Featured Application

The results of this study can be used as a reference for establishing ergonomic interventions for fruit farming.

Abstract

Farmers are often exposed to risk factors for musculoskeletal disorders through lifting, carrying heavy loads, and sustained or repeated full-body bending. Several relevant studies on ergonomic interventions have been conducted for specific agricultural tasks, such as harvesting and pruning, by experts without involving farmers. This study introduces ergonomic interventions to mitigate risk factors in a farming organization that cultivates peaches as the main crop based on ergonomic analysis of the entire peach farming cycle; subjective and objective evaluations of the proposed interventions are also performed. The ergonomic analysis and interventions were established based on consultations provided by an ergonomist, the government, and the organization members. Engineering controls were introduced for powered carts, sorters, and stools to reduce load carrying and awkward postures; moreover, thermal or cooling vests, winter shoes and gloves, and farmer hats were provided to alleviate cold or heat stresses. Administrative controls such as education/training and adjusting work–rest cycles were also recommended after considering the characteristics of the risk factors identified. The scores of the questionnaire survey from the organization members were high (>4.1 out of 5 for five questions), and postural loads for unstable postures by RULA were significantly reduced so as to avoid fast or immediate changes for the postures or working methods assessed. The study results are expected to help promote farmers’ health and enhance farming efficiency.

1. Introduction

Agriculture, mining, and construction are considered the three major industries that involve high amounts of risk; in the agriculture industry, the severity of agricultural diseases and accidents continues to increase because of the aging agricultural population [1]. Work-related musculoskeletal disorders (WMSDs) have been classified as the most common nonfatal injuries and illnesses in farmers [2,3,4]. The International Labour Organization reported that around 160 million work-related illnesses occur per year worldwide, among which WMSDs feature prominently, with extensive occupational health and economic consequences [5]. In Korea, the prevalence of occupational diseases in farmers was 5.0% in 2020. Among these occupational diseases, musculoskeletal disorders (MSDs) occupied approximately 84.6%, followed by circulatory system diseases (3.0%), skin diseases (2.9%), and nervous system diseases (2.1%). Among MSDs, back pain (47.3%) was identified as the most prevalent, followed by knee (27.3%) and shoulder (6.9%) disorders [6].

The WMSD risk factors with the highest priority in agriculture include lifting and carrying heavy loads (>22.5 kg), sustained or repeated full-body bending (stooping), and highly repetitive hand work (clipping and cutting) [2,7,8,9,10,11]. Further, some agricultural activities are difficult in terms of not only the physical effort involved but also the duration of the activity, with farmers working for more than 8 h per day and often without adequate rest [7]. In addition, farmers are exposed to extreme weather conditions (low and high temperatures, severe rain, and wind, etc.), and farm-machinery-related body vibrations and low-frequency noise contribute to spinal pain [12]. Based on these points, it has been postulated that farmers are exposed to a multitude of WMSD risk factors [13].

Based on a literature survey, Benos et al. [14] reported that harvesting (51.9%) was most frequently referred to in the 27 selected investigations, followed by load carrying (11.1%), pruning (7.4%), planting (3.7%), digging (3.7%), peeling (3.7%), sorting (3.7%), and weeding (3.7%) among manual operations that cause WMSDs. Of the risk factors associated with the development of WMSDs, stooping, or prolonged trunk flexion (51.9%), was identified as a risk factor in a majority of the selected papers; repetitive movement (29.6%) was identified as the second most-reported risk factor, followed by age (22.2%), heavy carrying and lifting (14.8%), and gender and kneeling (11.1% each) [14].

Thus, ergonomic interventions for reducing agricultural work-related musculoskeletal loadings, which can help prevent WMSDs in agriculture, are required. To this end, several studies have focused on ergonomic interventions for particular tasks in crop cultivation and not on the overall agricultural work. Silverstein et al. [15] evaluated an ergonomically designed bag for coffee harvesting. Pranav and Patel [16] developed an ergonomic tool for manual harvesting of oranges in hilly regions. Other ergonomic-intervention-related studies include ergo bucket carriers and easy lift [17]; an apple picking bucket [18]; hand-glove materials for farming activities [19]; magnifier inspection, a lift assist system, and a smokeless method for calming bees in apiculture [20]; corrective insoles [21]; ergonomic baskets for tealeaf plucking [22]; and ergonomic interventions for weeding, weighing beef calves, and growing vegetables [23,24,25]. Fathallah [2] reviewed the extent of MSDs in agriculture and employed a historic perspective on how ergonomic interventions have been used to reduce the health effects of labor-intensive agriculture.

Farmers have more knowledge and experience regarding farming tasks, but they are generally not aware that the risk factors involved in their occupations can be addressed with ergonomics [13]. Ergonomic interventions without worker participation are much less likely to be practical or acceptable [26]. For ensuring the success of ergonomic interventions, a participatory approach involving farmers and ergonomists is needed. However, most existing studies on this topic are mainly based on the expertise of ergonomists without farmer participation.

Most farmers focus on producing high-quality agricultural produce and reducing costs rather than controlling WMSD risk factors that can help improve their own health [20]. In Korea, WMSD cases are expected to increase significantly with the ageing of the farming population. This study aims to (1) ergonomically analyze all agricultural tasks performed during peach farming in a Korean farming organization located in a city in the southern part of Korea, from pruning in January to composting work in December; (2) introduce ergonomic interventions for controlling the musculoskeletal loadings analyzed; and (3) subjectively and objectively evaluate the interventions implemented. All processes associated with this study were conducted in 2020 and were based on the participatory approach, in which an ergonomist, farmers, and the Rural Development Agency (RDA, an affiliation of the Ministry of Agriculture, Food and Rural Affairs of Korea) participated. The RDA financially supported this study and provided the protocol for this study and information on interventions adopted in other farming organizations. It is expected that this study can help improve the health and safety of farmers as well as farming work efficiency.

2. Materials and Methods

2.1. Participants

Nine male members of a peach cultivating organization voluntarily participated in the study. Their ages ranged from 59 to 78; mean ± standard deviation: −67.2 ± 5.67 years. The participants had >30 years of agricultural work experience. The organization grows peaches as the main crop; some members also cultivate apples. The organization of the study consisted of a small voluntary meeting with nine members for exchanging information on peach farming and selling peaches jointly, the members of which were self-employed farmers. The members and their family members performed most faming activities.

2.2. Data Collection

Data for ergonomic analysis, which included monthly crop-growing phases, agricultural work activities, and their risk factors by phase, were collected through discussions between the author and members of the organization. During the discussion, the levels of the risk factors were determined, which were calculated as the product of frequency and intensity for each agricultural task. The values of frequency and intensity ranged from 1 to 3; the higher the values, the higher are the frequency and intensity. The scores for the frequency and intensity were assigned as in Table 1.

Table 1.

Scores and descriptions for frequency and intensity.

Ergonomic interventions were evaluated using a questionnaire rated on a 5-point Likert scale (1. very low or unsatisfied to 5. very high or satisfied). The questionnaire was composed of five questions related to the improvement of work safety, safety consciousness, necessity of interventions, effectiveness of interventions, and general satisfaction. The questionnaire survey was administered to all nine members of the farming organization at the end of the ergonomic intervention project.

2.3. Ergonomic Assessment

Postural loads or musculoskeletal loadings before and after introducing the ergonomic interventions were assessed through the rapid upper-limb assessment (RULA) [27]. Although RULA focuses on evaluation of the upper-limb postures, including the trunk, with only two classifications for leg postures, this study adopted RULA for assessing postural loads because (1) it is often employed for rating postural loads in agriculture [28], and (2) it may be a better method for estimating postural loads, including awkward or unstable lower-limb postures and associations with MSDs, compared to other representative observational techniques [29,30,31,32,33]. The author selected and assessed the posture for each of six tasks (six postures in total) that seemed to be most stressful among those performed by the head farmer of the organization after viewing videos and photographs for working scenes before and after introducing engineering interventions. The six tasks were chosen for comparing postural loads before and after introducing engineering interventions (see Table 2). The videos and photographs were reviewed in the author’s university laboratory for selecting a posture for each of six tasks assessed.

RULA

RULA was developed by McAtamney and Corlett [27]. It provided a quick assessment of the loading on the musculoskeletal system due to the postures of the neck, trunk and upper limbs, muscle function, and external loads exerted. Based on the grand score of its coding system, four action levels, which indicate the level of intervention required to reduce the risks of injury due to physical loading on the worker, were suggested:

- Action level 1: posture is acceptable if it is not maintained or repeated for long periods;

- Action level 2: further investigation is needed, and changes may be needed;

- Action level 3: investigation and changes are required soon;

- Action level 4: investigation and changes are required immediately.

2.4. Procedure for Ergonomic Interventions

Ergonomic interventions were introduced in four stages:

- The work analysis was performed, which included monthly examination of crop-growing phases and analyzing agricultural work activities by phase, work duration, materials handled, etc.

- The risk factors for each monthly crop-growing phase were identified and classified according to four aspects (4 M): man, machine, mediating factors (e.g., materials, environment), and management. The risk assessment for each factor categorized under 4 M was based on the frequency and severity of the activities investigated.

- Possible interventions to avoid or minimize potential injuries and disabilities, including WMSDs, were established based on the effectiveness, efficiency, cost, and applicability of the interventions. Ergonomic interventions were prioritized for high-risk tasks within the allowed budget.

- Ergonomic interventions for the assessed farming activities were implemented and evaluated. The interventions included both administrative and engineering controls for mitigating musculoskeletal loadings and abating WMSDs in peach farming: providing small and inexpensive equipment or safeguards; education/training on exercise or stretching and physiotherapy; adjusting work–rest cycles, etc. All processes for ergonomic interventions were performed in consultation with the farming organization.

2.5. Budget for Interventions

The budget for ergonomic interventions was set at USD 49,915 (KRW 59,000,000). The RDA provided financial support of USD 42,301 (KRW 50,000,000), while the rest (USD 7614 (KRW 9,000,000)) was borne by the organization.

3. Results

3.1. Work Analysis

The work analysis showed that annual peach farming is performed in the order of pruning, pesticide spraying, flower and fruit thinning, wrapping fruit into paper bags, harvesting, and sorting/packaging (Table 2). Among the farming activities, pruning is conducted twice a year (January–February and June–September), and pesticide spraying is performed 10–15 times a year (March to August). In May and June, the peaches are wrapped in paper bags to protect them from rain, birds, and insects because the peaches are somewhat ripe.

Table 2.

Work and risk analysis results.

3.2. Risk Analysis

The risk factors associated with peach farming as per the crop-growing phases were analyzed via consultation with the farming organization (Table 2). The analysis was performed in terms of the 4 M criteria stated above. During the analysis, the degrees of risk factors for the crop-growing phases and 4 M were obtained. Manual material handling tasks involved in harvesting, pesticide spraying, and composting, and awkward postures during working at a height for pruning, thinning flower and fruit, wrapping fruits in paper bags, and harvesting were identified as the riskiest tasks (risk score: 9), followed by noise, vibration, overturn of the speed sprayer, pesticide poisoning, and pesticide inhalation (risk score: 6). Exposures to low and high temperatures during pruning, flower and fruit thinning, wrapping fruits in bags, sorting and packaging, and composting were identified as relatively less risky tasks compared to other activities (risk score: 4).

3.3. Ergonomic Interventions

3.3.1. Engineering Interventions

Cart

Conventionally, a one-wheel manual cart is used for transporting compost bags (20 kg/bag) and harvested peaches when composting or harvesting peaches (Figure 1a). Operators need to manually pull or push the cart during operation, which requires a considerable amount of force. Since the cart has a single wheel, its center of gravity keeps changing, which forces the operators to exert greater force than that required by the loaded weight in the cargo box during operation. This exerts a large load on the lower back, shoulders, and arms of the operator, which can cause back and shoulder/arm-related discomfort, pain, and disorders. Further, it is difficult to transport large amounts of products, such as compost and harvested peaches, at once because of the small cargo box and considerable amount of force required to operate the cart. Consequently, this lowers the transport efficiency. In general, 3–4 bags of compost or two boxes of harvested peaches (20–25 kg/box) are transported at once. The postural load was assessed as RULA action level 4 when performing these tasks, and the results indicate that such tasks require immediate investigation and corrective actions (Table 2).

Figure 1.

Two types of carts: (a) one-wheel manual cart; (b) powered cart with tracked wheels.

A powered cart equipped with tracked wheels was introduced to reduce the postural load to an acceptable level (Figure 1b). The powered cart engine uses gasoline as fuel; thus, it is not environmentally friendly because of the exhaust gas and noise, and the exhaust can also affect the health of the operators and others in the vicinity. However, it is more suitable for use on sloped areas because of its high engine power. The cart costs about USD 3380 (KRW 40,000,000). Three members of the organization purchased the powered cart with tracked wheels without height adjustability. These carts have advantages in that their center of gravity remains constant during motion, thereby reducing the amount of force required to operate the cart. This in turn allows the transportation of more bags of compost or boxes of harvested peaches (maximum load allowance = 500 kg). Thus, 25 bags of compost or 10–12 boxes of peaches at the maximum can be transported based on the size of the cargo box in one trip, which improves the transport efficiency by 5–8 times. Further, when this cart is introduced for transporting compost or harvested peaches, the postural load is reduced to RULA action level 1, which is acceptable for most workers when not maintained or repeated for long periods [27].

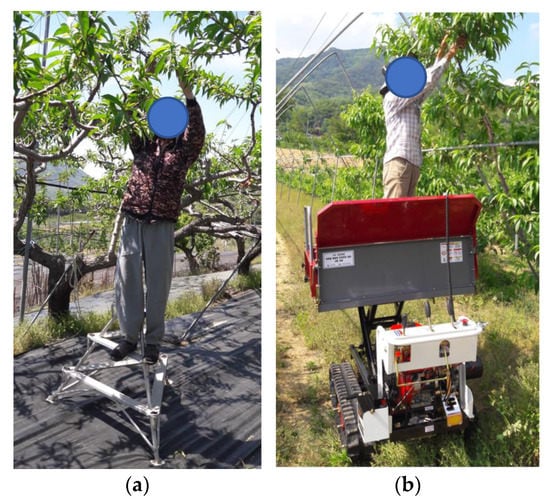

Cart with Height-Adjustable Lift

Farmers work in several unstable postures when pruning, thinning flowers and fruits, and wrapping fruits in paper bags. Their arms are flexed to near their range of motion (ROM), and their legs and feet are poorly supported or in unevenly balanced postures. The footrest on which the operator stands has an unstable center of gravity, and therefore, there is a constant risk of falling (Figure 2a). In pruning work, postural loads increase because it is necessary to exert force while assuming an unstable posture. This posture was evaluated as RULA action level 4 (Table 2).

Figure 2.

Work postures involved in pruning, flower and fruit thinning, and wrapping fruits in paper bags: (a) posture on traditional footrest; (b) posture on height-adjustable cargo box.

To minimize postural loads, a height-adjustable powered cart with tracked wheels was introduced for the abovementioned tasks. This is a powered cart with tracked wheels that has a height-adjustable cargo box (or stowage). The cargo box is hydraulically adjustable by a height of 1.5 m. This cart is more expensive than a simple powered cart by at least USD 677 (KRW 800,000). The members of the organization were allowed to select two types of carts based on their needs. Six members purchased the height-adjustable powered cart. This cart allows farmers to perform tasks such as pruning, thinning flowers and fruits, and wrapping fruits in paper bags with the height-adjusted cargo box based on the working position while ensuring safe and stable postures (Figure 2b). The improved posture was rated as RULA action level 2, which does not require soon or immediate changes.

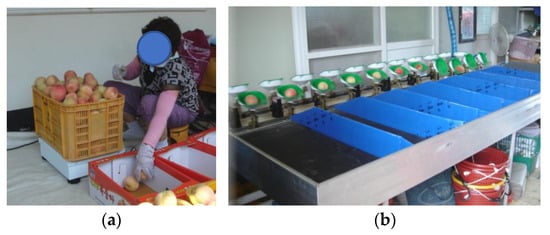

Fruit Sorter

The task of sorting harvested peaches is performed manually while sitting in awkward postures on a low farm stool, wherein the knee is severely flexed or in a squatting posture (Figure 3a). This posture places a significant musculoskeletal load on the knees and lower back, which can cause discomfort, pain, and WMSDs if the posture is maintained for long periods. The posture was analyzed to be very stressful with an RULA action level of 4.

Figure 3.

Sorting harvested peaches: (a) manual sorting; (b) automatic sorting.

This project adopted an automatic sorter for alleviating musculoskeletal loadings (Figure 3b). The machine automatically sorts harvested peaches depending upon their weight once the farmers load the harvested peaches into the machine. This machine eliminates manual sorting with the exception of loading and unloading. The loading and unloading tasks are conducted during manual sorting as well. The adoption may reduce physical stress for sorting peaches but may also reduce employment for one or more sorting farmers or increase sorting efficiency without reducing employment.

Other Engineering Interventions

Several pesticides are used in peach farming from March to August. New pesticides or pesticides left after use are scattered haphazardly in farmhouses or peach farms, and they are not stored appropriately. Therefore, there may be a risk of inhalation by humans, who may mistake these substances for beverages or come into contact with the pesticide (Figure 4a). A dedicated box with a lock was therefore provided to safely store the pesticide in a designated place (Figure 4b). Protective clothing was also adopted to prevent pesticide poisoning during spraying (Figure 4c).

Figure 4.

Pesticide-related interventions: (a) old storage; (b) new storage; (c) protective clothing.

Pruning and composting tasks are performed at low temperatures in winter. Most farmhouses in the organization are located at the foothills of mountains, and therefore, the temperature is cooler during winter (below −5 °C). Thermal vests that dissipate heat and shoes for winter farming were provided to the members to ensure protection against low temperatures in the fields (Figure 5a,b). Further, the shoes protect feet from the risk of being crushed by heavy objects or pricked by sharp objects. In contrast, pesticide spraying and harvesting are tasks that are performed for several hours in the summer, when the temperature is above 35 °C. Cooling vests and farmer hats were adopted to minimize heat stress and provide respite from the hot temperatures (Figure 5c,d).

Figure 5.

Interventions against cold and heat: (a) thermal vest; (b) agricultural shoes; (c) cooling vest; (d) farmer hat.

Farmers wear gloves woven with thread (Figure 6a) during working. In this scenario, farmers may be prone to injuries, such as hand scratches, stabbings, and cuts, by sharp objects such as knives or shears, peach tree branches, and grasses with sharp leaves, especially when pruning. Cut-resistant winter gloves were therefore supplied to prevent such injuries and prepare for the cold (Figure 6b).

Figure 6.

Different types of work gloves: (a) woven glove; (b) cut-resistant winter glove.

In Korea, a considerable amount of agricultural work is performed in seated positions on the ground or low stools with the knee and lower back severely flexed as in sorting, especially in field farming (Figure 3a). To avoid these awkward postures in field farming, height-adjustable agricultural stools with wheels were recommended. The stool helps reduce postural stress acting on the knee and lower back, as shown in Figure 7. Further, the stool makes it easy for farmers to move and work at different locations. The posture shown in Figure 7 was assessed as RULA action level 2.

Figure 7.

Height-adjustable agricultural stool.

3.3.2. Administrative Interventions

This project introduced administrative controls or interventions for agricultural work to improve peach farming workloads where engineering controls are difficult or expensive to implement. Only administrative controls were proposed for machines involved in pesticide spraying and for the management of harvesting and sorting/packaging. Administrative controls were adopted with engineering interventions to increase the effects of engineering control. For example, both controls were suggested in the material/environment part in pruning tasks, the man part in flower and fruit thinning and wrapping fruits in bags, man and material/environment parts in harvesting, sorting/packaging, and the material/environment part in composting.

Farmers work long hours (from early morning to late evening) during busy seasons performing tasks such as pruning, thinning flower and fruit, wrapping fruits in bags, harvesting, sorting/packaging, and composting, even under bad weather conditions in the summers and winters. The farmers not only lack the time to rest but also do not have adequate resting areas. It was recommended that farmers take over 10 min of rest for every 1–2 h of work to minimize the physical stresses caused by the long working hours; further, it was recommended that the farmers drink sufficient amounts of water during rest.

Other recommendations for administrative controls were as follows:

- Periodic machine maintenance: to minimize vibration and noise generated when spraying pesticide using a speed sprayer.

- Instruction or warning on using speed sprayers: to mitigate the risk of overturning of the speed sprayer when working in uneven regions.

- Education/training for stretching and physiotherapy: to relieve muscle fatigue caused by unstable postures and repetitive motions during thinning flower and fruit, wrapping fruits in bags, and harvesting. Some physiotherapists were invited to provide the necessary education/training.

- Education/training for wearing protective clothing: to mitigate the tendency of not wearing protective clothing because of the heat.

3.4. Evaluation of Ergonomic Interventions

Awkward or unstable postures during pruning, thinning flower and fruit, wrapping fruits in paper bags, harvesting, sorting/packaging, and composting were assessed using RULA, and it was found that each task was RULA action level 4. After introducing the recommended interventions (Table 2), the postural loads for the corresponding tasks were reduced to RULA action level 1 or 2, which do not require corrective actions soon or immediately.

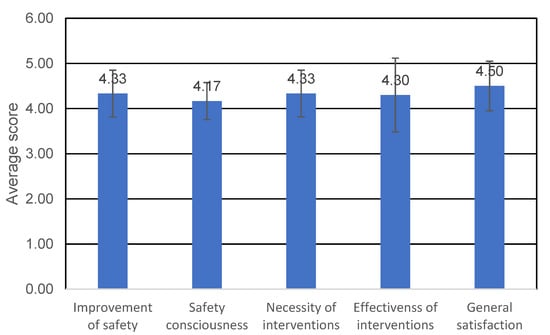

Four weeks after implementing the ergonomic interventions, a questionnaire survey was administered to all members of the organization on a five-point Likert scale to investigate the satisfaction and effectiveness of the interventions. The results of the survey are shown in Figure 8; the average scores for all five items adopted in the questionnaire survey were >4.1, indicating that all members agreed with the benefits, necessity, and effectiveness of the interventions, in addition to being satisfied with the proposed measures.

Figure 8.

Results of questionnaire survey.

4. Discussion

This study addresses participatory ergonomic interventions recommended for an annual peach farming cycle in a Korean farming organization. Most existing studies focus on interventions for parts of the agricultural work, such as pruning, load carrying, harvesting, and sorting [2,15,16,17,18,19,20,21,22,23,24,25]. In contrast, an ergonomic analysis was conducted for all tasks performed during the entire agricultural work cycle of peach farming in this study, and interventions were proposed based on the results of the ergonomic analysis. The interventions focused on crop-specific tasks by considering variations in agricultural work; thus, this study presents a procedure for participatory ergonomics and the effects of ergonomic interventions in a farming organization. The procedures and results from this study can be applied to other types of crop farming activities and in industries.

Both engineering and administrative controls or only administrative controls were introduced based on the characteristics of the risk factors depending on agricultural practices categorized under the 4 M criteria. Engineering controls, including powered carts (with adjustable height) and fruit sorters, were implemented for harvesting, pruning, thinning flower and fruit, wrapping fruits in paper bags, composting (load carrying), and sorting, which require lifting and carrying heavy loads as well as severe or full-body bending (stooping, squatting, kneeling, etc.). These were identified as the main farming tasks that cause WMSDs [2,7,8,9,10,11,14]. Postural loads for six awkward postures occurring in the above tasks were classified as RULA action level 4 and were reduced to action level 1 or 2 after implementing the interventions. The engineering controls implemented in this study can help promote farmers’ health, including WMSDs. Further, the scores of subjective evaluations obtained through a questionnaire survey were found to be high (>4.1 for five questions).

Although the subjective risk scores for most risk factors where engineering interventions were introduced, including pruning, pesticide spraying, thinning flower and fruit, wrapping fruits in bags, and harvesting, agreed with the objective assessments at the highest score or level (i.e., subjective risk score of 9 and RULA action level of 4), the two evaluations may be different from each other for sorting and packaging, i.e., subjective risk score of 6 (<highest score of 9) and RULA action level of 4 (Table 2). This may be attributed to the simple method of obtaining subjective risk scores by multiplying the frequency and intensity for a farming risk factor categorized under 4 M. The simple method, instead of a more scientific method such as the RULA, was adopted so that farmers without knowledge of ergonomics could easily participate in this study.

All members of the farming organization purchased powered carts or height-adjustable powered carts; the other engineering interventions were selectively adopted based on the needs of each member within the assigned budget. The total budget of USD 44,840 (KRW 53,000,000), excluding the consulting fee charged by the ergonomist (USD 5075 (KRW 6,000,000)), was distributed equally among the members. If the cost for interventions selected by a member exceeded the allocated budget, he had to pay the excess.

All members of the organization and the ergonomist (the author of this study) participated in all processes of the ergonomic interventions, from the identification of risk factors during the crop phase to evaluation of the interventions. All ergonomic interventions adopted in this study were suggested in consultations with all members of the organization and the ergonomist. The interventions were evaluated subjectively by the members and objectively using the ergonomics tool of RULA by the author. Thus, the interventions were implemented according to a participatory approach involving the government (financial support), an ergonomics expert, and the farmers. The participatory approach ensures success of the interventions [34] and is beneficial for preventing WMSDs [35]. Ergonomics plays an important role in health promotion and injury prevention among farm workers [36]. Ergonomic interventions have been successful in the past in preventing over 50% of WMSDs in professions such as agriculture where the employees are exposed to high-level WMSD risk factors [35,37,38]. Thus, the interventions proposed in this study are expected to be successfully adopted in farming households to increase agricultural work efficiency while promoting the health of farmers by preventing WMSDs.

In general, farmers are not aware of the risk factors involved in their work. This study helped identify and address the risks in peach farming through the participatory approach with an ergonomics expert. Although most farmers were more interested in improving the efficiency of their agricultural work and quality of produce rather than their own health [20], this approach can be considered an opportunity for the famers to gain interest in their health and wellbeing as well as to reap the benefits of ergonomics in agriculture.

Although this study addresses the entire cycle of participatory ergonomic interventions, from identification of risk factors to evaluation of the interventions, follow-up studies need to be conducted over several years after introduction of the interventions to identify additional health-related issues that may contribute to WMSDs. This study was conducted with a small number of farmers with a specific focus on peach farming. Hence, further studies with a large number of farmers as well as different types of crops are recommended.

5. Conclusions

This study adopted participatory ergonomic interventions for improving work environment for a peach farming organization. The engineering and administrative interventions were introduced based on ergonomic analysis of the entire annual peach farming cycle. The interventions were effective at reducing postural loads and were satisfactory to the farmers participated in this study. It is expected that the interventions may help promote farmers’ health (especially WMSDs) and enhance peach farming work efficiency.

Funding

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (Ministry of Science and ICT) (No. 2021R1F1A1045921) and the Rural Development Agency (RDA)—an affiliation of the Ministry of Agriculture, Food and Rural Affairs of Korea.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Conflicts of Interest

The author declares no conflict of interest.

References

- Rural Development Agency (RDA). Guidelines for Support Project of Small Agricultural Equipment for Improving Work Environment; RDA: Jeonju, Korea, 2008. [Google Scholar]

- Fathallah, F.A. Musculoskeletal disorders in labor-intensive agriculture. Appl. Ergon. 2010, 41, 738–743. [Google Scholar] [CrossRef] [PubMed]

- McCurdy, S.A.; Samuels, S.J.; Carroll, D.J.; Beaumont, J.J.; Morrin, L.A. Agricultural injury in California migrant Hispanic farm workers. Am. J. Ind. Med. 2003, 44, 225–235. [Google Scholar] [CrossRef] [PubMed]

- Villarejo, D.; Baron, S.L. The occupational health status of hired farm workers. Occup. Med. 1999, 14, 613–635. [Google Scholar]

- Niu, S. Ergonomics and occupational safety and health: An ILO perspective. Appl. Ergon. 2010, 41, 744–753. [Google Scholar] [CrossRef] [PubMed]

- Agricultural Disease Survey. 2020. Available online: https://blog.naver.com/nong-up/222397762320 (accessed on 28 October 2021).

- Meyers, J.M.; Miles, J.A.; Faucett, J.; Janowitz, I.; Tejeda, D.G.; Kabashima, J.N. Ergonomics in agriculture: Workplace priority setting in the nursery industry. Am. Ind. Hyg. Assoc. J. 1997, 58, 121–126. [Google Scholar] [CrossRef]

- Meyers, J.M.; Miles, J.A.; Faucett, J.; Janowitz, I.; Tejeda, T.G.; Duraj, V.; Kabashima, J.; Smith, R. High risk tasks for musculoskeletal disorders in agricultural fieldwork. In Proceedings of the IEA 2000/HFES 2000 Congress, San Diego, CA, USA, 30 July–4 August 2000; pp. 3616–3619. [Google Scholar]

- Meyer, J.M.; Miles, J.A.; Tejeda, D.G.; Janowitz, I.; Tejeda, T.G.; Kabashima, J.N. Priority risk factors for back injury in agricultural field work: Vineyard ergonomics. J. Agromed. 2001, 8, 37–52. [Google Scholar] [CrossRef]

- Kirkhorn, S.R.; Earle-Richardson, G.; Banks, R.J. Ergonomic risks and musculoskeletal disorders in production agriculture: Recommendations for effective research to practice. J. Agromed. 2010, 15, 281–299. [Google Scholar] [CrossRef]

- Dianat, I.; Afshari, D.; Sarmasti, N.; Sangdeh, M.S.; Azaddel, R. Work posture, working conditions and musculoskeletal outcomes in agricultural workers. Int. J. Ind. Ergon. 2020, 77, 102941. [Google Scholar] [CrossRef]

- Raczkiewicz, D.; Saran, T.; Sarecka-Hujar, B.; Bojar, I. Work conditions in agriculture as risk factors of spinal pain in postmenopausal women. Int. J. Occup. Saf. Ergon. 2019, 25, 250–256. [Google Scholar] [CrossRef]

- Kee, D.; Haslam, R. Prevalence of work-related musculoskeletal disorders in agriculture workers in Korea and preventative interventions. Work 2019, 84, 763–775. [Google Scholar] [CrossRef] [Green Version]

- Benos, L.; Tsaopoulos, D.; Bochtis, D. A review on ergonomics in agriculture. Part I: Manual operations. Appl. Sci. 2020, 10, 1905. [Google Scholar] [CrossRef] [Green Version]

- Silverstein, B.A.; Bao, S.S.; Russell, S.; Stewart, K. Water and coffee: A systems approach to improving coffee harvesting work in Nicaragua. Hum. Factors 2012, 54, 925–939. [Google Scholar] [CrossRef] [PubMed]

- Pranav, P.K.; Patel, T. Impact of ergonomic intervention in manual orange harvester among the workers of hilly region in India. Work 2016, 54, 179–187. [Google Scholar] [CrossRef] [PubMed]

- Fathallah, F.A.; Tang, S.C.H.; Waters, T. Development and evaluation of ergonomic interventions for bucket handling on farms. Hum. Factors 2016, 58, 758–776. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Earle-Richardson, G.; Jenkins, P.; Fulmer, S.; Mason, C.; Burdick, P.; May, J. An ergonomic intervention to reduce back strain among apple harvest workers in New York State. Appl. Ergon. 2005, 35, 327–334. [Google Scholar] [CrossRef] [PubMed]

- Chauhan, H.; Satapathy, S.; Sahoo, A.K.; Mishtra, D. Mitigation of ergonomic risk factors in agriculture through suitable hand-glove materials. Mater. Today Proc. 2020, 26, 561–565. [Google Scholar] [CrossRef]

- Fels, D.I.; Blackler, A.; Cook,, D.; Foth, M. Ergonomics in apiculture: A case study based on inspecting movable frame hives for healthy bee activities. Heliyon 2019, 5, e01973. [Google Scholar] [CrossRef] [Green Version]

- Kristanto, A.; Neubert, M.S.; Gross, M.T.; Puntumetakul, R.; Kaber, D.B.; Sessomboon, W. Effects of corrective insole on leg muscle activation and lower extremity alignment in rice farmers with pronated foot: A preliminary report. Foot 2021, 46, 101771. [Google Scholar] [CrossRef]

- Bhattacharyya, N.; Chakrabarti, D. Ergonomic basket design to reduce cumulative trauma disorders in tea leaf plucking operation. Work 2012, 41, 1234–1238. [Google Scholar] [CrossRef] [Green Version]

- Kishtwaria, J.K.; Rana, A. Ergonomic interventions in weeding operations for drudgery reduction of hill farm women of India. Work 2012, 41, 4349–4355. [Google Scholar] [CrossRef] [Green Version]

- Southard, S.A.; Freeman, J.H.; Drum, J.E.; Mirka, G.A. Ergonomic interventions for the reduction of back and shoulder biomechanical loading when weighing calves. Int. J. Ind. Eng. 2007, 37, 103–110. [Google Scholar] [CrossRef]

- Chapman, L.J.; Newenhouse, A.C.; Meyer, R.H.; Taveira, A.D.; Karsh, B.-T.; Ehlers, J.J.; Palermo, T. Evaluation of an intervention to reduce musculoskeletal hazards among fresh market vegetable growers. Appl. Ergon. 2004, 35, 57–66. [Google Scholar] [CrossRef] [PubMed]

- Hignett, S.; Wilson, J.R.; Morris, W. Finding ergonomic solutions- participatory approaches: In-depth review. Occup. Med. 2005, 55, 200–207. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- McAtamney, L.; Corlett, E.N. RULA: A survey method for the investigation of work-related upper limb disorders. Appl. Ergon. 1993, 24, 91–99. [Google Scholar] [CrossRef]

- Gómez-Galán, M.; Callejón-Ferre, Á.-J.; Pérez-Alonso, J.; Díaz-Pérez, M.; Carrillo-Castrillo, J.A. Musculoskeletal risks: RULA bibliometric review. Int. J. Environ. Res. Public Health 2020, 17, 4354. [Google Scholar] [CrossRef] [PubMed]

- Kee, D.; Karwowski, W. A comparison of three observational techniques for assessing postural loads in industry. Int. J. Occup. Saf. Ergon. 2007, 13, 3–14. [Google Scholar] [CrossRef] [Green Version]

- Kee, D. An empirical comparison of OWAS, RULA and REBA based on self-reported discomfort. Int. J. Occup. Saf. Ergon. 2020, 26, 285–295. [Google Scholar] [CrossRef]

- Kee, D. Comparison of OWAS, RULA and REBA for assessing potential work-related musculoskeletal disorders. Int. J. Ind. Ergon. 2021, 83, 103140. [Google Scholar] [CrossRef]

- Kee, D.; Na, S.; Chung, M.K. Comparison of the Ovako Working Posture Analysis System, Rapid Upper Limb Assessment, and Rapid Entire Body Assessment based on the maximum holding times. Int. J. Ind. Ergon. 2020, 77, 102943. [Google Scholar] [CrossRef]

- Kee, G. Systematic comparison of OWAS, RULA, and REBA based on a literature review. Int. J. Environ. Res. Public Health 2022, 19, 595. [Google Scholar] [CrossRef]

- Hagg, G.M. Corporate initiatives in ergonomics-an introduction. Appl. Ergon. 2003, 34, 3–15. [Google Scholar] [CrossRef]

- Zalk, D.M. Grassroots ergonomics: Initiating an ergonomics program utilizing participatory techniques. Ann. Occup. Hyg. 2001, 45, 283–289. [Google Scholar] [CrossRef]

- Naeini, H.S.; Karuppiah, K.; Tamrin, S.B.; Dalal, K. Ergonomics in agriculture: An approach in prevention of work-related musculoskeletal disorders (WMSDs). J. Agric. Environ. Sci. 2014, 3, 33–51. [Google Scholar]

- Hagberg, M.; Wegman, D.H. Prevalence rates and odds ratios of shoulder–neck diseases in different occupational groups. Br. J. Ind. Med. 1987, 44, 602–610. [Google Scholar] [CrossRef] [PubMed]

- Fine, L.J.; Punnett, L.; Keyserling, W.M. An epidemiological study of postural risk factors for back disorders in industry. In Muscular Disorders at Work; Buckle, P., Ed.; Taylor and Francis: London, UK, 1987; pp. 108–109. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).