Sensitivity Analysis for Transient Thermal Problems Using the Complex-Variable Finite Element Method

Abstract

1. Introduction

2. Background

2.1. Finite Element Method Formulation for Transient Heat Transfer Problems

2.2. Numerical Differentiation by CTSE

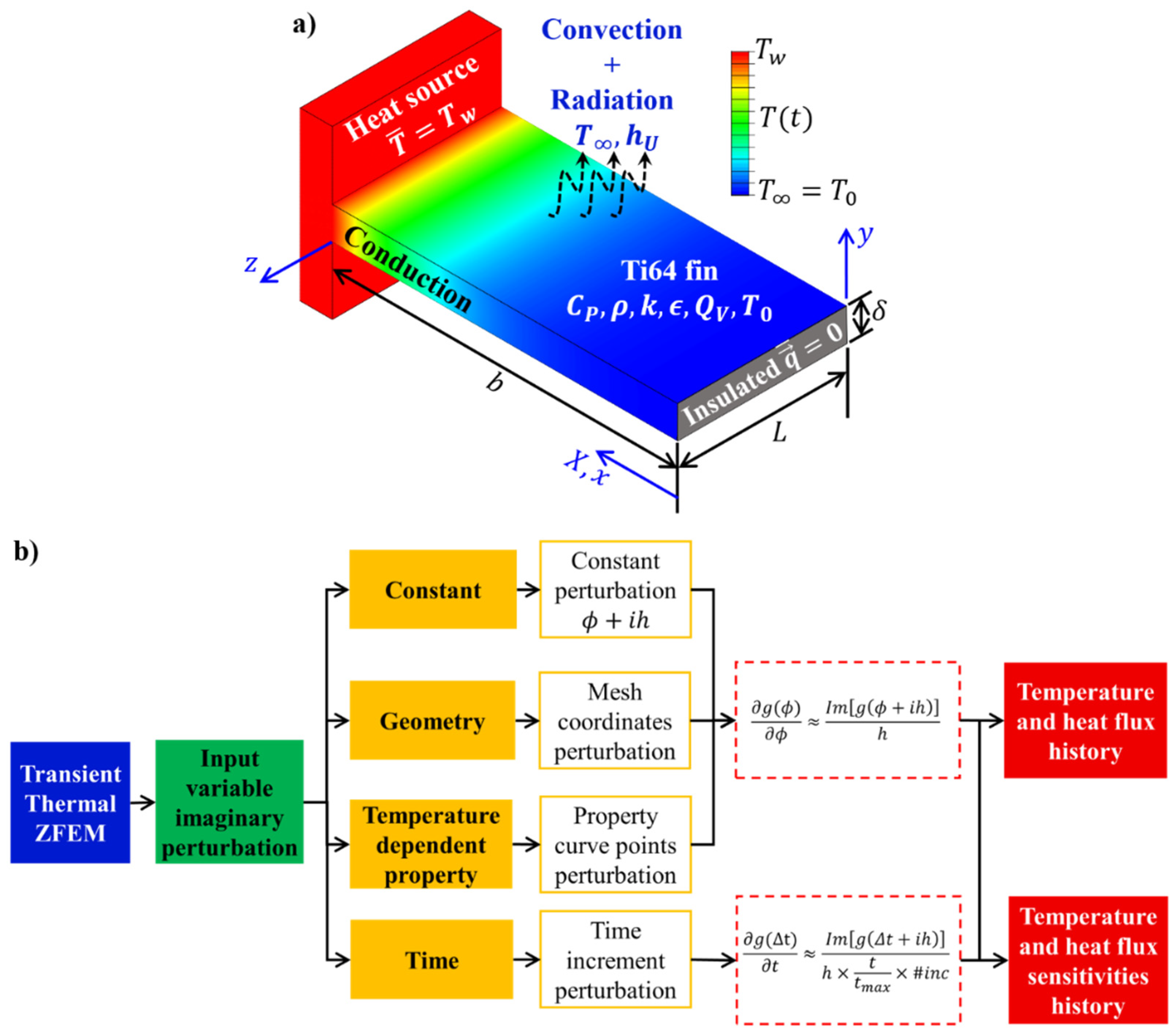

3. Sensitivity Analysis in Transient Heat Transfer Problems Using Transient Thermal ZFEM

- Constant inputs: to obtain sensitivities with respect to the input variables in the model that are constant, the procedure presented in Equation (13) can be applied with only a small imaginary perturbation applied to the variable of interest. For instance, to obtain sensitivities with respect to , we evaluated the model is evaluated with a value of .

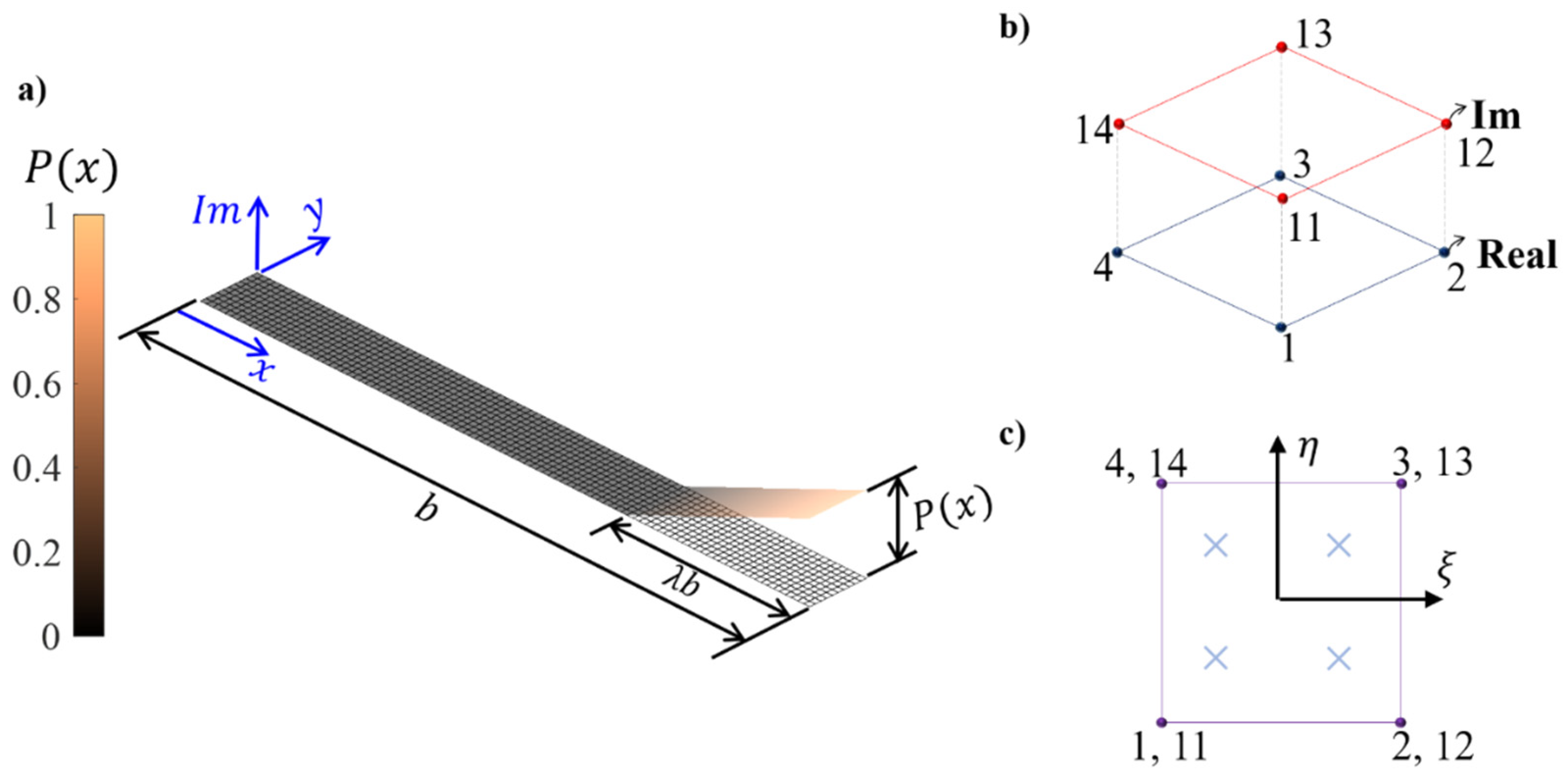

- Geometry sensitivities: to obtain sensitivities with respect to geometric shapes, perturbations to the geometry are required. In Transient Thermal ZFEM, the domain shape is represented by the nodal coordinates. As previously mentioned, the nodal coordinates are converted to complex-variable. For reference, Figure 2a shows a mesh where the nodal coordinates are in the plane xy, and the out of plane represents the imaginary component . Moreover, Figure 2b shows the representation of a planar element with real and imaginary coordinates. To obtain sensitivities with respect to the geometry, the imaginary component of the nodal coordinates should be perturbed according to the following guidelines: First, the direction of the perturbation should be selected. For instance, considering sensitivities with respect to the length in the fin problem (see Figure 2a), as is parallel to the and its boundaries normal to that axis, the perturbation should be applied by translating the imaginary nodal coordinates along the direction of positive axis. Second, a fraction of the nodes () should be selected in the mesh to be perturbed. As presented in Figure 2a, can take values from zero to one. The selected value for this fraction depends on the balance between precision and computational time. This parameter is problem-dependent and could be determined with convergence analysis. However, previous works have shown that considering a value of large enough to perturb at least two elements normal to the boundary is enough for most problems [60,71,86,87]. Next, a perturbation function is selected. In Figure 2a a linear is considered. This function has a minimum value of zero and a maximum value of one. The maximum and minimum values of are located along the geometric boundaries of dimension . Finally, the fraction of the imaginary coordinates of the nodes are shifted in the selected imaginary direction, a magnitude , and the sensitivity is obtained following Equation (13). An example of this perturbation scheme is presented in Figure 2a, where the wireframe mesh presents the real components of the nodal coordinates and surface pointing out of the plane, representing the perturbation on the imaginary axis.

- Temperature-dependent properties: to obtain sensitivities with respect to temperature-dependent properties, the properties should be defined for any given temperature; therefore, fitting or interpolating from experimental values is necessary. After fitting, the perturbation is applied by shifting units in the imaginary axis of the resulting temperature-dependent curve, and the perturbed function is used to perform the calculations as usual. This procedure is analogous to the perturbation of a constant parameter. Finally, Equation (13). is used to obtain the numerical sensitivities. An example of the fin problem is presented in Section 4.3.

- Time sensitivities: to obtain sensitivities with respect to time, the time increment is perturbed by a value in the imaginary component. Then the standard solution method is applied. After the model is solved, the time sensitivities are calculated using Equation (15). The time function in the denominator of Equation (15) compared to Equation (13) is a consequence of the numerical time integration of the imaginary perturbation associated where is the total number of converged times increments in the solution. A convergence study should be performed on the time increment to determine the correct balance between computational time and accuracy.

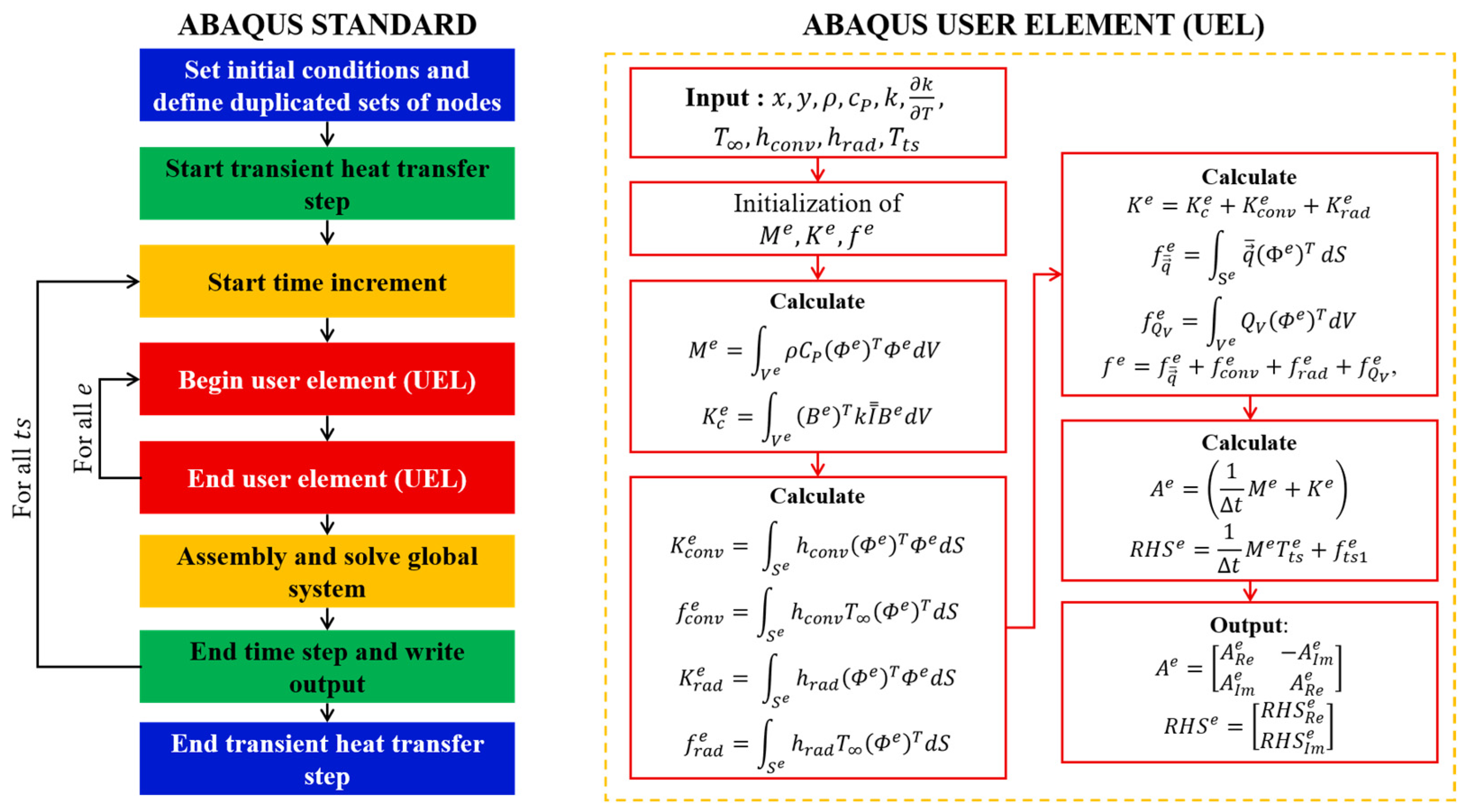

Solution of Complex-Valued System of Equations: Cauchy-Riemann Matrix Notation

4. Numerical Example: Transient Fin Problem

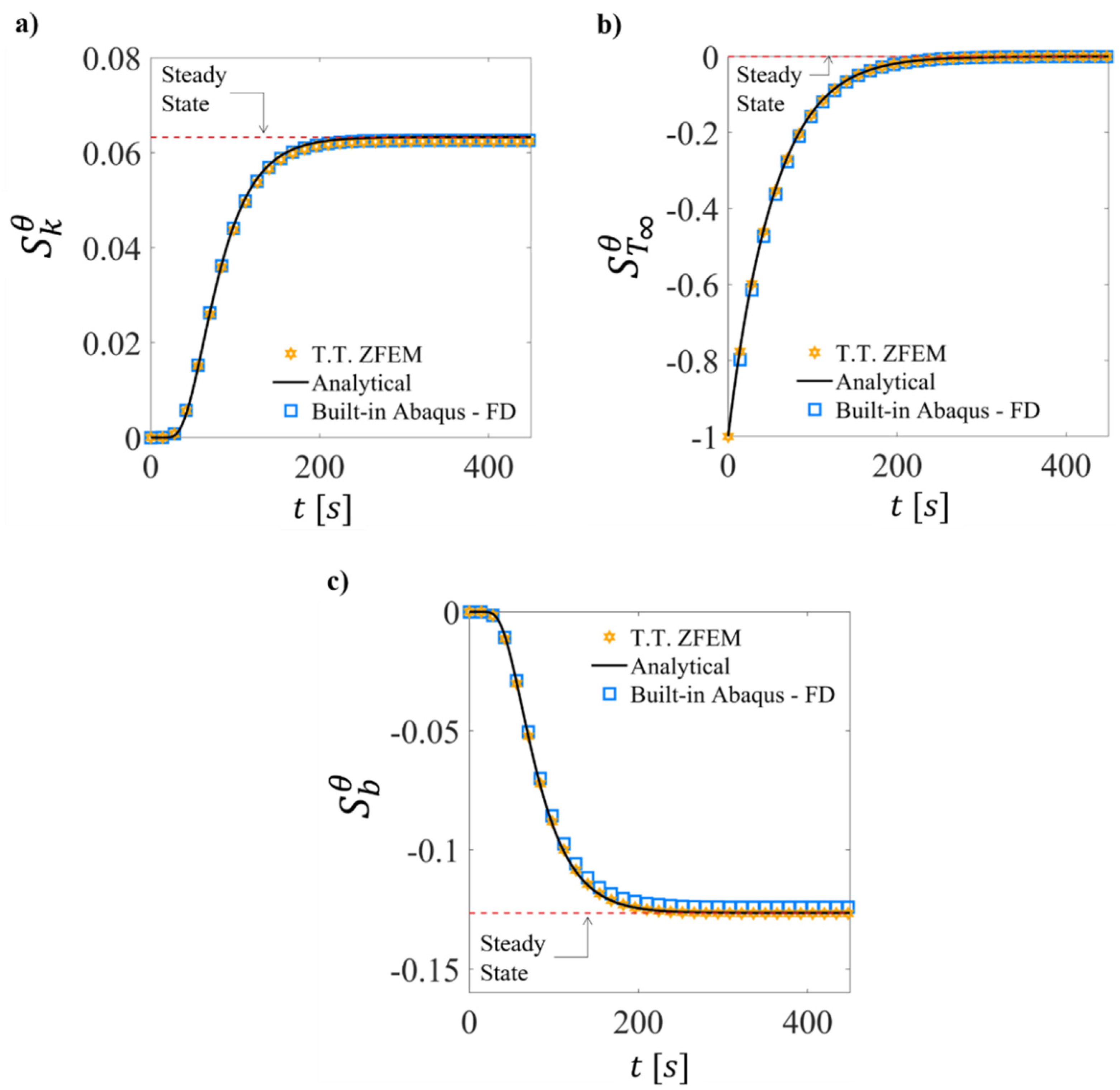

4.1. Sensitivity Analysis of Temperature History

Computational Efficiency of Transient Thermal ZFEM

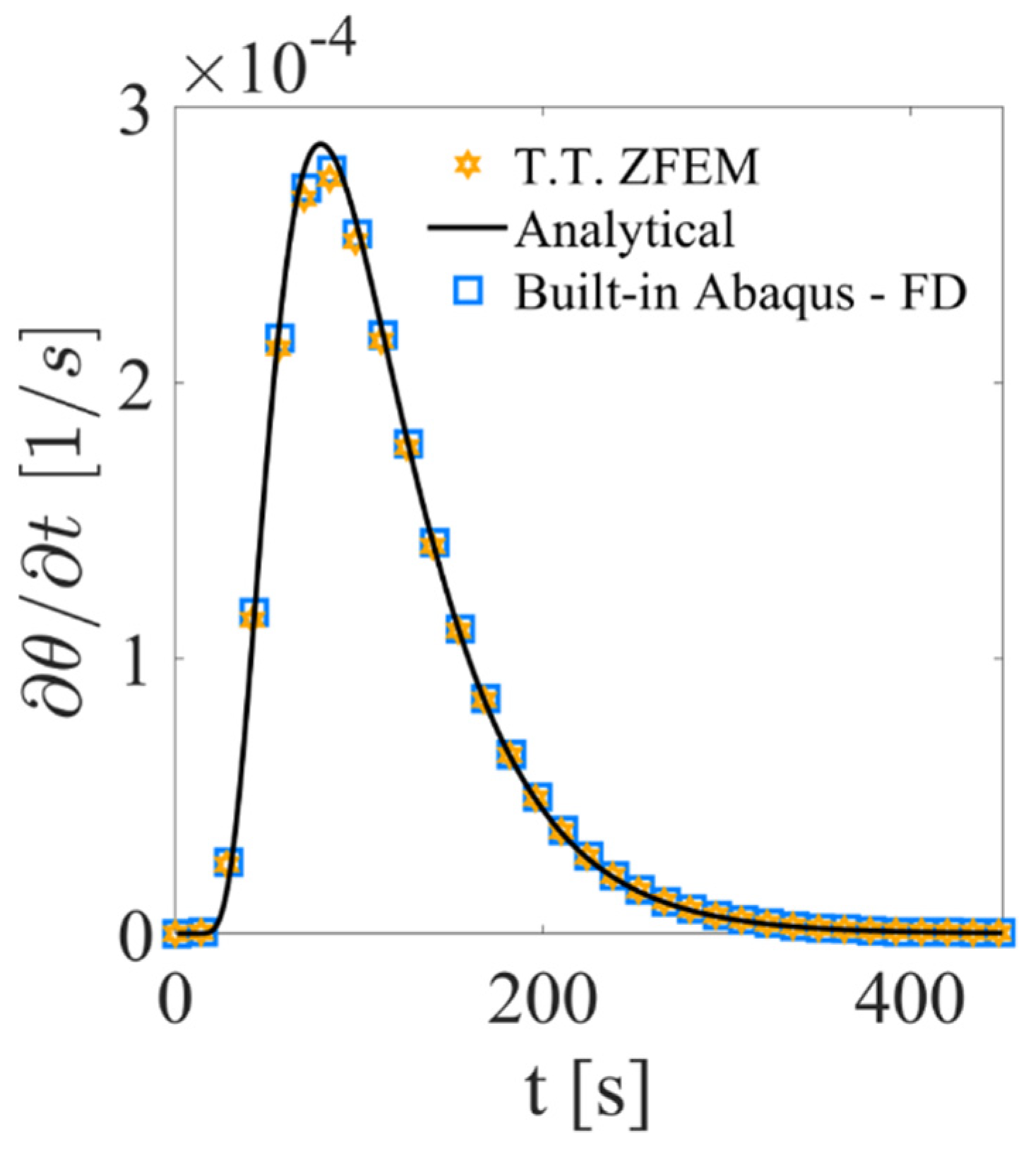

4.2. Heating Rate

4.3. Sensitivity Analysis of Temperature History for a Fin with Temperature-Dependent Specific Heat

4.4. Sensitivity Analysis of the Heat Flux History: Defining the Fin’s Performance

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Joardder, M.U.H.; Hasan Masud, M.; Joardder, M.U.H.; Masud, M.H. Possible solution of food preservation techniques. In Food Preservation in Developing Countries: Challenges and Solutions; Springer International Publishing: Berlin, Germany, 2019; pp. 199–218. [Google Scholar]

- Mo, J.; Groot, R.D.; McCartney, G.; Guo, E.; Bent, J.; van Dalen, G.; Schuetz, P.; Rockett, P.; Lee, P.D. Ice crystal coarsening in ice cream during cooling: A comparison of theory and experiment. Crystals 2019, 9, 321. [Google Scholar] [CrossRef]

- Zou, H.; Pei, P.; Wang, C.; Hao, D. A numerical Study on heat transfer performances of horizontal ground heat exchangers in ground-Source heat pumps. PLoS ONE 2021, 16, e0250583. [Google Scholar] [CrossRef] [PubMed]

- Kant, K.; Biwole, P.H.; Shukla, A.; Sharma, A.; Gorjian, S. Heat transfer and energy storage performances of phase change materials encapsulated in honeycomb cells. J. Energy Storage 2021, 38, 102507. [Google Scholar] [CrossRef]

- Huan, H.; Liu, L.; Huan, B.; Chen, X.; Zhan, J.; Liu, Q. A theoretical investigation of modelling the temperature measurement in oil pipelines with edge devices. Meas. J. Int. Meas. Confed. 2021, 168, 108440. [Google Scholar] [CrossRef]

- Kotrbacek, P.; Bellerova, H.; Luks, T.; Raudensky, M. Heat transfer correlations for secondary cooling in continuous casting. Steel Res. Int. 2021, 92, 2000465. [Google Scholar] [CrossRef]

- Stieven, G.d.M.; Soares, D.d.R.; Oliveira, E.P.; Lins, E.F. Interfacial heat transfer coefficient in unidirectional permanent mold casting: Modeling and inverse estimation. Int. J. Heat Mass Transf. 2021, 166, 120765. [Google Scholar] [CrossRef]

- Inyushkin, A.V.; Taldenkov, A.N.; Ralchenko, V.G.; Bolshakov, A.P.; Khomich, A.V. Isotope effect in thermal conductivity of polycrystalline CVD-Diamond: Experiment and theory. Crystals 2021, 11, 322. [Google Scholar] [CrossRef]

- Gu, C.; Lian, J.; Bao, Y.; Xiao, W.; Münstermann, S. Numerical study of the effect of inclusions on the residual stress distribution in high-Strength martensitic steels during cooling. Appl. Sci. 2019, 9, 455. [Google Scholar] [CrossRef]

- Thi, V.D.; Khelifa, M.; Oudjene, M.; El Ganaoui, M.; Rogaume, Y. Finite element analysis of heat transfer through timber elements exposed to fire. Eng. Struct. 2017, 143, 11–21. [Google Scholar] [CrossRef]

- Lee, H.; Seong, J.; Chung, W. Correlation analysis of heat curing and compressive strength of carbon nanotube–Cement mortar composites at Sub-Zero temperatures. Crystals 2021, 11, 1182. [Google Scholar] [CrossRef]

- Righetti, G.; Zilio, C.; Doretti, L.; Longo, G.A.; Mancin, S. On the design of phase change materials based thermal management systems for electronics cooling. Appl. Therm. Eng. 2021, 196, 117276. [Google Scholar] [CrossRef]

- Alhusseny, A.; Al-Fatlawi, A.; Al-Aabidy, Q.; Nasser, A.; Al-Zurfi, N. Dissipating the heat generated in high-Performance electronics using graphitic foam heat-Sinks cooled with a dielectric liquid. Int. Commun. Heat Mass Transf. 2021, 127, 105478. [Google Scholar] [CrossRef]

- Nakazawa, Y.; Imajo, S.; Matsumura, Y.; Yamashita, S.; Akutsu, H. Thermodynamic picture of dimer-Mott organic superconductors revealed by heat capacity measurements with external and chemical pressure control. Crystals 2018, 8, 143. [Google Scholar] [CrossRef]

- Cui, W.; Gawecka, K.A.; Taborda, D.M.G.; Potts, D.M.; Zdravković, L. Time-Step constraints in transient coupled finite element analysis. Int. J. Numer. Methods Eng. 2016, 106, 953–971. [Google Scholar] [CrossRef]

- Wcisło, B.; Pamin, J. Local and non-Local thermomechanical modeling of elastic-Plastic materials undergoing large strains. Int. J. Numer. Methods Eng. 2017, 109, 102–124. [Google Scholar] [CrossRef]

- Jahan, S.A.; El-Mounayri, H. A thermomechanical analysis of conformal cooling channels in 3D printed plastic injection molds. Appl. Sci. 2018, 8, 2567. [Google Scholar] [CrossRef]

- Jantos, D.R.; Hackl, K.; Junker, P. An accurate and fast regularization approach to thermodynamic topology optimization. Int. J. Numer. Methods Eng. 2019, 117, 991–1017. [Google Scholar] [CrossRef]

- Moges, T.; Yan, W.; Lin, S.; Ameta, G.; Fox, J.; Witherell, P. Quantifying uncertainty in laser powder bed fusion additive manufacturing models and simulations. In Proceedings of the Solid Freeform Fabrication 2018: Proceedings of the 29th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 13–15 August 2018; pp. 1913–1928. [Google Scholar]

- Pierre, T.; Jiménez-Saelices, C.; Seantier, B.; Grohens, Y. Transient pulsed technique to characterize the radiative and conductive properties of bio aerogels. Int. J. Therm. Sci. 2017, 116, 63–72. [Google Scholar] [CrossRef]

- Frivaldsky, M.; Pavelek, M.; Donic, T. Modeling and experimental verification of induction heating of thin molybdenum sheets. Appl. Sci. 2021, 11, 647. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, J.; Ni, H.; Zhu, Y.; Wang, X.; Wan, X.; Chen, K. Optimization of AlSi10MgMn alloy heat treatment process based on orthogonal test and grey relational analysis. Crystals 2021, 11, 385. [Google Scholar] [CrossRef]

- Alam, T.; Kumar, R. Stagnation point transient heat flux measurement analysis from coaxial thermocouples. Meas. J. Int. Meas. Confed. 2018, 128, 352–361. [Google Scholar] [CrossRef]

- Manjhi, S.K.; Kumar, R. Stagnation point transient heat flux measurement analysis from coaxial thermocouples. Exp. Heat Transf. 2018, 31, 405–424. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, K.; Duan, J.; Lei, J.; Wu, J.; Xu, J.; Zhang, K.; Duan, J.; Lei, J.; Wu, J.; et al. Systematic comparison on convective heat transfer characteristics of several pin fins for turbine cooling. Crystals 2021, 11, 977. [Google Scholar] [CrossRef]

- Ye, B.; Rubel, M.R.H.; Li, H. Design and optimization of cooling plate for battery module of an electric vehicle. Appl. Sci. 2019, 9, 754. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, T.; Prakash, S.; Jaluria, Y. Experimental and numerical study of transient electronic chip cooling by liquid flow in microchannel heat sinks. Numer. Heat Transf. Part A Appl. 2014, 65, 627–643. [Google Scholar] [CrossRef]

- Annaratone, D. Transient heat transfer. SpringerBriefs Appl. Sci. Technol. 2011, 1–46. [Google Scholar] [CrossRef]

- Incropera, F.; Dewitt, D.; Bergman, T.; Lavine, A. Fundamentals of Heat and Mass Transfer, 6th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; ISBN 978-0-471-45728-2. [Google Scholar]

- Shevchuk, I.V. Unsteady conjugate laminar heat transfer of a rotating non-Uniformly heated disk: Application to the transient experimental technique. Int. J. Heat Mass Transf. 2006, 49, 3530–3537. [Google Scholar] [CrossRef]

- Indinger, T.; Shevchuk, I.V. Transient laminar conjugate heat transfer of a rotating disk: Theory and numerical simulations. Int. J. Heat Mass Transf. 2004, 47, 3577–3581. [Google Scholar] [CrossRef]

- Lienhard, J.H.; Lienhard, J.H. A Heat Transfer Textbook, 5th ed.; Phlogiston Press: Cambridge, MA, USA, 2020; ISBN 0486837351. [Google Scholar]

- Li, F.; Ning, J.; Liang, S.Y. Analytical modeling of the temperature using uniform moving heat source in planar induction heating process. Appl. Sci. 2019, 9, 1445. [Google Scholar] [CrossRef]

- Llano-Sánchez, L.E.; Domínguez-Cajeli, D.M.; Ruiz-Cárdenas, L.C. Thermal transfer analysis of tubes with extended surface with fractal design. Rev. Fac. Ing. 2018, 27, 31–37. [Google Scholar] [CrossRef]

- Levin, P.P.; Shitzer, A.; Hetsroni, G. Numerical optimization af a PCM-Based heat sink with internal fins. Int. J. Heat Mass Transf. 2013, 61, 638–645. [Google Scholar] [CrossRef]

- Sinha, K.K.; Ahirwar, P. Computational analysis of heat sink or extended surface. Int. Res. J. Eng. Technol. 2017, 4, 70–79. [Google Scholar]

- Rincón Tabares, J.S.; Perdomo-Hurtado, L.; Aragón, J.L. Study of gasketed-Plate heat exchanger performance based on energy efficiency indexes. Appl. Therm. Eng. 2019, 159, 113902. [Google Scholar] [CrossRef]

- Rahimi-Gorji, M.; Pourmehran, O.; Hatami, M.; Ganji, D.D. Statistical optimization of microchannel heat sink (mchs) geometry cooled by different nanofluids using RSM analysis. Eur. Phys. J. Plus 2015, 130, 1–21. [Google Scholar] [CrossRef]

- Viguerie, A.; Auricchio, F. Numerical solution of additive manufacturing problems using a two-Level method. Int. J. Numer. Methods Eng. 2021. [Google Scholar] [CrossRef]

- Galati, M.; Di Mauro, O.; Iuliano, L. Finite element simulation of multilayer electron beam melting for the improvement of build quality. Crystals 2020, 10, 532. [Google Scholar] [CrossRef]

- Fan, H.; Wang, R.; Xu, Z.; Duan, H.; Chen, D. Migration and enrichment behaviors of Ca and Mg elements during cooling and crystallization of boron-Bearing titanium slag melt. Crystals 2021, 11, 888. [Google Scholar] [CrossRef]

- Feng, Z.; Wen, Z.; Lu, G.; Zhao, Y. Influence of cooling scenarios on the evolution of microstructures in nickel-Based single crystal superalloys. Crystals 2022, 12, 74. [Google Scholar] [CrossRef]

- Kawaguchi, G.; Yamamoto, H.M. Control of organic superconducting field-Effect transistor by cooling rate. Crystals 2019, 9, 605. [Google Scholar] [CrossRef]

- Razavi, S.; Gupta, H.V. What do we mean by sensitivity analysis? The need for comprehensive characterization of “global” Sensitivity in earth and environmental systems models. Water Resour. Res. 2015, 51, 3070–3092. [Google Scholar] [CrossRef]

- Özisik, M.N.; Orlande, H.R.B. Inverse Heat Transfer; Routledge: London, UK, 2018. [Google Scholar]

- Du, W.F.; Zhuo, S.; Yang, L.; Zhao, R.C. Numerical simulation and parameter sensitivity analysis of coupled heat transfer by PCCS containment wall. Appl. Therm. Eng. 2017, 113, 867–877. [Google Scholar] [CrossRef]

- Wang, C.; Matthies, H.G. Non-Probabilistic interval process model and method for uncertainty analysis of transient heat transfer problem. Int. J. Therm. Sci. 2019, 144, 147–157. [Google Scholar] [CrossRef]

- Mirkoohi, E.; Ning, J.; Bocchini, P.; Fergani, O.; Chiang, K.-N.; Liang, S. Thermal modeling of temperature distribution in metal additive manufacturing considering effects of build layers, latent heat, and temperature-Sensitivity of material properties. J. Manuf. Mater. Process. 2018, 2, 63. [Google Scholar] [CrossRef]

- Lane, B.; Heigel, J.; Ricker, R.; Zhirnov, I.; Khromschenko, V.; Weaver, J.; Phan, T.; Stoudt, M.; Mekhontsev, S.; Levine, L. Measurements of melt pool geometry and cooling rates of individual laser traces on IN625 bare plates. Integr. Mater. Manuf. Innov. 2020, 9, 16–30. [Google Scholar] [CrossRef]

- Milani Shirvan, K.; Ellahi, R.; Mirzakhanlari, S.; Mamourian, M. Enhancement of heat transfer and heat exchanger effectiveness in a double pipe heat exchanger filled with porous media: Numerical simulation and sensitivity analysis of turbulent fluid flow. Appl. Therm. Eng. 2016, 109, 761–774. [Google Scholar] [CrossRef]

- Martins, J.R.R.A.; Hwang, J.T. Review and Unification of Methods for Computing Derivatives of Multidisciplinary Computational Models. Am. Inst. Aeronaut. Astronaut. 2013, 51, 2582–2599. [Google Scholar] [CrossRef]

- Baydin, A.G.; Pearlmutter, B.A.; Radul, A.A.; Siskind, J.M. Automatic differentiation in machine learning: A survey. J. Mach. Learn. Res. 2015, 18, 1–43. [Google Scholar]

- Jayapragasam, P.; Le Bideau, P.; Loulou, T. Computing sensitivity coefficients by using complex differentiation: Application to heat conduction problem. Numer. Heat Transf. Part B Fundam. 2018, 74, 729–745. [Google Scholar] [CrossRef]

- Margossian, C.C. A review of automatic differentiation and its efficient implementation. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2019, 9, e1305. [Google Scholar] [CrossRef]

- Garza, J.E.; Millwater, H.R. Sensitivity Analysis in Structural Dynamics using the ZFEM Complex Variable Finite Element Method. In Proceedings of the 54th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2013; pp. 1–16. [Google Scholar] [CrossRef][Green Version]

- Squire, W.; Trapp, G. Using complex variables to estimate derivatives of real functions. SIAM Rev. 1998, 40, 110–112. [Google Scholar] [CrossRef]

- Lyness, J.N.; Moler, C.B. Numerical differentiation of analytic functions. SIAM J. Numer. Anal. 1967, 4, 202–210. [Google Scholar] [CrossRef]

- Cui, M.; Gao, X.; Chen, H. A new inverse approach for the equivalent gray radiative property of a non-Gray medium using a modified zonal method and the complex-Variable-differentiation method. J. Quant. Spectrosc. Radiat. Transf. 2011, 112, 1336–1342. [Google Scholar] [CrossRef]

- Gao, X.W.; He, M.C. A new inverse analysis approach for multi-region heat conduction bem using complex-Variable-Differentiation method. Eng. Anal. Bound. Elem. 2005, 29, 788–795. [Google Scholar] [CrossRef]

- Voorhees, A.; Millwater, H.; Bagley, R. Complex variable methods for shape sensitivity of finite element models. Finite Elem. Anal. Des. 2011, 47, 1146–1156. [Google Scholar] [CrossRef]

- Millwater, H.; Wagner, D.; Baines, A.; Lovelady, K. Improved WCTSE method for the generation of 2D weight functions through implementation into a commercial finite element code. Eng. Fract. Mech. 2013, 109, 302–309. [Google Scholar] [CrossRef]

- Jaluria, Y. Solution of inverse problems in thermal systems. J. Therm. Sci. Eng. Appl. 2020, 12. [Google Scholar] [CrossRef]

- Daouas, N. An Alternative sensitivity method for a two-Dimensional inverse heat conduction-radiation problem based on transient hot-Wire measurements. Numer. Heat Transf. Part B Fundam. 2018, 73, 106–128. [Google Scholar] [CrossRef]

- Zhou, Z.F.; Xu, T.Y.; Chen, B. Algorithms for the estimation of transient surface heat flux during ultra-Fast surface cooling. Int. J. Heat Mass Transf. 2016, 100, 1–10. [Google Scholar] [CrossRef]

- Cui, M.; Gao, X.; Zhang, J. A new approach for the estimation of temperature-Dependent thermal properties by solving transient inverse heat conduction problems. Int. J. Therm. Sci. 2012, 58, 113–119. [Google Scholar] [CrossRef]

- Cui, M.; Yang, K.; Xu, X.L.; Wang, S.D.; Gao, X.W. A modified levenberg-Marquardt algorithm for simultaneous estimation of multi-Parameters of boundary heat flux by solving transient nonlinear inverse heat conduction problems. Int. J. Heat Mass Transf. 2016, 97, 908–916. [Google Scholar] [CrossRef]

- Cui, M.; Li, N.; Liu, Y.; Gao, X. Robust Inverse approach for two-Dimensional transient nonlinear heat conduction problems. J. Thermophys. Heat Transf. 2015, 29, 253–262. [Google Scholar] [CrossRef]

- Voorhees, A.; Bagley, R.; Millwater, H.; Golden, P. Application of Complex Variable Methods for Fatigue Sensitivity Analysis. In Proceedings of the 50th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Palm Springs, CA, USA, 4–7 May 2009; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2009; p. 2711. [Google Scholar]

- Voorhees, A.; Millwater, H.; Bagley, R.; Golden, P. Fatigue sensitivity analysis using complex variable methods. Int. J. Fatigue 2012, 40, 61–73. [Google Scholar] [CrossRef]

- Wagner, D.; Millwater, H. 2D weight function development using a complex taylor series expansion method. Eng. Fract. Mech. 2012, 86, 23–37. [Google Scholar] [CrossRef]

- Millwater, H.; Wagner, D.; Baines, A.; Montoya, A. A virtual crack extension method to compute energy release rates using a complex variable finite element method. Eng. Fract. Mech. 2016, 162, 95–111. [Google Scholar] [CrossRef]

- Wagner, D.; Garcia, M.J.; Montoya, A.; Millwater, H. A finite element-Based adaptive energy response function method for 2D curvilinear progressive fracture. Int. J. Fatigue 2019, 127, 229–245. [Google Scholar] [CrossRef]

- Ramirez-Tamayo, D.; Soulami, A.; Gupta, V.; Restrepo, D.; Montoya, A.; Millwater, H. A complex-Variable cohesive finite element subroutine to enable efficient determination of interfacial cohesive material parameters. Eng. Fract. Mech. 2021, 247, 107638. [Google Scholar] [CrossRef]

- Montoya, A.; Fielder, R.; Gomez-Farias, A.; Millwater, H. Finite-Element sensitivity for plasticity using complex variable methods. J. Eng. Mech. 2015, 141, 04014118. [Google Scholar] [CrossRef]

- Fielder, R.; Montoya, A.; Millwater, H.; Golden, P. Residual stress sensitivity analysis using a complex variable finite element method. Int. J. Mech. Sci. 2017, 133, 112–120. [Google Scholar] [CrossRef]

- Gomez-Farias, A.; Montoya, A.; Millwater, H. Complex finite element sensitivity method for creep analysis. Int. J. Press. Vessel. Pip. 2015, 132–133, 27–42. [Google Scholar] [CrossRef]

- Fielder, R.; Millwater, H.; Montoya, A.; Golden, P. Efficient estimate of residual stress variance using complex variable finite element methods. Int. J. Press. Vessel. Pip. 2019, 173, 101–113. [Google Scholar] [CrossRef]

- Chun, J. Reliability-Based design optimization of structures using complex-Step approximation with sensitivity analysis. Appl. Sci. 2021, 11, 4708. [Google Scholar] [CrossRef]

- Montoya, A.; Millwater, H. Sensitivity analysis in thermoelastic problems using the complex finite element method. J. Therm. Stress. 2017, 40, 302–321. [Google Scholar] [CrossRef]

- Garza, J.; Millwater, H. Multicomplex newmark-Beta time integration method for sensitivity analysis in structural dynamics. AIAA J. 2015, 53, 1188–1198. [Google Scholar] [CrossRef]

- Navarro, J.D.; Millwater, H.R.; Montoya, A.H.; Restrepo, D. Arbitrary-Order sensitivity analysis in phononic metamaterials using the multicomplex taylor series expansion method coupled with bloch’s theorem. J. Appl. Mech. 2022, 89, 1–43. [Google Scholar] [CrossRef]

- Taler, J.; Ocłoń, P. Finite element method in steady-State and transient heat conduction. In Encyclopedia of Thermal Stresses; Springer: Dordrecht, The Netherlands, 2014; pp. 1604–1633. [Google Scholar]

- Logan, D.L. A First Course in the Finite Element Method; Cengage Learning: Boston, MA, USA, 2011; ISBN 9781133169055. [Google Scholar]

- Morville, S.; Carin, M.; Peyre, P.; Gharbi, M.; Carron, D.; Le Masson, P.; Fabbro, R. 2D longitudinal modeling of heat transfer and fluid flow during multilayered direct laser metal deposition process. J. Laser Appl. 2012, 24, 032008. [Google Scholar] [CrossRef]

- de La Batut, B.; Fergani, O.; Brotan, V.; Bambach, M.; El Mansouri, M. Analytical and numerical temperature prediction in direct metal deposition of Ti6Al4V. J. Manuf. Mater. Process. 2017, 1, 3. [Google Scholar] [CrossRef]

- Ramirez Tamayo, D.; Montoya, A.; Millwater, H. Complex-Variable finite-Element method for mixed mode fracture and interface cracks. AIAA J. 2018, 56, 4632–4637. [Google Scholar] [CrossRef]

- Montoya, A.; Ramirez-Tamayo, D.; Millwater, H.; Kirby, M. A complex-Variable virtual crack extension finite element method for elastic-Plastic fracture mechanics. Eng. Fract. Mech. 2018, 202, 242–258. [Google Scholar] [CrossRef]

- Price, G.B. An Introduction to Multicomplex Spaces and Functions, 1st ed.; CRC Press: Boca Raton, FL, USA, 1991. [Google Scholar]

- Fike, J.; Alonso, J. The Development of Hyper-Dual Numbers for Exact Second-Derivative Calculations. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011; American Institute of Aeronautics and Astronautics (AIAA): Reston, VA, USA, 2011; pp. 1–17. [Google Scholar]

- Parry, L.; Ashcroft, I.A.; Wildman, R.D. Understanding the effect of laser scan strategy on residual stress in selective laser melting through thermo-Mechanical simulation. Addit. Manuf. 2016, 12, 1–15. [Google Scholar] [CrossRef]

| Parameter Type | Parameter of Interest | Value | Units |

|---|---|---|---|

| Material Properties | |||

| Boundary Conditions | |||

| Initial Conditions | |||

| Geometry | |||

| NRMSE | ||||

|---|---|---|---|---|

| ZFEM | 0.003 | 0.011 | 0.002 | 0.003 |

| FD | 0.003 | 0.009 | 0.009 | 0.019 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rincon-Tabares, J.-S.; Velasquez-Gonzalez, J.C.; Ramirez-Tamayo, D.; Montoya, A.; Millwater, H.; Restrepo, D. Sensitivity Analysis for Transient Thermal Problems Using the Complex-Variable Finite Element Method. Appl. Sci. 2022, 12, 2738. https://doi.org/10.3390/app12052738

Rincon-Tabares J-S, Velasquez-Gonzalez JC, Ramirez-Tamayo D, Montoya A, Millwater H, Restrepo D. Sensitivity Analysis for Transient Thermal Problems Using the Complex-Variable Finite Element Method. Applied Sciences. 2022; 12(5):2738. https://doi.org/10.3390/app12052738

Chicago/Turabian StyleRincon-Tabares, Juan-Sebastian, Juan C. Velasquez-Gonzalez, Daniel Ramirez-Tamayo, Arturo Montoya, Harry Millwater, and David Restrepo. 2022. "Sensitivity Analysis for Transient Thermal Problems Using the Complex-Variable Finite Element Method" Applied Sciences 12, no. 5: 2738. https://doi.org/10.3390/app12052738

APA StyleRincon-Tabares, J.-S., Velasquez-Gonzalez, J. C., Ramirez-Tamayo, D., Montoya, A., Millwater, H., & Restrepo, D. (2022). Sensitivity Analysis for Transient Thermal Problems Using the Complex-Variable Finite Element Method. Applied Sciences, 12(5), 2738. https://doi.org/10.3390/app12052738