Figure 10.

Guidelines on how to support asymmetry between VR and traditional conferencing tools.

Guideline 1: Identify the Use Case and Assign Roles and Tasks. Our case study, supporting previous work [27,55], demonstrated that a clear division of roles and tasks may ease up the collaboration process in asymmetric distributed settings. Hence, based on the scenario of asymmetric VR and the pattern of knowledge transfer, all collaborators should be assigned roles to ensure that every participant has a shared understanding of their and others’ tasks and how mixed-reality space accommodates these. In particular, this would support the dimensions of asymmetry (e.g., transportation, team interdependence and power balance [56]) as well as potentially ensure team dynamics and collaborative tasks accomplishment despite the limitations of asymmetry.

Guideline 2: Present the Value and Limitations via Training. To accomplish efficient digitally hybrid collaboration, all the users should be aware of why VR is used to supplement their work activities and what the value and functionality of the VR software is. The users should receive specific training on remote or HMD use since the capabilities and UX is different depending on the user group. For VR-users, training would increase the usability of the system, which positively affects feelings of control and reduces the stress associated with the use of novel technology. For remote users, training would raise awareness of the possibilities of VR, prepare them for the limitations of non-interactive users and educate them on how to overcome these.

Guideline 3: Nominate and Train the Key VR User. In addition to regular training, our findings suggest that at least one person, who is familiar with the VR environment and defined as the key VR user, should be present in every session or be available online, either as a user or as a facilitator. This lowers the bar for using a new technology and speeds up technology acceptance [68].

Guideline 4: Embrace Voice Interaction. Since the main link between the two digital worlds is direct communication via voice, the use of it should be emphasized to the greatest extent possible. Special techniques, similar to the “think-aloud” approach, may be integrated into the collaboration process to raise employees’ confidence and support trust and open discussions, as well as more concrete instructions from non-HMD users. This would positively affect the team interdependence dimension [56], the quality of communication in general, and the accomplishment of shared goals [69].

Guideline 5: Increase Visual Fidelity. The major goal of asymmetric VR setup is to share the spatial understanding of virtual simulated space and the virtual objects inside it, related to the information richness dimension [56]. Hence, visual clarity is a critical factor affecting the quality of asymmetric industrial collaboration, and it can be enhanced in several directions. One of them, suggested previously [28], would be to provide a static and stable video picture that would be streamed to non-HMD users. By implementing a virtual camera that can be manipulated by VR-users, it is possible to increase the quality of pictures from VE and support more detailed observations for non-HMD users. Furthermore, enhancing VR-users’ visibility would positively affect the collaboration of both user groups. That would include using graphics and animations to visualize VR-users’ movements in VE and their interactions with virtual objects.

Guideline 6: Support the Collaboration directly in VR. Previous work demonstrated that the role of VE’s features on the overall user perception is more significant than the platform used [54,58]. Hence, when creating VR systems to support industrial working activities, both VR-users and non-HMD users should be considered. In case of the VR software being initially developed to support single-user interactions, additional functionality should be considered to add transparency to VR-users’ actions and enhance the collaboration practices. This can be achieved by integrating supportive collaborative tools to visualize the users and the objects with which they interact. Highlights, pointers and teleportation trajectory were suggested by experts among other solutions, which would further contribute to information richness.

5.4. Limitations and Future Work

A limitation of this study is its narrow focus on a single company’s work processes. Despite the value of presented asymmetry to industrial scenarios, the influence of asymmetry in distributed settings should be further explored in the work processes of other large manufacturers, as well as in other fields and contexts. Additionally, further work on using asymmetric VR, and especially a comparison of collaborative activities in multi-user distributed VR and in similar asymmetric VR, would shed more light on the topic, since both setups have advantages, limitations and application scenarios [60]. Future research may also look into advancing the scalability of the approach and expanding the asymmetry towards portable devices.

To further advance the communication and teamwork quality, it is critical to address the lack of immersion and interaction of the non-HMD user. Additionally, it is critical to identify resource-efficient ways to increase the sense of co-presence when merging the use of VR and traditional conferencing tools. Our results demonstrated the desire to obtain at least some level of control, which suggests the use of VR user interfaces designed for 2D screens. In this case, it is not obvious to what extent freedom of interaction and control for non-HMD users would affect the collaboration practices. The symmetry between 2D and 3D VR asymmetry when applied remotely in an industrial context is another topic to investigate, since it holds the potential to advance the feel of co-presence without massive costs.

6. Conclusions

With a recent shift towards remote work practices, and the rapid development of emerging technologies, collaboration over the mixed-reality continuum is becoming a more prominent research topic in HCI and CSCW fields. VR in combination with other maturing technologies of Industry 4.0 offers a way to shift and optimize traditional industrial operations. Evidence has shown that VR is an efficient production tool [6,11,46,49] to support product development and related processes, especially for geographically dispersed teams. Immersive VE, with realistic simulations and multi-user support, may significantly reduce costs and project span by offering a digital space for many industrial operations that are difficult, dangerous, or time consuming. However, due to many external factors, the wide adoption of VR technology is still not possible.

This study explored the asymmetry between VR-platform and the traditional conferencing tool (Microsoft Teams) to facilitate the collaboration of multinational departments in the pipeline of maintenance method development and documentation creation. The study stands out from the existing work by involving domain experts as participants in realistic industrial scenarios. The study demonstrated that distributed asymmetric VR is a low-cost and scalable solution that can easily integrate with current industrial remote working practices. Furthermore, not only does it positively influence the adoption of VR in the industrial context, but also enhances Lean and Agile practices. Based on expert insight, we identified four use cases in the field of Industrial Maintenance, which would greatly benefit from distributed asymmetric VR: maintenance method development, technical documentation creation, global training, and virtual maintenance assessment. To further boost the adoption of VR technologies in the industrial context, we provided a list of guidelines on how to support the asymmetry between VR and traditional conferencing tools. The guidelines address the asymmetry from three perspectives: organization (assign roles and tasks based on the use case, explain the value of VR to the employees and nominate the key VR user), collaboration (embrace voice interaction), and technology (advance visual fidelity and support collaboration directly in VR).

Author Contributions

Conceptualization, A.B., P.B.P., H.H., M.T. and S.S.; methodology, A.B., P.B.P., H.H. and S.S.; software, A.B., J.M. and K.R.; validation, J.M., J.H., M.T. and S.S.; formal analysis, A.B., P.B.P. and P.T.; investigation, A.B., P.B.P., P.T., H.H. and S.S.; resources, M.T. and S.S.; data curation, A.B. and P.B.P.; writing—original draft preparation, A.B., P.B.P. and P.T.; writing—review and editing, A.B., P.B.P., P.T., J.M., J.H., H.H., R.R., M.T. and S.S.; visualization, A.B.; supervision, M.T. and S.S.; project administration, R.R., M.T. and S.S.; funding acquisition, R.R., M.T. and S.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Business Finland Human Optimized XR (HUMOR) co-innovation project, grant number # 3913/31/2019.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Not applicable.

Acknowledgments

We would like to warmly thank KONE researchers and employees for participating in this case and for their valuable input to the research process. We also thank research assistants Topi Nieminen and Jesse Sydänmäki for their contribution to the COVE-VR development process.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Churchill, E.F.; Snowdon, D. Collaborative virtual environments: An introductory review of issues and systems. Virtual Real. 1998, 3, 3–15. [Google Scholar] [CrossRef]

- Guo, Z.; Zhou, D.; Chen, J.; Geng, J.; Lv, C.; Zeng, S. Using virtual reality to support the product’s maintainability design: Immersive maintainability verification and evaluation system. Comput. Ind. 2018, 101, 41–50. [Google Scholar] [CrossRef]

- Ferreira, W.D.P.; Armellini, F.; De Santa-Eulalia, L.A. Simulation in industry 4.0: A state-of-the-art review. Comput. Ind. Eng. 2020, 149, 106868. [Google Scholar] [CrossRef]

- Wolfartsberger, J. Analyzing the potential of Virtual Reality for engineering design review. Autom. Constr. 2019, 104, 27–37. [Google Scholar] [CrossRef]

- Andaluz, V.H.; Sánchez, J.S.; Sánchez, C.R.; Quevedo, W.X.; Varela, J.; Morales, J.L.; Cuzco, G. Multi-User Industrial Training and Education Environment. In Augmented Reality, Virtual Reality, and Computer Graphics; De Paolis, L.T., Bourdot, P., Eds.; Springer International Publishing: Cham, Switzerland, 2018; Volume 10851, pp. 533–546. ISBN 978-3-319-95281-9. [Google Scholar]

- Shaw, E.; Roper, T.; Nilsson, T.; Lawson, G.; Cobb, S.V.G.; Miller, D. The Heat Is On: Exploring User Behaviour in a Multisensory Virtual Environment for Fire Evacuation. In Proceedings of the 2019 CHI Conference on Human Factors in Computing Systems, ACM, Glasgow, UK, 2 May 2019; pp. 1–13. [Google Scholar]

- Wang, Q.H.; Li, J.R. A desktop VR prototype for industrial training applications. Virtual Real. 2004, 7, 187–197. [Google Scholar] [CrossRef]

- Berni, A.; Borgianni, Y. Applications of Virtual Reality in Engineering and Product Design: Why, What, How, When and Where. Electronics 2020, 9, 1064. [Google Scholar] [CrossRef]

- Murray, N.; Fernando, T.; Aouad, G. A Virtual Environment for the Design and Simulated Construction of Prefabricated Buildings. Virtual Real. 2003, 6, 244–256. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Liu, H.; Kang, S.-C.; Al-Hussein, M. Virtual reality applications for the built environment: Research trends and opportunities. Autom. Constr. 2020, 118, 103311. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.-G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Pedersen, G.; Koumaditis, K. Virtual Reality (VR) in the Computer Supported Cooperative Work (CSCW) Domain: A Mapping and a Pre-Study on Functionality and Immersion. In Virtual, Augmented and Mixed Reality. Industrial and Everyday Life Applications; Chen, J.Y.C., Fragomeni, G., Eds.; Springer International Publishing: Cham, Switzerland, 2020; Volume 12191, pp. 136–153. ISBN 978-3-030-49697-5. [Google Scholar]

- Burova, A.; Mäkelä, J.; Hakulinen, J.; Keskinen, T.; Heinonen, H.; Siltanen, S.; Turunen, M. Utilizing VR and Gaze Tracking to Develop AR Solutions for Industrial Maintenance. In Proceedings of the 2020 CHI Conference on Human Factors in Computing Systems, Honolulu, HI, USA, 21 April 2020; ACM: New York, NY, USA, 2020; pp. 1–13. [Google Scholar]

- Choi, S.; Jung, K.; Noh, S.D. Virtual reality applications in manufacturing industries: Past research, present findings, and future directions. Concurr. Eng. 2015, 23, 40–63. [Google Scholar] [CrossRef]

- De Silva, R.K.J.; Rupasinghe, T.D.; Apeagyei, P. A collaborative apparel new product development process model using virtual reality and augmented reality technologies as enablers. Int. J. Fash. Des. Technol. Educ. 2018, 12, 1–11. [Google Scholar] [CrossRef]

- Berg, L.P.; Vance, J.M. An Industry Case Study: Investigating Early Design Decision Making in Virtual Reality. J. Comput. Inf. Sci. Eng. 2016, 17, 11001. [Google Scholar] [CrossRef]

- Wolfartsberger, J.; Zenisek, J.; Wild, N. Supporting Teamwork in Industrial Virtual Reality Applications. Procedia Manuf. 2020, 42, 2–7. [Google Scholar] [CrossRef]

- Wang, P.; Wu, P.; Chi, H.-L.; Li, X. Adopting lean thinking in virtual reality-based personalized operation training using value stream mapping. Autom. Constr. 2020, 119, 103355. [Google Scholar] [CrossRef]

- Guo, Z.; Zhou, D.; Zhou, Q.; Zhang, X.; Geng, J.; Zeng, S.; Lv, C.; Hao, A. Applications of virtual reality in maintenance during the industrial product lifecycle: A systematic review. J. Manuf. Syst. 2020, 56, 525–538. [Google Scholar] [CrossRef]

- Di Gironimo, G.; Mozzillo, R.; Tarallo, A. From virtual reality to web-based multimedia maintenance manuals. Int. J. Interact. Des. Manuf. 2013, 7, 183–190. [Google Scholar] [CrossRef]

- Konstantinidis, F.K.; Kansizoglou, I.; Santavas, N.; Mouroutsos, S.G.; Gasteratos, A. MARMA: A Mobile Augmented Reality Maintenance Assistant for Fast-Track Repair Procedures in the Context of Industry 4.0. Machines 2020, 8, 88. [Google Scholar] [CrossRef]

- Gavish, N.; Gutiérrez, T.; Webel, S.; Rodríguez, J.; Peveri, M.; Bockholt, U.; Tecchia, F. Evaluating virtual reality and augmented reality training for industrial maintenance and assembly tasks. Interact. Learn. Environ. 2013, 23, 778–798. [Google Scholar] [CrossRef]

- Palmarini, R.; Erkoyuncu, J.A.; Roy, R.; Torabmostaedi, H. A systematic review of augmented reality applications in maintenance. Robot. Comput. Manuf. 2018, 49, 215–228. [Google Scholar] [CrossRef] [Green Version]

- Zaker, R.; Coloma, E. Virtual reality-integrated workflow in BIM-enabled projects collaboration and design review: A case study. Vis. Eng. 2018, 6, 4. [Google Scholar] [CrossRef] [Green Version]

- Gugenheimer, J.; Stemasov, E.; Frommel, J.; Rukzio, E. ShareVR: Enabling Co-Located Experiences for Virtual Reality between HMD and Non-HMD Users. In Proceedings of the 2017 CHI Conference on Human Factors in Computing Systems, Denver, CO, USA, 2 May 2017; ACM: New York, NY, USA, 2017; pp. 4021–4033. [Google Scholar]

- Harris, J.; Hancock, M. To Asymmetry and Beyond: Improving Social Connectedness by Increasing Designed Interdependence in Cooperative Play. In Proceedings of the 2019 CHI Conference on Human Factors in Computing Systems, Glasgow, UK, 2 May 2019; ACM: New York, NY, USA, 2019; pp. 1–12. [Google Scholar]

- Thoravi Kumaravel, B.; Nguyen, C.; DiVerdi, S.; Hartmann, B. TransceiVR: Bridging Asymmetrical Communication Between VR Users and External Collaborators. In Proceedings of the 33rd Annual ACM Symposium on User Interface Software and Technology, Virtual Event, 20 October 2020; ACM: New York, NY, USA, 2020; pp. 182–195. [Google Scholar]

- Voida, A.; Voida, S.; Greenberg, S.; He, H.A. Asymmetry in Media Spaces. In Proceedings of the ACM 2008 Conference on Computer Supported Cooperative Work—CSCW ’08, San Diego, CA, USA, 8–12 November 2008; ACM Press: New York, NY, USA, 2008; p. 313. [Google Scholar]

- Kim, S.; Billinghurst, M.; Kim, K. Multimodal interfaces and communication cues for remote collaboration. J. Multimodal User Interfaces 2020, 14, 313–319. [Google Scholar] [CrossRef]

- Burova, A.; Heinonen, H.; Palma, P.B.; Keskinen, T.; Hakulinen, J.; Opas, V.; Mäkelä, J.; Ronkainen, K.; Siltanen, S.; Raisamo, R.; et al. Toward Efficient Academia-Industry Collaboration: A Case Study of Joint VR System Development. In Proceedings of the Mindtrek 2021: Academic Mindtrek 2021, Virtual Event, 1–3 June 2021. [Google Scholar]

- Burova, A.; Mäkelä, J.; Heinonen, H.; Palma, P.B.; Hakulinen, J.; Opas, V.; Siltanen, S.; Raisamo, R.; Turunen, M. Asynchronous industrial collaboration: How virtual reality and virtual tools aid the process of maintenance method development and documentation creation. Comput. Ind. 2022, in press. [CrossRef]

- Narasimha, S.; Dixon, E.; Bertrand, J.W.; Madathil, K.C. An empirical study to investigate the efficacy of collaborative immersive virtual reality systems for designing information architecture of software systems. Appl. Ergon. 2019, 80, 175–186. [Google Scholar] [CrossRef]

- Ben Hadj, R.; Trigui, M.; Aifaoui, N. Toward an integrated CAD assembly sequence planning solution. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 229, 2987–3001. [Google Scholar] [CrossRef]

- Kovar, J.; Mouralova, K.; Ksica, F.; Kroupa, J.; Andrs, O.; Hadas, Z. Virtual Reality in Context of Industry 4.0 Proposed Projects at Brno University of Technology. In Proceedings of the 2016 17th International Conference on Mechatronics—Mechatronika (ME), Prague, Czech Republic, 7–9 December 2016; pp. 1–7. [Google Scholar]

- Hoda, R.; Salleh, N.; Grundy, J. The Rise and Evolution of Agile Software Development. IEEE Softw. 2018, 35, 58–63. [Google Scholar] [CrossRef]

- Dallasega, P.; Revolti, A.; Sauer, P.; Schulze, F.; Rauch, E. BIM, Augmented and Virtual Reality empowering Lean Construction Management: A project simulation game. Procedia Manuf. 2020, 45, 49–54. [Google Scholar] [CrossRef]

- Gamlin, A.; Breedon, P.; Medjdoub, B. Immersive Virtual Reality Deployment in a Lean Manufacturing Environment. In Proceedings of the 2014 International Conference on Interactive Technologies and Games, Nottingham, UK, 16–17 October 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 51–58. [Google Scholar]

- Nevo, S.; Chengalur-Smith, I. Enhancing the Performance of Software Development Virtual Teams through the Use of Agile Methods: A Pilot Study. In Proceedings of the 2011 44th Hawaii International Conference on System Sciences, Kauai, HI, USA, 4–7 January 2011; pp. 1–10. [Google Scholar]

- Li, B.; Lou, R.; Posselt, J.; Segonds, F.; Merienne, F.; Kemeny, A. Multi-View VR System for Co-Located Multidisciplinary Collaboration and Its Application in Ergonomic Design. In Proceedings of the 23rd ACM Symposium on Virtual Reality Software and Technology, Gothenburg, Sweden, 8–10 November 2017; ACM: New York, NY, USA, 2017; pp. 1–2. [Google Scholar]

- Schina, L.; Lazoi, M.; Lombardo, R.; Corallo, A. Virtual Reality for Product Development in Manufacturing Industries. In Augmented Reality, Virtual Reality, and Computer Graphics; De Paolis, L.T., Mongelli, A., Eds.; Springer International Publishing: Cham, Switzerland, 2016; Volume 9768, pp. 198–207. ISBN 978-3-319-40620-6. [Google Scholar]

- Tea, S.; Panuwatwanich, K.; Ruthankoon, R.; Kaewmoracharoen, M. Multiuser immersive virtual reality application for real-time remote collaboration to enhance design review process in the social distancing era. J. Eng. Des. Technol. 2021, 20, 281–298. [Google Scholar] [CrossRef]

- Stapelberg, R.F. Handbook of Reliability, Availability, Maintainability and Safety in Engineering Design. Springer: London, UK, 2009. [Google Scholar]

- Du, J.; Shi, Y.; Zou, Z.; Zhao, D. CoVR: Cloud-Based Multiuser Virtual Reality Headset System for Project Communication of Remote Users. J. Constr. Eng. Manag. 2018, 144, 04017109. [Google Scholar] [CrossRef]

- García, A.A.; Bobadilla, I.G.; Figueroa, G.A.; Ramírez, M.P.; Román, J.M. Virtual reality training system for maintenance and operation of high-voltage overhead power lines. Virtual Real. 2016, 20, 27–40. [Google Scholar] [CrossRef]

- Bailey, J.O.; Bailenson, J.N. Virtual Reality and Collaboration; Oxford University Press: Oxford, UK, 2014. [Google Scholar]

- Aromaa, S.; Väänänen, K. Suitability of virtual prototypes to support human factors/ergonomics evaluation during the design. Appl. Ergon. 2016, 56, 11–18. [Google Scholar] [CrossRef] [PubMed]

- Freitas, F.; Winkler, I.; Gomes, M.; Oliveira, H. Virtual Reality on Product Usability Testing: A Systematic Literature Review. In Proceedings of the Anais do Simpósio de Realidade Virtual e Aumentada (SVR), Online, 7 November 2020; pp. 373–379. [Google Scholar]

- Wolfartsberger, J.; Zenisek, J.; Sievi, C.; Silmbroth, M. A Virtual Reality Supported 3D Environment for Engineering Design Review. In Proceedings of the 2017 23rd International Conference on Virtual System & Multimedia (VSMM), Dublin, UK, 31 October–4 November 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–8. [Google Scholar]

- Felip, F.; Galán, J.; García-García, C.; Mulet, E. Influence of presentation means on industrial product evaluations with potential users: A first study by comparing tangible virtual reality and presenting a product in a real setting. Virtual Real. 2019, 24, 439–451. [Google Scholar] [CrossRef]

- Schwarz, S.; Regal, G.; Kempf, M.; Schatz, R. Learning Success in Immersive Virtual Reality Training Environments: Practical Evidence from Automotive Assembly. In Proceedings of the 11th Nordic Conference on Human-Computer Interaction: Shaping Experiences, Shaping Society, Tallinn, Estonia, 25 October 2020; ACM: New York, NY, USA, 2020; pp. 1–11. [Google Scholar]

- Schäfer, A.; Reis, G.; Stricker, D. A Survey on Synchronous Augmented, Virtual and Mixed Reality Remote Collaboration Systems. arXiv 2021, arXiv:210205998 Cs. [Google Scholar]