Bone: An Outstanding Composite Material

Abstract

1. Introduction

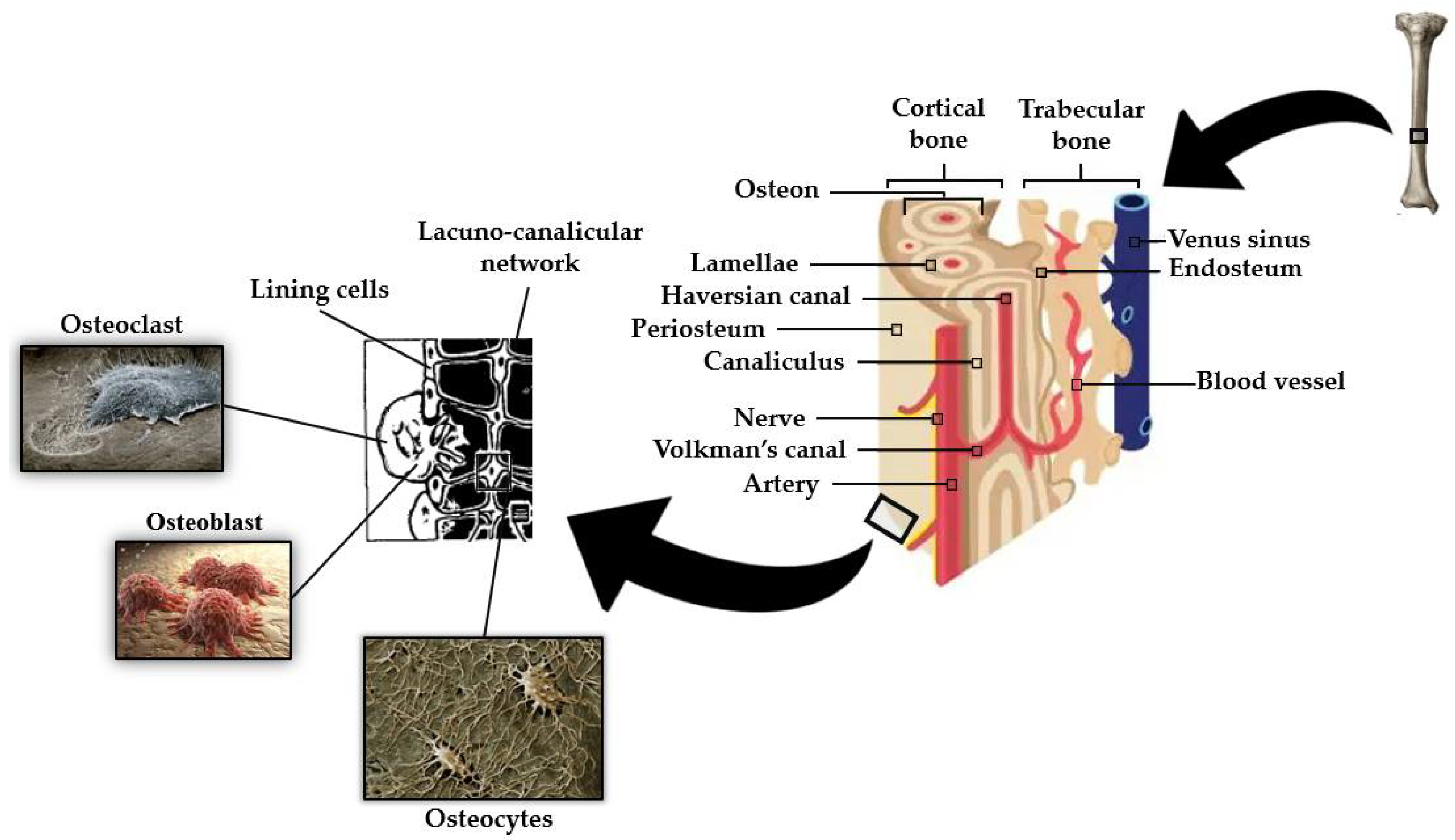

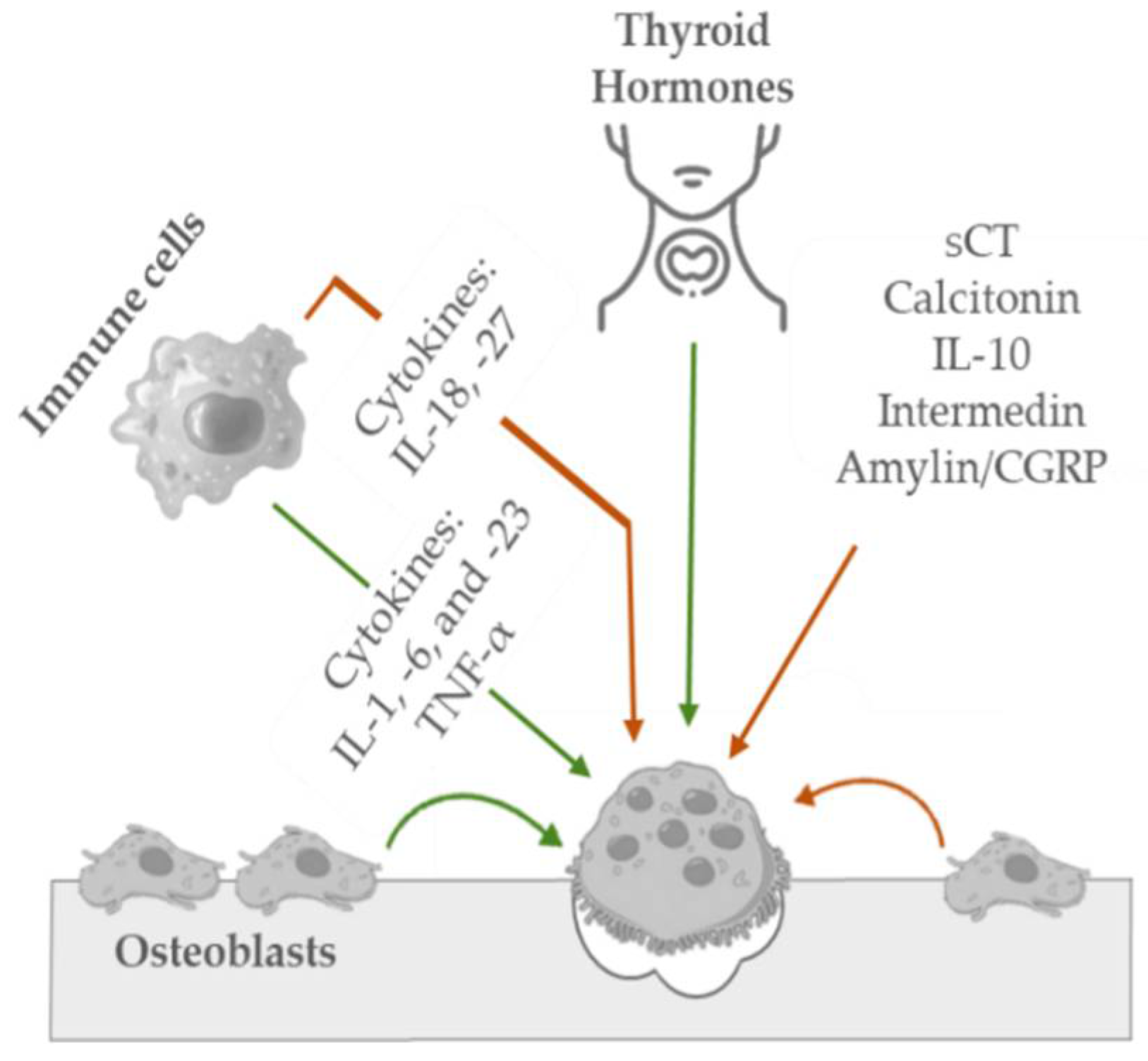

2. Nanostructure

3. Microstructure

4. Macrostructure

5. Mechanical Behavior

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adams, M.A. Functional anatomy of the musculoskeletal system. In Gray’s Anatomy: The Anatomical Basis of Clinical Practice, 41st ed.; Standring, S., Ed.; Elsevier Health Sciences: London, UK, 2015; Volume 1, pp. 81–122. [Google Scholar]

- Bonucci, E. Basic composition and structure of bone. In Mechanical Testing of Bone and the Bone-Implant Interface, 1st ed.; An, Y.H., Draughn, R.A., Eds.; CRC Press: Boca Raton, FL, USA, 2000; pp. 3–22. [Google Scholar]

- Péoc’h, M. Normal histological architecture of tissue. In Biomechanics and Biomaterials in Orthopedics; Springer: London, UK, 2004; pp. 189–191. [Google Scholar]

- Keller, T.S.; Liebschner, M.A. Tensile and Compression Testing of Bone. In Mechanical Testing of Bone and the Bone-Implant Interface, 1st ed.; An, Y.H., Draughn, R.A., Eds.; CRC Press: London, UK, 2000; pp. 175–206. [Google Scholar]

- Rosa, N.; Simoes, R.; Magalhães, F.D.; Marques, A.T. From mechanical stimulus to bone formation: A review. Med. Eng. Phys. 2015, 37, 719–728. [Google Scholar] [CrossRef] [PubMed]

- Koons, G.L.; Diba, M.; Mikos, A.G. Materials design for bone-tissue engineering. Nat. Rev. Mater. 2020, 5, 584–603. [Google Scholar] [CrossRef]

- Bouchbinder, E.; Brener, E.A. Viscoelastic fracture of biological composites. J. Mech. Phys. Solids 2011, 59, 2279–2293. [Google Scholar] [CrossRef]

- Libonati, F.; Vergani, L. Understanding the structure–property relationship in cortical bone to design a biomimetic composite. Compos. Struct. 2016, 139, 188–198. [Google Scholar] [CrossRef]

- Ahn, T.; Gidley, D.W.; Thornton, A.W.; Wong-Foy, A.G.; Orr, B.G.; Kozloff, K.M.; Banaszak Holl, M.M. Hierarchical Nature of Nanoscale Porosity in Bone Revealed by Positron Annihilation Lifetime Spectroscopy. ACS nano 2021, 15, 4321–4334. [Google Scholar] [CrossRef]

- Pai, S.; Kwon, J.; Liang, B.; Cho, H.; Soghrati, S. Finite element analysis of the impact of bone nanostructure on its piezoelectric response. Biomech. Model. Mechanobiol. 2021, 20, 1689–1708. [Google Scholar] [CrossRef]

- Shekaran, A.; García, A.J. Extracellular matrix-mimetic adhesive biomaterials for bone repair. J. Biomed. Mater. Res. A 2011, 96, 261–272. [Google Scholar] [CrossRef]

- Törnquist, E.; Gentile, L.; Prévost, S.; Diaz, A.; Olsson, U.; Isaksson, H. Comparison of small-angle neutron and X-ray scattering for studying cortical bone nanostructure. Sci. Rep. 2020, 10, 14552. [Google Scholar] [CrossRef]

- Leo, L.; Bridelli, M.G.; Polverini, E. Reversible processes in collagen dehydration: A molecular dynamics study. Arch. Biochem Biophys 2021, 714, 109079. [Google Scholar] [CrossRef]

- Gordon, M.K.; Hahn, R.A. Collagens. Cell Tissue Res. 2010, 339, 247–257. [Google Scholar] [CrossRef]

- Hillgärtner, M.; Linka, K.; Itskov, M. Worm-like chain model extensions for highly stretched tropocollagen molecules. J. Biomech. 2018, 80, 129–135. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Luo, D.; Wang, T. Hierarchical structures of bone and bioinspired bone tissue engineering. Small 2016, 12, 4611–4632. [Google Scholar] [CrossRef] [PubMed]

- Friedrich, J. Analyzing Interactions between Cells and Extracellular Matrix by Atomic Force Microscopy. Ph.D. Thesis, Technischen Universität Dresden, Dresden, Germany, 2009. [Google Scholar]

- Gültekin, O. Computational Inelasticity of Fibrous Biological Tissues with a Focus on Viscoelasticity, Damage and Rupture; Verlag der Technischen Universität Graz: Graz, Austria, 2019. [Google Scholar]

- Van Gulick, L.; Saby, C.; Morjani, H.; Beljebbar, A. Age-related changes in molecular organization of type I collagen in tendon as probed by polarized SHG and Raman microspectroscopy. Sci. Rep. 2019, 9, 7280. [Google Scholar] [CrossRef] [PubMed]

- Fonseca, J.E. Bone: A story of breakthroughs, a promising future. Medicographia 2012, 34, 142–148. [Google Scholar]

- Keaveny, T.M.; Morgan, E.F.; Yeh, O.C. Bone mechanics. In Standard Handbook of Biomedical Engineering & Design, 1st ed.; Kutz, M., Ed.; McGraw-Hill: New York, NY, USA, 2003; pp. 200–222. [Google Scholar]

- Morgan, E.F.; Barnes, G.L.; Einhorn, T.A. The bone organ system: Form and function. Osteoporosis 2008, 1, 3–25. [Google Scholar] [CrossRef]

- Reznikov, N.; Bilton, M.; Lari, L.; Stevens, M.M.; Kröger, R. Fractal-like hierarchical organization of bone begins at the nanoscale. Science 2018, 360, eaao2189. [Google Scholar] [CrossRef]

- Wang, Y.; Ural, A. A finite element study evaluating the influence of mineralization distribution and content on the tensile mechanical response of mineralized collagen fibril networks. J. Mech. Behav. Biomed. Mater. 2019, 100, 103361. [Google Scholar] [CrossRef]

- Fratzl, P.; Gupta, H.S.; Paschalis, E.P.; Roschger, P. Structure and mechanical quality of the collagen–mineral nano-composite in bone. J. Mater. Chem. 2004, 14, 2115–2123. [Google Scholar] [CrossRef]

- Chen, P.-Y.; Toroian, D.; Price, P.A.; McKittrick, J. Minerals form a continuum phase in mature cancellous bone. Calcif. Tissue Int. 2011, 88, 351–361. [Google Scholar] [CrossRef]

- Zamiri, A.; De, S. Mechanical properties of hydroxyapatite single crystals from nanoindentation data. J. Mech. Behav. Biomed. Mater. 2011, 4, 146–152. [Google Scholar] [CrossRef]

- White, T.D.; Black, M.T.; Folkens, P.A. Human Osteology, 3rd ed.; Academic Press: Oxford, UK, 2012. [Google Scholar]

- Pang, S.; Schwarcz, H.P.; Jasiuk, I. Interfacial bonding between mineral platelets in bone and its effect on mechanical properties of bone. J. Mech. Behav. Biomed. Mater. 2021, 113, 104132. [Google Scholar] [CrossRef] [PubMed]

- Barkaoui, A.; Hambli, R.; Tavares, J.M.R. Effect of material and structural factors on fracture behaviour of mineralised collagen microfibril using finite element simulation. Comput. Methods Biomech. Biomed. Eng. 2015, 18, 1181–1190. [Google Scholar] [CrossRef] [PubMed]

- Trackman, P.C. Enzymatic and non-enzymatic functions of the lysyl oxidase family in bone. Matrix Biol. 2016, 52, 7–18. [Google Scholar] [CrossRef] [PubMed]

- Garnero, P. The contribution of collagen crosslinks to bone strength. BoneKEy Rep. 2012, 1, 182. [Google Scholar] [CrossRef]

- McNerny, E.M.; Gong, B.; Morris, M.D.; Kohn, D.H. Bone fracture toughness and strength correlate with collagen cross-link maturity in a dose-controlled lathyrism mouse model. J. Bone Miner. Res. 2015, 30, 455–464. [Google Scholar] [CrossRef]

- Depalle, B.; Qin, Z.; Shefelbine, S.J.; Buehler, M.J. Influence of cross-link structure, density and mechanical properties in the mesoscale deformation mechanisms of collagen fibrils. J. Mech. Behav. Biomed. Mater. 2015, 52, 1–13. [Google Scholar] [CrossRef]

- Banse, X.; Sims, T.; Bailey, A. Mechanical properties of adult vertebral cancellous bone: Correlation with collagen intermolecular cross-links. J. Bone Miner. Res. 2002, 17, 1621–1628. [Google Scholar] [CrossRef]

- Siegmund, T.; Allen, M.R.; Burr, D.B. Failure of mineralized collagen fibrils: Modeling the role of collagen cross-linking. J. Biomech. 2008, 41, 1427–1435. [Google Scholar] [CrossRef]

- Siegmund, T.; Allen, M.; Burr, D. A ductile-to-brittle transition in bone failure due to non-enzymatic collagen-crosslinks-A computational study. Trans. Orthop. Res. Soc. 2007, 32, 35. [Google Scholar]

- Vashishth, D.; Wu, P.; Gibson, G. Age-related loss in bone toughness is explained by non-enzymatic glycation of collagen. Trans. Orthop. Res. Soc. 2004, 29, 497. [Google Scholar]

- Allen, M.R.; Gineyts, E.; Leeming, D.J.; Burr, D.B.; Delmas, P.D. Bisphosphonates alter trabecular bone collagen cross-linking and isomerization in beagle dog vertebra. Osteoporos. Int. 2008, 19, 329–337. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Ahn, A.C.; Grodzinsky, A.J. Relevance of collagen piezoelectricity to “Wolff’s Law”: A critical review. Med. Eng. Phys. 2009, 31, 733–741. [Google Scholar] [CrossRef] [PubMed]

- Jilka, R.L.; Noble, B.; Weinstein, R.S. Osteocyte apoptosis. Bone 2013, 54, 264–271. [Google Scholar] [CrossRef] [PubMed]

- Maghsoudi-Ganjeh, M.; Wang, X.; Zeng, X. Computational investigation of the effect of water on the nanomechanical behavior of bone. J. Mech. Behav. Biomed. Mater. 2020, 101, 103454. [Google Scholar] [CrossRef] [PubMed]

- Masic, A.; Bertinetti, L.; Schuetz, R.; Chang, S.-W.; Metzger, T.H.; Buehler, M.J.; Fratzl, P. Osmotic pressure induced tensile forces in tendon collagen. Nat. Commun. 2015, 6, 5942. [Google Scholar] [CrossRef]

- Keaveney, T.M. Cancellous bone. In Handbook of Biomaterial Properties; Black, J., Hastings, G., Eds.; Springer Science & Business Media: Dordrecht, The Netherlands, 2013; pp. 15–23. [Google Scholar]

- Yoa, H. Mechanical Testing of Bone and Bone-Like Materials Using Image Correlation Strain Measurement Technique; Xi’an Jiaotong University: Xi’an, China, 2007. [Google Scholar]

- Weld-Moore, R. The Use of Quantitative Ultrasound to Investigate Bone Strength in the Facial Skeleton; Trinity College: Dublin, Ireland, 2018. [Google Scholar]

- Schwiedrzik, J.; Raghavan, R.; Bürki, A.; LeNader, V.; Wolfram, U.; Michler, J.; Zysset, P. In situ micropillar compression reveals superior strength and ductility but an absence of damage in lamellar bone. Nat. Mater. 2014, 13, 740–747. [Google Scholar] [CrossRef]

- Doblaré, M.; García, J.M.; Gómez, M.J. Modelling bone tissue fracture and healing: A review. Eng. Fract. Mech. 2004, 71, 1809–1840. [Google Scholar] [CrossRef]

- Arnett, T. Osteocytes—Human Bone; Bone Research Society: Peterborough, UK, 2015. [Google Scholar]

- Arnett, T.; Manzano, J. Osteoclast Resorption; Bone Research Society: Peterborough, UK, 2015. [Google Scholar]

- Mackenzie, K. Osteocytes; Bone Research Society: Peterborough, UK, 2015. [Google Scholar]

- International Osteoporosis Foundation. Available online: https://www.osteoporosis.foundation/health-professionals/about-osteoporosis/bone-biology (accessed on 16 March 2022).

- Kohli, N.; Ho, S.; Brown, S.J.; Sawadkar, P.; Sharma, V.; Snow, M.; García-Gareta, E. Bone remodelling in vitro: Where are we headed?—A review on the current understanding of physiological bone remodelling and inflammation and the strategies for testing biomaterials in vitro. Bone 2018, 110, 38–46. [Google Scholar] [CrossRef]

- Moharrer, Y.; Boerckel, J.D. Tunnels in the rock: Dynamics of osteocyte morphogenesis. Bone 2021, 153, 116104. [Google Scholar] [CrossRef]

- Kola, S.K.; Begonia, M.T.; Tiede-Lewis, L.M.; Laughrey, L.E.; Dallas, S.L.; Johnson, M.L.; Ganesh, T. Osteocyte lacunar strain determination using multiscale finite element analysis. Bone Rep. 2020, 12, 100277. [Google Scholar] [CrossRef]

- Ramani-Mohan, R.-K.; Schwedhelm, I.; Finne-Wistrand, A.; Krug, M.; Schwarz, T.; Jakob, F.; Walles, H.; Hansmann, J. Deformation strain is the main physical driver for skeletal precursors to undergo osteogenesis in earlier stages of osteogenic cell maturation. J. Tissue Eng Regen Med. 2018, 12, e1474–e1479. [Google Scholar] [CrossRef] [PubMed]

- Kameo, Y.; Ozasa, M.; Adachi, T. Computational framework for analyzing flow-induced strain on osteocyte as modulated by microenvironment. J. Mech. Behav. Biomed. Mater. 2022, 126, 105027. [Google Scholar] [CrossRef] [PubMed]

- Mak, A.; Zhang, J. Numerical simulation of streaming potentials due to deformation-induced hierarchical flows in cortical bone. J. Biomech. Eng. 2001, 123, 66–70. [Google Scholar] [CrossRef] [PubMed]

- Scheiner, S.; Pivonka, P.; Hellmich, C. Poromicromechanics reveals that physiological bone strains induce osteocyte-stimulating lacunar pressure. Biomech. Model. Mechanobiol. 2016, 15, 9–28. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Garrigle, M.J.M.; Vaughan, T.J.; McNamara, L.M. In silico study of bone tissue regeneration in an idealised porous hydrogel scaffold using a mechano-regulation algorithm. Biomech. Model. Mechanobiol. 2018, 17, 5–18. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.; Sellman, D.P.; Bahraini, A.; Hagan, M.L.; Elsherbini, A.; Vanpelt, K.T.; Marshall, P.L.; Hamrick, M.W.; McNeil, A.; McNeil, P.L.; et al. Mechanical Loading Disrupts Osteocyte Plasma Membranes Which Initiates Mechanosensation Events in Bone. J. Orthop. Res. 2018, 36, 653–662. [Google Scholar] [CrossRef]

- Burra, S.; Nicolella, D.P.; Francis, W.L.; Freitas, C.J.; Mueschke, N.J.; Poole, K.; Jiang, J.X. Dendritic processes of osteocytes are mechanotransducers that induce the opening of hemichannels. Proc. Natl. Acad. Sci. USA 2010, 107, 13648–13653. [Google Scholar] [CrossRef]

- Spasic, M.; Jacobs, C.R. Lengthening primary cilia enhances cellular mechanosensitivity. Eur. Cells Mater. 2017, 33, 158–168. [Google Scholar] [CrossRef]

- Hemmatian, H.; Bakker, A.D.; Klein-Nulend, J.; van Lenthe, G.H. Alterations in osteocyte lacunar morphology affect local bone tissue strains. J. Mech. Behav. Biomed. Mater. 2021, 123, 104730. [Google Scholar] [CrossRef]

- Hamed, E.; Jasiuk, I. Multiscale damage and strength of lamellar bone modeled by cohesive finite elements. J. Mech. Behav. Biomed. Mater. 2013, 28, 94–110. [Google Scholar] [CrossRef]

- Kaya, S.; Basta-Pljakic, J.; Seref-Ferlengez, Z.; Majeska, R.J.; Cardoso, L.; Bromage, T.G.; Zhang, Q.; Flach, C.R.; Mendelsohn, R.; Yakar, S. Lactation-induced changes in the volume of osteocyte lacunar-canalicular space alter mechanical properties in cortical bone tissue. J. Bone Miner. Res. 2017, 32, 688–697. [Google Scholar] [CrossRef] [PubMed]

- Sang, W.; Li, Y.; Guignon, J.; Liu, X.S.; Ural, A. Structural role of osteocyte lacunae on mechanical properties of bone matrix: A cohesive finite element study. J. Mech. Behav. Biomed. Mater. 2022, 125, 104943. [Google Scholar] [CrossRef] [PubMed]

- Burr, D.B. Stress concentrations and bone microdamage: John Currey’s contributions to understanding the initiation and arrest of cracks in bone. Bone 2019, 127, 517–525. [Google Scholar] [CrossRef] [PubMed]

- Josephson, T.O.; Moore, J.P.; Maghami, E.; Freeman, T.A.; Najafi, A.R. Computational study of the mechanical influence of lacunae and perilacunar zones in cortical bone microcracking. J. Mech. Behav. Biomed. Mater. 2021, 126, 105029. [Google Scholar] [CrossRef]

- Uda, Y.; Azab, E.; Sun, N.; Shi, C.; Pajevic, P.D. Osteocyte Mechanobiology. Curr. Osteoporos. Rep. 2017, 15, 318–325. [Google Scholar] [CrossRef]

- Dallas, S.L.; Prideaux, M.; Bonewald, L.F. The osteocyte: An endocrine cell… and more. Endocr. Rev. 2013, 34, 658–690. [Google Scholar] [CrossRef]

- Lemaire, T.; Capiez-Lernout, E.; Kaiser, J.; Naili, S.; Rohan, E.; Sansalone, V. A multiscale theoretical investigation of electric measurements in living bone. Bull. Math. Biol. 2011, 73, 2649–2677. [Google Scholar] [CrossRef]

- Bonewald, L.F. The amazing osteocyte. J. Bone Miner. Res. 2011, 26, 229–238. [Google Scholar] [CrossRef]

- Dutta, S.K.; Datta, D. Composition of musculoskeletal structures. In Applied Orthopaedic Biomechanics, 1st ed.; Dutta, S.K., Datta, D., Eds.; BI Publications Pvt Ltd.: New Delhi, India, 2008; pp. 29–37. [Google Scholar]

- Mckibbin, B. The biology of fracture healing in long bones. J. Bone Jt. Surg. Br. 1978, 60-B, 150–162. [Google Scholar] [CrossRef]

- Cartmell, S.; Rupani, A.; Balint, R. Osteoblasts and their applications in bone tissue engineering. Cell Health Cytoskelet. 2012, 49, 49–61. [Google Scholar] [CrossRef]

- Aarden, E.M.; Nijweide, P.J.; Burger, E.H. Function of osteocytes in bone. J. Cell. Biochem. 1994, 55, 287–299. [Google Scholar] [CrossRef] [PubMed]

- George, D.; Allena, R.; Remond, Y. Integrating molecular and cellular kinetics into a coupled continuum mechanobiological stimulus for bone reconstruction. Contin. Mech. Thermodyn. 2019, 31, 725–740. [Google Scholar] [CrossRef]

- Martin, M.; Sansalone, V.; Cooper, D.M.; Forwood, M.R.; Pivonka, P. Mechanobiological osteocyte feedback drives mechanostat regulation of bone in a multiscale computational model. Biomech. Model. Mechanobiol. 2019, 18, 1475–1496. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Wang, H.; Hao, Z. A numerical bone regeneration model incorporating angiogenesis, considering oxygen-induced secretion of vascular endothelial growth factor and vascular remodeling. J. Biomech. 2021, 127, 110656. [Google Scholar] [CrossRef]

- Peyroteo, M.; Belinha, J.; Natal Jorge, R. Load adaptation through bone remodeling: A mechanobiological model coupled with the finite element method. Biomech. Model. Mechanobiol. 2021, 20, 1495–1507. [Google Scholar] [CrossRef]

- Isaksson, H. Recent advances in mechanobiological modeling of bone regeneration. Mech. Res. Commun. 2012, 42, 22–31. [Google Scholar] [CrossRef]

- Ascenzi, M.-G.; Kawas, N.P.; Lutz, A.; Kardas, D.; Nackenhorst, U.; Keyak, J.H. Individual-specific multi-scale finite element simulation of cortical bone of human proximal femur. J. Comput. Phys. 2013, 244, 298–311. [Google Scholar] [CrossRef]

- Morgan, E.F.; Keaveny, T.M. Dependence of yield strain of human trabecular bone on anatomic site. J. Biomech. 2001, 34, 569–577. [Google Scholar] [CrossRef]

- McCalden, R.W.; McGeough, J.A.; Barker, M.B. Age-related changes in the tensile properties of cortical bone. The relative importance of changes in porosity, mineralization, and microstructure. J. Bone Jt. Surg. Am. 1993, 75, 1193–1205. [Google Scholar] [CrossRef]

- Cowin, S.C. Bone poroelasticity. J. Biomech. 1999, 32, 217–238. [Google Scholar] [CrossRef]

- Weinbaum, S.; Cowin, S.C.; Zeng, Y. A model for the excitation of osteocytes by mechanical loading-induced bone fluid shear stresses. J. Biomech. 1994, 27, 339–360. [Google Scholar] [CrossRef]

- Shore, S.W.; Unnikrishnan, G.U.; Hussein, A.I.; Morgan, E.F. Bone biomechanics. In Orthopaedic Biomechanics; Winkelstein, B.A., Ed.; CRC Press: Boca Raton, FL, USA, 2013; pp. 3–47. [Google Scholar]

- Porteous, M.; Bäuerle, S. Techniques and Principles for the Operating Room; Georg Thieme Verlag: Stuttgart, Germany, 2010. [Google Scholar]

- Dutta, S.K.; Datta, D. Long bone shape its mechanical significance. In Applied Orthopaedic Biomechanics, 1st ed.; Dutta, S.K., Datta, D., Eds.; BI Publications Pvt Ltd.: New Delhi, India, 2008; pp. 41–49. [Google Scholar]

- Taddei, F.; Cristofolini, L.; Martelli, S.; Gill, H.S.; Viceconti, M. Subject-specific finite element models of long bones: An in vitro evaluation of the overall accuracy. J. Biomech. 2006, 39, 2457–2467. [Google Scholar] [CrossRef] [PubMed]

- Papini, M.; Zdero, R.; Schemitsch, E.H.; Zalzal, P. The biomechanics of human femurs in axial and torsional loading: Comparison of finite element analysis, human cadaveric femurs, and synthetic femurs. J. Biomech. Eng. 2007, 129, 12–19. [Google Scholar] [CrossRef] [PubMed]

- Hench, L.L.; Wilson, J. Introduction. In An Introduction to Bioceramics; World Scientific: Singapore, 1993; pp. 1–24. [Google Scholar]

- Currey, J. Cortical bone. In Handbook of Biomaterial Properties, 1st ed.; Black, J., Hastings, G., Eds.; Springer Science & Business Media: London, UK, 1998; Volume I, pp. 3–13. [Google Scholar]

- Morawska-Chochół, A.; Chłopek, J.; Szaraniec, B.; Domalik-Pyzik, P.; Balacha, E.; Boguń, M.; Kucharski, R. Influence of the intramedullary nail preparation method on nail’s mechanical properties and degradation rate. Mater. Sci. Eng. C 2015, 51, 99–106. [Google Scholar] [CrossRef] [PubMed]

- Ramakrishna, S.; Mayer, J.; Wintermantel, E.; Leong, K.W. Biomedical applications of polymer-composite materials: A review. Compos. Sci. Technol. 2001, 61, 1189–1224. [Google Scholar] [CrossRef]

- Byrne, D.P.; Lacroix, D.; Prendergast, P.J. Simulation of fracture healing in the tibia: Mechanoregulation of cell activity using a lattice modeling approach. J. Orthop. Res. 2011, 29, 1496–1503. [Google Scholar] [CrossRef]

- Wang, X.; Nyman, J.S.; Dong, X.; Leng, H.; Reyes, M. Fundamental Biomechanics in Bone Tissue Engineering; Morgan & Claypool: San Rafael, CA, USA, 2010. [Google Scholar]

- Neto, R.B.; Rossi, J.D.M.B.A.; Leivas, T.P. Experimental determination of bone cortex holding power of orthopedic screw. Rev. Hosp. Clin. Fac. Med. Sao Paulo 1999, 54, 181–186. [Google Scholar] [CrossRef]

- Drake, R.L.; Vogl, A.W.; Mitchell, A.W.M. Gray’s Basic Anatomy, 2nd ed.; Elsevier Health Sciences: Amsterdam, The Netherlands, 2016; pp. 265–340. [Google Scholar]

- Munford, M.J.; Ng, K.G.; Jeffers, J.R. Mapping the multi-directional mechanical properties of bone in the proximal tibia. Adv. Funct. Mater. 2020, 30, 2004323. [Google Scholar] [CrossRef]

- Hashemi, J.; Chandrashekar, N.; Gill, B.; Beynnon, B.D.; Slauterbeck, J.R.; Schutt, R.t.C.; Mansouri, H.; Dabezies, E. The geometry of the tibial plateau and its influence on the biomechanics of the tibiofemoral joint. J. Bone Jt. Surg. Am. 2008, 90, 2724–2734. [Google Scholar] [CrossRef]

- Hurwitz, D.E.; Sumner, D.R.; Andriacchi, T.P.; Sugar, D.A. Dynamic knee loads during gait predict proximal tibial bone distribution. J. Biomech. 1998, 31, 423–430. [Google Scholar] [CrossRef]

- Lu, T.-W.; O’Connor, J.J.; Taylor, S.J.G.; Walker, P.S. Validation of a lower limb model with in vivo femoral forces telemetered from two subjects. J. Biomech. 1997, 31, 63–69. [Google Scholar] [CrossRef]

- Lu, T.-W.; O’Connor, J.J.; Taylor, S.J.G.; Walker, P.S. Comparison of telemetered femoral forces with model calculations. J. Biomech. 1998, 31, 47. [Google Scholar] [CrossRef]

- Taylor, S.J.G.; Walker, P.S.; Perry, J.S.; Cannon, F.R.C.S.; Woledge, R. The forces in the distal femur and the knee during walking and other activities measured by telemetry. J. Arthroplast. 1998, 13, 428–437. [Google Scholar] [CrossRef]

- Taylor, S.J.G.; Walker, P.S. Forces and moments telemetered from two distal femoral replacements during various activities. J. Biomech. 2001, 34, 839–848. [Google Scholar] [CrossRef]

- Wehner, T.; Claes, L.; Simon, U. Internal loads in the human tibia during gait. Clin. Biomech. 2009, 24, 299–302. [Google Scholar] [CrossRef]

- Taylor, W.R.; Heller, M.O.; Bergmann, G.; Duda, G.N. Tibio-femoral loading during human gait and stair climbing. J. Orthop. Res. 2004, 22, 625–632. [Google Scholar] [CrossRef]

- Nagura, T.; Matsumoto, H.; Kiriyama, Y.; Chaudhari, A.; Andriacchi, T.P. Tibiofemoral joint contact force in deep knee flexion and its consideration in knee osteoarthritis and joint replacement. J. Appl. Biomech. 2006, 22, 305–313. [Google Scholar] [CrossRef]

- D’Lima, D.D.; Townsend, C.P.; Arms, S.W.; Morris, B.A.; Colwell, C.W., Jr. An implantable telemetry device to measure intra-articular tibial forces. J. Biomech. 2005, 38, 299–304. [Google Scholar] [CrossRef]

- Zhao, D.; Banks, S.A.; D’Lima, D.D.; Colwell, C.W.; Fregly, B.J. In vivo medial and lateral tibial loads during dynamic and high flexion activities. J. Orthop. Res. 2007, 25, 593–602. [Google Scholar] [CrossRef]

- Kim, H.J.; Fernandez, J.W.; Akbarshahi, M.; Walter, J.P.; Fregly, B.J.; Pandy, M.G. Evaluation of predicted knee-joint muscle forces during gait using an instrumented knee implant. J. Orthop. Res. 2009, 27, 1326–1331. [Google Scholar] [CrossRef]

- D’Angeli, V.; Belvedere, C.; Ortolani, M.; Giannini, S.; Leardini, A. Load along the tibial shaft during activities of daily living. J. Biomech. 2014, 47, 1198–1205. [Google Scholar] [CrossRef] [PubMed]

- Ellis, M.I.; Seedhom, B.B.; Wright, V. Forces in the knee joint whilst rising from a seated position. J. Biomed. Eng. 1984, 6, 113–120. [Google Scholar] [CrossRef]

- Wilk, K.E.; Escamilla, R.F.; Fleisig, G.S.; Barrentine, S.W.; Andrews, J.R.; Boyd, M.L. A comparison of tibiofemoral joint forces and electromyographic activity during open and closed kinetic chain exercises. Am. J. Sports Med. 1996, 24, 518–527. [Google Scholar] [CrossRef] [PubMed]

- Dahlkvist, N.J.; Mayo, P.; Seedhom, B.B. Forces during squatting and rising from a deep squat. Eng. Med. 1982, 11, 69–76. [Google Scholar] [CrossRef]

- Norman, T.L.; Vashishtht, D.; Burr, D.B. Fracture toughness of human bone under tension. J. Biomech. 1995, 28, 309–320. [Google Scholar] [CrossRef]

- Phelps, J.B.; Hubbard, G.B.; Wang, X.; Agrawal, C.M. Microstructural heterogeneity and the fracture toughness of bone. J. Biomed. Mater. Res. A 2000, 51, 735–741. [Google Scholar] [CrossRef]

- Morais, J.J.L.; de Moura, M.F.S.F.; Pereira, F.A.M.; Xavier, J.; Dourado, N.; Dias, M.I.R. The double cantilever beam test applied to mode I fracture characterization of cortical bone tissue. J. Mech. Behav. Biomed. 2010, 3, 446–453. [Google Scholar] [CrossRef]

- Norman, T.L.; Nivargikar, V.; Burr, D.B. Resistance to crack growth in human cortical bone is greater in shear than in tension. J. Biomech. 1996, 29, 1023–1031. [Google Scholar] [CrossRef]

- Dourado, N.; Pereira, F.A.M.; de Moura, M.F.S.F.; Morais, J.J.L.; Dias, M.I.R. Bone fracture characterization using the end notched flexure test. Mater. Sci. Eng. C 2013, 33, 405–410. [Google Scholar] [CrossRef]

- Zimmermann, E.A.; Launey, M.E.; Ritchie, R.O. The significance of crack-resistance curves to the mixed-mode fracture toughness of human cortical bone. Biomaterials 2010, 31, 5297–5305. [Google Scholar] [CrossRef]

- Pereira, F.A.M.; de Moura, M.F.S.F.; Dourado, N.; Morais, J.J.L.; Dias, M.I.R. Bone fracture characterization under mixed-mode I+II loading using the single leg bending test. Biomech. Model. Mechanobiol. 2014, 13, 1331–1339. [Google Scholar] [CrossRef] [PubMed]

- Pereira, F.A.M.; de Moura, M.F.S.F.; Dourado, N.; Morais, J.J.L.; Silva, F.G.A.; Dias, M.I.R. Bone fracture characterization under mixed-mode I+II loading using the MMB test. Eng. Fract. Mech. 2016, 166, 151–163. [Google Scholar] [CrossRef]

- Wang, X.; Puram, S. The toughness of cortical bone and its relationship with age. Ann. Biomed. Eng. 2004, 32, 123–135. [Google Scholar] [CrossRef]

- Yang, Q.D.; Cox, B.N.; Nalla, R.K.; Ritchie, R.O. Fractur.re length scales in human cortical bone: The necessity of non-linear fracture models. Biomaterials 2006, 27, 2095–2113. [Google Scholar] [CrossRef] [PubMed]

- An, Y.H.; Barfield, W.R.; Draughn, R.A. Basic concepts of mechanical property measurement and bone biomechanics. In Mechanical Testing of Bone and the Bone-Implant Interface, 1st ed.; An, Y.H., Draughn, R.A., Eds.; CRC Press: Boca Raton, FL, USA, 2000; pp. 23–40. [Google Scholar]

- Arnold, P.A. Validation of Mechanical Response Tissue Analysis by Three-Point Mechanical Bending of Artificial Human Ulnas. Bachelor’s Thesis, Ohio University, Athens, OH, USA, 2013. [Google Scholar]

- Carnelli, D. Orientation and Length-Scale Dependent Mechanical Properties in Lamellar Bone at the Micro and Nanostructural Hierarchical Levels. Politecnico di Milano, Milan, Italy, 2010.

- Colabella, L.; Cisilino, A.P.; Häiat, G.; Kowalczyk, P. Mimetization of the elastic properties of cancellous bone via a parameterized cellular material. Biomech. Model. Mechanobiol. 2017, 16, 1485–1502. [Google Scholar] [CrossRef] [PubMed]

- Keaveny, T.M. Cancellous bone. In Handbook of Biomaterial Properties, 1st ed.; Black, J., Hastings, G., Eds.; Springer Science & Business Media: London, UK, 1998; Volume I, pp. 15–23. [Google Scholar]

- Parkinson, H.; Fazzalari, N.L. Characterisation of trabecular bone structure. In Skeletal Aging and Osteoporosis, 1st ed.; Silva, M.J., Gefen, A., Aviv, R., Eds.; Studies in Mechanobiology, Tissue Engineering and Biomaterials; Springer: London, UK, 2013; pp. 31–51. [Google Scholar]

- Rahmoun, J.; Chaari, F.; Markiewicz, E.; Drazetic, P. Micromechanical modeling of the anisotropy of elastic biological composites. Multiscale Model. Simul. 2009, 8, 326–336. [Google Scholar] [CrossRef]

- Kini, U.; Nandeesh, B.N. Physiology of bone formation, remodeling, and metabolism In Radionuclide and Hybrid. Bone Imaging, 1st ed.; Fogelman, I., Gnanasegaran, G., van der Wall, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 29–57. [Google Scholar]

- Zhu, L.; Luo, D.; Liu, Y. Effect of the nano/microscale structure of biomaterial scaffolds on bone regeneration. Int. J. Oral Sci. 2020, 12, 6. [Google Scholar] [CrossRef]

- Park, S.B.; Sung, M.H.; Uyama, H.; Han, D.K. Poly (glutamic acid): Production, composites, and medical applications of the next-generation biopolymer. Prog. Polym. Sci. 2021, 113, 101341. [Google Scholar] [CrossRef]

- Naboni, R.; Kunic, A. Bone-inspired 3D printed structures for construction applications. Gestão Tecnol. Proj. 2019, 14, 111–124. [Google Scholar] [CrossRef]

- Burns, L. Bio-Inspired Design of Aerospace Composite Joints. Ph.D. Thesis, RMIT University, Melbourne, Australia, 2012. [Google Scholar]

| Activity | Knee Contact Force (×BW) | Study 1 | Reference | |||

|---|---|---|---|---|---|---|

| Medial | Lateral | |||||

| 1st Peak | 2nd Peak | |||||

| Level walking | 3.2 | In vivo | [104] | |||

| 2.8 | Simulation | [105] | ||||

| <2.4 | 2.4 | 1 | In vivo | [103] | ||

| 2.2–2.5 | 2.37–2.51 | Similar | In vivo | [106] | ||

| 2.8 | In vivo | [107] | ||||

| 3.3 | Simulation | [108] | ||||

| 3.1 | Simulation | [109] | ||||

| 4.0 | In vivo | [110] | ||||

| 2.8 | In vivo | [111] | ||||

| 2 | 1.5 | In vivo | [112] | |||

| 1.3–1.5 | 1.3–1.5 | 0.8–1.15 | In vivo | [113] | ||

| 2.8 | Simulation | [105] | ||||

| 3.3 | Simulation | [108] | ||||

| 2.9 | In vivo | [114] | ||||

| Stair | Ascending | 2.28–2.5 | 2.28 | - | In vivo | [106] |

| 2.8 | In vivo | [107] | ||||

| 5.3 | In vivo | [110] | ||||

| 2.9 | In vivo | [111] | ||||

| 5.4 | Simulation | [109] | ||||

| 2.63–2.81 | 2.8 | - | In vivo | [106] | ||

| Descending | 3.1 | In vivo | [107] | |||

| 3.3 | In vivo | [111] | ||||

| Rising from chair | 2.09 | - | - | In vivo | [106] | |

| 2.6 | In vivo | [111] | ||||

| 3.38–7.89 | In vivo | [115] | ||||

| Jogging | 3.6 | In vivo | [107] | |||

| Squats | 7.3 | In vivo | [110] | |||

| 6.3 | In vivo | [116] | ||||

| 4.7–5.6 | In vivo | [117] | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosa, N.; Moura, M.F.S.F.; Olhero, S.; Simoes, R.; Magalhães, F.D.; Marques, A.T.; Ferreira, J.P.S.; Reis, A.R.; Carvalho, M.; Parente, M. Bone: An Outstanding Composite Material. Appl. Sci. 2022, 12, 3381. https://doi.org/10.3390/app12073381

Rosa N, Moura MFSF, Olhero S, Simoes R, Magalhães FD, Marques AT, Ferreira JPS, Reis AR, Carvalho M, Parente M. Bone: An Outstanding Composite Material. Applied Sciences. 2022; 12(7):3381. https://doi.org/10.3390/app12073381

Chicago/Turabian StyleRosa, Natacha, Marcelo F. S. F. Moura, Susana Olhero, Ricardo Simoes, Fernão D. Magalhães, António Torres Marques, João P. S. Ferreira, Ana Rita Reis, Mariana Carvalho, and Marco Parente. 2022. "Bone: An Outstanding Composite Material" Applied Sciences 12, no. 7: 3381. https://doi.org/10.3390/app12073381

APA StyleRosa, N., Moura, M. F. S. F., Olhero, S., Simoes, R., Magalhães, F. D., Marques, A. T., Ferreira, J. P. S., Reis, A. R., Carvalho, M., & Parente, M. (2022). Bone: An Outstanding Composite Material. Applied Sciences, 12(7), 3381. https://doi.org/10.3390/app12073381