Research on Output Voltage Stability of Non-Contact Excitation Motor

Abstract

:1. Introduction

2. Mathematical Model of Non-Contact Excitation Motor

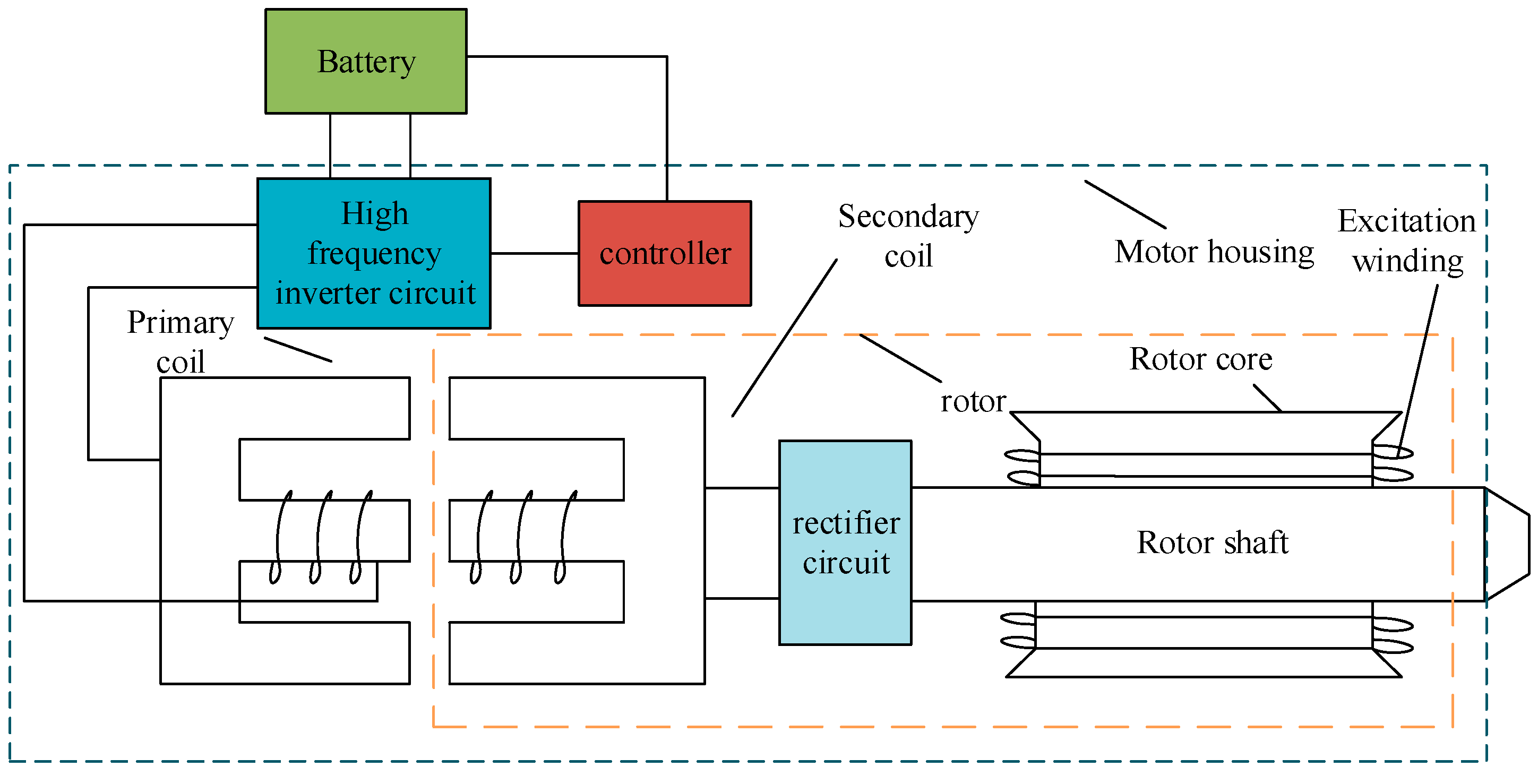

2.1. The Working Principle of Non-Contact Excitation Motor

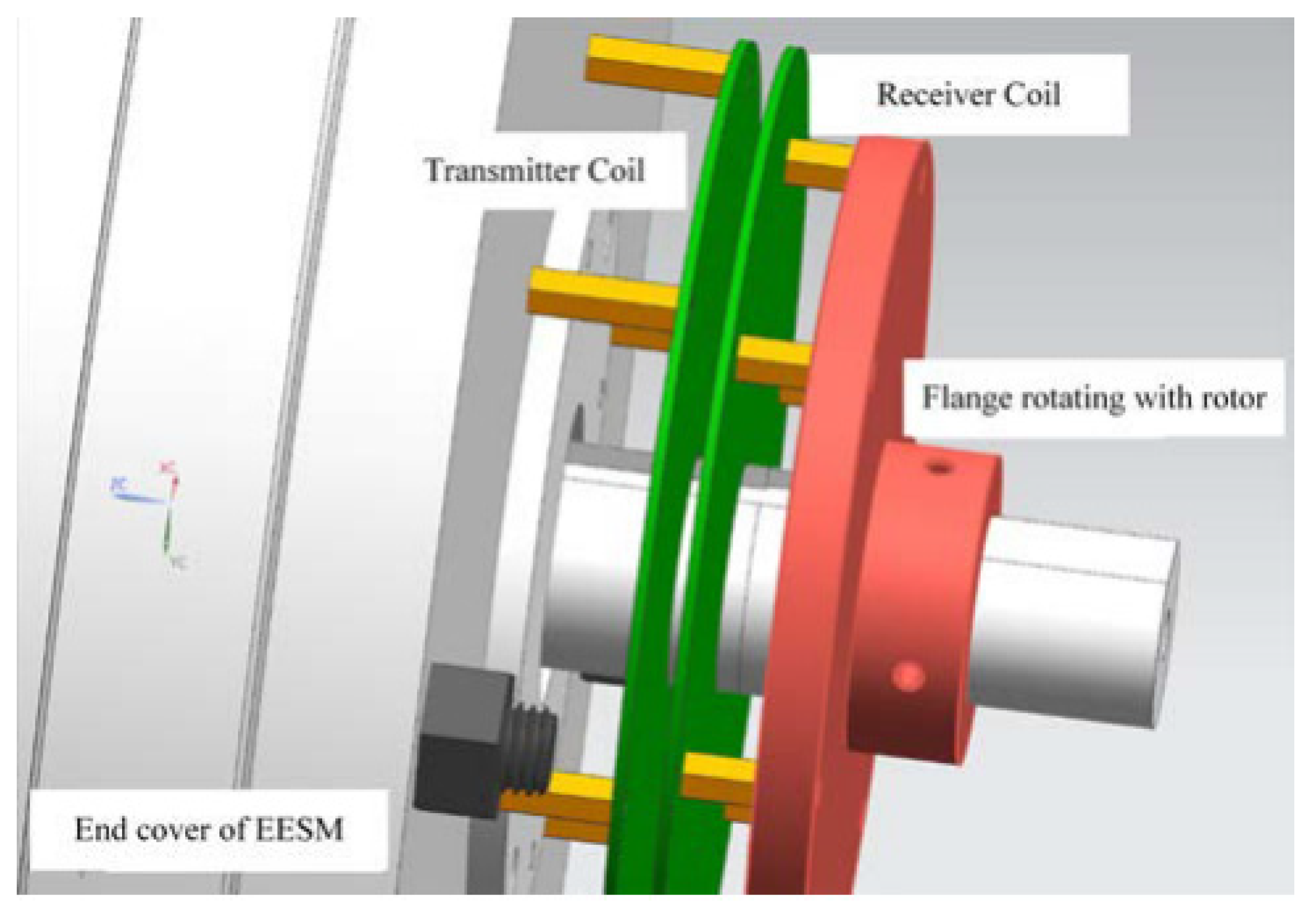

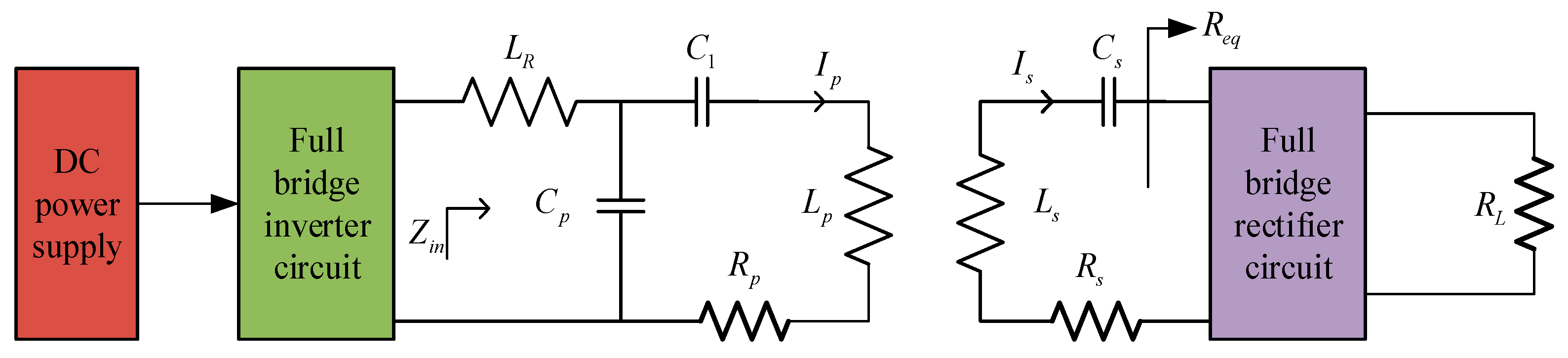

2.2. Analysis of Electromagnetic Coupling Device

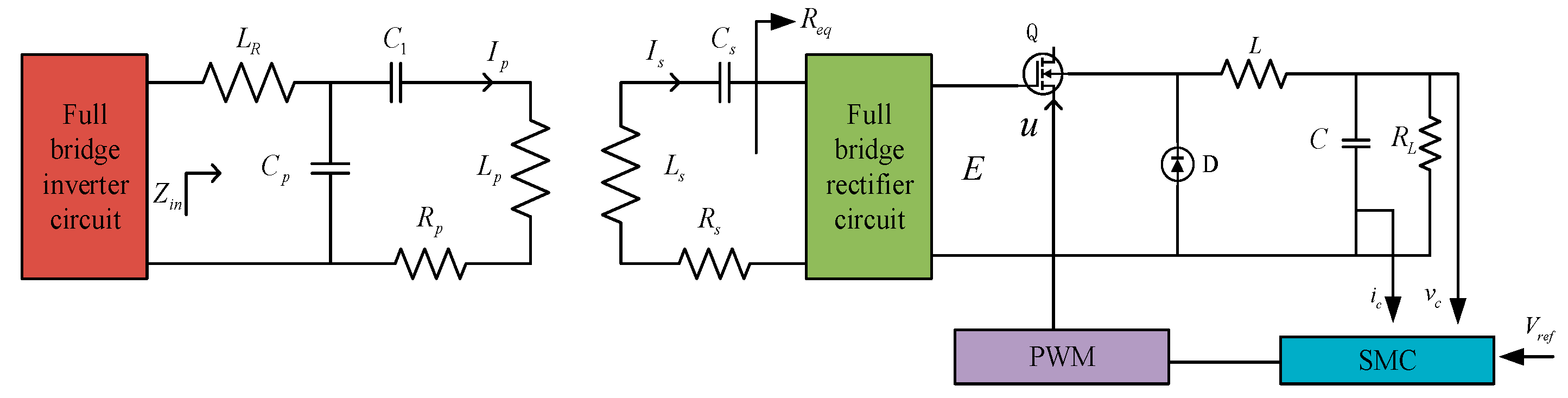

3. System Topology and Principle

4. Comparison of Traditional Sliding Mode Control and Improved Sliding Mode Control

4.1. Traditional Sliding Mode Control

4.2. Improved Sliding Mode Control

5. Simulated Analysis

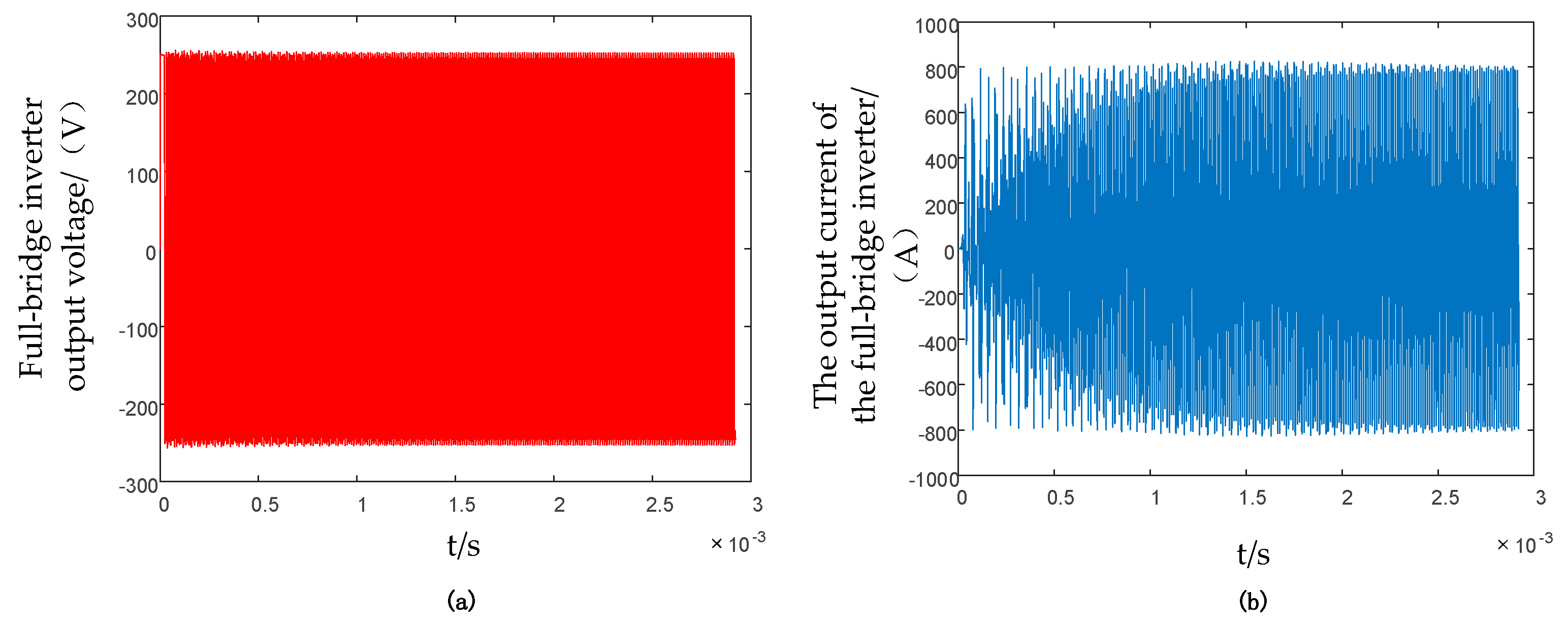

5.1. Voltage and Current Output by the Full-Bridge Inverter Circuit

5.2. Voltage and Current Output from Resonant Circuit

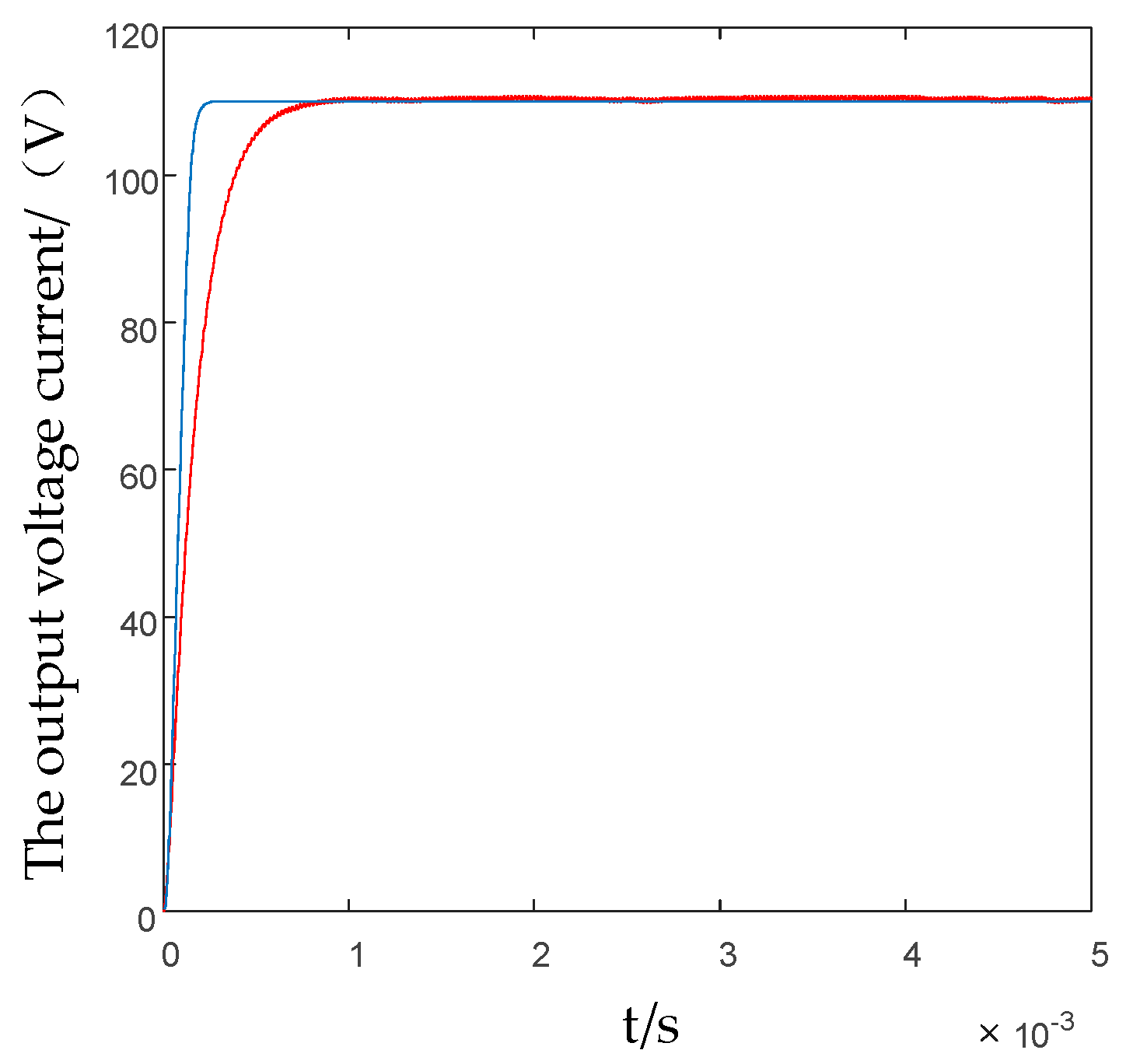

5.3. Output Voltage Stability Comparison for Stable Loads

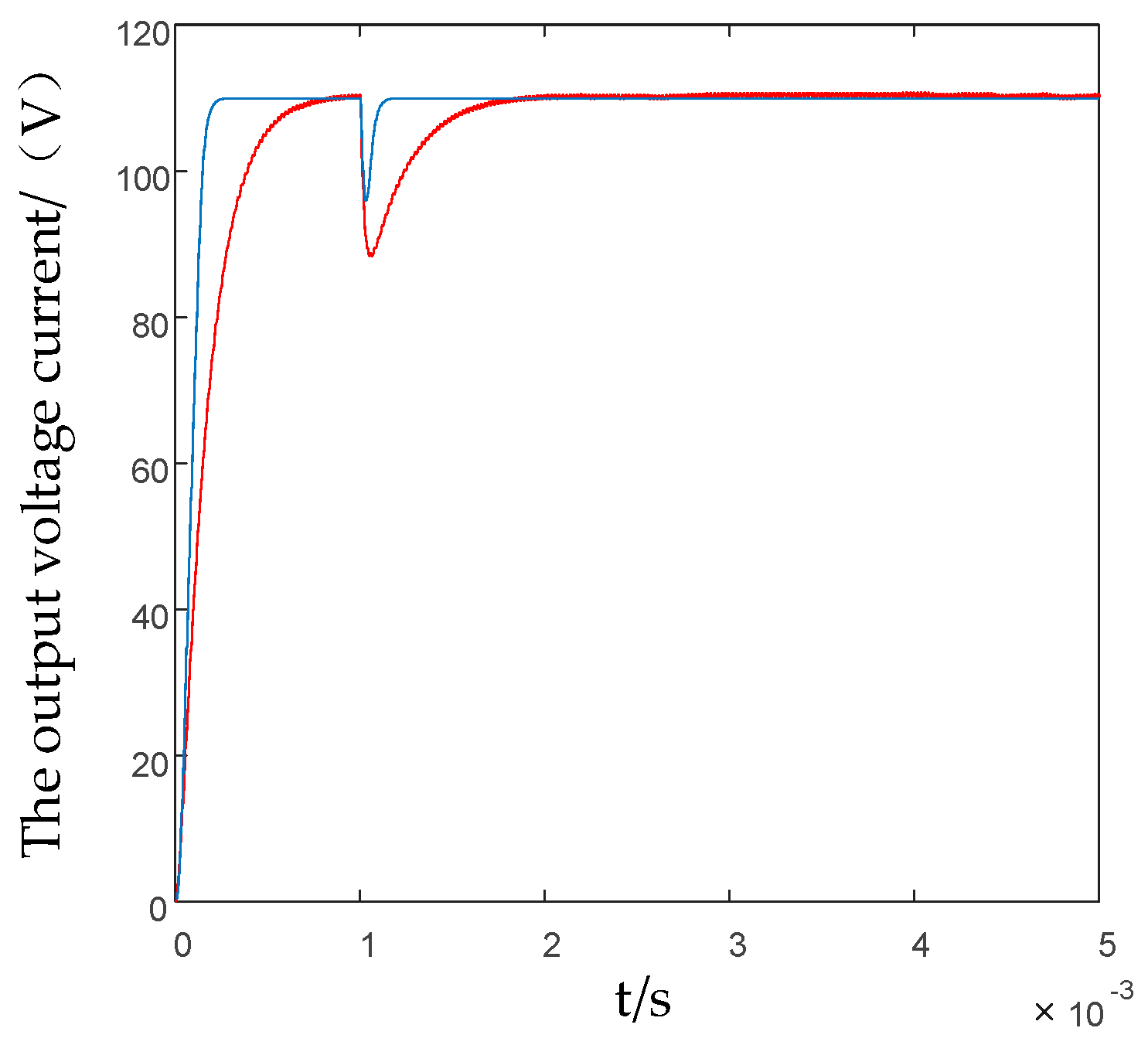

5.4. Output Voltage Stability Comparison of Variable Loads

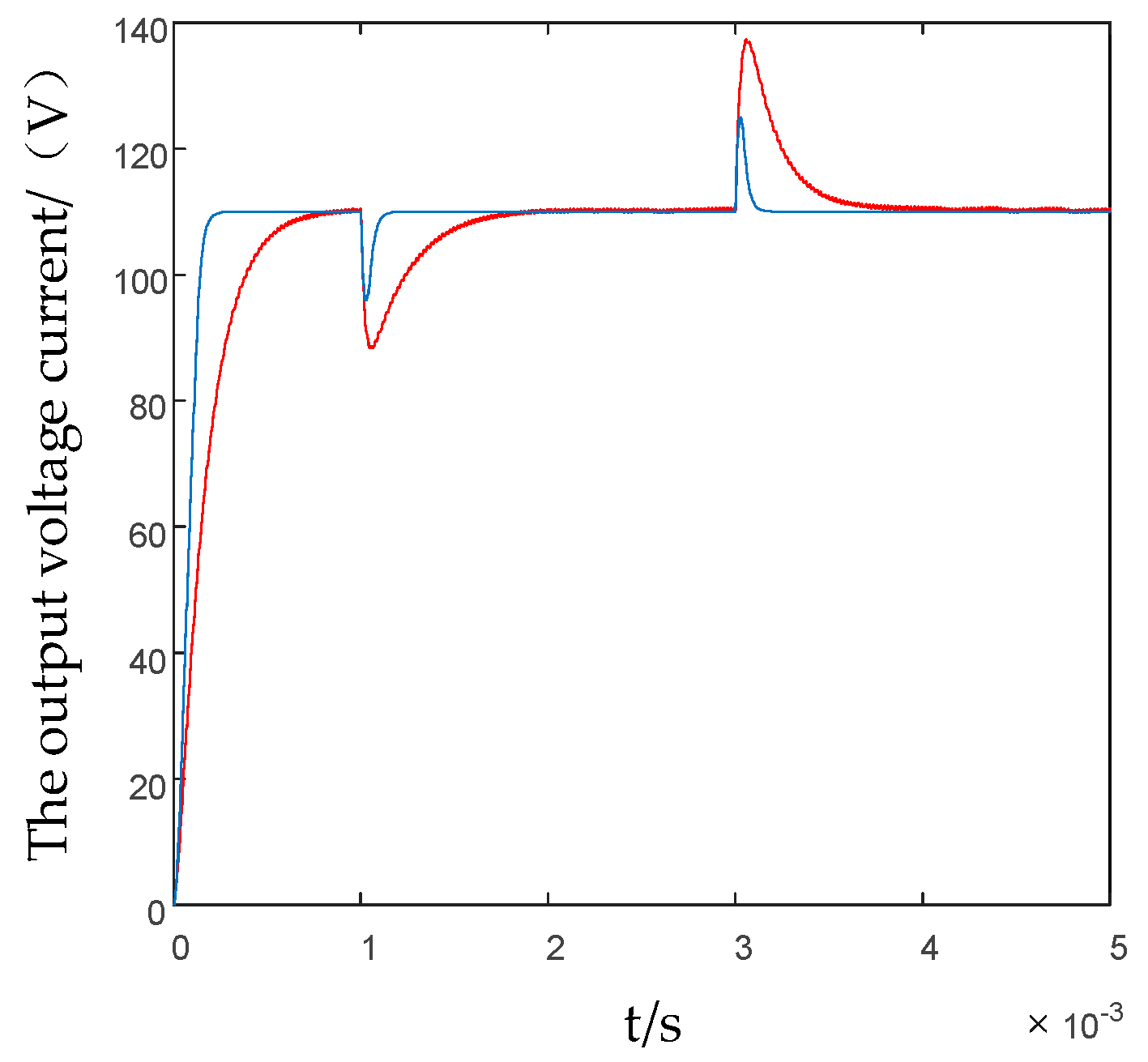

5.5. Comparison of Output Voltage Stability under Variable Load for Two Consecutive Times

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, L.; Xu, H.; Sun, X. A novel strategy of control performance improvement for six-phase permanent magnet synchronous hub motor drives of EVs under new European driving cycle. IEEE Trans. Veh. Technol. 2021, 70, 5628–5637. [Google Scholar] [CrossRef]

- Suhail, M.; Akhtar, I.; Kirmani, S. Development of Progressive Fuzzy Logic and ANFIS Control for Energy Management of Plug-In Hybrid Electric Vehicle. IEEE Access 2021, 9, 62219–62231. [Google Scholar] [CrossRef]

- Mahdavian, A.; Shojaei, A.; Mccormick, S. Drivers and Barriers to Implementation of Connected, Automated, Shared, and Electric Vehicles: An Agenda for Future Research. IEEE Access 2021, 9, 22195–22213. [Google Scholar] [CrossRef]

- Sun, X.; Shi, Z.; Cai, Y.; Lei, G.; Guo, Y.; Zhu, J. Driving-cycle design optimization of a permanent magnet hub motor drive system for a four-wheel-drive electric vehicle. IEEE Trans. Transp. Electrif. 2020, 6, 1115–1125. [Google Scholar] [CrossRef]

- Diao, K.; Sun, X.; Lei, G.; Guo, Y.; Zhu, J. Multiobjective system level-oriented optimization method for switched reluctance motor drive systems using finite element model. IEEE Trans. Ind. Electron. Electron. 2020, 67, 10055–10064. [Google Scholar] [CrossRef]

- Rezaei, A.; Burl, J.B.; Rezaei, M. Catch Energy Saving Opportunity in Charge-Depletion Mode, A Real-Time Controller For Plug-in Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2018, 67, 11234–11237. [Google Scholar] [CrossRef]

- Yilmaz, M.; Krein, P.T. Review of Battery Charger Topologies, Charging Power Levels, and Infrastructure for Plug-In Electric and Hybrid Vehicles. IEEE Trans. Power Electron. 2013, 28, 2151–2169. [Google Scholar] [CrossRef]

- Chen, L.; Xu, H.; Sun, X.; Cai, Y. Three-vector-based model predictive torque control for a permanent magnet synchronous motor of EVs. IEEE Trans. Transp. Electrif. 2021, 7, 1454–1465. [Google Scholar] [CrossRef]

- Karttunen, J.; Kallio, S.; Honkanen, J.; Peltoniemi, P.; Silventoinen, P. Partial Current Harmonic Compensation in Dual Three-Phase PMSMs Considering the Limited Available Voltage. IEEE Trans. Ind. Electron. 2017, 64, 1038–1048. [Google Scholar] [CrossRef]

- Sun, X.; Chen, L.; Jiang, H.; Yang, Z.; Chen, J.; Zhang, W. High-performance control for a bearingless permanent magnet synchronous motor using neural network inverse scheme plus internal model controllers. IEEE Trans. Ind. Electron. 2016, 63, 3479–3488. [Google Scholar] [CrossRef]

- Jin, Z.; Sun, X.; Lei, G.; Guo, Y.; Zhu, J. Sliding mode direct torque control of SPMSMs based on a hybrid wolf optimization algorithm. IEEE Trans. Ind. Electron. 2022, 69, 4534–4544. [Google Scholar] [CrossRef]

- Kou, J.; Gao, Q.; Sha, Z.; Teng, Y.; Xu, D. A rotor position detection method at high speed for electrically excited synchronous motor. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–5. [Google Scholar]

- Sulaiman, E.; Kosaka, T.; Matsui, N. High Power Density Design of 6-Slot–8-Pole Hybrid Excitation Flux Switching Machine for Hybrid Electric Vehicles. IEEE Trans. Magn. 2011, 47, 4453–4456. [Google Scholar] [CrossRef]

- Han, Y.; Wu, X.; He, G.; Hu, Y.; Ni, K. Nonlinear Magnetic Field Vector Control with Dynamic-Variant Parameters for High-Power Electrically Excited Synchronous Motor. IEEE Trans. Power Electron. 2020, 35, 11053–11063. [Google Scholar] [CrossRef]

- Alarifi, I.M.; Asmatulu, R. Structural analysis and wear behavior of different graphite-based brushes for aircraft starter generator application. Adv. Compos. Hybrid Mater. 2021, 4, 162–172. [Google Scholar]

- Nozawa, R.; Kobayashi, R.; Tanifuji, H. Excitation system by contactless power transfer system with the primary series capacitor method. In Proceedings of the Power Electronics Conference, Hiroshima, Japan, 16–20 March 2014; Volume 21, pp. 1115–1121. [Google Scholar]

- Duong, T.P.; Lee, J.W. Experimental Results of High-Efficiency Resonant Coupling Wireless Power Transfer Using a Variable Coupling Method. IEEE Microw. Wirel. Compon. Lett. 2011, 21, 442–444. [Google Scholar] [CrossRef]

- Raminosoa, T.; Wiles, R.H.; Wilkins, J. Novel Rotary Transformer Topology with Improved Power Transfer Capability for High-Speed Applications. IEEE Trans. Ind. Appl. 2020, 56, 277–286. [Google Scholar] [CrossRef]

- Ardila, V.; Ramírez, F.; Suárez, A. Nonlinear Analysis of a High-Power Oscillator Inductively Coupled to an External Resonator. IEEE Microw. Wirel. Compon. Lett. 2021, 31, 737–740. [Google Scholar] [CrossRef]

- Sun, X.; Diao, K.; Lei, G.; Guo, Y.; Zhu, J. Real-time HIL emulation for a segmented-rotor switched reluctance motor using a new magnetic equivalent circuit. IEEE Trans. Power Electron. 2020, 35, 3841–3849. [Google Scholar] [CrossRef]

- Fu, M.; Tang, Z.; Ma, C. Analysis and Optimized Design of Compensation Capacitors for A Megahertz WPT System Using Full-Bridge Rectifier. IEEE Trans Ind. Inf. 2018, 15, 95–104. [Google Scholar] [CrossRef]

- Janson, K.; Jarvik, J. AC-DC converter with parametric reactive power compensation. IEEE Trans. Ind. Electron. 1999, 46, 554–562. [Google Scholar] [CrossRef]

- Yi, J.; Wei, H. Steady-state voltage reactive compensation method for half-wavelength transmission lines considering equivalent power supply impedance. CSEE J. Power Energy Syst. 2020, 6, 841–847. [Google Scholar]

- Wu, J.; Sun, P.W.X. Reactive Power Optimization Control for Bidirectional Dual-Tank Resonant DC-DC Converters for Fuel Cells Systems. IEEE Trans. Power Electron. 2020, 35, 9202–9214. [Google Scholar] [CrossRef]

- Chen, L.; Wang, H.; Sun, X.; Cai, Y.; Li, K.; Diao, K.; Wu, J. Development of digital control system for a belt-driven starter generator SSRM for HEVs. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2020, 234, 975–984. [Google Scholar]

- Zheng, C.; Dragičević, T.; Zhang, J.; Chen, R.; Blaabjerg, F. Composite Robust Quasi-Sliding Mode Control of DC-DC Buck Converter with Constant Power Loads. IEEE Trans. Emerg. Sel. Top. Power Electron. 2020, 9, 1455–1464. [Google Scholar] [CrossRef]

- Wu, H.; Mu, T.; Ge, H.; Xing, Y. Full-Range Soft-Switching-Isolated Buck-Boost Converters with Integrated Interleaved Boost Converter and Phase-Shifted Control. IEEE Trans. Power Electron. 2015, 31, 987–999. [Google Scholar] [CrossRef]

- Naik, B.S.; Suresh, Y.; Venkataramanaiah, J. A Hybrid Nine-Level Inverter Topology with Boosting Capability and Reduced Component Count. IEEE Trans. 2020, 68, 316–320. [Google Scholar] [CrossRef]

- Rana, N.; Banerjee, S.; Giri, S.K. Modeling, Analysis and Implementation of an Improved Interleaved Buck-Boost Converter. IEEE Trans. Circuits Syst. II: Express Briefs 2021, 68, 2588–2592. [Google Scholar] [CrossRef]

- Al-Baidhani, H.; Salvatierra, T.; Ordonez, R. Simplified Nonlinear Voltage-Mode Control of PWM DC-DC Buck Converter. IEEE Trans. Energy Convers. 2020, 36, 431–440. [Google Scholar] [CrossRef]

- Kolluri, S.; Narasamma, N.L. A New Isolated Auxiliary Current Pump Module for Load Transient Mitigation of Isolated/No isolated Step-Up/Step-Down DC-DC Converter. IEEE Trans. Power Electron. 2015, 30, 5991–6000. [Google Scholar] [CrossRef]

- Hou, N.; Song, W.; Zhu, Y. Dynamic and static performance optimization of dual active bridge DC-DC converters. J. Mod. Power Syst. Clean Energy 2018, 6, 607–618. [Google Scholar] [CrossRef] [Green Version]

- Fu, Z.; Wang, Y.; Tao, F.; Si, P. An Adaptive Nonsingular Terminal Sliding Mode Control for Bidirectional DC-DC Converter in Hybrid Energy Storage Systems. Can. J. Electr. Comput. Eng. 2020, 43, 282–289. [Google Scholar] [CrossRef]

- Xu, J.; Sun, Y.; Xu, G. Current Fed LC Series Resonant Converter with Load Independent Voltage Gain Characteristics for Wide Voltage Range Applications. IEEE Trans. Power Electron. 2021, 36, 11509–11522. [Google Scholar] [CrossRef]

- Xu, Y.; Lu, C.; Yu, Z.; Chen, J.; Xu, S.; Wang, Y.; He, X. Multi-mode Constant Power Control Strategy for LCC Resonant Capacitor Charging Power Supply Based on State Plane Analysis. IEEE Trans. Power Electron. 2020, 36, 8399–8412. [Google Scholar] [CrossRef]

- Sun, X.; Cao, J.; Lei, G.; Guo, Y.; Zhu, J. A robust deadbeat predictive controller with delay compensation based on composite sliding mode observer for PMSMs. IEEE Trans. Power Electron. 2021, 36, 10742–10752. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, H.; Lu, F. Capacitive Power Transfer with Series-Parallel Compensation for Step-Up Voltage Output. IEEE Trans. Ind. Electron. 2021, 69, 5604–5614. [Google Scholar] [CrossRef]

- Sun, X.; Wu, J.; Lei, G.; Guo, Y.; Zhu, J. Torque ripple reduction of SRM drive using improved direct torque control with sliding mode controller and observer. IEEE Trans. Ind. Electron. 2021, 68, 9334–9345. [Google Scholar] [CrossRef]

- Sun, X.; Feng, L.; Diao, K.; Yang, Z. An improved direct instantaneous torque control based on adaptive terminal sliding mode for a segmented-rotor SRM. IEEE Trans. Ind. Electron. 2021, 68, 10569–10579. [Google Scholar] [CrossRef]

- Sun, X.; Cao, J.; Lei, G.; Guo, Y.; Zhu, J. A composite sliding mode control for SPMSM drives based on a new hybrid reaching law with disturbance compensation. IEEE Trans. Transp. Electrif. 2021, 7, 1427–1436. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, J.; Qin, F. A Capacitor Current and Capacitor Voltage Ripple Controlled SIDO CCM Buck Converter with Wide Load Range and Reduced Cross Regulation. IEEE Trans. Ind. Electron. 2021, 69, 270–281. [Google Scholar] [CrossRef]

- Song, P.; Cui, C.; Bai, Y. Robust Output Voltage Regulation for DC-DC Buck Converters under Load Variations via Sampled-Data Sensorless Control. IEEE Access 2018, 66, 10688–10698. [Google Scholar] [CrossRef]

- Kang, J.; Liu, Y.; Sun, L. A Primary-Side Control Method of Wireless Power Transfer for Motor Electric Excitation. In Proceedings of the 2019 14th IEEE Conference on Industrial Electronics and Applications (ICIEA), Xi’an, China, 19–21 June 2019; Volume 32, pp. 2423–2428. [Google Scholar]

| Specification | Value | Specificatin | Value |

|---|---|---|---|

| LR (μH) | 20 | CS (nF) | 36 |

| CP (nF) | 175 | RS (Ω) | 0.075 |

| C1 (nF) | 45 | E (V) | 200 |

| LP (μH) | 0.076 | L (μH) | 544 |

| RP (Ω) | 0.075 | C (nF) | 8 |

| LS (μH) | 0.075 | RL (Ω) | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, K.; Meng, X.; Sun, X. Research on Output Voltage Stability of Non-Contact Excitation Motor. Appl. Sci. 2022, 12, 3666. https://doi.org/10.3390/app12073666

Li K, Meng X, Sun X. Research on Output Voltage Stability of Non-Contact Excitation Motor. Applied Sciences. 2022; 12(7):3666. https://doi.org/10.3390/app12073666

Chicago/Turabian StyleLi, Ke, Xuan Meng, and Xiaodong Sun. 2022. "Research on Output Voltage Stability of Non-Contact Excitation Motor" Applied Sciences 12, no. 7: 3666. https://doi.org/10.3390/app12073666

APA StyleLi, K., Meng, X., & Sun, X. (2022). Research on Output Voltage Stability of Non-Contact Excitation Motor. Applied Sciences, 12(7), 3666. https://doi.org/10.3390/app12073666