Investigation of the Influence of Neutron Irradiation on Cladded Nuclear Reactor Pressure Vessel Steel Blocks by Magnetic Adaptive Testing

Abstract

:1. Introduction

2. Materials and Methods

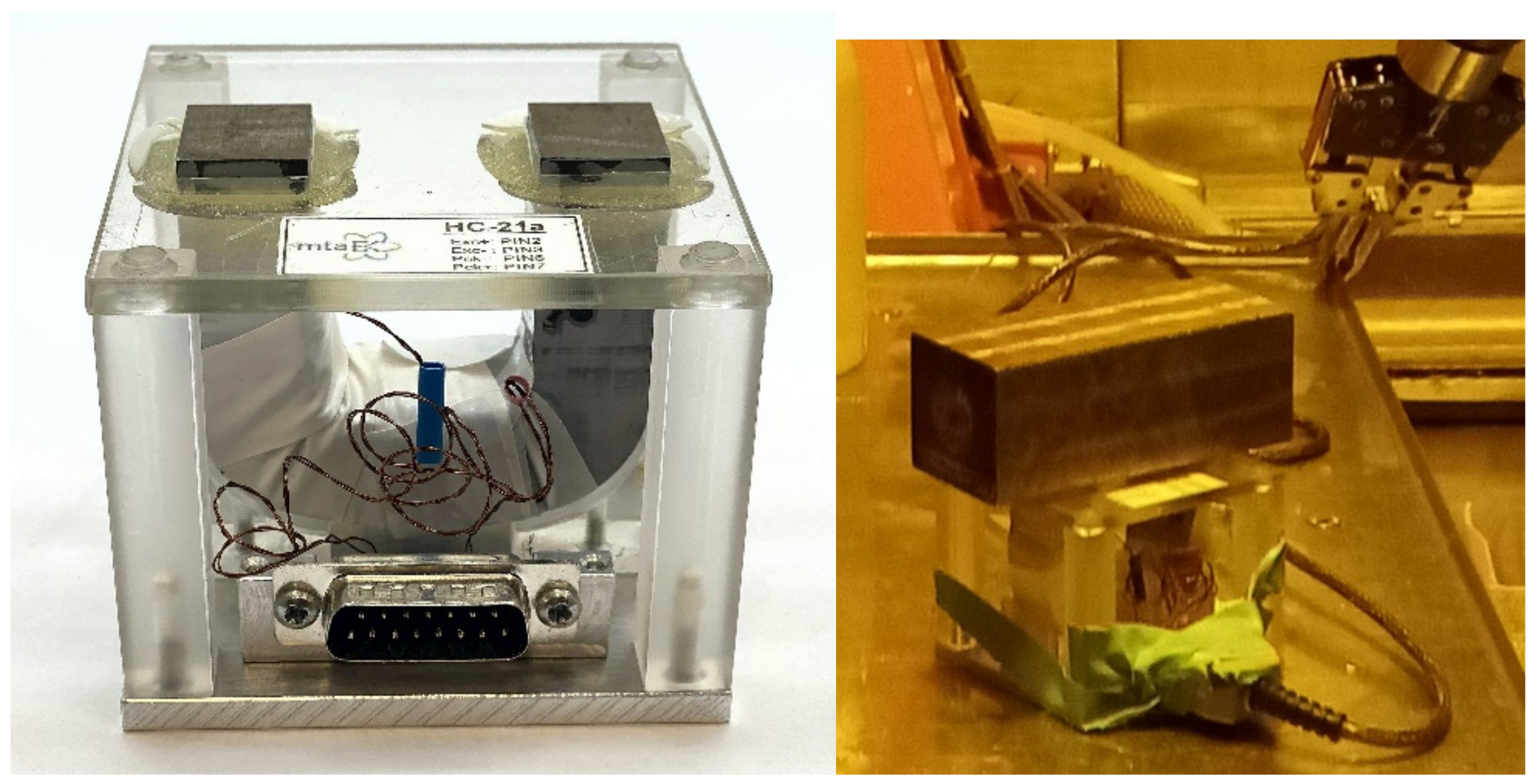

2.1. Sample Preparation

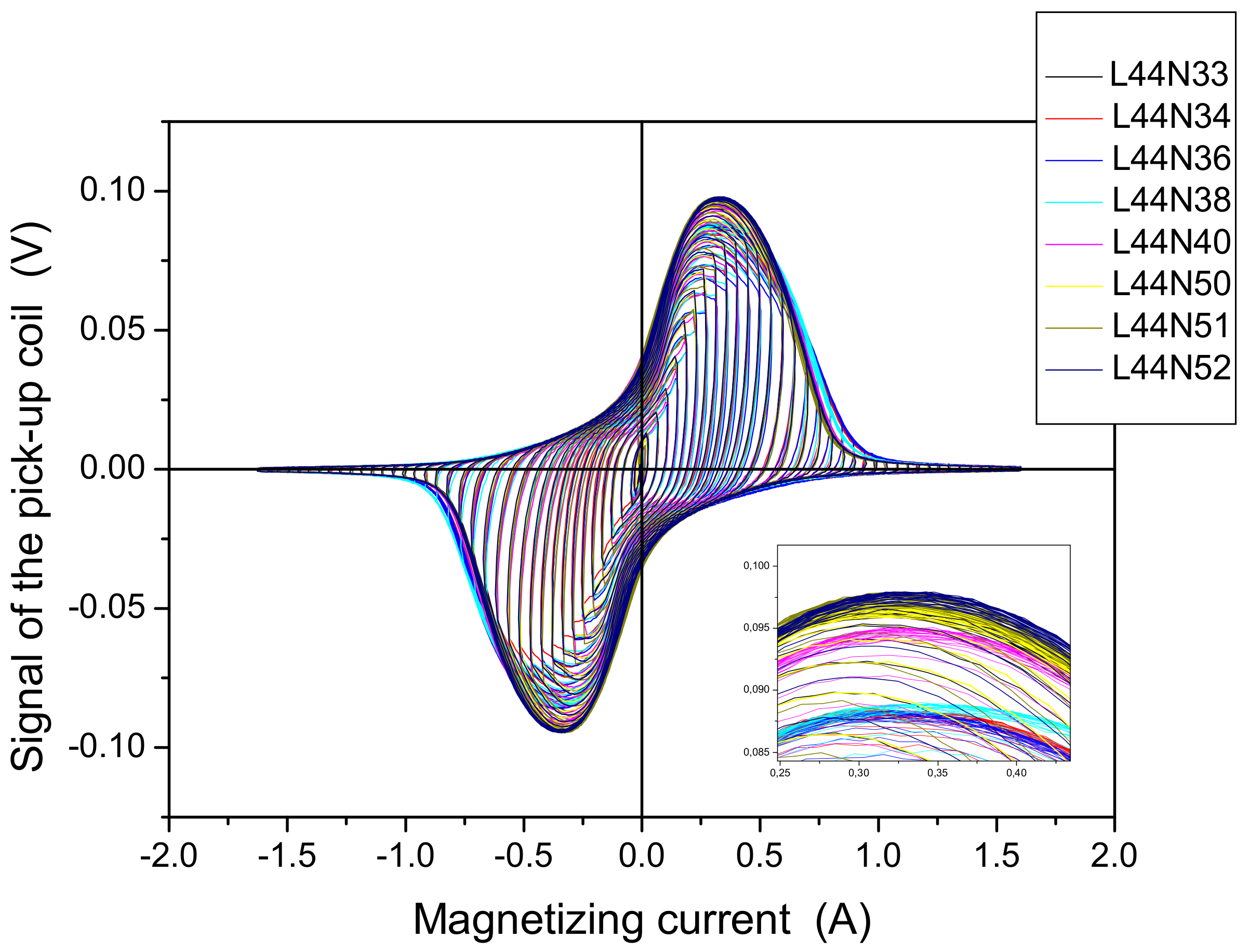

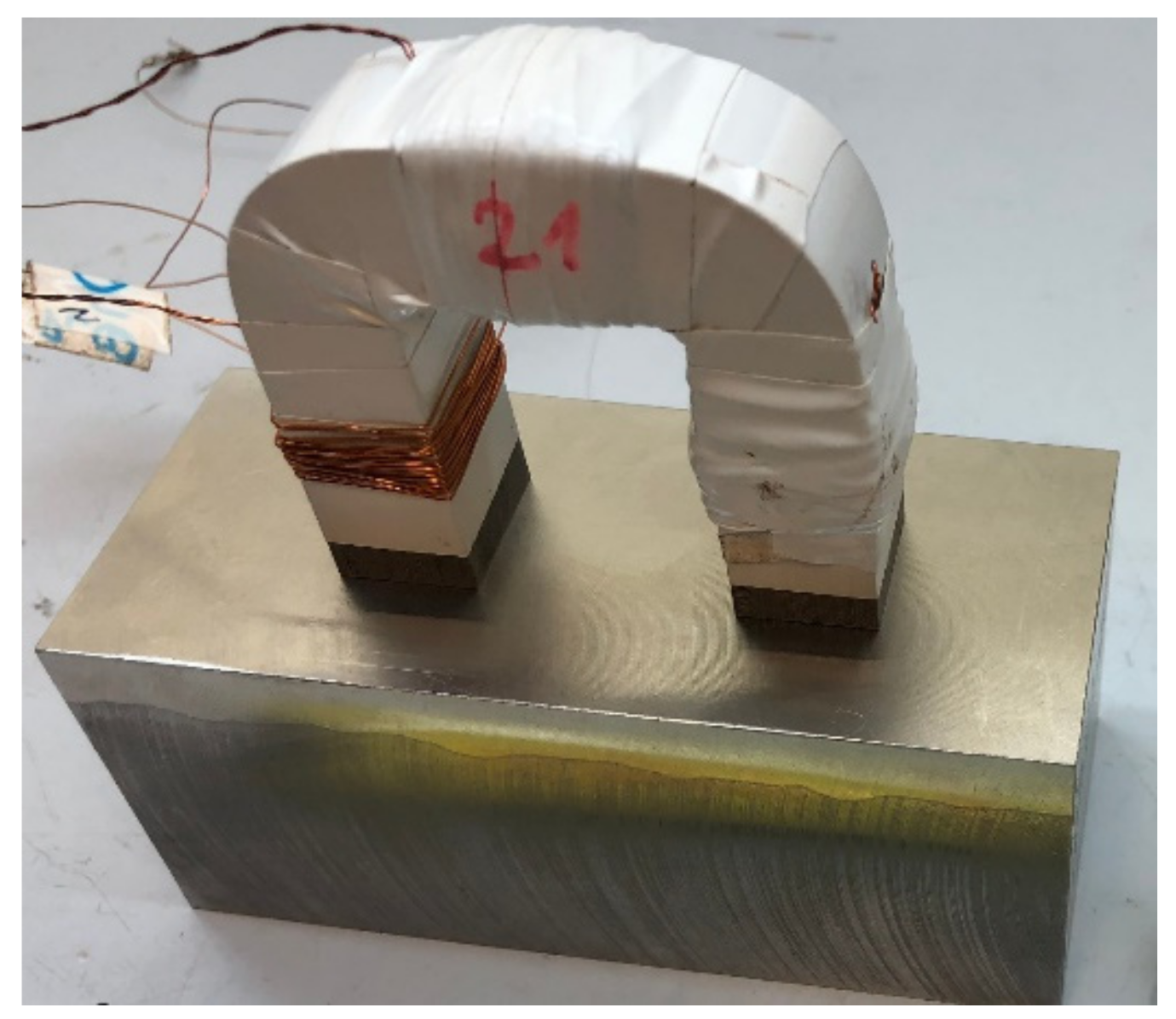

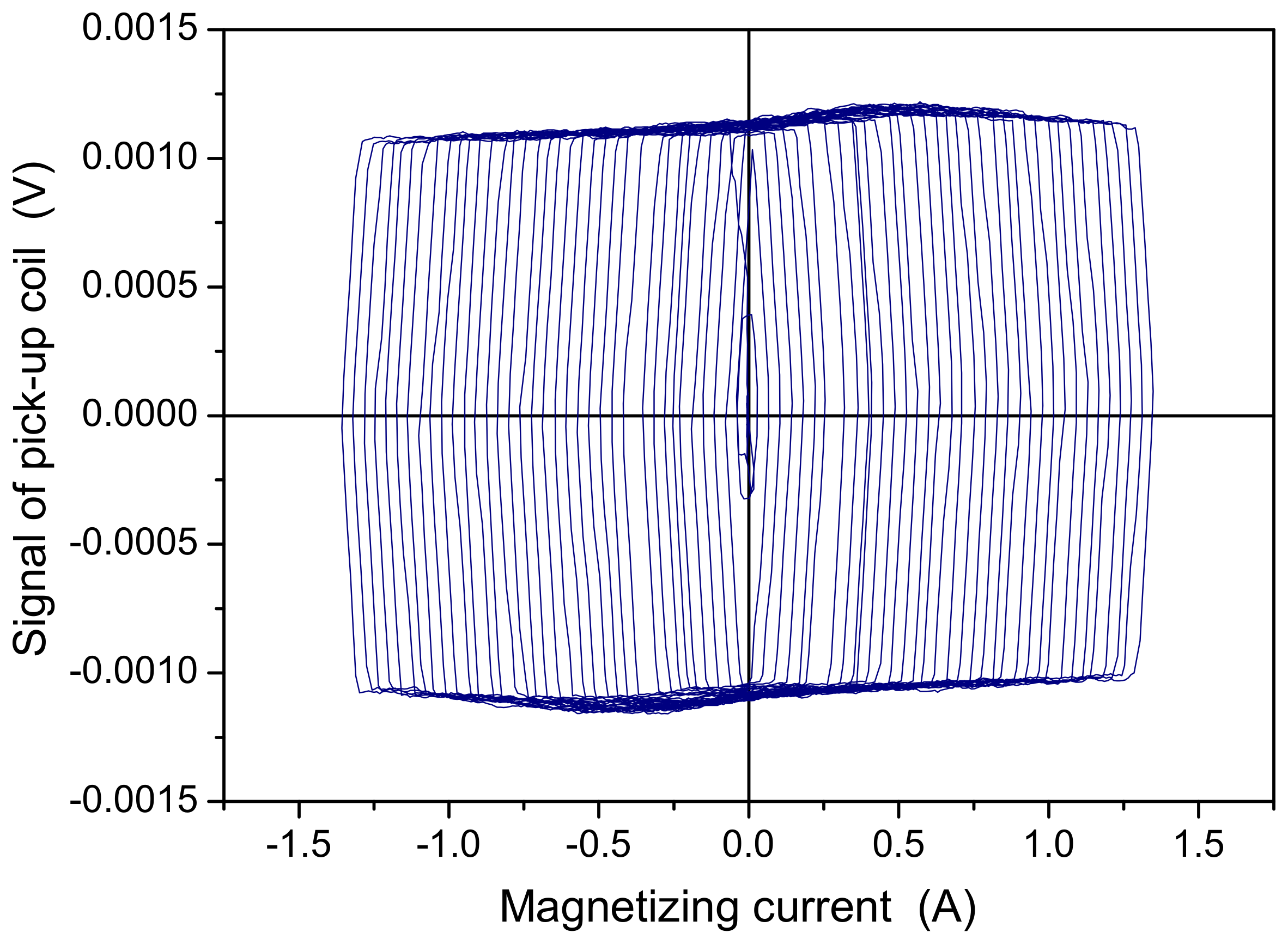

2.2. Magnetic Adaptive Testing

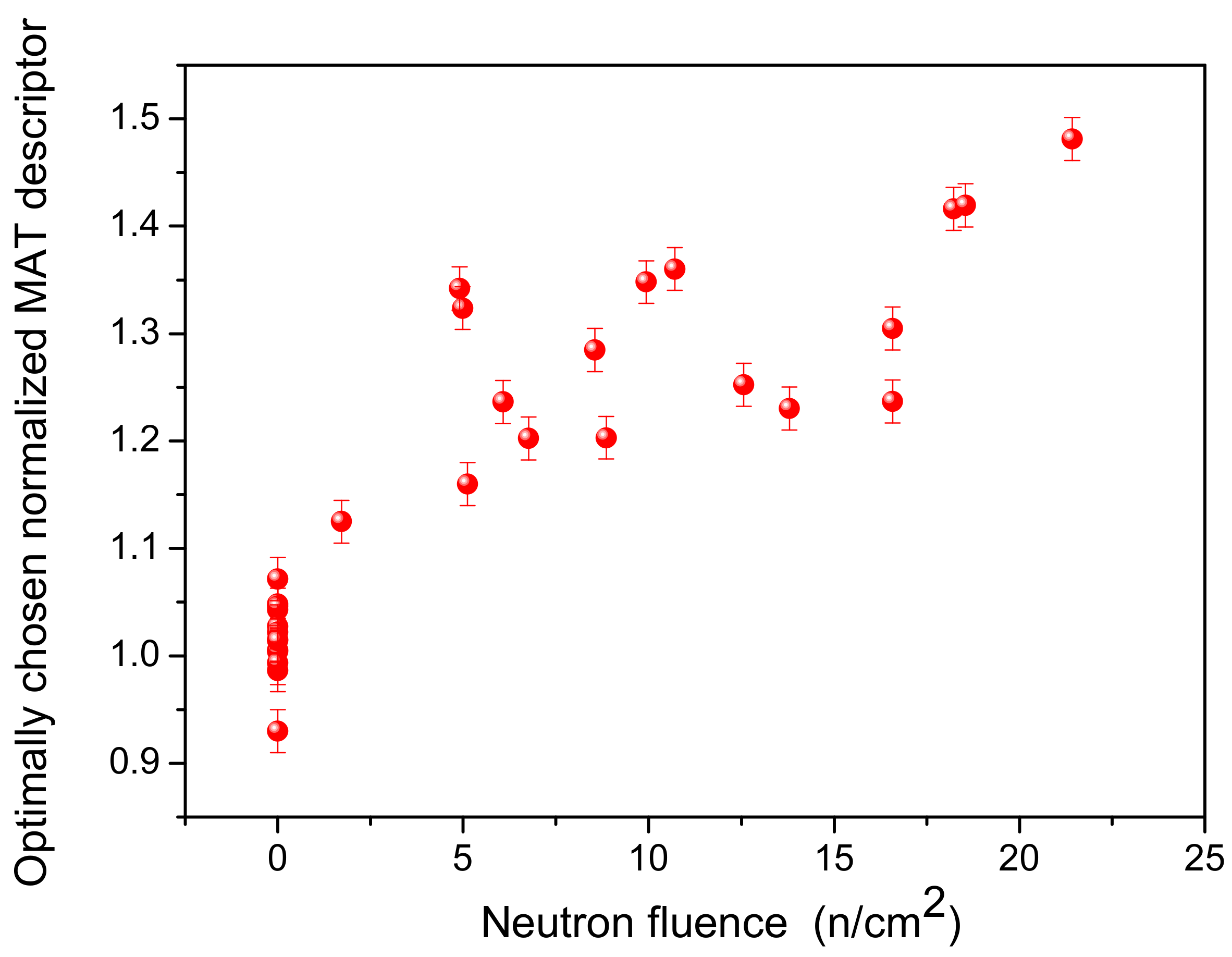

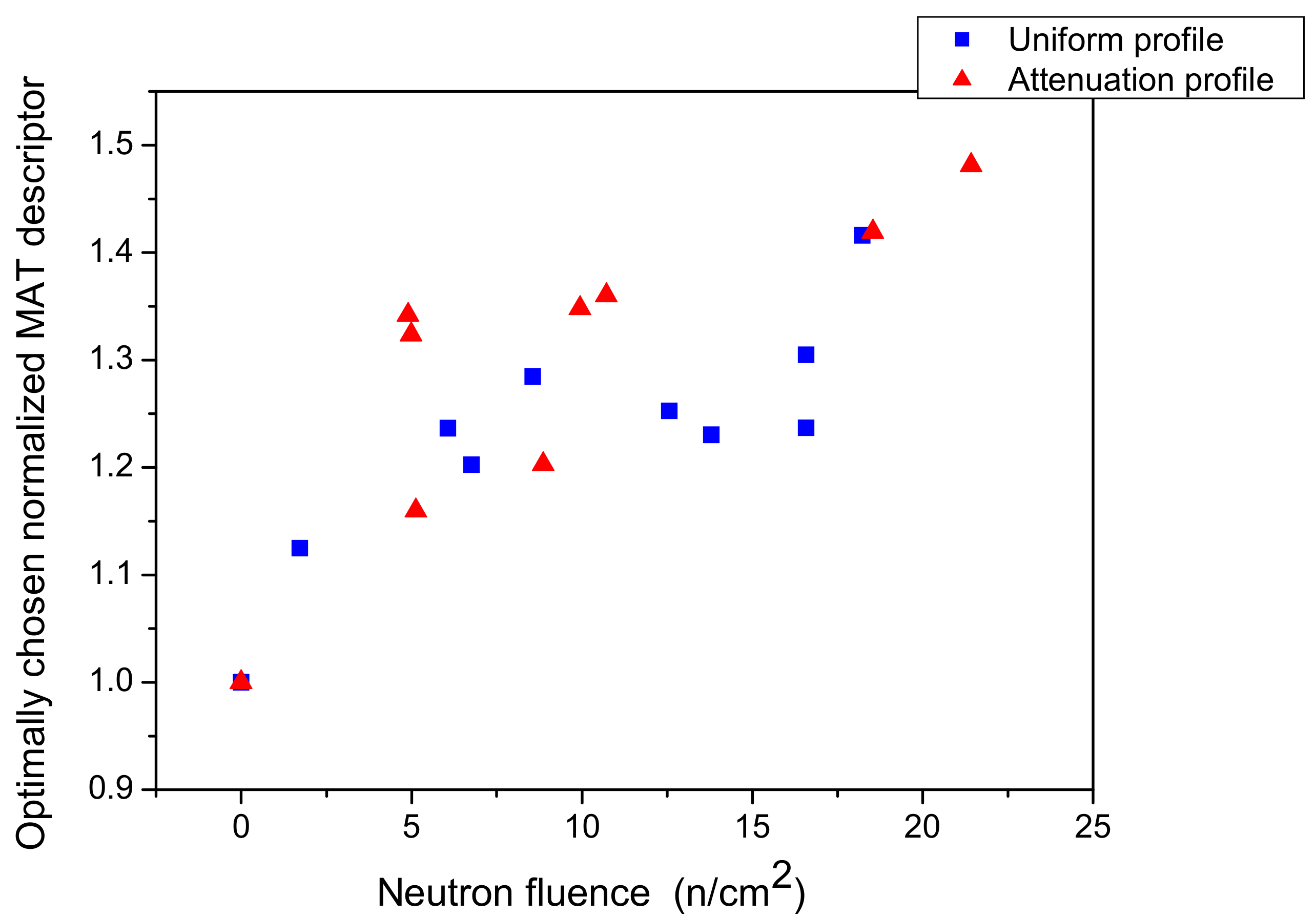

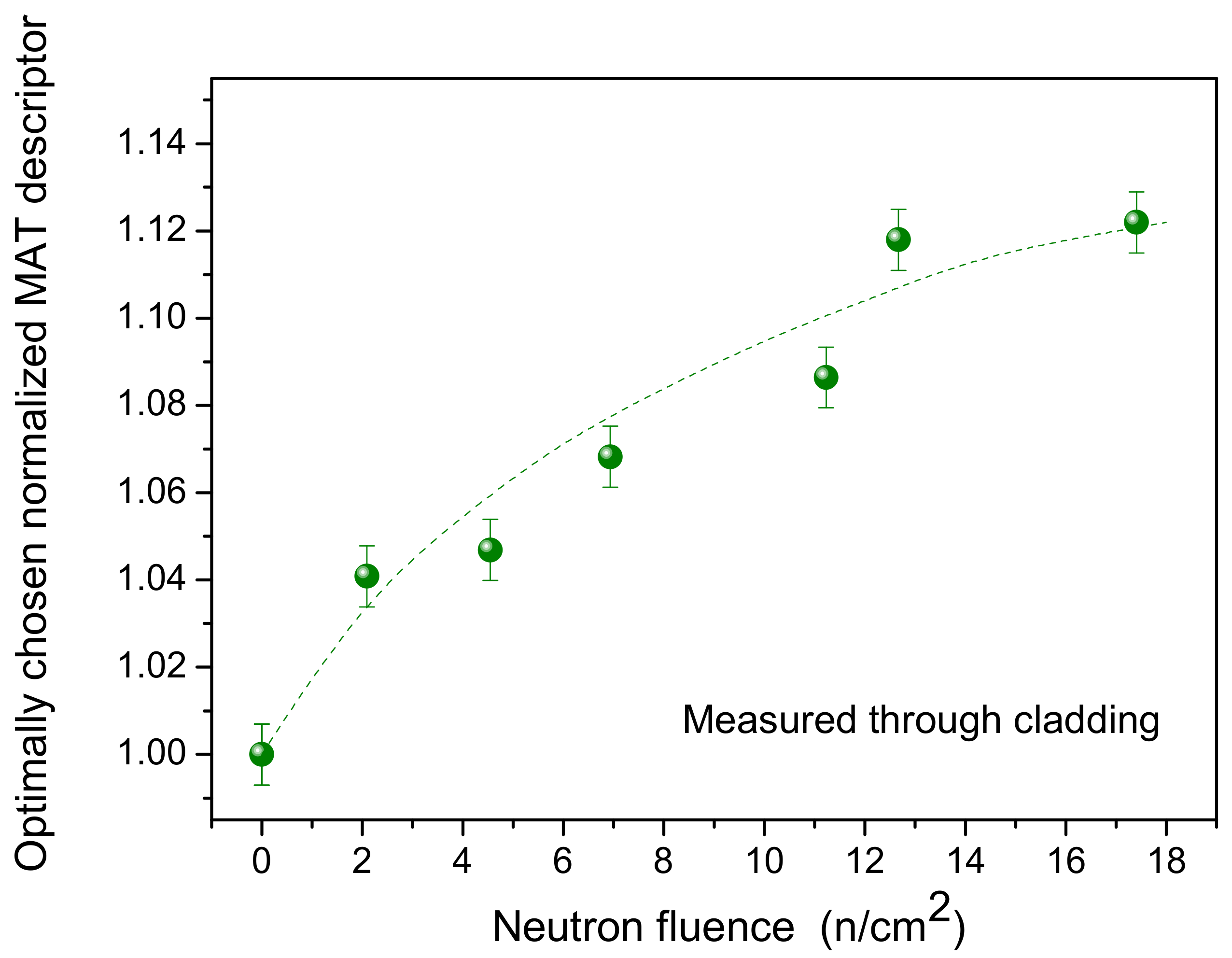

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Koutsky, J.; Kocık, J. Radiation Damage of Structural Materials; Elsevier: Amsterdam, The Netherlands, 1994. [Google Scholar]

- Ferreño, D.; Gorrochategui, I.; Gutiérrez-Solana, F. Degradation due to neutron embrittlement of nuclear vessel steels: A critical review about the current experimental and analytical techniques to characterise the material, with particular emphasis on alternative methodologies. In Nuclear Power—Control, Reliability and Human Factors; Tsvetkov, P., Ed.; IntechOpen Limited: London, UK, 2011; ISBN 9789533075990. Available online: http://www.intechopen.com/articles/show/title/non-destructive-testing-for-ageing-management-of-nuclear-power-components (accessed on 14 May 2020).

- Kronmüller, H.; Fähnle, M. Micromagnetism and the Microstructure of Ferromagnetic Solids; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Jiles, D.C. Magnetic methods in nondestructive testing. In Encyclopedia of Materials Science and Technology; Buschow, K.H.J., Ed.; Elsevier Press: Oxford, UK, 2001; p. 6021. [Google Scholar]

- Tomáš, I. Non-destructive Magnetic Adaptive Testing of ferromagnetic materials. J. Magn. Magn. Mater. 2004, 268, 178–185. [Google Scholar] [CrossRef]

- Tomáš, I.; Vértesy, G. Magnetic Adaptive Testing. In Nondestructive Testing Methods and New Applications; Omar, M., Ed.; IntechOpen: London, UK, 2021; ISBN 978-953-51-0108-6. Available online: http://www.intechopen.com/articles/show/title/magnetic-adaptive-testing (accessed on 10 July 2020).

- Vértesy, G.; Gasparics, A.; Uytdenhouwen, I.; Szenthe, I.; Gillemot, F.; Chaouadi, R. Nondestructive investigation of neutron irradiation generated structural changes of reactor steel material by magnetic hysteresis method. Metals 2020, 10, 642. [Google Scholar] [CrossRef]

- Tomáš, I.; Vértesy, G.; Gillemot, F.; Székely, R. Nondestructive Magnetic Adaptive Testing of Nuclear Reactor Pressure Vessel Steel Degradation. J. Nucl. Mater. 2013, 432, 371–377. [Google Scholar] [CrossRef]

- Vértesy, G.; Gasparics, A.; Szenthe, I.; Rabung, M.; Kopp, M.; Griffin, J.M. Analysis of Magnetic Nondestructive Measurement Methods for Determination of the Degradation of Reactor Pressure Vessel Steel. Materials 2021, 14, 5256. [Google Scholar] [CrossRef] [PubMed]

- Uytdenhouwen, I.; Chaouadi, R. Effect of neutron irradiation on the mechanical properties of an A508 Cl.2 forging irradiated in a BAMI capsule. Proc. ASME 2020, 1, PVP2020-21513, V001T01A060. [Google Scholar]

- Uytdenhouwen, I.; Chaouadi, R.; NOMAD Consortium Members. Effect of neutron irradiation on the mechanical properties of an A508 Cl. 2 and 15kH2NMFA irradiated in the NOMAD_3 rig in the BR2 cooling water. Proc. ASME 2021, 1, PVP2021-61969, V001T01A024. [Google Scholar]

- Uytdenhouwen, I.; Chaouadi, R.; NOMAD Consortium Members. NOMAD: Non-destructive evaluation (NDE) system for the inspection of operation-induced material degradation in nuclear power plants—Overview of the neutron irradiation campaigns. Proc. ASME 2020, 7, PVP2020-21512, V007T07A003. [Google Scholar] [CrossRef]

- Vértesy, G.; Gasparics, A.; Szenthe, I.; Uytdenhouwen, I. Interpretation of Nondestructive Magnetic Measurements on Irradiated Reactor Steel Material. Appl. Sci. 2021, 11, 3650. [Google Scholar] [CrossRef]

- Rabung, M.; Kopp, M.; Gasparics, A.; Vértesy, G.; Szenthe, I.; Uytdenhouwen, I.; Szielasko, K. Micromagnetic Characterization of Operation-Induced Damage in Charpy Specimens of RPV Steels. Appl. Sci. 2021, 11, 2917. [Google Scholar] [CrossRef]

- Tomáš, I.; Kadlecová, J.; Vértesy, G. Measurement of flat samples with rough surfaces by Magnetic Adaptive Testing. IEEE Trans. Magn. 2012, 48, 1441–1444. [Google Scholar] [CrossRef]

| C | Mn | Si | S | P | Cr | Ni | Mo | Cu |

|---|---|---|---|---|---|---|---|---|

| 0.201 | 0.578 | 0.27 | 0.0085 | 0.0091 | 0.372 | 0.668 | 0.599 | 0.0472 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vértesy, G.; Gasparics, A.; Szenthe, I.; Uytdenhouwen, I. Investigation of the Influence of Neutron Irradiation on Cladded Nuclear Reactor Pressure Vessel Steel Blocks by Magnetic Adaptive Testing. Appl. Sci. 2022, 12, 2074. https://doi.org/10.3390/app12042074

Vértesy G, Gasparics A, Szenthe I, Uytdenhouwen I. Investigation of the Influence of Neutron Irradiation on Cladded Nuclear Reactor Pressure Vessel Steel Blocks by Magnetic Adaptive Testing. Applied Sciences. 2022; 12(4):2074. https://doi.org/10.3390/app12042074

Chicago/Turabian StyleVértesy, Gábor, Antal Gasparics, Ildikó Szenthe, and Inge Uytdenhouwen. 2022. "Investigation of the Influence of Neutron Irradiation on Cladded Nuclear Reactor Pressure Vessel Steel Blocks by Magnetic Adaptive Testing" Applied Sciences 12, no. 4: 2074. https://doi.org/10.3390/app12042074

APA StyleVértesy, G., Gasparics, A., Szenthe, I., & Uytdenhouwen, I. (2022). Investigation of the Influence of Neutron Irradiation on Cladded Nuclear Reactor Pressure Vessel Steel Blocks by Magnetic Adaptive Testing. Applied Sciences, 12(4), 2074. https://doi.org/10.3390/app12042074