The Properties and Durability of Self-Leveling and Thixotropic Mortars with Recycled Sand

Abstract

:Featured Application

Abstract

1. Introduction

- A lack of quality/purity in recycled materials;

- A lack of national instructions for recycling in new concrete in some countries;

- Low replacement rates in low-grade concrete allowed by Standards;

- A lack of documented information available regarding the origins of waste;

- Variable quality of feedstock;

- Contamination risks;

- A lack of trust of end-users in the quality/purity of recycled materials;

- The low price of virgin materials;

- The processing costs of demolition waste to secure high-quality material for recycling.

- (1)

- Reduction in the recycled aggregate porosity:

- ▪

- Accelerated carbonation. The old mortar layer on the RAs contains a high amount of calcium hydroxide and calcium silicate hydrate. The method involves a carbonation reaction with CO2 under the presence of water. The corresponding carbonated products show a volume expansion and partially occupy or even close the porosity of the RAs [19,20].

- ▪

- ▪

- ▪

- ▪

- (2)

- Reduction in the old mortar layer on recycled aggregate surface:

- ▪

- ▪

- Thermal treatment. The heating of the recycled concrete causes the dehydration of old cement stone, which leads to the separation of old mortar layer from the aggregate particles [31].

- (3)

- Property improvement without recycled aggregate modification:

- ▪

- The mixing approach. This involves an atypical mixing of concrete components [32]. In the two-stage mixing approach (TSMA), the mixing water is divided into two portions. In the sand enveloped mixing approach (SEMA), sand and 75% of water are mixed at first, and then the cement is added. After further mixing, the remaining water and coarse aggregate are added. The aim of the approach is to generate a thin cement slurry on the surface of recycled concrete aggregate during the first water addition that covers pores and cracks of the recycled concrete aggregates.

- ▪

- The addition of fiber. The addition of short monofilament fibers in RAC is aimed to control the cracks opening and propagation by the “fibre bridge effect”, thus overcoming the brittle failure mode of the RAC and increasing its tensile and flexural strength [33]

2. Materials and Methods

2.1. Materials

2.2. Methods

- (a)

- a cooling phase, in which the temperature moved from 5 °C (±2 °C) to −20 °C (±2 °C) at a constant rate of 5 °C/h (±0.5 °C/h);

- (b)

- a constant phase in which the temperature was kept constant at −20 °C (±2 °C) for two hours;

- (c)

- a heating phase in which the temperature returns to 5 °C (±2 °C) at the same velocity as step.

3. Results and Discussion

- the poorer mechanical properties of recycled sand in comparison to the natural sand used;

- the higher porosity of recycled sand;

- the presence of adherent cement paste on aggregate;

- the moisture conditions of aggregate;

- a weaker interfacial transition zone (ITZ).

- the formation of gypsum (calcium sulphate dihydrate), leading to softening and loss of concrete strength:Ca(OH)2 + Na2SO4⋅10H2O = CaSO4⋅2H2O + 2NaOH + 8H2O

- The higher amount of gypsum converts tricalcium aluminate (C3A) in the mortars to ettringite (calcium aluminate trisulphate). The expansive reaction leads to high internal stresses and cracking:3CaO⋅1Al2O3 + 26H2O + 3(CaSO4⋅2H2O) = 3CaO⋅1Al2O3⋅3CaSO4⋅32H2O

- The dehydration–dehydroxylation of calcium silicate hydrate (C–S–H gel) in RSPX and RSRX mortars not only involves the cement matrix, but also the recycled aggregate, mainly composed by concrete rubble.

- The higher amount of water vapor produced can easily escape in the more porous structures of mortars produced with recycled aggregate.

4. Conclusions

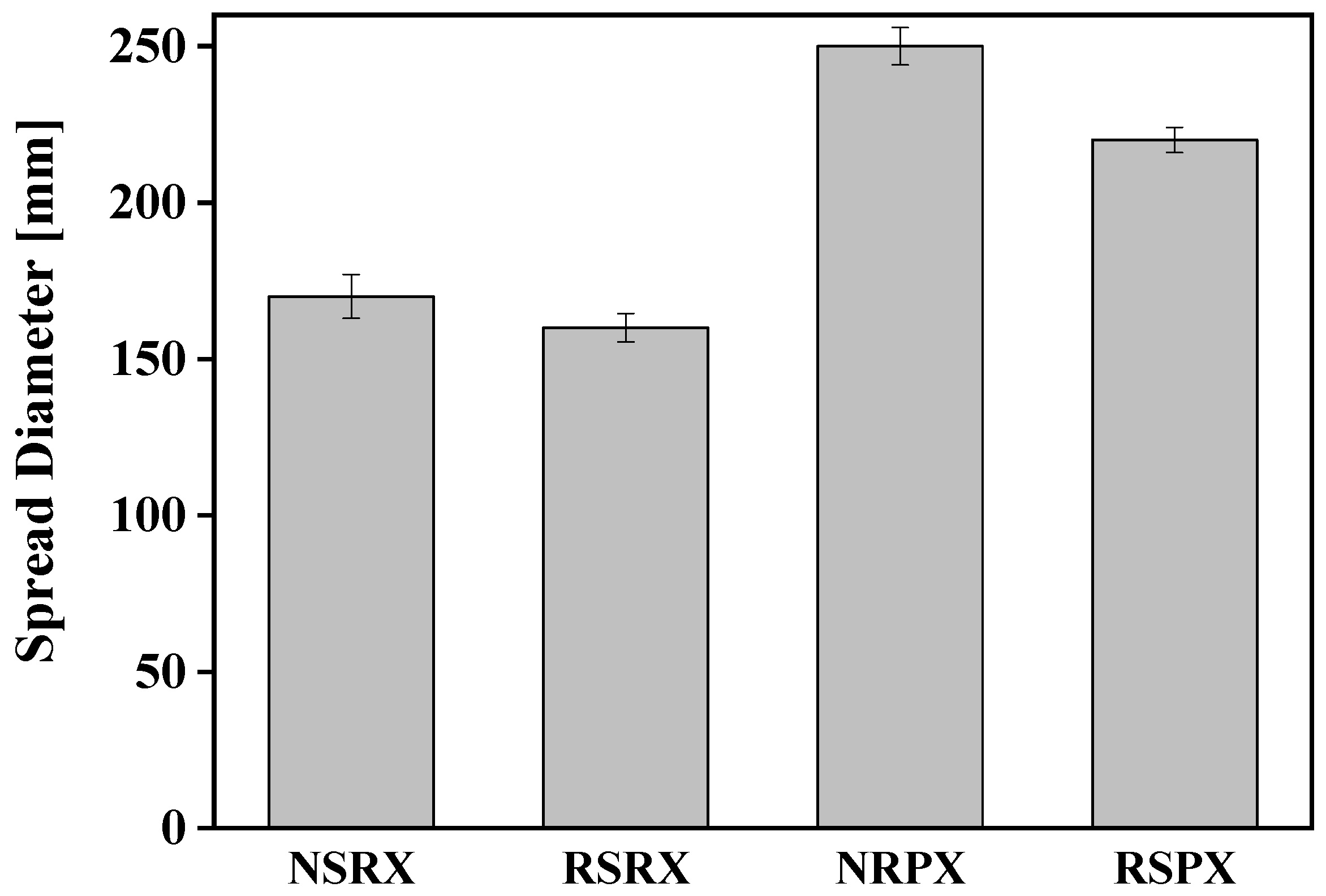

- The use of pre-saturated RS prevented the absorption of free water during the mixing. The workability of RSRX and RSPX mortars was 6% and 12% lower than that of the control mixes, respectively.

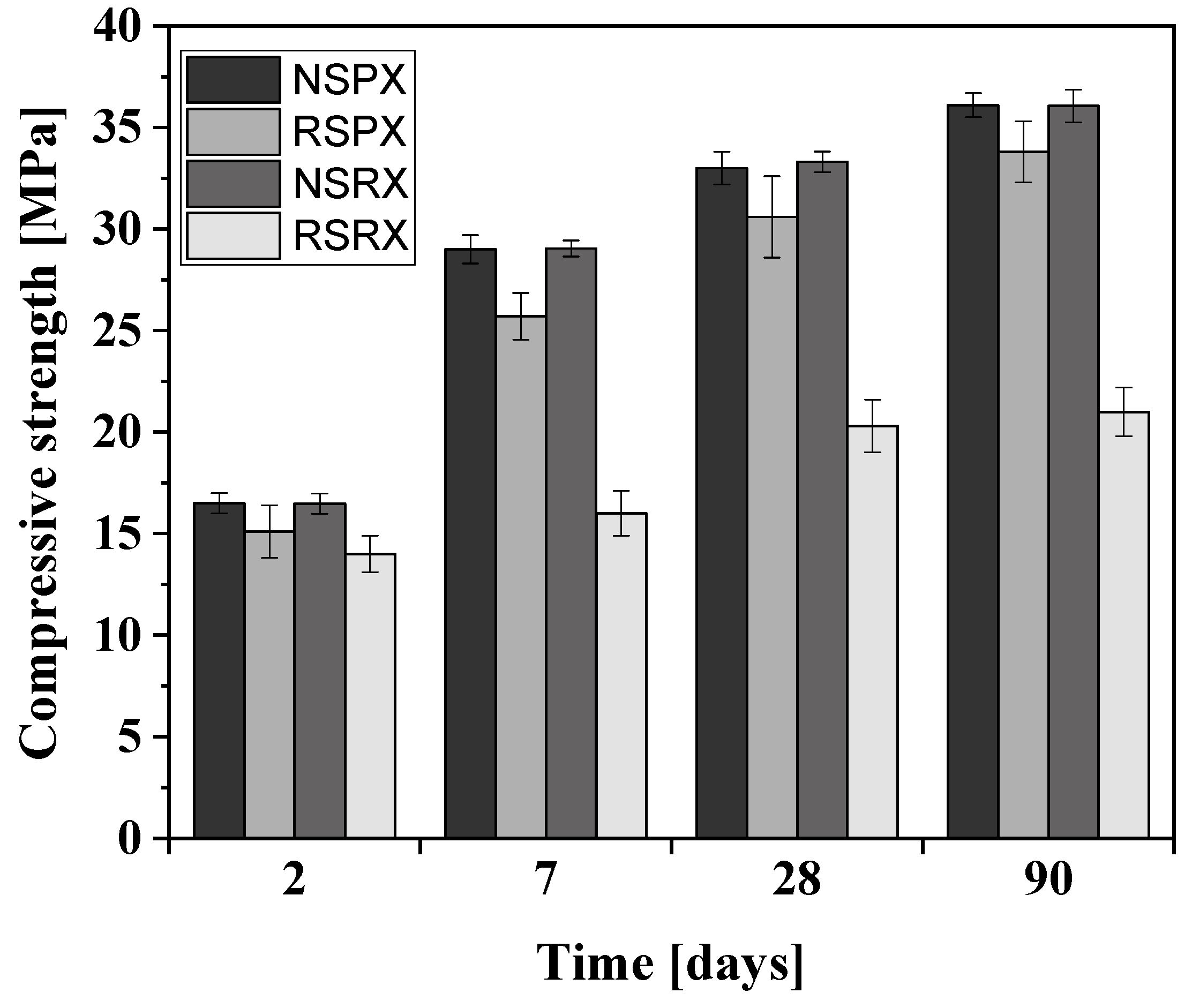

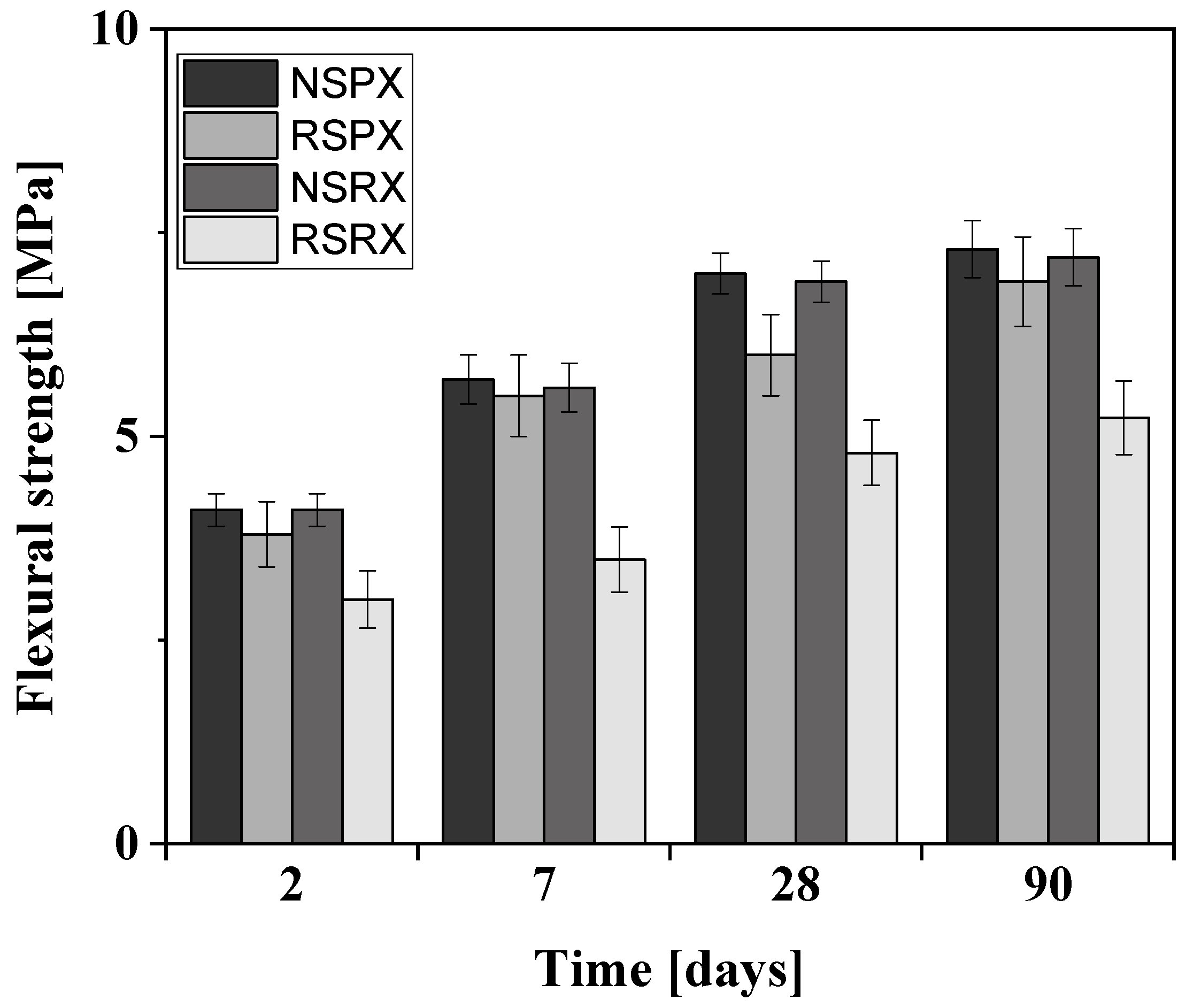

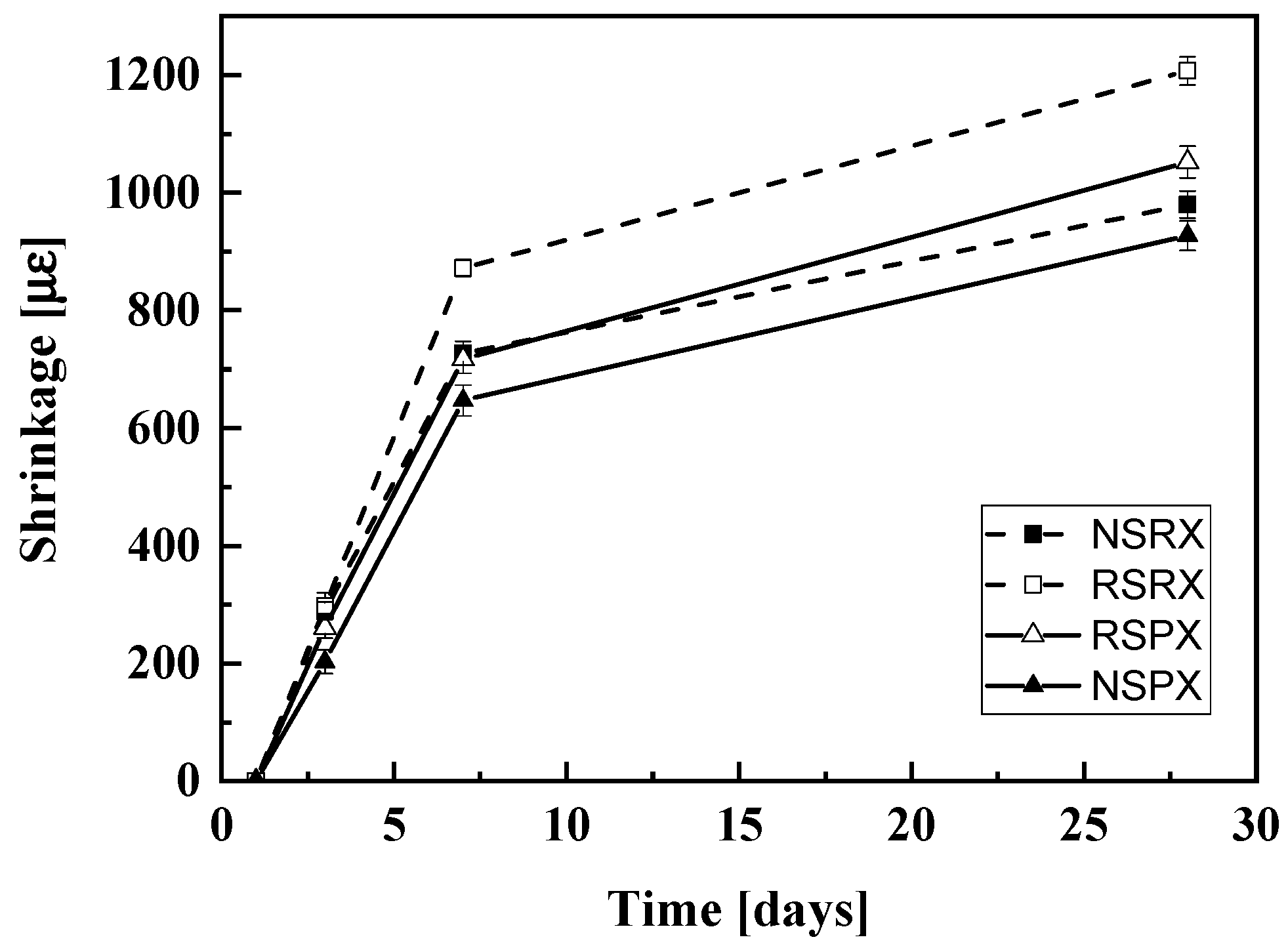

- The thixotropic and self-leveling mortars produced with recycled aggregate showed porosities of 35.6% and 32.6%, respectively. The higher porosity affected both their drying shrinkage behaviour and mechanical properties. In particular, RSRX mortars showed an increase of 23.1% in the drying shrinkage and a loss of about 40% in the compressive strength compared to the control mortar. RSPX mortar showed a loss of about 6% in the compressive strength and an increase of 13.5% in the drying shrinkage with respect to the control mix. The variation in properties was more pronounced in the thixotropic mortars, where the chemical additives contributed to the fast water consumption that partially hindered the wettability of adherent cement paste on recycled aggregate.

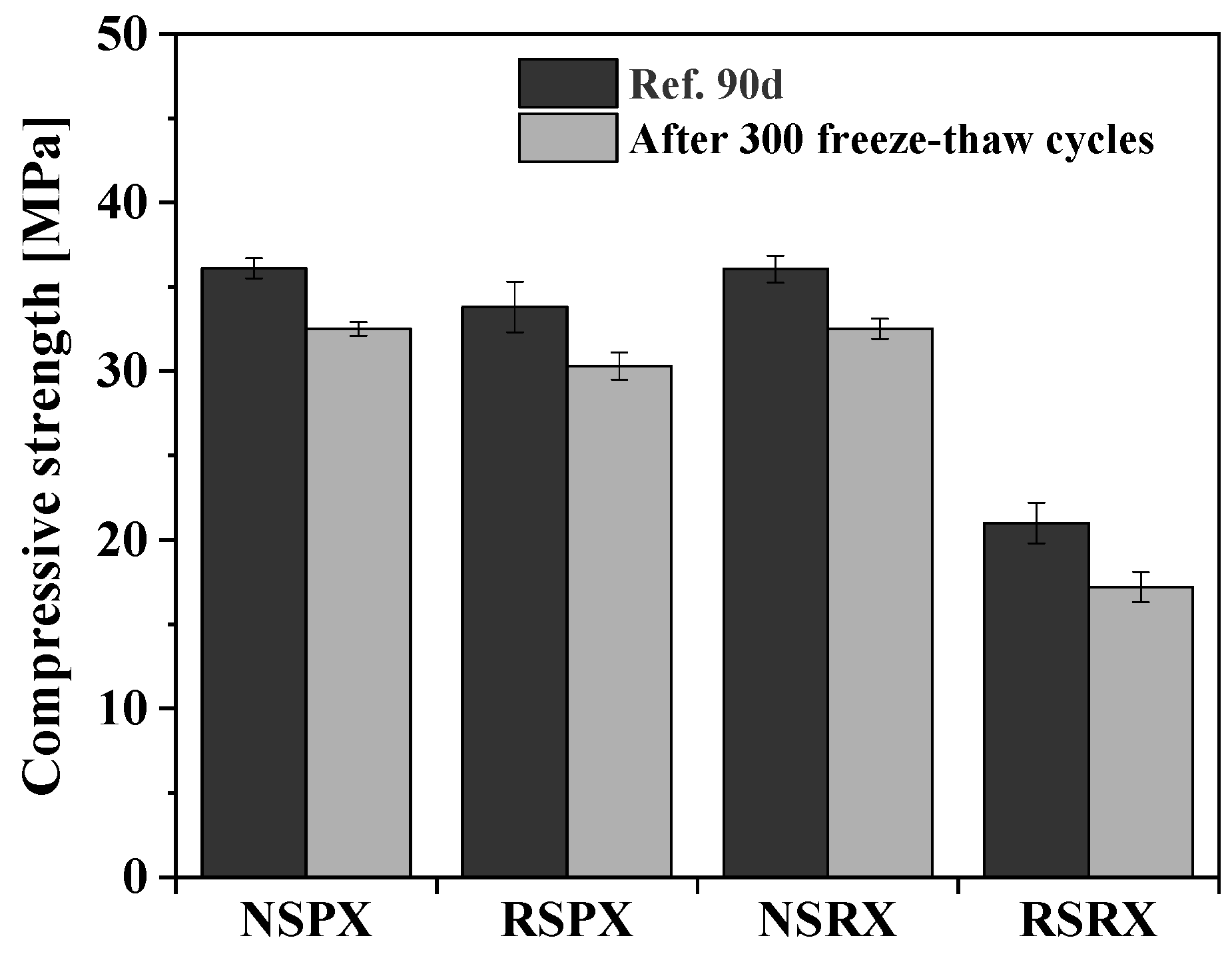

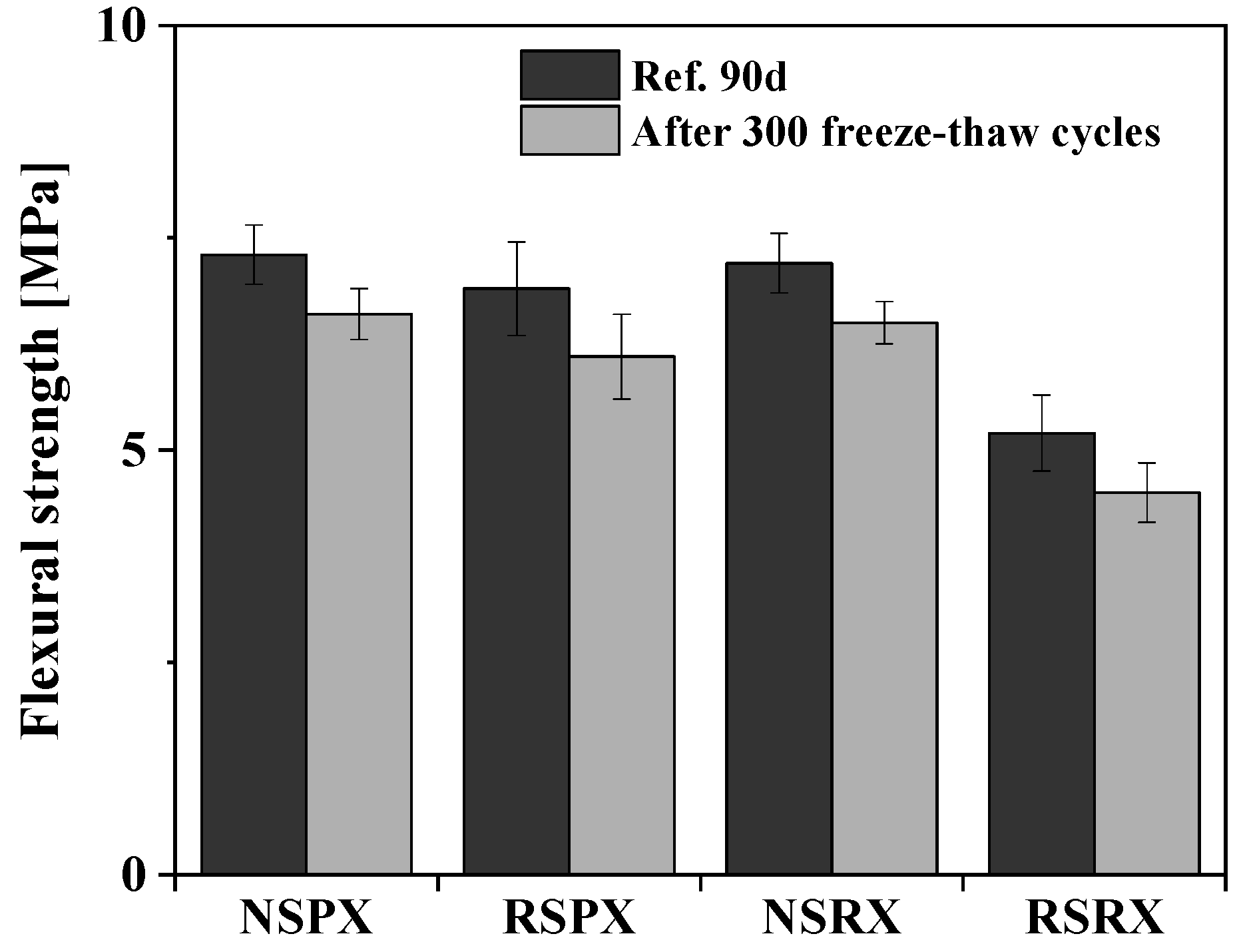

- After 300 freeze–thaw (F-T) cycles, RSRX and RSPX mortars, respectively, lost 11.6% and 14% of their initial compressive strength. Their greater porosity favours the dissipation of hydraulic pressures, resulting in a freezing and thawing resistance that is comparable to that of the control mortars, which experienced a loss of strength of about 10%.

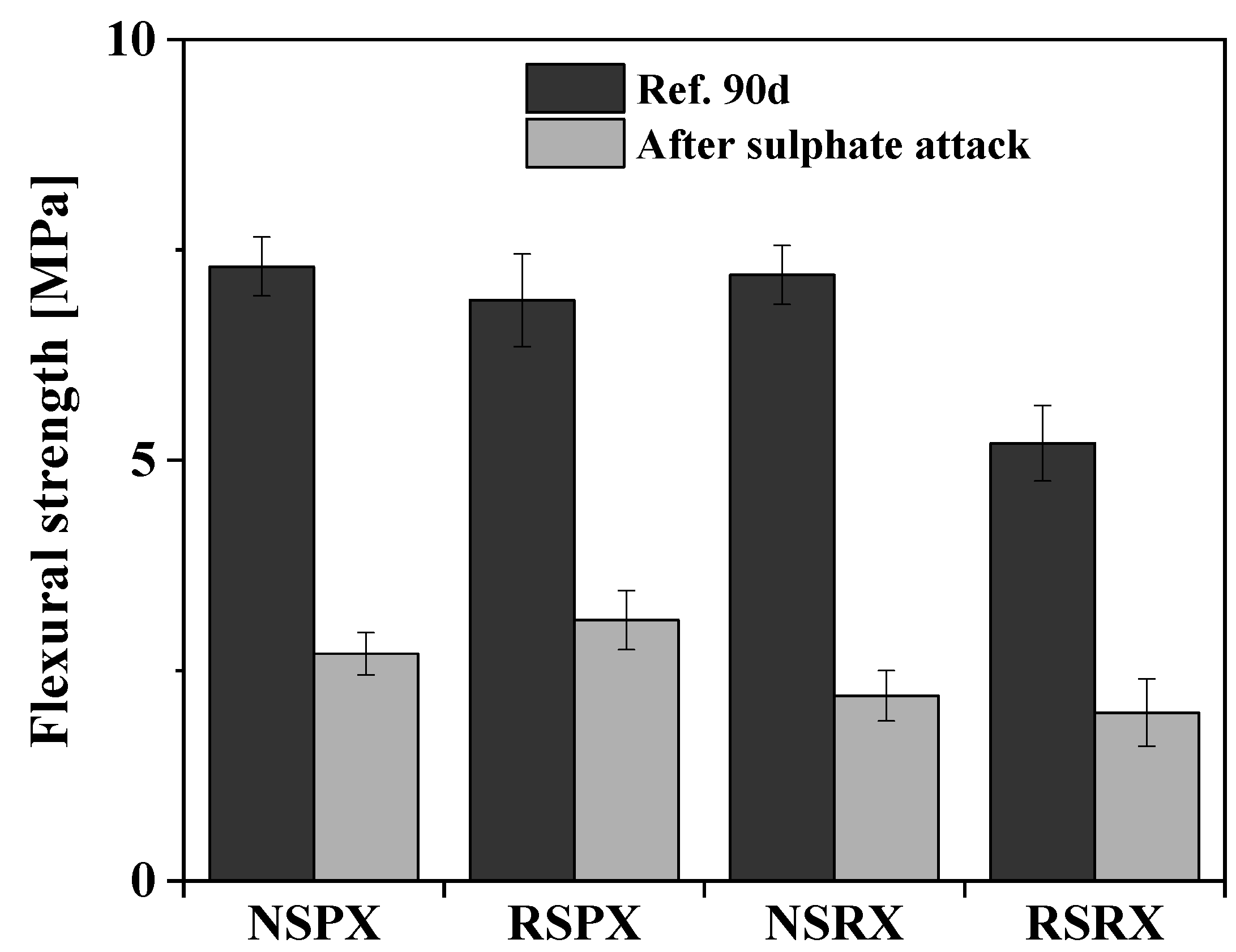

- After a period of 6 months under sulphate attack, the self-leveling and thixotropic mortars with recycled aggregate showed a loss of compressive strength of about 55% and 62% respectively. Conversely, the decrease in the corresponding control mixes was 63% and 69%, respectively. The greater extent of porosity in RSRX and RSPX mortars, even favouring the ESA kinetics, reduces the internal restriction of mortar to deform and the generated internal stresses due to the formation of expansive products.

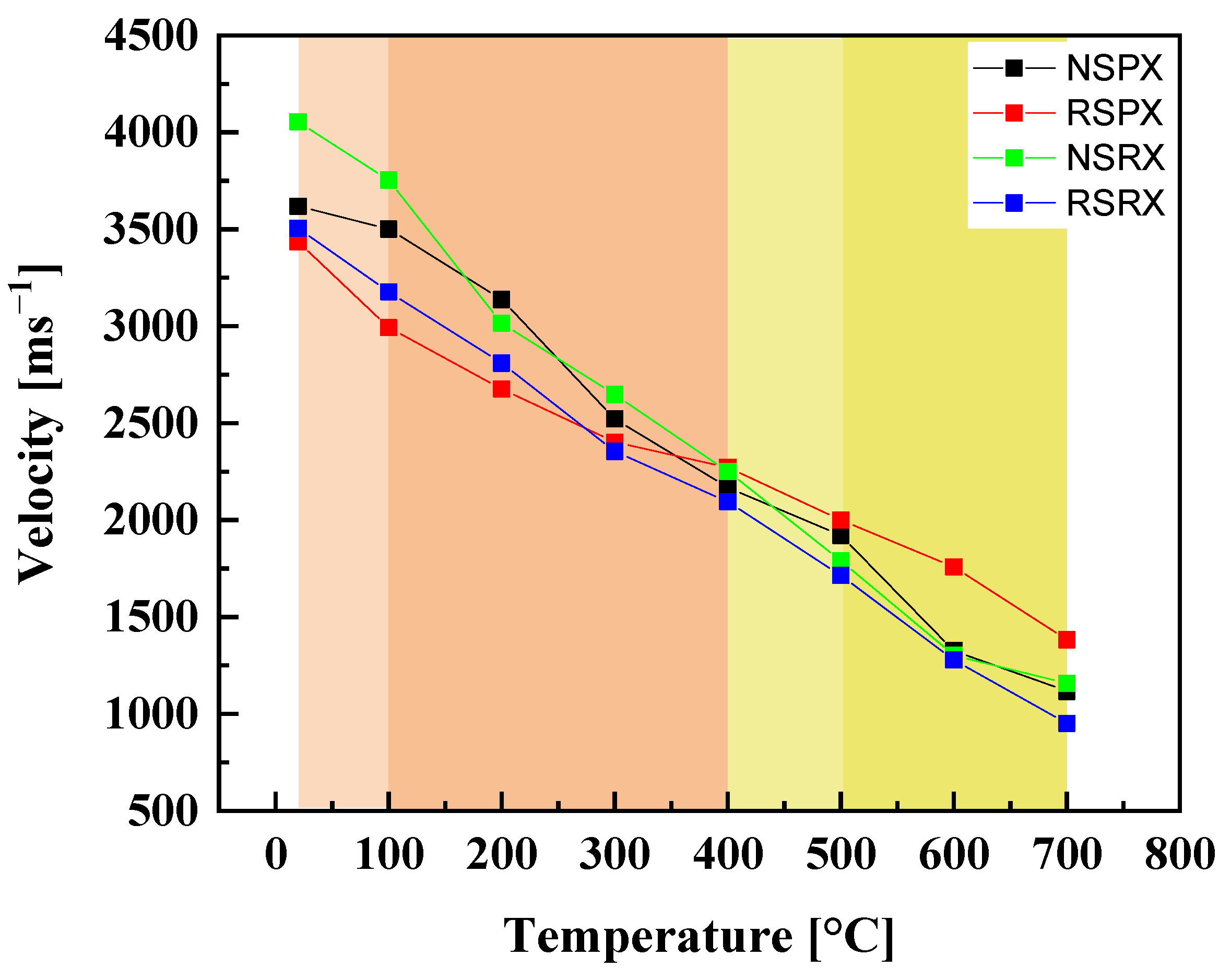

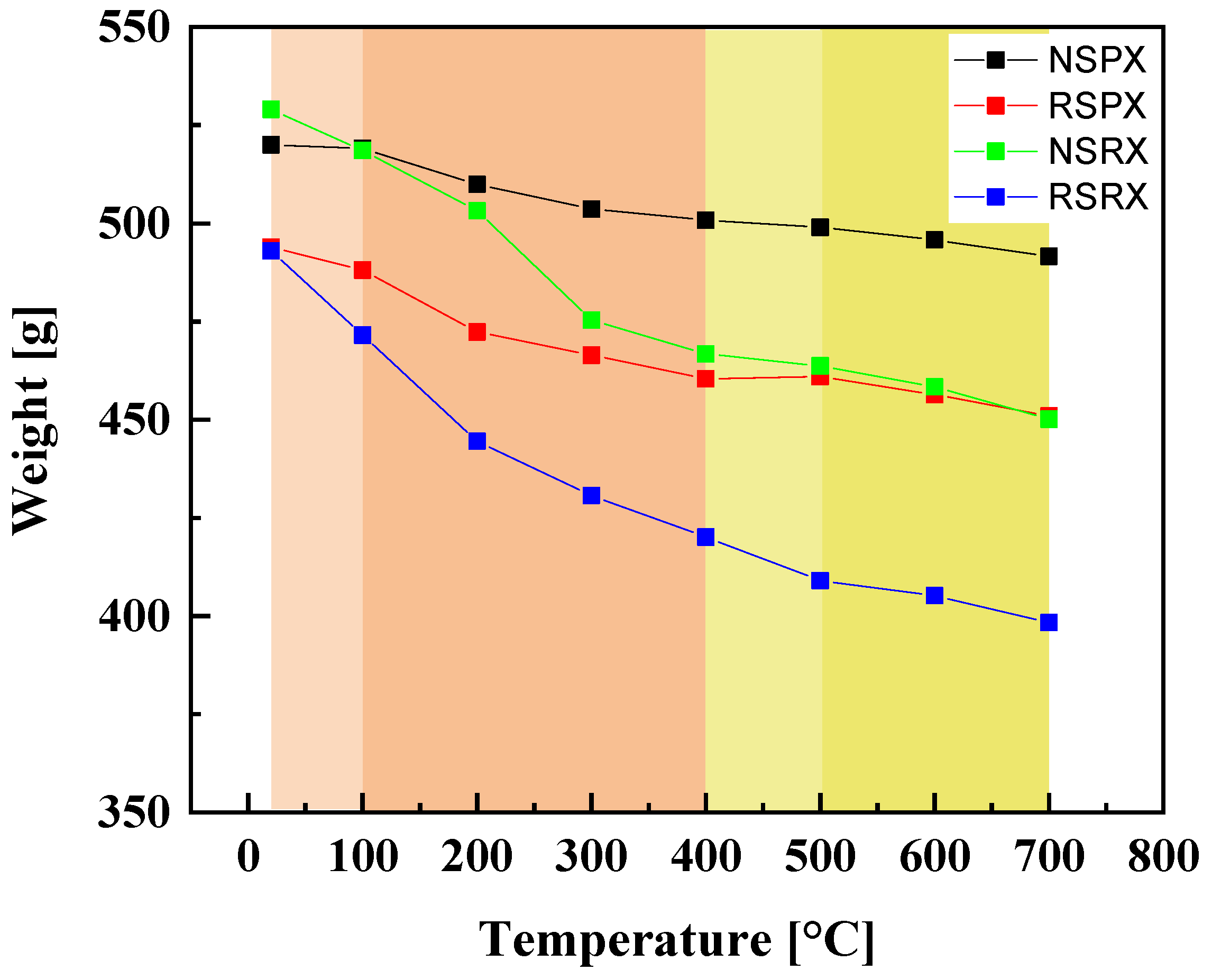

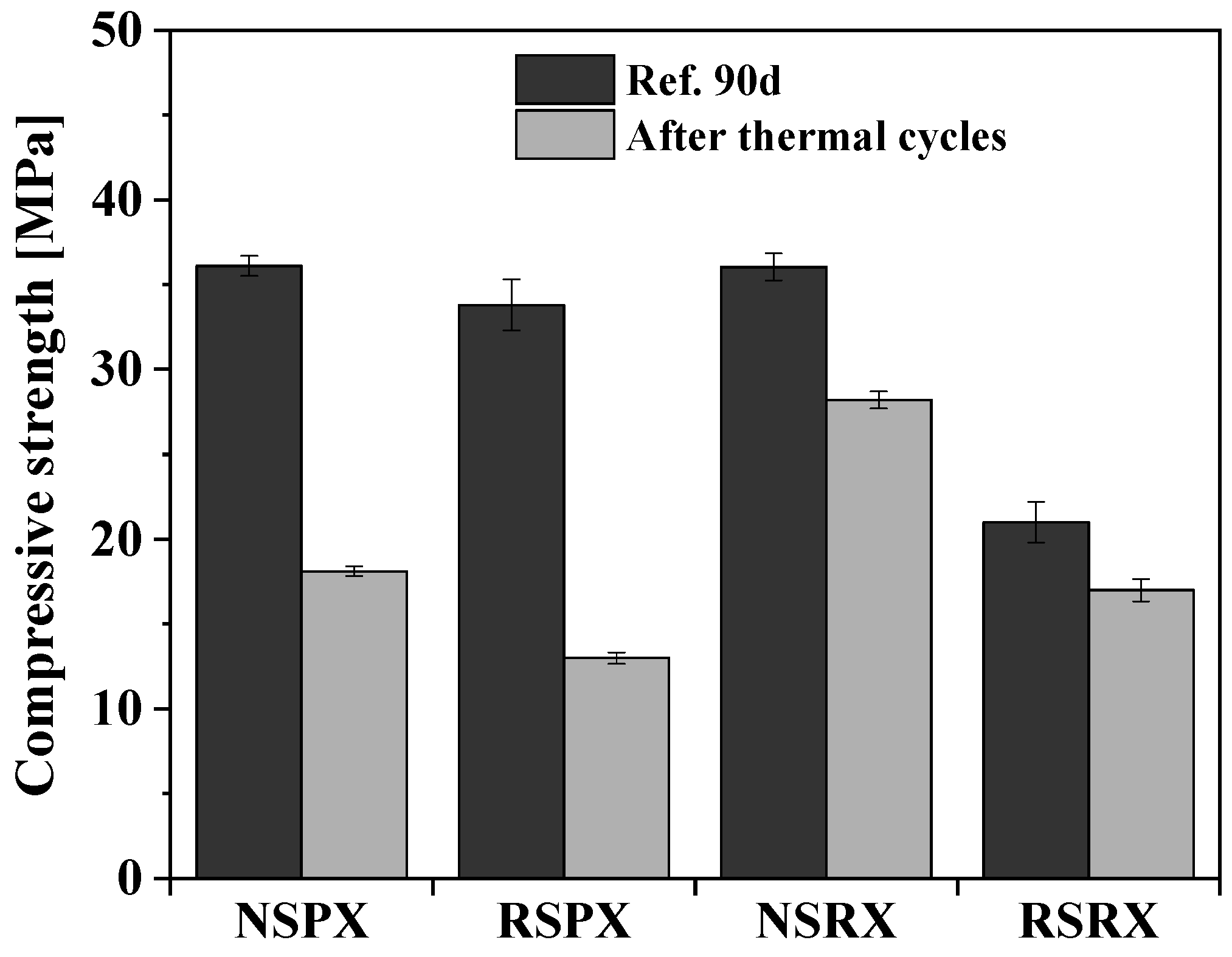

- The decline in the mortars’ compressive strength containing recycled aggregate, after exposure at high temperatures up to 700 °C, is about 55% for RSPX and 19% for RSRX. This is comparable to that of the control mixes. In the 100–400 °C temperature range, a significant decrease in UPV, equal to 28.9% for RSPX, 36.9% for NRPX, 30.8% for RSRX, and 37.1% for NRSX, is observed and can be attributed to the dehydration–dehydroxylation of calcium silicate hydrate. Furthermore, a steeper decrease in UPV was measured in the 20–100 °C interval for mortars with recycled aggregate. This can be explained by the greater ease of water vapour to escape in mortars that are more porous and of the fine-cracks to develop, under vapour pressure, from the original defect of the recycled aggregate at the pore boundaries.

Author Contributions

Funding

Conflicts of Interest

References

- Bonoli, A.; Zanni, S.; Serrano-Bernardo, F. Sustainability in Building and Construction within the Framework of Circular Cities and European New Green Deal. The Contribution of Concrete Recycling. Sustainability 2021, 13, 2139. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Candamano, S.; Crea, F.; Gazzaniga, G.; Pastore, T. The combined use of admixtures for shrinkage reduction in one-part alkali activated slag-based mortars and pastes. Constr. Build. Mater. 2020, 248, 118682. [Google Scholar] [CrossRef]

- Candamano, S.; Crea, F.; Iorfida, A. Mechanical characterization of basalt fabric-reinforced alkali-activated matrix composite: A preliminary investigation. Appl. Sci. 2020, 10, 2865. [Google Scholar] [CrossRef] [Green Version]

- Martínez, P.S.; Cortina, M.G.; Martínez, F.F.; Sánchez, A.R. Comparative study of three types of fine recycled aggregates from construction and demolition waste (CDW), and their use in masonry mortar fabrication. J. Clean. Prod. 2016, 118, 162–169. [Google Scholar] [CrossRef] [Green Version]

- Celikten, S.; Canbaz, M. Utilization of chrome ore concentration plant tailings as fine aggregate in ready mixed concrete. J. Selcuk.-Tech. 2018, 2018, 162–172. [Google Scholar]

- Wahlström, M.; Bergmans, J.; Teittinen, T.; Bachér, J.; Smeets, A.; Paduart, A. Eionet Report—ETC/WMGE 2020/1 Construction and Demolition Waste: Challenges and Opportunities in a Circular Economy; European Environment Agency (EEA): Copenhagen, Denmark, 2020. [Google Scholar]

- Tam, V.W. Economic comparison of concrete recycling: A case study approach. Resour. Conserv. Recycl. 2008, 52, 821–828. [Google Scholar] [CrossRef] [Green Version]

- Hameed, M.; Chini, A. Impact of transportation on cost and energy for recycled concrete aggregate. In Proceedings of the ASC 46th Annual Meeting, Boston, MA, USA, 7–10 April 2010; pp. 187–194. [Google Scholar]

- Ohemeng, E.A.; Ekolu, S.O. Comparative analysis on costs and benefits of producing natural and recycled concrete aggregates: A South African case study. Case Stud. Constr. Mater. 2020, 13, e00450. [Google Scholar] [CrossRef]

- Gavriletea, M.D. Environmental impacts of sand exploitation. Analysis of sand market. Sustainability 2017, 9, 1118. [Google Scholar] [CrossRef] [Green Version]

- Leal Filho, W.; Hunt, J.; Lingos, A.; Platje, J.; Vieira, L.W.; Will, M.; Gavriletea, M.D. The unsustainable use of sand: Reporting on a global problem. Sustainability 2021, 13, 3356. [Google Scholar] [CrossRef]

- European Standard EN, 206-1; Specification, Performance, Production and Conformity. European Committee for Standardization: Brussels, Belgium, 2000.

- Lotfi, S.; Rem, P.; Deja, J.; Mróz, R. An experimental study on the relation between input variables and output quality of a new concrete recycling process. Constr. Build. Mater. 2017, 137, 128–140. [Google Scholar] [CrossRef]

- Xuan, D.; Zhan, B.; Poon, C.S. Assessment of mechanical properties of concrete incorporating carbonated recycled concrete aggregates. Cem. Concr. Compos. 2016, 65, 67–74. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A comprehensive review on recycled aggregate and recycled aggregate concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Xie, T.; Gholampour, A.; Ozbakkaloglu, T. Toward the development of sustainable concretes with recycled concrete aggregates: Comprehensive review of studies on mechanical properties. J. Mater. Civ. Eng. 2018, 30, 04018211. [Google Scholar] [CrossRef]

- Silva, R.V.; Brito, J.; de Dhir, R.K. Fresh-State performance of recycled aggregate concrete: A review. Constr. Build. Mater. 2018, 178, 19–31. [Google Scholar] [CrossRef]

- Del Bosque, I.S.; Zhu, W.; Howind, T.; Matías, A.; De Rojas, M.S.; Medina, C. Properties of interfacial transition zones (ITZs) in concrete containing recycled mixed aggregate. Cem. Concr. Compos. 2017, 81, 25–34. [Google Scholar] [CrossRef] [Green Version]

- Tam, V.W.; Butera, A.; Le, K.N.; Li, W. Utilising CO2 technologies for recycled aggregate concrete: A critical review. Constr. Build. Mater. 2020, 250, 118903. [Google Scholar] [CrossRef]

- Liang, C.; Pan, B.; Ma, Z.; He, Z.; Duan, Z. Utilization of CO2 curing to enhance the properties of recycled aggregate and prepared concrete: A review. Cem. Concr. Compos. 2020, 105, 103446. [Google Scholar] [CrossRef]

- Singh, L.P.; Bisht, V.; Aswathy, M.S.; Chaurasia, L.; Gupta, S. Studies on performance enhancement of recycled aggregate by incorporating bio and nano materials. Constr. Build. Mater. 2018, 181, 217–226. [Google Scholar] [CrossRef]

- García-González, J.; Rodríguez-Robles, D.; Wang, J.; De Belie, N.; Morán-del Pozo, J.M.; Guerra-Romero, M.I.; Juan-Valdés, A. Quality improvement of mixed and ceramic recycled aggregates by biodeposition of calcium carbonate. Constr. Build. Mater. 2017, 154, 1015–1023. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Cao, Z.; Ling, T.C.; Zheng, J. Performance of mortar prepared with recycled concrete aggregate enhanced by CO2 and pozzolan slurry. Cem. Concr. Compos. 2018, 86, 130–138. [Google Scholar] [CrossRef]

- Luo, Z.; Li, W.; Tam, V.W.; Xiao, J.; Shah, S.P. Current progress on nanotechnology application in recycled aggregate concrete. J. Sustain. Cem.-Based Mater. 2019, 8, 79–96. [Google Scholar] [CrossRef]

- Gao, C.; Huang, L.; Yan, L.; Jin, R.; Chen, H. Mechanical properties of recycled aggregate concrete modified by nano-particles. Constr. Build. Mater. 2020, 241, 118030. [Google Scholar] [CrossRef]

- Lei, B.; Li, W.; Tang, Z.; Li, Z.; Tam, V.W. Effects of environmental actions, recycled aggregate quality and modification treatments on durability performance of recycled concrete. J. Mater. Res. Technol. 2020, 9, 13375–13389. [Google Scholar] [CrossRef]

- Candamano, S.; Crea, F.; Coppola, L.; De Luca, P.; Coffetti, D. Influence of acrylic latex and pre-treated hemp fibers on cement based mortar properties. Constr. Build. Mater. 2021, 273, 121720. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance enhancement of recycled concrete aggregate—A review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Saravanakumar, P.; Abhiram, K.; Manoj, B. Properties of treated recycled aggregates and its influence on concrete strength characteristics. Constr. Build. Mater. 2016, 111, 611–617. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Effect of different aggregate treatment techniques on the freeze-thaw and sulfate resistance of recycled aggregate concrete. Cold Reg. Sci. Technol. 2020, 178, 103126. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G.; Zhang, M.H.; Tam, C.T.; Foo, T.W.J. Microwave-Assisted beneficiation of recycled concrete aggregates. Constr. Build. Mater. 2011, 25, 3469–3479. [Google Scholar] [CrossRef]

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of recycled concrete aggregate and their influence in new concrete production. Resour. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Lei, B.; Li, W.; Liu, H.; Tang, Z.; Tam, V.W. Synergistic effects of polypropylene and glass fiber on mechanical properties and durability of recycled aggregate concrete. Int. J. Concr. Struct. Mater. 2020, 14, 37. [Google Scholar] [CrossRef]

- Wang, C.; Xiao, J.; Zhang, G.; Li, L. Interfacial properties of modeled recycled aggregate concrete modified by carbonation. Constr. Build. Mater. 2016, 105, 307–320. [Google Scholar] [CrossRef]

- Bai, G.; Zhu, C.; Liu, C.; Liu, B. An evaluation of the recycled aggregate characteristics and the recycled aggregate concrete mechanical properties. Constr. Build. Mater. 2020, 240, 117978. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Improving the mechanical properties of recycled concrete aggregate using chopped basalt fibers and acid treatment. Constr. Build. Mater. 2017, 140, 328–335. [Google Scholar] [CrossRef]

- Dong, J.F.; Wang, Q.Y.; Guan, Z.W. Material properties of basalt fibre reinforced concrete made with recycled earthquake waste. Constr. Build. Mater. 2017, 130, 241–251. [Google Scholar] [CrossRef]

- Larbi, J.A.; Heijnen, W.M.M.; Brouwer, J.P.; Mulder, E. Preliminary laboratory investigation of thermally treated recycled concrete aggregate for general use in concrete. In Waste Management Series; Elsevier: Amsterdam, The Netherlands, 2000; Volume 1, pp. 129–139. [Google Scholar]

- Kou, S.C.; Zhan, B.J.; Poon, C.S. Use of a CO2 curing step to improve the properties of concrete prepared with recycled aggregates. Cem. Concr. Compos. 2014, 45, 22–28. [Google Scholar] [CrossRef]

- Chi, B.; Lu, W.; Ye, M.; Bao, Z.; Zhang, X. Construction waste minimization in green building: A comparative analysis of LEED-NC 2009 certified projects in the US and China. J. Clean. Prod. 2020, 256, 120749. [Google Scholar] [CrossRef]

- Restuccia, L.; Spoto, C.; Ferro, G.A.; Tulliani, J.M. Recycled mortars with C & D waste. Procedia Struct. Integr. 2016, 2, 2896–2904. [Google Scholar]

- Silva Neto, G.A.D.; Leite, M.B. Study of the influence of the mortar fine recycled aggregate ratio and the mixing sequence on the behavior of new mortars. Ambiente Construído 2018, 18, 53–69. [Google Scholar] [CrossRef]

- Katz, A.; Kulisch, D. Performance of mortars containing recycled fine aggregate from construction and demolition waste. Mater. Struct. 2017, 50, 199. [Google Scholar] [CrossRef]

- Roque, S.; Maia Pederneiras, C.; Brazão Farinha, C.; de Brito, J.; Veiga, R. Concrete-Based and mixed waste aggregates in rendering mortars. Materials 2020, 13, 1976. [Google Scholar] [CrossRef] [Green Version]

- Mora-Ortiz, R.S.; Munguía-Balvanera, E.; Díaz, S.A.; Magaña-Hernández, F.; Angel-Meraz, D.; Bolaina-Juárez, Á. Mechanical behavior of masonry mortars made with recycled mortar aggregate. Materials 2020, 13, 2373. [Google Scholar] [CrossRef] [PubMed]

- Anderberg, A.; Wadsö, L. Drying and hydration of cement based self-leveling flooring compounds. Dry. Technol. 2007, 25, 1995–2003. [Google Scholar] [CrossRef]

- Dong, W.; Fang, C.; Hu, R. Influence of Redispersible Powder on Properties of Self-Leveling Mortar of Ternary Cementitious System. Materials 2020, 13, 5703. [Google Scholar] [CrossRef] [PubMed]

- Georgin, J.F.; Ambroise, J.; Péra, J.; Reynouard, J.M. Development of self-leveling screed based on calcium sulfoaluminate cement: Modelling of curling due to drying. Cem. Concr. Compos. 2008, 30, 769–778. [Google Scholar] [CrossRef]

- Cui, J. The Influence of Redispersible Powder on Mechanical Properties of EPS Light-Aggregate Concrete. Applied Mechanics and Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; Volume 651, pp. 173–176. [Google Scholar]

- Sun, S.B.; Li, J.J.; Zhao, L. The Effect of Re-Dispersible Polymer Powders on Cement-Based Self-Leveling Mortar. In Key Engineering Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2017; Volume 730, pp. 395–400. [Google Scholar]

- Jung, K.C.; Chang, S.H. Evaluation of shrinkage-induced stress in a runway repaired using compliant polymer concrete. Compos. Struct. 2016, 158, 217–226. [Google Scholar] [CrossRef]

- Sobala, M.; Nosal, K.; Pichniarczyk, P. Effect of methyl cellulose on the properties of adhesive cement mortars. Cem. Lime Concr. 2010, 6, 359–365. [Google Scholar]

- Cortes, D.D.; Kim, H.K.; Palomino, A.M.; Santamarina, J.C. Rheological and mechanical properties of mortars prepared with natural and manufactured sands. Cem. Concr. Res. 2008, 38, 1142–1147. [Google Scholar] [CrossRef]

- Maza, M.; Naceri, A.; Zitouni, S. Physico-Mechanical properties of mortar made with binary natural fine aggregates (dune sand and crushed sand) with and without chemical admixture. Asian J. Civ. Eng. 2016, 17, 663–682. [Google Scholar]

- Lee, G.C.; Choi, H.B. Study on interfacial transition zone properties of recycled aggregate by micro-hardness test. Constr. Build. Mater. 2013, 40, 455–460. [Google Scholar] [CrossRef]

- Le, T.; Le Saout, G.; Garcia-Diaz, E.; Betrancourt, D.; Rémond, S. Hardened behavior of mortar based on recycled aggregate: Influence of saturation state at macro-and microscopic scales. Constr. Build. Mater. 2017, 141, 479–490. [Google Scholar] [CrossRef] [Green Version]

- Contreras, M.; Teixeira, S.R.; Lucas, M.C.; Lima, L.C.N.; Cardoso, D.S.L.; Da Silva, G.A.C.; Gregório, G.C.; de Souza, A.E.; Dos Santos, A. Recycling of construction and demolition waste for producing new construction material (Brazil case-study). Constr. Build. Mater. 2016, 123, 594–600. [Google Scholar] [CrossRef] [Green Version]

- Hejduk, A.; Czajka, S.; Lulek, J. Impact of co-processed excipient particles solidity and circularity on critical quality attributes of orodispersible minitablets. Powder Technol. 2021, 387, 494–508. [Google Scholar] [CrossRef]

- Reis, G.S.D.; Quattrone, M.; Ambrós, W.M.; Grigore Cazacliu, B.; Hoffmann Sampaio, C. Current applications of recycled aggregates from construction and demolition: A review. Materials 2021, 14, 1700. [Google Scholar] [CrossRef]

- Evangelista, L.; Guedes, M.; De Brito, J.; Ferro, A.C.; Pereira, M.F. Physical, chemical and mineralogical properties of fine recycled aggregates made from concrete waste. Constr. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- Rodrigues, F.; Carvalho, M.T.; Evangelista, L.; De Brito, J. Physical–Chemical and mineralogical characterization of fine aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2013, 52, 438–445. [Google Scholar] [CrossRef] [Green Version]

- Awoyera, P.O.; Okoro, U.C. Filler-ability of highly active metakaolin for improving morphology and strength characteristics of recycled aggregate concrete. Silicon 2019, 11, 1971–1978. [Google Scholar] [CrossRef]

- Pederneiras, C.M.; Durante, M.D.P.; Amorim, Ê.F.; Ferreira, R.L.D.S. Incorporation of recycled aggregates from construction and demolition waste in paver blocks. Rev. IBRACON Estrut. Mater. 2020, 13, e13405. [Google Scholar] [CrossRef]

- Hansen, T.C. (Ed.) Recycling of Demolished Concrete and Masonry; CRC Press: Boca Raton, FL, USA, 1992. [Google Scholar]

- Tam, V.W.; Gao, X.F.; Tam, C.M. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Z.; Remond, S.; Damidot, D.; Xu, W. Influence of fine recycled concrete aggregates on the properties of mortars. Constr. Build. Mater. 2015, 81, 179–186. [Google Scholar] [CrossRef]

- González-Fonteboa, B.; González-Taboada, I.; Carro-López, D.; Martínez-Abella, F. Influence of the mixing procedure on the fresh state behaviour of recycled mortars. Constr. Build. Mater. 2021, 299, 124266. [Google Scholar] [CrossRef]

- Miranda, L.F.; Selmo, S.M. CDW recycled aggregate renderings: Part I—Analysis of the effect of materials finer than 75 μm on mortar properties. Constr. Build. Mater. 2006, 20, 615–624. [Google Scholar] [CrossRef]

- UNI EN 1015–3:2007; Consistency of Wet Mortar. European Committee for Standardization: Brussels, Belgium, 2007.

- UNI EN 1015-11:2001; Methods of Test for Mortar for Masonry—Determination of Flexural and Compressive Strength of Hardened Mortar. European Committee for Standardization: Brussels, Belgium, 1999.

- UNI EN 12617-4:2003; Hidraulic Shrinkage of Cement Mortar Products and Systems for the Protection and Repair of Concrete Structures—Test Methods—Determination of Shrinkage and Expansion. European Committee for Standardization: Brussels, Belgium, 2003.

- UNI 11060:2003; Cultural Heritage—Natural and Artificial Stones—Determination of Density and Voids. European Committee for Standardization: Brussels, Belgium, 2003.

- UNI 8019-4.3; Determination of Sulfate Ions Penetration. European Committee for Standardization: Brussels, Belgium, 1979.

- UNI 7087:2017; Concrete—Determination of the Resistance to the Degrade Due to Freeze-Thaw Cycles. European Committee for Standardization: Brussels, Belgium, 2017.

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Giuggiolini, M.; Moriconi, G. Use of rubble from building demolition in mortars. Waste Manag. 2002, 22, 893–899. [Google Scholar] [CrossRef]

- Corinaldesi, V. Mechanical behavior of masonry assemblages manufactured with recycled-aggregate mortars. Cem. Concr. Compos. 2009, 31, 505–510. [Google Scholar] [CrossRef]

- De Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- López-Gayarre, F.; Serna, P.; Domingo-Cabo, A.; Serrano-López, M.A.; López-Colina, C. Influence of recycled aggregate quality and proportioning criteria on recycled concrete properties. Waste Manag. 2009, 29, 3022–3028. [Google Scholar] [CrossRef]

- Gómez-Soberón, J.M. Porosity of recycled concrete with substitution of recycled concrete aggregate: An experimental study. Cem. Concr. Res. 2002, 32, 1301–1311. [Google Scholar] [CrossRef] [Green Version]

- Poon, C.S.; Shui, Z.H.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Mari, A. Microstructure analysis of hardened recycled aggregate concrete. Mag. Concr. Res. 2006, 58, 683–690. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Li, T.; Xiong, Z.; Sun, Y. Effects of lithium carbonate on performances of sulphoaluminate cement-based dual liquid high water material and its mechanisms. Constr. Build. Mater. 2018, 161, 374–380. [Google Scholar] [CrossRef]

- Telesca, A.; Marroccoli, M.; Coppola, L.; Coffetti, D.; Candamano, S. Tartaric acid effects on hydration development and physico-mechanical properties of blended calcium sulphoaluminate cements. Cem. Concr. Compos. 2021, 124, 104275. [Google Scholar] [CrossRef]

- Torkittikul, P.; Chaipanich, A. Utilization of ceramic waste as fine aggregate within Portland cement and fly ash concretes. Cem. Concr. Compos. 2010, 32, 440–449. [Google Scholar] [CrossRef]

- Thomson, M.; Lindqvist, J.E.; Elsen, J.; Groot, C.J.W.P. 2.5 Porosity of Mortars. Report 28: Characterisation of Old Mortars with Respect to their Repair-State-of-the-Art Report of RILEM Technical Committee 167-COM; RILEM Publications: Bagneux, France, 2007; Volume 28, p. 75. [Google Scholar]

- Mao, Y.; Liu, J.; Shi, C. Autogenous shrinkage and drying shrinkage of recycled aggregate concrete: A review. J. Clean. Prod. 2021, 295, 126435. [Google Scholar] [CrossRef]

- Wu, J.; Jing, X.; Wang, Z. Uni-Axial compressive stress-strain relation of recycled coarse aggregate concrete after freezing and thawing cycles Constr. Build. Mater. 2017, 134, 210–219. [Google Scholar] [CrossRef]

- Li, Y.; Wang, R.; Li, S.; Zhao, Y. Assessment of the freeze–thaw resistance of concrete incorporating carbonated coarse recycled concrete aggregates. J. Ceram. Soc. Jpn. 2017, 125, 837–845. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Y.; Shang, X.; Zhang, Y. Experimental research on durability of recycled aggregate concrete under freeze-thaw cycles. J. Phys. Conf. Ser. 2017, 870, 012018. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Wang, R.; Zhao, Y. Effect of coupled deterioration by freeze-thaw cycle and carbonation on concrete produced with coarse recycled concrete aggregates. J. Ceram. Soc. Jpn. 2017, 125, 36–45. [Google Scholar] [CrossRef] [Green Version]

- Júnior, N.A.; Silva, G.A.O.; Ribeiro, D.V. Effects of the incorporation of recycled aggregate in the durability of the concrete submitted to freeze-thaw cycles. Constr. Build. Mater. 2018, 161, 723–730. [Google Scholar] [CrossRef]

- Richardson, A.; Coventry, K.; Bacon, J. Freeze/thaw durability of concrete with recycled demolition aggregate compared to virgin aggregate concrete. J. Clean Prod. 2011, 19, 272–277. [Google Scholar] [CrossRef]

- Cao, W.L.; Liang, M.B.; Dong, H.Y.; Zhang, J.W. Experimental study on basic mechanical properties of recycled concrete after freeze–thaw cycles. J. Nat. Disasters 2012, 21, 184–190. [Google Scholar]

- Zou, C.Y.; Fan, Y.H.; Hu, Q. Experimental study on the basic mechanical property of recycled concrete after freeze–thaw. Build. Struct. 2010, 40, 434–438. [Google Scholar]

- Algourdin, N.; Nguyen, Q.N.A.; Mesticou, Z.; Larbi, A.S. Durability of recycled fine mortars under freeze–thaw cycles. Constr. Build. Mater. 2021, 291, 123330. [Google Scholar] [CrossRef]

- Rangel, C.S.; Amario, M.; Pepe, M.; Martinelli, E.; Filho, R.D.T. Durability of structural recycled aggregate concrete subjected to freeze-thaw cycles. Sustainability 2020, 12, 6475. [Google Scholar] [CrossRef]

- Müllauer, W.; Beddoe, R.E.; Heinz, D. Sulfate attack expansion mechanisms. Cem. Concr. Res. 2013, 52, 208–215. [Google Scholar] [CrossRef]

- Bizzozero, J.; Gosselin, C.; Scrivener, K.L. Expansion mechanisms in calcium aluminate and sulfoaluminate systems with calcium sulfate. Cem. Concr. Res. 2014, 56, 190–202. [Google Scholar] [CrossRef]

- Dhir, R.K.; Limbachiya, M.C.; Leelawat, T. BS 5328, BS 882. Suitability of recycled concrete aggregate for use in BS 5328 designated mixes. Proc. Inst. Civ. Eng.-Struct. Build. 1999, 134, 257–274. [Google Scholar] [CrossRef]

- Bulatović, V.; Melešev, M.; Radeka, M.; Radonjanin, V.; Lukić, I. Evaluation of sulfate resistance of concrete with recycled and natural aggregates. Constr. Build. Mater. 2017, 152, 614–631. [Google Scholar] [CrossRef]

- Bai, J. Durability of sustainable construction materials. In Sustainability of Construction Materials; Woodhead Publishing: Cambridge, MA, USA, 2016; pp. 397–414. [Google Scholar]

- Tang, S.W.; Yao, Y.; Andrade, C.; Li, Z.J. Recent durability studies on concrete structure. Cem. Concr. Res. 2015, 78, 143–154. [Google Scholar] [CrossRef]

- Santillán, L.R.; Locati, F.; Villagrán-Zaccardi, Y.A.; Zega, C.J. Long-Term sulfate attack on recycled aggregate concrete immersed in sodium sulfate solution for 10 years. Mater. Constr. 2020, 70, e212. [Google Scholar] [CrossRef]

- Boudali, S.; Kerdal, D.E.; Ayed, K.; Abdulsalam, B.; Soliman, A.M. Performance of self-compacting concrete incorporating recycled concrete fines and aggregate exposed to sulphate attack. Constr. Build. Mater. 2016, 124, 705–713. [Google Scholar] [CrossRef]

- Poole, A.B.; Thomas, A. A staining technique for the identification of sulphates in aggregates and concretes. Mineral. Mag. 1975, 40, 315–316. [Google Scholar] [CrossRef]

- Xuan, D.X.; Shui, Z.H. Temperature dependence of thermal induced mesocracks around limestone aggregate in normal concrete. Fire Mater. Int. J. 2010, 34, 137–146. [Google Scholar] [CrossRef]

- Li, B.; Zhang, Y.; Selyutina, N.; Smirnov, I.; Deng, K.; Liu, Y.; Miao, Y. Thermally-Induced mechanical degradation analysis of recycled aggregate concrete mixed with glazed hollow beads. Constr. Build. Mater. 2021, 301, 124350. [Google Scholar] [CrossRef]

- Dündar, B.; Çınar, E.; Çalışkan, A.N. An investigation of high temperature effect on pumice aggregate light mortars with brick flour. Res. Eng. Struct. Mat. 2020, 6, 241–255. [Google Scholar] [CrossRef]

- Hernández, M.G.; Anaya, J.J.; Izquierdo, M.A.G.; Ullate, L.G. Application of micromechanics to the characterization of mortar by ultrasound. Ultrasonics 2002, 40, 217–221. [Google Scholar] [CrossRef]

- Flores-Ales, V.; Alducin-Ochoa, J.M.; Martín-del-Río, J.J.; Torres-Gonzalez, M.; Jimenez-Bayarri, V. Physical-Mechanical behaviour and transformations at high temperature in a cement mortar with waste glass as aggregate. J. Build. Eng. 2020, 29, 101158. [Google Scholar] [CrossRef]

- Guo, M.Z.; Chen, Z.; Ling, T.C.; Poon, C.S. Effects of recycled glass on properties of architectural mortar before and after exposure to elevated temperatures. J. Clean. Prod. 2015, 101, 158–164. [Google Scholar] [CrossRef]

- Heap, M.J.; Lavallée, Y.; Laumann, A.; Hess, K.U.; Meredith, P.G.; Dingwell, D.B.; Huismann, S.; Weise, F. The influence of thermal-stressing (up to 1000 C) on the physical, mechanical, and chemical properties of siliceous-aggregate, high-strength concrete. Constr. Build. Mater. 2013, 42, 248–265. [Google Scholar] [CrossRef]

- Sarhat, S.R.; Sherwood, E.G. Residual mechanical response of recycled aggregate concrete after exposure to elevated temperatures. J. Mater. Civ. Eng. 2013, 25, 1721–1730. [Google Scholar] [CrossRef]

- Khaliq, W. Mechanical and physical response of recycled aggregates high-strength concrete at elevated temperatures. Fire Saf. J. 2018, 96, 203–214. [Google Scholar] [CrossRef]

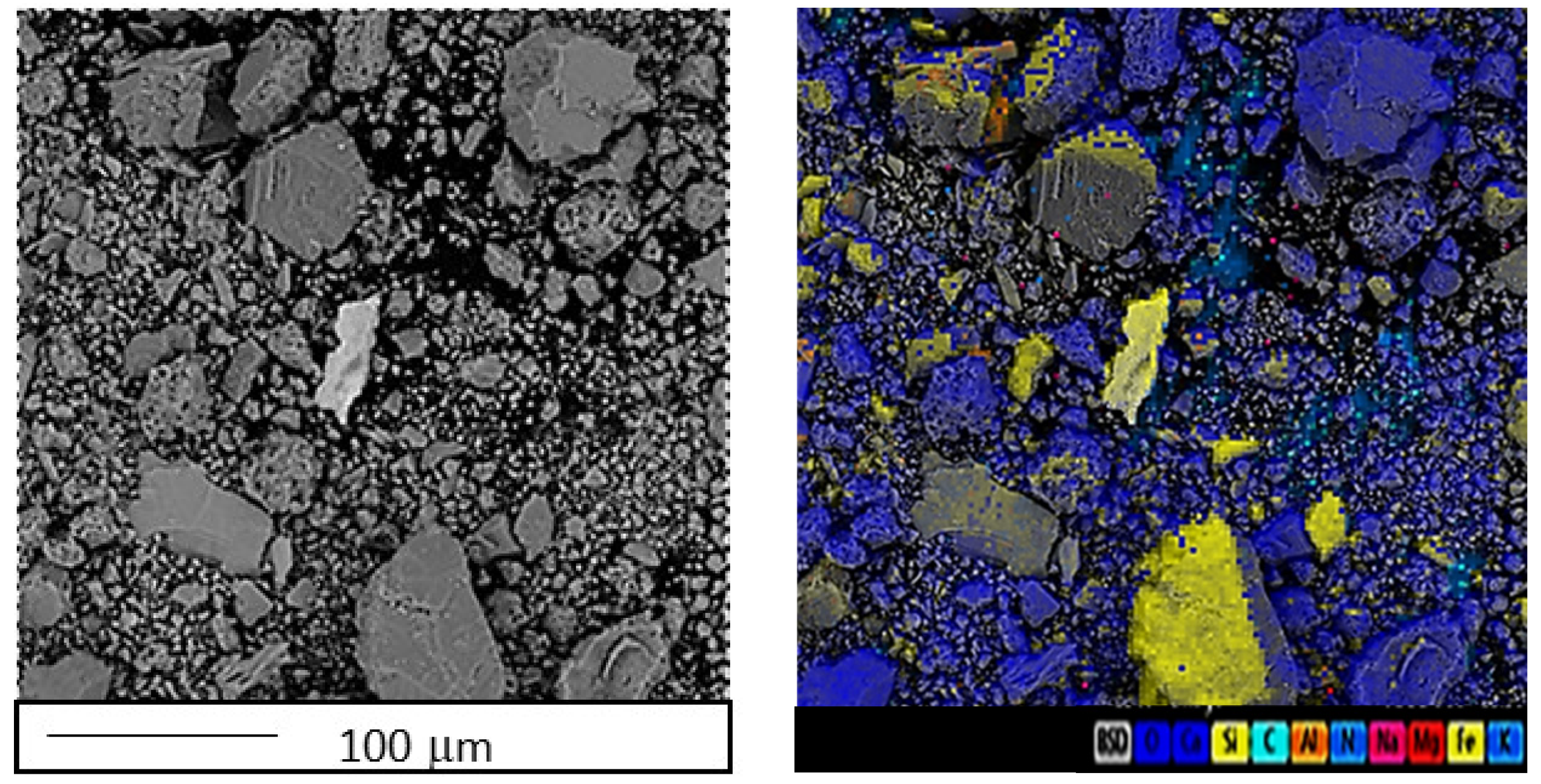

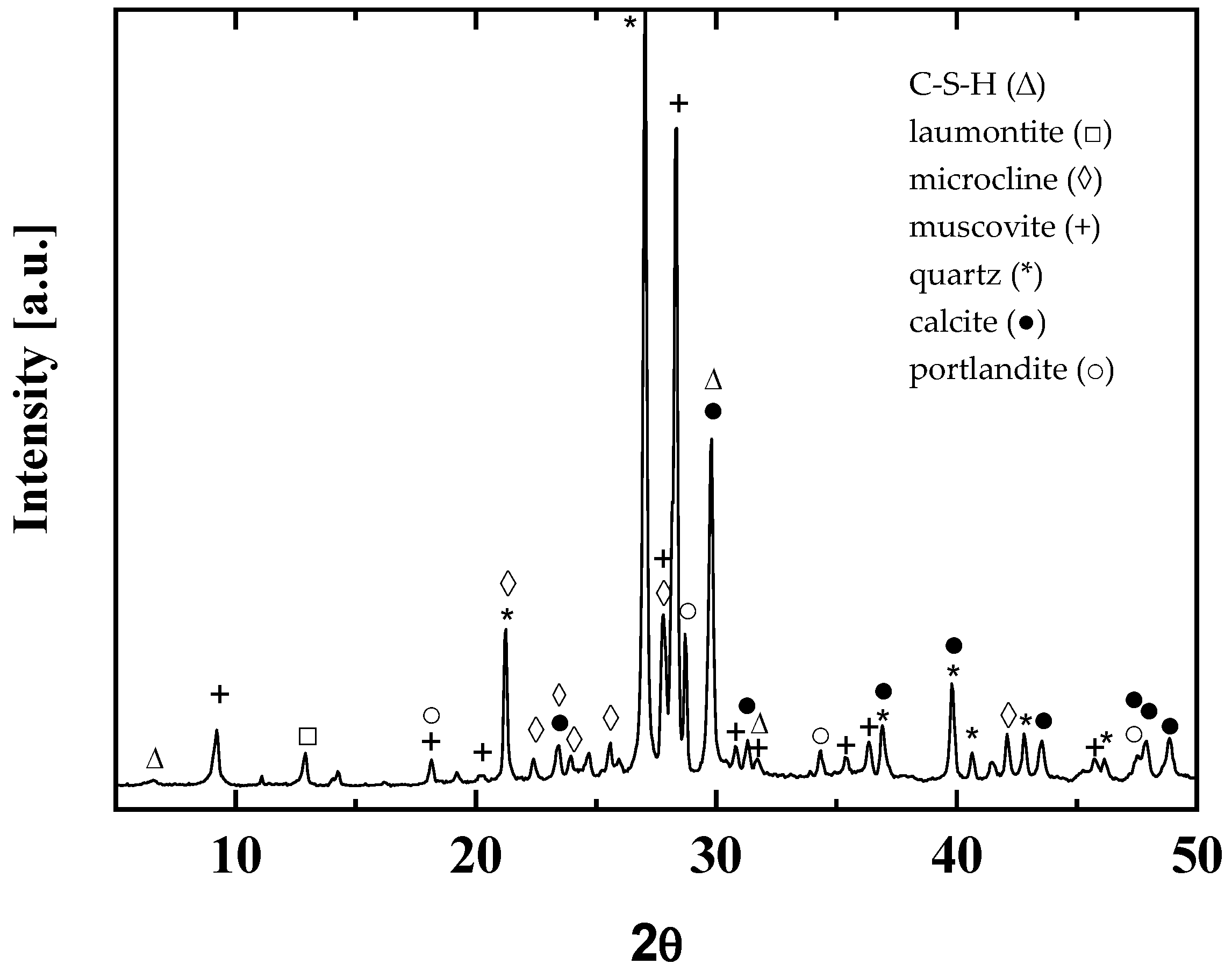

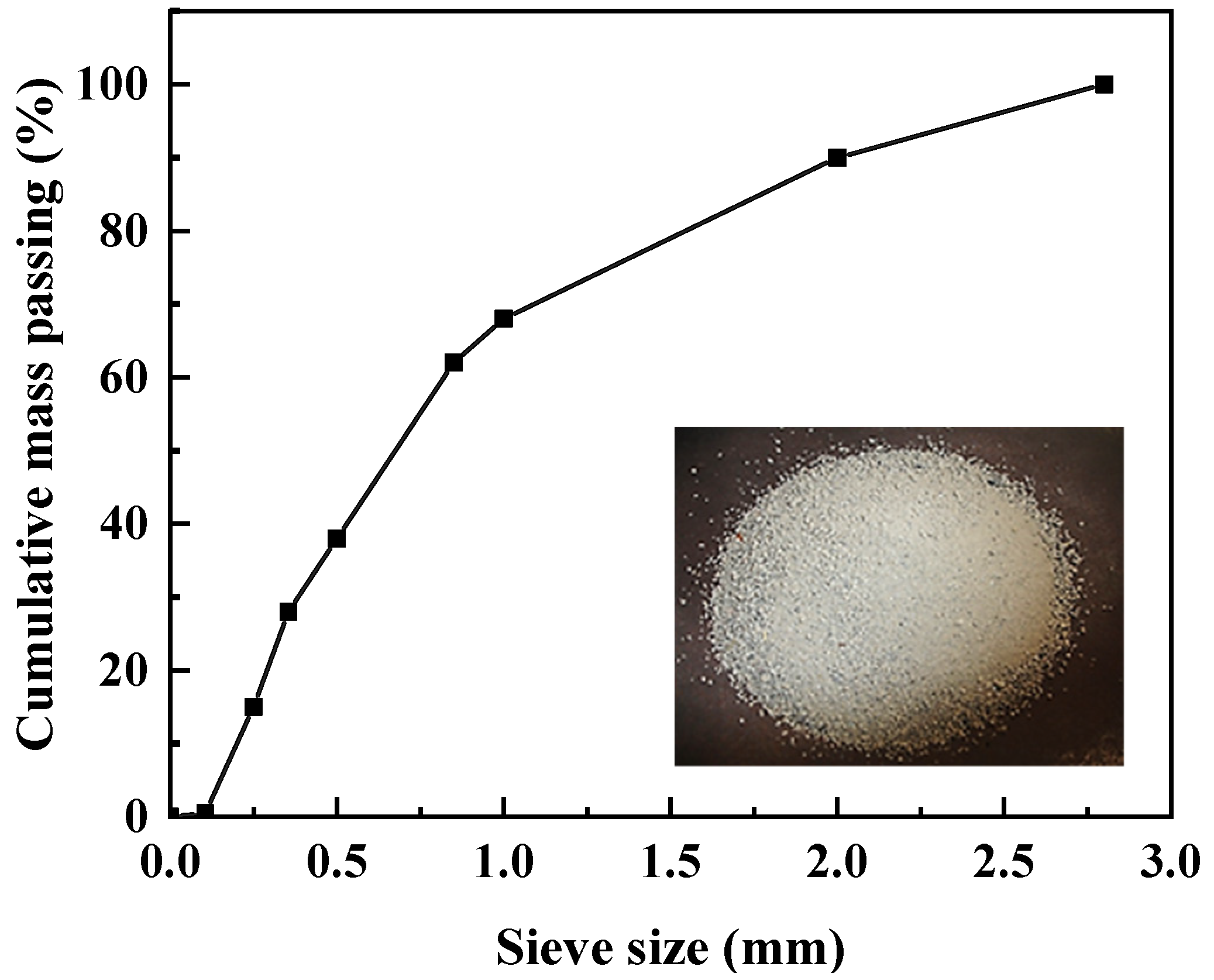

| Chemical Composition [%wt] | SiO2 | Al2O3 | K2O | Na2O | CaO | FeO | MgO | SO3 |

|---|---|---|---|---|---|---|---|---|

| Natural sand | 57.8 | 11.7 | 1.9 | 2.7 | 17.5 | 5.2 | 3.1 | 0.2 |

| Recycled sand | 27.6 | 9.3 | 2.0 | 0.4 | 52.5 | 6.1 | 2.0 | 0.4 |

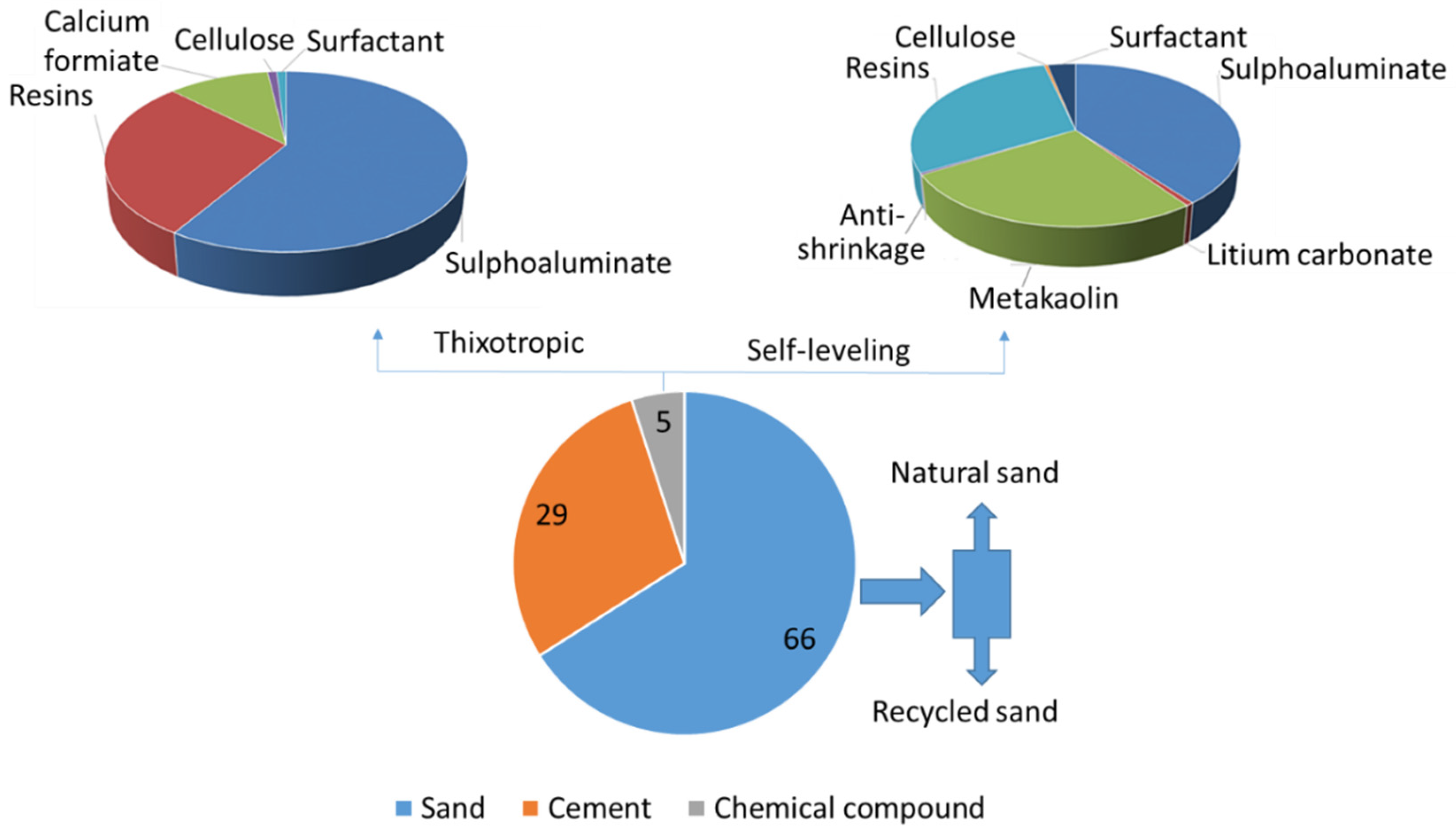

| Cement [kg] | Natural Sand [kg] | Recycled Sand [kg] | Water [kg] | Chemical Kit [kg] | |

|---|---|---|---|---|---|

| NSRX | 539.3 | 1227.3 | - | 279.0 | 93 |

| RSRX | 496.0 | - | 1128.7 | 256.6 | 85.5 |

| NRPX | 539.3 | 1227.3 | - | 279.0 | 93 |

| RSRX | 496.0 | - | 1128.7 | 256.6 | 85.5 |

| Test | Specimen Shape | Specimen Dimensions [cm] | Test Time [Days/Months/Cycles] | Standard |

|---|---|---|---|---|

| Workability | - | - | - | UNI EN 1015-3 [69] |

| Flexural strength | Prisms | 4 × 4 × 16 | 2, 7, 28, 90 days | EN 1015-11 [70] |

| Compressive strength | Post bending test pieces | 4 × 4 × 8 | 2, 7, 28, 90 days | EN 1015-11 [70] |

| Drying shrinkage | Prisms | 4 × 4 × 16 | 2, 7, 28, 90 days | EN 12617-4 [71] |

| Open/total porosity | Prisms | 4 × 4 × 16 | 28th curing day | UNI 11060:2003 [72] |

| Thermal cycles resistance | Prisms | 4 × 4 × 16 | - | - |

| Sulphate resistance | Prisms | 4 × 4 × 16 | 6 months | UNI 8019 [73] |

| Freeze–thaw resistance | Prisms | 4 × 4 × 16 | 300 cycles | UNI 7087 [74] |

| Mixes | Open Porosity (%) | Total Porosity (%) |

|---|---|---|

| NSPX | 17.3% | 25.8% |

| RSPX | 20.3% | 32.6% |

| NSRX | 20.5% | 28.8% |

| RSRX | 23.5% | 35.56% |

| Mixes | Sulphate Attack (6 Months) | Freeze–Thaw Cycles (300 Cycles) | |||||

|---|---|---|---|---|---|---|---|

| Δ Weight (%) | Δ Flexural Strength (%) | Δ Compressive Strength (%) | Penetration [cm] | Δ Weight (%) | Δ Flexural Strength (%) | Δ Compressive Strength (%) | |

| NSPX | −16.9% | −63.0% | −80.6% | 1.5 | −1.0% | −9.6% | −10.0% |

| RSPX | −15.8% | −55.1% | −79.3% | 1.7 | −1.0% | −11.6% | −10.4% |

| NSRX | −12.5% | −69.4% | −86.1% | 1.1 | −1.7% | −9.7% | −9.8% |

| RSRX | −11.7% | −61.8% | −77.1% | 1.2 | −1.2% | −14.0% | −18.1% |

| Mixes | Δ Weight (%) | Δ Compressive Strength (%) | Δ Flexural Strength (%) |

|---|---|---|---|

| NSPX | −5.5% | −49.9% | −52.1% |

| RSPX | −8.7% | −61.5% | −55.6% |

| NSRX | −14.9% | −21.8% | −44.4% |

| RSRX | −19.2% | −19.0% | −40.7% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Candamano, S.; Tassone, F.; Iacobini, I.; Crea, F.; De Fazio, P. The Properties and Durability of Self-Leveling and Thixotropic Mortars with Recycled Sand. Appl. Sci. 2022, 12, 2732. https://doi.org/10.3390/app12052732

Candamano S, Tassone F, Iacobini I, Crea F, De Fazio P. The Properties and Durability of Self-Leveling and Thixotropic Mortars with Recycled Sand. Applied Sciences. 2022; 12(5):2732. https://doi.org/10.3390/app12052732

Chicago/Turabian StyleCandamano, Sebastiano, Francesco Tassone, Ivan Iacobini, Fortunato Crea, and Piero De Fazio. 2022. "The Properties and Durability of Self-Leveling and Thixotropic Mortars with Recycled Sand" Applied Sciences 12, no. 5: 2732. https://doi.org/10.3390/app12052732

APA StyleCandamano, S., Tassone, F., Iacobini, I., Crea, F., & De Fazio, P. (2022). The Properties and Durability of Self-Leveling and Thixotropic Mortars with Recycled Sand. Applied Sciences, 12(5), 2732. https://doi.org/10.3390/app12052732