Study on Model and Experimental of Laser Scribing Parameter of Maskant in Chemical Milling for Aerospace Applications

Abstract

:1. Introduction

2. Theoretical Study on Laser Scribing Process

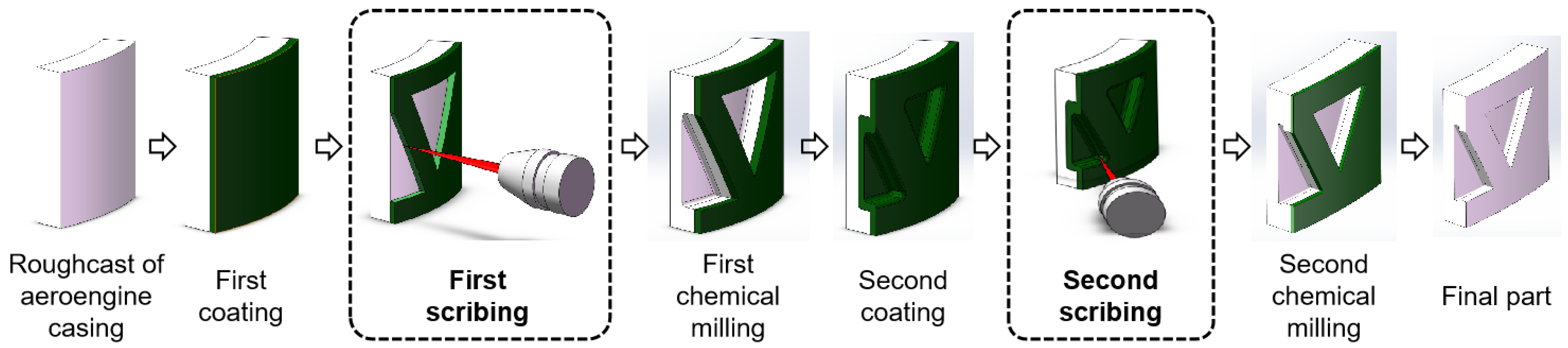

2.1. Laser Scribing Process Flow and Requirements

- (1)

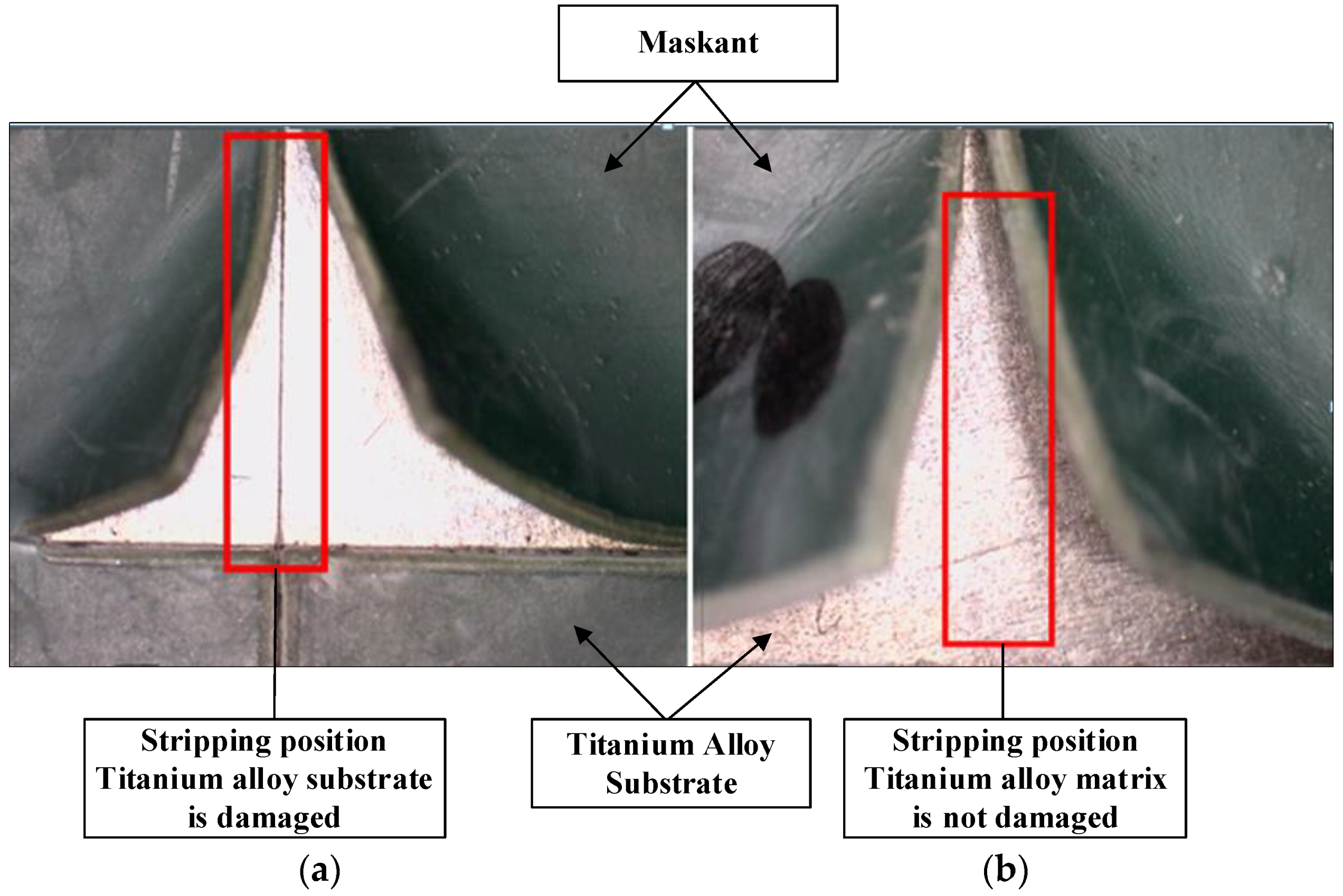

- The maskant scribing with the substrate should not be damaged;

- (2)

- The scribing lines are generally complex curves;

- (3)

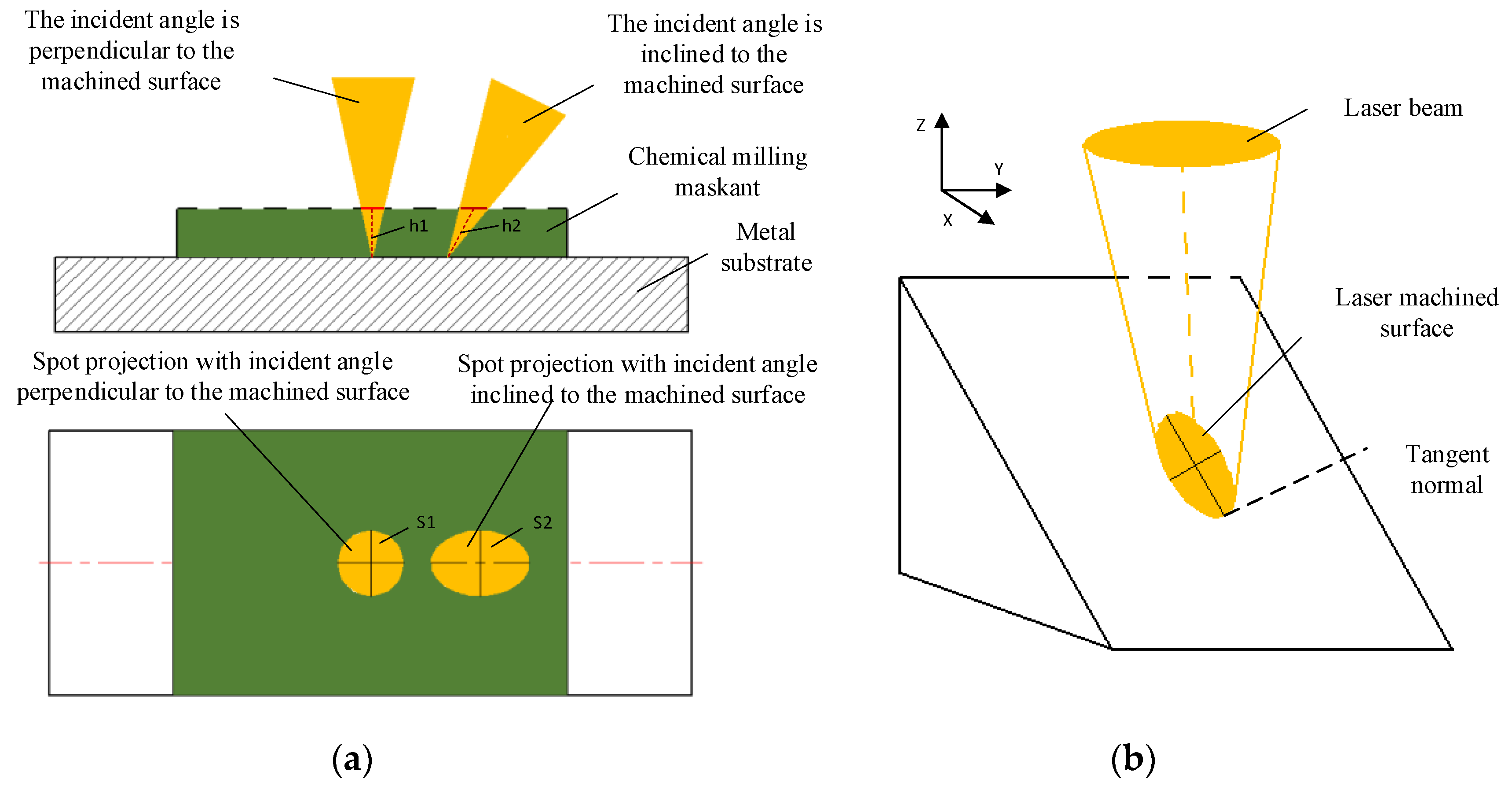

- First laser scribing needs to be perpendicular to the part surface according to the pattern;

- (4)

- Second laser scribing needs to be inclined to the sidewall, which is generated by first chemical milling;

- (5)

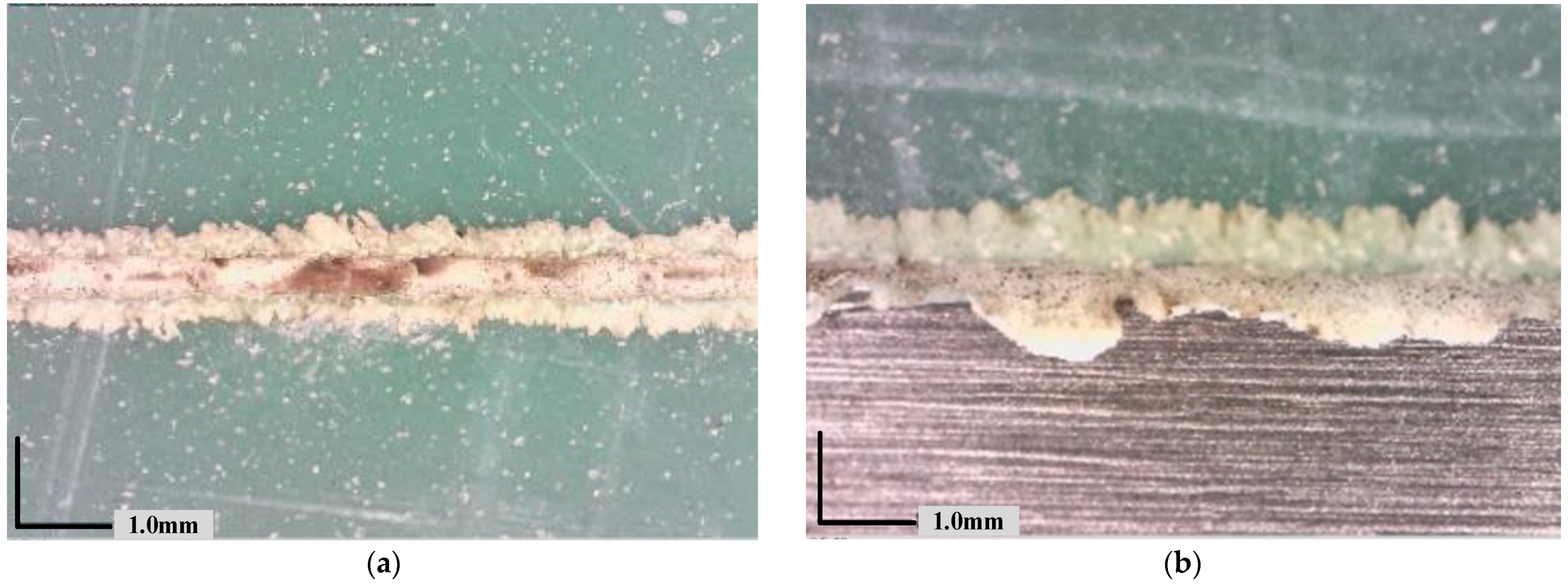

- The upper and lower edges of the scribing lines are continuous and smooth, with high accuracy;

- (6)

- The accuracy of second scribing is ±0.05 mm.

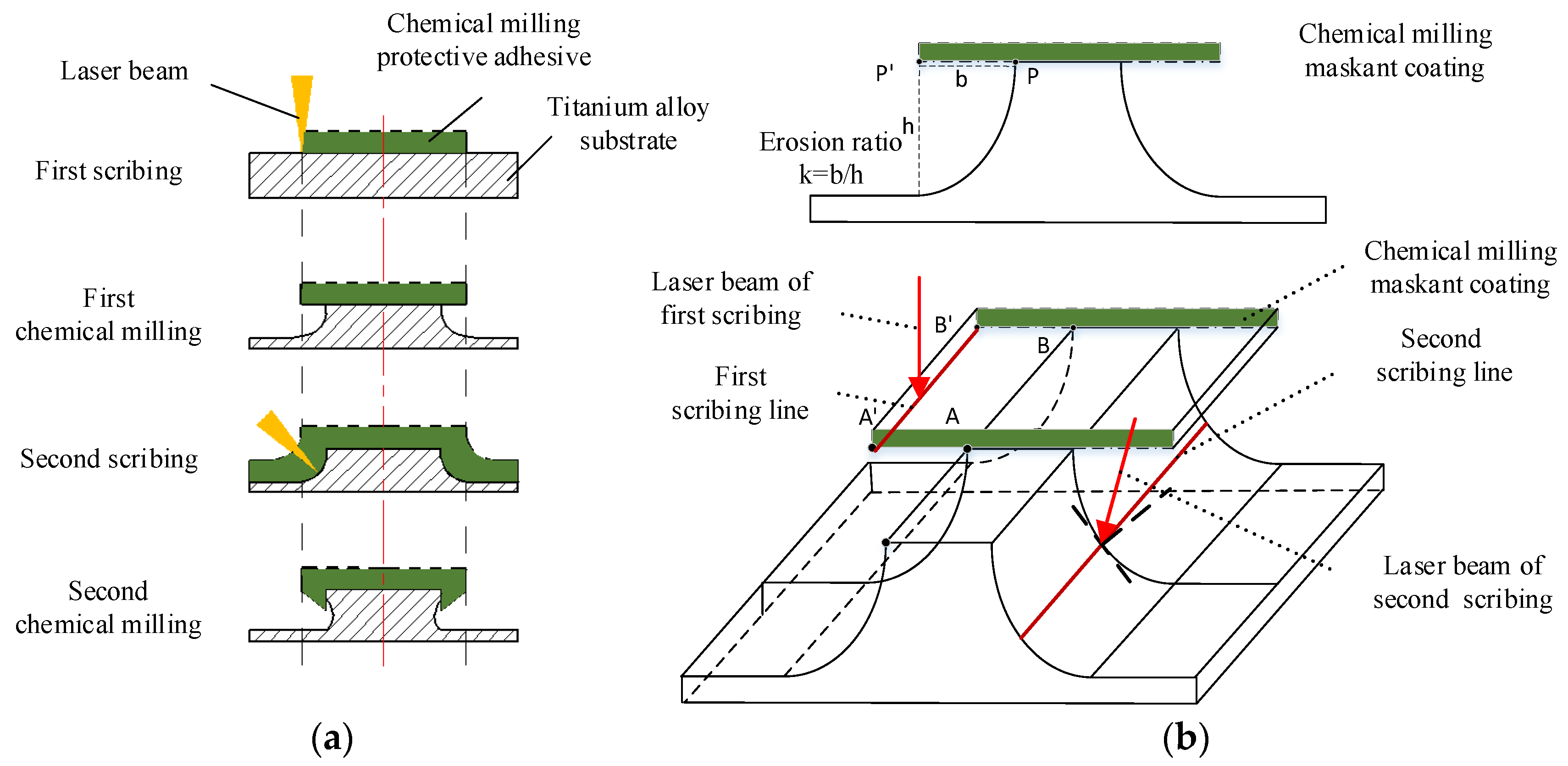

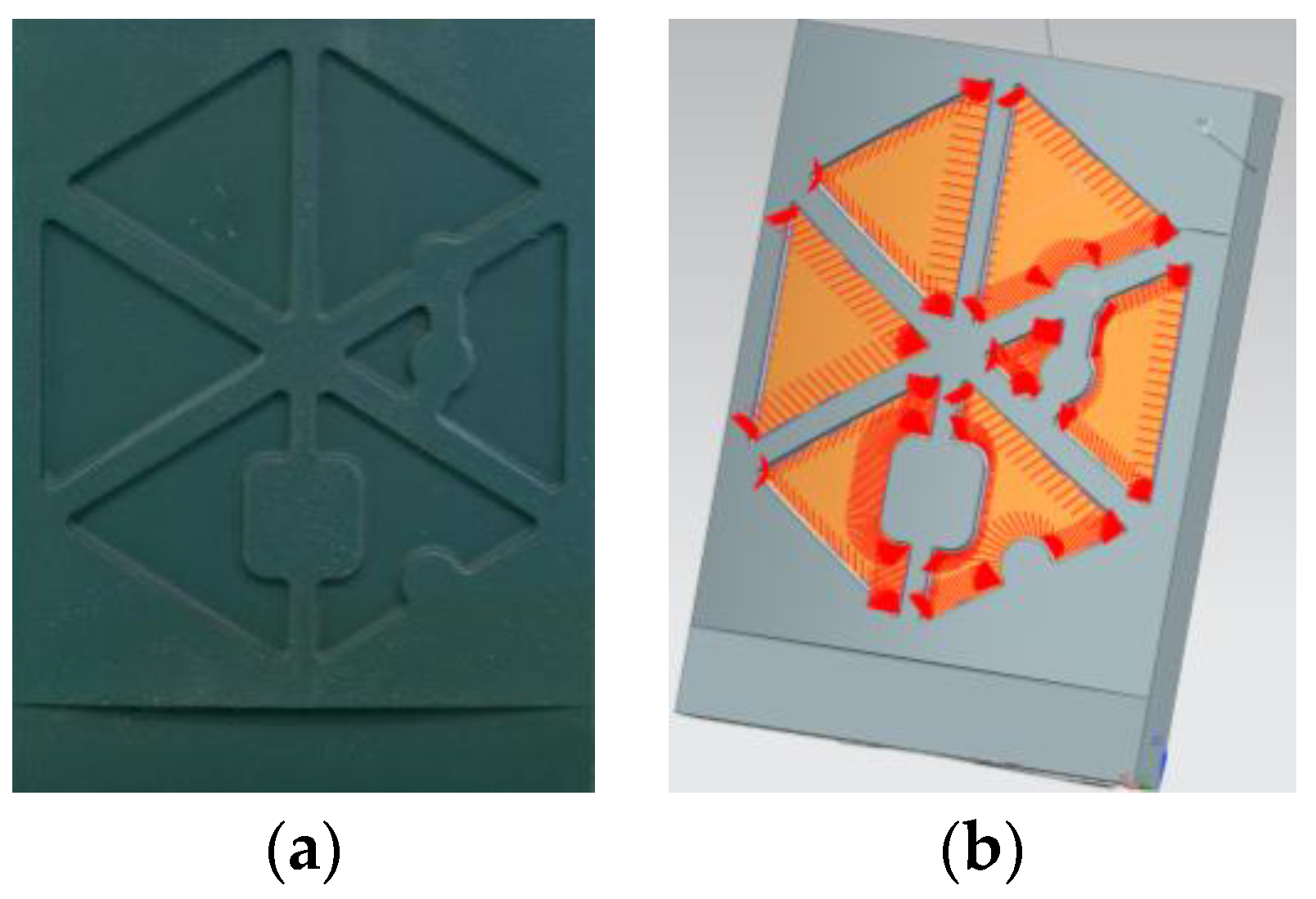

2.2. Laser Scribing Features and Trajectories

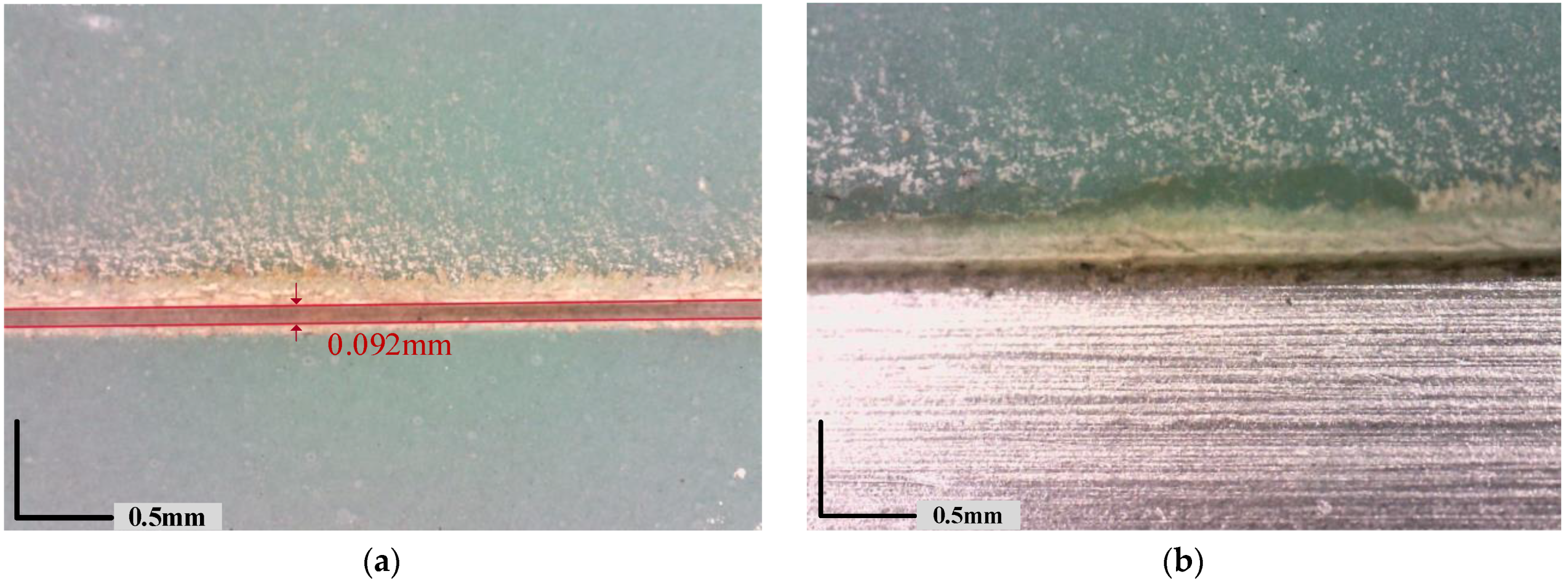

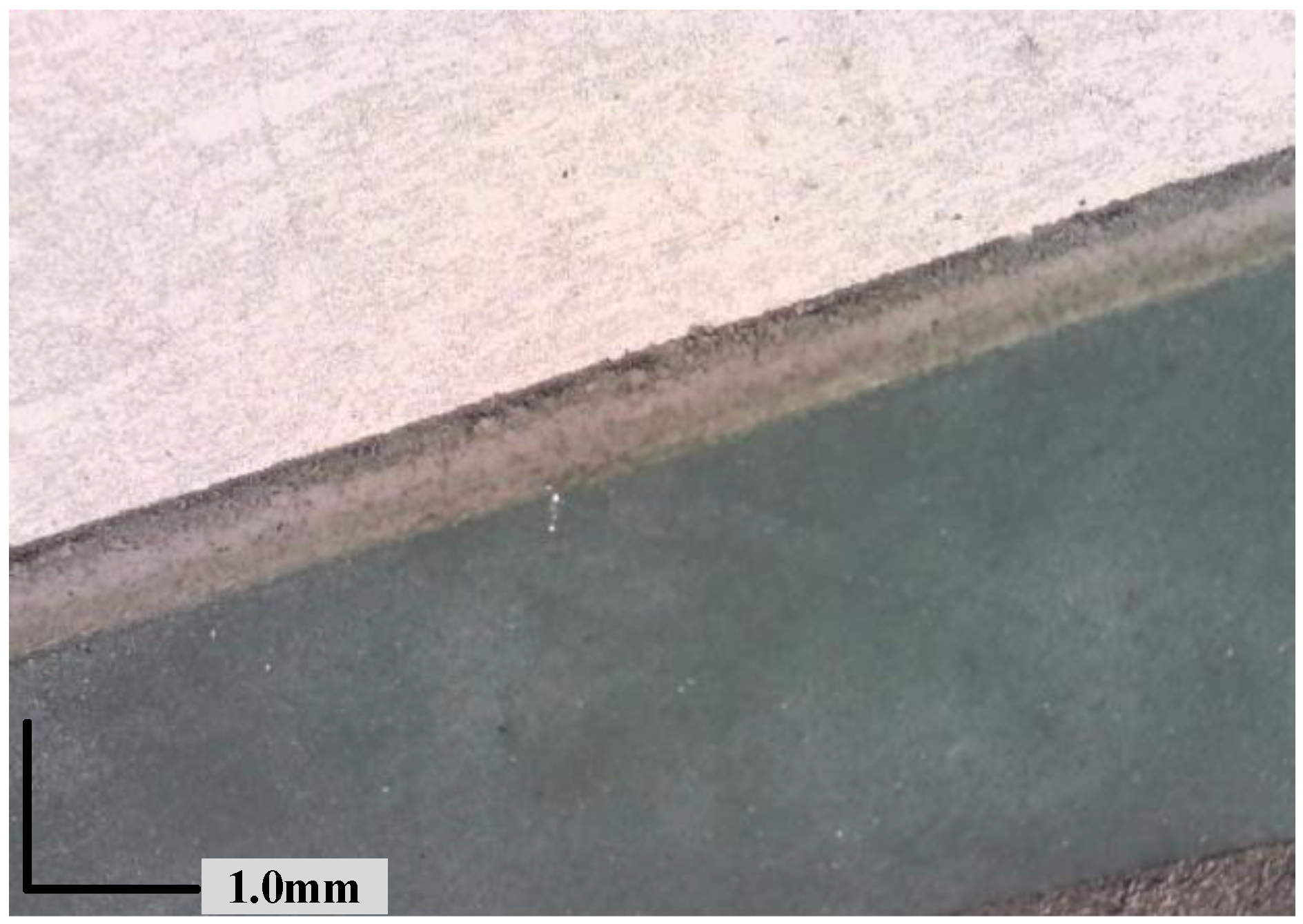

2.3. Laser Scribing Quality

3. Laser Scribing Mechanism and Theoretical Model

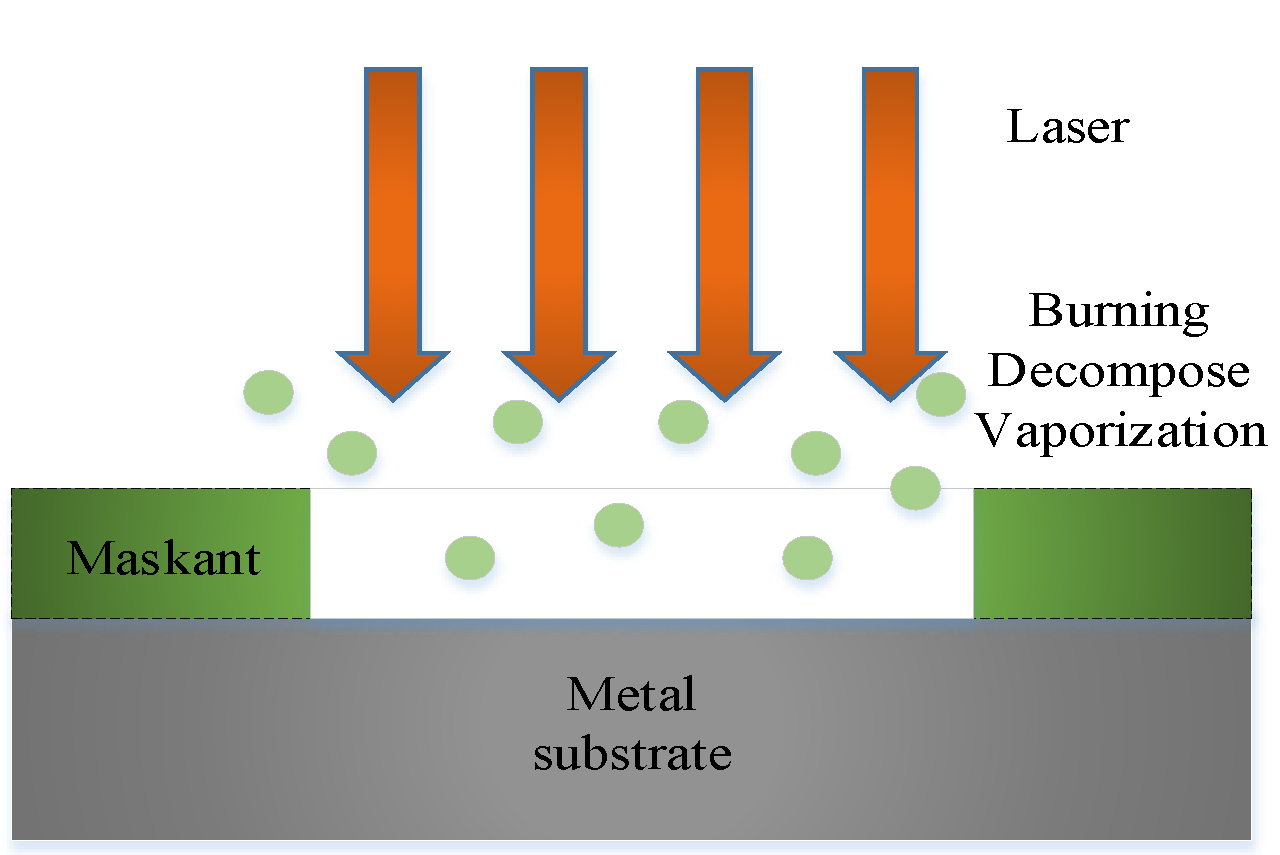

3.1. Mechanism and Process Parameters of Laser Scribing

3.2. Theoretical Model of Laser Scribing

3.2.1. Theoretical Model of Laser Scribing

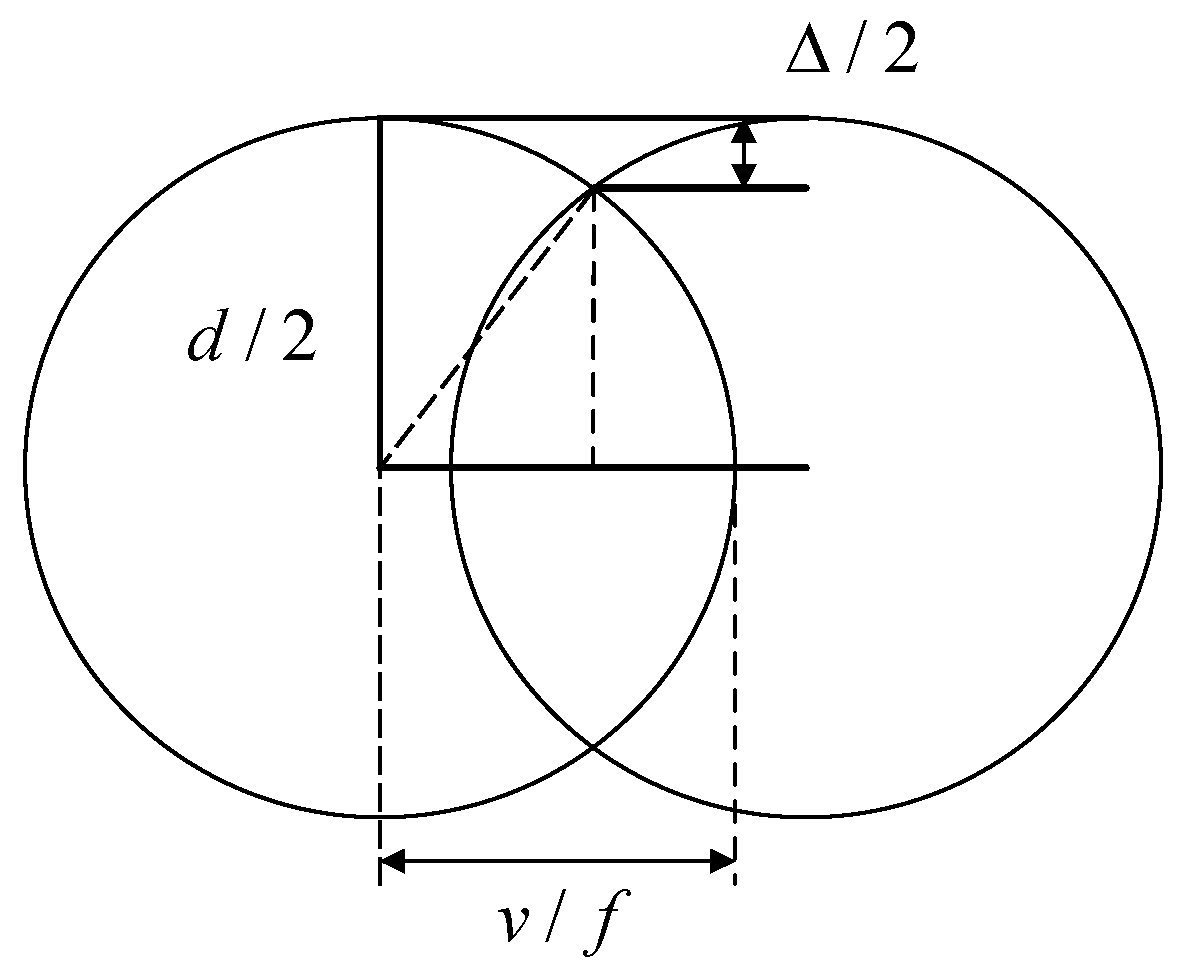

3.2.2. Cumulative Scribing Depth Model of Pulsed Laser

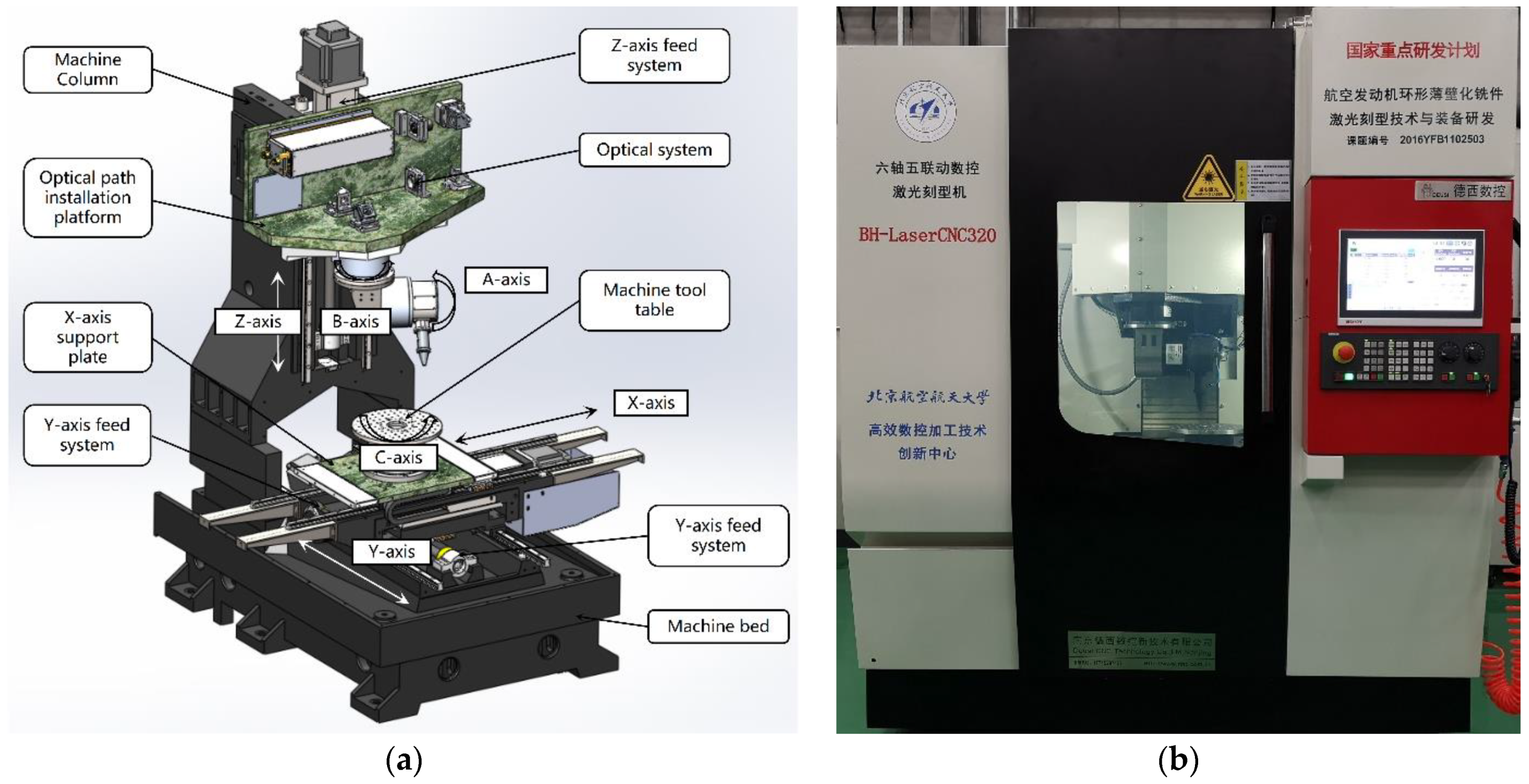

4. Laser Scribing Machine and Parameters of Experiment

4.1. Laser Scribing Machine

4.2. Experiment Parameters

5. Results and Discussion

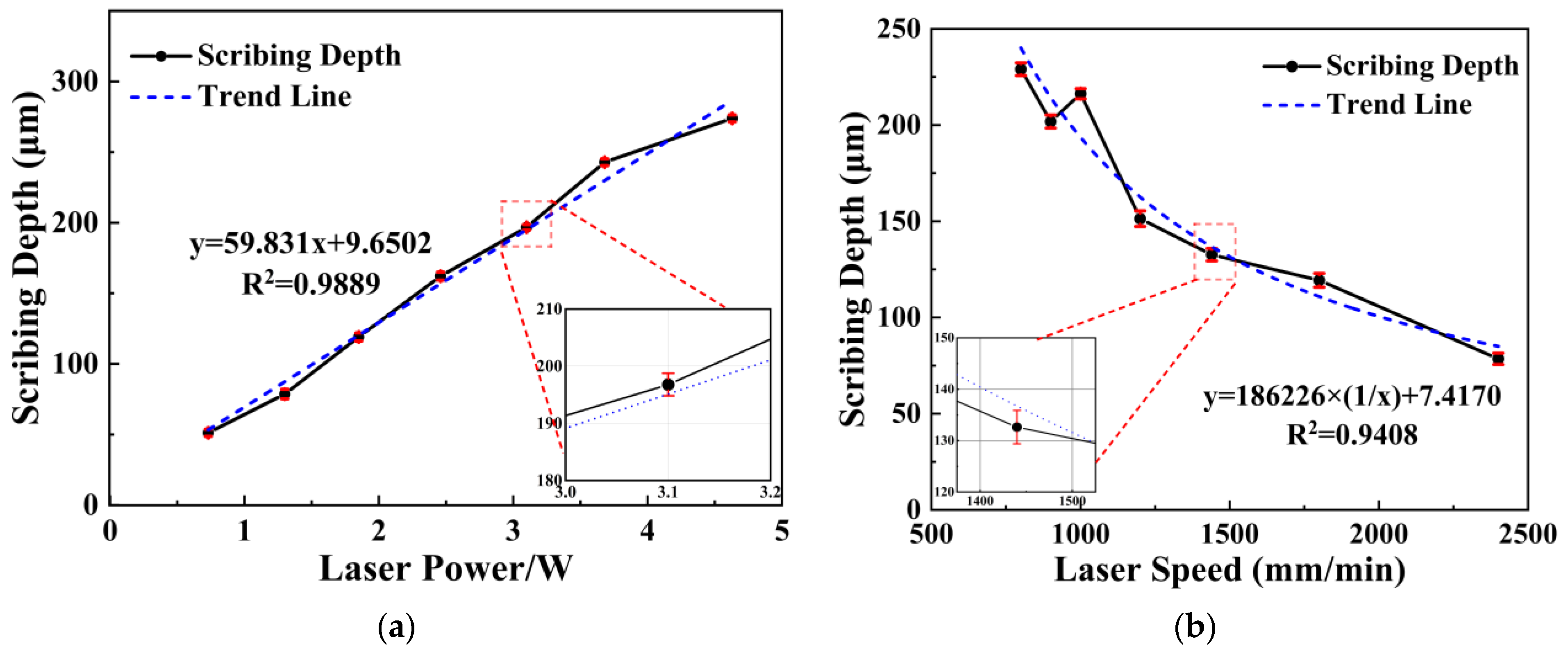

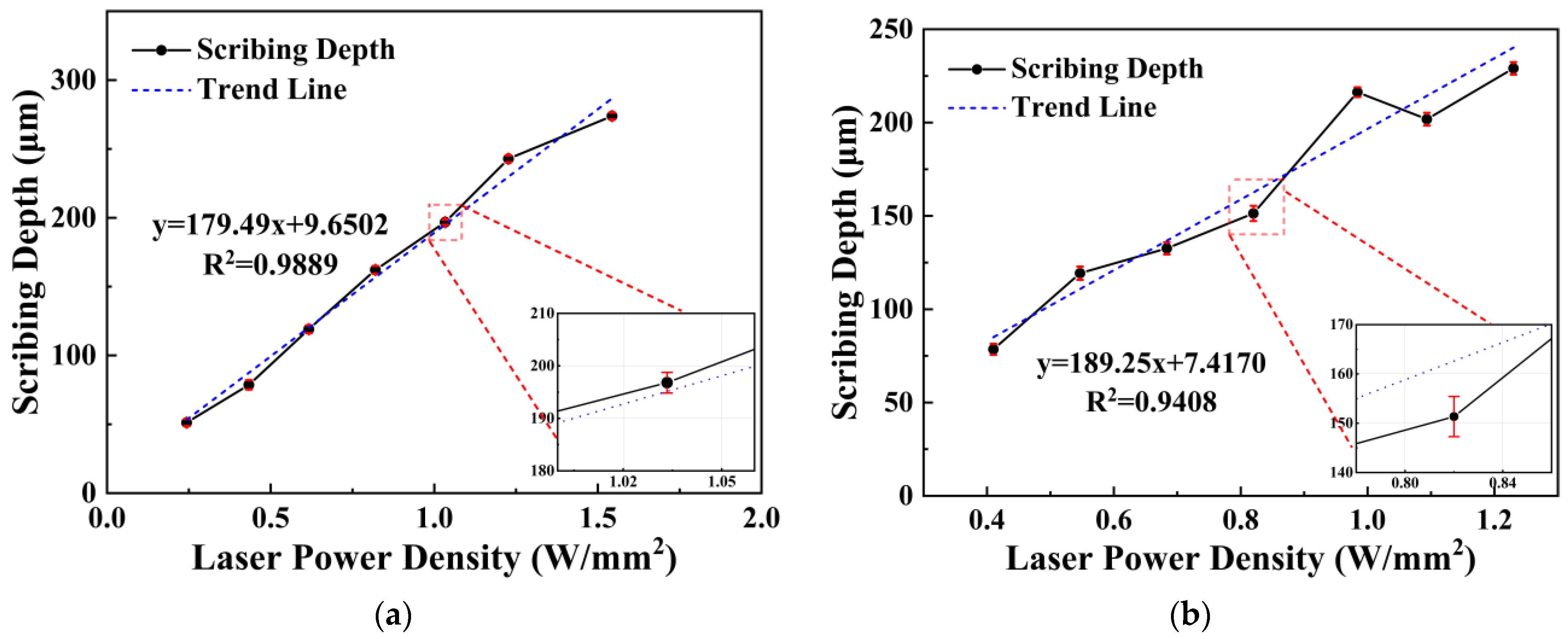

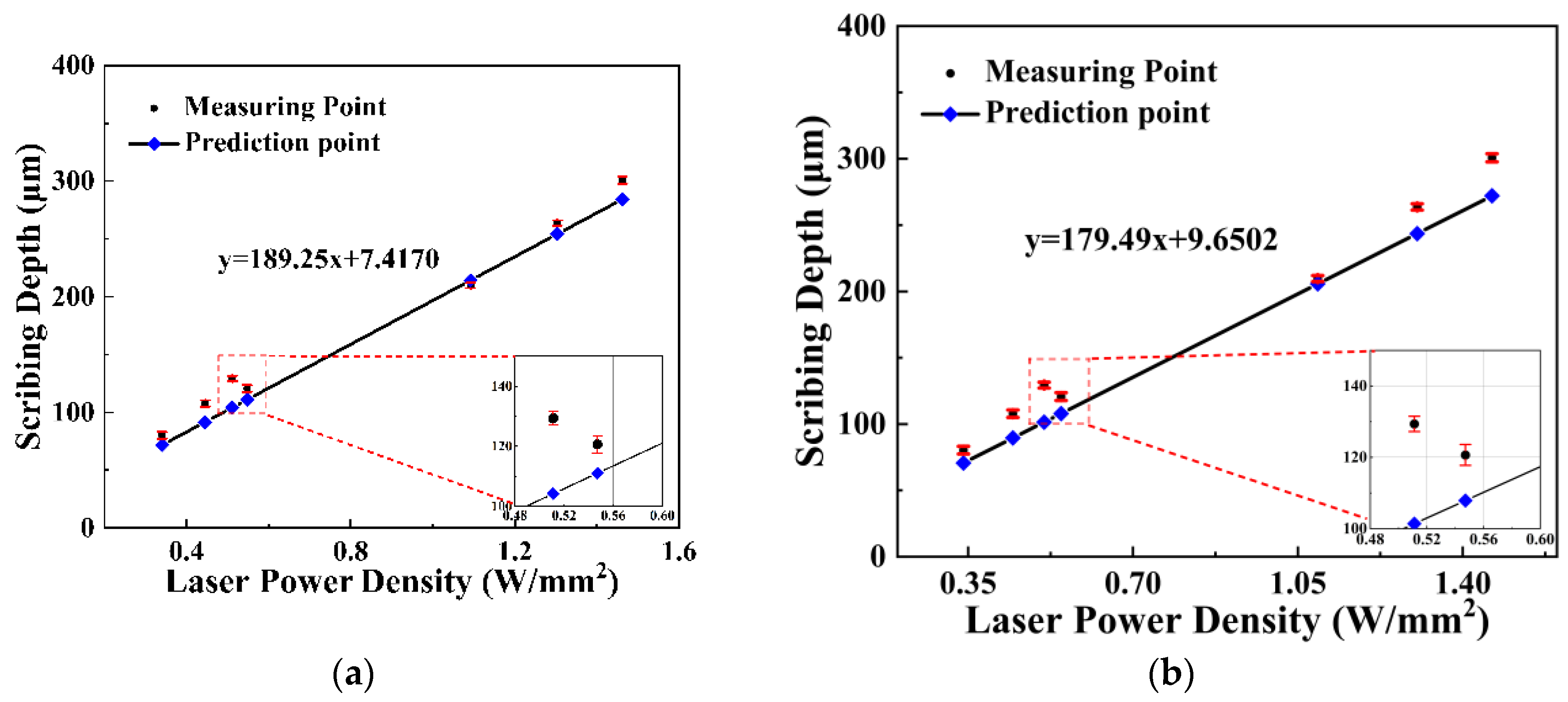

5.1. Verification and Analysis of Theoretical Model

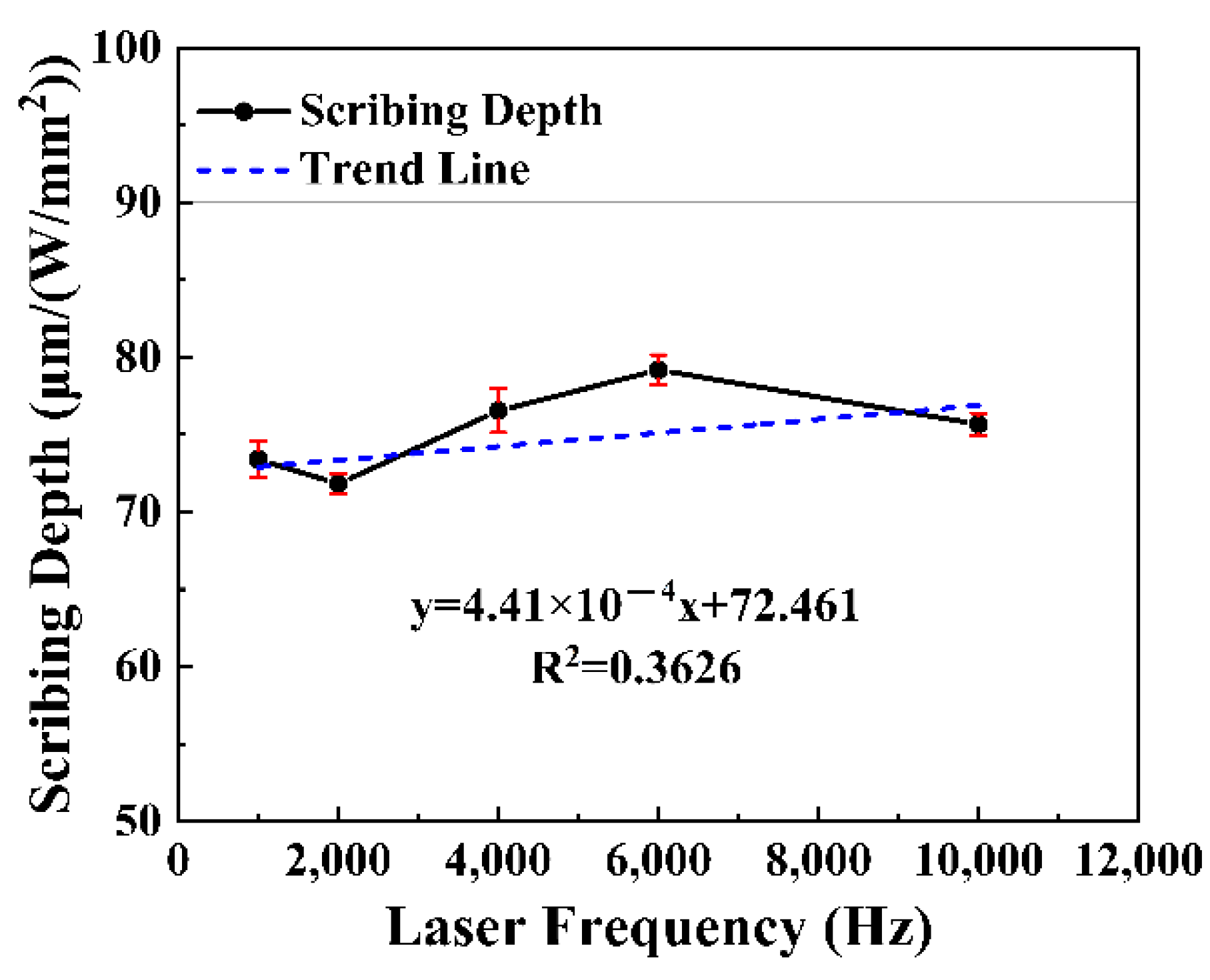

5.2. Influence and Analysis of Frequency on Scribing Depth

5.3. Experimental Results and Analysis of Laser Scribing Depth with Laser Incidence Angle

5.3.1. Result of Forward Angle

5.3.2. Result of Side Slope Angle

5.3.3. Discussion of Laser Scribing Depth with Laser Incidence Angle

6. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ezugwu, E.O.; Bonney, J.; Yamane, Y. An overview of the machinability of aeroengine alloys. J. Mater. Processing Technol. 2003, 134, 233–253. [Google Scholar] [CrossRef]

- DeForce, B.; Eden, T.J.; Pickering, H.W. Cold-Sprayed Aluminum Coatings for Magnesium Aircraft Components. Mater. Perform. 2009, 48, 40–44. [Google Scholar]

- Hansen, J.O.; Long, K.C.; Jackson, M.A.; Hodgens, H.M. Chemical Milling Process and Solution for Cast Titanium Alloys. U.S. Patent No. 6,793,838, 21 September 2004. [Google Scholar]

- Staebler, C.J., Jr. Advanced Chemical Milling Processes; Grumman Aerospace Corp.: Bethpage, NY, USA, 1971. [Google Scholar]

- Hot, J.; Dasque, A.; Topalov, J.; Mazars, V.; Ringot, E. Titanium valorization: From chemical milling baths to air depollution applications. J. Clean. Prod. 2020, 249, 119344. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T. Chemical Cutting Process. In Advanced Noncontact Cutting and Joining Technologies; Springer: Berlin/Heidelberg, Germany, 2018; pp. 11–25. [Google Scholar]

- Dini, J.W. Chemical Milling. Int. Metall. Rev. 2013, 20, 29–56. [Google Scholar] [CrossRef]

- Leone, C.; Lopresto, V.; Minutolo, F.M.C.; De Iorio, I.; Rinaldi, N. Laser ablation of maskant used in chemical milling process for aerospace applications. In Proceedings of the XVIII International Symposium on Gas Flow, Chemical Lasers, and High-Power Lasers, Sofia, Bulgaria, 30 August–3 September 2010; p. 77511M. [Google Scholar]

- Nelson, C. Method and Apparatus for Automated Chemical Milling of Compound Curved Surfaces. U.S. Patent No. 4,523,973, 18 June 1985. [Google Scholar]

- Gao, X.J.; Huang, Q.S.; Liu, B.Q.; Qiu, Z.F.; Kan, T.T. Research on Application of Three Dimensional Laser Cutting Technique in Chemical Milling and Welding Case. Mach. Des. Manuf. 2012, 7, 92–94. [Google Scholar] [CrossRef]

- Pantsar, H.; Ruusu, R.; Laakso, P.; Jansson, A. Advances in 3D laser processing in mold technology. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics, Scottsdale, AZ, USA, 30 October–2 November 2006; p. 204. [Google Scholar]

- Daly, R.T. Laser Scribing Apparatus. U.S. Patent No. 3,626,141, 7 December 1971. [Google Scholar]

- Gnanamuthu, D.S.; Moores, R.J.; Paton, N.E.; Vyhna, R.F. Non-Contact Scribing Process for Organic Maskants on Metals or alloys Thereof. U.S. Patent No. 4,716,270, 29 December 1987. [Google Scholar]

- Slysh, P. Laser Assisted Masking Process. U.S. Patent No. 5,147,680, 15 September 1992. [Google Scholar]

- Griffin, B.M. Aluminum Chemical Milling. 2003, p. 1159. Available online: https://www.academia.edu/download/45969448/Handbook-of-Aluminum.pdf#page=1172 (accessed on 10 February 2022).

- Cao, J.P.; Xu, Z.B.; Wang, B.C.; Chen, R.J. Influence of injection air pressure on the microcapillary formation within extruded plastic films. J. Mater. Sci. 2012, 47, 8188–8196. [Google Scholar] [CrossRef]

- LiYan, P.; Hui, W.; PengPeng, S.; Jian, W. Study on Laser Engraving Process Parameters of Protective Coatings on Titanium Alloy Substrate for Chemical Milling. Plat. Finish. 2021, 43, 29–35. [Google Scholar] [CrossRef]

- Arnold, N.; Bityurin, N.; Bauerle, D. Laser-induced thermal degradation and ablation of polymers: Bulk model. Appl. Surf. Sci. 1999, 138, 212–217. [Google Scholar] [CrossRef]

- Ko, S.H.; Pan, H.; Hwang, D.J.; Chung, J.; Ryu, S.; Grigoropoulos, C.P.; Poulikakos, D. High resolution selective multilayer laser processing by nanosecond laser ablation of metal nanoparticle films. J. Appl. Phys. 2007, 102, 093102. [Google Scholar] [CrossRef] [Green Version]

- Khoshaim, A.B.; Elsheikh, A.H.; Moustafa, E.B.; Basha, M.; Showaib, E.A. Experimental investigation on laser cutting of PMMA sheets: Effects of process factors on kerf characteristics. J. Mater. Res. Technol. 2021, 11, 235–246. [Google Scholar] [CrossRef]

- Dyer, P.E. Laser ablation: Processes and applications. In Proceedings of the Proceedings-Spie The International Society for Optical Engineering, Orlando, FL, USA, 21–22 April 1997; pp. 412–417. [Google Scholar]

- Caiazzo, F.; Curcio, F.; Daurelio, G.; Minutolo, F.M.C. Laser cutting of different polymeric plastics (PE, PP and PC) by a CO2 laser beam. J. Mater. Processing Technol. 2005, 159, 279–285. [Google Scholar] [CrossRef]

- Kaplan, A.F.H. Absorptivity modulation on wavy molten steel surfaces: The influence of laser wavelength and angle of incidence. Appl. Phys. Lett. 2012, 101, 151605. [Google Scholar] [CrossRef]

- Lee, J.M.; Watkins, K.G.; Steen, W.M. Angular laser cleaning for effective removal of particles from a solid surface. Appl. Phys. A-Mater. Sci. Processing 2000, 71, 671–674. [Google Scholar] [CrossRef]

- Smokvina Hanza, S.; Marohnić, T.; Iljkić, D.; Basan, R. Artificial Neural Networks-Based Prediction of Hardness of Low-Alloy Steels Using Specific Jominy Distance. Metals 2021, 11, 714. [Google Scholar] [CrossRef]

- Juez-Gil, M.; Erdakov, I.N.; Bustillo, A.; Pimenov, D.Y. A regression-tree multilayer-perceptron hybrid strategy for the prediction of ore crushing-plate lifetimes. J. Adv. Res. 2019, 18, 173–184. [Google Scholar] [CrossRef] [PubMed]

- Dixit, S.R.; Das, S.R.; Dhupal, D. Parametric optimization of Nd:YAG laser microgrooving on aluminum oxide using integrated RSM-ANN-GA approach. J. Ind. Eng. Int. 2018, 15, 333–349. [Google Scholar] [CrossRef] [Green Version]

- Teixidor, D.; Grzenda, M.; Bustillo, A.; Ciurana, J. Modeling pulsed laser micromachining of micro geometries using machine-learning techniques. J. Intell. Manuf. 2013, 26, 801–814. [Google Scholar] [CrossRef] [Green Version]

- Tehrani, A.F.; Imanian, E. A new etchant for the chemical machining of St304. J. Mater. Processing Technol. 2004, 149, 404–408. [Google Scholar] [CrossRef]

- Narisaranukul, N. Modeling and Analysis of the Chemical Milling Process. Doctoral Dissertation, Massachusetts Institute of Technology, Cambridge, MA, USA, 1997. [Google Scholar]

- Kumar, K.; Zindani, D.; Davim, J.P. Chemical Machining. In Advanced Machining and Manufacturing Processes; Springer: Berlin/Heidelberg, Germany, 2018; pp. 89–104. [Google Scholar]

- Phipps, C. Laser Ablation and Its Applications; Springer: Berlin/Heidelberg, Germany, 2007; Volume 129. [Google Scholar]

- Ready, J.; Farson, D.J.I. LIA Handbook of Laser Materials Processing; Laser Institute of America Magnolia Publishing: Orlando, FL, USA, 2001. [Google Scholar]

- Wissenbach, K. Tailored Light 2. Laser Application Technology; Springer: Berlin/Heidelberg, Germany, 2009; pp. 384–415. [Google Scholar]

- Yin, Z.; Liu, Q.; Sun, P.; Wang, J. Study on Nanosecond Laser Ablation of 40Cr13 Die Steel Based on ANOVA and BP Neural Network. Appl. Sci. 2021, 11, 331. [Google Scholar] [CrossRef]

- Colonna, G.; Pascazio, G.; Bonelli, F. Advanced model for the interaction of a Ti plume produced by a ns-pulsed laser in a nitrogen environment. Spectrochim. Acta Part B At. Spectrosc. 2021, 179, 106120. [Google Scholar] [CrossRef]

- Liedahl, D.A.; Rubenchik, A.; Libby, S.B.; Nikolaev, S.; Phipps, C.R. Pulsed laser interactions with space debris: Target shape effects. Adv. Space Res. 2013, 52, 895–915. [Google Scholar] [CrossRef] [Green Version]

| Num | Parameter | Value |

|---|---|---|

| 1 | Wavelength (μm) | 10.6 |

| 2 | Power output (W) | 30 |

| 3 | Power Stability | ±5% |

| 4 | Mode Quality (M2) | ≤1.2 |

| 5 | BeamWaist Diameter, mm (at 1/e2)4 | 2.5 ± 0.5 |

| 6 | Polarization | Linear |

| 7 | Focus diameter (μm) | 150 μm |

| 8 | Depth of focus (μm) | 583 μm |

| Num | Quantitative Parameters | Variable Parameters |

|---|---|---|

| 1 | Velocity: 200 mm/min; Frequency: 1000 Hz; Incident angles: 0°. | Duty ratios (%): 3, 7, 9, 11, 13, 15, 20 |

| 2 | Duty ratios: 9%; Frequency: 1000 Hz. Incident angles: 0° | Velocity (mm/min): 800, 900, 1000, 1200, 1500, 1800, 2400. |

| 3 | Duty ratios: 9%; Velocity: 1200 mm/min; Incident angles: 0° | Frequency (Hz): 1000, 2000, 4000, 6000, 10,000. |

| 4 | Duty ratios: 9%; Velocity: 1200 mm/min; Frequency: 1000 Hz. | Forward angle (°): −36, −30, −24, −18, −12, −6, 0, 6, 12, 18, 24, 30, 36. |

| 5 | Duty ratios: 9%; Velocity: 1200 mm/min; Frequency: 1000 Hz. | Side slope angle (°): 0, 7, 14, 21, 28, 35, 42. |

| Duty Ratios/% | 3 | 5 | 7 | 9 | 11 | 13 | 15 |

|---|---|---|---|---|---|---|---|

| Average power/W | 0.73 | 1.30 | 1.85 | 2.46 | 3.10 | 3.68 | 4.63 |

| Standard deviation/W | 0.080 | 0.12 | 0.012 | 0.020 | 0.027 | 0.012 | 0.059 |

| 3σ/W | 0.24 | 0.37 | 0.035 | 0.061 | 0.081 | 0.037 | 0.18 |

| Frequency/Hz | 1000 | 2000 | 4000 | 6000 | 10,000 |

|---|---|---|---|---|---|

| Average power/W | 2.44 | 2.66 | 2.83 | 3.11 | 3.58 |

| Standard deviation/W | 0.013 | 0.013 | 0.0096 | 0.017 | 0.10 |

| 3σ/W | 0.040 | 0.040 | 0.029 | 0.050 | 0.31 |

| Power/W | Scribing Speed (mm/min) | Laser Power Density/(W/mm2) | Measurement Average Value | Standard Deviation | Prediction Value of Equation (13) | Prediction Accuracy of Equation (13) | Prediction Value of Equation (14) | Prediction Accuracy of Equation (14) |

|---|---|---|---|---|---|---|---|---|

| 0.68 | 13.333 | 0.34 | 80.314 | 2.915 | 70.6766 | 88.00% | 71.762 | 89.35% |

| 2.67 | 40 | 0.445 | 107.766 | 2.857 | 89.5231 | 83.07% | 91.633 | 85.03% |

| 1.315 | 17.15 | 0.511 | 129.357 | 2.164 | 101.369 | 78.36% | 104.124 | 80.49% |

| 1.97 | 24 | 0.547 | 120.658 | 2.942 | 107.831 | 89.37% | 110.937 | 91.94% |

| 4.915 | 30 | 1.092 | 209.695 | 2.287 | 205.653 | 98.07% | 214.078 | 97.91% |

| 3.91 | 20 | 1.303 | 263.722 | 2.368 | 243.525 | 92.34% | 254.010 | 96.32% |

| 3.29 | 15 | 1.462 | 300.700 | 3.051 | 272.064 | 90.48% | 284.100 | 94.48% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Liu, Q.; Sun, P.; Ning, Z.; Wang, L. Study on Model and Experimental of Laser Scribing Parameter of Maskant in Chemical Milling for Aerospace Applications. Appl. Sci. 2022, 12, 2914. https://doi.org/10.3390/app12062914

Wang J, Liu Q, Sun P, Ning Z, Wang L. Study on Model and Experimental of Laser Scribing Parameter of Maskant in Chemical Milling for Aerospace Applications. Applied Sciences. 2022; 12(6):2914. https://doi.org/10.3390/app12062914

Chicago/Turabian StyleWang, Jian, Qiang Liu, Pengpeng Sun, Zhiwei Ning, and Liuquan Wang. 2022. "Study on Model and Experimental of Laser Scribing Parameter of Maskant in Chemical Milling for Aerospace Applications" Applied Sciences 12, no. 6: 2914. https://doi.org/10.3390/app12062914

APA StyleWang, J., Liu, Q., Sun, P., Ning, Z., & Wang, L. (2022). Study on Model and Experimental of Laser Scribing Parameter of Maskant in Chemical Milling for Aerospace Applications. Applied Sciences, 12(6), 2914. https://doi.org/10.3390/app12062914