Design of a Chaotic Trajectory Generator Algorithm for Mobile Robots

Abstract

:1. Introduction

Motivation

2. Chaotic Systems

- High sensibility to initial conditions;

- Deterministic with apparently random behavior;

- Non-periodic oscillations.

2.1. Chaotic Hénon Map

2.2. Fractal Dimension

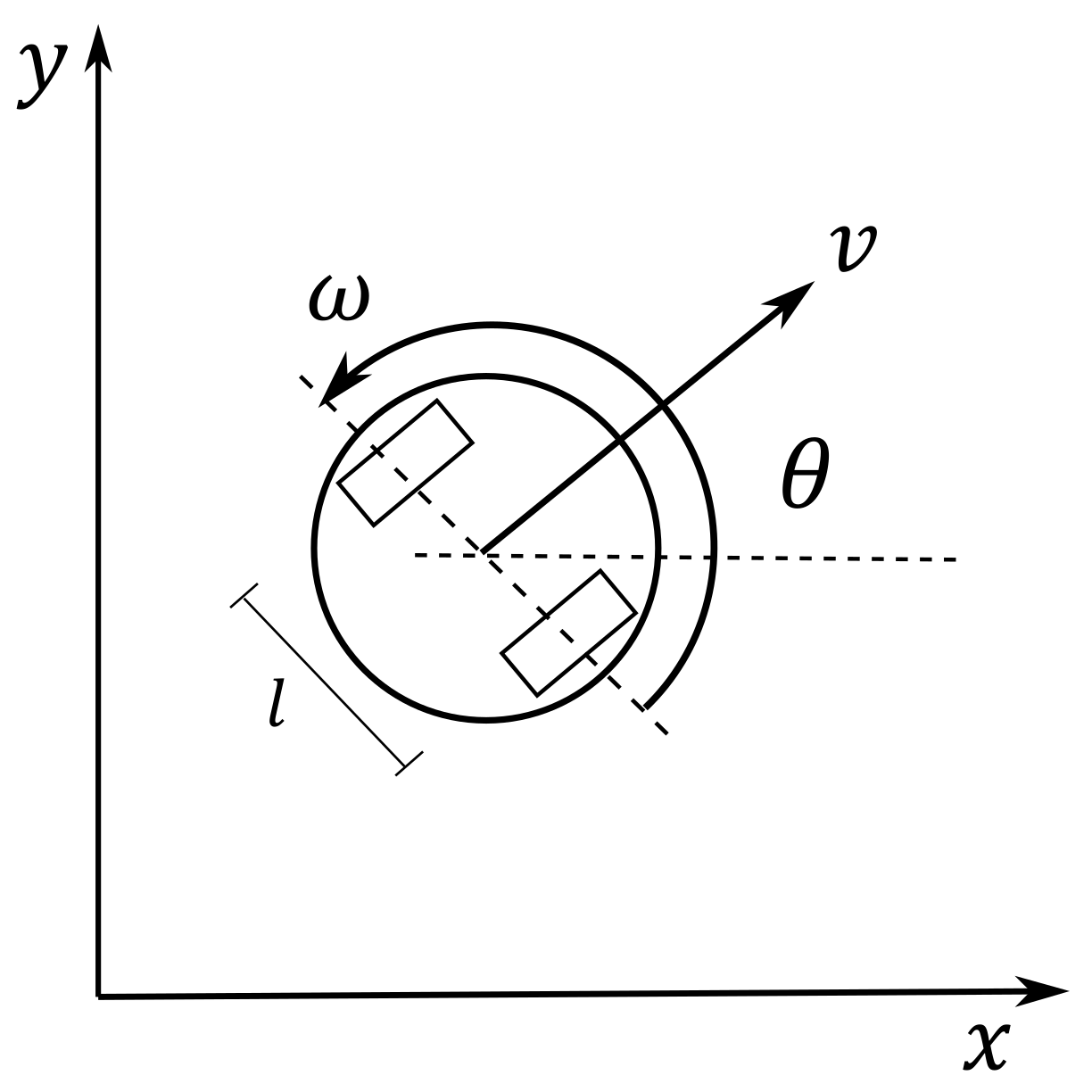

3. Mathematical Model of a Differential Drive Mobile Robot

- The robot moves in a perfectly flat surface without sliding, despite wheel resistance;

- Robot position is given by x, y, and coordinates, where represents the robot rotation in relation to the coordinate system.

4. Proposed Chaotic Trajectory Generator Algorithm for a Differential Drive Mobile Robot

| Algorithm 1. Proposed Algorithm |

| Input: Initial position of the robot in the work area, iterations |

| Output:, Left and right speeds for the mobile robot wheels |

| 1: , |

| , |

| n = 0; |

| While do |

| 2: |

| ; |

| 3: |

| ; |

| 4: |

| ; |

| 5: |

| ; |

| 6: s; |

| 7: . |

| end |

| return , |

Work Area Boundaries

5. Results

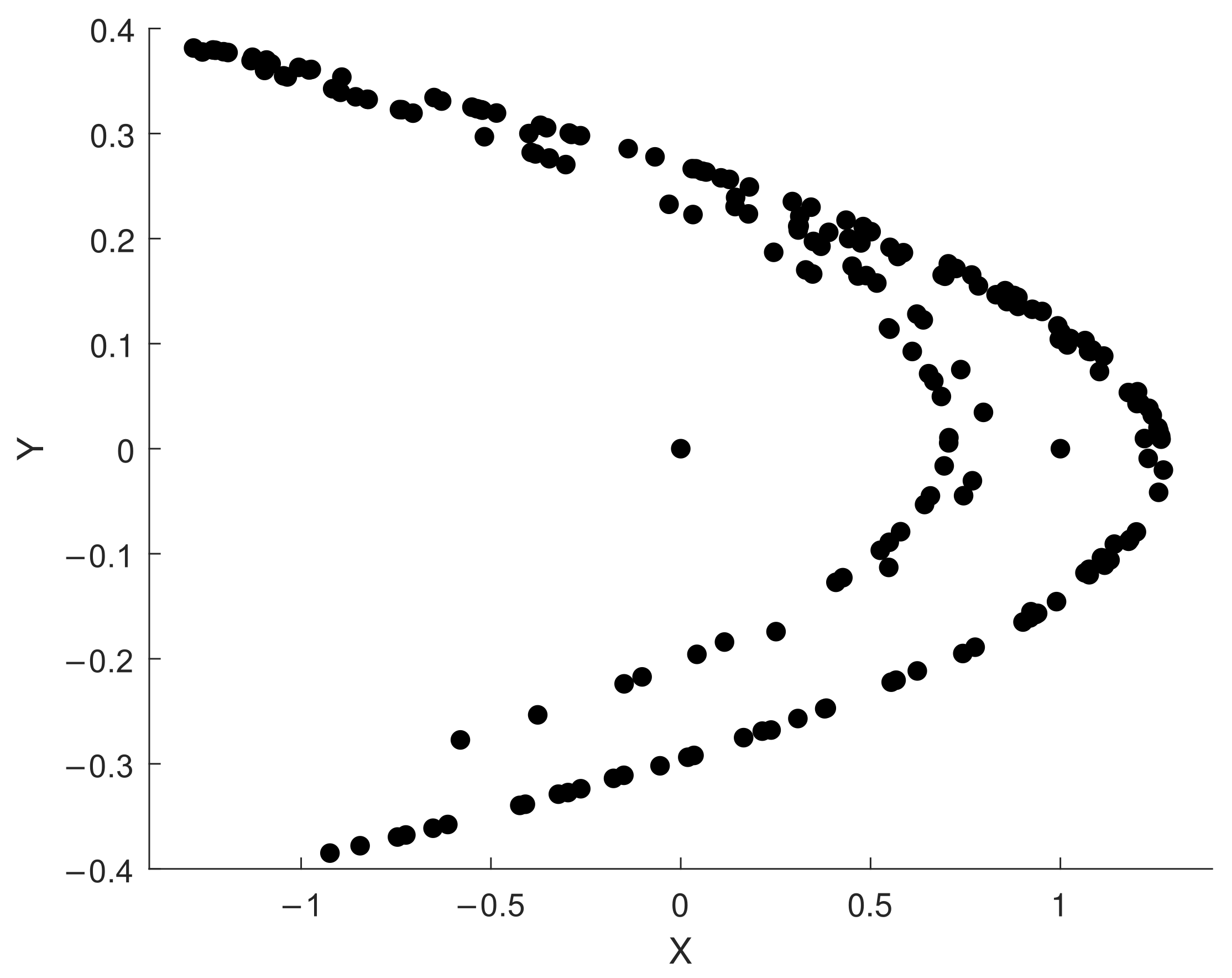

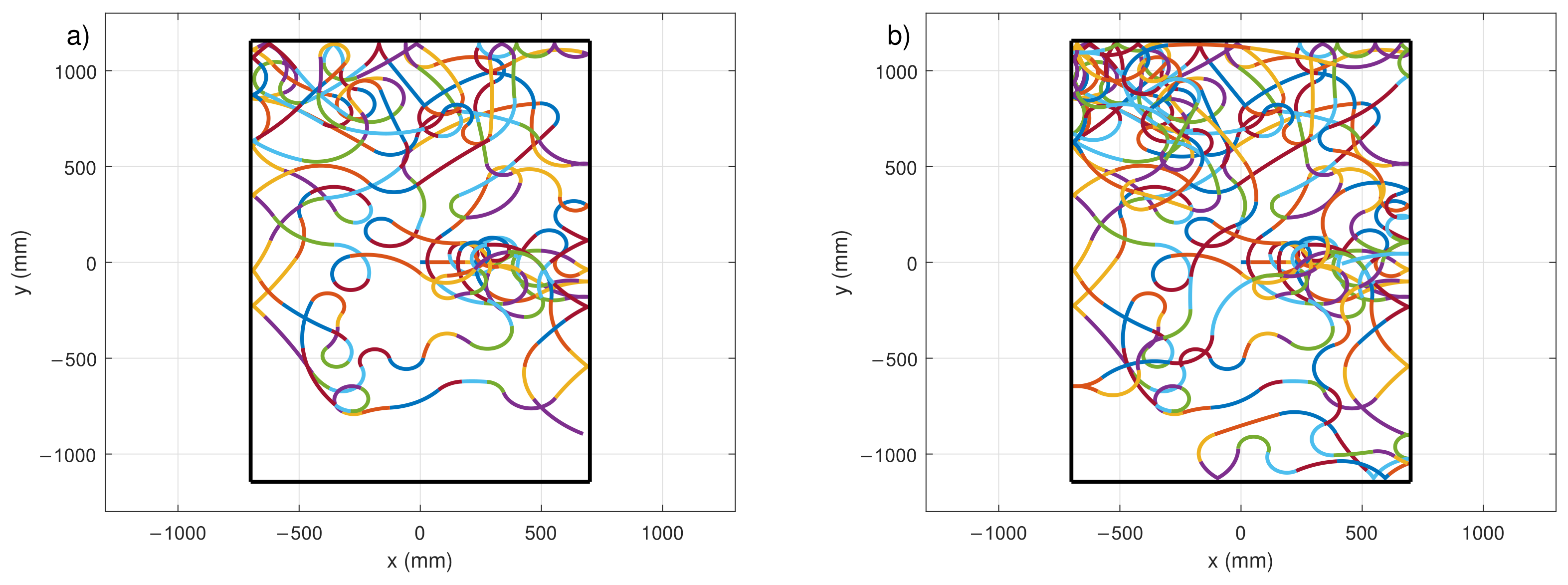

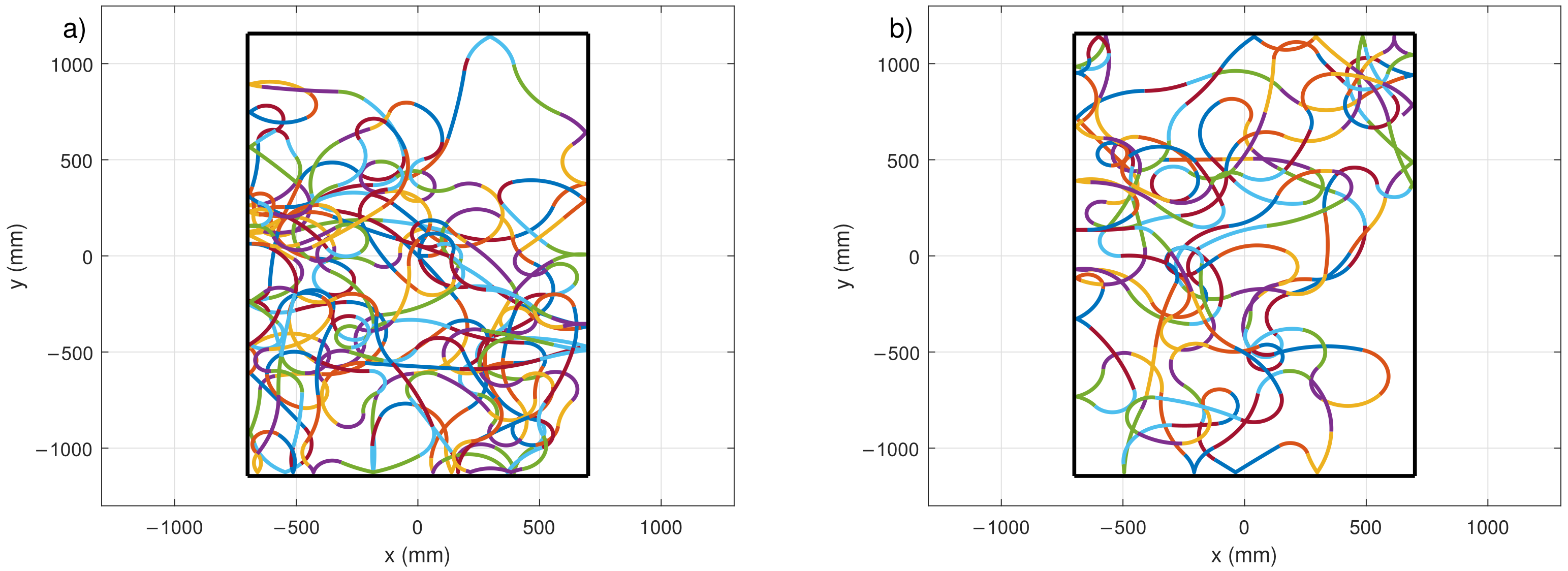

5.1. Coverage of the Work Area

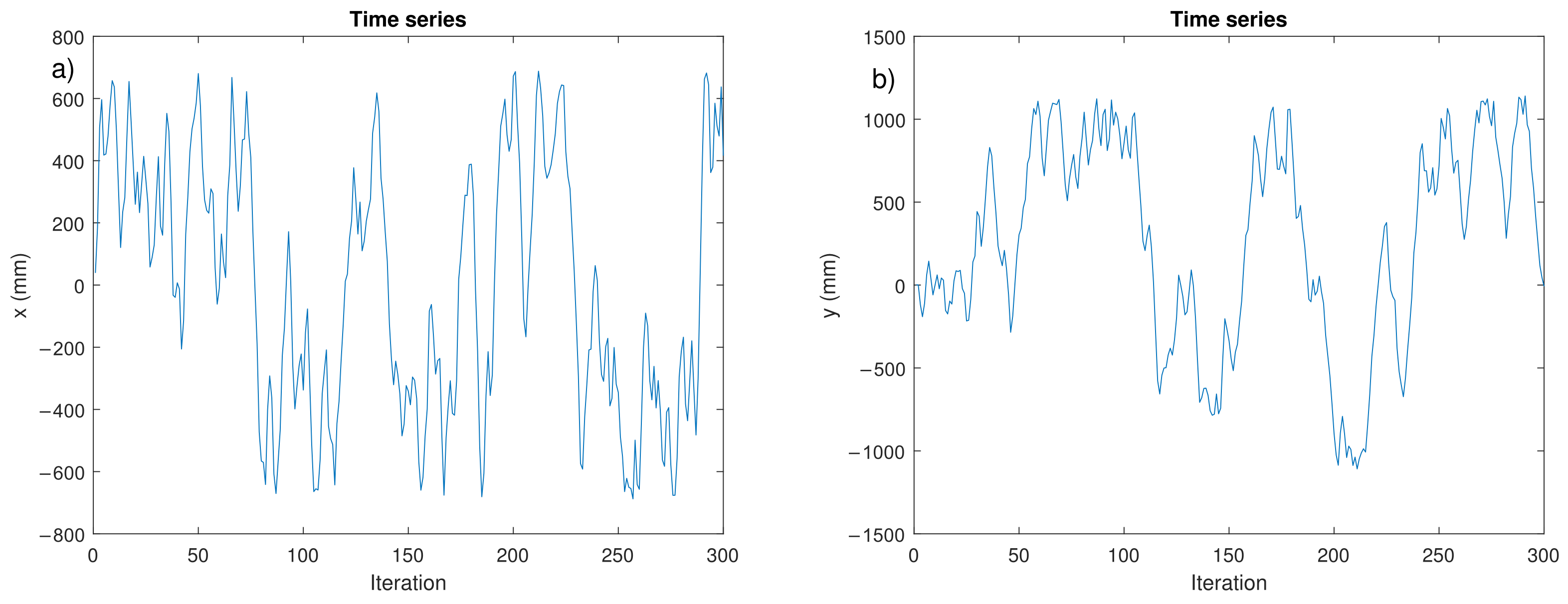

5.2. Gottwald–Melbourne Test

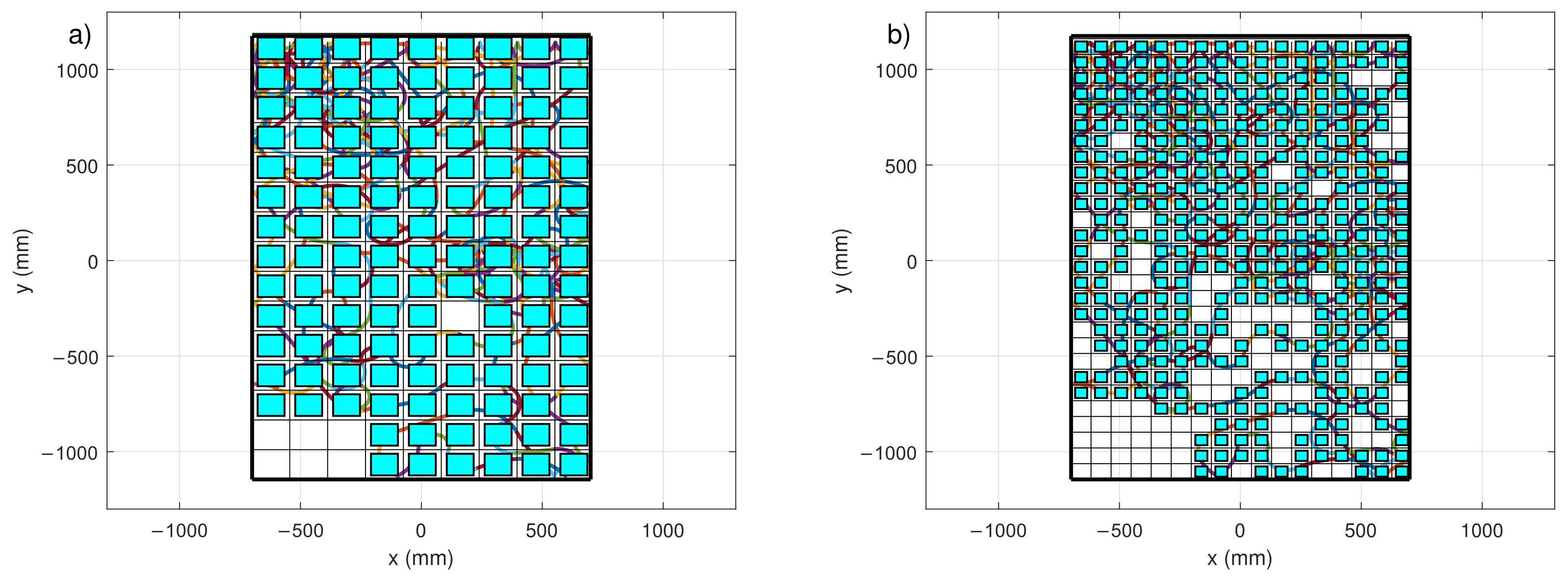

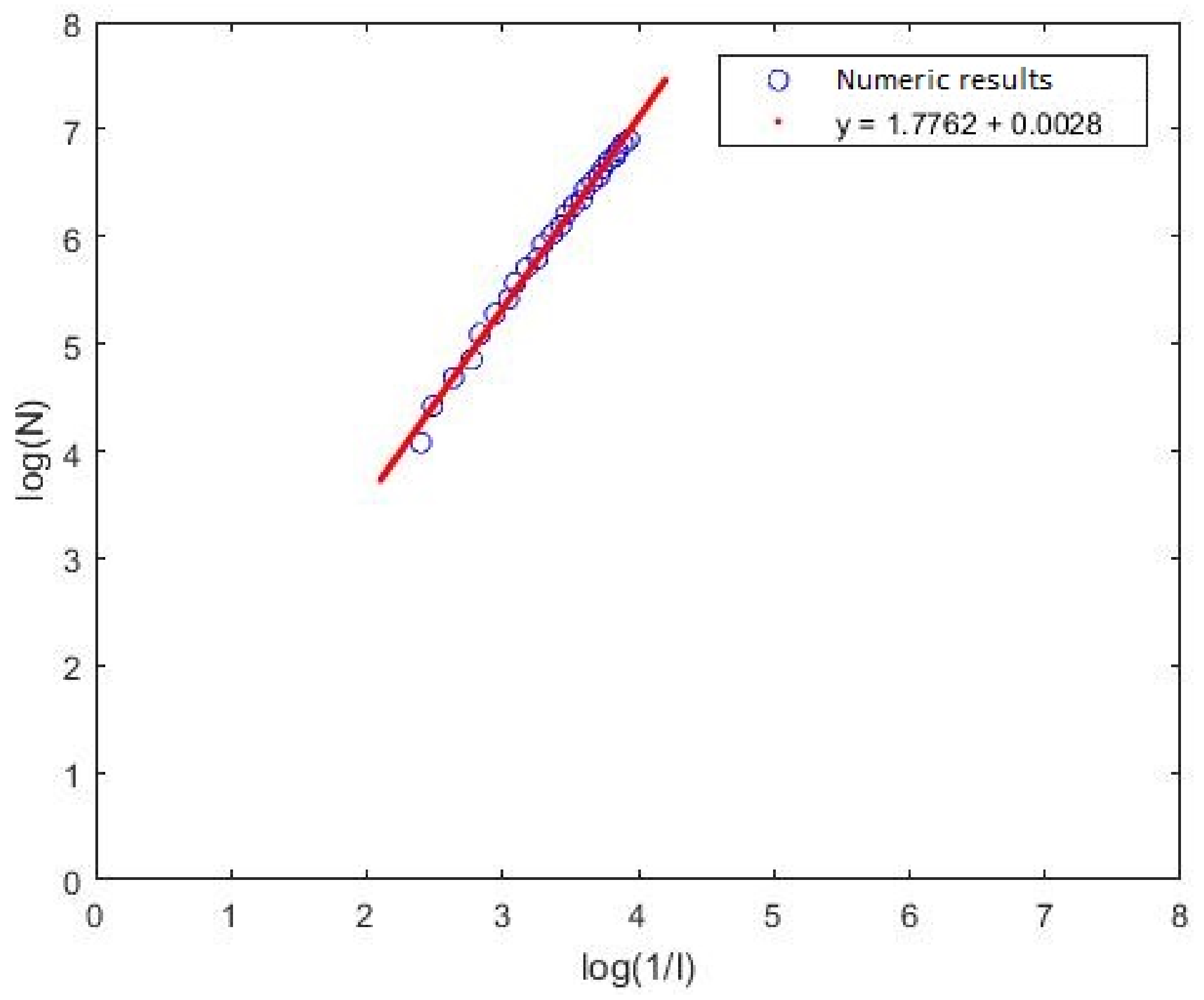

5.3. Box-Counting Test

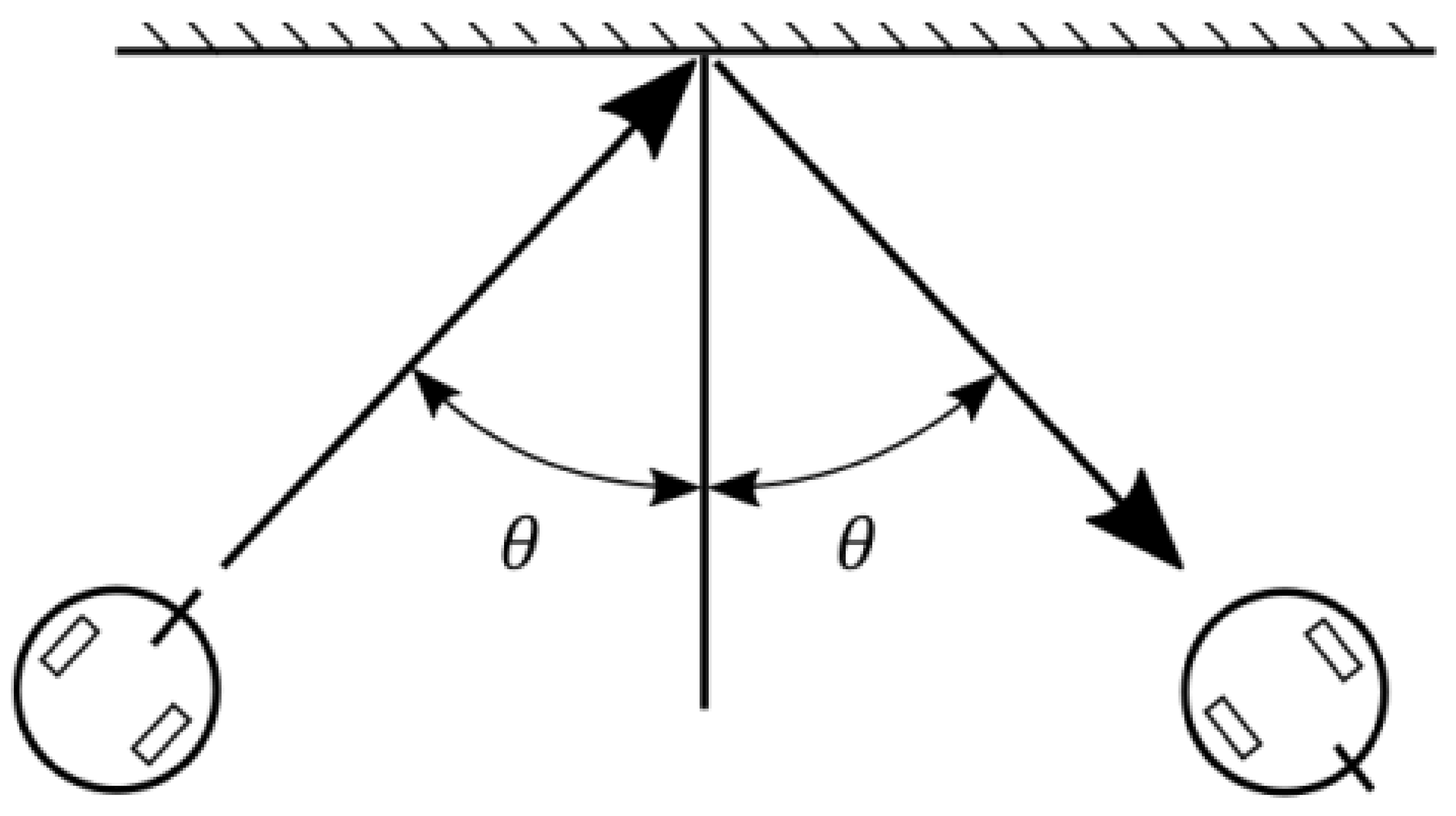

6. Multiple Robots

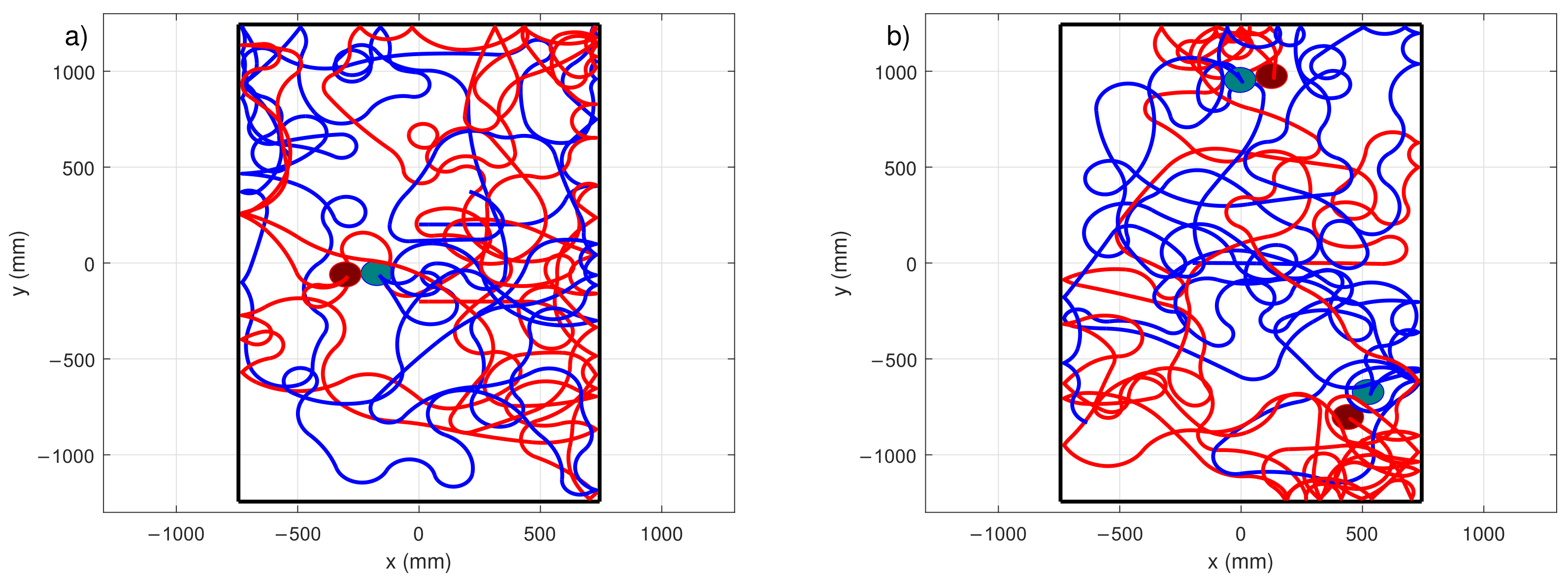

6.1. Two Mobile Robots in the Same Work Area

6.2. Three Mobile Robots in the Same Work Area

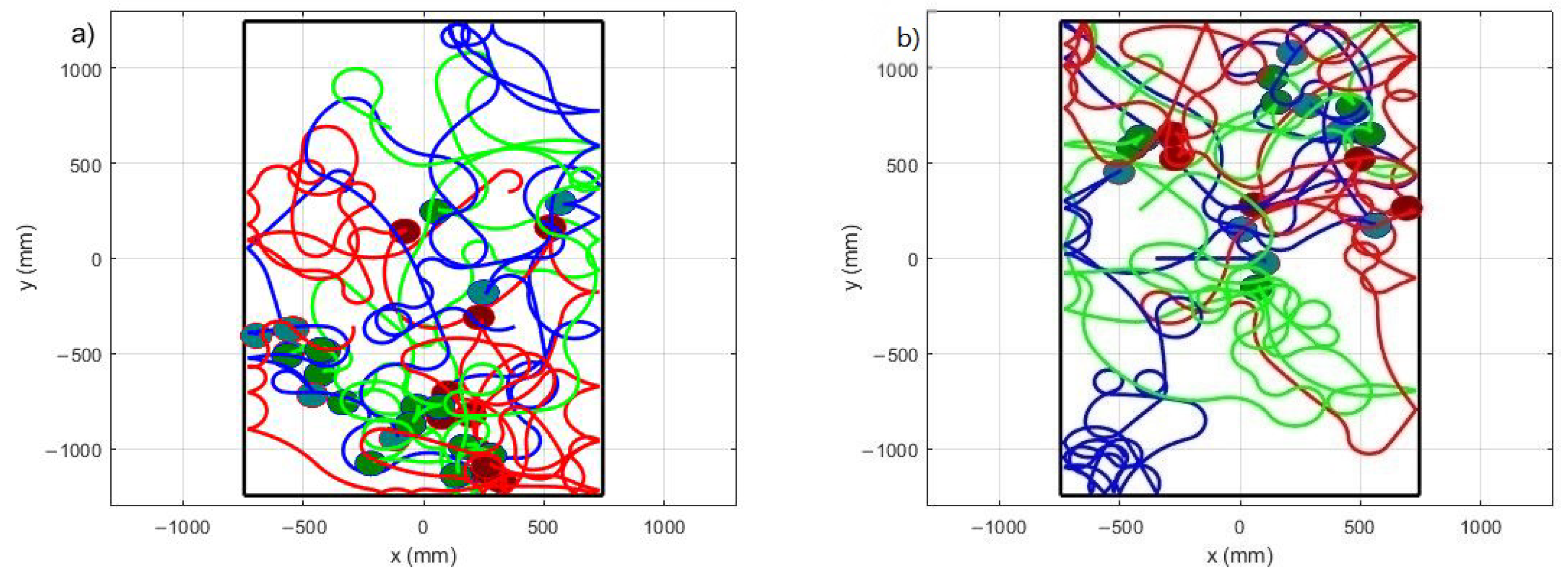

6.3. n-Mobile Robots in the Same Work Area

6.4. Presence of Chaos in Generated Trajectories for Multiple Mobile Robots

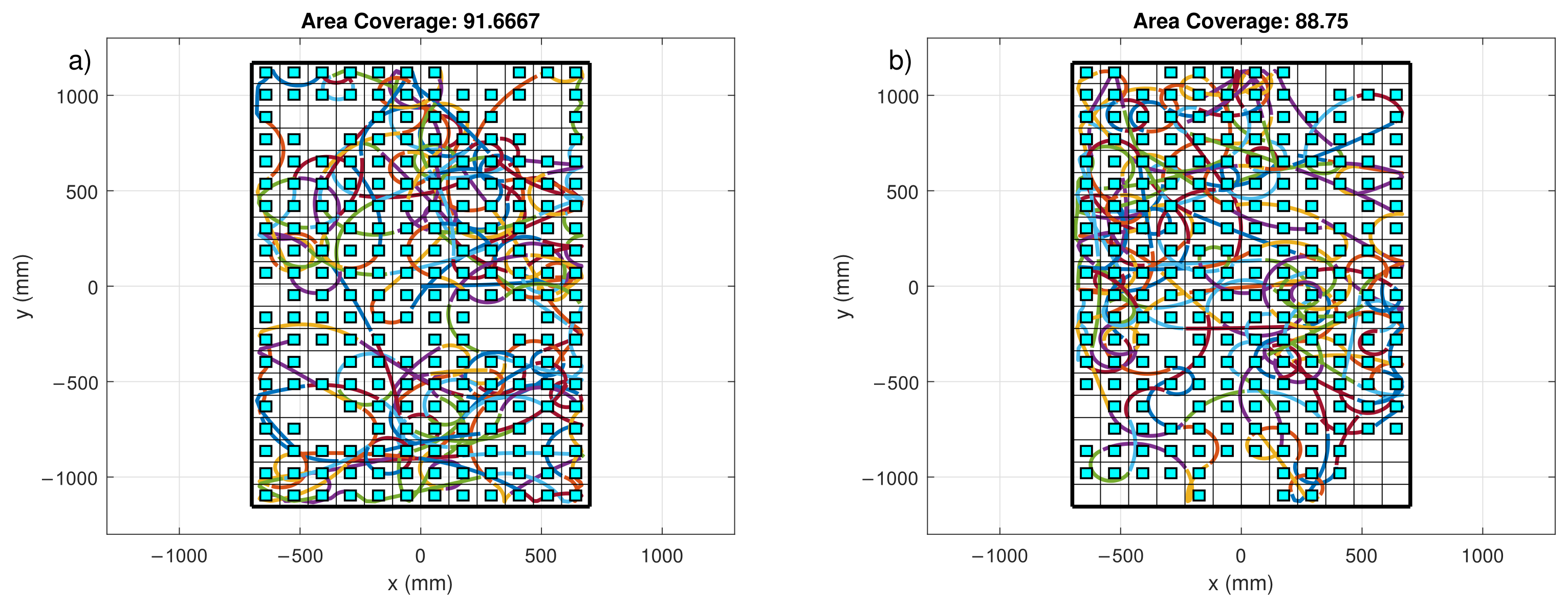

6.4.1. Coverage Percentage of the Test Area

6.4.2. Gottwald–Melbourne Test

6.4.3. Box-Counting Test

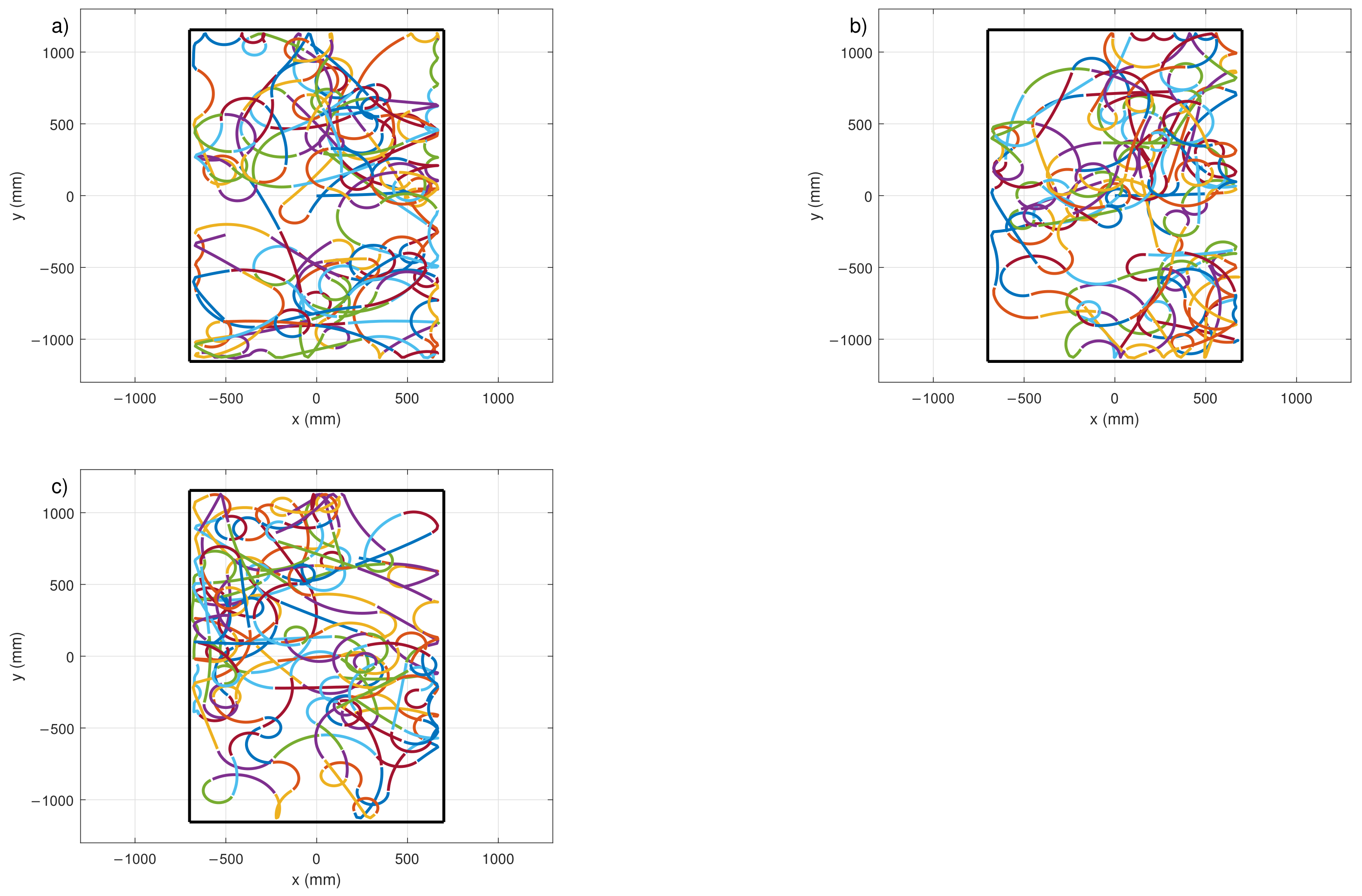

7. Experimental Results

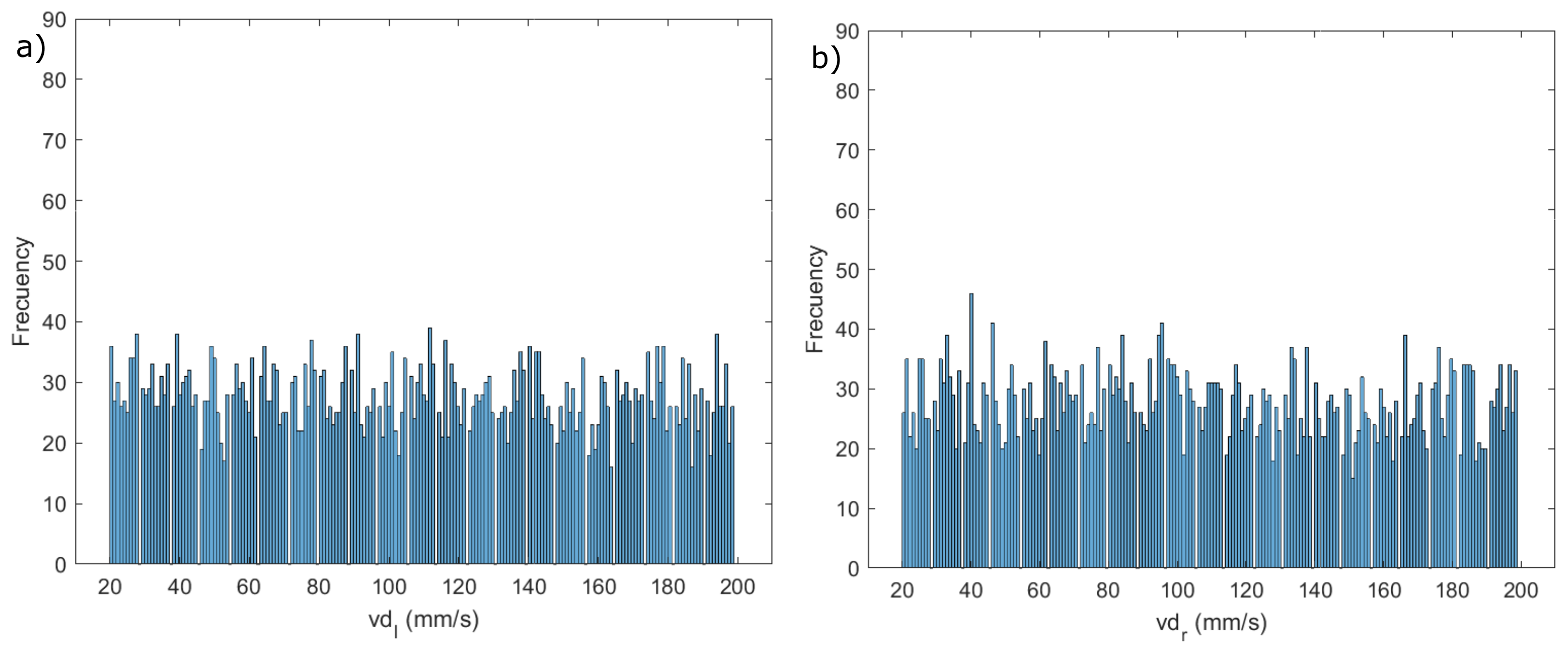

7.1. Materials

7.2. Methodology

- , , ;

- , , ;

- , , .

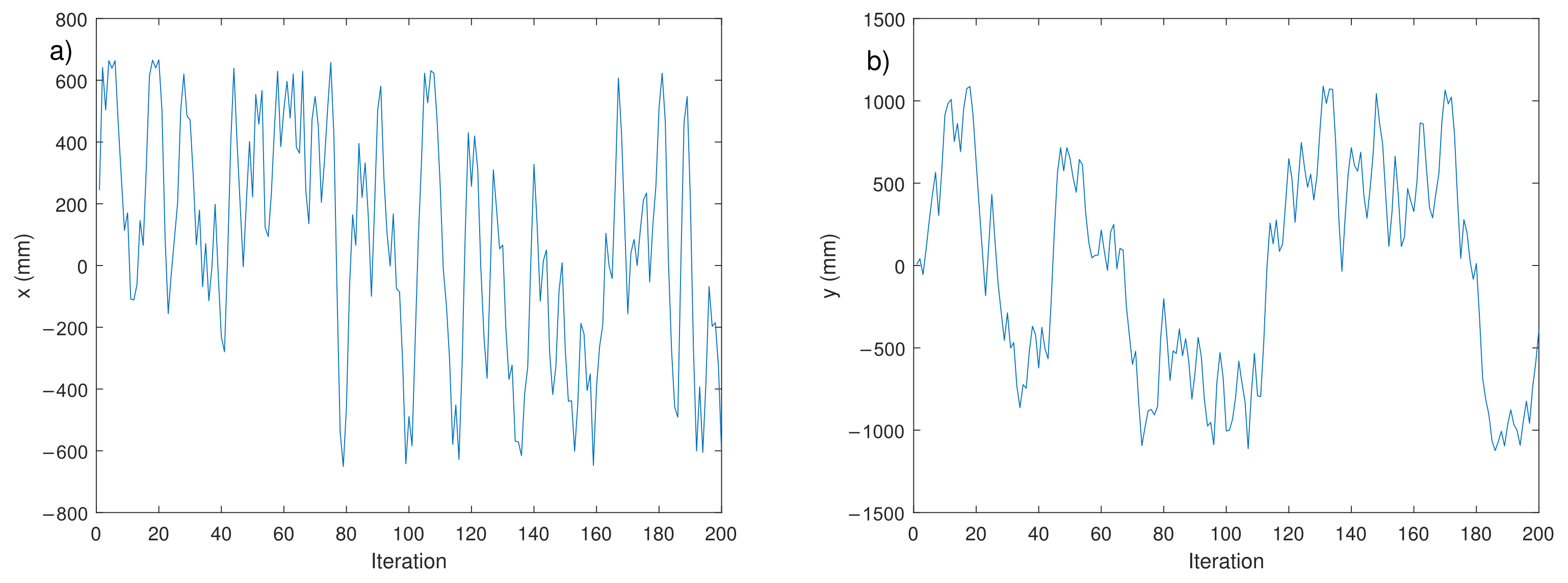

7.3. Coverage of the Work Area

7.4. Gottwald–Melbourne Test

7.5. Box-Counting Test

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, L.; Penq, H.; Kurths, J.; Yang, Y.; Schellnhuber, H. Chaos—Order transition in foraging behavior of ants. Proc. Natl. Acad. Sci. USA 2014, 111, 8392–8397. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nakamura, Y.; Sekiguchi, A. The Chaotic Mobile Robot. IEEE Trans. Rob. Autom. 2001, 17, 898–904. [Google Scholar] [CrossRef]

- Martins-Filho, L.; Macau, E. Kinematic control of mobile robots. ABCM Symp. Ser. Mech. 2006, 2, 258–264. [Google Scholar]

- Volos, C.K.; Kyprianidis, I.M.; Stouboulos, I.N. A chaotic path planning generator for autonomous mobile robots. Robot. Auton. Sys. 2012, 60, 651–656. [Google Scholar] [CrossRef]

- Curiac, D.; Volosencu, C. A 2D chaotic path planning for mobile robots accomplishing boundary surveillance missions in adversarial conditions. Comm. Nonlin. Sci. Num. Sim. 2014, 19, 3617–3627. [Google Scholar] [CrossRef]

- Pliego-Jiménez, J.; Martínez-Clark, R.; Cruz-Hernández, C.; Arellano-Delgado, A. Trajectory tracking of wheeled mobile robots using only Cartesian position measurements. Automatica 2021, 133, 109756. [Google Scholar] [CrossRef]

- Martínez-Clark, R.; Cruz-Hernández, C.; Pliego-Jiménez, J.; Arellano-Delgado, A. Control algorithms for the emergence of self-organized behaviors in swarms of differential-traction wheeled mobile robots. Int. J. Adv. Robot. Syst. 2018, 15, 172988141880643. [Google Scholar] [CrossRef]

- Montañez-Molina, C.; Pliego-Jiménez, J.; Cruz-Hernández, C. Chaotic velocity profile for surveillance tasks using a quadrotor. In Proceedings of the 2021 IEEE Conference on Control Technology and Applications (CCTA), San Diego, CA, USA, 9–11 August 2021. [Google Scholar]

- Nasr, S.; Mekki, H.; Bouallegue, K. A multi-scroll chaotic system for a higher coverage path planning of a mobile robot using flatness controller. Chaos Solitons Fractals 2018, 118, 366–375. [Google Scholar] [CrossRef]

- Majeed, A.I. Mobile Robot Motion Control Based on Chaotic Trajectory Generation. J. Eng. Sustain. Dev. 2010, 24, 26–33. [Google Scholar]

- Petavratzis, E.K.; Volos, C.K.; Moysis, L.; Stouboulos, I.N.; Nistazakis, H.E.; Tombras, G.S.; Valavanis, K.P. An Inverse Pheromone Approach in a Chaotic Mobile Robot’s Path Planning Based on a Modified Logistic Map. Technologies 2019, 7, 84. [Google Scholar] [CrossRef] [Green Version]

- Martins-Filho, L.; Luiz, S.; Machado, R.F.; Rocha, R.; Vale, V.S. Commanding mobile robots with chaos. In Proceedings of the ABCM Symposium Series in Mechatronics, Sao Paulo, SP, Brazil, 10–14 November 2004; Volume 1. [Google Scholar]

- Hénon, M. A Two-Dimensional Mapping with a Strange Atractor. Comm. Math. Phys. 1976, 50, 69–77. [Google Scholar] [CrossRef]

- Dictionary, Oxford English. In Oxford Dictionary of English, 3rd ed.; Oxford University Press: Oxford, UK, 2010; ISBN 0199571120.

- Torres, N. Caos en sistemas biológicos. Mat. Rev. Dig. Div. Mat. Real Soc. Mat. Esp. 2005, 1, 478–482. [Google Scholar]

- Besicovitch, A. On linear sets of points of fractional dimension. Math. Ann. 1929, 101, 161–193. [Google Scholar] [CrossRef]

- Suster, P.; Jadlovska, A. A Neural tracking trajectory of the mobile robot Khepera II internal model control structure. In Proceedings of the International Conference Process, Kouty nad Desnou, Czech Republic, Prague, 7–10 June 2010. [Google Scholar]

- Gottwald, G.A.; Melbourne, I. A new test for chaos in deterministic systems. Proc. R. Soc. Lond. A Math. Phys. Eng. Sci. R. Soc. 2004, 460, 603–611. [Google Scholar] [CrossRef] [Green Version]

- Mandelbrot, B.B. The Fractal Geometry of Nature; WH Freeman: New York, NY, USA, 1983; Volume 1, p. 173. [Google Scholar]

- Macmillan, K.; Foroutan-Pour, P.; Dutilleul; Smith, D. Advances in the implementation of the box-counting method of fractal dimension estimation. Appl. Math. Comp. 1999, 105, 195–210. [Google Scholar]

| Number of Robots | Coverage (%) |

|---|---|

| 1 | 18.1250 |

| 2 | 33.7500 |

| 3 | 46.4583 |

| 4 | 55.8333 |

| 5 | 63.3333 |

| 6 | 70.2083 |

| 7 | 75.8333 |

| 8 | 79.3750 |

| 9 | 82.0833 |

| 10 | 85.8300 |

| Number of Robots | Result for x | Result for y |

|---|---|---|

| 1 | 0.9837 | 0.9254 |

| 2 | 0.9461 | 0.9107 |

| 3 | 0.9540 | 0.9307 |

| 4 | 0.9863 | 0.9633 |

| 5 | 0.9554 | 0.9417 |

| 6 | 0.9899 | 0.9601 |

| 7 | 0.9919 | 0.9645 |

| 8 | 0.9621 | 0.9774 |

| 9 | 0.9619 | 0.9445 |

| 10 | 0.9769 | 0.9552 |

| Number of Robots | D |

|---|---|

| 1 | 1.7762 |

| 2 | 1.7863 |

| 3 | 1.7634 |

| 4 | 1.7787 |

| 5 | 1.7723 |

| 6 | 1.7636 |

| 7 | 1.7864 |

| 8 | 1.7741 |

| 9 | 1.7679 |

| 10 | 1.7769 |

| l | D | |||

|---|---|---|---|---|

| 59 | 0.0909 | 4.0775 | 2.3978 | 1.7004 |

| 108 | 0.0714 | 4.6821 | 2.6391 | 1.7742 |

| 225 | 0.0476 | 5.4161 | 3.0445 | 1.7789 |

| 329 | 0.0384 | 5.7960 | 3.2580 | 1.7789 |

| 447 | 0.0322 | 6.1025 | 3.4339 | 1.7770 |

| 570 | 0.0277 | 6.3456 | 3.5835 | 1.7707 |

| 709 | 0.0256 | 6.5638 | 3.7135 | 1.7675 |

| 848 | 0.0217 | 6.7428 | 3.8286 | 1.7611 |

| 995 | 0.0196 | 6.9027 | 3.9318 | 1.7556 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cetina-Denis, J.J.; Lopéz-Gutiérrez, R.M.; Cruz-Hernández, C.; Arellano-Delgado, A. Design of a Chaotic Trajectory Generator Algorithm for Mobile Robots. Appl. Sci. 2022, 12, 2587. https://doi.org/10.3390/app12052587

Cetina-Denis JJ, Lopéz-Gutiérrez RM, Cruz-Hernández C, Arellano-Delgado A. Design of a Chaotic Trajectory Generator Algorithm for Mobile Robots. Applied Sciences. 2022; 12(5):2587. https://doi.org/10.3390/app12052587

Chicago/Turabian StyleCetina-Denis, Juan José, Rosa Martha Lopéz-Gutiérrez, César Cruz-Hernández, and Adrian Arellano-Delgado. 2022. "Design of a Chaotic Trajectory Generator Algorithm for Mobile Robots" Applied Sciences 12, no. 5: 2587. https://doi.org/10.3390/app12052587

APA StyleCetina-Denis, J. J., Lopéz-Gutiérrez, R. M., Cruz-Hernández, C., & Arellano-Delgado, A. (2022). Design of a Chaotic Trajectory Generator Algorithm for Mobile Robots. Applied Sciences, 12(5), 2587. https://doi.org/10.3390/app12052587